1. Introduction

The textile industry has undergone significant changes over the years. In the past, most textile production was based in developed countries and focused on providing goods for their domestic markets. However, the rise of global trade and the globalization of production has led to a shift in the textile industry. Today, textile production is increasingly occurring in developing countries, where labor and resource costs are lower [

1]. This has allowed textile companies to remain competitive in the global marketplace. In addition, new technologies have also played a role in the evolution of the textile industry [

2].

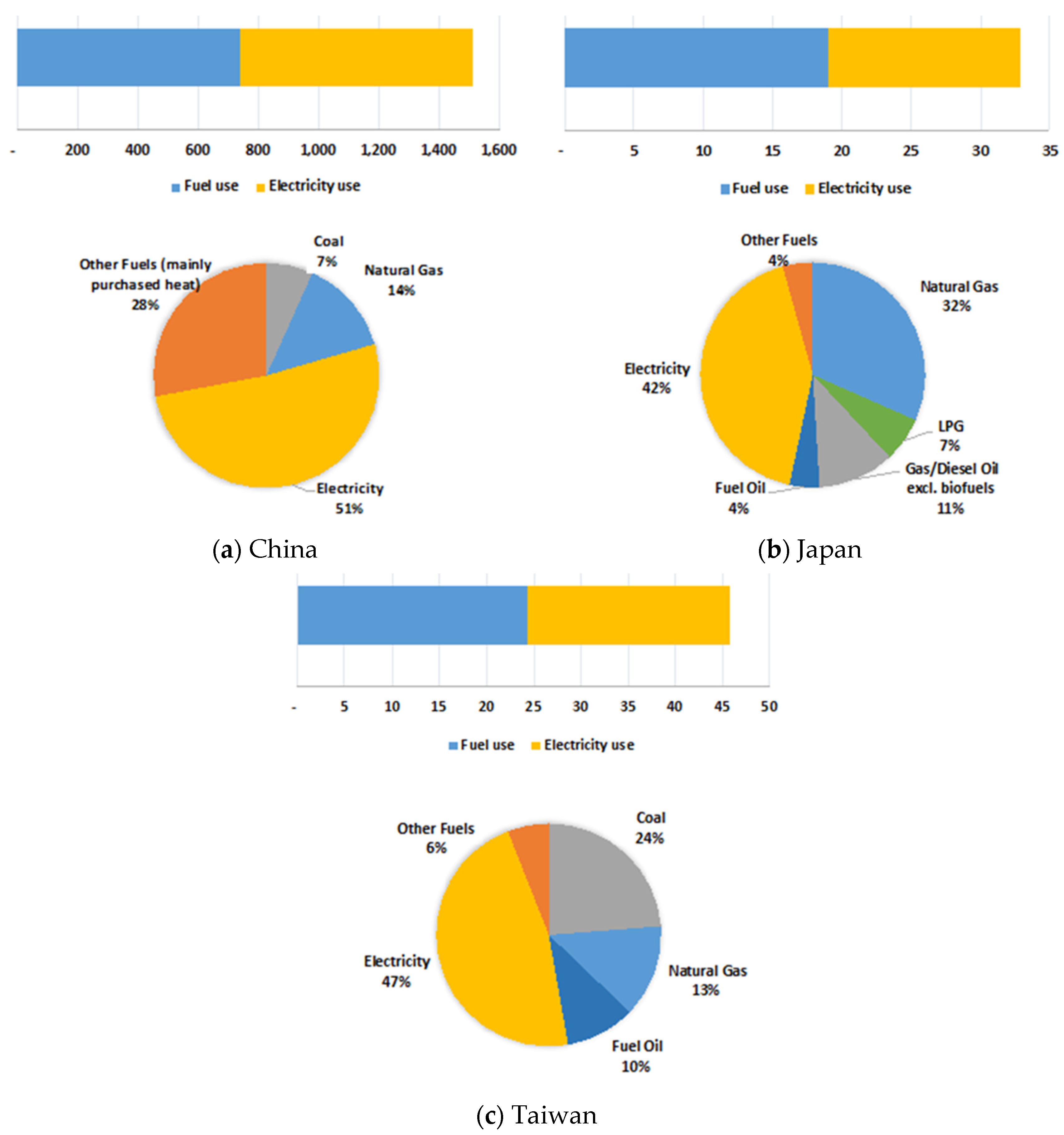

China is by far the world’s top textile exporter followed by the European Union (EU) and India, as shown in

Figure 1. Japan and Taiwan, which are the other two economies included in our study, are also among the top 10 textile exporters. The ranking of top exporters is slightly different when only considering clothing export. China is also the top exporter of clothing followed by the EU, Vietnam, Bangladesh, and Turkey [

3]. The textile industry has been growing rapidly in recent years, due to increasing demand from both developed and developing countries and world population growth. In particular, the rise of online or e-shopping has created a significant market for textile and apparel products [

4]. However, the textile industry faces several challenges. One key challenge is to reduce its environmental and climate impact [

5].

The textile industry accounts for around 2% of global anthropogenic greenhouse gas (GHG) emissions [

6]. As the effects of climate change become more apparent and as the world’s population continues to grow and consume more textile products, the textile and apparel industry must take serious actions to reduce its impact on the climate and environment [

5]. There are several ways to reduce the textile industry’s climate impact, from using more environmentally friendly materials to deploying more efficient- and low-carbon manufacturing processes. Thermal energy needs especially for heating processes are a significant challenge for climate change mitigation efforts in the textile industry [

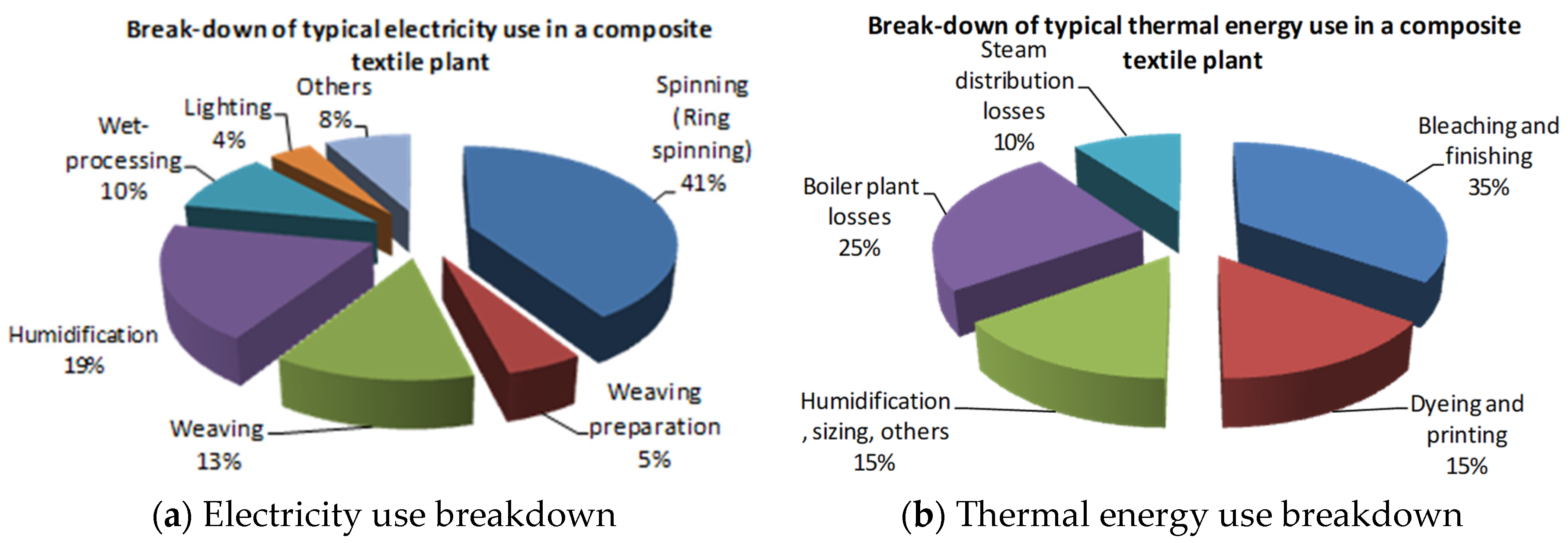

7]. Process heating often represents over half of the total final energy demand in the textile industry (see later for details). Almost all of this heat is currently provided by fossil fuels in most countries including China, Japan, and Taiwan, the three major economies we have focused on in this article.

There is a significant opportunity to decarbonize the textile sector by shifting heat production away from carbon-intensive fossil fuels to clean sources such as electrification where low- or zero-carbon electricity is used. Electrified heat supply through electric boilers has been widely studied in the literature. Besides, industrial electrification through high-temperature heat pumps is an emerging research topic and there is limited literature on it, especially for the textile industry. Electromagnetic technologies including induction, infrared, microwave, etc. for process heating have been scarcely explored in the literature at the level of industrial sectors and processes. The authors of this paper have prior experience working on these topics which are summarized below along with other relevant studies from the literature.

Hasanbeigi et al. [

8] studied a dedicated scenario for the electrification of combustion boilers. They concluded that electrification through electric boilers can initially increase the annual CO

2 emissions in the base year, however, they are projected to be much lower in 2050 as a result of electricity grid decarbonization. Zuberi et al. [

9] applied a bottom-up approach to investigate the techno-economic potentials of deploying electric boilers in different industrial sectors with a dedicated scenario for textiles. They also concluded that a higher grid emission factor than natural gas could initially lead to an increase in annual CO

2 emissions in the base year. Given these conclusions and the limited environmental impact, Zuberi et al. [

