Influencing Factors of a Cooling System Based on Low-Temperature Mine Water as a Direct Cooling Source

Abstract

1. Introduction

2. Analysis of Heat Source and Water Quality of Maoping Lead Zinc Mine

2.1. Heat Source Analysis

2.2. Water Quality Analysis of Mine Gushing Water

3. Materials and Methods

3.1. Parameters and Composition of the Experimental Platform

3.2. Methods

4. Discussion

4.1. Analysis of Factors Influencing the Cooling System

4.1.1. Impact of Inlet Air Volume on Cooling Effect

4.1.2. Impact of Inlet Air Temperature on Cooling Effect

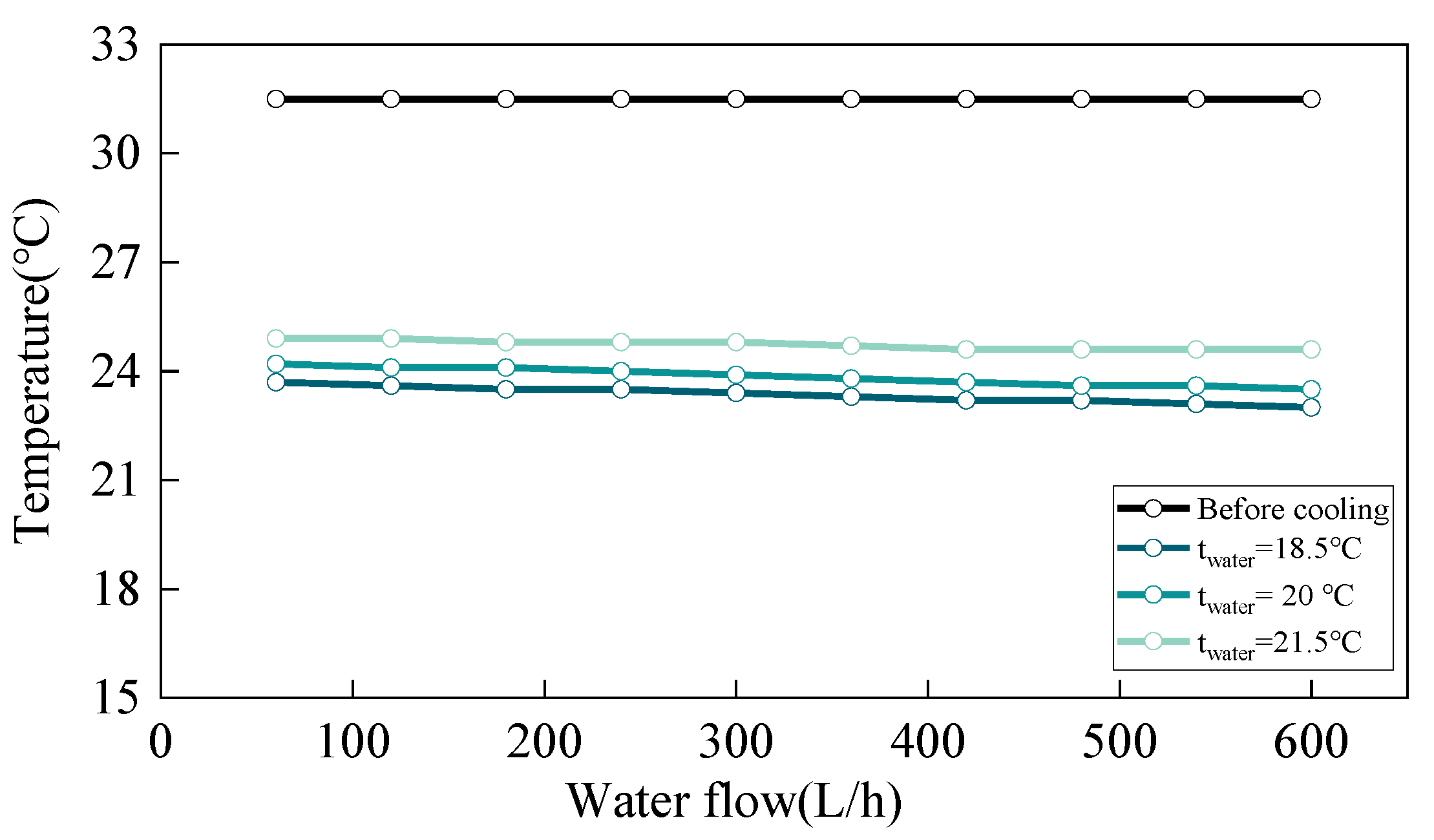

4.1.3. Impact of Pipeline Water Temperature on the Cooling Effect

4.1.4. Impact of Pipeline Water Flow on the Cooling Effect

4.2. Comprehensive Analysis of Cooling Effect

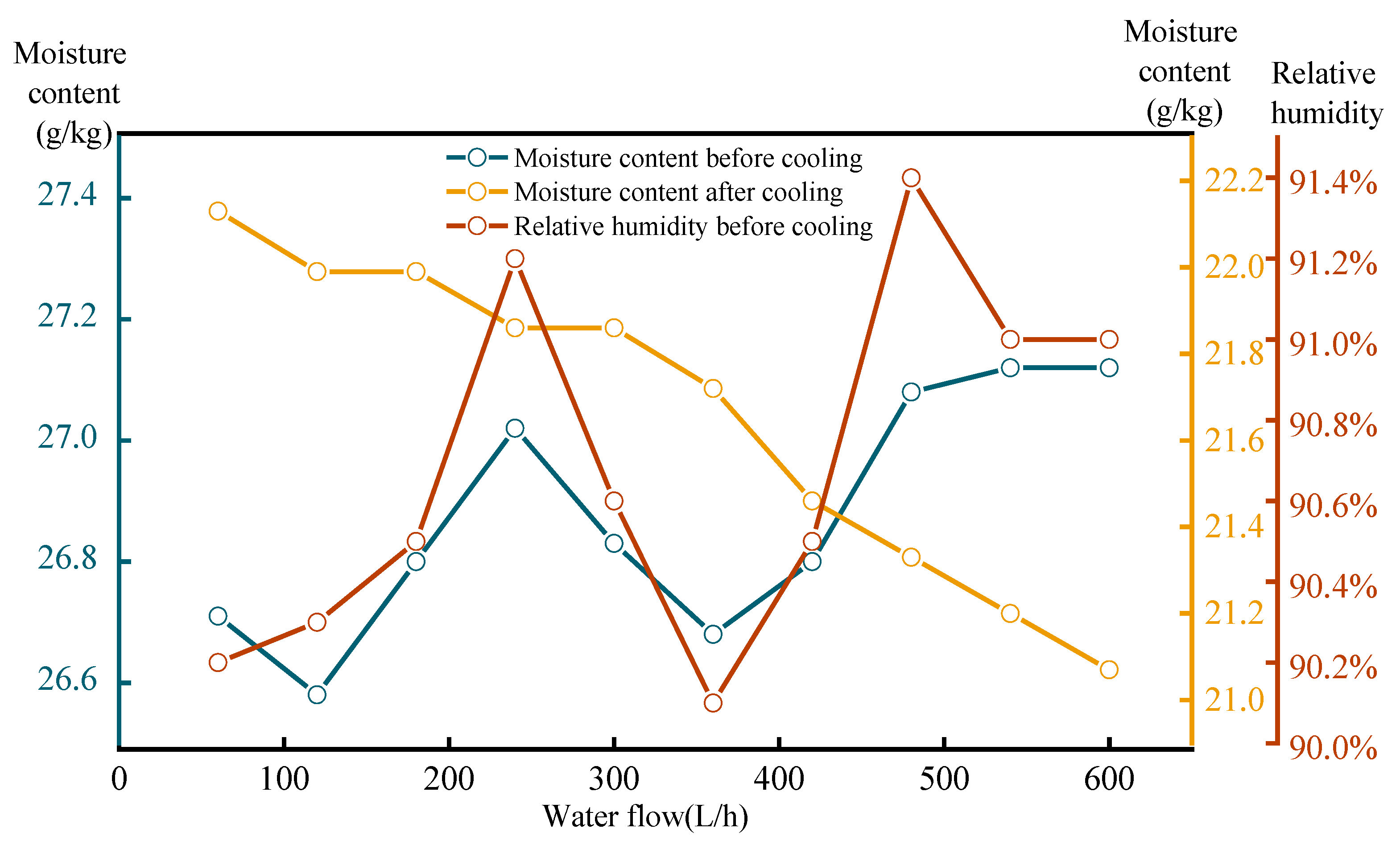

4.3. Analysis of Dehumidification Effect in the Cooling System

5. Conclusions

- (1)

