Theoretical and Experimental Studies of a PDMS Pneumatic Microactuator for Microfluidic Systems

Abstract

1. Introduction

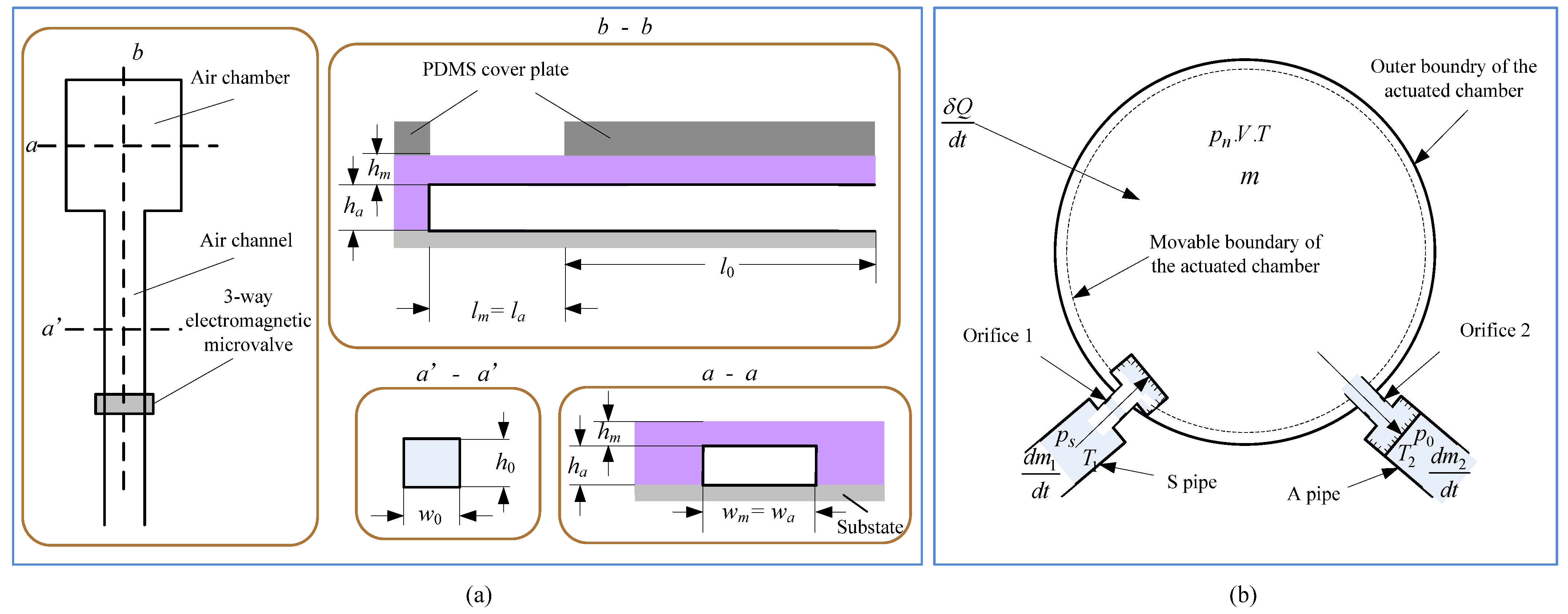

2. System Description

3. Model of the PDMS Pneumatic Microactuator

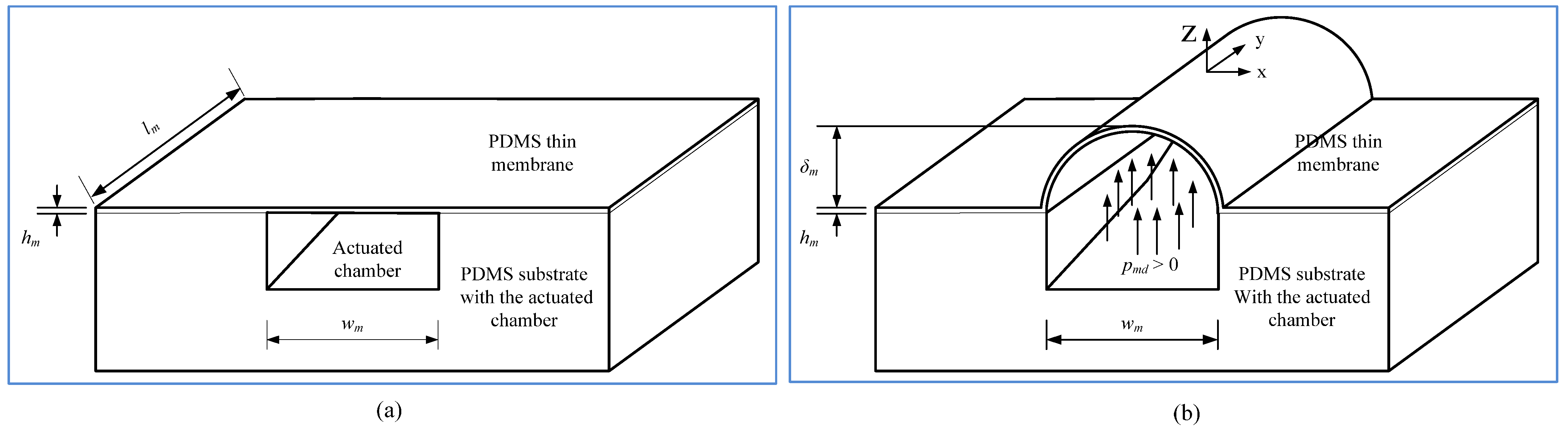

3.1. Deformation of the PDMS Thin Membrane

- Deformable Force Balance Equation of the PDMS Thin Membrane

- 2.

- Geometric Equation of PDMS Thin Membrane Deformation

- 3.

