1. Introduction

Nowadays, the small-scale Horizontal Axis Wind Turbines (HAWT) are commonly used in a wide range of services, most notably for powering building, which can be a promising solution to energy problems in remote and residential areas. However, installing HAWTs in urban areas can result in turbine fatigue due to extreme operating conditions such as unsteady wind profiles, high turbine rotor speeds and building obstacles [

1,

2,

3,

4]. Therefore, many studies have been performed in the last years focusing on quantifying the effects of wind loads on the dynamic behaviour such as vibrations of tower and tail of small-scale HAWTs. The effect of static and dynamic wind loads has been investigated through experimental measurements and numerical analysis [

5,

6,

7,

8]. Other studies have focused on the effect of wind turbulence intensity on the fatigue load and dynamic response for small and large wind turbines [

9,

10,

11].

Yawing is the dynamic response of HAWTs to the changing wind direction, which can be characterised by critical aspects in the case of small devices: this aspect has been investigated, for example, in [

12], where the effect of yaw angles on the power coefficient and mechanical behaviour (mainly thrust coefficient) of a small HAWT has been studied through experimental wind tunnel experiments and two numerical methods (Blade Element Momentum theory and the aeroelastic simulation software Fatigues, Aerodynamics, Structures and Turbulence). The tests were conducted using steady wind time series up to 60 s for each yaw angle test of 0°, ±22.5° and ±45°: the vibration spectra results to be mainly characterised by the frequency proportional to the passing of each blade, hence indicated 3P because it is three times the frequency of the rotor rotation. The fluctuation intensity decreases with the yaw angle because the distance between tower and blade increases.

In Dai et al. [

13], the effect of yaw angle on the performance of 2 MW wind turbine is studied using SCADA data: it results, as expected, that the output power decreases when the wind speed is kept constant and the yaw coefficient increases, but the effect depends on the control and on the load. When the inflow wind speed is close to the rated wind speed, the effect of yaw on the output power becomes weaker because pitch control has a stronger effect on output power than yaw in this region. Kragh and Hansen [

14] assessed the performance of 2.3 MW offshore wind turbine in order to potentially increase the power output with improved yaw alignment, based on the analysis of wind speed, direction, yaw angle and power production. Their results demonstrated about 20% loss in energy production due to the yaw error distribution.

Many investigations dealing with the study of the control method on the dynamic characteristics as well as performance of small and large scale HAWT were performed recently as reported for instance in [

15,

16,

17,

18,

19]. Another parameter which affects the dynamic response of the wind turbine is the solidity which has recently been attracting a certain attention in the literature. For instance, Lokesh et al. [

20] performed experimental measurements to investigate the effect of solidity on the dynamic characteristics of a vertical-axis wind turbine with leading-edge protuberance at different tip-speed ratio (TSR). The solidity was changed by changing blade number of three, four and five which corresponding to solidity ratio of 0.47, 0.68, and 0.72 respectively. The results demonstrated that the amplitude of vortex-induced vibration for three blades configuration is higher than for four and five configurations, while the vortex-induced vibration diminishes as the tip speed increases for the three bladed turbine, which led to better turbine operation. In addition, the three blades configuration diminishes the dynamic oscillations (buffeting oscillations) at both low and high TSR. Mabrouk and Hami [

21] studied the effect of blade number on the both aerodynamic performance and dynamic vibration characteristic of the Darrieus turbine geared transmission system at different TSR. The results showed that the vibration amplitude decreases with increasing blade number from two to four. It is shown that the three blades configuration is the optimum for both aerodynamic performance and dynamic vibration. There are recent studies as well as regards the effect of blade number on the aerodynamic performance of the wind turbine using experimental measurement and numerical calculation [

22,

23,

24,

25].

The general motivation of this work is that there are few studies on the effect of the number of blades on the dynamic response of small scale wind turbines. Therefore, this study is aimed at investigating this issue through experimental tests conducted at the “R. Balli” wind tunnel of the University of Perugia. Two different wind turbine configurations, namely three and five blades, were examined under different wind speed signal (ramp and harmonically oscillating). The structure of the manuscript is therefore the following:

Section 2 is devoted to the description of the experimental setup; the results are collected in

Section 3 and discussed in

Section 4; finally, the conclusions are drawn in

Section 5.

2. The Experimental Analysis

2.1. Wind Tunnel

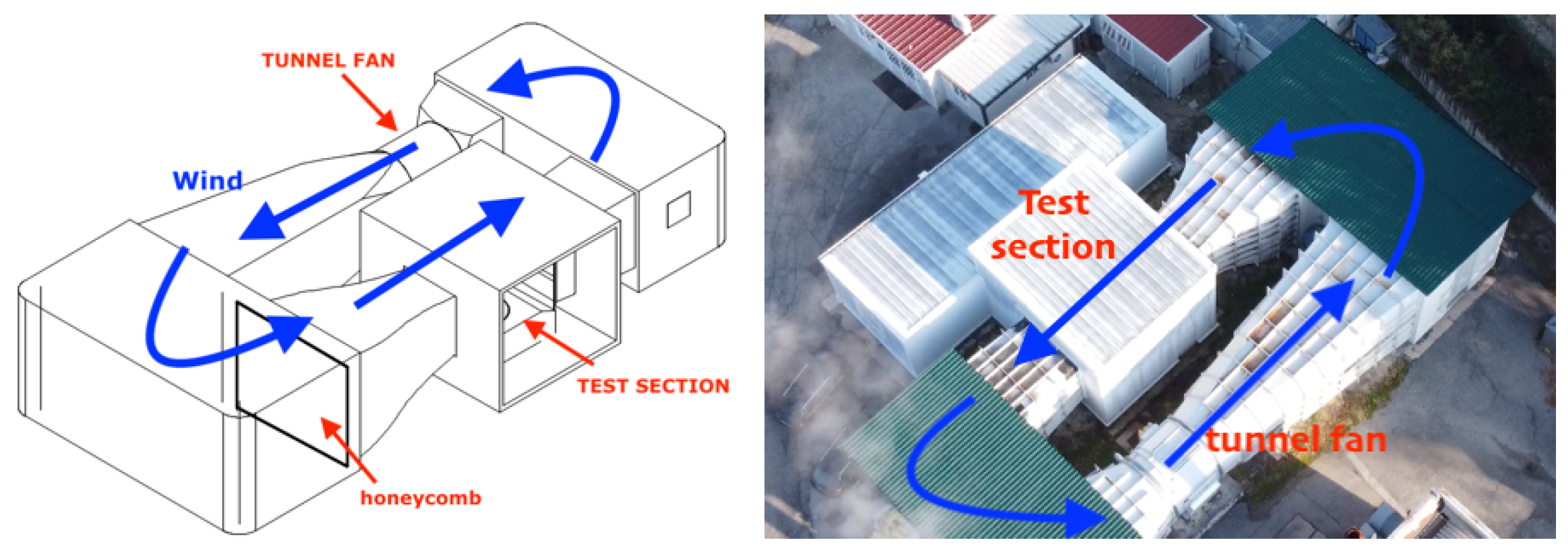

The experimental tests are carried out at the wind tunnel “Raffaele Balli” of the University of Perugia, whose layout is represented in

Figure 1.

The tunnel has a close circuit with an open test section. The air flow is generated by a fan driven by a 375 kW electrical motor. The maximum achievable speed is around 47 m/s, but the test studied in the paper are realized in a range of velocity between 4.5 and 11.5 m/s. The honeycomb before the test section ensures to carry out tests in laminar condition (turbulence measured by hot wire anemometer less than %). The dimensions of the sections are for the convergent and for the diffuser.

2.2. The Small Scale Horizontal Axis Wind Turbine

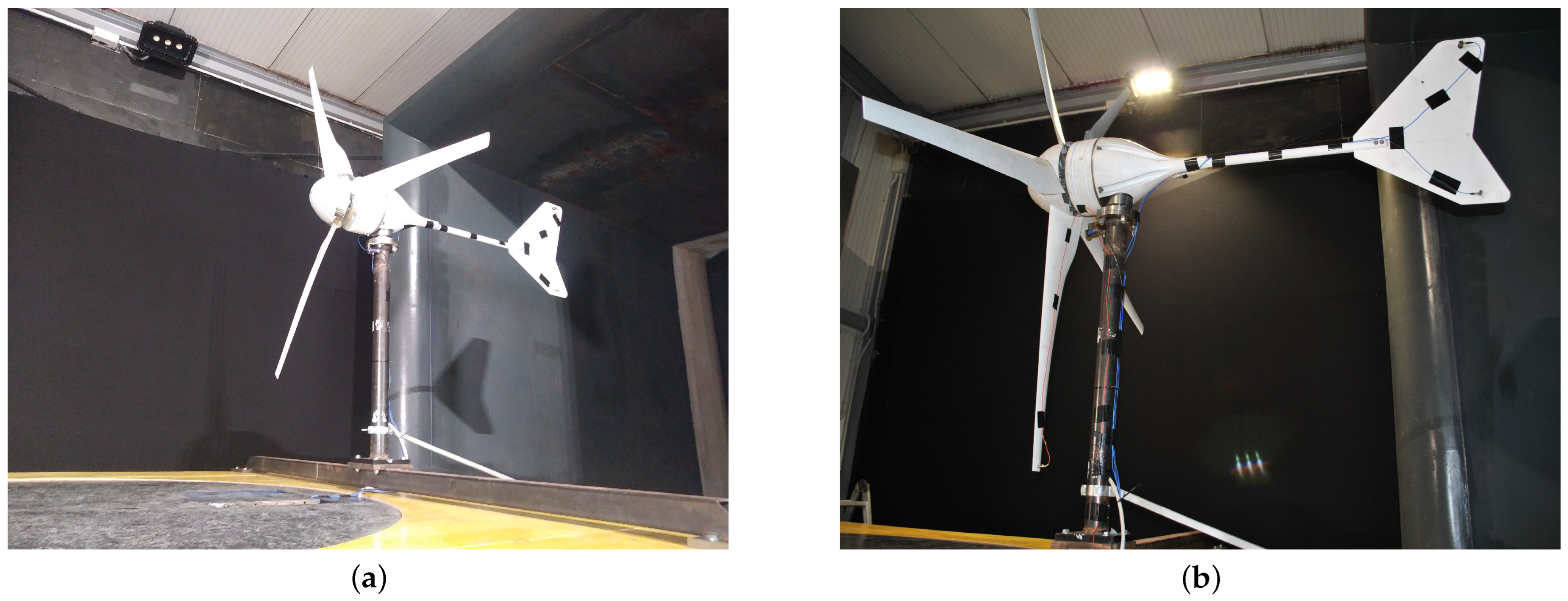

The subject of the experimental tests is a micro-wind turbine designed at the University of Perugia.

