Recent Advancements in Evacuated Tube Solar Water Heaters: A Critical Review of the Integration of Phase Change Materials and Nanofluids with ETCs

Abstract

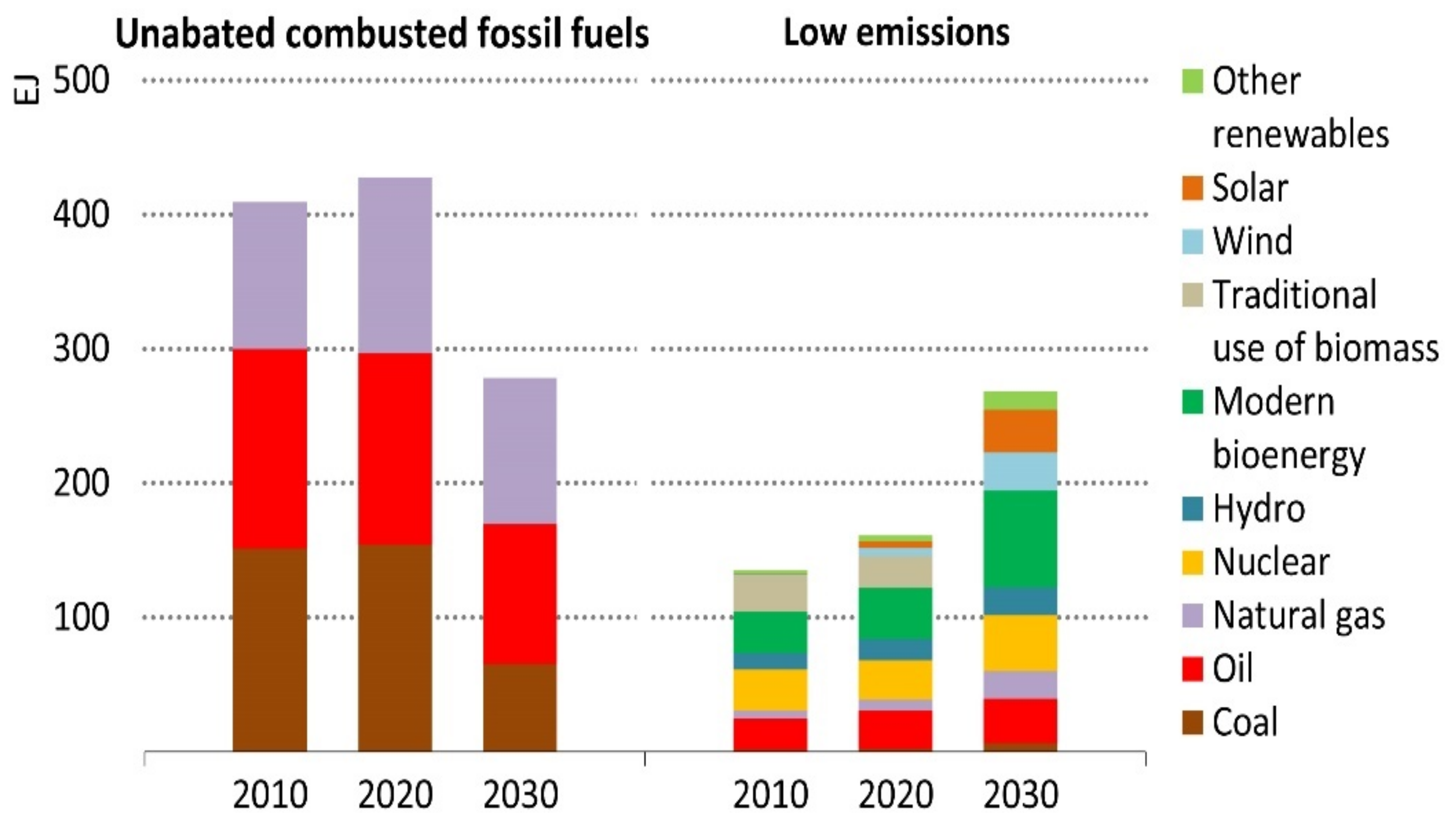

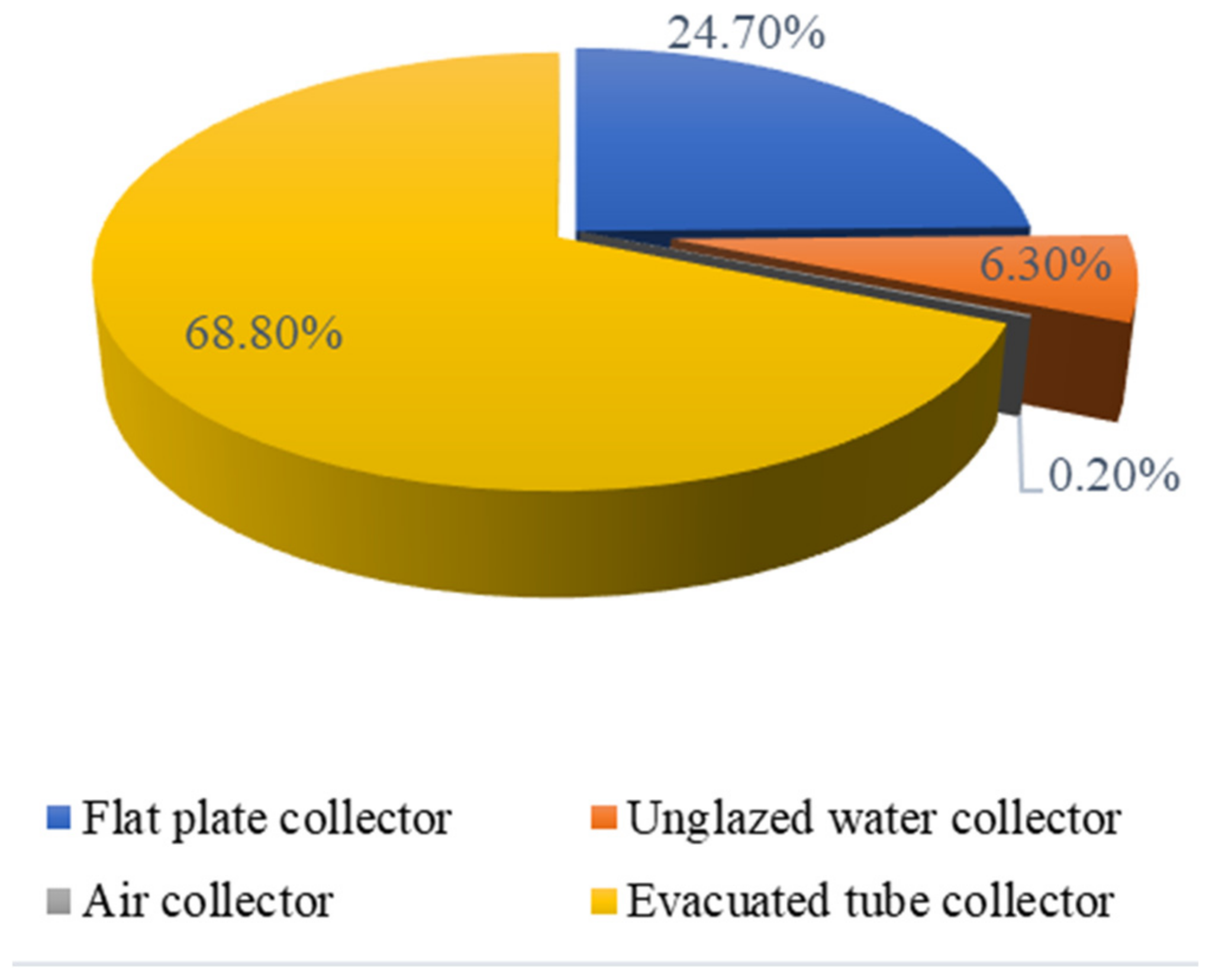

1. Introduction

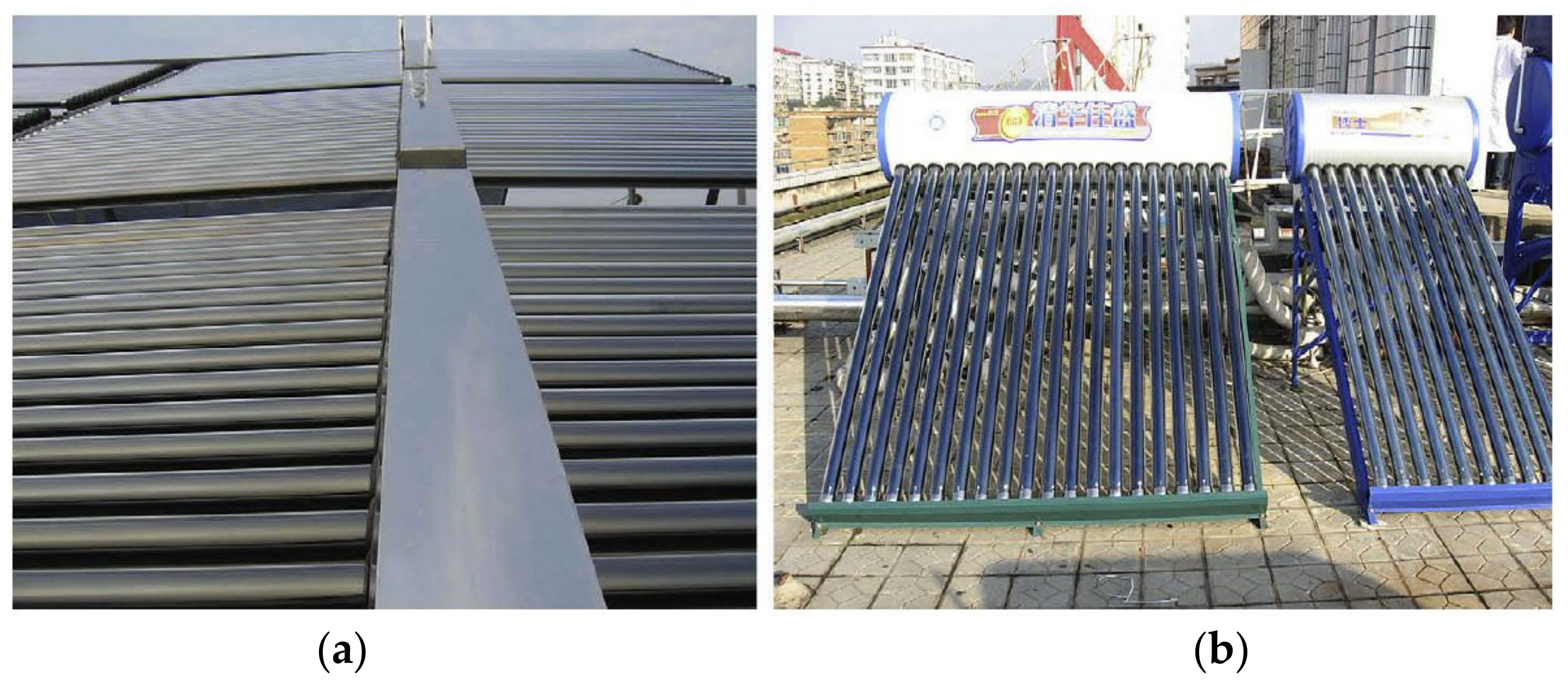

- (a)

- Flat plate solar water heater

- (b)