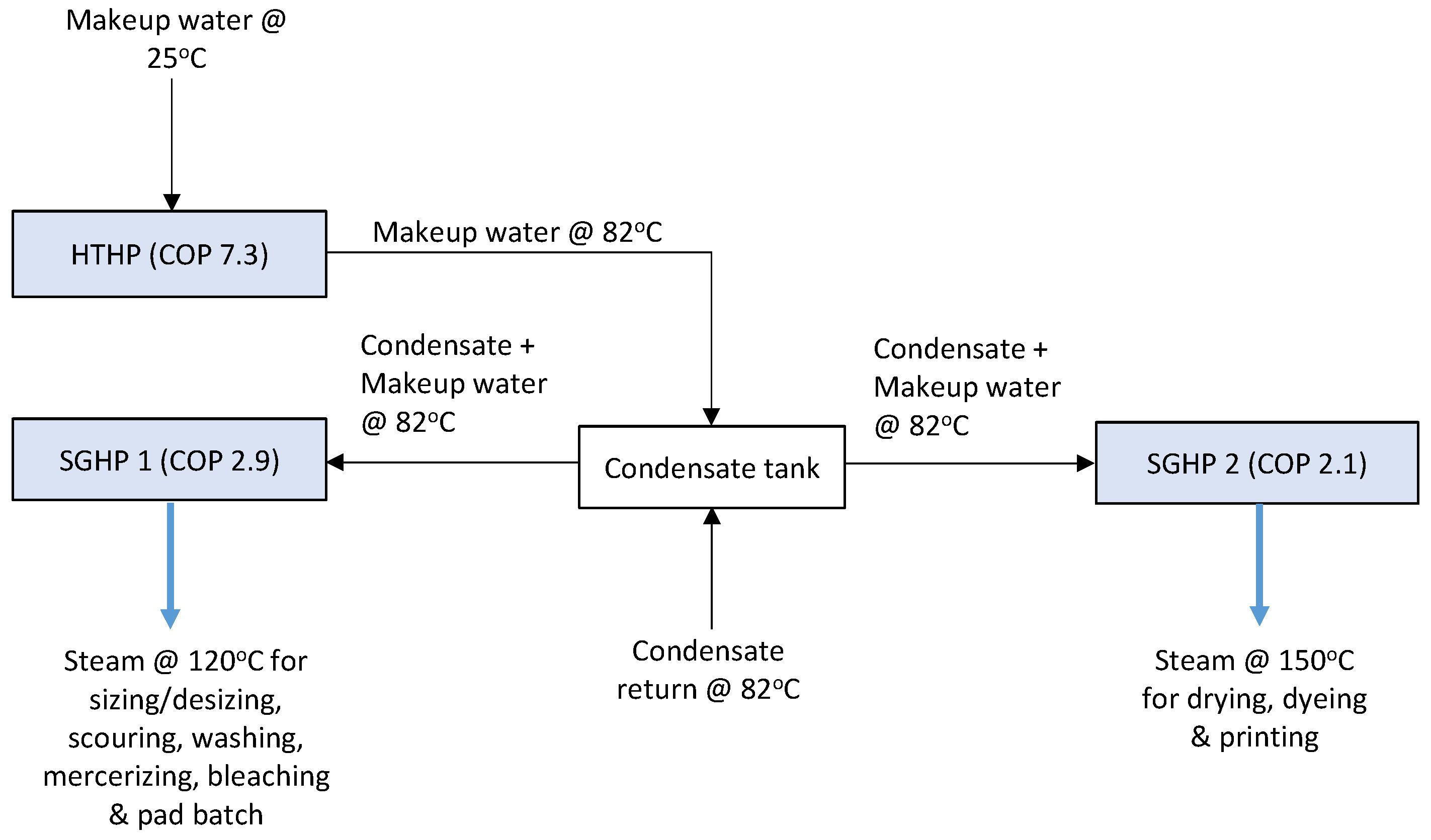

10] further investigated industrial heat pump (IHP) applications for electrified steam and hot water generation. They concluded that despite the current average electricity grid emission factor being higher than the emission factor of natural gas, electrified steam and hot water generation through IHP in the studied manufacturing processes can already decrease the annual CO

2 emissions in the base year 2021. This is mainly because the high efficiencies of IHPs as compared to combustion and electric boilers dominate all other limiting factors. Kosmadakis [

11] and Seck et al. [

12] have also demonstrated that IHP applications possess significant energy and emissions reduction potentials in industry. However, none of the aforementioned studies have analyzed IHP applications in the textile industry. The type of processes and unit operations in different manufacturing sectors are diverse and dedicated analyses must be performed to investigate specific industrial applications.

Besides, many researchers have also been interested in exploring novel technologies to achieve high-quality, time-efficient, low energy consumption, and eco-friendly textile processing [

13]. Electromagnetic heating is among the novel technologies that use wavelengths in the electromagnetic spectrum to process a wide range of products including textiles. As stated earlier, common examples are infrared, induction, microwaves, radio waves, and ultraviolet. Although different industries have used these techniques for specific applications for a long time now, their true potential has hardly been exploited especially for process heating [

14]. The major benefit of employing electromagnetic technologies is that they generate heat within a target material with high efficiency ultimately cutting energy use by up to half or more. Ratti and Mujumdar [

15] have demonstrated that infrared heating can be used in industry for surface drying or dehydration of thin sheets such as textiles. Elshemy and Haggag [

13] evaluated the current status of microwave technology including specific heating applications in textile manufacturing and concluded that the technology could significantly reduce cost, energy, and time, and enhance the properties of different fabrics for different end uses. Despite few electromagnetic heating technologies available in the market for textile wet-processing (see later in the results section), not many studies in the literature have analyzed these technologies for studying sector-level final energy savings and CO

2 emissions reduction potentials in the textile industry.

