Influence of Different Heat Loads and Durations on the Field Thermal Response Test

Abstract

1. Introduction

2. Materials and Methods

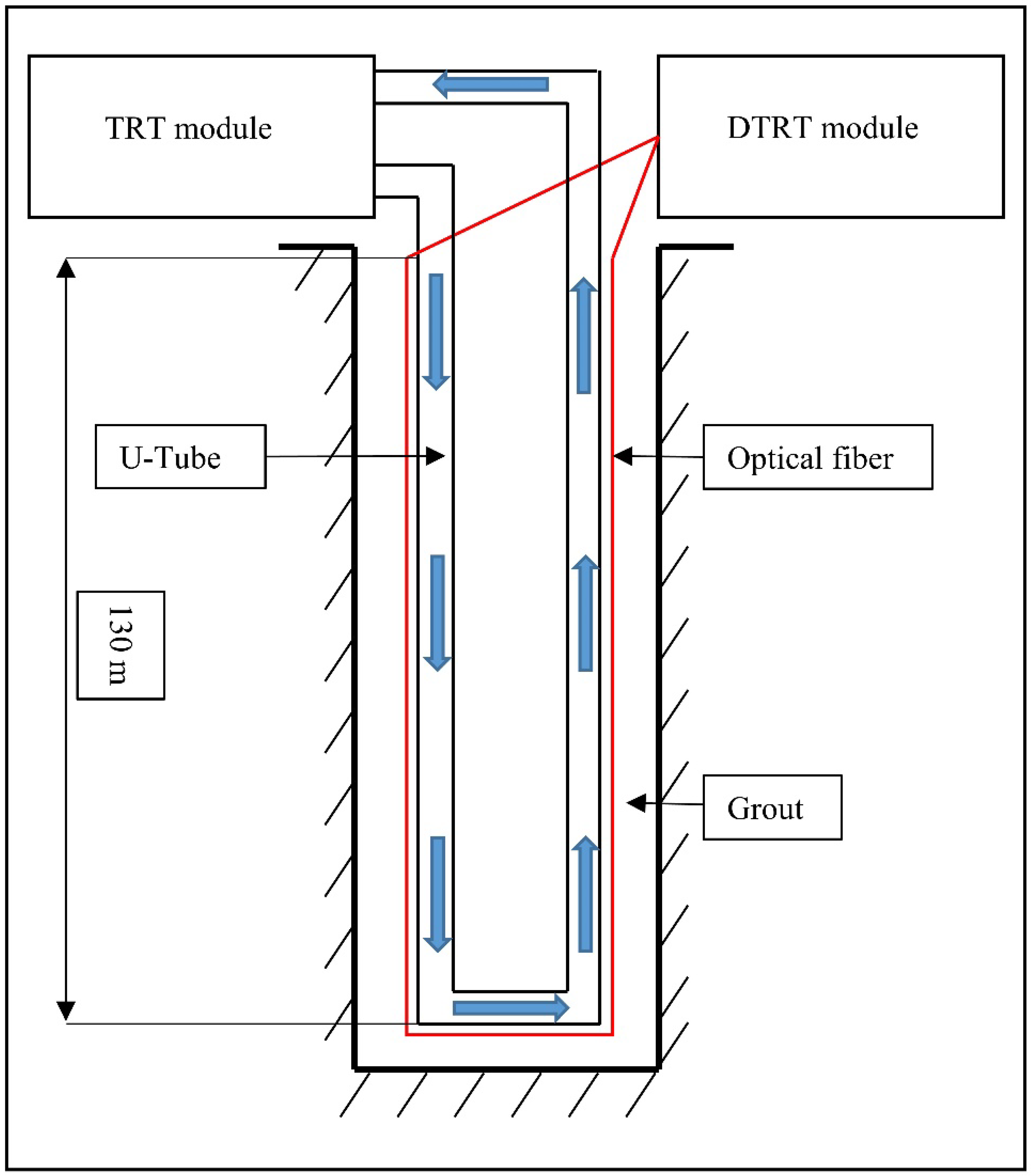

2.1. In-situ Test Principle

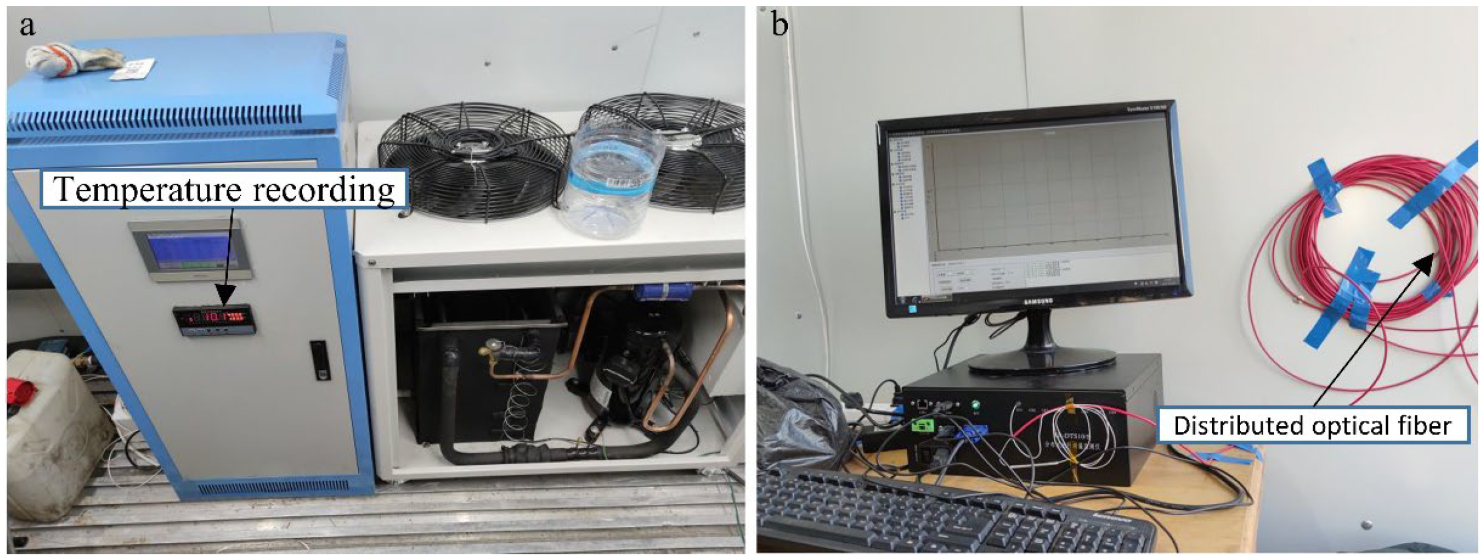

2.2. Field Test Procedure

2.3. Materials of the BHE

2.4. Field Test Procedure

2.5. Uncertainty Analysis

3. Results and Discussion

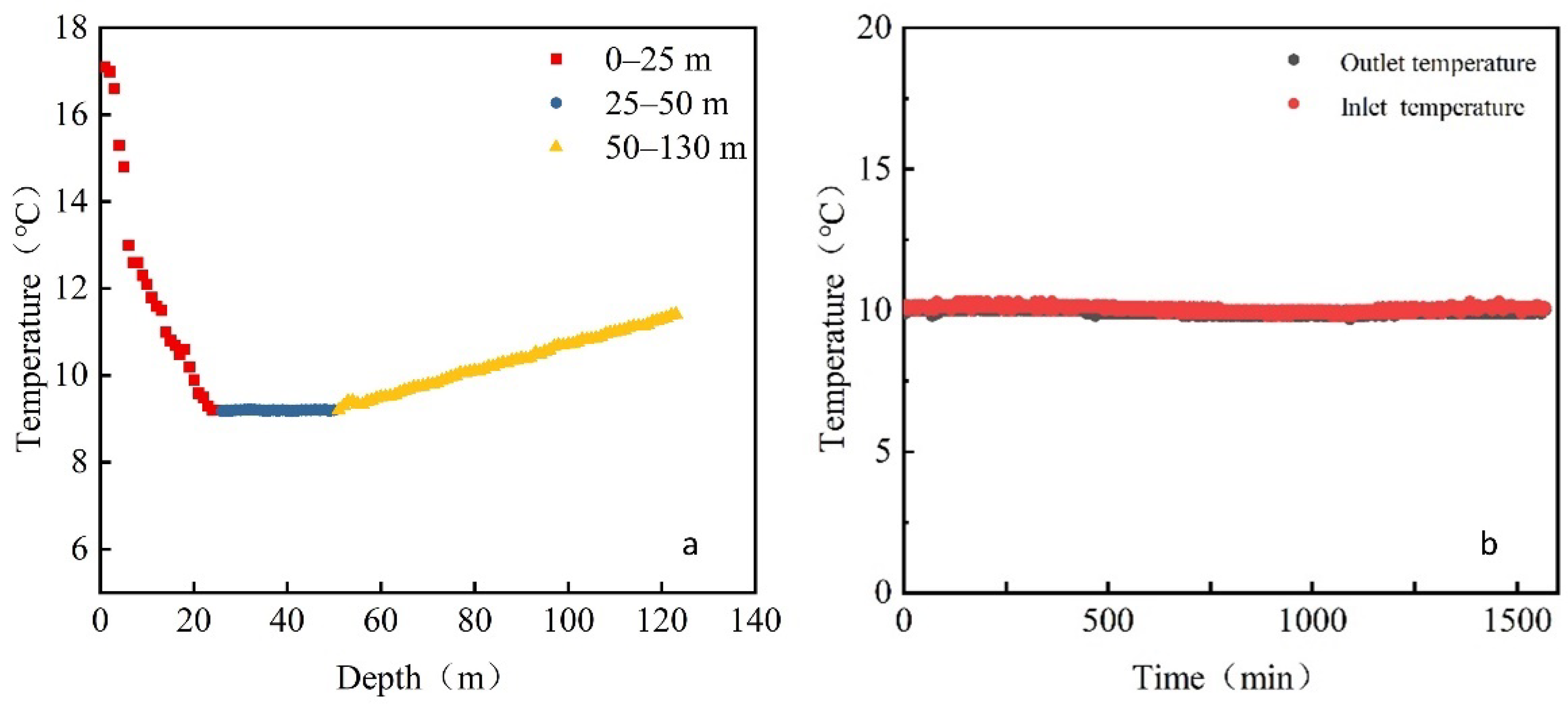

3.1. Determination of the Geothermal Conditions

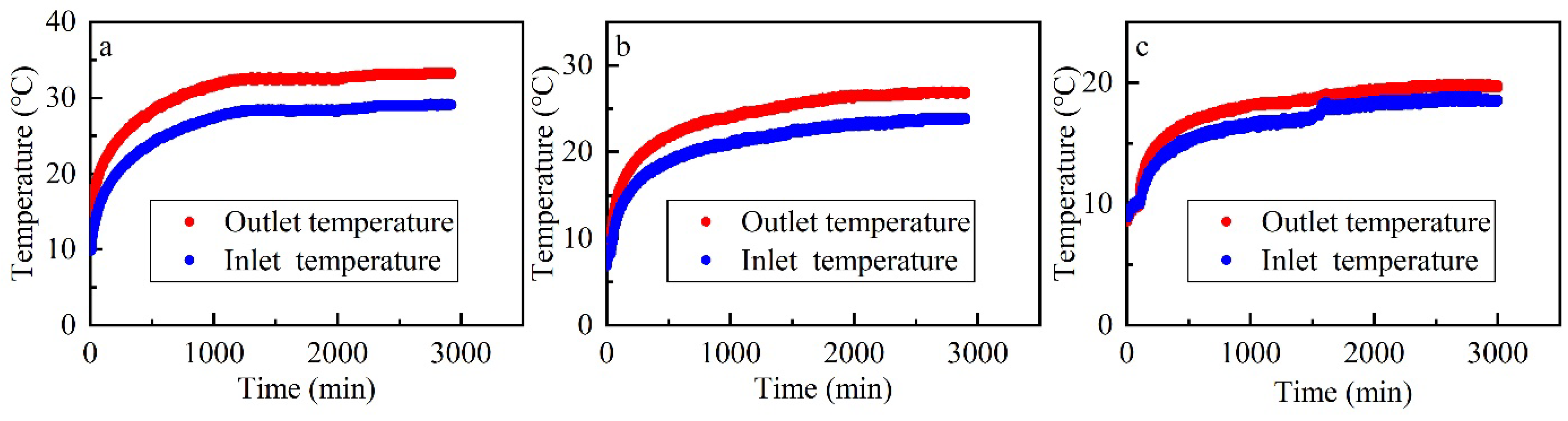

3.2. Influence of the Heat Load

3.3. Influence of the Test Time

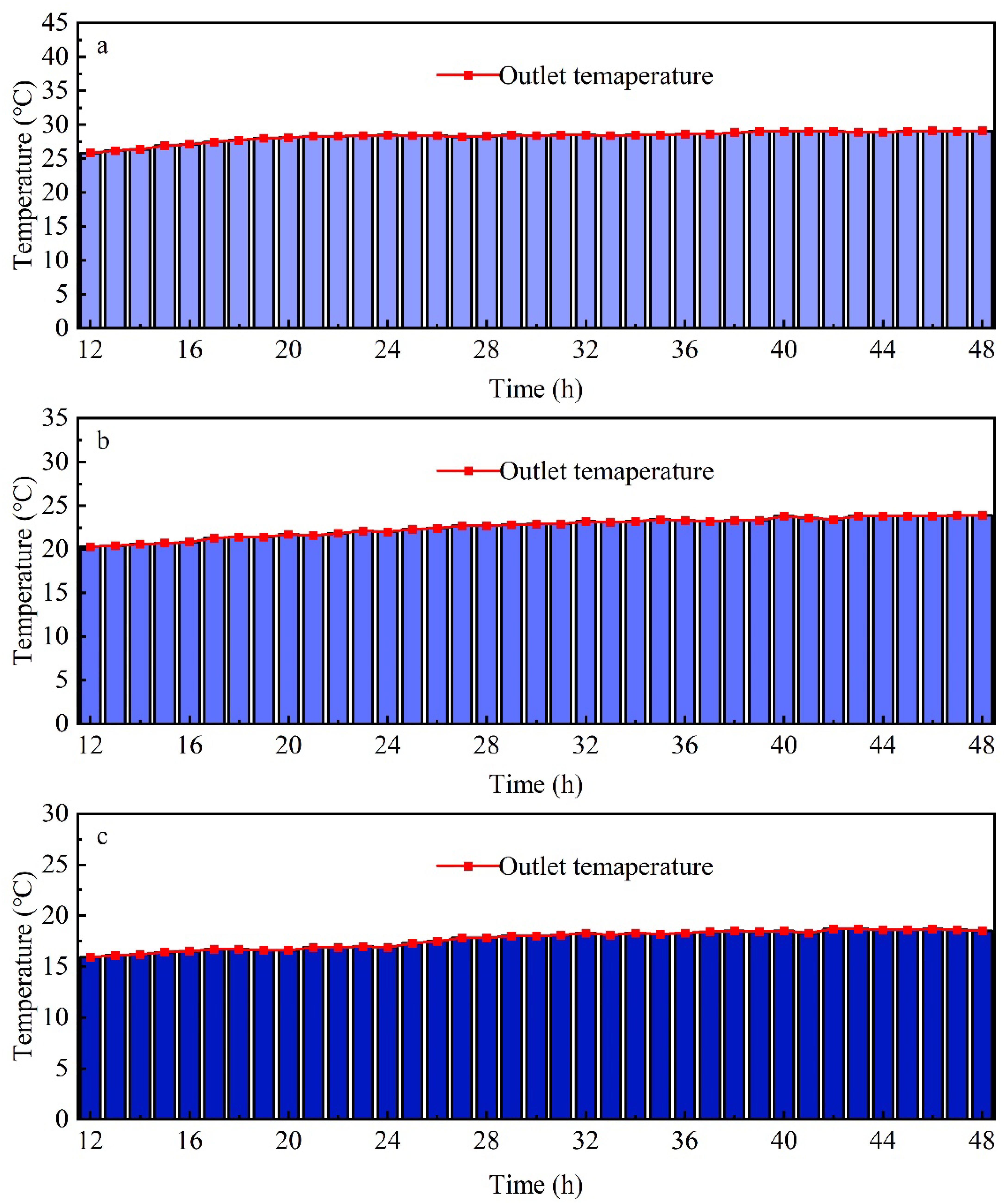

