Numerical Simulation Research on the Vibration of Helical Tube Arrays under Transverse Flow

Abstract

1. Introduction

2. Numerical and Modeling Method

2.1. CFD Method

2.2. CFD/CSD Coupling Method under Mode Superposition

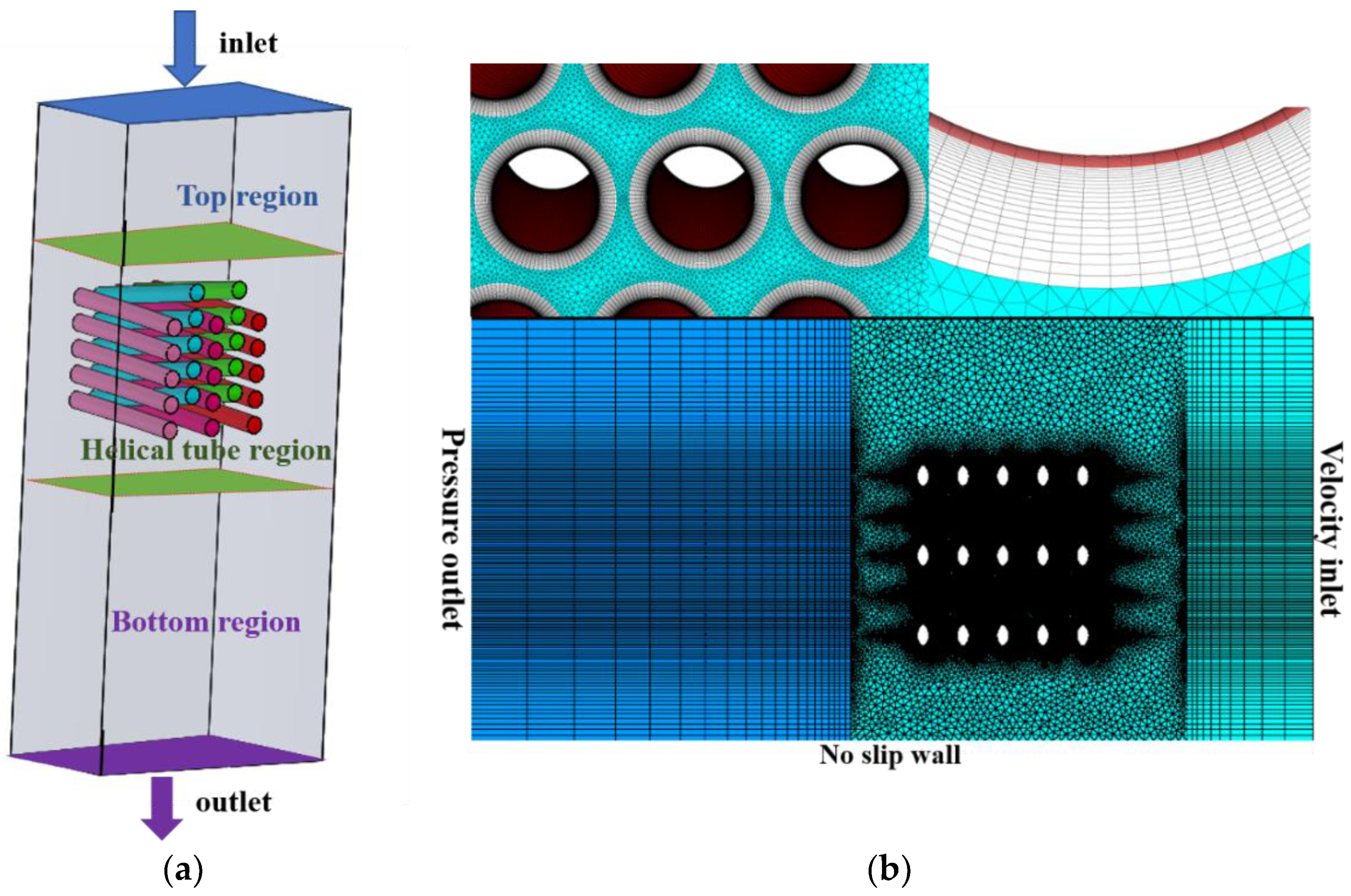

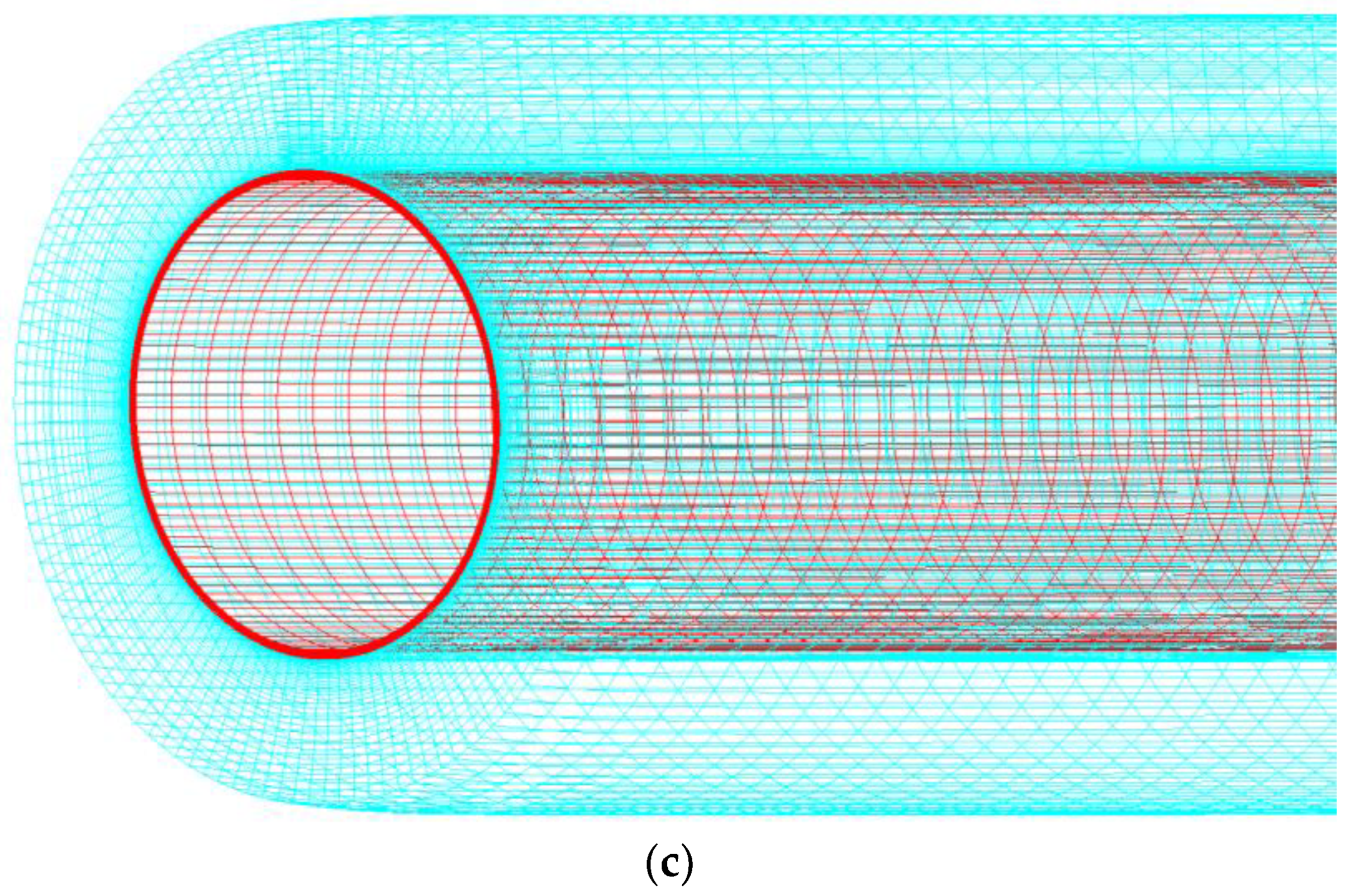

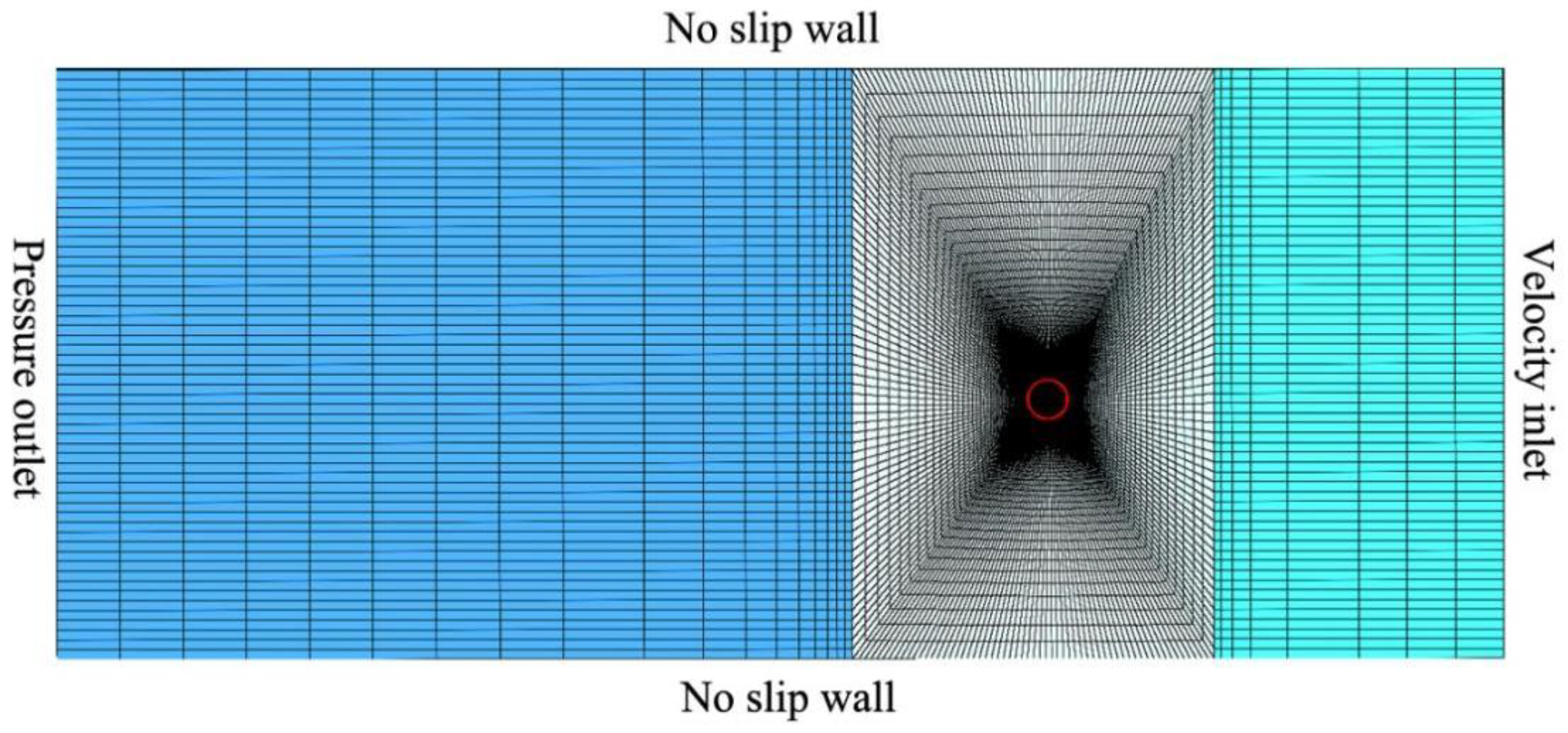

3. Computational Domain and Meshing Strategy

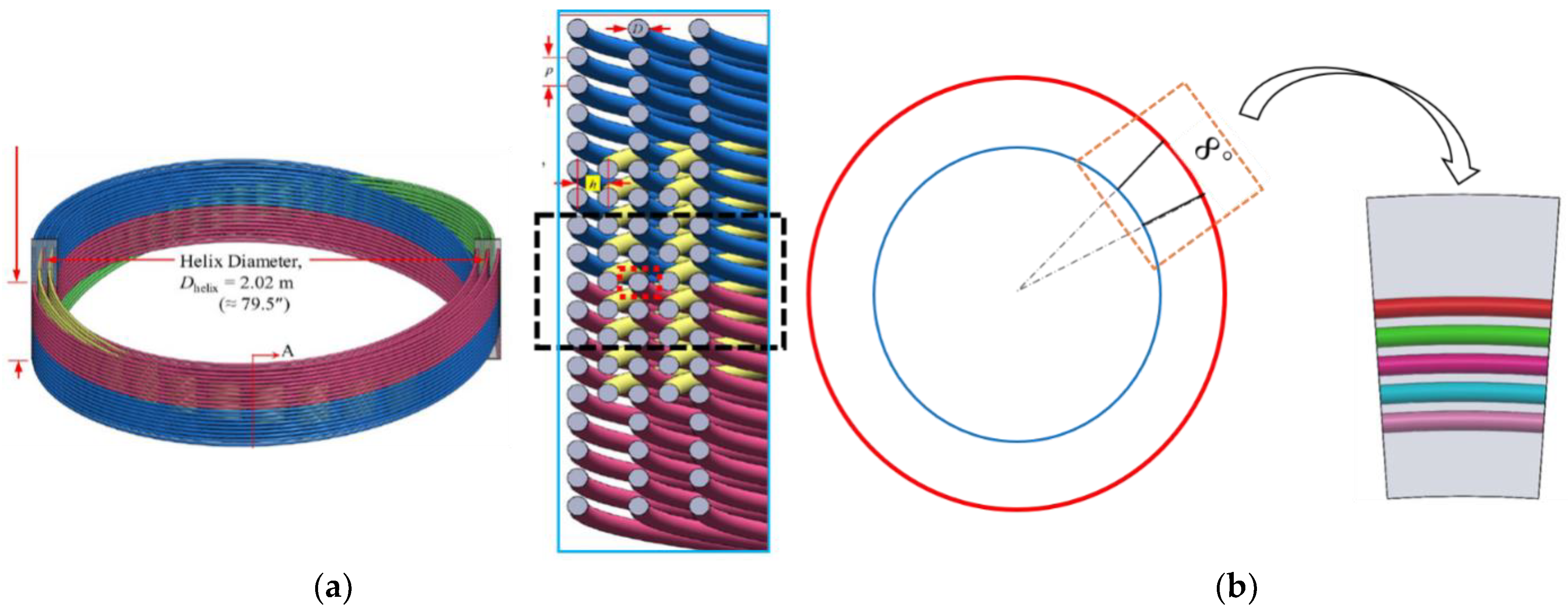

3.1. Physical Modeling

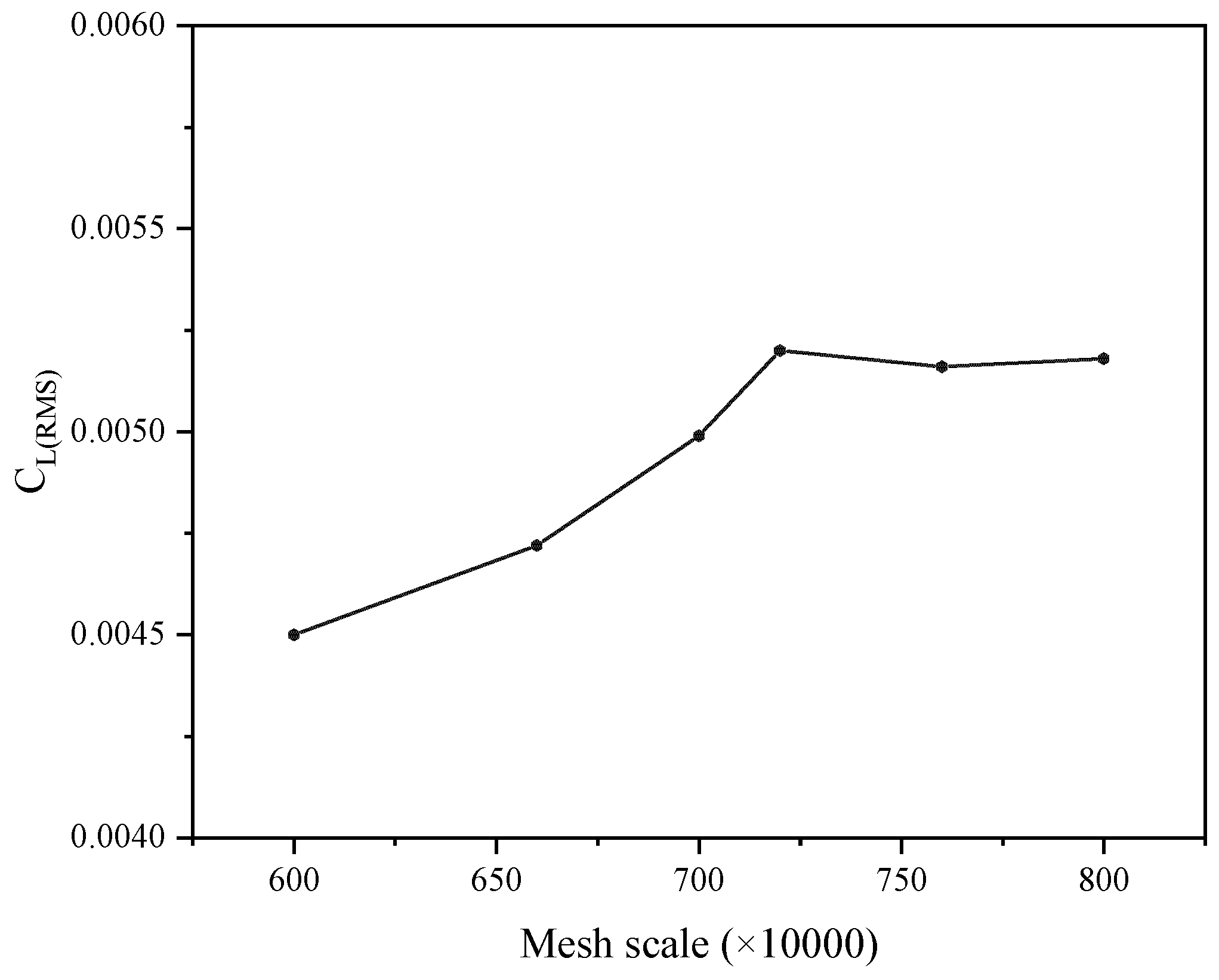

3.2. Grid Independence Test Analysis

4. Results and Discussion

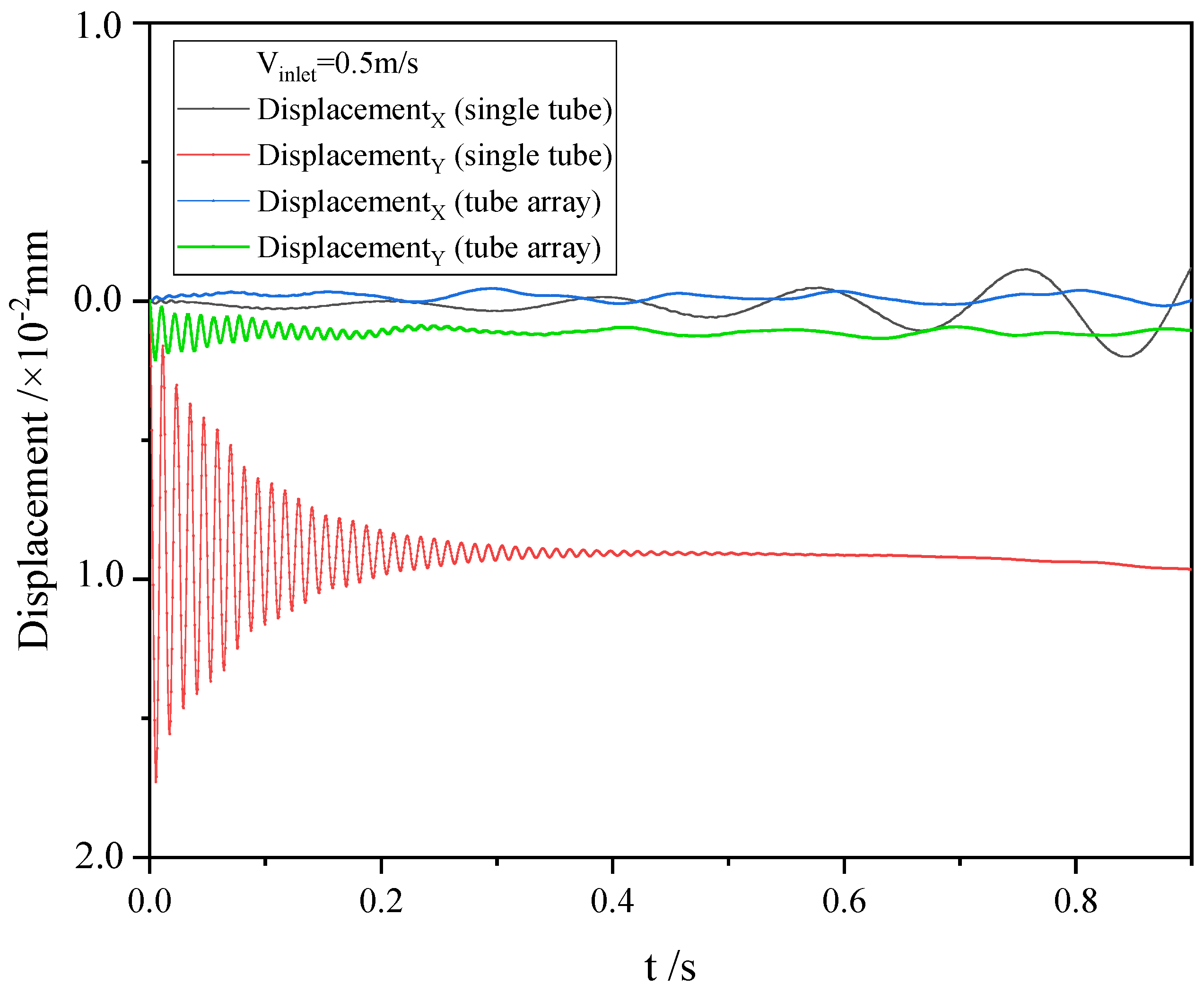

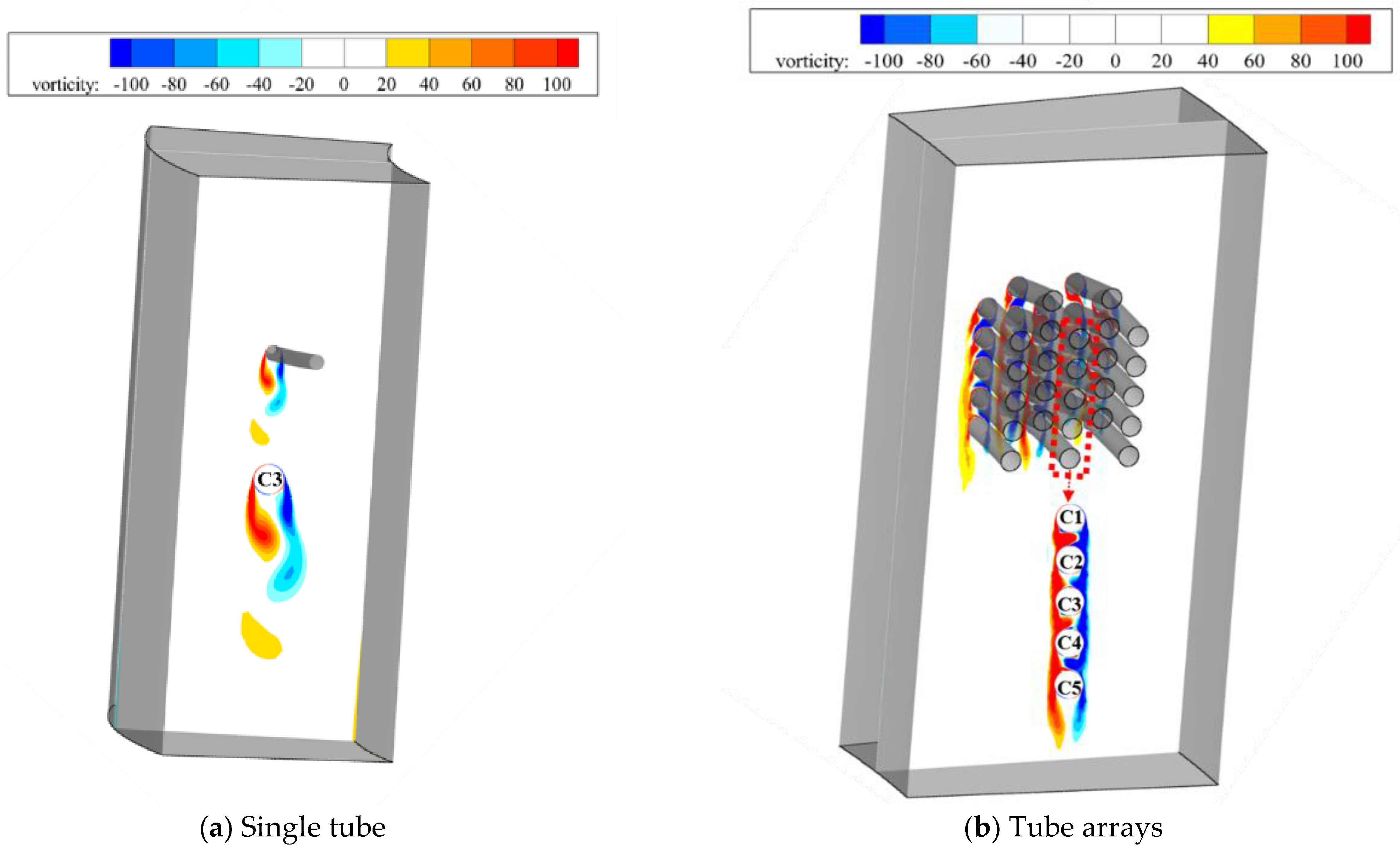