- Physical Equation of PDMS Thin Membrane Deformation

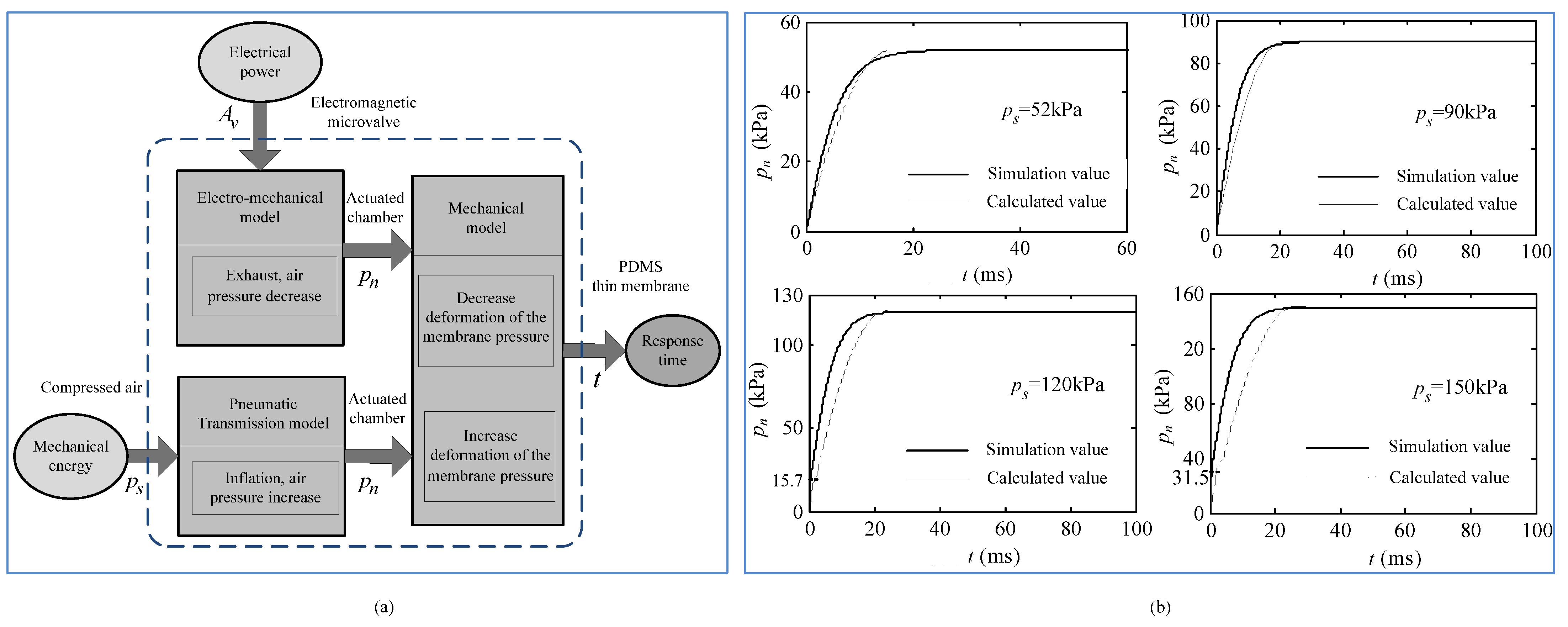

3.2. Response Time of the Actuated Microactuator

4. Results and Discussions

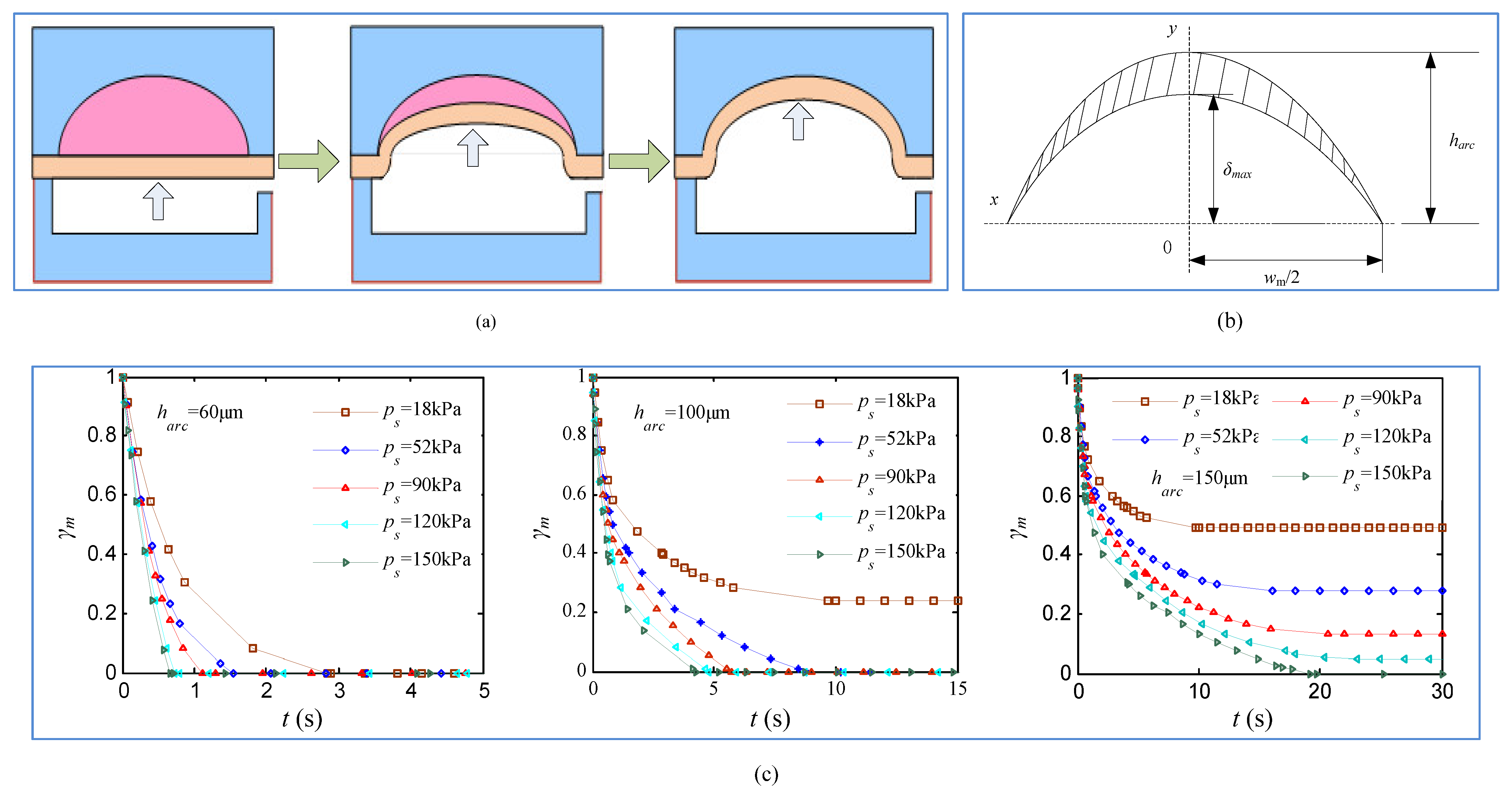

4.1. Analysis of Deformation Characteristics of PDMS Thin Membrane

4.2. Dynamic Response Performance of the Pneumatic Microactuator

4.3. Response Characteristics Analysis of Membrane Microvalve Integrated with the Microactuator

4.4. Experimental Operation of Valving and Mixing Integrated with the Microactuator

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| δmax | maximum deflection of membrane, μm | gz1 | potential energy flowing into actuated chamber, J/N |

| pn | air pressure of actuated chamber, Pa | gz2 | potential energy flowing out of actuated chamber, J/N |

| pl | liquid pressure on membrane, Pa | ps | air pressure of air supply, Pa |