- Evacuated tube solar water heater

1.1. Classification of ETC

- Water in glass tube-based collector

- U-Tube-based solar collector

- Heat pipe-based solar collector

1.1.1. Water in Glass Tube-Based Collector

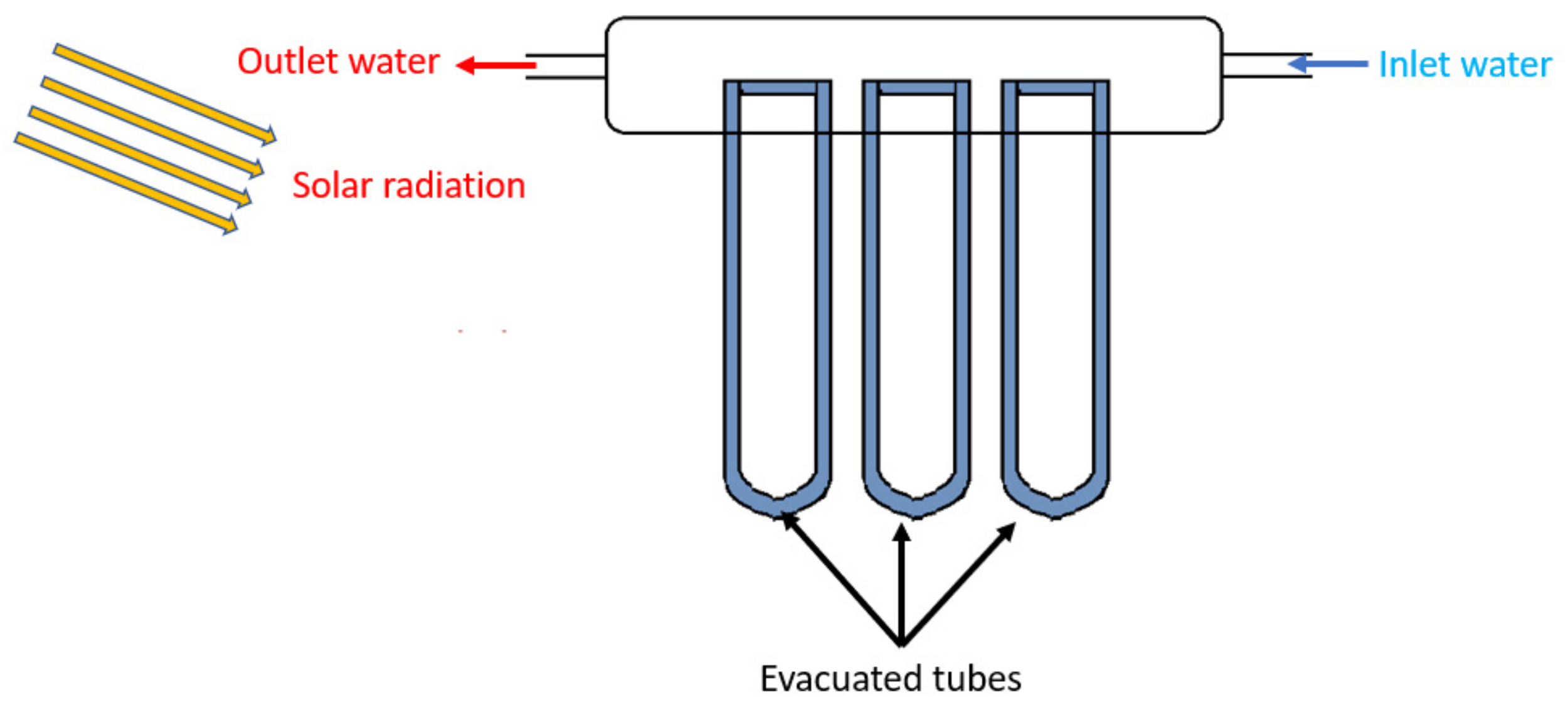

1.1.2. U-Tube-Based Solar Collector

1.1.3. Heat Pipe-Based Solar Collector

2. Advancements in Water in Glass Tube-Based Collector

2.1. Design Modifications

2.2. PCM Integration with ETC Systems

2.3. Nano-Fluid as Working Medium

3. Advancements in U-Tube-Based ETC Collectors

3.1. Design Modifications

3.2. PCM Integration with the ETC System

3.3. Nano Fluid Used

4. Advancements in Heat Pipe-Based ETC Collectors

4.1. Design Modifications

4.2. PCM Integration with ETC Systems

4.3. Nano Fluid Used

5. Other Modifications on Solar Water Heaters

6. Numerical Studies on ETCs

7. Economic, Environmental, and Life Cycle Assessment of ETCs

8. Conclusions

- ETC-based solar water heaters are a viable system for domestic and industrial hot water requirements. They also eliminate certain drawbacks of flat plate-based solar water heaters. Besides, ETCs are more adaptable to design modifications, and the inclusion of consistent efforts is required to improve the ETC-based collector’s design so that more solar insolation can be absorbed. Various extended surfaces or fins can also be incorporated that will help ETCs to perform within a specified temperature range.

- The utilization of nanofluids as working fluids increases the heat transfer rate due to the higher heat-carrying capacity of the nanoparticles.

- The intermittent nature of the hot water supply can be eliminated to some extent by the inclusion of thermal energy storage materials. The literature indicates that suitable PCMs can be a viable solution owing to their inherent properties. However, the successful utilization of the PCM highly depends on its proper filling and packing within the developed system.

- A loss of thermal energy significantly affects the performance of solar water heaters. Hence, appropriate insulating materials should be used across the piping network and the storage tanks.

9. Future Scope

- Consistent efforts are required to increase the absorbing capacity of solar radiation by the evacuated tube; hence, research work may be accelerated to explore more effective absorber coatings on the surface of the ETC.

- The literature indicates that on the evacuated type solar water heaters, fewer numerical studies have been performed; therefore, in addition to other approaches, it is suggested to expedite this methodology. Numerical techniques provide faster solutions, and it is also a convenient, economic, and less time-consuming method.

- Highly conductive fluid may be utilized as a working fluid in ETC-based water heaters; it can help to extract more heat from the ETC and transfer it to the water.

- Although several works have been reported in which PCMs are used with solar ETC water heaters, it is not well established so far. It is suggested to explore suitable PCMs and their proper integration techniques with solar water heaters so that the system can be compact and may provide hot water for longer durations in the absence of solar radiation.

- It has been observed that evacuated tubes are highly brittle in nature; hence, research work in this direction is required by utilizing nanofibers in the glass material to increase the strength and durability of the glass tube.

- Usually, the inner surface of an ETC is smooth. If it would be provided with artificial roughness and certain perturbation, it could be helpful to introduce turbulence into the flow, which may improve the heat transfer.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Energy, I.; Iea, A. Global energy outlook 2021: Pathways from Paris. Resour. Future 2021, 10–11. [Google Scholar]

- Huang, K.; Huang, K.; Su, B.; Li, T.; Ke, H.; Lin, M.; Wang, Q. Numerical simulation of the mixing behaviour of hot and cold fluids in the rectangular T-junction with/without an impeller. Appl. Therm. Eng. 2022, 204, 117942. [Google Scholar] [CrossRef]

- Chang, H.; Han, Z.; Li, X.; Ma, T.; Wang, Q. Experimental study on heat transfer performance of sCO2 near pseudo-critical point in airfoil-fin PCHE from viewpoint of average thermal-resistance ratio. Int. J. Heat Mass Transf. 2022, 196, 123257. [Google Scholar] [CrossRef]

- Morrison, G.L. Measurement and simulation of flow rate in a water-in-glass evacuated tube solar water heater. Sol. Energy 2006, 78, 257–267. [Google Scholar] [CrossRef]

- Morrison, G.L.; Budihardjo, I.; Behnia, M. Water-in-glass evacuated tube solar water heaters. Sol. Energy 2004, 76, 135–140. [Google Scholar] [CrossRef]

- Tang, R.; Li, Z.; Zhong, H.; Lan, Q. Assessment of uncertainty in mean heat loss coefficient of all glass evacuated solar collector tube testing. Energy Convers. Manag. 2006, 47, 60–67. [Google Scholar] [CrossRef]

- Budihardjo, I.; Morrison, G.L.; Behnia, M. Natural circulation flow through water-in-glass evacuated tube solar collectors. Sol. Energy 2007, 81, 1460–1472. [Google Scholar] [CrossRef]

- Shah, L.J.; Furbo, S. Theoretical flow investigations of an all glass evacuated tubular collector. Sol. Energy 2007, 81, 822–828. [Google Scholar] [CrossRef]

- Jaisankar, S.; Radhakrishnan, T.K.; Sheeba, K.N.; Suresh, S. Experimental investigation of heat transfer and friction factor characteristics of thermosyphon solar water heater system fitted with spacer at the trailing edge of Left-Right twisted tapes. Energy Convers. Manag. 2009, 50, 2638–2649. [Google Scholar] [CrossRef]

- Tang, R.; Gao, W.; Yu, Y.; Chen, H. Optimal tilt-angles of all-glass evacuated tube solar collectors. Energy 2009, 34, 1387–1395. [Google Scholar] [CrossRef]

- Budihardjo, I.; Morrison, G.L. Performance of water-in-glass evacuated tube solar water heaters. Sol. Energy 2009, 83, 116–123. [Google Scholar] [CrossRef]

- Ren, L.; Kong, F.; Wang, X.; Song, Y.; Li, X.; Zhang, F.; Wang, J. Triggering ambient polymer-based Li-O2 battery via photo-electro-thermal synergy. Nano Energy 2022, 98, 107248. [Google Scholar] [CrossRef]

- Chow, T.T.; Dong, Z.; Chan, L.S.; Fong, K.F.; Bai, Y. Performance evaluation of evacuated tube solar domestic hot water systems in Hong Kong. Energy Build. 2011, 43, 3467–3474. [Google Scholar] [CrossRef]

- Tang, R.; Yang, Y.; Gao, W. Comparative studies on thermal performance of water-in-glass evacuated tube solar water heaters with different collector tilt-angles. Sol. Energy 2011, 85, 1381–1389. [Google Scholar] [CrossRef]

- Chow, T.T.; Bai, Y.; Dong, Z.; Fong, K.F. Selection between single-phase and two-phase evacuated-tube solar water heaters in different climate zones of China. Sol. Energy 2013, 98, 265–274. [Google Scholar] [CrossRef]

- Tang, R.; Yang, Y. Nocturnal reverse flow in water-in-glass evacuated tube solar water heaters. Energy Convers. Manag. 2014, 80, 173–177. [Google Scholar] [CrossRef]

- Yao, K.; Li, T.; Tao, H.; Wei, J.; Feng, K. Performance evaluation of all-glass evacuated tube solar water heater with twist tape inserts using CFD. Energy Procedia 2015, 70, 332–339. [Google Scholar] [CrossRef]

- Bracamonte, J.; Parada, J.; Dimas, J.; Baritto, M. Effect of the collector tilt angle on thermal efficiency and stratification of passive water in glass evacuated tube solar water heater. Appl. Energy 2015, 155, 648–659. [Google Scholar] [CrossRef]