- Under the same air flow temperature and inlet water temperature, as the inlet air volume increased, the outlet air temperature of the heat exchanger increased, and the heat exchanger’s cooling capacity decreased. Within the experimental range, 127.2 m3/h was found to be the optimum inlet air volume, and the air flow temperature decreased the most, from 31.5 °C to 23.9 °C. As the inlet air volume continued to increase, the cooling range and cooling efficiency were reduced; the water flow rate was positively related to the cooling effect. With the increase in the water flow rate, the outlet temperature of the air flow at each operating point was continuously reduced, and the cooling effect of the heat exchanger was improved. The cooling efficiency of low-temperature water with a temperature of 20 °C for the air flow was about 13~25%. When the flow rate of the cold water was 360~420 L/h, the cooling efficiency of the cold water increased significantly. Therefore, a water flow rate of 420 L/h was selected as the optimum matching flow rate for the heat exchanger.

- (2)

- Under the same inlet air volume and inlet water flow, with the increase in the inlet water temperature of the pipeline, the outlet air temperature of the heat exchanger also increased, and the cooling efficiency of the heat exchanger decreased. When the water temperature increased from 18.5 °C to 21.5 °C, the cooling efficiency of the heat exchanger decreased by 4.4%. The water temperature of Maoping Coal Mine is about 20 °C all year round, and the wind temperature of 31.5 °C can be reduced to 23.9 °C in the industrial test site; with the increase in the air flow temperature, due to the increase in the heat transfer temperature difference between high-temperature air and low-temperature cold water, the internal heat exchange of the cooling system was strengthened, and the cooling efficiency of the heat exchanger was increased. We found 33.0 °C to be the optimum inlet air temperature, and the air flow cooling range was the largest, with a decrease of 24.3 °C; when the inlet air temperature rose from 28.5 °C to 33.0 °C, the cooling efficiency of the heat exchanger increased by 6.7%.

- (3)

- At a certain temperature, with the increase in the relative humidity of the air flow, the moisture content of the air flow also increased; with the increase in the cold water flow, the air temperature decreased continuously, and the moisture content of the air decreased as a whole. With a wind speed of 2 m/s, a wind temperature of 31.5 °C, and a wind humidity of more than 90%, the low-temperature water at 20 °C was able to reduce the original moisture content of 26.8 g/kg to 21.6 g/kg, and the moisture content was reduced by 5.2 g/kg. The four variables of air volume, air temperature, water temperature, and cold water flow were set as X1 (m3/h), X2 (°C), X3 (°C), and X4 (L/h), respectively, and the temperature difference before and after cooling was set as y (°C). A multiple linear regression analysis equation of the cooling system model was also proposed.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhao, X.D.; Zhou, X.; Zhao, Y.F.; Yu, W.L. Research progress of mining disaster prevention and control in deep metal mine. J. Cent. South Univ. (Sci. Technol. Ed.) 2021, 8, 2522–2538. [Google Scholar]

- Liu, H.X.; Wang, J.B.; Zhao, J.; Wang, X.; Zhu, D.M.; Xu, S. Key technical problems and solutions of deep well Mining. Min. Res. Dev. 2018, 5, 1–5. [Google Scholar]

- Chen, A.G. The causes, hazards and control measures of mine thermal damage. China Saf. Sci. J. 2004, 8, 6–9. [Google Scholar]

- Zhang, X.M.; Li, L.F.; Wang, Z.G. Thermal damage analysis and air flow temperature prediction in underground coal mine. J. Liaoning Tech. Univ. (Nat. Sci. Ed.) 2012, 6, 826–828. [Google Scholar]

- Staden, H.J.; Rensburg, J.F.; Groenewald, H.J. Optimal use of mobile cooling units in a deep-level gold mine. Int. J. Min. Sci. Technol. 2020, 4, 547–553. [Google Scholar] [CrossRef]

- Chen, P. A new type of mine centralized air conditioning system with compressed air supply. Min. Saf. Environ. Prot. 2004, 3, 1–3. [Google Scholar]

- Yang, D.D.; Wang, B.S.; Zhou, S.G. Application of cogeneration technology of heat, power and cooling in treatment of deep well heat damage. Coal Eng. 2012, 11, 118–120. [Google Scholar]