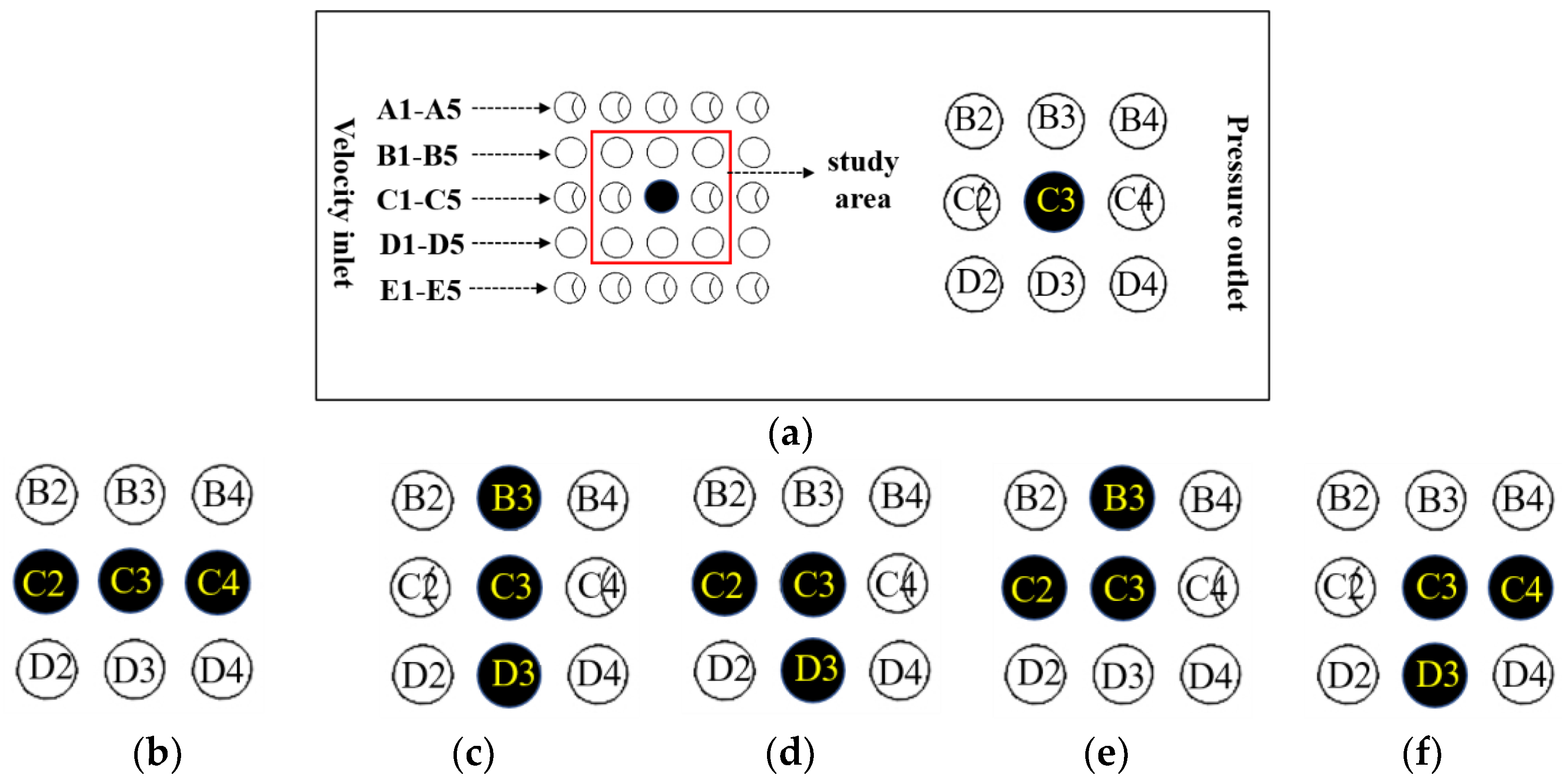

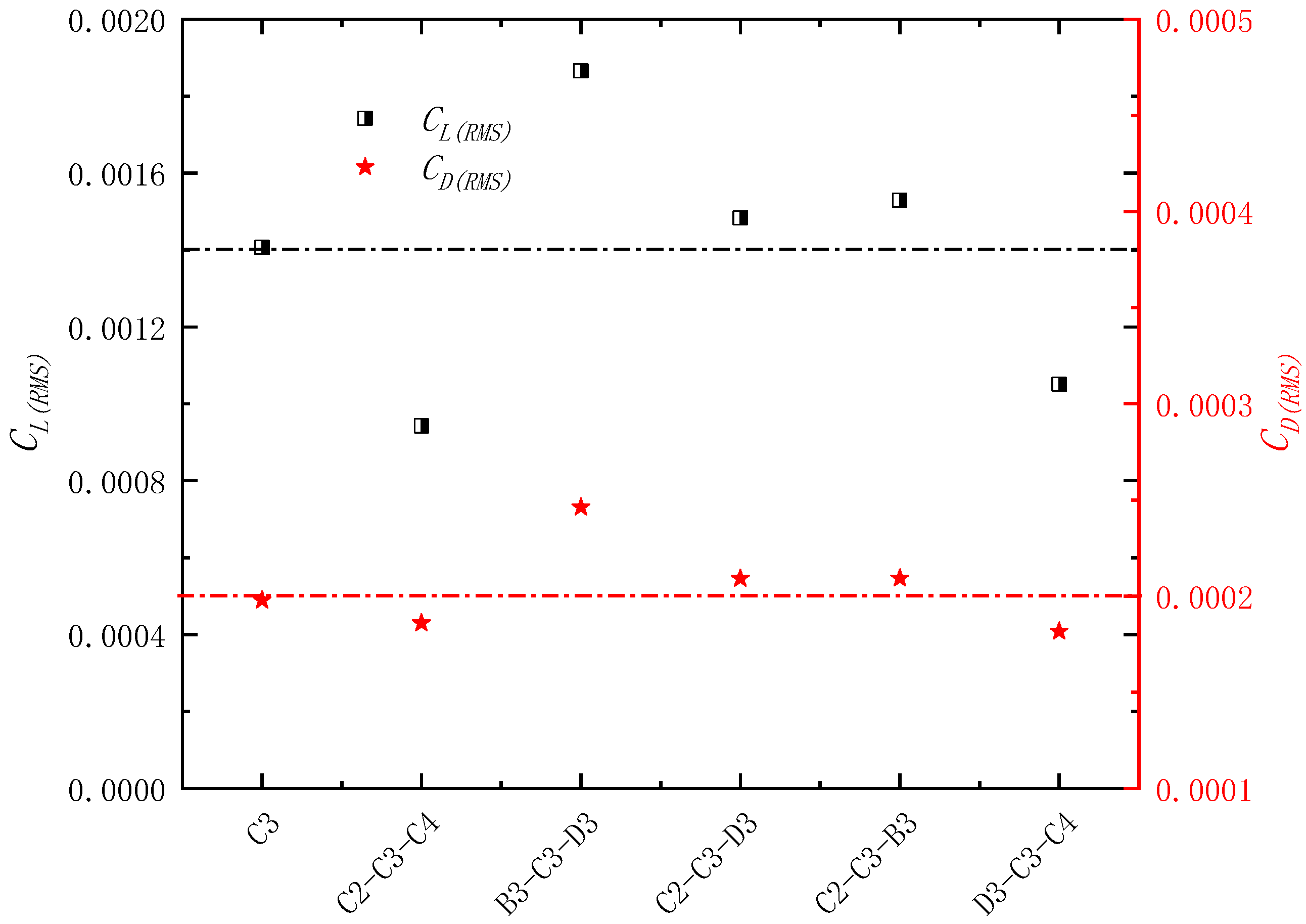

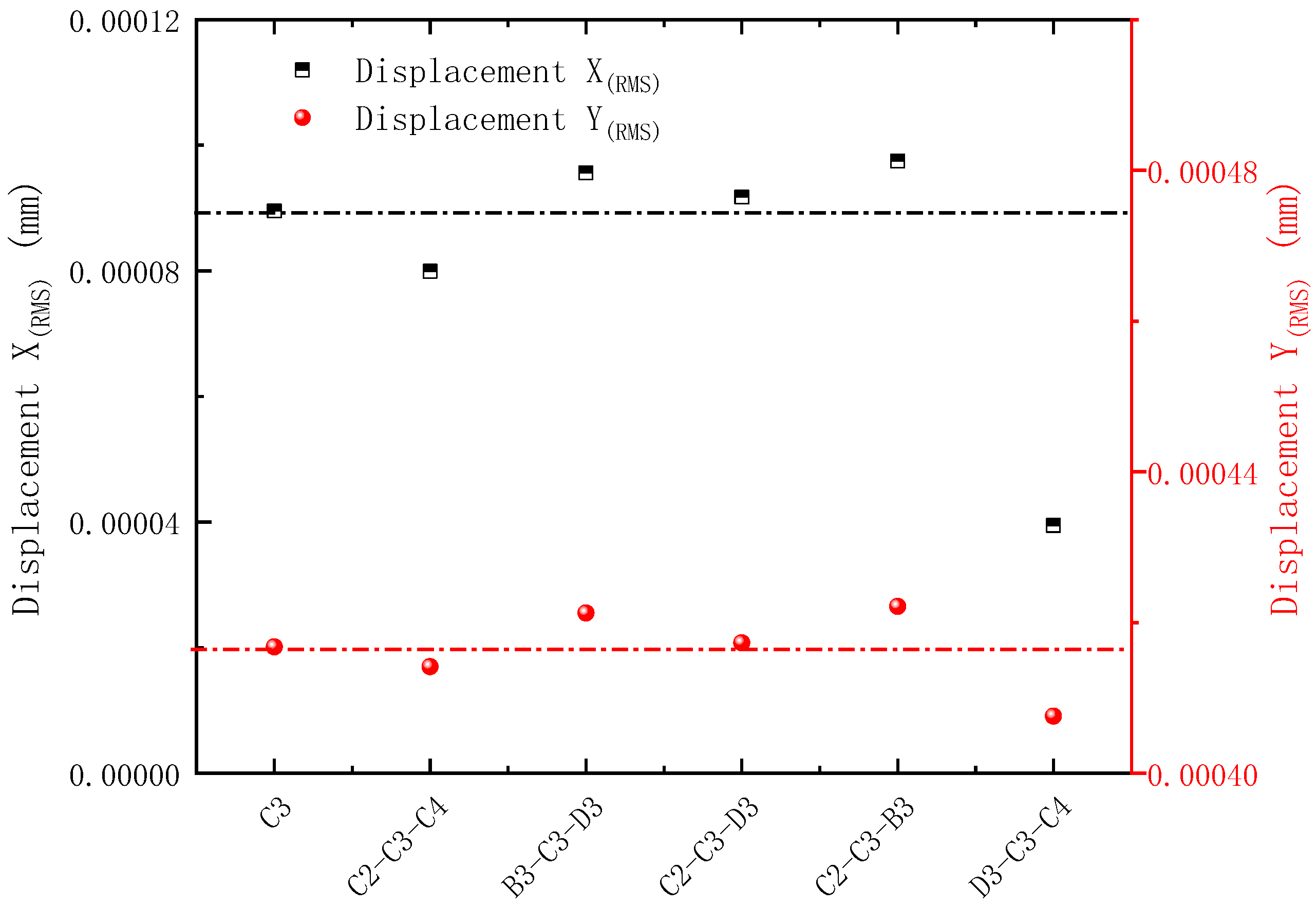

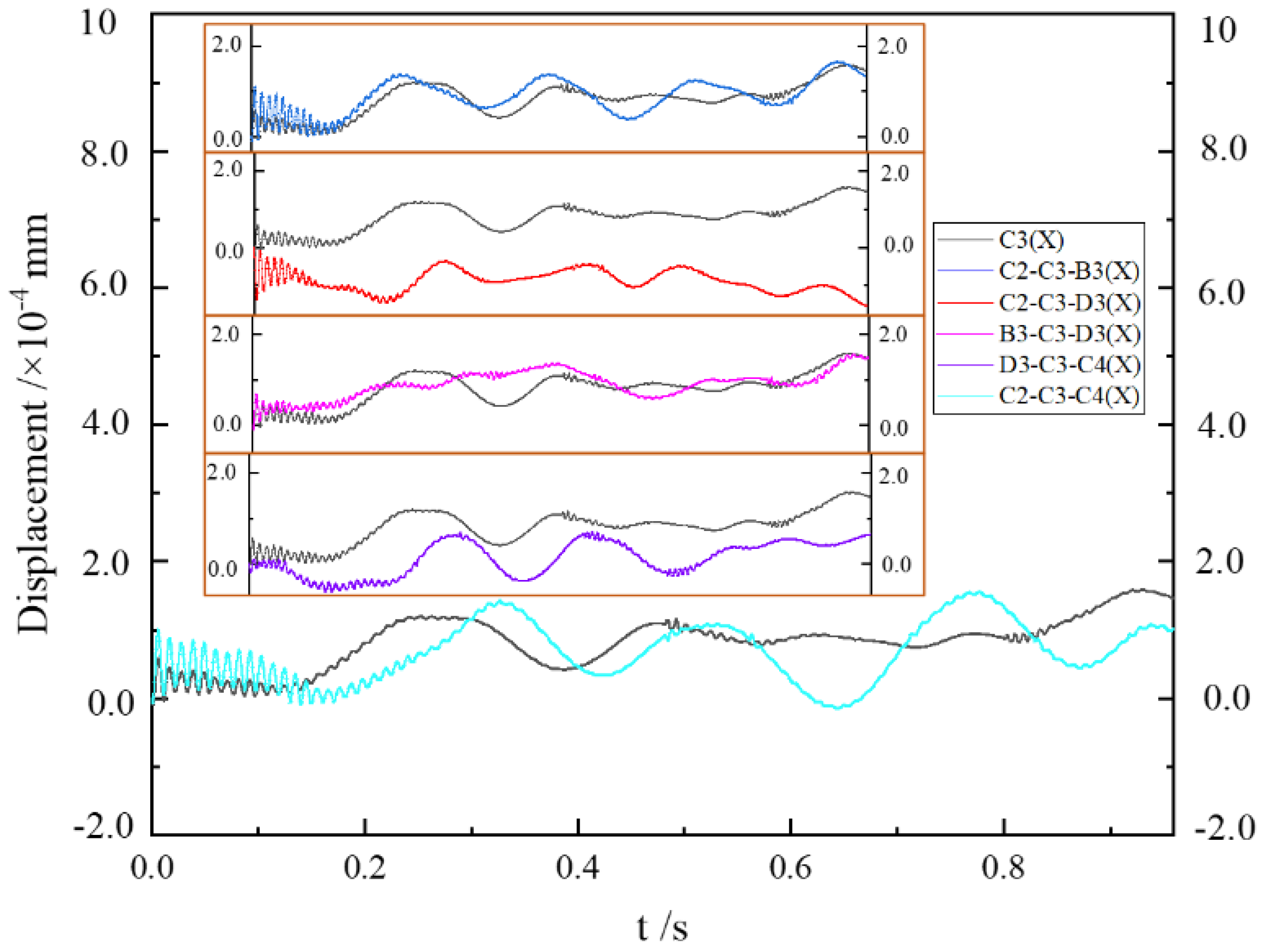

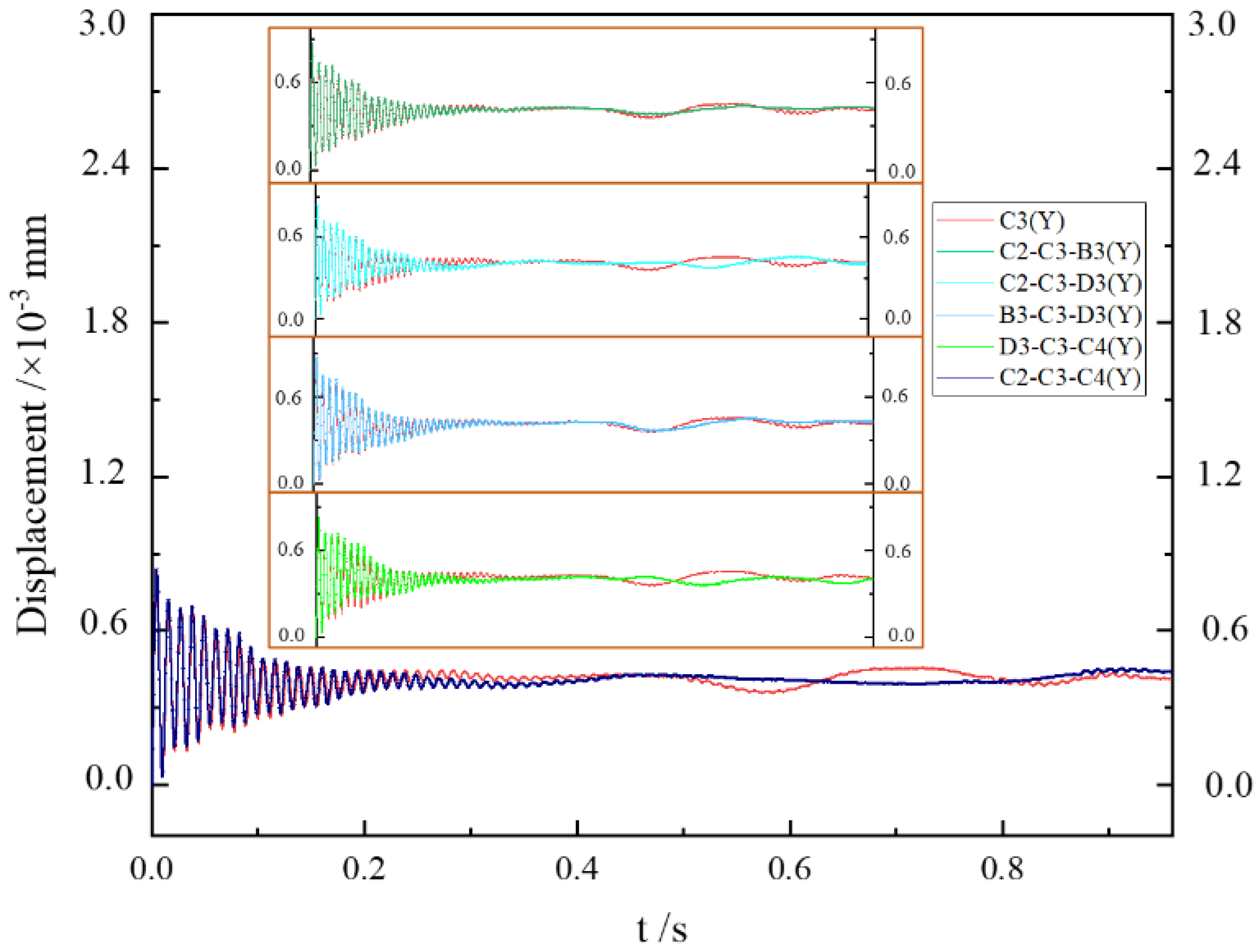

4.1. Influence of Tube Arrays and Single Tube on Target Tube Vibration

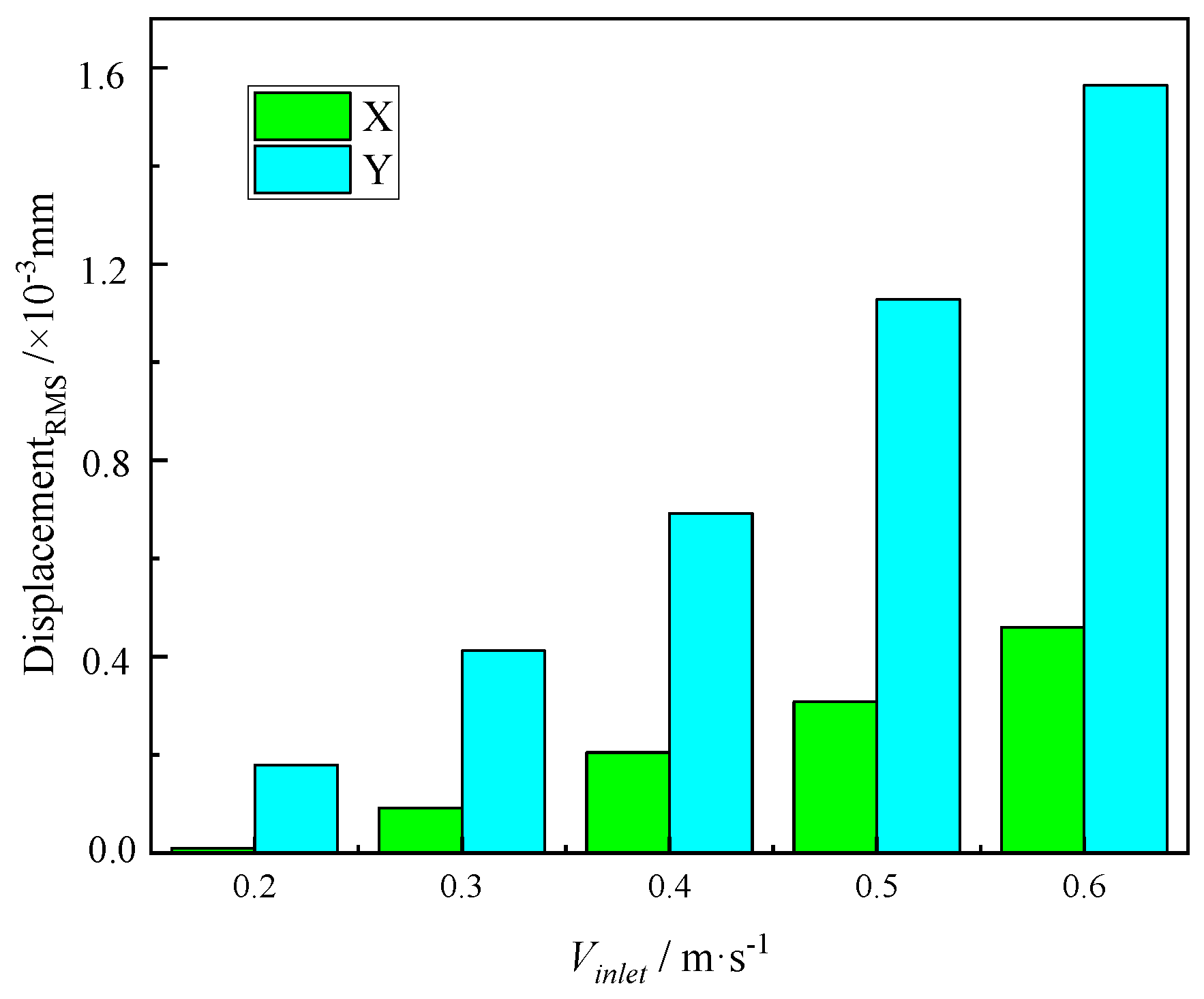

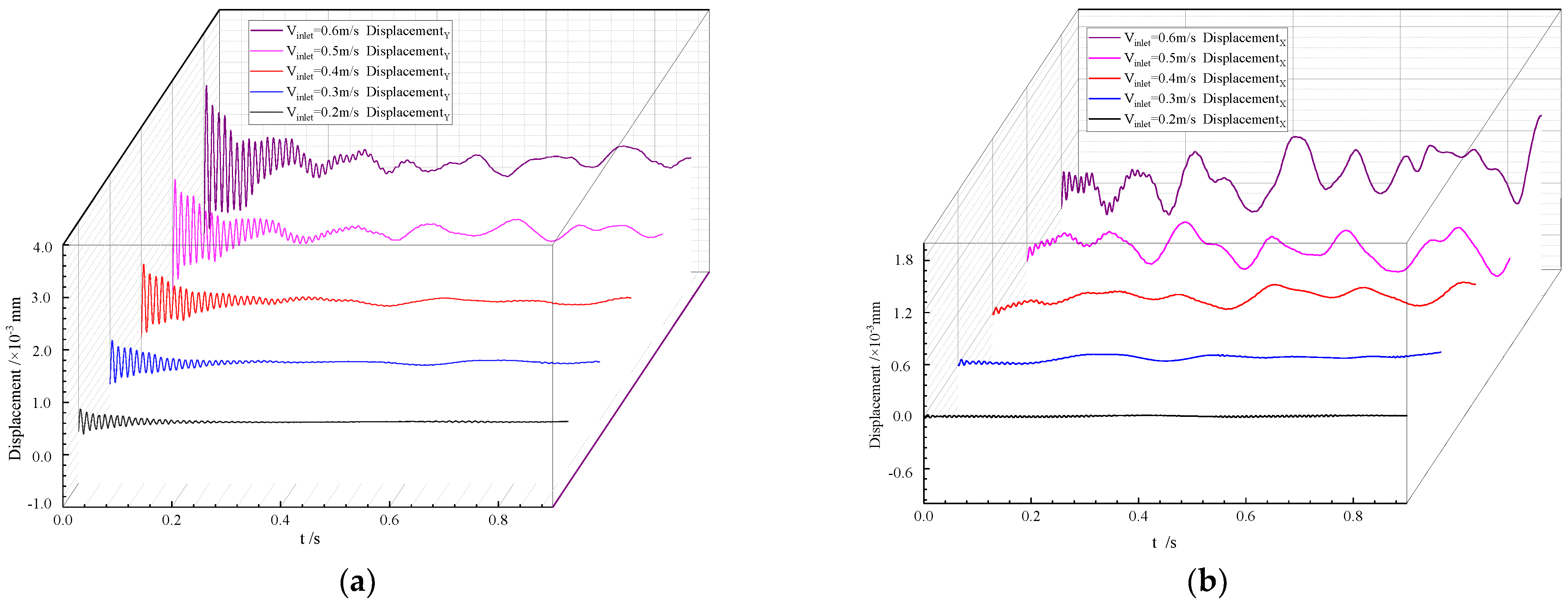

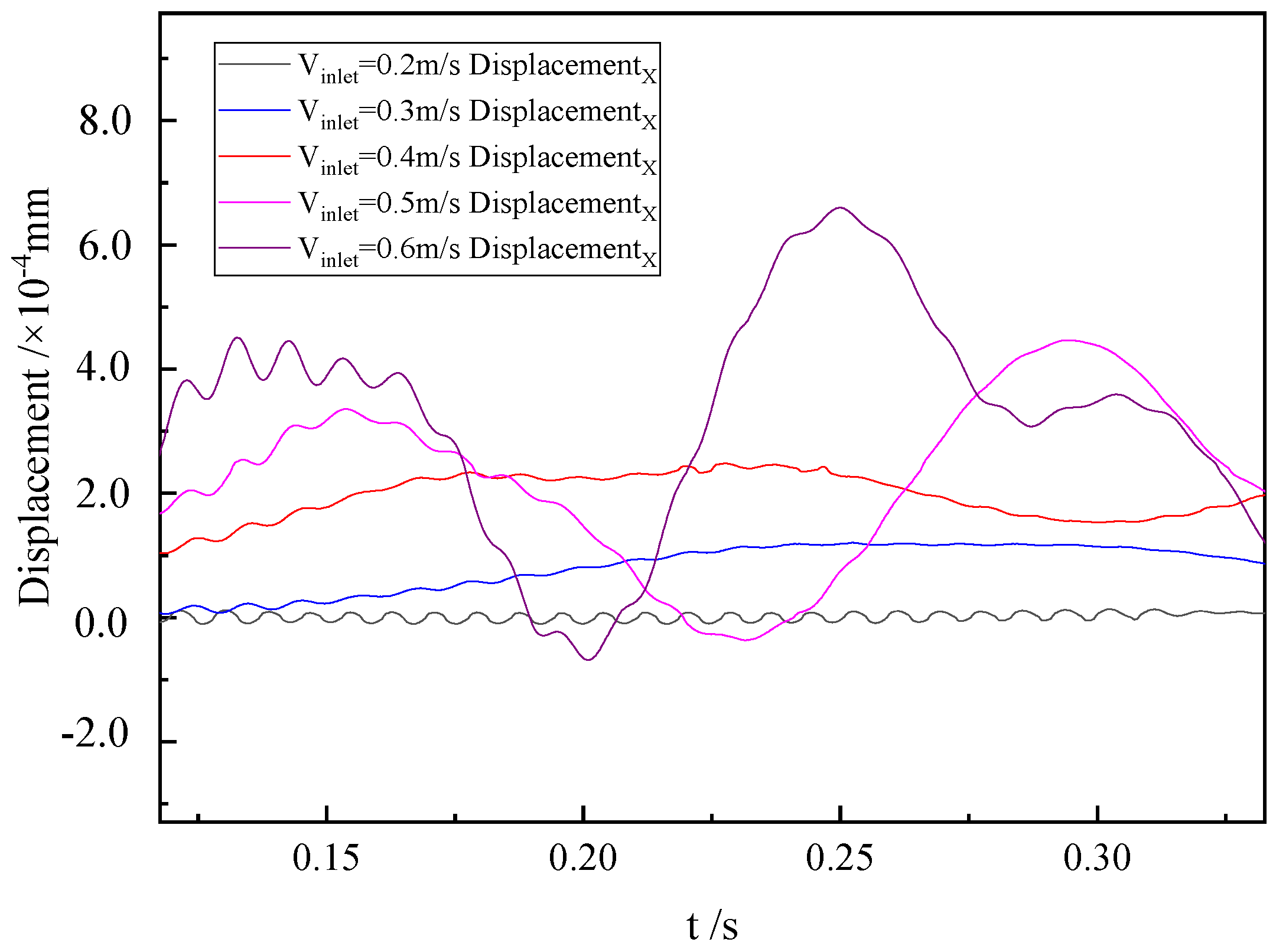

4.2. Vibration Behaviors at Different Velocities

4.3. Influence of Adjacent Tube Vibrations on Target Tube Vibration

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Weikl, M.; Braun, K.; Weiss, J. Coil-wound heat exchangers for molten salt applications. Energy Procedia 2014, 49, 1054–1060. [Google Scholar] [CrossRef]