- Alfaro-Ayala, J.A.; Martínez-Rodríguez, G.; Picón-Núñez, M.; Uribe-Ramírez, A.R.; Gallegos-Muñoz, A. Numerical study of a low temperature water-in-glass evacuated tube solar collector. Energy Convers. Manag. 2015, 94, 472–481. [Google Scholar] [CrossRef]

- Essa, M.A.; Mostafa, N.H. Theoretical and experimental study for temperature distribution and flow profile in all water evacuated tube solar collector considering solar radiation boundary condition. Sol. Energy 2017, 142, 267–277. [Google Scholar] [CrossRef]

- Gong, J.; Jiang, Z.; Luo, X.; Du, B.; Wang, J.; Lund, P.D. Straight-through all-glass evacuated tube solar collector for low and medium temperature applications. Sol. Energy 2020, 201, 935–943. [Google Scholar] [CrossRef]

- Jowzi, M.; Veysi, F.; Sadeghi, G. Experimental and numerical investigations on the thermal performance of a modified evacuated tube solar collector: Effect of the bypass tube. Sol. Energy 2019, 183, 725–737. [Google Scholar] [CrossRef]

- Li, Q.; Gao, W.; Lin, W.; Liu, T.; Zhang, Y.; Ding, X. Experiment and simulation study on convective heat transfer of all- glass evacuated tube solar collector. Renew. Energy 2020, 152, 1129–1139. [Google Scholar] [CrossRef]

- Sadeghi, G.; Najafzadeh, M.; Safarzadeh, H. Utilizing Gene-Expression Programming in Modelling the Thermal Performance of Evacuated Tube Solar Collectors. J. Energy Storage 2020, 30, 101546. [Google Scholar] [CrossRef]

- Kumar, P.M.; Mylsamy, K. Experimental investigation of solar water heater integrated with a nanocomposite phase change material Energetic and exergetic approach. J. Therm. Anal. Calorim. 2019, 136, 121–132. [Google Scholar] [CrossRef]

- Sabiha, M.A.; Saidur, R.; Hassani, S.; Said, Z.; Mekhilef, S. Energy performance of an evacuated tube solar collector using single walled carbon nanotubes nanofluids. Energy Convers. Manag. 2015, 105, 1377–1388. [Google Scholar] [CrossRef]

- Ghaderian, J.; Azwadi, N.; Sidik, C.; Kasaeian, A.; Ghaderian, S.; Okhovat, A.; Pakzadeh, A.; Samion, S.; Yahya, W.J. Performance of Copper Oxide/distilled water nanofluid in evacuated tube solar collector (ETSC) water heater with internal coil under thermosyphon system circulations. Appl. Therm. Eng. 2017, 121, 520–536. [Google Scholar] [CrossRef]

- Ghaderian, J.; Azwadi, N.; Sidik, C. International Journal of Heat and Mass Transfer An experimental investigation on the effect of Al 2 O 3/distilled water nanofluid on the energy efficiency of evacuated tube solar collector. Int. J. Heat Mass Transf. 2017, 108, 972–987. [Google Scholar] [CrossRef]

- Mahbubul, I.M.; Mumtaz, M.; Khan, A.; Ibrahim, N.I.; Al-sulaiman, F.A.; Saidur, R. Carbon nanotube nano fl uid in enhancing the ef fi ciency of evacuated tube solar collector. Renew. Energy 2018, 121, 36–44. [Google Scholar] [CrossRef]

- Manirathnam, A.S.; Manikandan, M.K.D.; Prakash, R.H.; Kumar, B.K.; Amarnath, M.D. Materials Today: Proceedings Experimental analysis on solar water heater integrated with Nano composite phase change material (SCi and CuO). Mater. Today Proc. 2021, 37, 232–240. [Google Scholar] [CrossRef]

- Saxena, G.; Gaur, M.K. Materials Today: Proceedings Energy, exergy and economic analysis of evacuated tube solar water heating system integrated with heat exchanger. Mater. Today Proc. 2020, 28, 2452–2462. [Google Scholar] [CrossRef]

- López-Núñez, A.; Alfaro-Ayala, J.A.; Ramírez-Minguela, J.J.; Cano-Banda, F.; Ruiz-Camacho, B.; Belman-Flores, J.M. Numerical analysis of the thermo-hydraulic performance and entropy generation rate of a water-in-glass evacuated tube solar collector using TiO2 water-based nanofluid and only water as working fluids. Renew. Energy 2022, 197, 953–965. [Google Scholar] [CrossRef]

- Du, B.; Lund, P.D.; Wang, J. Improving the accuracy of predicting the performance of solar collectors through clustering analysis with artificial neural network models. Energy Rep. 2022, 8, 3970–3981. [Google Scholar] [CrossRef]

- Zhang, X.R.; Yamaguchi, H. An experimental study on evacuated tube solar collector using supercritical CO2. Appl. Therm. Eng. 2008, 28, 1225–1233. [Google Scholar] [CrossRef]

- Ma, L.; Lu, Z.; Zhang, J.; Liang, R. Thermal performance analysis of the glass evacuated tube solar collector with U-tube. Build. Environ. 2010, 45, 1959–1967. [Google Scholar] [CrossRef]

- Liang, R.; Ma, L.; Zhang, J.; Zhao, D. Theoretical and experimental investigation of the filled-type evacuated tube solar collector with U tube. Sol. Energy 2011, 85, 1735–1744. [Google Scholar] [CrossRef]

- Liang, R.; Ma, L.; Zhang, J.; Zhao, L. Performance analysis of a new-design filled-type solar collector with double. Energy Build. 2013, 57, 220–226. [Google Scholar] [CrossRef]

- Liang, R.; Zhang, J.; Zhao, L.; Ma, L. Research on the universal model of filled-type evacuated tube with U-tube in uniform boundary condition. Appl. Therm. Eng. 2014, 63, 362–369. [Google Scholar] [CrossRef]

- Gao, Y.; Fan, R.; Zhang, X.Y.; AN, Y.J.; Wang, M.X.; Gao, Y.K.; Yu, Y. Thermal performance and parameter analysis of a U-pipe evacuated solar tube collector. Sol. Energy 2014, 107, 714–727. [Google Scholar] [CrossRef]

- Pandey, A.K.; Tyagi, V.V.; Rahim, N.A.; Kaushik, S.C.; Tyagi, S.K. Thermal performance evaluation of direct flow solar water heating system using exergetic approach. J. Therm. Anal. Calorim. 2015, 121, 1365–1373. [Google Scholar] [CrossRef]

- Cui, W.; Si, T.; Li, X.; Li, X.; Lu, L.; Ma, T.; Wang, Q. Heat transfer analysis of phase change material composited with metal foam-fin hybrid structure in inclination container by numerical simulation and artificial neural network. Energy Reports 2022, 8, 10203–10218. [Google Scholar] [CrossRef]

- Nie, X.; Zhao, L.; Deng, S.; Lin, X. Experimental study on thermal performance of U-type evacuated glass tubular solar collector with low inlet temperature. Sol. Energy 2017, 150, 192–201. [Google Scholar] [CrossRef]

- Korres, D.; Tzivanidis, C. A new mini-CPC with a U-type evacuated tube under thermal and optical investigation. Renew. Energy 2018, 128, 529–540. [Google Scholar] [CrossRef]

- Naik, B.K.; Bhowmik, M.; Muthukumar, P. Experimental investigation and numerical modelling on the performance assessments of evacuated U –Tube solar collector systems. Renew. Energy 2019, 134, 1344–1361. [Google Scholar] [CrossRef]

- Korres, D.N.; Tzivanidis, C.; Koronaki, I.P.; Nitsas, M.T. Experimental, numerical and analytical investigation of a U-type evacuated tube collectors’ array. Renew. Energy 2019, 135, 218–231. [Google Scholar] [CrossRef]