- Cao, Y. Application of thermoelectric cooling technology in mine. In Proceedings of the 2019 Symposium on Construction and Efficient Operation of Heating Engineering (Part 2); China Municipal Engineering North China Design and Research Institute Co., Ltd.: Tianjin, China, 2019; pp. 283–287. [Google Scholar]

- He, M.C. Research and Development of HEMS Deep well cooling system and Thermal damage control Countermeasures. Basic Sci. China 2008, 2, 11–16. [Google Scholar]

- Zhang, X.Y.; Bu, B.Y.; Liu, L.; Cao, T.R.; Ke, Y.P.; Du, Q.Q. Numerical simulation on cooling effect of working face under radiation cooling mode in deep well. Energies 2021, 14, 4428. [Google Scholar] [CrossRef]

- Pokhrel, S.; Kuyuk, A.F.; Kalantari, H. Techno-Economic trade-off between battery storage and ice thermal energy storage for application in renewable mine cooling system. Appl. Sci. 2020, 17, 6022. [Google Scholar] [CrossRef]

- Wang, M.; Liu, L.; Wang, S. Numerical investigation of heat transfer and phase change characteristics of cold load and storage functional CPB in deep mine. Front. Earth Sci. 2020, 8, 31. [Google Scholar] [CrossRef]

- Crawford, J.A.; Joubert, H.P.R.; Mathews, M.J.; Kleingeld, M. Optimised dynamic control philosophy for improved performance of mine cooling systems. Appl. Therm. Eng. 2019, 150, 50–60. [Google Scholar] [CrossRef]

- Zhang, Y.; Guo, D.M.; Jing, T. Energy consumption analysis of cooling system in Jiahe deep coal mine. In Applied Mechanics and Materials; Trans Tech Publications Ltd.: Bäch, Switzerland, 2011; pp. 117–119. [Google Scholar]

- Wang, C.L.; Cheng, L.; Hao, Y.J.; Jiang, M.W.; Chen, K.X.; Shao, K. Efficiency improvement and application of the groundwater heat pump cooling system in linglong gold mine. Geofluids 2022, 2022, 3191735. [Google Scholar] [CrossRef]

- Nikodem, S.; Dariusz, O.; Justyna, S. An evaluation of the functioning of cooling systems in the polish coal mine industry. Energies 2018, 11, 2267. [Google Scholar]

- Li, H.M.; Fu, K. Main technical problems and countermeasures of deep mining in coal mine. J. Min. Saf. Eng. 2006, 4, 468–471. [Google Scholar]

- Yuan, D.S.; Hou, J.J.; Jin, J.W. Analysis and calculation of heat source in high temperature mine. J. Henan Polytech. Univ. (Nat. Sci. Ed.) 2009, 3, 278–293. [Google Scholar]

| Heat Source | Heat Release or Heat Absorption (kW) | Proportion (%) |

|---|---|---|

| Heat release from backfill | 6505.00 | 91.81 |

| Heat release from mechanical and electrical equipment | 549.20 | 7.75 |

| Exothermic blasting | 30.72 | 0.44 |

| Surrounding endothermic rock | 78.50 | 100.00 |

| Wind Flow (m3/h) | Wind Temperature (°C) | Water Temperature (°C) | Water Flow (L/h) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 60 | 120 | 180 | 240 | 300 | 360 | 420 | 480 | 540 | 600 | |||

| Temperature Difference before and after Cooling (°C) | ||||||||||||

| 127.2 | 28.5 | 18.5 | 6.0 | 6.0 | 6.1 | 6.1 | 6.2 | 6.3 | 6.4 | 6.5 | 6.5 | 6.6 |