The device has been designed to be used for domestic purpose: the particularity of the blade profile consist on its low startup wind speed of about 3 m/s. It is ideal for domestic applications-thanks to the low weight and very low generated noise. The yawing of the turbine, to maintain the proper orientation of the rotor respect the wind direction, is passive through a tail fin.

In summary, the main features of the model object of the present study are:

More in detail, this paper is focused on the differences in the dynamic response of the turbine by changing the number of blades, in particular from three to five. To do this, different hubs of the rotors with the same size have been manufactured for the two configurations, to which the blades can be bolted.

More details about the wind tunnel and the features of the wind turbine are reported in Castellani et al. [

8].

2.3. Tests and Instrumentation

For the characterisation of the dynamic response of a rotating machine, the most interesting test is the ramp, in which the stress occurs over a wide frequency range. In this way, it is possible to understand the instabilities or the response in case of resonance, which can hardly be identified with a steady-state or sinusoidal test; also the dynamic of the rotor in raising in wind speed and production con be as well identified.

In particular, the paper focuses the study on two types of ramps for each configuration, one defined as “slow”, having a discrete speed increase of 0.278 m/s each 5 s, the other defined as “fast”, in which the increase is 0.556 m/s each 5 seconds.

The

Figure 4 represents the wind profile for each of the four tests. It is noted that the speeds range from about

m/s to

m/s, except for the three-blade slow ramp configuration where the wind was stopped at

m/s.

The instrumentation used to carry out the tests includes:

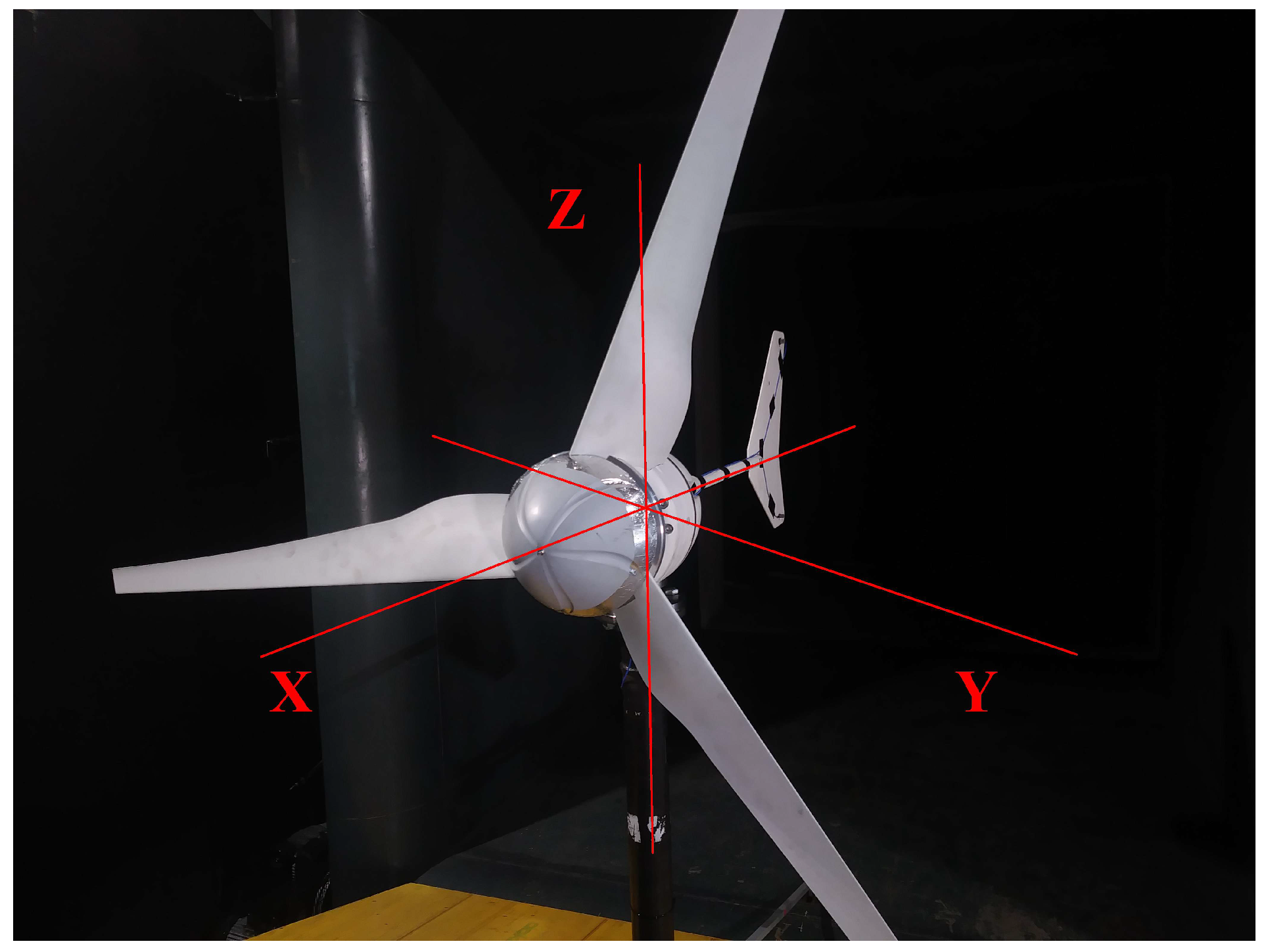

two triaxial accelerometers: the first placed at the top section of the tower fixed with epoxy glue, which allows to measure the acceleration of the tower in the Fore-Aft (FA) direction (in the paper it will be referred to as the X direction), Side-Side (SS) (Y direction) and vertical direction (Z) (

Figure 5); the second was positioned above the turbine nacelle;

two monoaxial accelerometers (SS direction) on the tail;

a tachometer to measure the angular velocity of the rotor by evaluating the frequency of passage of the single blade;

one cup anemometer upstream of the test chamber, to evaluate the wind speed blown in the tunnel.

The signals used for the present study were:

rpm signal;

wind speed;

accelerations in X and Y directions (

Figure 6).

3. Effects of Changing the Number of Blades

This section reports the post processing results of the data from the experimental measurements described in the

Section 2. In particular, the behaviour of the output signal from the tachometer (revolutions per minute) and from the accelerometers placed on the tower in the X and Y directions will be analysed, discussing the differences that occur by changing the number of blades from three to five.

The signals will be expressed as a function of time or frequency. Initially, the slope of each ramp will be analysed in the time domain and in the wind speed domain. As regards vibrations, being non-stationary signals, they will be studied through the use of Short Time Fourier Transform (STFT) and extracting the order magnitude from them.

3.1. Ramp Slope Analysis

As mentioned in

Section 2.3, the only wind speed range in which all four ramps can be compared is between

and

m/s.