- Bhowmik, M.; Muthukumar, P.; Anandalakshmi, R. Experimental based multilayer perceptron approach for prediction of evacuated solar collector performance in humid subtropical regions. Renew. Energy 2019, 143, 1566–1580. [Google Scholar] [CrossRef]

- Uniyal, A.; Prajapati, Y.K. Thermal Performance Study of a Copper U-Tube-based Evacuated Tube Solar Water Heater. In Energy Conversion and Green Energy Storage; CRC Press: Boca Raton, FL, USA, 2022; pp. 101–114. [Google Scholar] [CrossRef]

- Abokersh, M.H.; El-morsi, M.; Sharaf, O.; Abdelrahman, W. An Experimental Evaluation of Direct Flow Evacuated Tube Solar Collector Integrated with Phase Change Material. Energy. 2017, 139, 1111–1125. [Google Scholar] [CrossRef]

- Abokersh, M.H.; El-Morsi, M.; Sharaf, O.; Abdelrahman, W. On-demand operation of a compact solar water heater based on U-pipe evacuated tube solar collector combined with phase change material. Sol. Energy 2017, 155, 1130–1147. [Google Scholar] [CrossRef]

- Essa, M.A.; Mostafa, N.H.; Ibrahim, M.M. An experimental investigation of the phase change process e ff ects on the system performance for the evacuated tube solar collectors integrated with PCMs. Energy Convers. Manag. 2018, 177, 1–10. [Google Scholar] [CrossRef]

- Xue, H.S. Experimental investigation of a domestic solar water heater with solar collector coupled phase-change energy storage. Renew. Energy 2016, 86, 257–261. [Google Scholar] [CrossRef]

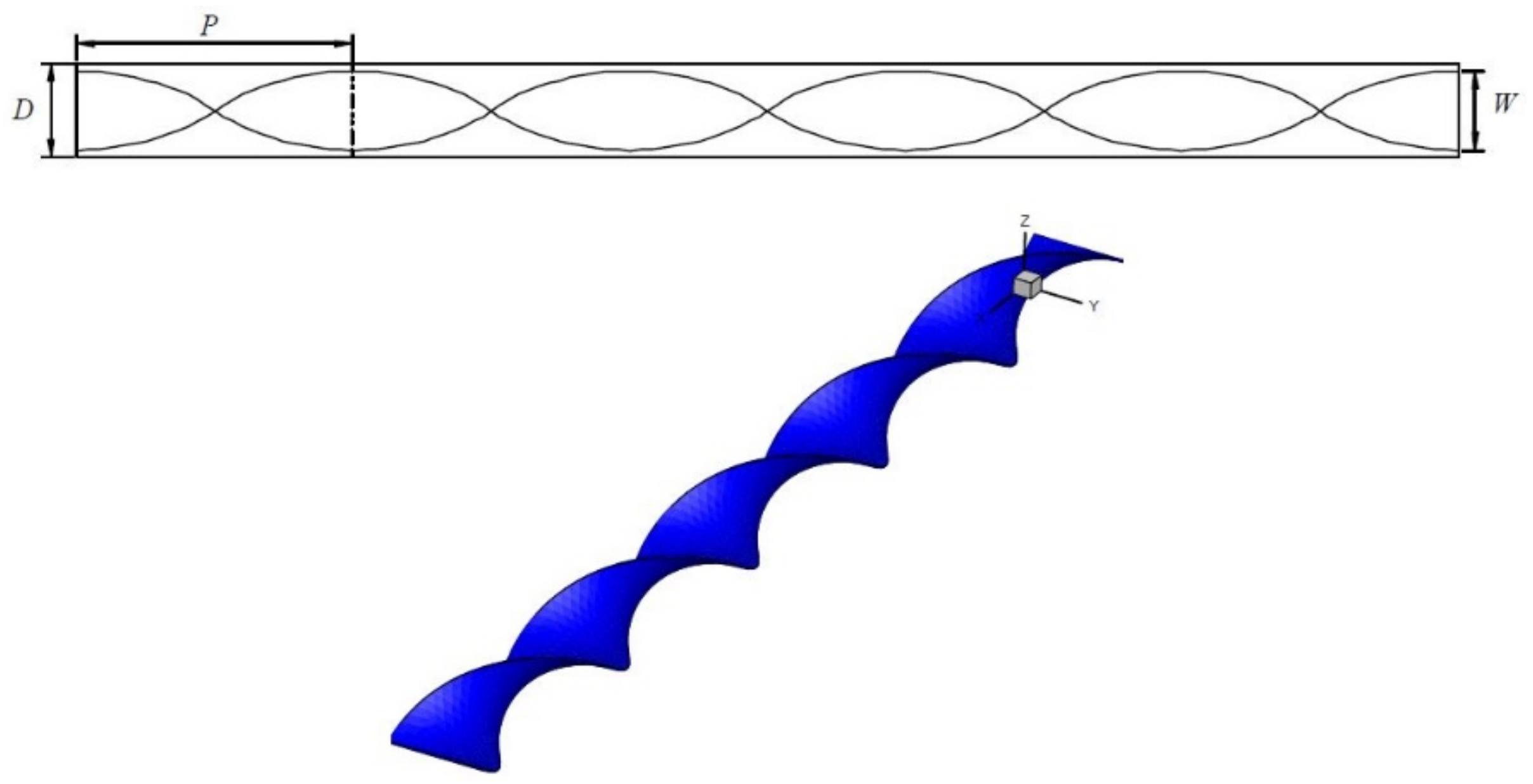

- Olfian, H.; Ajarostaghi SS, M.; Farhadi, M.; Ramiar, A. Melting and solidification processes of phase change material in evacuated tube solar collector with U-shaped spirally corrugated tube. Appl. Therm. Eng. 2021, 182, 116149. [Google Scholar] [CrossRef]

- Lim, C.S.; Sobhansarbandi, S. CFD modeling of an evacuated U-tube solar collector integrated with a novel heat transfer fluid. Sustain. Energy Technol. Assess. 2022, 52, 102051. [Google Scholar] [CrossRef]

- Feng, L.; Liu, J.; Lu, H.; Chen, Y.; Wu, S. A parametric study on the efficiency of a solar evacuated tube collector using phase change materials: A transient simulation. Renew. Energy 2022, 199, 745–758. [Google Scholar] [CrossRef]

- Olfian, H.; Ajarostaghi, S.S.M.; Ebrahimnataj, M.; Farhadi, M.; Arıcı, M. On the thermal performance of evacuated tube solar collector integrated with phase change material. Sustain. Energy Technol. Assess. 2022, 53, 102437. [Google Scholar] [CrossRef]

- Tong, Y.; Kim, J.; Cho, H. Effects of thermal performance of enclosed-type evacuated U-tube solar collector with multi-walled carbon nanotube / water nano fl uid. Renew. Energy 2015, 83, 463–473. [Google Scholar] [CrossRef]

- Kim, H.; Ham, J.; Park, C.; Cho, H. Theoretical investigation of the ef fi ciency of a U-tube solar collector using various nano fl uids. Energy 2016, 94, 497–507. [Google Scholar] [CrossRef]

- Kaya, H.; Arslan, K.; Eltugral, N. Experimental investigation of thermal performance of an evacuated U-Tube solar collector with ZnO / Etylene glycol-pure water nano fluids. Renew. Energy 2018, 122, 329–338. [Google Scholar] [CrossRef]