3.3.1. Change in the Outlet Temperature of the Heat Exchanger

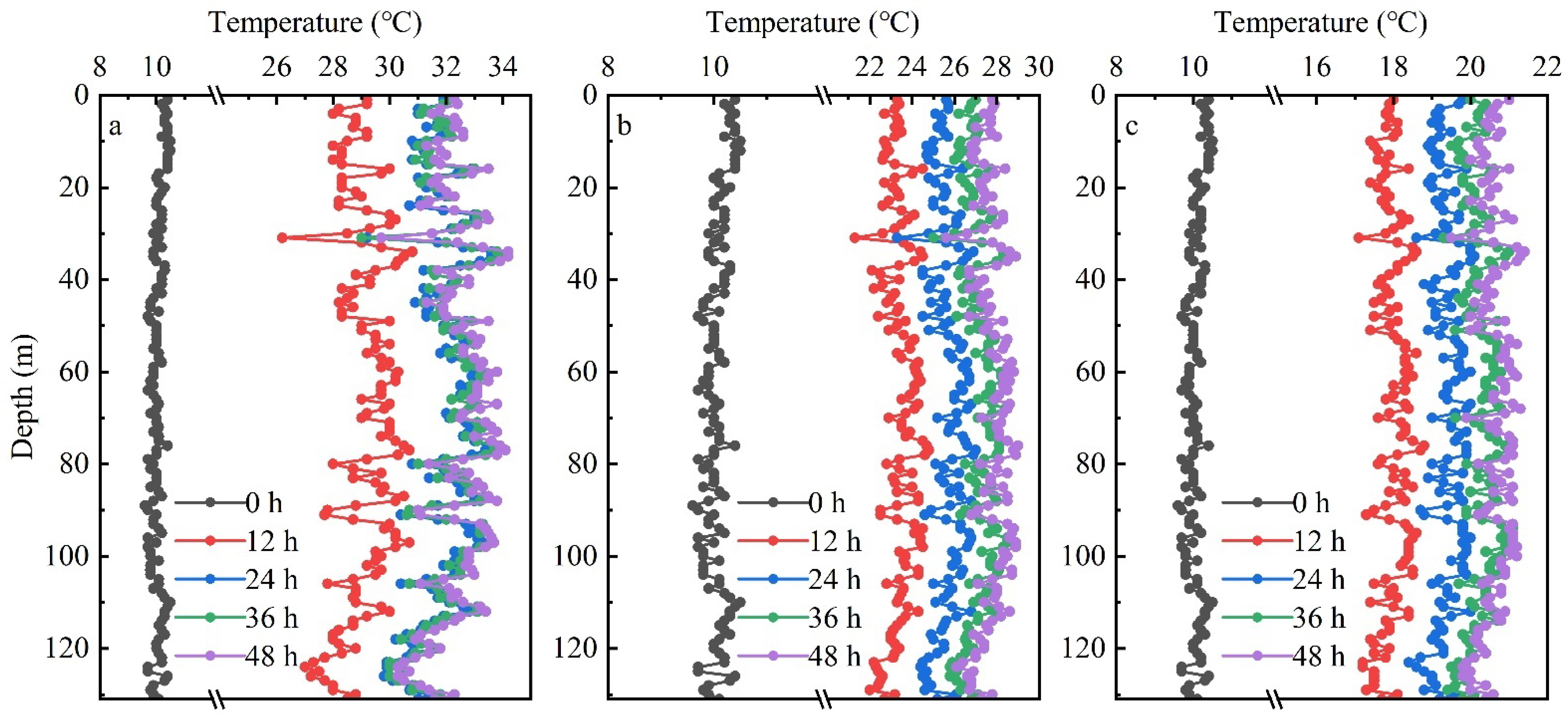

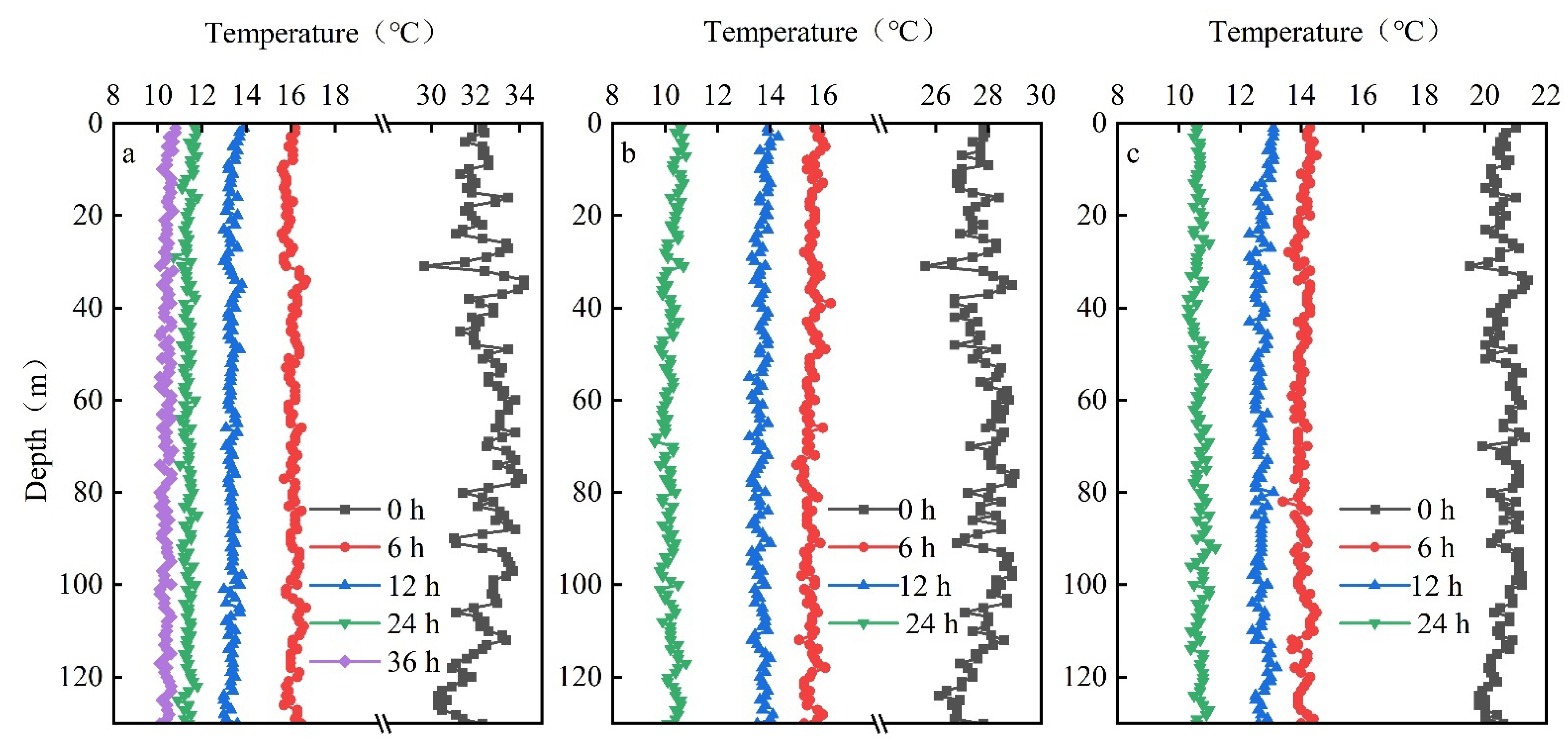

3.3.2. Formation Temperature Change

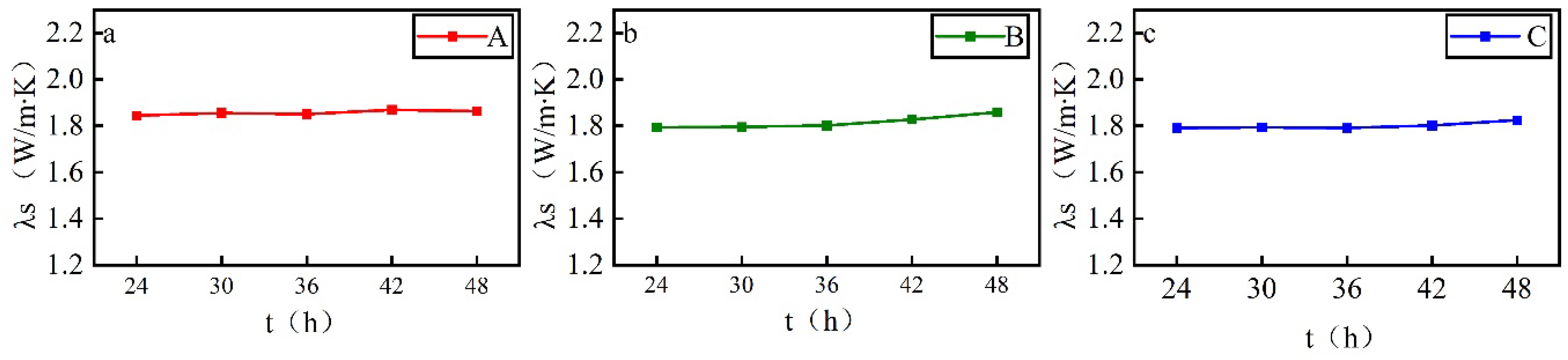

3.3.3. Thermal Conductivity under the Different Test Times

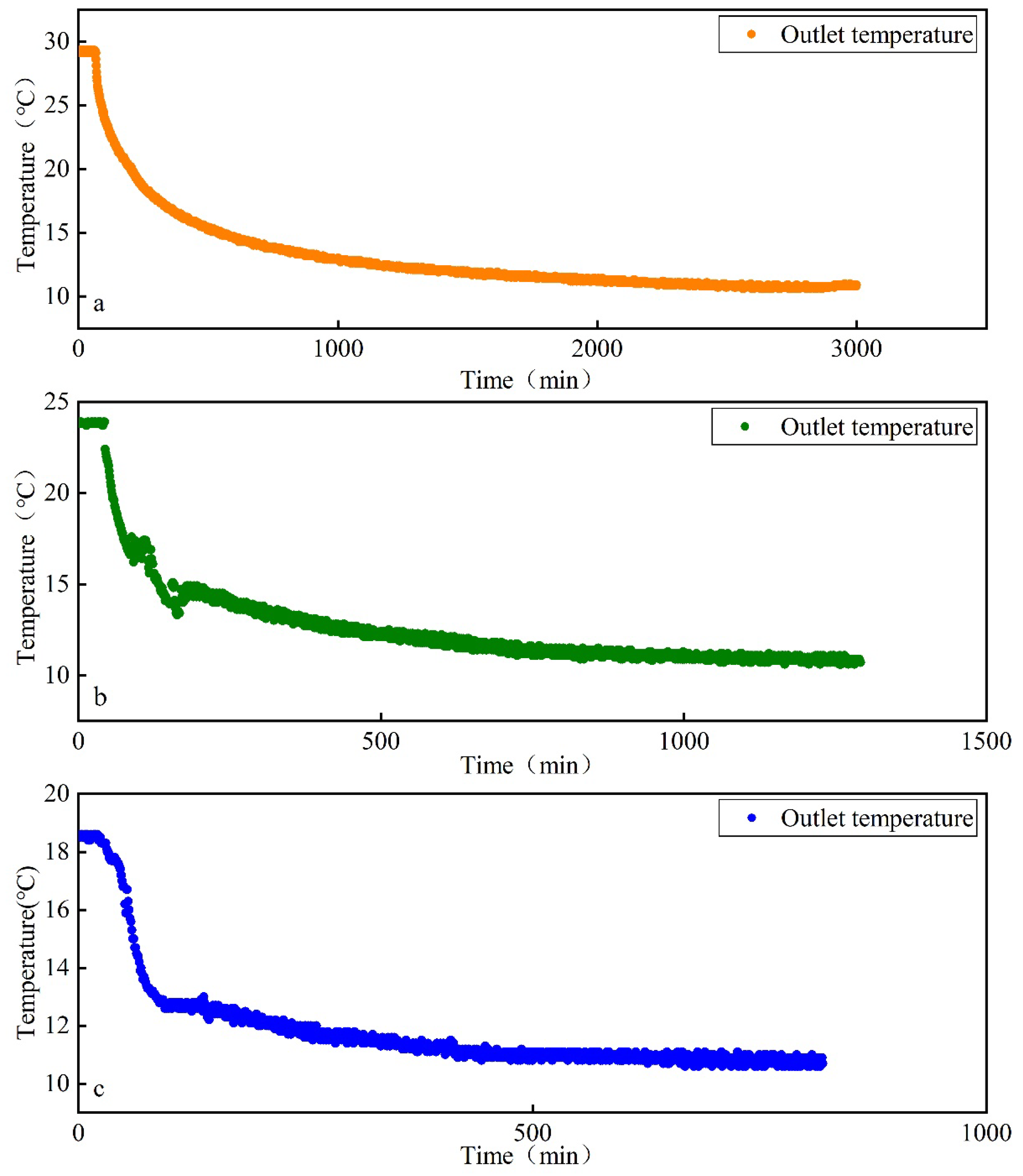

3.4. Formation Temperature Recovery Characteristics

4. Conclusions

- The bottom hole temperature (130 m) measured by the distributed optical fiber temperature sensor is 11.4 °C. The underground constant-temperature zone is located at depths from 25 to 50 m, the temperature-increasing zone is located at depths from 50 to 130 m, and the geothermal gradient is 3 °C/100 m.