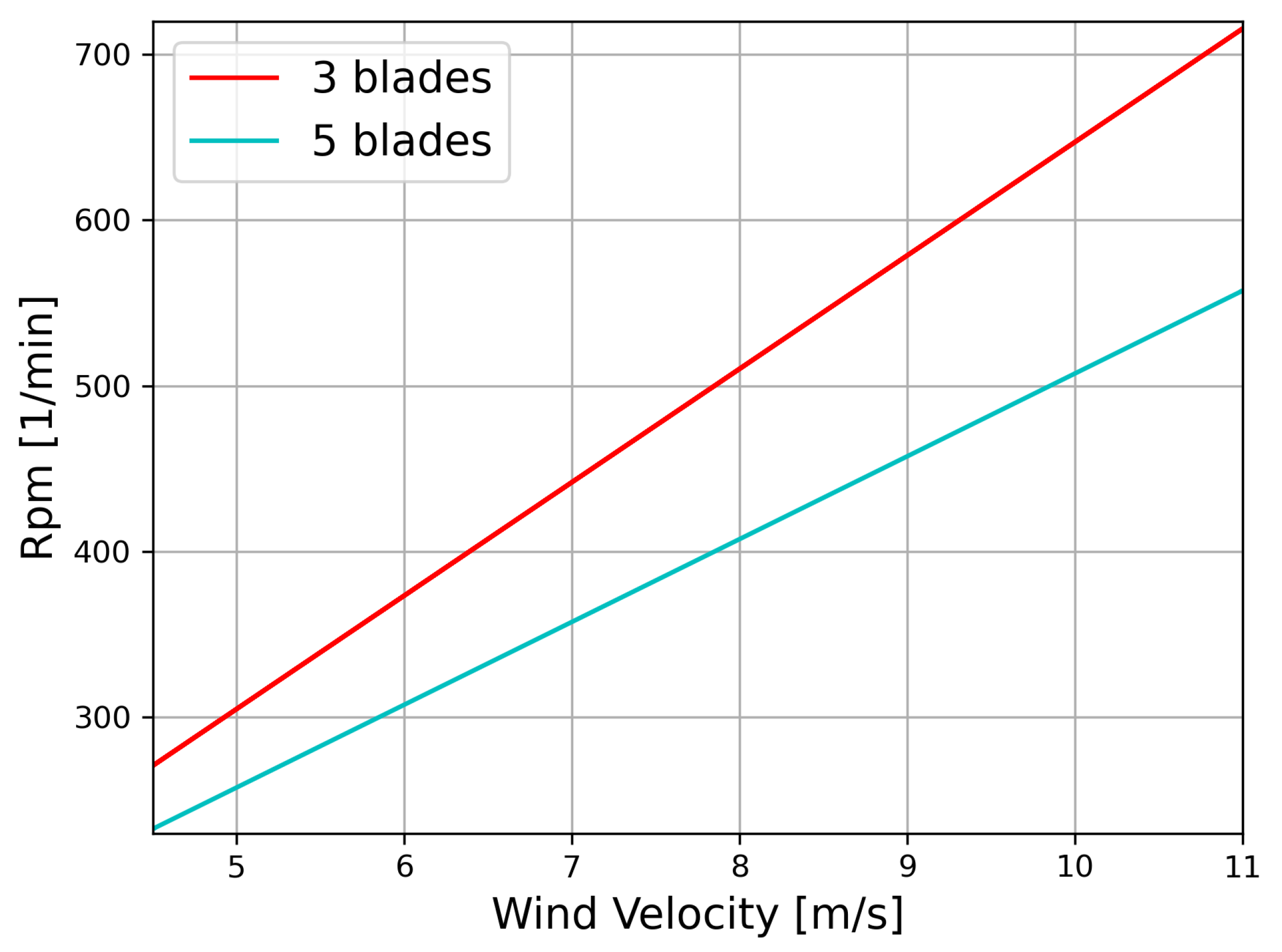

Figure 7 shows the trend of the rotor revolutions per minute (rpm) compared with the linearised input ramps in that interval.

The

Figure 7 shows how the 3-blades turbine, with the same input, works always at a higher number of rpm than the 5-blade machine, in accordance with what is explained in [

26].

Analysing the slope of this straight line with respect to time, it can be seen that passing from 3 to 5 blades leads to an average decrease in the slope in both ramps.

In

Figure 8 is shown a more detailed comparison, limited only to the fast ramp, between the linearized rpm of the 3 and 5 blade machine in relation to the wind speed.

Anyway, to make a more detailed comparison between the regressions (and therefore calculate slope, intercept and RMSE), it is necessary to compare them only in the common wind speed range, i.e., between 4.5 and 7.5 m/s. The results are proposed in

Figure 9 and

Table 1.

The data confirm that the speeds of the two turbines, if compared to the wind speed, are characterised by small differences for the two different ramps. The greater rpm slope occurs for the 3-blades machine: changing from three to five blades implies a percentage decrease in the rpm slope of about 35%. Therefore, the 5-blades, in addition to working always at lower rpm, also works at lower slopes of rpm: this fact demonstrate that the 3-blades machine is more reactive than the 5-blades, however the latter has the advantage that it is more stable at lower wind speed (and hence has a lower cut-in velocity). So, having also the intercepts close to zero, it could be more suitable for domestic use and with a higher capability to respond to weak highly variable gusts, for which it was indeed designed.

Furthermore, the regression gives acceptable values and very low mean absolute percentage error for each test.

3.2. Identification and Numerical Analysis

A numerical model has been developed through the use of system identification. This approach can be used to formulate mathematical models of dynamic system starting from measured data, with the purpose to reproduce the behaviour of a generic system.

The steps for system identification are:

The first step is to assume a generic structure of the system’s transfer function. The assumed validated second order mechanical model has the form of:

The data in input are the wind ramps shown in

Figure 4; in particular it has been checked how the results from the model obtained from the fast ramps have produced more accurate results, also because the slow ramp for the 3-blade is not complete. The output are the rpm values of each configuration (

Figure 7). Hence the model was trained with the fast ramp and the

values obtained for each configuration are then used to simulate different input, as for example the slower ramps or sinusoidal input.

3.2.1. Identification and Validation

The

Figure 10 shows how the model obtained can fit the real measured output for the two configurations in a reliable way. To simplify the process and to obtain better results, the input data (the wind ramps) was linearized as done in

Figure 7.

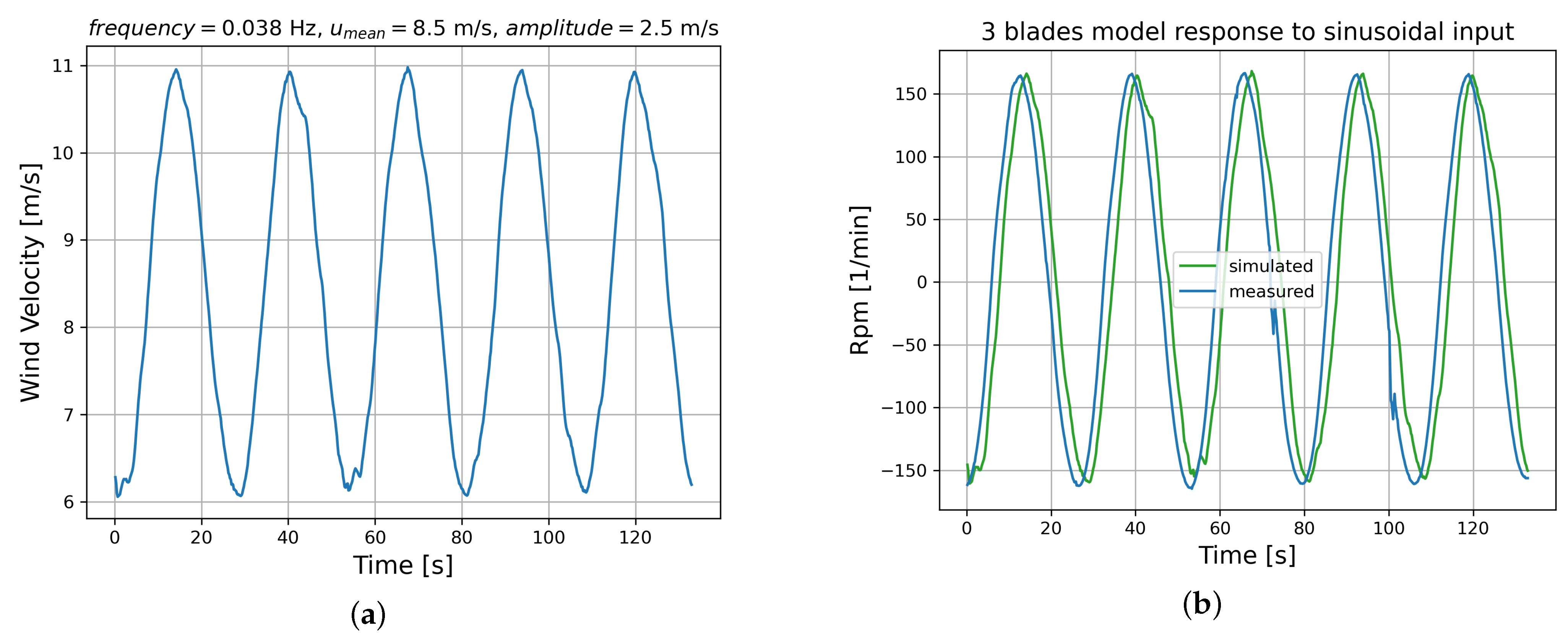

After calculating the parameters, the system was simulated with another different time varying input to validate the dynamical model for the three blades configuration. It was used a sinusoidal input as shown in

Figure 11a, that represent a real wind signal produced by the wind tunnel’s fan driven by the inverter. The signal is a low frequency sine (around 0.038 Hz), with mean value around 8.5 m/s and amplitude 2.5 m/s.

Figure 11b represents the real response to that input compared to the 3-blades model’s simulation. So the ramp-trained model can reproduce accurately the sinusoidal shape, the phase and the mean amplitude with a limited error.

3.2.2. Numerical Analysis

After that also a comparison was made on the power output of the two machines; the power of the wind turbine was obtained using the following equation:

in which

is the air density (assumed as the standard value 1.225 kg/m

),

U is the mean wind speed,

A is the rotor area and

is the power coefficient. For the estimation of the

, a look up table was used from [

22], in which the coefficients were calculated from experiments in the same turbines through:

where

V and

I are respectively the voltage and the generated current.