| Em | elastic modulus, kPa | p0 | initial air pressure of actuated chamber, Pa |

| vm | Poisson ratio | Fs | cross-sectional area of port S, m2 |

| Vm | volume of actuated chamber, m3 | Ap | Electromagnetic Microvalve 1 cross-sectional area, m2 |

| lm | length of thin PDMS membrane, m | kv1 | valve port flow coefficient |

| wm | width of thin PDMS membrane, m | kx1 | correction factor |

| tm | thickness of thin PDMS membrane, m | kx2 | flow resistance flow correction factor |

| E | tonal energy of the actuated chamber, J | ∆pmd | pmd incremental in a small range, Pa |

| l0 | length of air channel, m | ∆δmax | incremental maximum deflection, μm |

| w0 | width of air channel, m | Kmp | maximum deflection—pressure gain |

| h0 | depth of the air channel, m | t | Time, s |

| la | length of actuated chamber, m | u | fluid thermal conductivity, W m−1 K−1 |

| wa | width of actuated chamber, m | R | air constant, J/(mol·K) |

| ha | depth of actuated chamber, m | cp | specific heat at constant pressure, J/(kg·K) |

| m1 | mass flow rate flowing into actuated chamber, kg/s | cv | specific heat at constant volume, J/(kg·K) |

| m2 | mass flow rate flowing from the actuated chamber, kg/s | V0 | initial volume of actuated chamber, m3 |

| Am | Valve port area of membrane microvalve, m2 | Vm | increase volume of actuated chamber, m3 |

| A0 | Valve port area with fully opened, m2 | harc | depth of curved liquid microchannel, m |

| Amem | deformation area of PDMS thin membrane, m2 | γm | Valve opening of membrane microvalve |

| W | work of N2 in actuated chamber, J | 1/2c12 | kinetic energy flowing out of actuated chamber, J/m2 |

| i1 | enthalpy flowing into actuated chamber, J/kg | 1/2c12 | kinetic energy flowing into actuated chamber, J/m2 |

| i2 | enthalpy flowing out actuated chamber, J/kg | psub | air pressure cut-off point, Pa |