- With increasing heat load, the temperature difference between the inlet and outlet increases when reaching the quasi-stable state. The heat load imposes a slight effect on the thermal conductivity test results.

- During the heating test phase, the changing trend of the temperature in the formation is consistent with that of the outlet temperature, and it takes 36 h for the test to reach a quasi-stable state. The temperature rise at the initial stage of the test is obvious from 0 to 12 h. The temperature rise value from 0 to 12 h reaches 80% of the temperature rise range in the quasi-stable state. The heat load increases and the temperature rises faster, which helps to reach the quasi-stable state faster.

- Once the quasi-stable condition is reached, there are slight differences between the thermal conductivity test results obtained at the various test times, and the test time imposes a slight influence on the thermal conductivity test results.

- The temperature in the formation is different after test completion under the different test conditions, and the time needed to restore the initial temperature also varies. At the heat recovery stage, the changing trend of the temperature in the formation is consistent with that of the outlet temperature. A reduction in the heat load can shorten the time for the formation to recover the initial temperature. From the perspective of economic benefits and test accuracy, it is recommended to select a relatively high heat load of 8 kW and select 36 h as both the test duration and ground temperature recovery duration.

Author Contributions

Funding

Conflicts of Interest

References

- Chien, F.; Hsu, C.-C.; Ozturk, I.; Sharif, A.; Sadiq, M. The role of renewable energy and urbanization towards greenhouse gas emission in top Asian countries: Evidence from advance panel estimations. Renew. Energy 2022, 186, 207–216. [Google Scholar] [CrossRef]

- Sovacool, B.K. Contestation, contingency, and justice in the Nordic low-carbon energy transition. Energy Policy 2017, 102, 569–582. [Google Scholar] [CrossRef]

- Vakulchuk, R.; Overland, I.; Scholten, D. Renewable energy and geopolitics: A review. Renew. Sustain. Energy Rev. 2020, 122, 109547. [Google Scholar] [CrossRef]

- Li, K.; Liu, C.; Jiang, S.; Chen, Y. Review on hybrid geothermal and solar power systems. J. Clean. Prod. 2020, 250, 119481. [Google Scholar] [CrossRef]