| 20.0 | 4.8 | 4.8 | 4.9 | 4.9 | 5.0 | 5.1 | 5.2 | 5.2 | 5.3 | 5.3 | ||

| 21.5 | 4.8 | 4.8 | 4.9 | 4.9 | 5.0 | 5.1 | 5.2 | 5.2 | 5.3 | 5.3 | ||

| 30.0 | 18.5 | 6.9 | 6.9 | 7.0 | 7.0 | 7.1 | 7.2 | 7.3 | 7.4 | 7.4 | 7.5 | |

| 20.0 | 6.2 | 6.2 | 6.3 | 6.3 | 6.4 | 6.5 | 6.6 | 6.6 | 6.7 | 6.7 | ||

| 21.5 | 5.5 | 5.5 | 5.6 | 5.6 | 5.7 | 5.7 | 5.8 | 5.9 | 6.0 | 6.0 | ||

| 31.5 | 18.5 | 7.9 | 7.9 | 8.0 | 8.0 | 8.1 | 8.2 | 8.3 | 8.3 | 8.4 | 8.5 | |

| 20.0 | 7.3 | 7.3 | 7.4 | 7.4 | 7.5 | 7.6 | 7.7 | 7.7 | 7.8 | 7.8 | ||

| 21.5 | 6.6 | 6.6 | 6.7 | 6.7 | 6.8 | 6.9 | 7.0 | 7.0 | 7.1 | 7.1 | ||

| 33.0 | 18.5 | 8.8 | 8.8 | 8.9 | 8.9 | 9.0 | 9.1 | 9.2 | 9.3 | 9.3 | 9.4 | |

| 20.0 | 8.2 | 8.2 | 8.3 | 8.3 | 8.4 | 8.5 | 8.6 | 8.7 | 8.8 | 8.8 | ||

| 21.5 | 7.6 | 7.6 | 7.7 | 7.7 | 7.8 | 7.9 | 8.0 | 8.0 | 8.1 | 8.1 | ||

| 159.1 | 28.5 | 18.5 | 5.4 | 5.4 | 5.5 | 5.6 | 5.7 | 5.8 | 5.9 | 6.0 | 6.0 | 6.1 |

| 20.0 | 4.8 | 4.8 | 4.9 | 5.0 | 5.1 | 5.2 | 5.3 | 5.4 | 5.5 | 5.5 | ||

| 21.5 | 4.2 | 4.2 | 4.3 | 4.3 | 4.4 | 4.5 | 4.6 | 4.7 | 4.7 | 4.8 | ||

| 30.0 | 18.5 | 6.3 | 6.3 | 6.4 | 6.5 | 6.6 | 6.6 | 6.7 | 6.8 | 6.9 | 7.0 | |

| 20.0 | 5.5 | 5.5 | 5.6 | 5.6 | 5.7 | 5.8 | 5.9 | 6.0 | 6.0 | 6.1 | ||

| 21.5 | 4.9 | 4.9 | 5.0 | 5.1 | 5.2 | 5.2 | 5.3 | 5.4 | 5.5 | 5.5 | ||

| 31.5 | 18.5 | 7.3 | 7.3 | 7.4 | 7.5 | 7.6 | 7.7 | 7.8 | 7.9 | 8.0 | 8.0 | |

| 20.0 | 6.7 | 6.8 | 6.8 | 6.9 | 7.0 | 7.1 | 7.1 | 7.2 | 7.2 | 7.3 | ||

| 21.5 | 6.1 | 6.1 | 6.2 | 6.2 | 6.3 | 6.4 | 6.5 | 6.6 | 6.7 | 6.7 | ||

| 33.0 | 18.5 | 8.2 | 8.3 | 8.3 | 8.4 | 8.5 | 8.6 | 8.7 | 8.8 | 8.9 | 8.9 | |

| 20.0 | 7.6 | 7.6 | 7.7 | 7.7 | 7.8 | 7.9 | 8.0 | 8.1 | 8.2 | 8.3 | ||

| 21.5 | 7.0 | 7.0 | 7.1 | 7.1 | 7.2 | 7.3 | 7.4 | 7.5 | 7.6 | 7.6 | ||

| 190.9 | 28.5 | 18.5 | 4.9 | 4.9 | 5.0 | 5.1 | 5.2 | 5.3 | 5.5 | 5.6 | 5.6 | 5.7 |