- Reyes, J.N., Jr. NuScale plant safety in response to extreme events. Nucl. Technol. 2012, 178, 153–163. [Google Scholar] [CrossRef]

- Hoffer, N.V.; Anderson, N.A.; Sabharwall, P. Development and transient analysis of a helical-coil steam generator for high temperature reactors. J. Young Investig. 2011, 22, 40–50. [Google Scholar]

- Kim, E.K.; Kim, S.O. Sodium-Cooled Fast Reactor Helical Coil Steam Generator. In Proceedings of the Transactions of the Korean Nuclear Society Autumn Meeting, Jeju, Republic of Korea, 21–22 October 2010; p. 47. [Google Scholar]

- Connors, H., Jr. Fluid elastic vibration of tube arrays excited by cross flow. In Proceedings of the ASME Symposium on Flow-Induced Vibration in Heat Exchanger, Winter Annual Meeting, New Orleans, LA, USA, 9–14 December 1970; pp. 42–47. [Google Scholar]

- Tan, W.; Wu, H.; Zhu, G. Investigation of the Vibration Behavior of Fluidelastic Instability in Closely Packed Square Tube Arrays. Trans. Tianjin Univ. 2018, 25, 124–142. [Google Scholar] [CrossRef][Green Version]

- Qing-Lei, J.; Ji-Yun, Z.; Xian-Yuan, W. Analysis of Fluid-Induced Excitation Forces in Triangular Tube Arrays Based on the LES Method. In Proceedings of the 2013 21st International Conference on Nuclear Engineering, Chengdu, China, 29 June–2 August 2013. [Google Scholar]