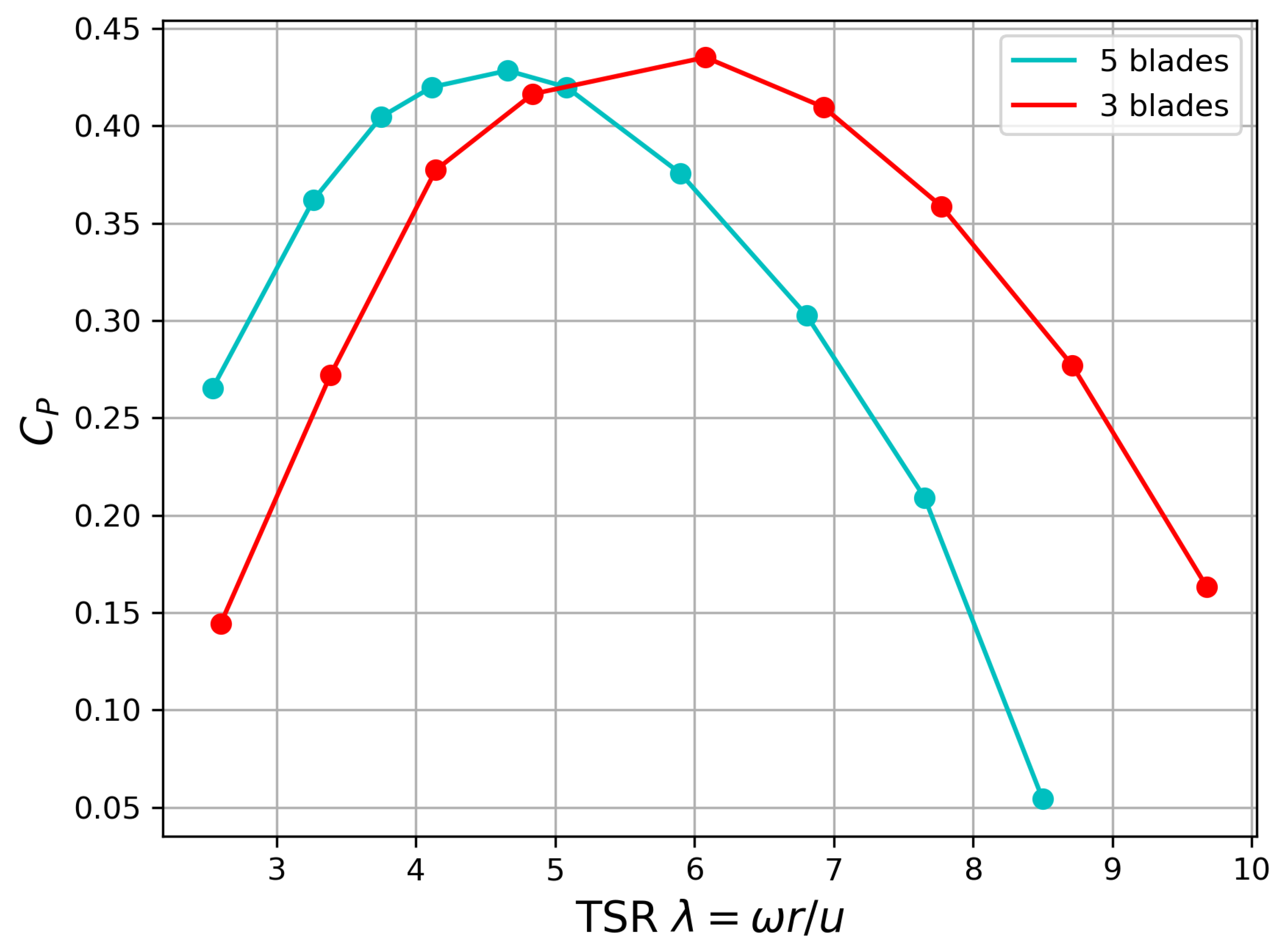

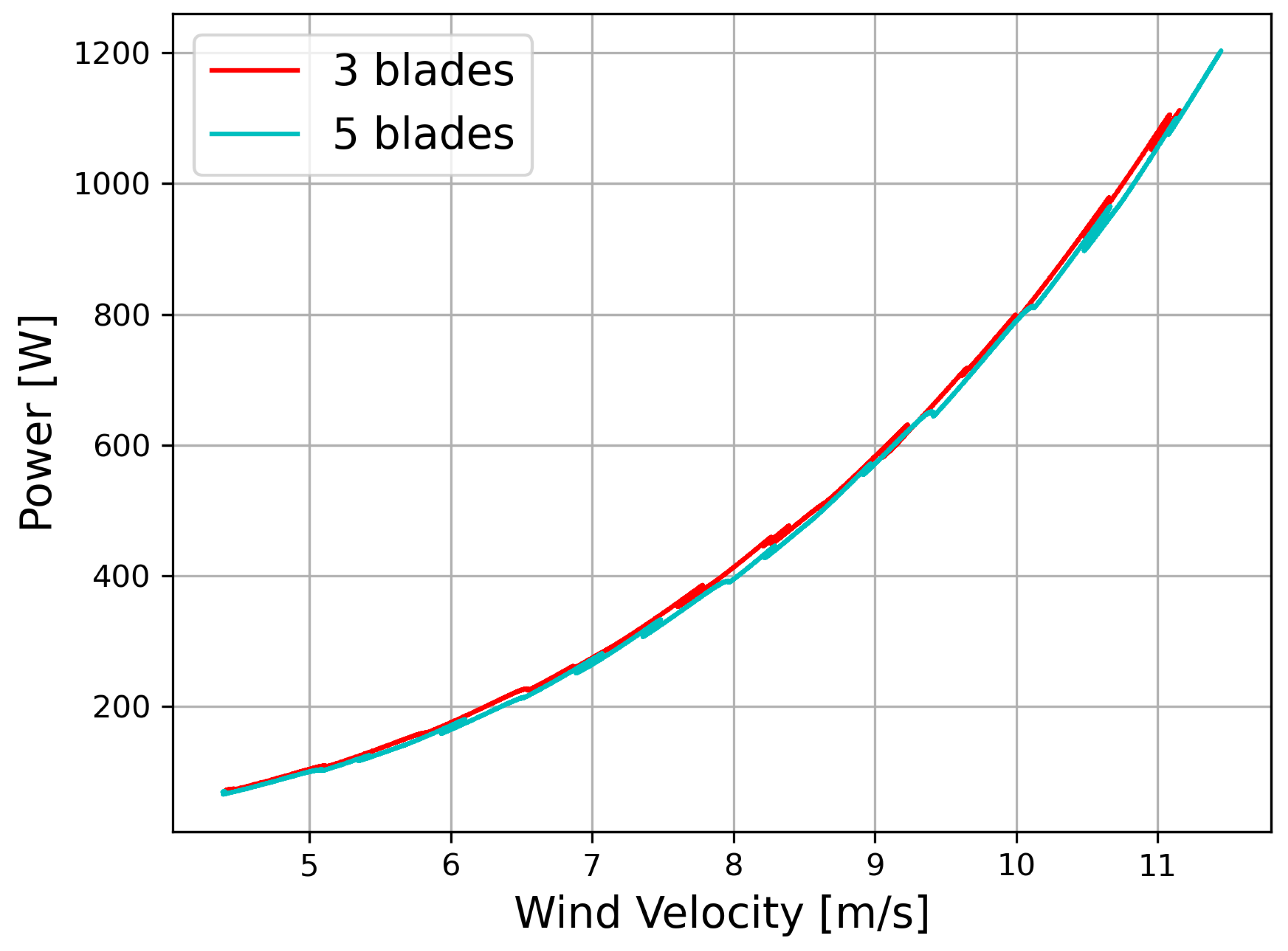

The results of

vs tip speed ratio (TSR) for the two machines are proposed in the

Figure 12.

From the ramp tests described above, was calculated, and therefore for each time step and for each configuration. In particular, a mean value of has been obtained for the 3 blades and for 5 blades, to which correspond a similar power coefficient for each configuration.

Figure 13 describes the trend of power vs wind velocity calculated for the two machines: the trend is very similar, due to the similar values of

.

That means that for the two turbine considered, with the same wind speed in input the revolution per minute is not the same (

Section 3.1 Figure 8) but the produced power is comparable.

3.3. Tower Acceleration Measurements

In the previous section, the differences between the two input ramps have been described, and in particular it has been described how the slow ramp, in order to obtain the same final values as the fast one, had to last twice as long. Regarding the analysis of vibrations, and therefore in the frequency domain, this fact is not secondary: since the sampling frequency is constant, the slow ramp produced a double number of values. This fact has two effects:

results containing twice the values lead to an increase in the operations to be done in the post processing phase;

the STFTs obtained from the slow ramp are more accurate, due to the fact that the changes of state were less rapid (they are closer to the hypothesis of quasi-stationarity).

However, despite the best accuracy, the STFTs calculated with the slow ramps doesn’t span to very high wind speed, because the test was interrupted once the speed of 7.5 m/s was reached (

Figure 4), and therefore only the data from the fast ramps will be used in next sections.

The picture shows the X and Y accelerations of the tower over rpm for the two different configurations.

For the 3-blades fore aft acceleration (X direction,

Figure 14a), the oscillation remains within a range of peak value of about

g. Furthermore, it can be observed that the signal has peaks around 350 rpm and after 600 rpm. As regards the 5-blades X acceleration, the same consideration can be made, with more evident resonances (up to 1 g), which arrive for different rpm.

Instead, accelerations in the side-side direction (Y,

Figure 14b) are in magnitude higher than those in the X direction (probably due to a slight rotor imbalance) and increasing after 500 rpm, but no substantial differences are appreciated between the two configurations.

It must to be said that at this point it is very difficult to compare the 5-blades turbine acceleration with the 3 blades, even because the 5-blades machine works at lower rpm range.