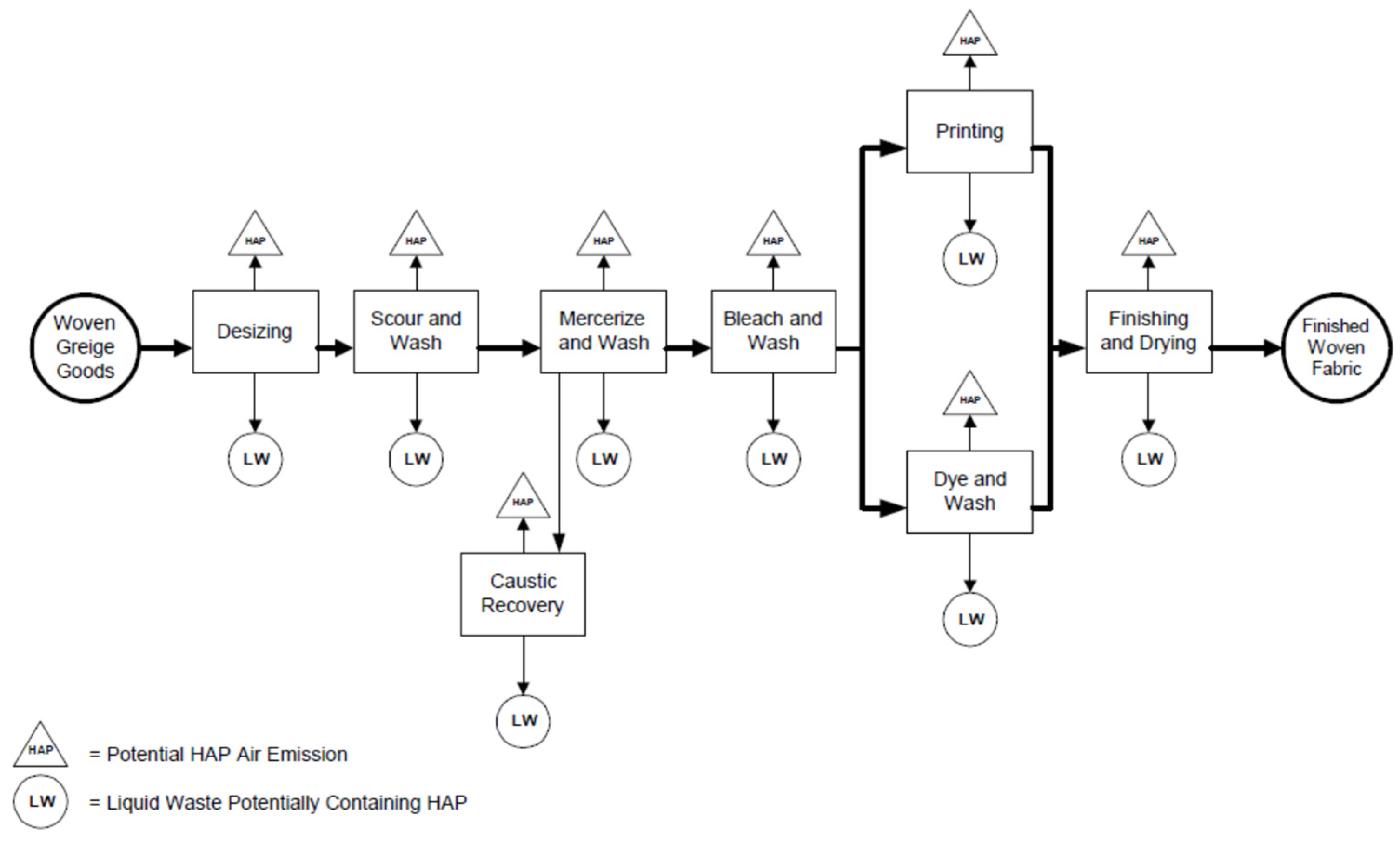

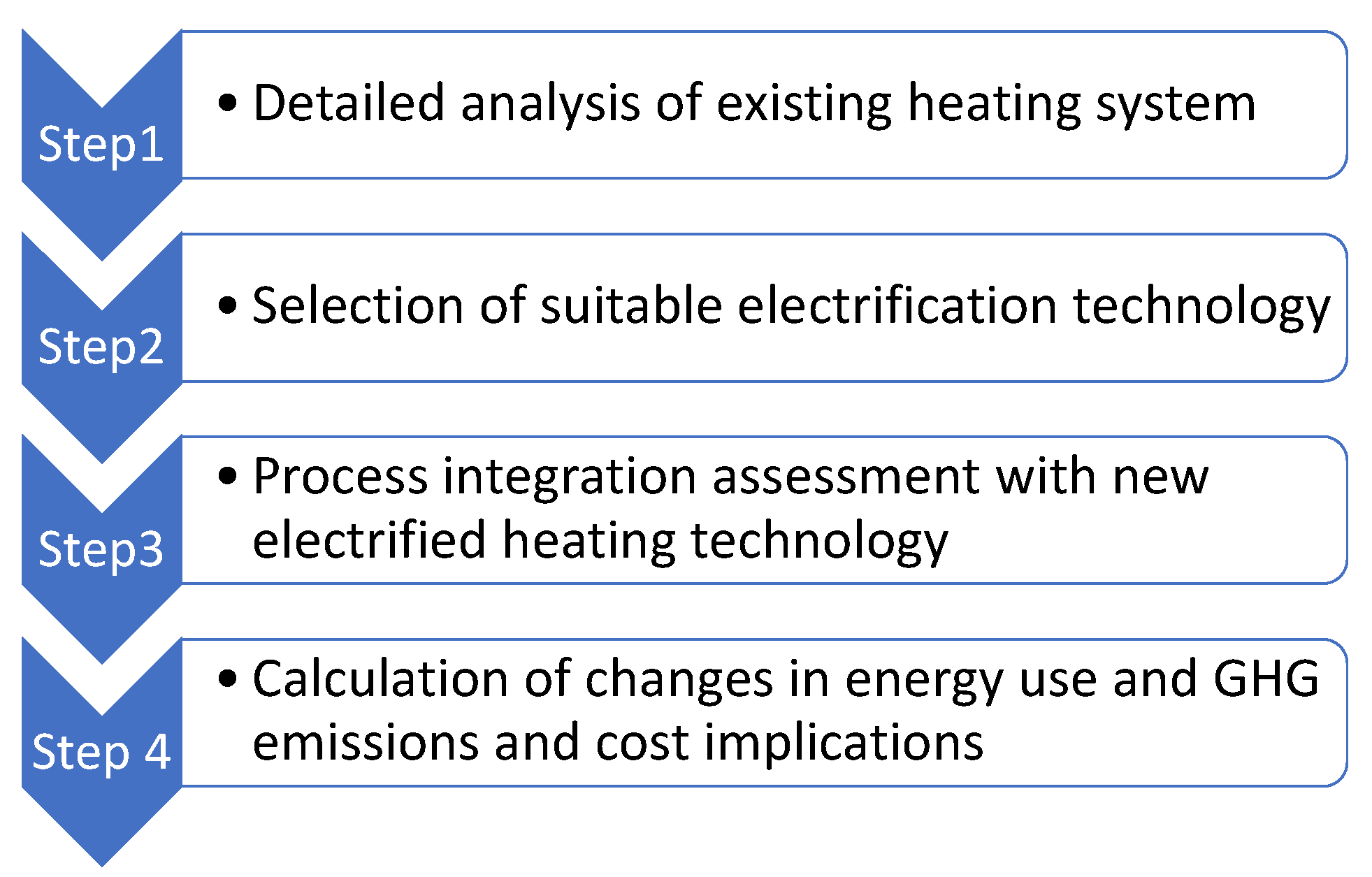

It is evident from the literature review that electrified process heating in the textile industry can be achieved through cross-cutting technologies like industrial heat pumps for steam and hot water generation without modifying the textile process equipment and/or through replacing the existing equipment with technologies that employ electromagnetic or resistance heating techniques for specific end-use applications such as infrared drying. This paper aims to fill the literature gaps by examining profiles of heat consumption in the textile wet-processing industry and the potential for electrification based on different heat demand profiles and electrification technologies available to meet those heating needs. More specifically, this paper is comprised of a bottom-up approach and technology-level techno-economic analysis for the electrification of the textile industry in China, Japan, and Taiwan. The technical assessment provides an analysis of the current state of energy use in the textile industry in these three economies, the technologies available, and the potential for electrification in this sector. Two technological pathways for the electrification of the textile wet-processing industry have been developed and analyzed. The pathways are (1) electrification through industrial heat pumps (cross-cutting technology pathway) and (2) electrification through textile end-use processes (process-specific technology pathway; only for seven major textile wet processes; see later for details). The energy costs per unit of production for each of the studied technologies have also been estimated. Finally, the impact of electrification of the textile industry on the electricity grid has been discussed.