- Xie, B.; Li, C.; Zhang, B.; Yang, L.; Xiao, G.; Chen, J. Evaluation of stearic acid/coconut shell charcoal composite phase change thermal energy storage materials for tankless solar water heater. Energy Built Environ. 2020, 1, 187–198. [Google Scholar] [CrossRef]

- Algarni, S.; Alqahtani, T.; Almutairi, K. Experimental investigation of an evacuated tube solar collector incorporating nano-enhanced PCM as a thermal booster. Appl. Therm. Eng. 2020, 180, 115831. [Google Scholar] [CrossRef]

- Kabeel, A.E.; Abdelgaied, M.; Elrefay, M.K. Thermal performance improvement of the modified evacuated U-tube solar collector using hybrid storage materials and low-cost concentrators. J. Energy Storage 2020, 29, 101394. [Google Scholar] [CrossRef]

- Riffat, S.B.; Zhao, X.; Doherty, P.S. Developing a theoretical model to investigate thermal performance of a thin membrane heat-pipe solar collector. Appl. Therm. Eng. 2005, 25, 899–915. [Google Scholar] [CrossRef]

- Azad, E. Theoretical and experimental investigation of heat pipe solar collector. Exp. Therm. Fluid Sci. 2008, 32, 1666–1672. [Google Scholar] [CrossRef]

- Redpath, D.A.G.; Eames, P.C.; Lo, S.N.G.; Griffiths, P.W. Experimental investigation of natural convection heat exchange within a physical model of the manifold chamber of a thermosyphon heat-pipe evacuated tube solar water heater. Sol. Energy 2009, 83, 988–997. [Google Scholar] [CrossRef]

- Arab, M.; Soltanieh, M.; Shafii, M.B. Experimental investigation of extra-long pulsating heat pipe application in solar water heaters. Exp. Therm. Fluid Sci. 2012, 42, 6–15. [Google Scholar] [CrossRef]

- Ayompe, L.M.; Duffy, A. Thermal performance analysis of a solar water heating system with heat pipe evacuated tube collector using data from a field trial. Sol. Energy 2013, 90, 17–28. [Google Scholar] [CrossRef]

- Beer, M. ScienceDirect The comparative field performance study of heat pipe evacuated tube collectors with standard design manifold header and parallel flow manifold header based on the metal foam structural element. Sol. Energy 2015, 122, 359–367. [Google Scholar] [CrossRef]

- Gill, L.; Mac Mahon, J.; Ryan, K. The performance of an evacuated tube solar hot water system in a domestic house throughout a year in a northern maritime climate (Dublin). Sol. Energy 2016, 137, 261–272. [Google Scholar] [CrossRef]

- Kumar, S.S.; Kumar, K.M.; Kumar, S.R.S. ScienceDirect Design of Evacuated Tube Solar Collector with Heat Pipe. Mater. Today Proc. 2017, 4, 12641–12646. [Google Scholar] [CrossRef]

- Daghigh, R.; Shafieian, A. Theoretical and experimental analysis of thermal performance of a solar water heating system with evacuated tube heat pipe collector. Appl. Therm. Eng. 2016, 103, 1219–1227. [Google Scholar] [CrossRef]

- Al-Joboory, H.N.S. Comparative experimental investigation of two evacuated tube solar water heaters of different configurations for domestic application of Baghdad-Iraq. Energy Build. 2019, 203, 109437. [Google Scholar] [CrossRef]

- Kotb, A.; Elsheniti, M.B.; Elsamni, O.A. Optimum number and arrangement of evacuated-tube solar collectors under various operating conditions. Energy Convers. Manag. 2019, 199, 112032. [Google Scholar] [CrossRef]

- Huang, X.; Wang, Q.; Yang, H.; Zhong, S.; Jiao, D.; Zhang, K.; Li, M.; Pei, G. Theoretical and experimental studies of impacts of heat shields on heat pipe evacuated tube solar collector. Renew. Energy 2019, 138, 999–1009. [Google Scholar] [CrossRef]

- Elsheniti, M.B.; Kotb, A.; Elsamni, O. Thermal performance of a heat-pipe evacuated-tube solar collector at high inlet temperatures. Appl. Therm. Eng. 2019, 154, 315–325. [Google Scholar] [CrossRef]

- Shafieian, A.; Khiadani, M.; Nosrati, A. Thermal performance of an evacuated tube heat pipe solar water heating system in cold season. Appl. Therm. Eng. 2019, 149, 644–657. [Google Scholar] [CrossRef]

- Tamuli, B.R.; Nath, S.; Bhanja, D. Performance enhancement of a dual heat pipe array based evacuated tube solar water heater for north eastern India climatic condition: A numerical approach. Appl. Therm. Eng. 2022, 118597. [Google Scholar] [CrossRef]

- Naghavi, M.S.; Ong, K.S.; Badruddin, I.A.; Mehrali, M.; Silakhori, M.; Metselaar, H.S.C. Theoretical model of an evacuated tube heat pipe solar collector integrated with phase change material. Energy 2015, 91, 911–924. [Google Scholar] [CrossRef]

- Papadimitratos, A.; Sobhansarbandi, S.; Pozdin, V. Evacuated tube solar collectors integrated with phase change materials. Sol. Energy 2016, 129, 10–19. [Google Scholar] [CrossRef]

- Sekret, R. Experimental study of evacuated tube collector/storage system containing paraf fi n as a PCM. Energy 2016, 114, 1063–1072. [Google Scholar]

- Wu, W.; Dai, S.; Liu, Z.; Dou, Y.; Hua, J.; Li, M.; Wang, X.; Wang, X. Experimental study on the performance of a novel solar water heating system with and without PCM. Sol. Energy 2018, 171, 604–612. [Google Scholar] [CrossRef]

- Bazri, S.; Bazri, S.; Badruddin, I.A.; Naghavi, M.S.; Seng, O.K.; Wongwises, S. An analytical and comparative study of the charging and discharging processes in a latent heat thermal storage tank for solar water heater system. Sol. Energy 2019, 185, 424–438. [Google Scholar] [CrossRef]

- Pawar, V.R.; Sobhansarbandi, S. CFD modeling of a thermal energy storage based heat pipe evacuated tube solar collector. J. Energy Storage 2020, 30, 101528. [Google Scholar] [CrossRef]

- Chopra, K.; Pathak, A.K.; Tyagi, V.V.; Pandey, A.K.; Anand, S.; Sari, A. Thermal performance of phase change material integrated heat pipe evacuated tube solar collector system: An experimental assessment. Energy Convers. Manag. 2020, 203, 112205. [Google Scholar] [CrossRef]

- Chopra, K.; Tyagi, V.V.; Pandey, A.K.; Sharma, R.K.; Sari, A. PCM integrated glass in glass tube solar collector for low and medium temperature applications: Thermodynamic & techno-economic approach. Energy 2020, 198, 117238. [Google Scholar]

- Li, B.; Zhai, X. Experimental investigation and theoretical analysis on a mid-temperature solar collector/storage system with composite PCM. Appl. Therm. Eng. 2017, 124, 34–43. [Google Scholar] [CrossRef]

- Sobhansarbandi, S.; Martinez, P.M.; Papadimitratos, A.; Zakhidov, A.; Hassanipour, F. Evacuated tube solar collector with multifunctional absorber layers. Sol. Energy 2017, 146, 342–350. [Google Scholar] [CrossRef]

- Naghavi, M.S.; Ong, K.S.; Badruddin, I.A.; Mehrali, M.; Metselaar, H.S.C. Thermal performance of a compact design heat pipe solar collector with latent heat storage in charging/discharging modes. Energy 2017, 127, 101–115. [Google Scholar] [CrossRef]