To overcome the problem of non-stationarity, it is necessary to pass to the time and frequency domain (through the use of the STFT), and to compare the amplitude of the vibration orders.

3.3.1. Order Tracking

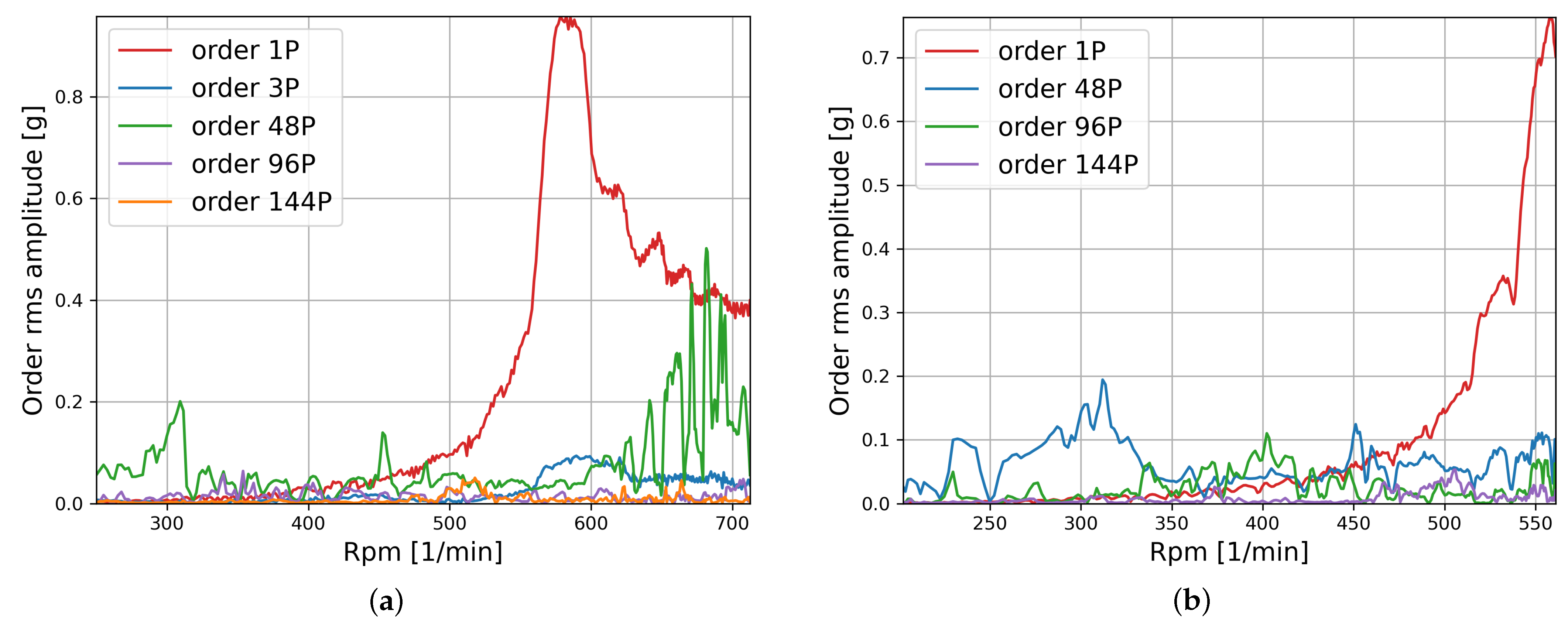

Through order tracking, it is possible to relate the tower vibrations directly or indirectly to the rotational speed of the shaft. From a design point of view, this is very important because the vibration related to the rotation can be relevant even without amplification of the resonance. In particular, the order spectrum of the two accelerations in the two configurations are presented in

Figure 15.

From the graphs, the main sources of vibrations appear to be respectively:

the 48P order in the FA direction, more evident in the 5-blades, especially the harmonics 96P and 144P (

Figure 15a), which probably has electrical origin;

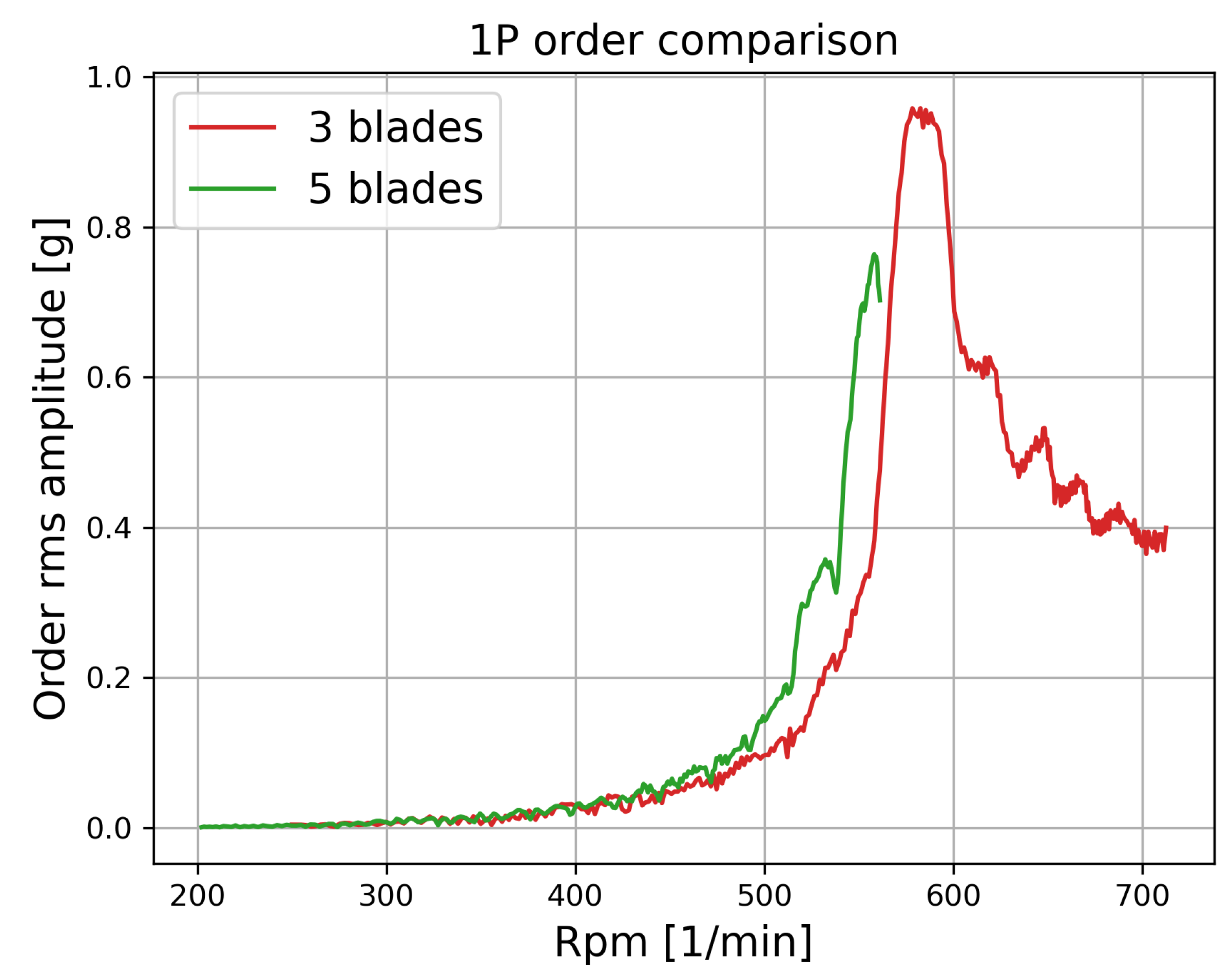

the 1P order in the SS direction, an indication of a probable imbalance present, as expected, mostly in the 3-blade (

Figure 15b).

Given the absence of 3P harmonics of appreciable amplitude in the 3-blades, it seems that the effects of the passage of the blades can be neglected. The same cannot be said in the 5 blades, given the presence of a peak at 5P in

Figure 15a. In the 3-blades in the X direction there is also a presence of a vibration of order 24P.

The following

Figure 16 and

Figure 17 show, more in detail, the trend of the main vibration orders during the test, and therefore plotted together with the rpm.

As for the X direction, in the 3-blade and 5-blade the presence of the 48P is different during the test. In any case, it must be said that in the 3-blade (

Figure 16a) the higher root mean square values are obtained for rpm higher than 650, which is a speed at which the 5-blade has not been operated. Instead, in the 5-blade machine (

Figure 16b) there are isolated peaks (for example at 200, 375 and 550 rpm) that even reach

g. The 1P vibration is quite similar for each configuration.

For the Y direction (

Figure 17), the order tracking responses of the two machines are quite similar, both in amplitude and for principal orders.