- Lund, J.W.; Toth, A.N. Direct utilization of geothermal energy 2020 worldwide review. Geothermics 2021, 90, 101915. [Google Scholar] [CrossRef]

- Huang, Y.; Zhang, Y.; Hu, Z.; Lei, H.; Wang, C.; Ma, J. Economic analysis of heating for an enhanced geothermal system based on a simplified model in Yitong Basin, China. Energy Sci. Eng. 2019, 7, 2658–2674. [Google Scholar] [CrossRef]

- Zhao, X.-G.; Wan, G. Current situation and prospect of China׳s geothermal resources. Renew. Sustain. Energy Rev. 2014, 32, 651–661. [Google Scholar] [CrossRef]

- Mott, A.; Baba, A.; Hadi Mosleh, M.; Ökten, H.E.; Babaei, M.; Gören, A.Y.; Feng, C.; Recepoğlu, Y.K.; Uzelli, T.; Uytun, H.; et al. Boron in geothermal energy: Sources, environmental impacts, and management in geothermal fluid. Renew. Sustain. Energy Rev. 2022, 167, 112825. [Google Scholar] [CrossRef]

- Galgaro, A.; Dalla Santa, G.; Zarrella, A. First Italian TRT database and significance of the geological setting evaluation in borehole heat exchanger sizing. Geothermics 2021, 94, 102098. [Google Scholar] [CrossRef]

- Hakala, P.; Vallin, S.; Arola, T.; Martinkauppi, I. Novel use of the enhanced thermal response test in crystalline bedrock. Renew. Energy 2022, 182, 467–482. [Google Scholar] [CrossRef]

- Zhang, C.; Lu, J.; Wang, X.; Xu, H.; Sun, S. Effect of geological stratification on estimated accuracy of ground thermal parameters in thermal response test. Renew. Energy 2022, 186, 585–595. [Google Scholar] [CrossRef]

- Mogensen, P. Fluid to duct wall heat transfer in duct system heat storages. In International Conference on Subsurface Heat Storage in Theory and Practice; Swedish Council for Building Research: Stockholm, Sweden, 1983. [Google Scholar]

- Lamarche, L.; Kajl, S.; Beauchamp, B. A review of methods to evaluate borehole thermal resistances in geothermal heat-pump systems. Geothermics 2010, 39, 187–200. [Google Scholar] [CrossRef]

- Wilke, S.; Menberg, K.; Steger, H.; Blum, P. Advanced thermal response tests: A review. Renew. Sustain. Energy Rev. 2020, 119, 109575. [Google Scholar] [CrossRef]

- Badenes, B.; Mateo Pla, M.Á.; Magraner, T.; Soriano, J.; Urchueguía, J.F. Theoretical and Experimental Cost–Benefit Assessment of Borehole Heat Exchangers (BHEs) According to Working Fluid Flow Rate. Energies 2020, 13, 4925. [Google Scholar] [CrossRef]

- Franco, A.; Conti, P. Clearing a Path for Ground Heat Exchange Systems: A Review on Thermal Response Test (TRT) Methods and a Geotechnical Routine Test for Estimating Soil Thermal Properties. Energies 2020, 13, 2965. [Google Scholar] [CrossRef]

- Lhendup, T.; Aye, L.; Fuller, R.J. In-situ measurement of borehole thermal properties in Melbourne. Appl. Therm. Eng. 2014, 73, 287–295. [Google Scholar] [CrossRef]

- ASHRAE Handbook-HVAC Applications; ASHRAE: Atlanta, GA, USA, 2015; Chapter 34.

- Morchio, S.; Fossa, M.; Beier, R.A. Study on the best heat transfer rate in thermal response test experiments with coaxial and U-pipe borehole heat exchangers. Applied Thermal Engineering 2022, 200. [Google Scholar] [CrossRef]

- Zhang, Y.; Hao, S.; Yu, Z.; Fang, J.; Zhang, J.; Yu, X. Comparison of test methods for shallow layered rock thermal conductivity between in situ distributed thermal response tests and laboratory test based on drilling in northeast China. Energy Build. 2018, 173, 634–648. [Google Scholar] [CrossRef]

- Urchueguía, J.; Lemus-Zúñiga, L.-G.; Oliver-Villanueva, J.-V.; Badenes, B.; Pla, M.; Cuevas, J. How Reliable Are Standard Thermal Response Tests? An Assessment Based on Long-Term Thermal Response Tests Under Different Operational Conditions. Energies 2018, 11, 3347. [Google Scholar] [CrossRef]

- Badenes, B.; Mateo Pla, M.; Lemus-Zúñiga, L.; Sáiz Mauleón, B.; Urchueguía, J. On the Influence of Operational and Control Parameters in Thermal Response Testing of Borehole Heat Exchangers. Energies 2017, 10, 1328. [Google Scholar] [CrossRef]

- Wang, F.-H.; Feng, C.-C.; Yan, L.; Wang, X.-K. Numerical and experimental evaluation on methods for parameter identification of thermal response tests. J. Cent. South Univ. 2012, 19, 816–823. [Google Scholar] [CrossRef]

- Yu, X.; Zhang, Y.; Deng, N.; Wang, J.; Zhang, D.; Wang, J. Thermal response test and numerical analysis based on two models for ground-source heat pump system. Energy Build. 2013, 66, 657–666. [Google Scholar] [CrossRef]