- Azad, E. Experimental analysis of thermal performance of solar collectors with different numbers of heat pipes versus a flow-through solar collector. Renew. Sustain. Energy Rev. 2017, 82, 1–6. [Google Scholar] [CrossRef]

- Chopra, K.; Tyagi, V.V.; Pathak, A.K.; Pandey, A.K.; Sari, A. Experimental performance evaluation of a novel designed phase change material integrated manifold heat pipe evacuated tube solar collector system. Energy Convers. Manag. 2019, 198, 111896. [Google Scholar] [CrossRef]

- Noie, S.H.; Heris, S.Z.; Kahani, M.; Nowee, S.M. Heat transfer enhancement using Al2O3/water nanofluid in a two-phase closed thermosyphon. Int. J. Heat Fluid Flow 2009, 30, 700–705. [Google Scholar] [CrossRef]

- Shafieian, A.; Osman, J.J.; Khiadani, M.; Nosrati, A. Enhancing heat pipe solar water heating systems performance using a novel variable mass flow rate technique and different solar working fluids. Sol. Energy 2019, 186, 191–203. [Google Scholar] [CrossRef]

- Ozsoy, A.; Corumlu, V. Thermal performance of a thermosyphon heat pipe evacuated tube solar collector using silver-water nano fl uid for commercial applications. Renew. Energy 2018, 122, 26–34. [Google Scholar] [CrossRef]

- Feliński, P.; Sekret, R. Effect of PCM application inside an evacuated tube collector on the thermal performance of a domestic hot water system. Energy Build. 2017, 152, 558–567. [Google Scholar] [CrossRef]

- Mohammed, H.A.; Hasan, H.A.; Wahid, M.A. Heat transfer enhancement of nanofluids in a double pipe heat exchanger with louvered strip inserts. Int. Commun. Heat Mass Transf. 2013, 40, 36–46. [Google Scholar] [CrossRef]

- Essa, M.A.; Rofaiel, I.Y.; Ahmed, M.A. Experimental and theoretical analysis for the performance of evacuated tube collector integrated with helical finned heat pipes using PCM energy storage. Energy 2020, 206, 118166. [Google Scholar] [CrossRef]

- Hong, S.J.; Park, S.J.; Kim, B.R.; Kim, D.H.; Kim, J.H.; Kim, M.S.; Park, C.W. Design and experimental investigation of stainless-steel based chevron-hydroformed manifold of evacuated heat pipe solar collector. Sol. Energy 2022, 232, 186–195. [Google Scholar] [CrossRef]

- Siqueira, D.A.; Vieira, L.G.M.; Damasceno, J.J.R. Analysis and performance of a low-cost solar heater. Renew. Energy 2011, 36, 2538–2546. [Google Scholar] [CrossRef]

- Chong, K.K.; Chay, K.G.; Chin, K.H. Study of a solar water heater using stationary V-trough collector. Renew. Energy 2012, 39, 207–215. [Google Scholar] [CrossRef]

- Marmoush, M.M.; Rezk, H.; Shehata, N.; Henry, J.; Gomaa, M.R. A novel merging Tubular Daylight Device with Solar Water Heater e Experimental study. Renew. Energy 2018, 125, 947–961. [Google Scholar] [CrossRef]

- Yassen, T.A.; Mokhlif, N.D.; Eleiwi, M.A. Performance investigation of an integrated solar water heater with corrugated absorber surface for domestic use. Renew. Energy 2019, 138, 852–860. [Google Scholar] [CrossRef]

- Touaba, O.; Ait Cheikh, M.S.; Slimani, M.E.A.; Bouraiou, A.; Ziane, A.; Necaibia, A.; Harmim, A. Experimental investigation of solar water heater equipped with a solar collector using waste oil as absorber and working fluid. Sol. Energy 2020, 199, 630–644. [Google Scholar] [CrossRef]

- Dhinakaran, R.; Muraliraja, R.; Elansezhian, R.; Baskar, S.; Satish, S.; Shaisundaram, V.S. Utilization of solar resource using phase change material assisted solar water heater and the influence of nano filler. Mater. Today: Proc. 2021, 37, 1281–1285. [Google Scholar] [CrossRef]

- Wang, T.; Diao, Y.; Zhao, Y.; Liang, L.; Wang, Z.; Chen, C. A comparative experimental investigation on thermal performance for two types of vacuum tube solar air collectors based on flat micro-heat pipe arrays (FMHPA). Sol. Energy 2020, 201, 508–522. [Google Scholar] [CrossRef]

- Zhang, X.; You, S.; Ge, H.; Gao, Y.; Xu, W.; Wang, M.; He, T.; Zheng, X. Thermal performance of direct-flow coaxial evacuated-tube solar collectors with and without a heat shield. Energy Convers. Manag. 2014, 84, 80–87. [Google Scholar] [CrossRef]

- Wang, P.Y.; Li, S.F.; Liu, Z.H. Collecting performance of an evacuated tubular solar high-temperature air heater with concentric tube heat exchanger. Energy Convers. Manag. 2015, 106, 1166–1173. [Google Scholar] [CrossRef]

- Yanhua, L.; Wengang, H.; Hongwen, Y.; Mingxin, L. Performance and economic evaluation of evacuated tube solar collector with auxiliary electric heater for rural heating. Energy Procedia 2019, 158, 186–191. [Google Scholar] [CrossRef]

- Sokhansefat, T.; Kasaeian, A.; Rahmani, K.; Heidari, A.H.; Aghakhani, F.; Mahian, O. Thermoeconomic and environmental analysis of solar flat plate and evacuated tube collectors in cold climatic conditions. Renew. Energy 2018, 115, 501–508. [Google Scholar] [CrossRef]

- García, J.L.; Porras-prieto, C.J.; Benavente, R.M.; Gomez-villarino, T.; Mazarron, F.R. Profitability of a solar water heating system with evacuated tube collector in the meat industry. Renew. Energy 2019, 131, 966–976. [Google Scholar] [CrossRef]

- Tewari, K.; Dev, R. Exergy, environmental and economic analysis of modified domestic solar water heater with glass-to-glass PV module. Energy 2019, 170, 1130–1150. [Google Scholar] [CrossRef]

- Brondani, M. Economic-Environmental Comparison between Flat Plate and Evacuated Tube Solar Collectors. Glob. NEST J. Glob. NEST Int. J. 2018, 16, 1100–1110. [Google Scholar] [CrossRef]

| S.N. | Author | Year | Experimental (E)/Numerical (N) | Key Features | Outcome |

|---|---|---|---|---|---|

| 1. | Yao et al. [17] | 2015 | E | Twisted inserts | There is a 9.29% increase in the Nusselt number of the modified ETC as compared with the conventional one. |

| 2. | Essa et al. [20] | 2017 | E and N | Temperature and streamlined patterns | Solar radiation intensity and incidence angle have a great impact on the flow structure developed inside the tube. |

| 3. | Ghardian et al. [27] | 2017 | E | Al2O3 as a nanofluid and Triton X-100 as a surfactant | The results revealed that the maximum efficiency was obtained as 57.63% for the flow rate of 60 L per h at 0.06% nanofluid by volume. |

| 4. | Kumar et al. [25] | 2018 | E | Paraffin wax as a PCM and silica as a nanoparticle | The energy efficiency of ETCs is improved up to 74.79% with a nanocomposite and 69.63% with a PCM. |

| 5. | Jowzi et al. [22] | 2019 | E | Bypass tube | More uniformity in temperature distribution has been observed by introducing the bypass tube, and the efficiency is increased by 11%. |

| 6. | Gong et al. [21] | 2020 | E | Dewar-type collector | Nusselt number of the straight-through glass tube collector was four times higher than the Dewar tube collector. |