References

- Zheng, D.; Wang, Z.; Wu, J.; Li, S.; Li, W.; Zhang, H.; Xia, L. A raman immunosensor based on SERS and microfluidic chip for all-fiber detection of brain natriuretic peptide. Infrared Phys. Technol. 2022, 125, 104252. [Google Scholar] [CrossRef]

- Sjoberg, R.G.; Leyrat, A.A.; Pirone, D.M.; Chen, C.S.; Quake, S.R. Versatile, fully automated, microfluidic cell culture system. Anal. Chem. 2007, 79, 8557–8563. [Google Scholar] [CrossRef] [PubMed]

- Guan, Y.; Yang, T.; Wu, J. Mixing and transport enhancement in microchannels by electrokinetic flows with charged surface heterogeneity. Phys. Fluids 2021, 33, 042006. [Google Scholar] [CrossRef]

- Yang, T.; Peng, J.; Shu, Z.; Shu, Z.; Sekar, P.K.; Li, S. Determination of the membrane transport properties of jurkat cells with a microfluidic device. Micromachines 2019, 10, 832. [Google Scholar] [CrossRef] [PubMed]

- Jiang, B.; Guo, H.; Chen, D.; Zhou, M. Microscale investigation on the wettability and bonding mechanism of oxygen plasma-treated PDMS microfluidic chip. Appl. Surf. Sci. 2022, 574, 151704. [Google Scholar] [CrossRef]

- Chen, S.; Sun, Y.; Fan, F.; Chen, S.; Zhang, Y.; Zhang, Y.; Meng, X.; Lin, J.-M. Present status of microfluidic PCR chip in nucleic acid detection and future perspective. TrAC Trends Anal. Chem. 2022, 157, 116737. [Google Scholar] [CrossRef]

- Araci, I.E.; Agaoglu, S.; Lee, J.Y.; Yepes, L.R.; Diep, P.; Martini, M.; Schmidt, A. Flow stabilization in wearable microfluidic sensors enables noise suppression. Lab Chip 2019, 19, 3899–3908. [Google Scholar] [CrossRef]

- Araci, I.E.; Quake, S.R. Microfluidic very large scale integration (mVLSI) with integrated micromechanical valves. Lab Chip 2012, 12, 2803–2806. [Google Scholar] [CrossRef]

- Whitesides, G.M. The origins and the future of microfluidics. Nature 2006, 442, 368–373. [Google Scholar] [CrossRef]

- ESackmann, K.; Fulton, A.L.; Beebe, D.J. The present and future role of microfluidics in biomedical research. Nature 2014, 507, 181–189. [Google Scholar] [CrossRef]

- Raj, A.; Suthanthiraraj, P.P.A.; Sen, A.K. Pressure-driven flow through PDMS-based flexible microchannels and their applications in microfluidics. Microfluid. Nanofluidics. 2018, 22, 128. [Google Scholar] [CrossRef]

- Hong, J.W.; Quake, S.R. Integrated nanoliter systems. Nat. Biotechnol. 2003, 21, 1179–1183. [Google Scholar] [CrossRef] [PubMed]

- Melin, J.; Quake, S.R. Microfluidic large-scale integration: The evolution of design rules for biological automation. Annu. Rev. Biophys. Biomol. Struct. 2007, 36, 213–231. [Google Scholar] [CrossRef] [PubMed]

- Thorsen, T.; Maerkl, S.J.; Quake, S.R. Microfluidic large-scale integration. Science 2002, 298, 580–584. [Google Scholar] [CrossRef]

- Srinivasan, B.; Lee, J.S.; Hohnbaum, J.; Tung, S.; Kim, J. Performance evaluation of a pneumatic-based micromixer for bioconjugation reaction. In Proceedings of the 2010 5th IEEE International Conference on Nano/micro Engineered and Molecular Systems, Xiamen, China, 20–23 January 2010; pp. 810–814. [Google Scholar]

- Wang, X.; Ma, X.; An, L.; Kong, X.; Xu, Z.; Wang, J. A pneumatic micromixer facilitating fluid mixing at a wide range flow rate for the preparation of quantum dots. Sci. China Chem. 2013, 56, 799–805. [Google Scholar] [CrossRef]