4. Discussion and Policy Recommendations

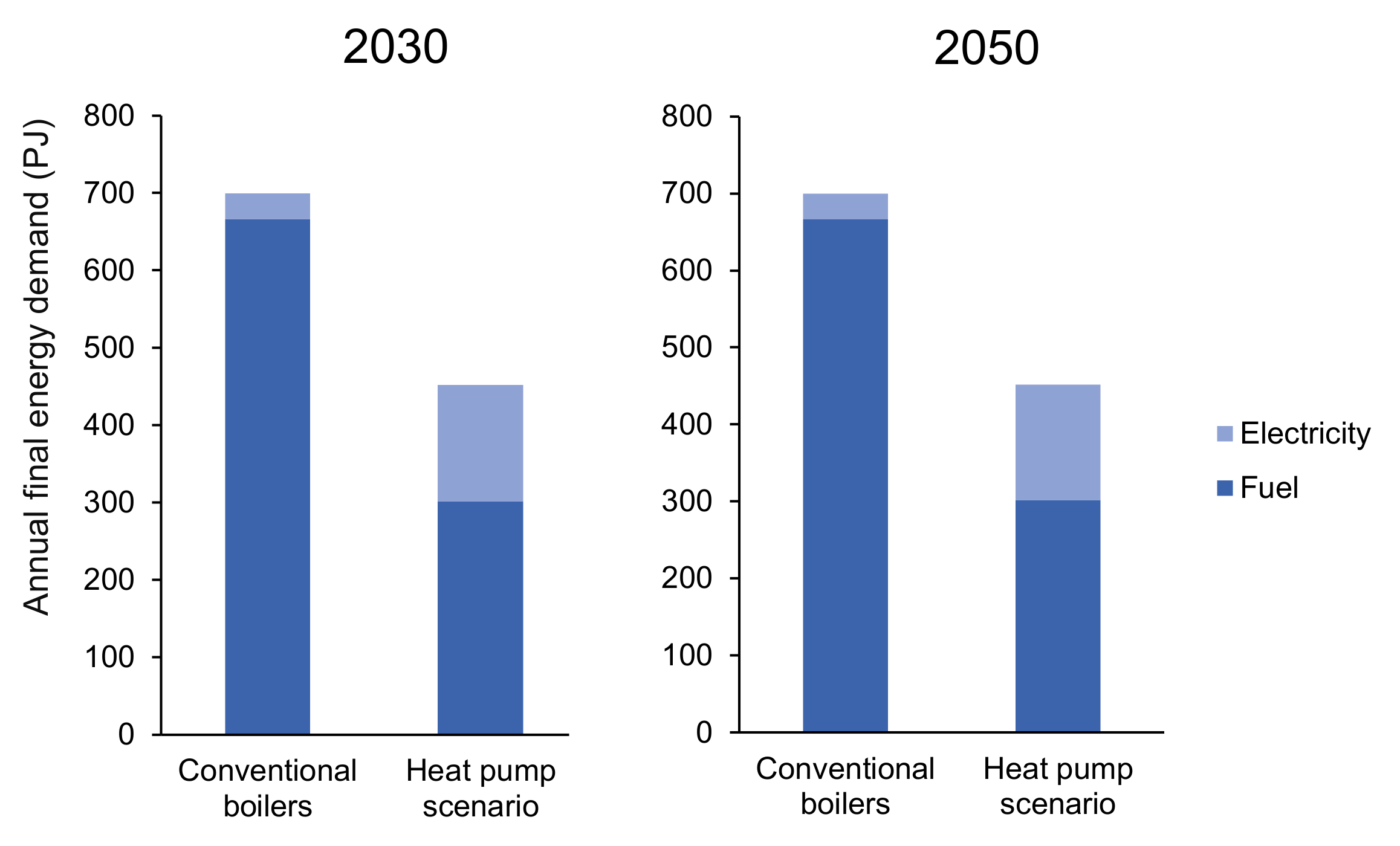

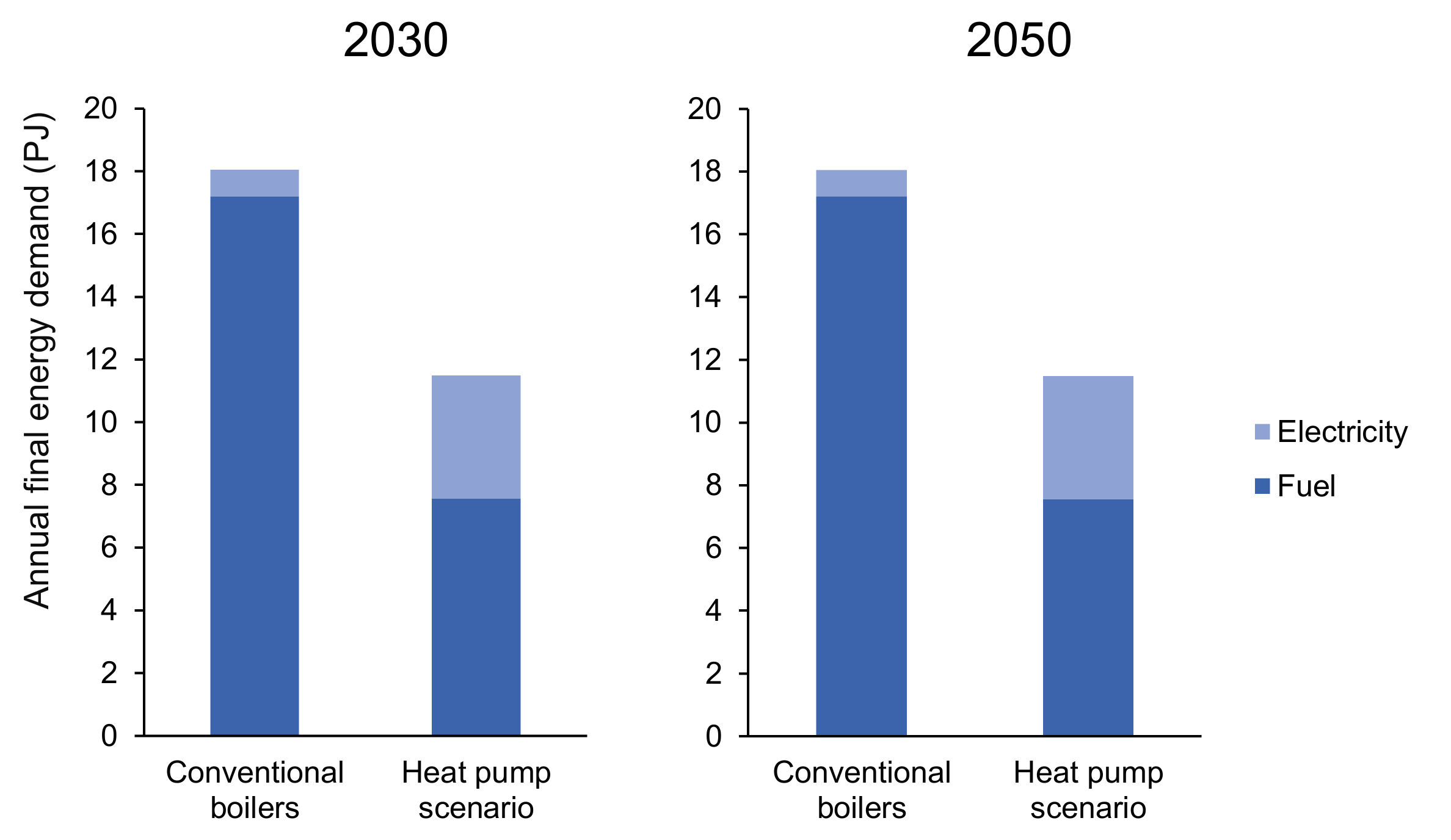

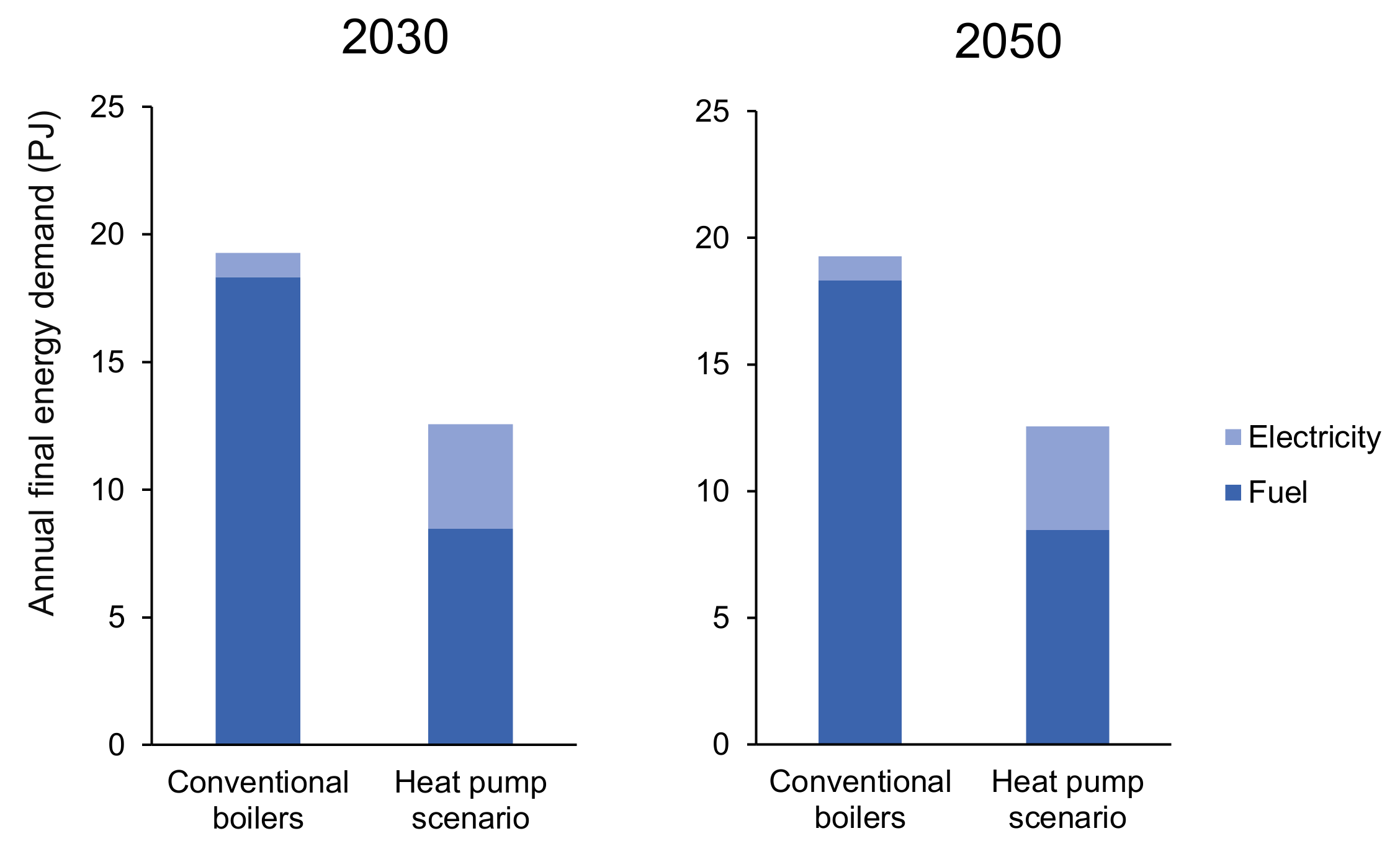

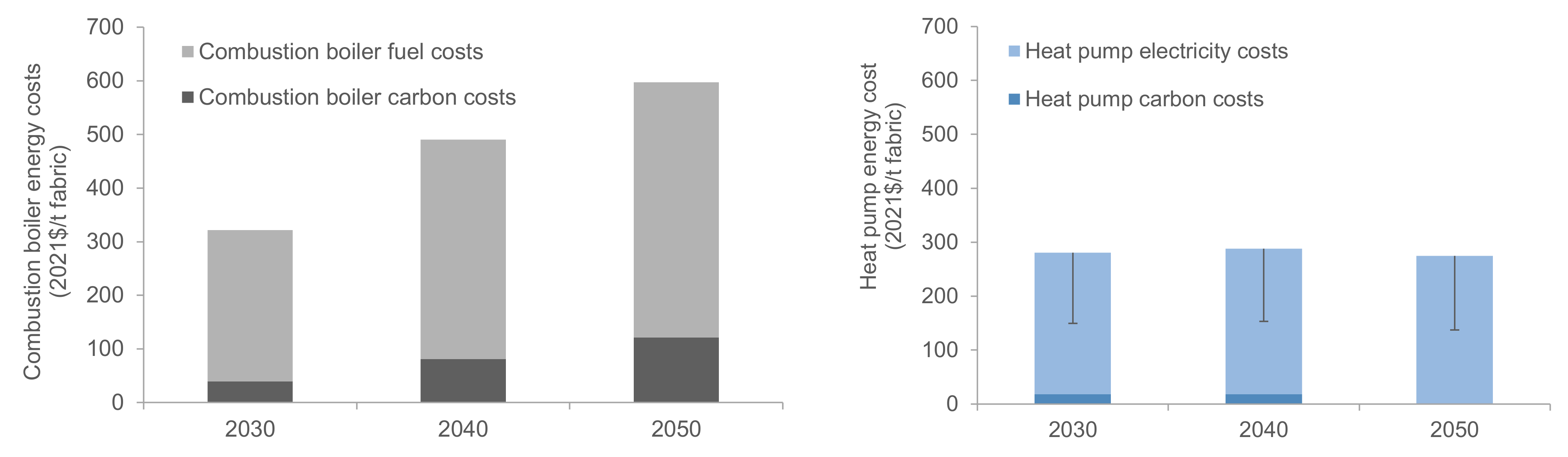

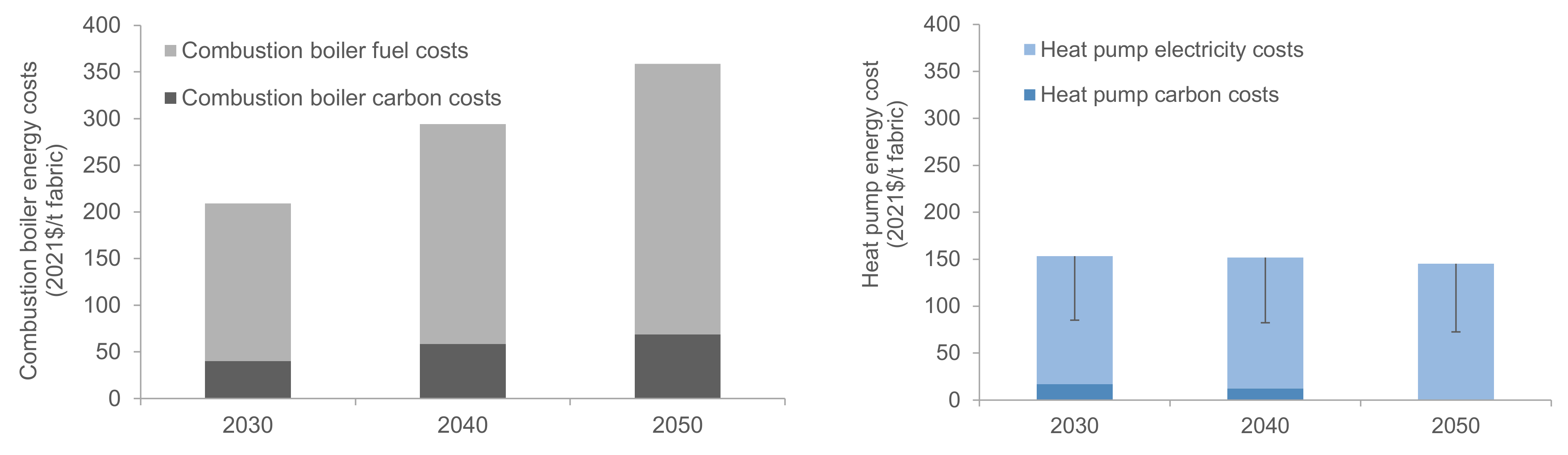

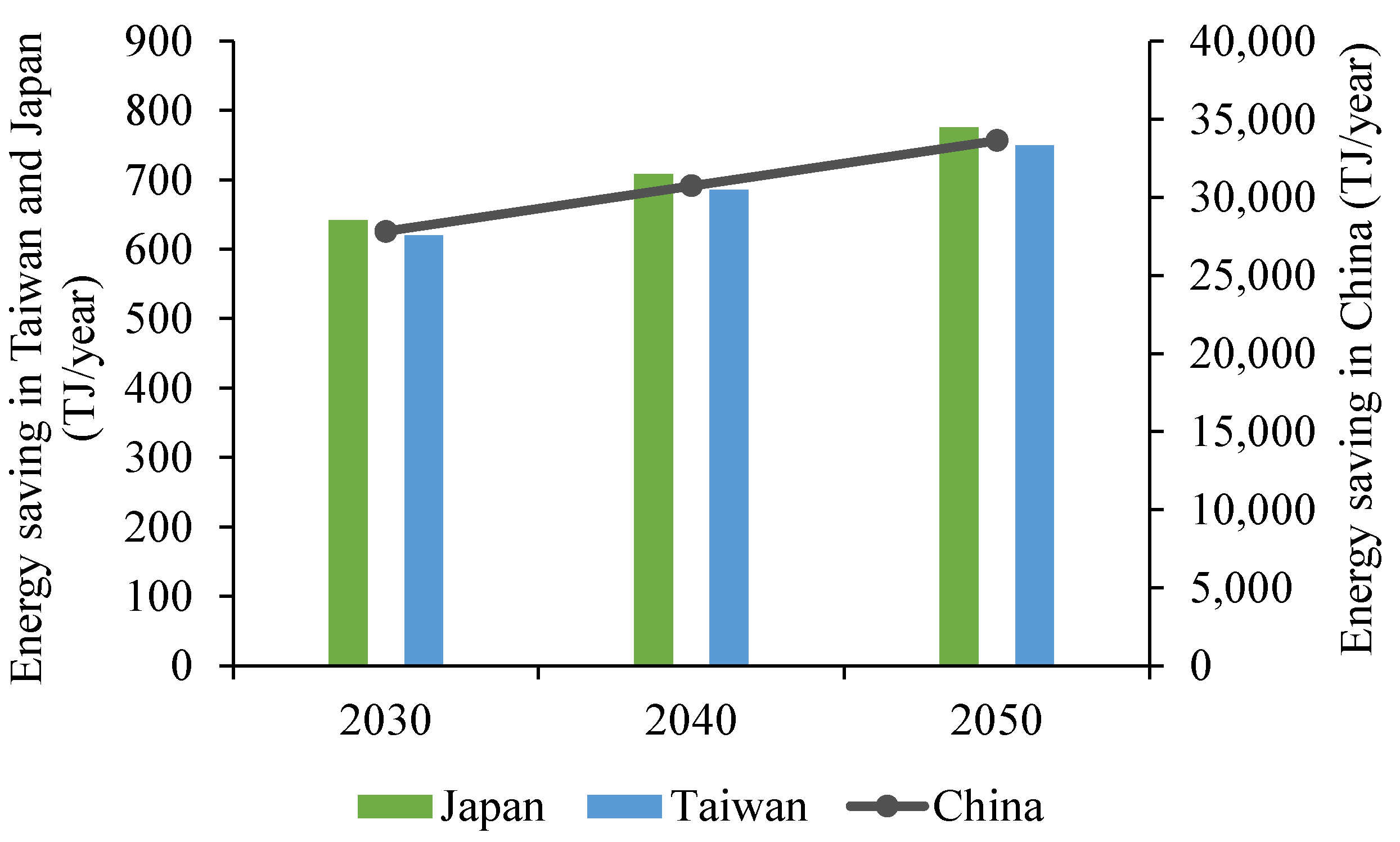

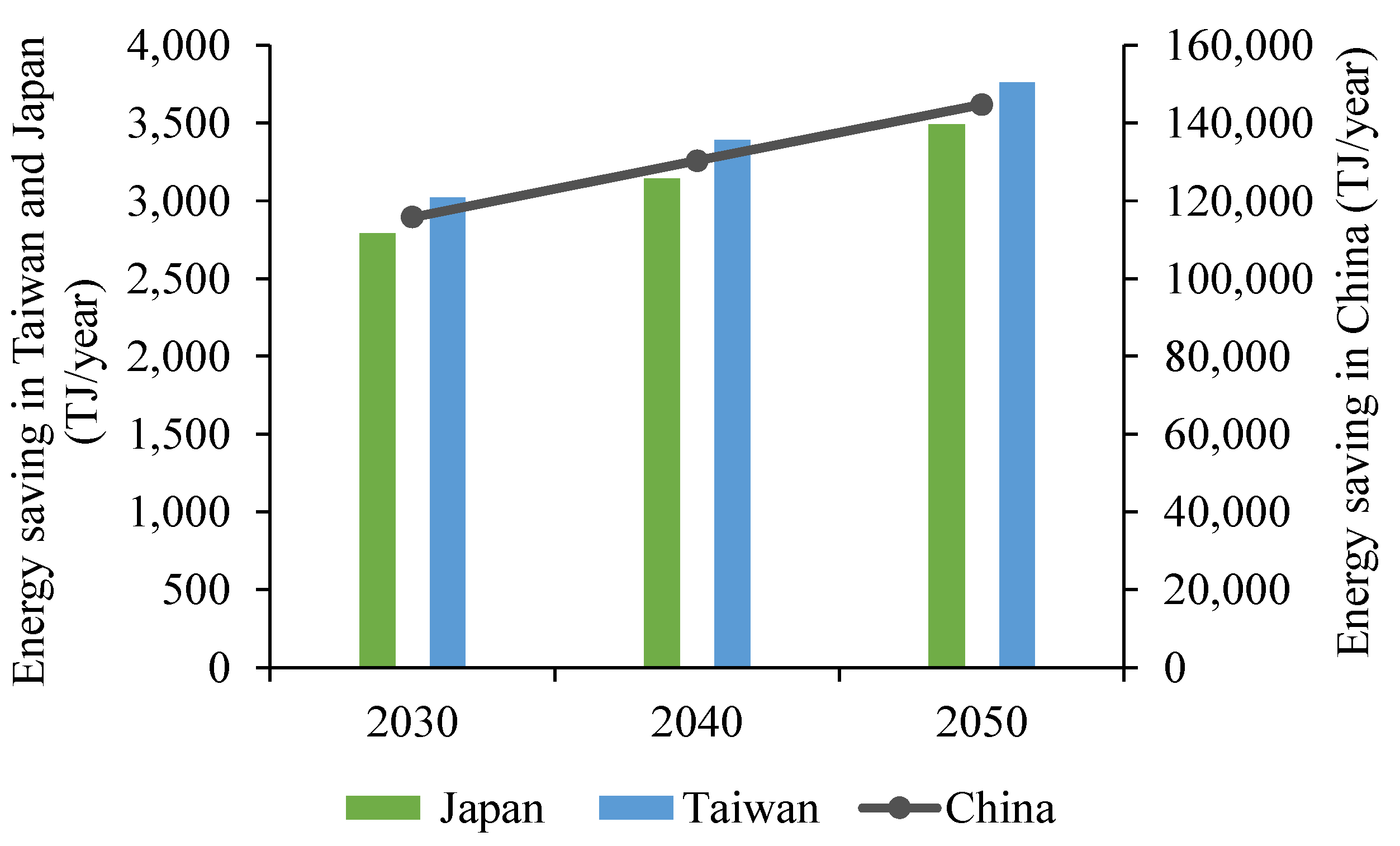

The total potential final energy savings due to industrial heat pump applications are estimated to be around 248, 6.6, and 6.5 PJ per year in China, Japan, and Taiwan, respectively in 2050. On the other hand, electrification through end-use processes could lead to potential final energy savings of about 145, 3.5, and 3.8 PJ per year in China, Japan, and Taiwan, respectively in 2050. It must be noted that the results of the two pathways are not directly comparable because only seven end-use wet processes have been studied in the second pathway analysis mainly due to a lack of technical data for the remaining processes. Furthermore, the substantial reduction in annual final energy demand in both scenarios is due to the increase in the efficiency and lower energy intensity of the electrified heating systems.