| 20.0 | 4.2 | 4.2 | 4.3 | 4.4 | 4.5 | 4.6 | 4.7 | 4.8 | 4.9 | 5.0 | ||

| 21.5 | 3.5 | 3.5 | 3.6 | 3.7 | 3.8 | 3.9 | 4.1 | 4.2 | 4.3 | 4.4 | ||

| 30.0 | 18.5 | 5.8 | 5.8 | 5.9 | 6.0 | 6.0 | 6.1 | 6.2 | 6.3 | 6.4 | 6.4 | |

| 20.0 | 5.1 | 5.1 | 5.2 | 5.3 | 5.4 | 5.5 | 5.6 | 5.7 | 5.7 | 5.8 | ||

| 21.5 | 4.4 | 4.4 | 4.5 | 4.6 | 4.6 | 4.7 | 4.8 | 4.8 | 4.9 | 5.0 | ||

| 31.5 | 18.5 | 6.8 | 6.8 | 6.9 | 7.0 | 7.1 | 7.2 | 7.3 | 7.4 | 7.4 | 7.5 | |

| 20.0 | 6.1 | 6.1 | 6.2 | 6.2 | 6.3 | 6.4 | 6.5 | 6.6 | 6.7 | 6.7 | ||

| 21.5 | 5.4 | 5.4 | 5.5 | 5.6 | 5.7 | 5.8 | 5.9 | 6.0 | 6.1 | 6.1 | ||

| 33.0 | 18.5 | 7.7 | 7.7 | 7.8 | 7.9 | 8.0 | 8.1 | 8.2 | 8.3 | 8.3 | 8.4 | |

| 20.0 | 6.9 | 6.9 | 7.0 | 7.1 | 7.2 | 7.4 | 7.5 | 7.5 | 7.6 | 7.6 | ||

| 21.5 | 6.2 | 6.2 | 6.3 | 6.3 | 6.4 | 6.5 | 6.6 | 6.7 | 6.8 | 6.9 | ||

| 222.7 | 28.5 | 18.5 | 4.5 | 4.5 | 4.6 | 4.7 | 4.8 | 4.9 | 5.0 | 5.1 | 5.2 | 5.3 |

| 20.0 | 3.7 | 3.7 | 3.8 | 3.9 | 4.0 | 4.2 | 4.3 | 4.3 | 4.4 | 4.5 | ||

| 21.5 | 2.9 | 2.9 | 3.0 | 3.1 | 3.2 | 3.3 | 3.5 | 3.6 | 3.6 | 3.7 | ||

| 30.0 | 18.5 | 5.4 | 5.4 | 5.5 | 5.6 | 5.7 | 5.8 | 6.0 | 6.1 | 6.1 | 6.2 | |

| 20.0 | 4.7 | 4.8 | 4.9 | 5.0 | 5.1 | 5.2 | 5.3 | 5.4 | 5.5 | 5.5 | ||

| 21.5 | 3.7 | 3.7 | 3.8 | 3.9 | 4.0 | 4.1 | 4.3 | 4.4 | 4.5 | 4.6 | ||

| 31.5 | 18.5 | 6.3 | 6.3 | 6.4 | 6.5 | 6.6 | 6.7 | 6.8 | 6.9 | 7.0 | 7.1 | |

| 20.0 | 5.5 | 5.5 | 5.6 | 5.7 | 5.8 | 5.9 | 6.0 | 6.1 | 6.1 | 6.2 | ||

| 21.5 | 4.7 | 4.8 | 4.9 | 5.0 | 5.1 | 5.2 | 5.3 | 5.4 | 5.5 | 5.6 | ||

| 33.0 | 18.5 | 7.3 | 7.4 | 7.5 | 7.6 | 7.7 | 7.8 | 7.9 | 8.0 | 8.0 | 8.1 | |

| 20.0 | 6.5 | 6.5 | 6.6 | 6.7 | 6.8 | 6.9 | 7.0 | 7.1 | 7.1 | 7.2 | ||

| 21.5 | 5.7 | 5.7 | 5.8 | 5.9 | 6.0 | 6.2 | 6.3 | 6.4 | 6.4 | 6.5 | ||

| 254.5 | 28.5 | 18.5 | 4.2 | 4.2 | 4.3 | 4.4 | 4.5 | 4.6 | 4.7 | 4.8 | 4.9 | 5.0 |