- Jo, J.C.; Jhung, M.J. Flow-induced vibration and fretting-wear predictions of steam generator helical tubes. Nucl. Eng. Des. 2008, 238, 890–903. [Google Scholar] [CrossRef]

- Yuan, H.; Solberg, J.; Merzari, E.; Kraus, A.; Grindeanu, I. Flow-induced vibration analysis of a helical coil steam generator experiment using large eddy simulation. Nucl. Eng. Des. 2017, 322, 547–562. [Google Scholar] [CrossRef]

- Lee, S.; Delgado, M.; Hassan, Y. Experimental investigation of the isothermal flow field across slant 5-tube bundles in helically coiled steam generator geometry using PIV. Nucl. Eng. Des. 2018, 338, 261–268. [Google Scholar] [CrossRef]

- Delgado, M.; Hassan, Y.A.; Anand, N.K. Experimental flow visualization study using particle image velocimetry in a helical coil steam generator with changing lateral pitch geometry. Int. J. Heat Mass Transf. 2019, 133, 756–768. [Google Scholar] [CrossRef]

- Lv, J.; Wang, F.; Guo, L.; Liu, Z. CFD/CSD approach to predict hypersonic aerothermoelastic response of a wing. Procedia Eng. 2015, 126, 123–127. [Google Scholar] [CrossRef][Green Version]

- Chung, H.; Cao, S.; Philen, M.; Beran, P.S.; Wang, K.G. Cfd-csd coupled analysis of underwater propulsion using a biomimetic fin-and-joint system. Comput. Fluids 2018, 172, 54–66. [Google Scholar] [CrossRef]

- Carrión, M.; Steijl, R.; Woodgate, M.; Barakos, G.; Munduate, X.; Gomez-Iradi, S. Aeroelastic analysis of wind turbines using a tightly coupled CFD–CSD method. J. Fluids Struct. 2014, 50, 392–415. [Google Scholar] [CrossRef]

- Ma, L.; Zhao, Q.; Zhao, M. Computation analyses of aeroelastic loads of rotor based on CFD/CSD coupling method. J. Aeronaut. 2017, 38, 53–66. [Google Scholar]

- Tang, D.; Bao, S.; Luo, L.; Zhu, H.; Cui, H. A CFD/CSD coupled method with high order and its applications in flow induced vibrations of tube arrays in cross flow. Ann. Nucl. Energy 2019, 130, 347–356. [Google Scholar] [CrossRef]