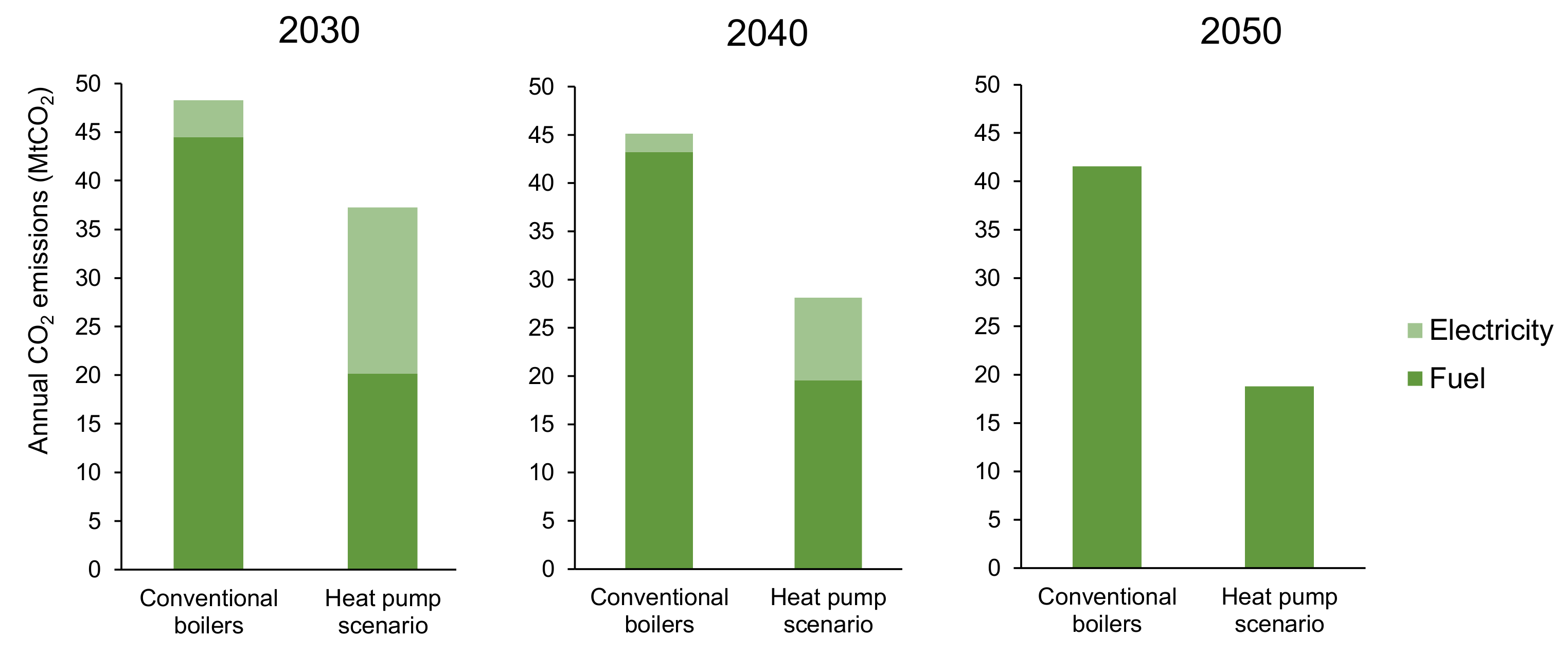

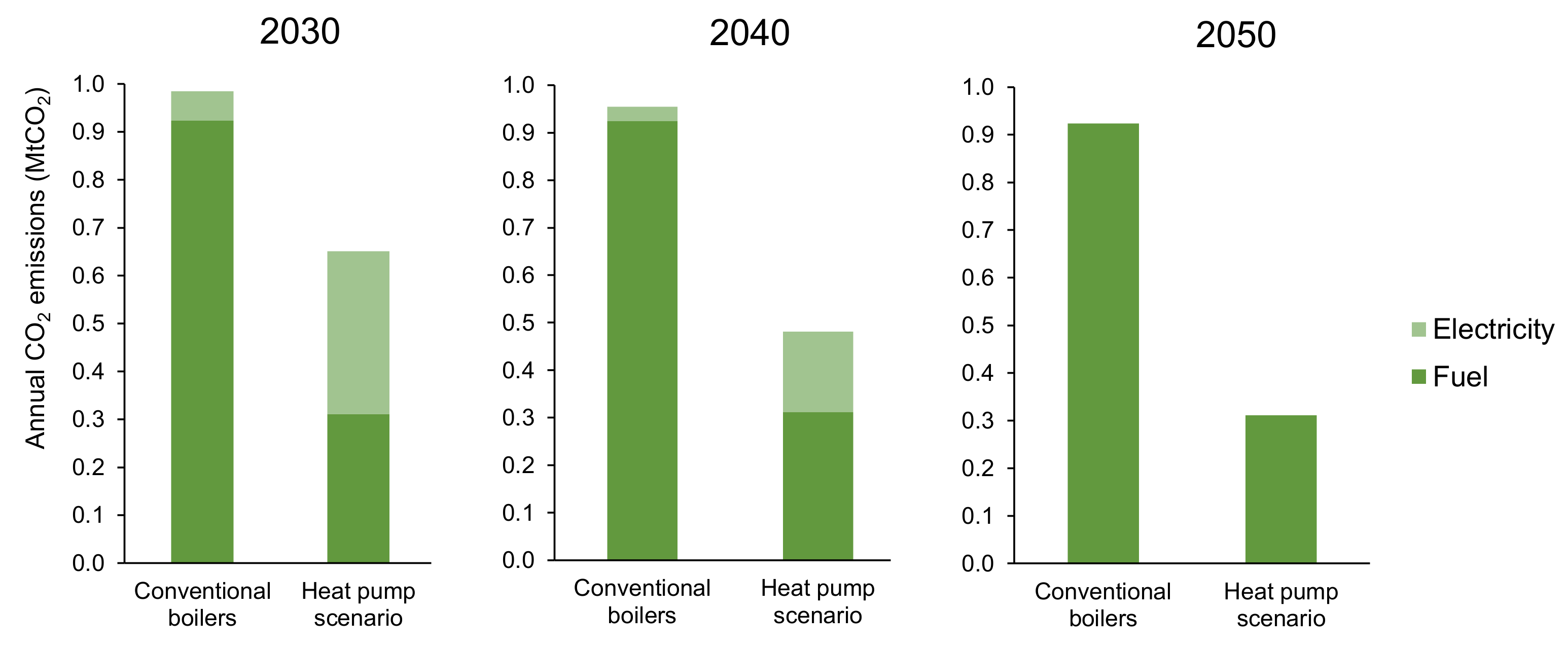

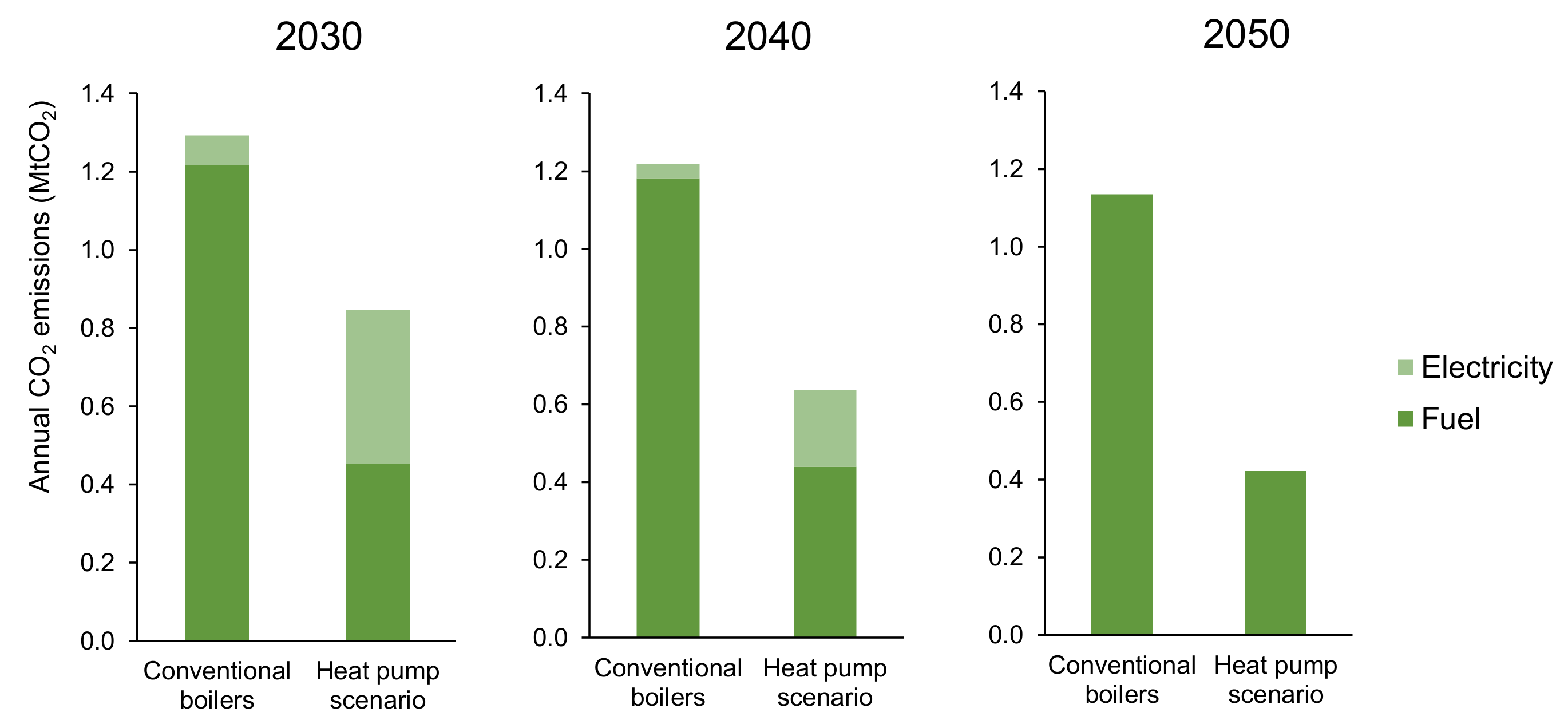

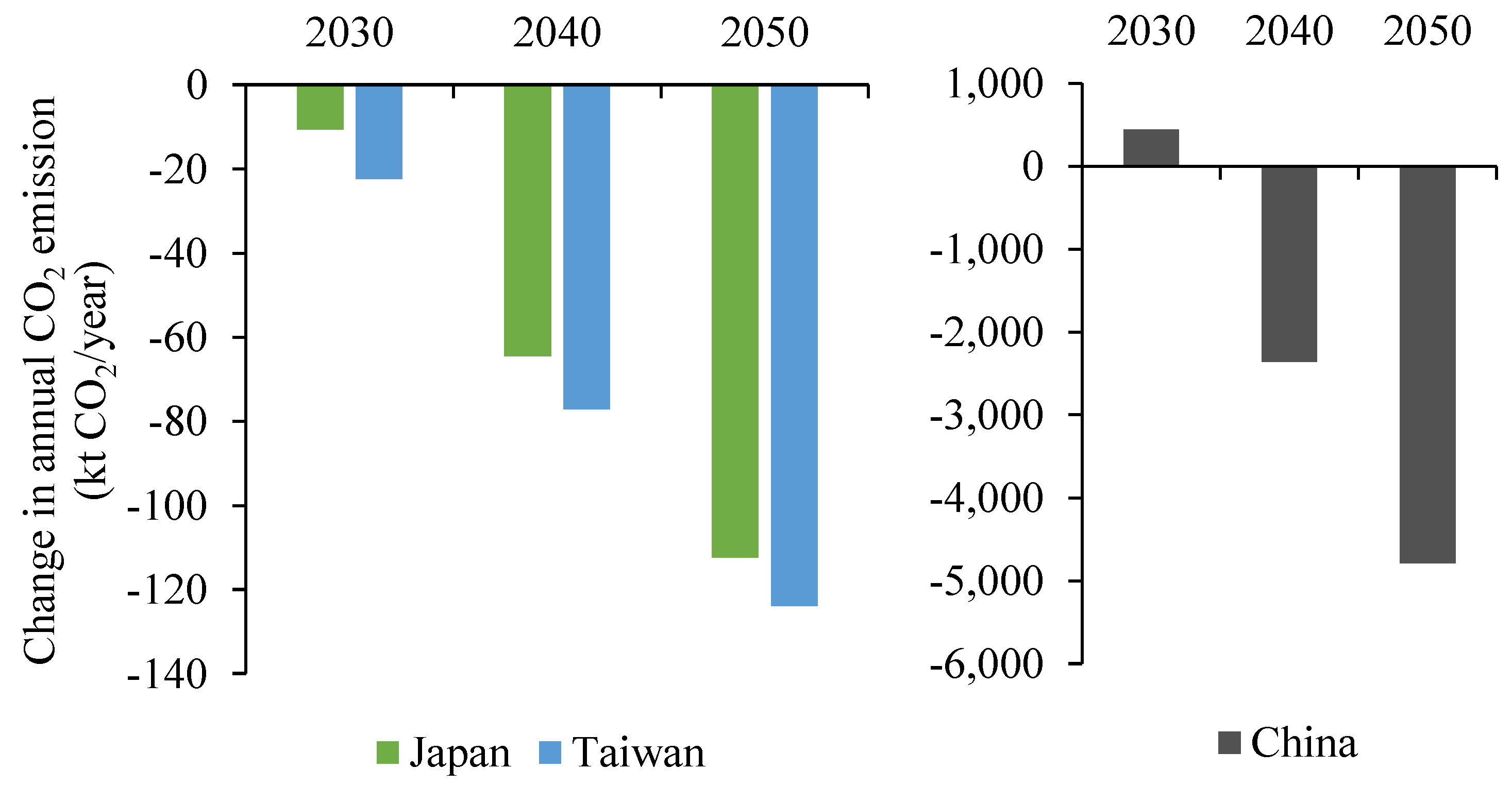

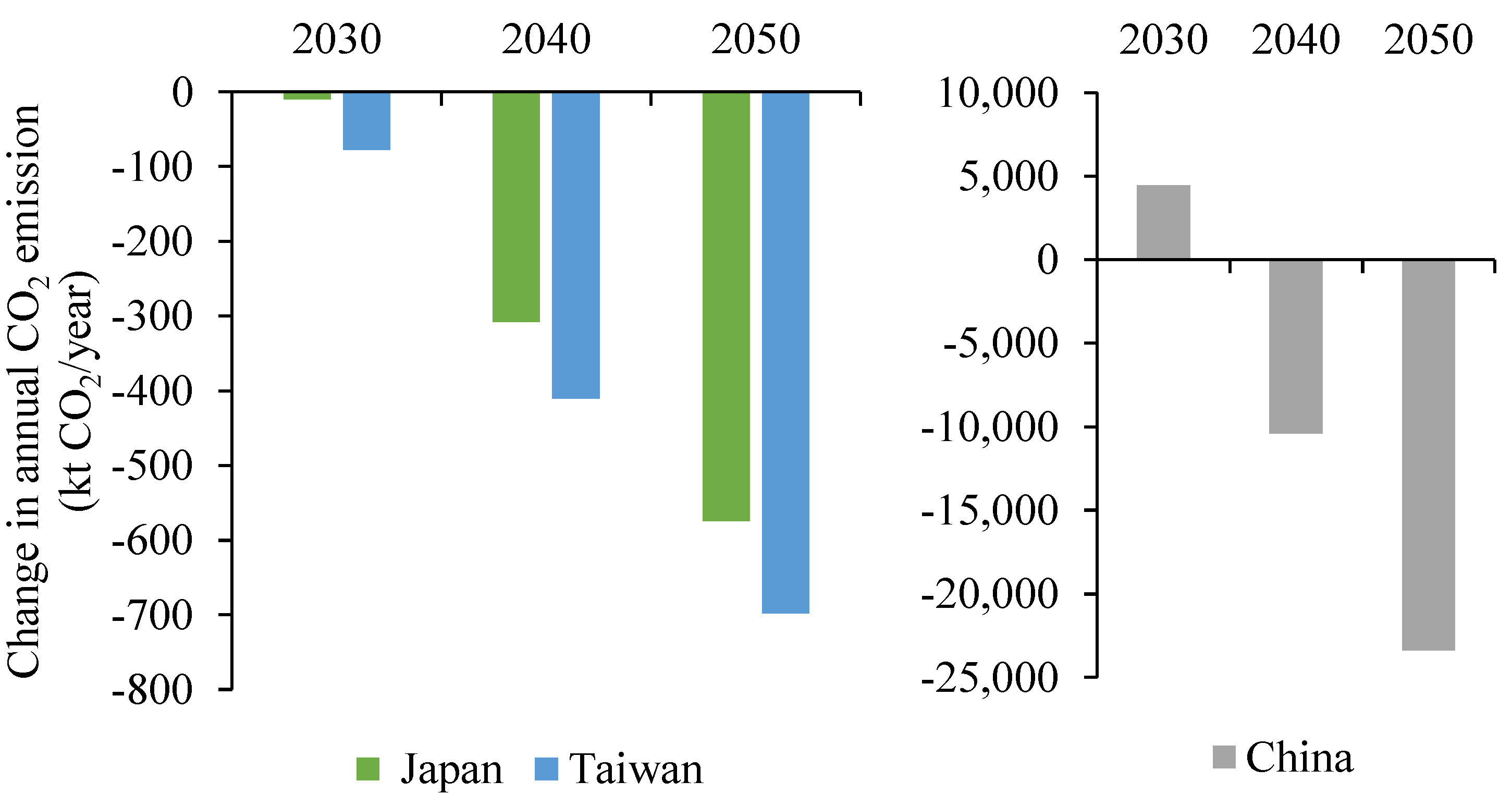

If the average national grid electricity is used, only electrification of the textile industry through industrial heat pumps can result in CO2 emissions reduction in 2030 in all three economies. Electrification of the seven wet processes can result in CO2 emissions reduction in 2030 in Japan and Taiwan, but not in China. This is because the average electricity grid emission intensity for China is high and the grid is not decarbonized enough to result in CO2 emissions reduction from the electrification of end-use processes despite the reduction in final energy use. However, electrification is projected to result in a substantial reduction in annual CO2 emissions in 2040 and 2050 under both electrification technology pathway scenarios. This is because of efficiency improvement and the assumed carbon neutrality in 2050 in China, Japan, and Taiwan. It is evident that electrification of industrial process heat has the potential to reduce CO2 emissions from the textile industry when the electricity grid is decarbonized enough, but the infrastructure and competing demands for renewable electricity resources pose challenges to realizing these reductions in China, Japan, and Taiwan.

In practice, electrification projects will be implemented at the plant level. If a given textile plant in any region electrifies its process heating demand today and purchases renewable electricity through a power purchase agreement, then the CO2 emissions reductions from electrification can be achieved immediately. Therefore, our country/region-level results should not be interpreted in a way that electrification cannot be beneficial now and we should wait until the electricity grid is decarbonized. However, in general, investing in the electricity grid and increasing the share of renewable energy in the power sector energy mix will help to accelerate industrial electrification and contribute to large quantities of CO2 emissions reduction.

The electricity grid is a complex, interconnected system linking generation resources to customers with varying and variable electricity needs. Electricity generation from renewable resources has increased over time in these three economies, but the electricity grid still has a very high carbon intensity in these countries. Managing the grid’s resources, infrastructure, and energy flows is a considerable undertaking that will continue to be complicated by trends toward more distributed generation resources, renewable resources, and electrification. Additional pressure will be placed on an already strained grid system as multiple sectors, including transportation and buildings in addition to industry, move to electrify to access renewable resources and reduce their emissions. To deliver electrification at scale, investments will be needed to build or upgrade key infrastructure, including renewable electricity production, energy transmission, and distribution networks, and end-user infrastructure [

47].