- Liu, X.; Li, S. Control method experimental research of micro chamber air pressure via a novel electromagnetic microvalve. In Proceedings of the 2017 4th International Conference on Information Science and Control Engineering, ICISCE, Changsha, China, 24–23 July 2017; pp. 700–705. [Google Scholar]

- Lee, J.N.; Park, C.; Whitesides, G.M. Solvent compatibility of poly(dimethylsiloxane)-based microfluidic devices. Anal. Chem. 2003, 75, 6544–6554. [Google Scholar] [CrossRef]

- Nguyen, P.H.; Zhang, W. Design and computational modeling of fabric soft pneumatic actuators for wearable assistive devices. Sci. Rep. 2020, 10, 9638. [Google Scholar] [CrossRef]

- PDMS Elastomeric Film Materials. Available online: https://zhuanlan.zhihu.com/p/149539550 (accessed on 4 September 2022). In Chinese.

- Hardy, B.S.; Uechi, K.; Zhen, J.; Kavehpour, H.P. The deformation of flexible PDMS microchannels under a pressure driven flow. Lab Chip 2009, 9, 935–938. [Google Scholar] [CrossRef]

- Cui, H.; Li, Z.; Jin, G. Preparation and performance analysis of a PDMS-membrane microvalve. Microfabr. Technol. 2004, 3, 70–75. [Google Scholar]

- Kartalov, E.P.; Scherer, A.; Quake, S.R.; Taylor, C.R.; Anderson, W.F. Experimentally validated quantitative linear model for the device physics of elastomeric microfluidic valves. J. Appl. Phys. 2007, 101, 064505. [Google Scholar] [CrossRef]

- Lee, S.W.; Kim, D.J.; Ahn, Y.; Chai, Y.G. Simple structured polydimethylsiloxane microvalve actuated by external air pressure. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2006, 220, 1283–1288. [Google Scholar] [CrossRef]

- Yang, Q.; Kobrin, P.; Seabury, C.; Narayanaswamy, S.; Christian, W. Mechanical modeling of fluid-driven polymer lenses. Appl. Opt. 2008, 47, 3658–3668. [Google Scholar] [CrossRef] [PubMed]

- Chung, J.; Issadore, D.; Ullal, A.; Lee, K.; Weissleder, R.; Lee, H. Rare cell isolation and profiling on a hybrid magnetic/size-sorting chip. Biomicrofluidics 2013, 7, 054107. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Li, S.; Bao, G. Numerical simulation on the response characteristics of a pneumatic micro actuator for microfluidic chips. J. Lab. Autom. 2016, 21, 412–422. [Google Scholar] [CrossRef][Green Version]

- Cao, Z.; Chen, F.; Bao, N.; He, H.; Xu, P.; Jana, S.; Jung, S.; Lianb, H.; Lu, C. Droplet sorting based on the number of encapsulated particles using a solenoid valve. Lab Chip 2013, 13, 171–178. [Google Scholar] [CrossRef] [PubMed]

- Yang, G. Elastic-plastic mechanics, 2nd ed.; Tsinghua University Press: Beijing, China, 2013. (In Chinese) [Google Scholar]

- Li, L.; Li, H.; Kou, G.; Yang, D.; Hu, W.; Peng, J.; Li, S. Dynamic camouflage characteristics of a thermal infrared film inspired by honeycomb structure. J. Bionic Eng. 2022, 19, 458–470. [Google Scholar] [CrossRef]

- Li, S.; Jia, H.; Li, M.; Wang, D.; Qin, Z.; Chen, H. Theory and special test method of superelastic constitutive model. Elastomer 2011, 21, 58–64. [Google Scholar]

- Liu, H. Mechanics of Materials, 6th ed.; Higher Education Press: Beijing, China, 2017. (In Chinese) [Google Scholar]

- Yu, B. Microfluidic Large Scale Integration and Its Application in Image Based Microflow Cytometry. Master’s Thesis, University of Waterloo, Waterloo, ON, Canada, 2010; pp. 35–41. [Google Scholar]