| 7. | Li et al. [23] | 2020 | E and N | Double-row all-glass ETC | The declination angle has a great impact on the efficiency of ETCs, and a high amount of heat was stored with increases in the declination angle. |

| 8. | Maniratanam et al. [30] | 2020 | E | Cu- and Si-based nanocomposite. | The energy efficiency of the systems, i.e., without PCMs, with PCMs, and with a nanocomposite PCM was 33.8%, 38.3%, and 41.7%, respectively. |

| 9. | Du et al. [33] | 2021 | N | Different artificial neural network | For accurate prediction, the convolutional neural network model proved to be the best ANN model. |

| 10. | Lopez et al. [32] | 2022 | E | CuO used as a nanoparticle | There are maximum reductions in the entropy generation rate of 87.5%, 65.5%, and 14.71% due to viscous effects, heat transfer, and heat loss by using nanofluid as the working fluid. |

| S.N. | Author | Year | E/N | Key Features | Outcome |

|---|---|---|---|---|---|

| 1 | Naik et al. [41] | 2015 | N | Different working mediums | Optimized selected length and low mass flow rate of the fluid favors in increasing the outlet temperature of the fluid. |

| 2. | H. Shen Xue [51] | 2016 | E | Ba(OH)2·8H2O as a PCM and BaCO3 used as a nucleant | Solar radiation and initial water temperature have impacts on system performance. |

| 3. | Abokersh et al. [48] | 2017 | E and N | Paraffin wax as a PCM | The simultaneous long-term predictions based on regression modeling show that the average annual efficiency is 71.8%, 85.7%, and 40.5% for the un-finned, finned, and FSWHS systems, respectively. |

| 4. | Naik et al. [44] | 2019 | E and N | - | The solar intensity, inlet temperature, and mass flow rate of the fluid have a significant role on the useful heat absorbed by the fluid. |

| 5. | Algarni et al. [60] | 2020 | E | Copper-based nano-enhanced PCM | Addition of 0.33 wt% of copper/PCM composite to the ETSC increases the efficiency by 32%. ETSC/Ne-PCM system can provide hot water up to 50 °C for about 2 h longer than typical ETC systems with a specific mass flow of 0.08 L/min. |

| 6. | Olfian et al. [52] | 2021 | N | Paraffin wax as a PCM and a spirally corrugated tube | Corrugated tube increases the collector efficiency by 21.55% as compared to a smooth tube. |

| 7. | Kabeel et al. [61] | 2020 | E | Hybrid storage materials | Daily thermal efficiency is improved by up to 72% in increasing the mass concentration of graphite in hybrid storage materials. |

| 8. | Feng et al. [54] | 2022 | N | Multi-walled carbon nanotubes integrated with PCM | The mass flow rate of HTF and the mass fraction of the nanoparticle of MWCNT may increase the thermal performance of ETC-PCM systems. |

| 9. | Olfian et al. [55] | 2022 | N | Paraffin wax | Thermal energy process is increased by 20%, and the optimal diameter for charging and discharging is 6 mm. |

| S.N. | Author | Year | E/N | Key Features | Outcome |

|---|---|---|---|---|---|

| 1. | Felinski et al. [79] | 2017 | E | Paraffin used as a PCM | The total amount of useful heat obtained from the paraffin-integrated ETC/S system was increased by 45–79%, depending on the mass flow rate of the heating medium during the discharge cycle. |

| 2. | Felinski et al. [93] | 2017 | E | Hydrotreated technical-grade paraffin with a melting point of 58 °C was used as a PCM | The charging efficiency of the evacuated tube collector/storage was obtained in the range of 33 to 66%, which depends on the solar radiation intensity and the temperature of the PCM. |

| 3. | Wu et al. [80] | 2018 | E | Oscillating heat pipe and paraffin wax used as a PCM | On summer nights, the exit water temperature (EWT) with PCMs can stay over 50 °C. On winter nights, COP with PCMs is over 3.0, which can make the EWT reach 50 °C in a much shorter time than that of without PCMs. |

| 4 | Hasan et al. [94] | 2019 | E | Paraffin used as a PCM | The enhancement in the overall daily efficiency of the heat pipe system over the thermosyphon system was 22.5% for no load, 42.5% for intermittent loading, and 32.4% for continuous loading. |

| 5 | Shafieian et al. [91] | 2019 | N | - | Hot water consumption pattern had a remarkable impact on the optimum design of the ETCs. Lowering the flow rate of the fluid had a positive impact on the outlet temperature of the fluid. |

| 6. | Essa et al. [95] | 2020 | E | Helically finned heat pipe | The helical fins were found to achieve daily efficiency enhancements over the conventional one by 15% and 13.6% for the flow rates of 0.5 and 0.665 L/min, respectively. |

| 7. | Chopra et al. [83] | 2020 | E | Stearic acid as a PCM | The daily thermal efficiency of the evacuated tube solar collector with and without phase change materials was varied in the range of 42–55% and 79–87%, respectively, and the daily thermal efficiency for both the systems was maximum at the flow rate of 20 L per h. |

| 8. | Chopra et al. [84] | 2020 | E | Stearic acid as a PCM | ETC/S obtained higher energy and exergy efficiencies in comparison to the ETC/WS design. The maximum attained values of average daily energy efficiency for ETC/S and ETC/WS were 78.36% and 54.10%, respectively, at a flow rate of 24 L per h. |

| 9. | Tamuli et al. [76] | 2022 | E | Dual-heat pipe array-based ETC | Average efficiency varies between 70–80%, and there is an enhancement in heat extraction by 15–20% using an additional heat pipe. |

| 10 | Hong et al. [96] | 2022 | E and N | Stainless-steel-based hydroformed manifold | There is a 29% increase in the convective heat transfer coefficient of the chevron-hydroformed manifold compared with the smooth-hydroformed manifold. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Uniyal, A.; Prajapati, Y.K.; Ranakoti, L.; Bhandari, P.; Singh, T.; Gangil, B.; Sharma, S.; Upadhyay, V.V.; Eldin, S.M. Recent Advancements in Evacuated Tube Solar Water Heaters: A Critical Review of the Integration of Phase Change Materials and Nanofluids with ETCs. Energies 2022, 15, 8999. https://doi.org/10.3390/en15238999

Uniyal A, Prajapati YK, Ranakoti L, Bhandari P, Singh T, Gangil B, Sharma S, Upadhyay VV, Eldin SM. Recent Advancements in Evacuated Tube Solar Water Heaters: A Critical Review of the Integration of Phase Change Materials and Nanofluids with ETCs. Energies. 2022; 15(23):8999. https://doi.org/10.3390/en15238999

Chicago/Turabian StyleUniyal, Arun, Yogesh K. Prajapati, Lalit Ranakoti, Prabhakar Bhandari, Tej Singh, Brijesh Gangil, Shubham Sharma, Viyat Varun Upadhyay, and Sayed M. Eldin. 2022. "Recent Advancements in Evacuated Tube Solar Water Heaters: A Critical Review of the Integration of Phase Change Materials and Nanofluids with ETCs" Energies 15, no. 23: 8999. https://doi.org/10.3390/en15238999

APA StyleUniyal, A., Prajapati, Y. K., Ranakoti, L., Bhandari, P., Singh, T., Gangil, B., Sharma, S., Upadhyay, V. V., & Eldin, S. M. (2022). Recent Advancements in Evacuated Tube Solar Water Heaters: A Critical Review of the Integration of Phase Change Materials and Nanofluids with ETCs. Energies, 15(23), 8999. https://doi.org/10.3390/en15238999