Developing a coherent power sector strategy is essential to accelerate the pace of power sector decarbonization which is a prerequisite to beneficial electrification of industry. Utilities, policymakers, industry, and other stakeholders should pay attention to this potential increase in demand for renewable electricity, and the associated need for more renewable electricity generation, additional energy storage, demand response programs, transmission and distribution system expansion, and grid modernization. Ensuring that sufficient renewable resources are brought online and connected to demand centers will be critical to a smooth energy transition and rapid multisector electrification [

47].

Furthermore, while there are numerous benefits to electrifying industrial processes, including reduced energy demand and emissions, barriers such as high electricity prices, lack of capital, inadequate energy supply infrastructure, etc., still inhibit the development and deployment of electrified technologies [

8]. Hence, different stakeholders are required to work together to solve significant challenges in renewable electricity generation and transmission, technology development and deployment, and workforce development.

It is hence recommended that the textile industry initiates partnerships with academia, think tanks, and other stakeholders to develop or scale electrification technologies. Government should provide incentives for electrification technology development and demonstration. Government and utilities should provide financial incentives in the form of tax credits or grants for pilot projects and demonstration of emerging electrification technologies in the textile industry. The government in partnership with the industry should create or support an industrial electrification information dissemination platform. This should include the development and dissemination of case studies. Utilities should provide information about their electric rates, market structures, and grid upgrade implications of industrial electrification. The textile industry should provide training for employees and contractors about electrified technologies. Government and utilities should support such training programs. Government and utilities should work together to increase renewable electricity generation capacity and enhance the grid’s transmission and distribution capabilities in these three economies.

5. Conclusions

This paper aims to investigate the potential for electrification of process heating in the textile industry in China, Japan, and Taiwan. The two electrification technology pathways analyzed are (1) electrification through industrial heat pumps and (2) electrification through textile end-use processes. The potential energy savings, CO2 abatement, and costs for the two pathways have been quantified. The results show that the total potential final energy savings due to electrification in both the technology pathway scenarios could be substantially large. However, the results of the two pathways are not directly comparable because only seven end-use wet processes have been studied in the second pathway analysis. In addition, given the assumptions and limitations regarding energy intensities of the end-use electrified technologies in the second technology pathway analysis, the estimated annual potential energy savings can be considered rather conservative.