3.3.2. Waterfall

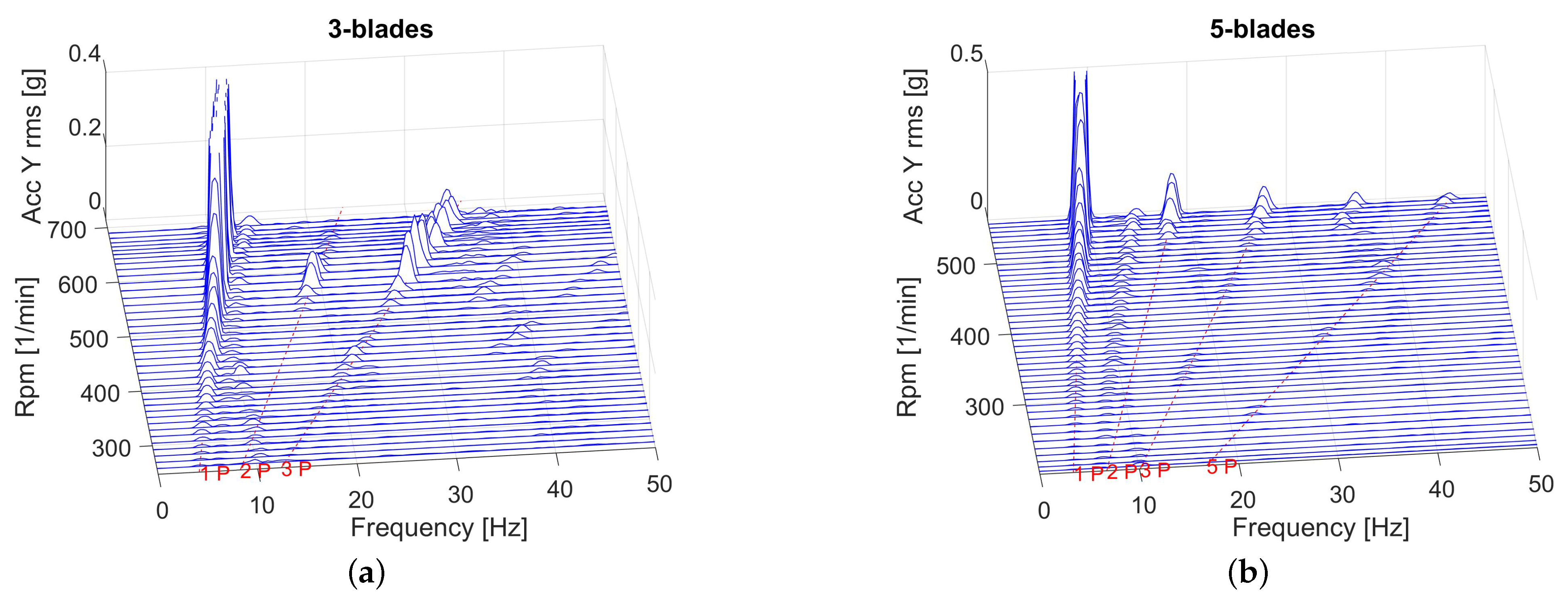

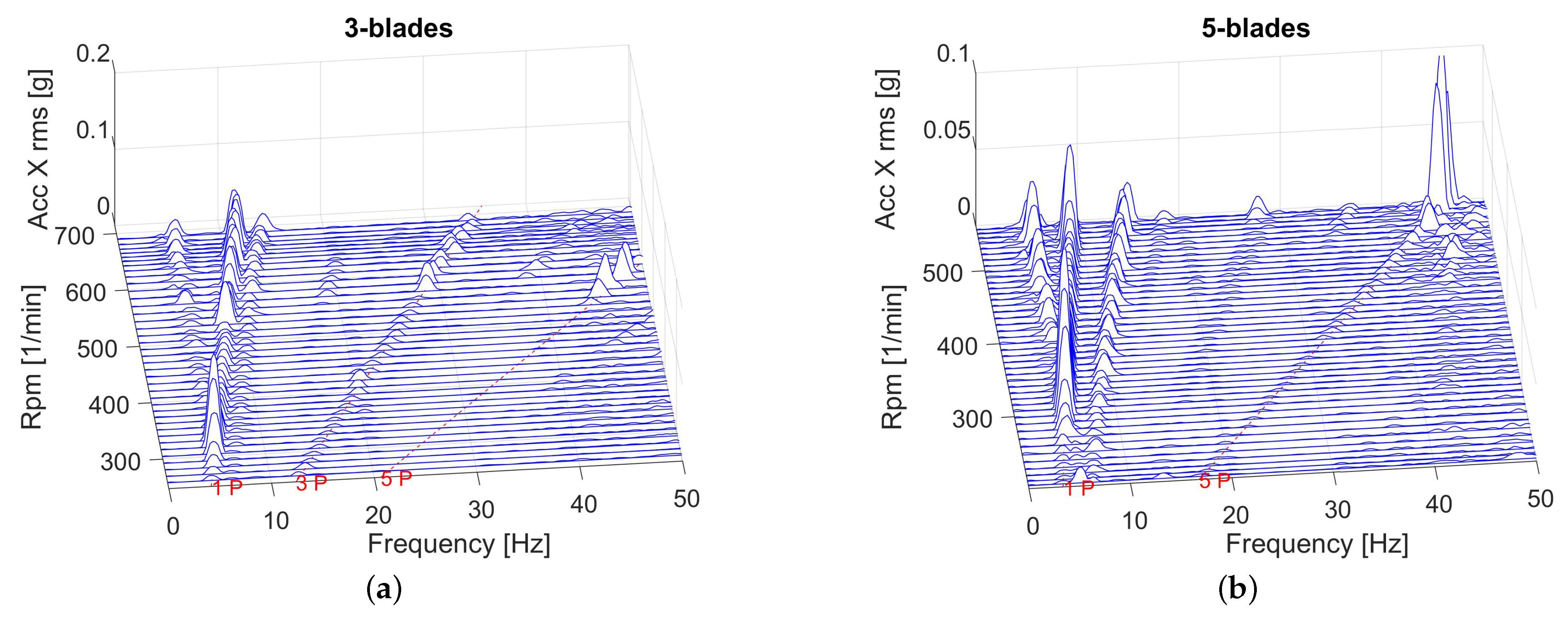

The following STFTs (up to 50 Hz) confirm the higher involvement of the first orders of the 5-blade configuration both in FA and SS direction. In both directions there is an increase in vibration around 10 Hz, in which the 1P line probably crosses one of the first natural frequencies of the structure, much more evident in the side-side direction and 5-blade machine (

Figure 18b). In the X direction, for the 5-blade machine, there is an important resonance around 45 Hz (

Figure 19b).

Regarding the acceleration in the Y direction, the STFTs (

Figure 18) confirms that there are small differences between the two configurations. In particular, with 1P, the turbines give similar response to 2P and 3P for the same rpm and frequency.

In the following STFTs the same accelerations of

Figure 18 and

Figure 19 are represented in a wider frequency domain. Focus is placed on the involvement of the 48P (and its harmonics 96P and 144P), especially for the 5-blade turbine (

Figure 20b). In particular, in the 5-blade and X direction (

Figure 21b), the 48P excites two resonances at 200 Hz and 300 Hz, unlike the 3-blade in which the acceleration root mean square is more centred on high frequencies.

Looking to a frequency domain between 200 and 1200 Hz, an obvious difference in behaviour in Y direction (

Figure 20) is that the response is much cleaner for the 3-blade machine.

4. Discussion

4.1. Dynamic Behaviour

The same sinusoidal wind signal described in

Section 3.2 (

Figure 11a) was given in input to the 5 blade model. The results are proposed in the

Figure 22, compared with the results of the 3 blade.

In each of the two responses, the mean value was subtracted. The 5-blade model trained with ramp can simulate successfully many aspects of the turbine’s behaviour. The sinusoidal pattern is reproduced in phase with the 3-blade, but the most important fact is that the lower rpm amplitude for the 5-blade case is simulated properly.

That means that ramp tests gave the possibility to develop a mathematical model for each turbine, validated with sinusoidal type input. Such models can be used for the simulation of different wind inputs, i.e., ramps with any slope or input of any type as sine function with different frequency or amplitude.

4.2. Summary of Results

Comparing the two machines in the wind speed range of 4.5–7.5 m/s, it results that the rpm slope vs wind velocity of the 3-blades is higher of 35% compared to the 5-blade. These results demonstrate that the 5-blade turbine is more suitable than the 3-blade for the domestic use, hence for real wind speed and turbulence, despite the worse general reactivity.

As regards the power aspect, as explained in

Section 3.2.2, linking the results obtained in [

22] with the ramp test described in

Section 3.1, it can be assumed that the 5-blade extracts the same power than the 3-blade, even rotating at lower rpm. The fact is interesting because that means that the produced power is not the main aspect, as others (i.e., operating wind velocity and vibrations) have a greater influence on the evaluation of pros and cons of each type of turbine.

As regards the tower vibrations in fore aft direction (X), the 5-blade has greater peak values, due to the greater sensibility to 48P order and its harmonics 96P and 144P, but the lower range of rpm does not allow the machine to reach critical frequencies and therefore resonances which have been observed in the three blades (

Figure 16a). In particular, the 48P in the 5 blades acts for three different rpm condition (at 200, 370 and 500 rpm,

Figure 16b), differently from the 3-blade in which that contribution is present for values of rpm greater than 650.

The main order involved in the tower accelerations in side side direction (Y) is the 1P, due probably to an imbalance of the rotor. The vibrations in time and frequency domains of the two machines are quite similar, and also 1P has similar contribution in the two turbines (

Figure 23). Anyway, the magnitude of vibration due to 1P (in all directions considered) is higher in the 3-blade turbine (

Figure 15 and

Figure 17) but, as can be shown in

Figure 23, it is not easy to make an absolute comparison as the machines are not synchronised in rpm.

4.3. Interpretation of Vibration Scenario

4.3.1. General Consideration

A general outlook to the results introduced in the previous section can bring to some important conclusions. The order vibration can be classified according to its origin, for example:

Mechanical: imbalances, bearings, shaft misalignment, gear meshing, yaw error;

Aerodynamics: shadow effect, vortex shedding, wind shear, blade vibration, turbulence;

Electrical: generator.