- Zou, Q.; Ding, L.; Wang, H.; Wang, J.; Zhang, L. Two-degree-of-freedom flow-induced vibration of a rotating circular cylinder. Ocean Eng. 2019, 191, 106505. [Google Scholar] [CrossRef]

- Ma, Y.; Luan, Y.; Xu, W. Hydrodynamic features ofthree equally spaced, long flexible cylinders undergoing flow-induced vibration. Eur. J. Mech./B Fluids 2020, 79, 386–400. [Google Scholar] [CrossRef]

- Guo, K.; Xu, W.; Jia, Z.; Tan, W. Investigation of Fluid-Elastic Instability in Tube Arrays at Low Mass Damping Parameters in Cross-Flow. J. Press. Vessel. Technol. 2020, 142, 011401. [Google Scholar] [CrossRef]

- Hai, B.S.Z.; Di, T.; Wei, Y.; Xipeng, H. Numerical simulation of coupled vibration between heat transfer tube bundles under the lateral action of single-phase fluid. Nucl. Power Eng. 2020, 243, 120–124. [Google Scholar]

- Achenbach, E. Distribution of local pressure and skin friction around a circular cylinder in cross-flow up to Re = 5 × 106. J. Fluid Mech. 1968, 34, 625–639. [Google Scholar] [CrossRef]

- Lee, S.J.; Hassan, Y.A. Numerical investigation of helical coil tube bundle in turbulent cross flow using large eddy simulation. Int. J. Heat Fluid Flow 2020, 82, 108529. [Google Scholar] [CrossRef]

- Duan, R.-Q.; Jiang, S.-Y. Numerical investigation of gas flow distribution and thermal mixing in helically coiled tube bundle. J. Nucl. Sci. Technol. 2008, 45, 704–711. [Google Scholar] [CrossRef]

- Tang, D.; Bao, S.; Lv, B.; Cui, H.; Luo, L.; Xu, M. Investigation of shedding patterns and its influences on lift performances of a cylinder bundle in cross flow. J. Mech. Sci. Technol. 2019, 33, 2651–2663. [Google Scholar] [CrossRef]

- Ni, W.; Zhang, X.; Xu, F.; Zhang, W.; Kang, Z. Numerical investigation of bifurcation characteristics under perturbations in vortex induced vibration of cylinder with two degrees of freedom. Ocean Eng. 2019, 188, 106318. [Google Scholar] [CrossRef]

- Bao, S.; Zhu, H.; Tang, D.; Yuan, W.; Huang, X. Numerical Simulation Research on Coupling Vibration of Heat Transfer Tube Bundles under Lateral Action of Single-Phase Fluid. Nucl. Power Eng. 2020, 41, 111–115. [Google Scholar]

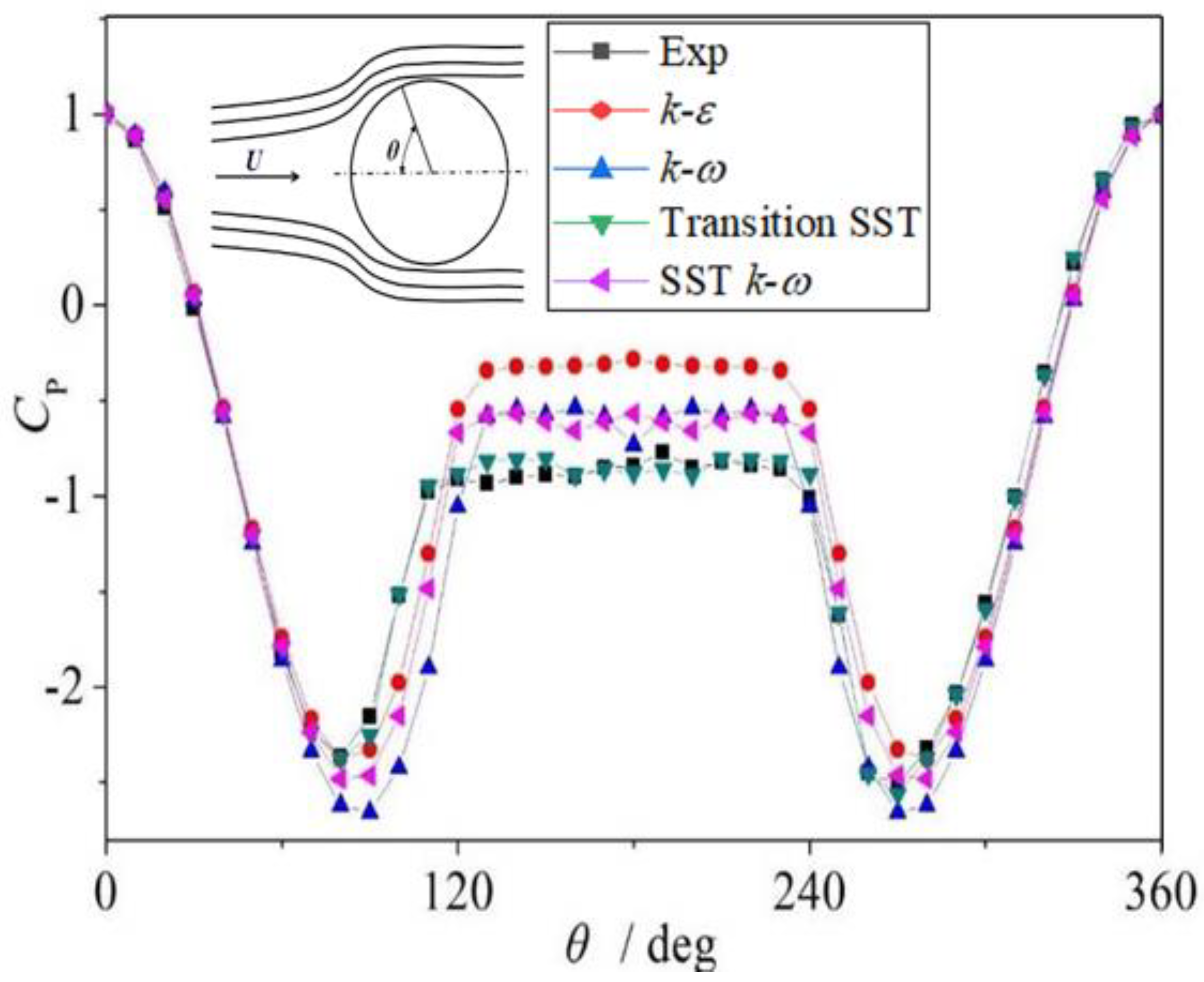

| Model | Deviation at Maximum Negative CP | Range Maximum Deviation | |

|---|---|---|---|

| RANS model | k-ε | 8.12% | 64.53% |

| k-ω | 23.34% | 40.10% | |

| SST k-ω | 14.47% | 26.74% | |

| Transition SST | 2.51% | 8.70% |

| Project | Content |

|---|---|

| Solution type | Pressure-based |

| Solution method | Steady + transient |

| Turbulence model | Transition SST |

| Fluid medium | Water |

| Entrance condition | Velocity inlet |

| Export condition | Pressure outlet |

| Left and right boundary of flow field | Symmetry |

| Tube wall | No slip wall |

| Vinlet/m·s−1 | Type | Radial Root Mean Square Displacement/mm |

|---|---|---|

| 0.5 | Tube arrays | 4.081 × 10−4 |

| Single tube | 6.111 × 10−4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ding, Z.; Bai, X.; Zhai, Y.; Yang, J.; Liu, D.; Yang, Y.; Tang, D. Numerical Simulation Research on the Vibration of Helical Tube Arrays under Transverse Flow. Energies 2022, 15, 9082. https://doi.org/10.3390/en15239082

Ding Z, Bai X, Zhai Y, Yang J, Liu D, Yang Y, Tang D. Numerical Simulation Research on the Vibration of Helical Tube Arrays under Transverse Flow. Energies. 2022; 15(23):9082. https://doi.org/10.3390/en15239082

Chicago/Turabian StyleDing, Zhenyu, Xilan Bai, Yanfei Zhai, Jiahuan Yang, Dawei Liu, Yin Yang, and Di Tang. 2022. "Numerical Simulation Research on the Vibration of Helical Tube Arrays under Transverse Flow" Energies 15, no. 23: 9082. https://doi.org/10.3390/en15239082

APA StyleDing, Z., Bai, X., Zhai, Y., Yang, J., Liu, D., Yang, Y., & Tang, D. (2022). Numerical Simulation Research on the Vibration of Helical Tube Arrays under Transverse Flow. Energies, 15(23), 9082. https://doi.org/10.3390/en15239082