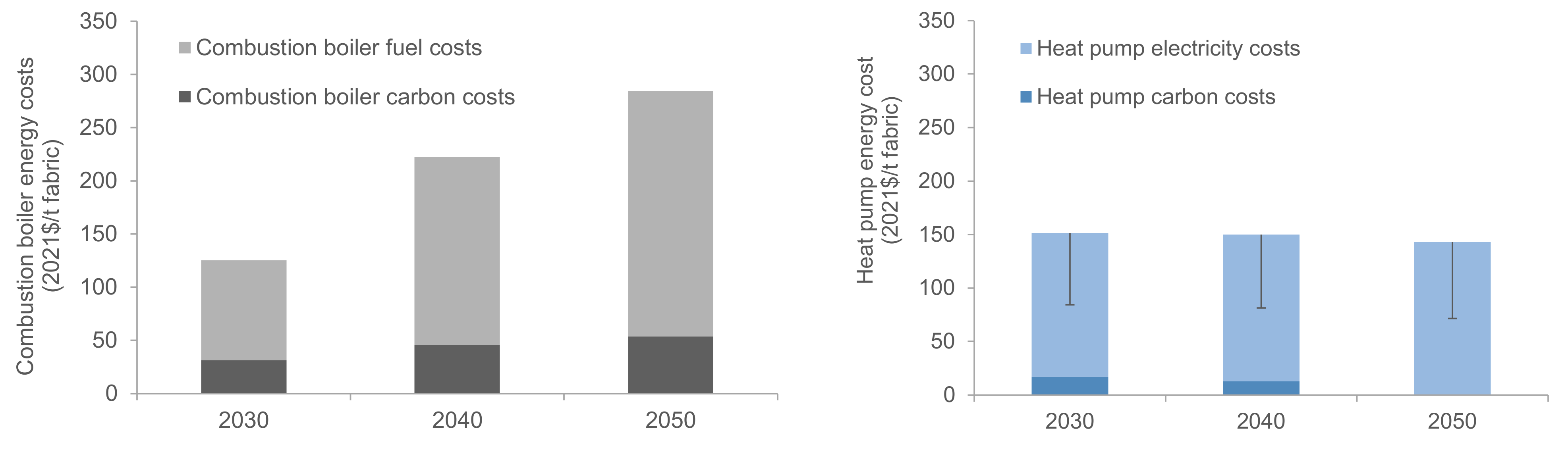

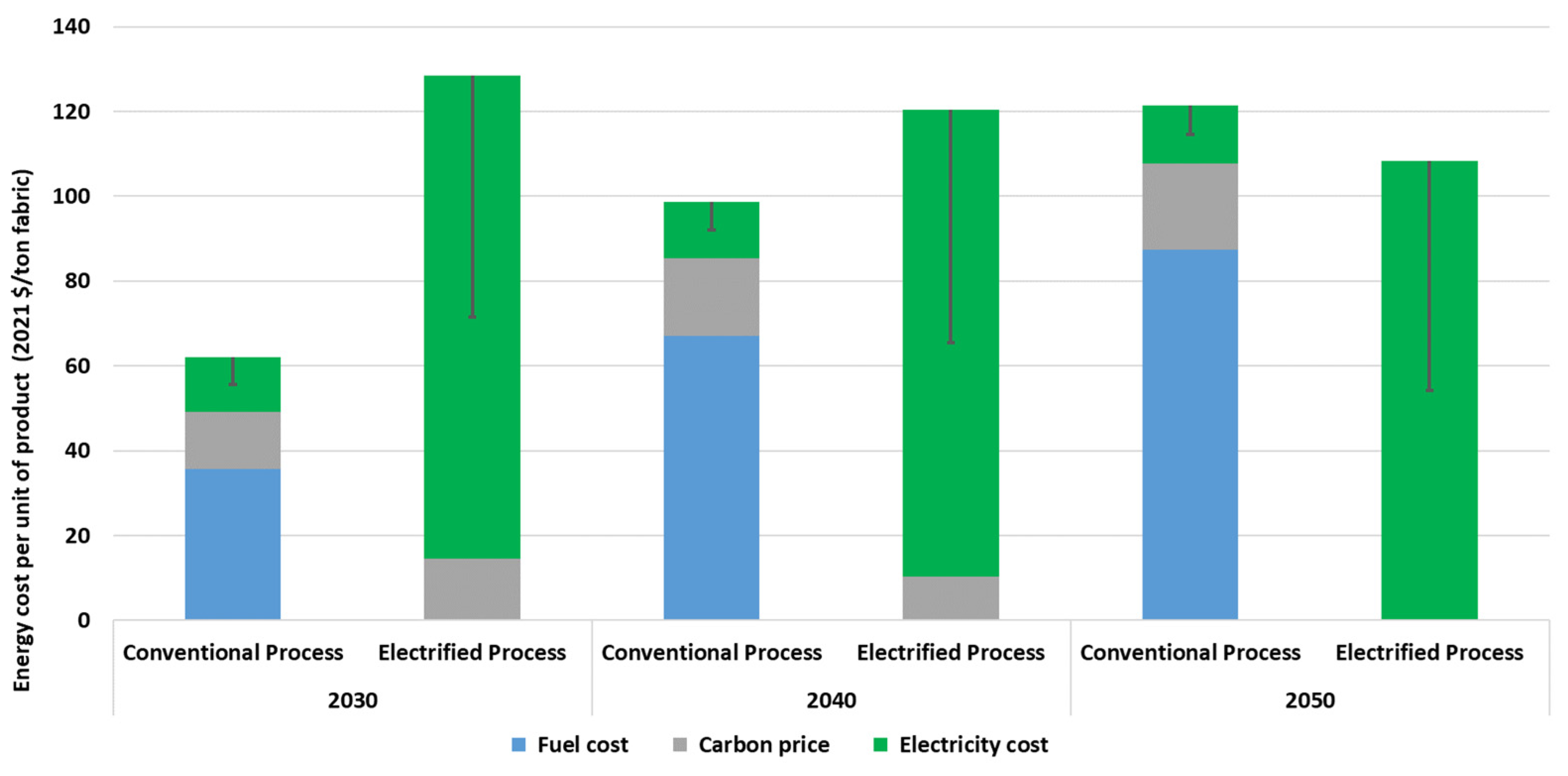

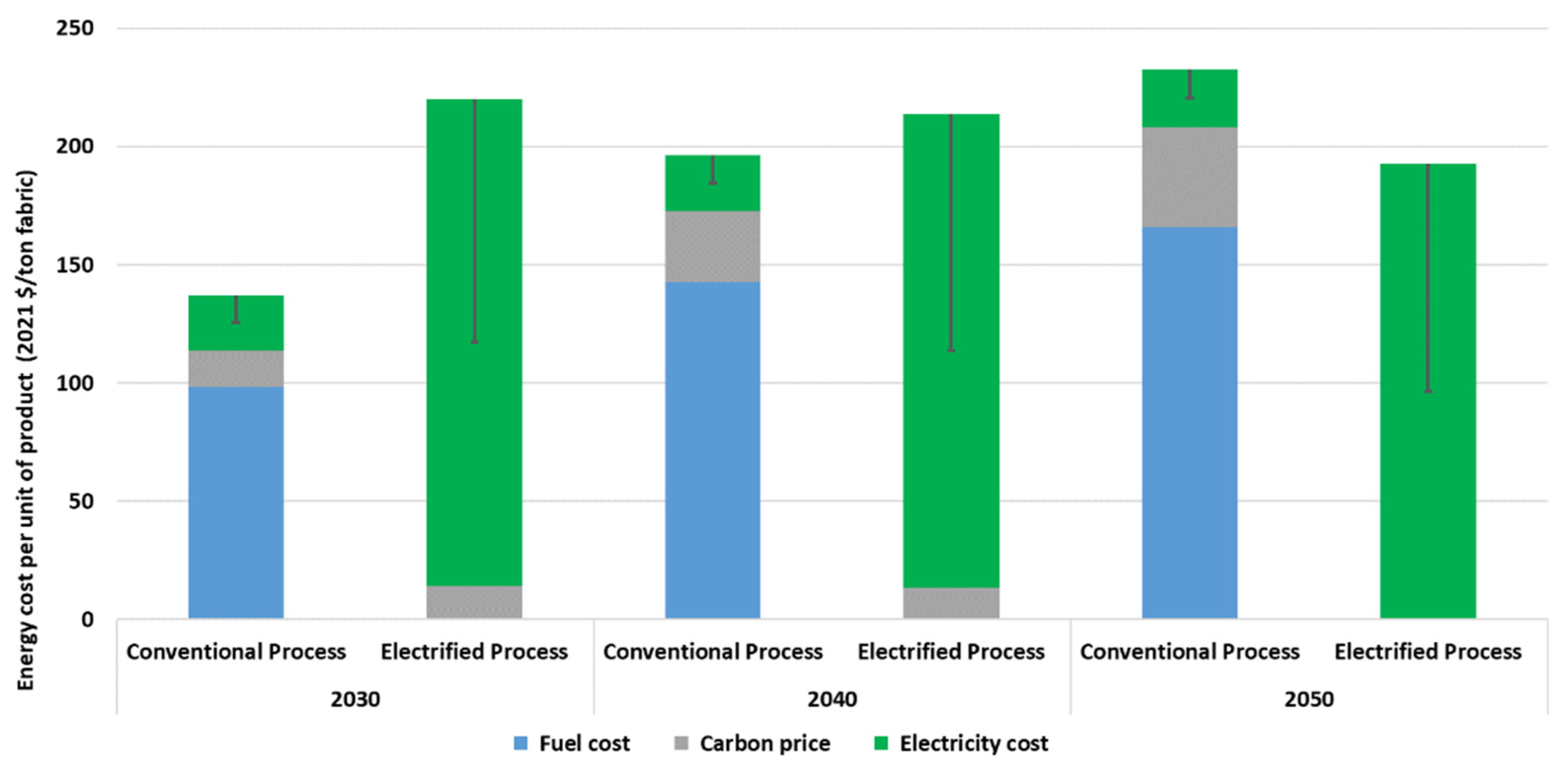

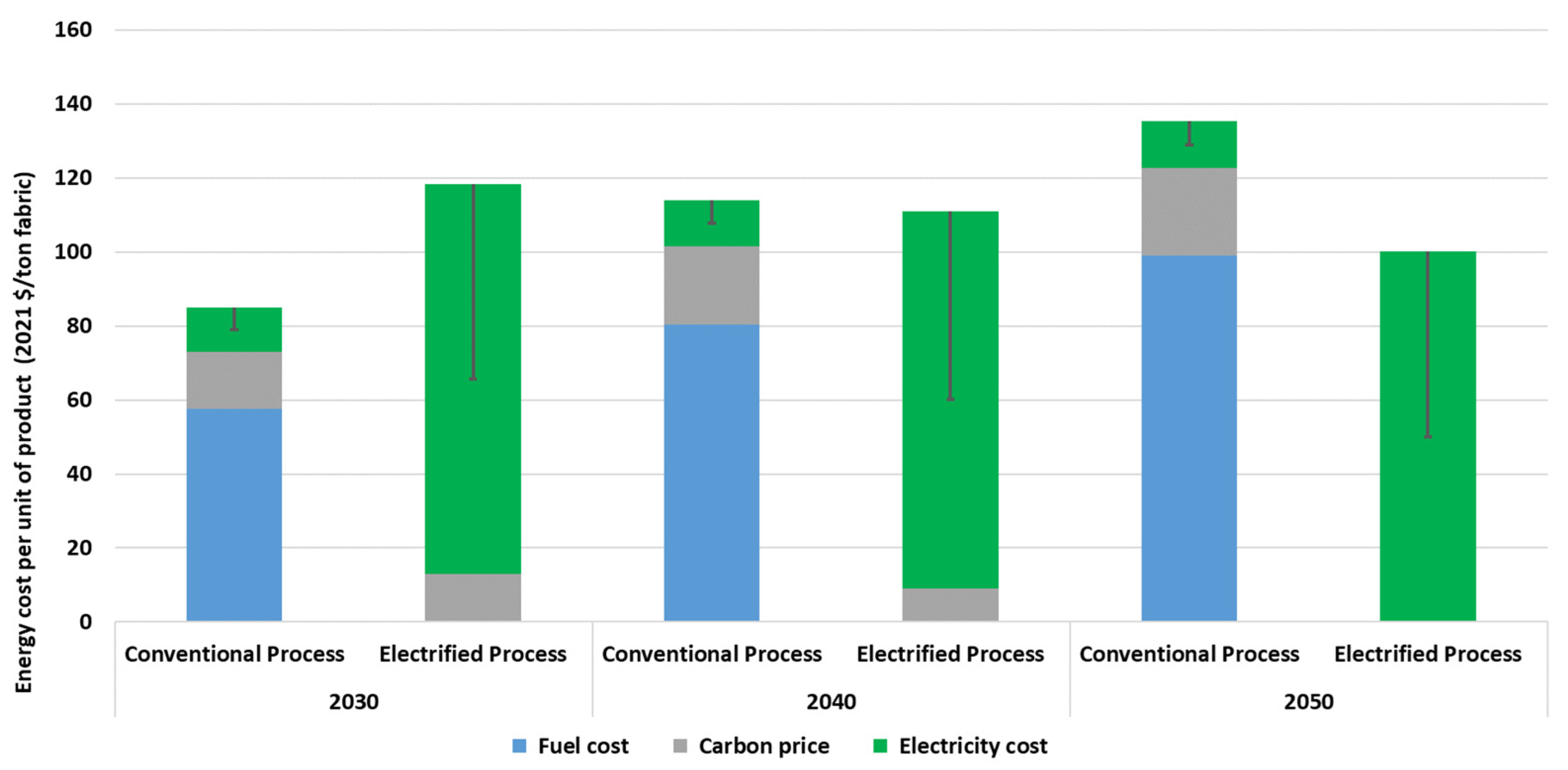

It is also concluded that the impact of the CO2 emissions resulting from the electrification is highly dependent on the carbon intensity of the electricity used with the electrified process. Furthermore, only in the case of industrial heat pumps, the costs per unit of production are found to be lower than the conventional systems. This is because heat pumps have high efficiency and will result in substantial overall final energy savings compared to existing technologies. For the second technology pathway, the electrified processes have higher energy costs per unit of production compared to the conventional process in the near term. However, under both pathways, the electrified processes have a lower energy cost in 2050 compared to conventional systems.

Despite the numerous benefits of electrifying thermal processes in the textile wet-processing industry, including reduced energy demand and emissions, barriers still inhibit the development and deployment of electrified technologies. To overcome the barriers, this paper provides recommendations that will require all stakeholders to work together to solve significant challenges including renewable electricity generation and distribution, technology improvements and deployment, workforce development, economic feasibility, etc. It is further concluded that wide-scale electrification of process heating in the textile wet- processing industry will require major changes to the electricity system and individual sites in China, Japan, and Taiwan, and the coordination efforts among different stakeholders to plan these changes must be intensified as early as possible.