Obviously, the overall spectrum is given by the combination of all these factors and therefore it is not easy to decompose perfectly the vibration and the causes that induced it. Anyway, looking at the order spectrum (

Figure 15) and making assumptions about test conditions and the technical characteristics of turbines, is possible to exclude some of the previous mentioned causes and so to concentrate on the origin of main order of vibrations, like 1P (side side direction) and 48P (fore aft direction).

The wind tunnel conditions exclude the origins of turbulence and wind shear (both 1P, eventually), in particular:

the wind tunnel is designed to minimise the turbulence on the test section, which is less than %;

the wind profile generated can be considered practically constant.

The features of the turbines exclude also the vibrations due to yaw error and shaft tilt (the angle between the rotor shaft in the FA plane and the horizontal axis), because the turbine has a rudder with long tail fin, as can be seen from

Figure 6. So it is easy to conclude that the yaw error is very small and in the first case negligible, and then the shaft tilt is not present in the turbine. Causes due to shaft misalignment and gear meshing can also be excluded, given the absence of a gearbox in the considered machine.

The aerodynamic interaction of blade passing is the cause of one of the most important reasons of vibration in wind turbines, which is repeated as each blade passes in front of the tower. But in this case, the

Figure 15 shows that there are no relevant peaks either at order 3P for the 3-blade neither at order 5P for 5-blade (with respect to 1P or 48P), so it can be assumed that the blade passing is not so relevant for the two turbines of the study.

4.3.2. 1P Order Explanation

In the

Section 3.3.1, it has been discussed that for the considered turbines the main orders of vibrations are the 1P (mainly in the Y direction) and 48P (mainly in the X direction). From the above considerations, the 1P order is probably due to two main factors:

rotor imbalance: mass imbalances are caused by a not homogeneous mass distribution in the rotor. The main effect is an additional centrifugal force that rotates at the same speed as the rotor, hence 1P.

blade vibration: the aeroelastic interaction between blade and tower can however be considered reciprocal and therefore not only the passage of the blades excites the tower, but also the vibration of the tower excites the blades.

As regards 1P order (

Figure 15), the rms acceleration values in Y direction is around ten times (both in the 3-blade and 5-blade configuration) that the corresponding in the X direction, therefore the rotor imbalance (radial component) is much higher than the blade vibration contribution.

4.3.3. 48P Order Explanation

The 48P component cannot be related back to the tower-blade interference in correspondence of the passage of the blade, as mentioned in

Section 4.3.1. The explanation of this harmonic is due to the electromechanical coupling of the machine, i.e., with the synchronous generator. The machine is equipped with a permanent magnet generator (PMG) with 8 pole pairs (16 poles). The number 48 is obtained from the product between 16 (poles) and 3, that is the number of the phases of stator (three-phase generator). The first harmonic (48P) is followed by the second (96P) and the third (144P), in a more relevant way in the 5-blade turbine (

Figure 15).

Hence, the generator vibrates and transmits the vibration to the entire structure (and also to the tower). The direction of the oscillation depends on the electromagnetic nature of the interference between the poles and the stator, which justifies its presence not only in the radial direction, but also in the axial direction. In particular, in the Y direction the acceleration’s rms is greater of % for 3-blade and lower of 40% for the 5-blade.

As regards the difference in the blade number, in the fore aft direction the rms values are quite similar changing from 3 blades to 5 blades (the difference is only around 5%); in the side side direction an appreciable reduction of 46% of rms in the 5-blade configuration occurs. The disadvantage of the 5-blades is, as said, the greater sensibility to the second and third harmonic of 48P.

5. Conclusions

In the present study, a research about the dynamic and aeroelastic response of a small wind turbine in the wind tunnel has been presented, in particular about the differences by changing the number of blade from three to five. The study is motivated by the fact that micro-wind works on a wide speed range and therefore it is more likely to encounter critical speeds and resonances. The small wind turbine under investigation has been tested for a wind speed range from 4.5 to 11.5 m/s, controlling the wind in the tunnel in order to have two different ramps (slower and faster).

The first comparison has been made about the slope of the rpm line vs time and wind speed. It has been demonstrated that the 3-blade configuration works at higher rpm and has a significant higher slope. But this fact, as explained in

Section 3.1 and

Section 4.2, involves lower stability at low wind speeds, which are more representative of real urban conditions.

Through the ramp tests a numerical model for each turbine was developed and validated through a real sinusoidal test in the wind tunnel for the 3-blades configuration. Then an estimation of power output was done by the used of power coefficients look-up tables: it was found that the power extracted (for the same wind speed) is practically the same in the two investigated configurations, due to the very similar values, despite the lower rpm range of the 5-blade machine.

Then the study moved to the vibration scenario: the tower accelerations in the FA and SS directions, through the use of STFT and order analysis.

Some peculiar behaviours of the machine are:

remarkable contribution of 1P to the SS vibration, higher in the 3-blade;

the lower stress that occurs in the 5-blades, due to the lower speed of rotation, and its consequent improved reliability;

great contribution of 48P in all directions, due to the electrical generator;

the negligible effect of the passage of the blades.

Furthermore, from the comparison of the two configurations it has been possible to individuate the origin of the 48P order, as it is present in the two machine in similar way. This fully demonstrate how important can be the electromechanical coupling in such a small wind energy conversion system.

In conclusion, the results obtained from the three different approaches (rpm slope, power estimation and vibration analysis) show the advantages to choose the configuration with more blades, which implies lower operational wind speed (also lower cut in velocity), the same power extracted, lower vibration levels (lower contribution to 1P,

Figure 23), and so more reliability.

Future investigations will be devoted to analysing more in deep the role of the electrical control for improving the machine response as well as damping the most important harmonics in order to make these small devices much more compliant for residential applications.

Author Contributions

Conceptualization, A.E., M.V. and F.N.; methodology, A.E. and M.V.; numerical analysis, M.V.; investigation, M.V.; resources, M.V.; data curation, M.V.; writing—original draft preparation, F.C., F.N., A.E. and M.V.; writing—review and editing F.C., A.E., F.N. and M.V.; Supervising F.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Data are available upon request to the authors.

Acknowledgments

The authors acknowledge Matteo Becchetti from the University of Perugia for contributing to the experimental campaign for the study.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Sunderland, K.; Woolmington, T.; Blackledge, J.; Conlon, M. Small wind turbines in turbulent (urban) environments: A consideration of normal and Weibull distributions for power prediction. J. Wind Eng. Ind. Aerodyn. 2013, 121, 70–81. [Google Scholar] [CrossRef]

- Sang, L.Q.; Murata, J.; Morimoto, M.; Kamada, Y.; Maeda, T.; Li, Q. Experimental investigation of load fluctuation on horizontal axis wind turbine for extreme wind direction change. J. Fluid Sci. Technol. 2017, 12, JFST0005. [Google Scholar] [CrossRef]

- Lubitz, W.D. Impact of ambient turbulence on performance of a small wind turbine. Renew. Energy 2014, 61, 69–73. [Google Scholar] [CrossRef]

- Pagnini, L.C.; Burlando, M.; Repetto, M.P. Experimental power curve of small-size wind turbines in turbulent urban environment. Appl. Energy 2015, 154, 112–121. [Google Scholar] [CrossRef]

- Castellani, F.; Becchetti, M.; Astolfi, D.; Cianetti, F. Dynamic experimental and numerical analysis of loads for a horizontal axis micro wind turbine. In Proceedings of the Research and Innovation on Wind Energy on Exploitation in Urban Environment Colloquium, Riva del Garda, Italy, 15–16 June 2017; pp. 79–90. [Google Scholar]

- Meng, J.; Dai, K.; Zhao, Z.; Mao, Z.; Camara, A.; Zhang, S.; Mei, Z. Study on the aerodynamic damping for the seismic analysis of wind turbines in operation. Renew. Energy 2020, 159, 1224–1242. [Google Scholar] [CrossRef]

- Castellani, F.; Berno, F.; Becchetti, M.; Astolfi, D.; Piccioni, E. Analyzing the Unsteady Dynamic Behaviour of a Small Wind Turbine for Urban Applications. In Proceedings of the Colloquium on Research and Innovation on Wind Energy on Exploitation in Urban Environment Colloquium, Riva del Garda, Italy, 6–7 September 2018; pp. 245–254. [Google Scholar]

- Castellani, F.; Astolfi, D.; Becchetti, M.; Berno, F. Experimental and numerical analysis of the dynamical behavior of a small horizontal-axis wind turbine under unsteady conditions: Part I. Machines 2018, 6, 52. [Google Scholar] [CrossRef]

- Lopez-Villalobos, C.; Rodriguez-Hernandez, O.; Campos-Amezcua, R.; Hernandez-Cruz, G.; Jaramillo, O.; Mendoza, J. Wind turbulence intensity at La Ventosa, Mexico: A comparative study with the IEC61400 standards. Energies 2018, 11, 3007. [Google Scholar] [CrossRef]

- Wilson, S.; Clausen, P. Aspects of the dynamic response of a small wind turbine blade in highly turbulent flow: Part 1 measured blade response. Wind Eng. 2007, 31, 217–231. [Google Scholar] [CrossRef]

- Anup, K.; Whale, J.; Evans, S.P.; Clausen, P.D. An investigation of the impact of wind speed and turbulence on small wind turbine operation and fatigue loads. Renew. Energy 2020, 146, 87–98. [Google Scholar]