| 20.0 | 3.2 | 3.2 | 3.3 | 3.4 | 3.5 | 3.6 | 3.8 | 3.9 | 3.9 | 4.0 | ||

| 21.5 | 2.3 | 2.3 | 2.4 | 2.5 | 2.6 | 2.7 | 2.8 | 2.9 | 3.0 | 3.0 | ||

| 30.0 | 18.5 | 5.1 | 5.1 | 5.2 | 5.3 | 5.4 | 5.5 | 5.7 | 5.8 | 5.8 | 5.9 | |

| 20.0 | 4.1 | 4.1 | 4.2 | 4.3 | 4.4 | 4.5 | 4.6 | 4.7 | 4.8 | 4.9 | ||

| 21.5 | 3.2 | 3.2 | 3.3 | 3.4 | 3.5 | 3.6 | 3.7 | 3.7 | 3.8 | 3.9 | ||

| 31.5 | 18.5 | 6.0 | 6.0 | 6.1 | 6.2 | 6.3 | 6.4 | 6.6 | 6.7 | 6.7 | 6.8 | |

| 20.0 | 4.9 | 4.9 | 5.0 | 5.1 | 5.2 | 5.3 | 5.5 | 5.6 | 5.7 | 5.8 | ||

| 21.5 | 4.1 | 4.1 | 4.2 | 4.3 | 4.4 | 4.5 | 4.6 | 4.7 | 4.8 | 4.9 | ||

| 33.0 | 18.5 | 7.0 | 7.0 | 7.1 | 7.2 | 7.3 | 7.4 | 7.5 | 7.6 | 7.7 | 7.8 | |

| 20.0 | 6.0 | 6.0 | 6.1 | 6.2 | 6.3 | 6.5 | 6.6 | 6.6 | 6.7 | 6.8 | ||

| 21.5 | 5.0 | 5.1 | 5.2 | 5.3 | 5.4 | 5.5 | 5.6 | 5.7 | 5.7 | 5.8 | ||

| Value | Standard Error | Confidence Interval | |

|---|---|---|---|

| a | −0.46904 | 0.13584 | −0.73597~−0.20212 |

| b | −0.01613 | 0.00012 | −0.01636~−0.01589 |

| c | 0.62258 | 0.00324 | 0.61621~0.62894 |

| d | −0.50467 | 0.00444 | −0.51338~−0.49595 |

| e | 0.00141 | 0.00003 | 0.00135~0.00147 |

| Water Flow (L/h) | Inlet Temperature (°C) | Inlet Relative Humidity (%) | Moisture Content (g/kg) | Dew Point Temperature (°C) | Outlet Temperature (°C) | Outlet Relative Humidity (%) | Moisture Content (g/kg) |

|---|---|---|---|---|---|---|---|

| 60 | 31.5 | 90.2 | 26.71 | 30.17 | 26.6 | 99.9 | 22.13 |

| 120 | 31.4 | 90.3 | 26.58 | 30.08 | 26.5 | 99.9 | 21.99 |

| 180 | 31.5 | 90.5 | 26.80 | 30.17 | 26.5 | 99.9 | 21.99 |

| 240 | 31.5 | 91.2 | 27.02 | 30.21 | 26.4 | 99.9 | 21.86 |

| 300 | 31.6 | 90.6 | 26.83 | 30.31 | 26.4 | 99.9 | 21.86 |

| 360 | 31.6 | 90.1 | 26.68 | 30.37 | 26.3 | 99.9 | 21.72 |

| 420 | 31.6 | 90.5 | 26.8 | 30.33 | 26.1 | 99.9 | 21.46 |

| 480 | 31.6 | 91.4 | 27.08 | 30.35 | 26.0 | 99.9 | 21.33 |

| 540 | 31.6 | 91.0 | 27.12 | 30.31 | 25.9 | 99.9 | 21.20 |

| 600 | 31.7 | 91.0 | 27.12 | 30.33 | 25.8 | 99.9 | 21.07 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, H.; Cui, S.; Mu, X.; Tang, L.; Wang, Y.; Jian, C.; Chen, C. Influencing Factors of a Cooling System Based on Low-Temperature Mine Water as a Direct Cooling Source. Energies 2022, 15, 9071. https://doi.org/10.3390/en15239071

Jiang H, Cui S, Mu X, Tang L, Wang Y, Jian C, Chen C. Influencing Factors of a Cooling System Based on Low-Temperature Mine Water as a Direct Cooling Source. Energies. 2022; 15(23):9071. https://doi.org/10.3390/en15239071

Chicago/Turabian StyleJiang, Heguo, Shuwen Cui, Xingwang Mu, Lin Tang, Yuheng Wang, Congguang Jian, and Chen Chen. 2022. "Influencing Factors of a Cooling System Based on Low-Temperature Mine Water as a Direct Cooling Source" Energies 15, no. 23: 9071. https://doi.org/10.3390/en15239071

APA StyleJiang, H., Cui, S., Mu, X., Tang, L., Wang, Y., Jian, C., & Chen, C. (2022). Influencing Factors of a Cooling System Based on Low-Temperature Mine Water as a Direct Cooling Source. Energies, 15(23), 9071. https://doi.org/10.3390/en15239071