- Zhou, Y.; Zhao, L.; Wang, S. Determination and analysis of parameters for an in-situ thermal response test. Energy Build. 2017, 149, 151–159. [Google Scholar] [CrossRef]

- Gustafsson, A.M.; Westerlund, L. Multi-injection rate thermal response test in groundwater filled borehole heat exchanger. Renew. Energy 2010, 35, 1061–1070. [Google Scholar] [CrossRef]

- Choi, W.; Ooka, R. Effect of disturbance on thermal response test, part 1: Development of disturbance analytical model, parametric study, and sensitivity analysis. Renew. Energy 2016, 85, 306–318. [Google Scholar] [CrossRef]

- The Ministry of Housing and Urban–Rural Construction of China. Technical Code for GCHPs, 2009 ed.; GB 50366-2005; Chinese Building Industrial Press: Beijing, China, 2009. [Google Scholar]

- Zhang, C.; Guo, Z.; Liu, Y.; Cong, X.; Peng, D. A review on thermal response test of ground-coupled heat pump systems. Renew. Sustain. Energy Rev. 2014, 40, 851–867. [Google Scholar] [CrossRef]

- Choi, W.; Ooka, R. Effect of disturbance on thermal response test, part 2: Numerical study of applicability and limitation of infinite line source model for interpretation under disturbance from outdoor environment. Renew. Energy 2016, 85, 1090–1105. [Google Scholar] [CrossRef]

- Signorelli, S.; Bassetti, S.; Pahud, D.; Kohl, T. Numerical evaluation of thermal response tests. Geothermics 2007, 36, 141–166. [Google Scholar] [CrossRef]

- Bujok, P.; Grycz, D.; Klempa, M.; Kunz, A.; Porzer, M.; Pytlik, A.; Rozehnal, Z.; Vojčinák, P. Assessment of the influence of shortening the duration of TRT (thermal response test) on the precision of measured values. Energy 2014, 64, 120–129. [Google Scholar] [CrossRef]

- Nieto, I.M.; Blázquez, C.S.; Martín, A.F.; González-Aguilera, D. Analysis of the Influence of Reducing the Duration of a Thermal Response Test in a Water-Filled Geothermal Borehole Located in Spain. Energies 2020, 13, 6693. [Google Scholar] [CrossRef]

- Bozzoli, F.; Pagliarini, G.; Rainieri, S.; Schiavi, L. Short-time thermal response test based on a 3-D numerical model. J. Phys. Conf. Ser. 2012, 395, 012056. [Google Scholar] [CrossRef]

- Han, Z.; Zhang, S.; Li, B.; Ma, C.; Liu, J.; Ma, X.; Ju, X. Study on the influence of the identification model on the accuracy of the thermal response test. Geothermics 2018, 72, 316–322. [Google Scholar] [CrossRef]

- Han, Z.; Li, B.; Ma, C.; Hu, H.; Bai, C. Study on accurate identification of soil thermal properties under different experimental parameters. Energy Build. 2018, 164, 21–32. [Google Scholar] [CrossRef]

- ASHRAE. ASHRAE Handbook: HVAC Applications; ASHRAE: Atlanta, GA, USA, 2011. [Google Scholar]

| Item | Parameter | FY01 U-Tube |

|---|---|---|

| Borehole | Vertical depth (m) | 130 |

| Backfill material | Fine sand and bentonite | |

| Wellhead diameter (mm) | 150 | |

| PE pipe | External diameter (mm) | 32 |

| Internal diameter (mm) | 26 |

| Working Condition | Duration (h) | Heat Load (kW) |

|---|---|---|

| Initial ground temperature | 96 | 0 |

| A | 48 | 12 |

| R1 | 72 | 0 |

| B | 48 | 8 |

| R2 | 72 | 0 |

| C | 48 | 4 |

| R3 | 72 | 0 |

| Condition | Test Time (h) | 24 | 30 | 36 | 42 | 48 |

|---|---|---|---|---|---|---|

| A | Thermal conductivity (W/m∙K) | 1.846 | 1.856 | 1.852 | 1.871 | 1.864 |

| B | 1.794 | 1.796 | 1.803 | 1.828 | 1.859 | |

| C | 1.791 | 1.794 | 1.791 | 1.802 | 1.826 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, Y.; Zhang, Y.; Cheng, Y.; Zhang, Y.; Gao, X.; Deng, H.; Zhang, X. Influence of Different Heat Loads and Durations on the Field Thermal Response Test. Energies 2022, 15, 8759. https://doi.org/10.3390/en15228759

Ma Y, Zhang Y, Cheng Y, Zhang Y, Gao X, Deng H, Zhang X. Influence of Different Heat Loads and Durations on the Field Thermal Response Test. Energies. 2022; 15(22):8759. https://doi.org/10.3390/en15228759

Chicago/Turabian StyleMa, Yongjie, Yanjun Zhang, Yuxiang Cheng, Yu Zhang, Xuefeng Gao, Hao Deng, and Xin Zhang. 2022. "Influence of Different Heat Loads and Durations on the Field Thermal Response Test" Energies 15, no. 22: 8759. https://doi.org/10.3390/en15228759

APA StyleMa, Y., Zhang, Y., Cheng, Y., Zhang, Y., Gao, X., Deng, H., & Zhang, X. (2022). Influence of Different Heat Loads and Durations on the Field Thermal Response Test. Energies, 15(22), 8759. https://doi.org/10.3390/en15228759