- Castellani, F.; Astolfi, D.; Natili, F.; Mari, F. The yawing behavior of horizontal-axis wind turbines: A numerical and experimental analysis. Machines 2019, 7, 15. [Google Scholar] [CrossRef]

- Dai, J.; Yang, X.; Hu, W.; Wen, L.; Tan, Y. Effect investigation of yaw on wind turbine performance based on SCADA data. Energy 2018, 149, 684–696. [Google Scholar] [CrossRef]

- Kragh, K.A.; Hansen, M.H. Potential of power gain with improved yaw alignment. Wind Energy 2015, 18, 979–989. [Google Scholar] [CrossRef]

- Battisti, L.; Benini, E.; Brighenti, A.; Dell’Anna, S.; Castelli, M.R. Small wind turbine effectiveness in the urban environment. Renew. Energy 2018, 129, 102–113. [Google Scholar] [CrossRef]

- Balduzzi, F.; Bianchini, A.; Ferrari, L. Microeolic turbines in the built environment: Influence of the installation site on the potential energy yield. Renew. Energy 2012, 45, 163–174. [Google Scholar] [CrossRef]

- Bianchi, S.; Bianchini, A.; Ferrara, G.; Ferrari, L. Small wind turbines in the built environment: Influence of flow inclination on the potential energy yield. J. Turbomach. 2014, 136, 041013. [Google Scholar] [CrossRef]

- Balduzzi, F.; Bigalli, S.; Bianchini, A. A hybrid BEM-CFD model for effective numerical siting analyses of wind turbines in the urban environment. J. Phys. Conf. Ser. 2018, 1037, 072029. [Google Scholar] [CrossRef]

- Yuan, C.; Li, J.; Xie, Y.; Bai, W.; Wang, J. Investigation on the Effect of the Baseline Control System on Dynamic and Fatigue Characteristics of Modern Wind Turbines. Appl. Sci. 2022, 12, 2968. [Google Scholar] [CrossRef]

- Lokesh, U.; Kirthika, N.; Madhan, K.M.; Maheswaran, C.; Ramaswami, S.; Pillai, S.N. Effect of solidity on the dynamic behaviour of the Darrieus turbine with leading-edge protuberance. IOP Conf. Ser. Earth Environ. Sci. 2021, 850, 012038. [Google Scholar] [CrossRef]

- Mabrouk, I.B.; El Hami, A. Effect of number of blades on the dynamic behavior of a Darrieus turbine geared transmission system. Mech. Syst. Signal Process. 2019, 121, 562–578. [Google Scholar] [CrossRef]

- Eltayesh, A.; Castellani, F.; Burlando, M.; Hanna, M.B.; Huzayyin, A.; El-Batsh, H.M.; Becchetti, M. Experimental and numerical investigation of the effect of blade number on the aerodynamic performance of a small-scale horizontal axis wind turbine. Alex. Eng. J. 2021, 60, 3931–3944. [Google Scholar] [CrossRef]

- Rezaeiha, A.; Montazeri, H.; Blocken, B. Towards optimal aerodynamic design of vertical axis wind turbines: Impact of solidity and number of blades. Energy 2018, 165, 1129–1148. [Google Scholar] [CrossRef]

- Eltayesh, A.; Hanna, M.B.; Castellani, F.; Huzayyin, A.; El-Batsh, H.M.; Burlando, M.; Becchetti, M. Effect of wind tunnel blockage on the performance of a horizontal axis wind turbine with different blade number. Energies 2019, 12, 1988. [Google Scholar] [CrossRef]

- Sagharichi, A.; Zamani, M.; Ghasemi, A. Effect of solidity on the performance of variable-pitch vertical axis wind turbine. Energy 2018, 161, 753–775. [Google Scholar] [CrossRef]

- Gasch, R.; Twele, J. Wind Power Plants: Fundamentals, Design, Construction and Operation; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2011. [Google Scholar]

Figure 1.

Schematic representation of the wind tunnel.

Figure 1.

Schematic representation of the wind tunnel.

Figure 2.

Three blades rotor (a) and five blades rotor (b).

Figure 2.

Three blades rotor (a) and five blades rotor (b).

Figure 3.

The two different complete configurations: three blades (a) and five blades (b).

Figure 3.

The two different complete configurations: three blades (a) and five blades (b).

Figure 4.

The four different types of input.

Figure 4.

The four different types of input.

Figure 5.

Detail of some of the instruments installed on the wind turbine. Red arrows: monoaxial (upper) and three-axial (lower) accelerometer. Green arrow: optic tacho sensor.

Figure 5.

Detail of some of the instruments installed on the wind turbine. Red arrows: monoaxial (upper) and three-axial (lower) accelerometer. Green arrow: optic tacho sensor.

Figure 6.

Convention for the directions.

Figure 6.

Convention for the directions.

Figure 7.

(Upper): rpm vs time (s) trend. (Lower): Wind Speed vs time.

Figure 7.

(Upper): rpm vs time (s) trend. (Lower): Wind Speed vs time.

Figure 8.

Comparison of the linearized rpm with wind speed for 3-blade and 5-blade turbine.

Figure 8.

Comparison of the linearized rpm with wind speed for 3-blade and 5-blade turbine.

Figure 9.

Rpm-wind speed interpolation. Comparison between slow and fast ramp for the 3-blade and 5-blade machine. (a) 3 blade hub with slow ramp; (b) 5 blade hub with slow ramp; (c) 3 blade hub with fast ramp; (d) 5 blade hub with fast ramp.

Figure 9.

Rpm-wind speed interpolation. Comparison between slow and fast ramp for the 3-blade and 5-blade machine. (a) 3 blade hub with slow ramp; (b) 5 blade hub with slow ramp; (c) 3 blade hub with fast ramp; (d) 5 blade hub with fast ramp.

Figure 10.

Numerical simulation of the 3 blades (a) and 5 blades (b) compared to measured data.

Figure 10.

Numerical simulation of the 3 blades (a) and 5 blades (b) compared to measured data.

Figure 11.

Left (a): real sinusoidal input. Right (b): three blades model and real response comparison (shifted to have zero mean).

Figure 11.

Left (a): real sinusoidal input. Right (b): three blades model and real response comparison (shifted to have zero mean).

Figure 12.

Power coefficient of the two turbine vs tip speed ratio.

Figure 12.

Power coefficient of the two turbine vs tip speed ratio.

Figure 13.

Comparison of power (W) vs wind velocity (m/s) trend between 3 blades and 5 blades.

Figure 13.

Comparison of power (W) vs wind velocity (m/s) trend between 3 blades and 5 blades.

Figure 14.

Measured tower’s acceleration comparison. (a) FF (X) acceleration. (b) SS (Y) acceleration.

Figure 14.

Measured tower’s acceleration comparison. (a) FF (X) acceleration. (b) SS (Y) acceleration.

Figure 15.

Order spectrum comparison. (a) FA direction (X), (b) SS direction (Y).

Figure 15.

Order spectrum comparison. (a) FA direction (X), (b) SS direction (Y).

Figure 16.

Principal orders of vibration (FA direction), for 3 blades (a) and 5 blades (b).

Figure 16.

Principal orders of vibration (FA direction), for 3 blades (a) and 5 blades (b).

Figure 17.

Principal orders of vibration (SS direction), for 3 blades (a) and 5 blades (b).

Figure 17.

Principal orders of vibration (SS direction), for 3 blades (a) and 5 blades (b).

Figure 18.

SS acceleration’s STFT comparison (up to 50 Hz). (a) 3 blades (b) 5 blades.

Figure 18.

SS acceleration’s STFT comparison (up to 50 Hz). (a) 3 blades (b) 5 blades.

Figure 19.

FA acceleration’s STFT comparison (up to 50 Hz). (a) 3 blades (b) 5 blades.

Figure 19.

FA acceleration’s STFT comparison (up to 50 Hz). (a) 3 blades (b) 5 blades.

Figure 20.

SS acceleration’s STFT comparison (up to 1200 Hz). (a) 3 blades (b) 5 blades.

Figure 20.

SS acceleration’s STFT comparison (up to 1200 Hz). (a) 3 blades (b) 5 blades.

Figure 21.

FA acceleration’s STFT comparison (up to 1000 Hz). (a) 3 blades (b) 5 blades.

Figure 21.

FA acceleration’s STFT comparison (up to 1000 Hz). (a) 3 blades (b) 5 blades.

Figure 22.

Different response of the 3-blade and 5-blade model to sinusoidal input.

Figure 22.

Different response of the 3-blade and 5-blade model to sinusoidal input.

Figure 23.

1P order comparison in SS direction (Y).

Figure 23.

1P order comparison in SS direction (Y).

Table 1.

Metrics of the slow and fast ramp tests for 3 and 5 blade turbine.

Table 1.

Metrics of the slow and fast ramp tests for 3 and 5 blade turbine.

| Configuration | Slope | Intercept | RMSE | R2 Score | MAPE% |

|---|

| 3 blades, slow ramp | 66.43 | −36.53 | 32.681 | 0.988 | 1.297 |

| 5 blades, slow ramp | 49.61 | 2.71 | 19.578 | 0.988 | 1.2244 |

| 3 blades, fast ramp | 69.58 | −44.73 | 53.519 | 0.982 | 1.6851 |

| 5 blades, fast ramp | 51.05 | 0.53 | 34.419 | 0.98 | 1.6748 |

| Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).