- Wen, S.; Huang, P. Theory of Tribology, 2nd ed.; Tsinghua University Press: Beijing, China, 2008. (In Chinese) [Google Scholar]

- Vlassak, J.J.; Nix, W.D. A new bulge test technique for the determination of Young’s modulus and Poisson’s ratio of thin films. J. Mater. Res. 1992, 7, 3242–3249. [Google Scholar] [CrossRef]

- Yu, J.; Wei, Y. Finite Element Stress Analysis of Incompressible Hyperelastic Materials; Southwest Jiaotong University Press: Chengdu, China, 1998; Volume 33, pp. 41–45. (In Chinese) [Google Scholar]

- Ying, C. Gas Transport Theory and Applications; Tsinghua University Press: Beijing, China, 1990; pp. 50–52. [Google Scholar]

- Wu, P.; Little, W.A. Measurement of friction factors for the flow of gases in very fine channels used for microminiature Joule-Thomson refrigerators. Cryogenics 1983, 23, 273–277. [Google Scholar]

- Li, H.; Xu, G.; Li, S. Flow characteristics analysis of Laval type fuel flow control valve. J. Mech. Electr. Eng. 2012, 29, 1036–1045. [Google Scholar]

- Liu, X.; Li, S. Fabrication of a three-Layer PDMS pneumatic microfluidic chip for micro liquid sample operation. SLAS Technol. Transl. Life Sci. Innov. 2019, 25, 151–161. [Google Scholar] [CrossRef] [PubMed]

- Rodríguez, G.A.A.; Rossi, C.; Zhang, K. Multi-physics system modeling of a pneumatic micro actuator. Sens. Actuators A 2008, 141, 489–498. [Google Scholar] [CrossRef]

- GOuyang, G.; Tong, Z.; Gao, W.; Wang, K.; Akram, M.N.; Kartashov, V.; Chen, X.Y. Polymer-based multiple diffraction modulator for speckle reduction. Proc. SPIE 2010, 7387, 73871F. [Google Scholar]

- Lu, X. Research on a Soft Robotic Tongue with Pnuematic Actuation. Master’s Thesis, Nanjing University of Science and Technology, Nanjing, China, 2019; pp. 5–6. [Google Scholar]

- Qian, P.; Pu, C.; Liu, L.; Lv, P.; Paez, L.M.R. A novel pneumatic actuator based on high-frequency longitudinal vibration friction reduction. Sens. Actuators A Phys. 2022, 344, 113731. [Google Scholar] [CrossRef]

- Lee, Y.-K.; Tabeling, P.; Shih, C.; Ho, C.-M. Characterization of a MEMS-fabricated mixing device. In Proceedings of the ASME 2000 International Mechanical Engineering Congress and Exposition. Micro-Electro-Mechanical Systems (MEMS), Orlando, FL, USA, 5–10 November 2000; pp. 505–511. [Google Scholar]

- Maliani, A.D.E.; Hassouni, M.E.; Berthoumieu, Y.; Aboutajdine, D. Generic multivariate model for color texture classification in RGB color space. Int. J. Multimed. Inf. Retr. 2014, 4, 217–231. [Google Scholar] [CrossRef][Green Version]

- Nazari, M.; Rashidib, S.; Esfahania, J.A. Mixing process and mass transfer in a novel design of induced-charge electrokinetic micromixer with a conductive mixing-chamber. Int. Commun. Heat Mass Transf. 2019, 108, 104293. [Google Scholar] [CrossRef]

- Lee, C.; Fu, L. Recent advances and applications of micromixers. Sens. Actuators B Chem. 2018, 259, 677–702. [Google Scholar] [CrossRef]

| Parameter | Value (µm) | ||

|---|---|---|---|

| Design Scheme 1 | Design Scheme 2 | Design Scheme 3 | |

| la | 500 | 500 | 500 |

| lm | 500 | 500 | 500 |

| wa | 200 | 300 | 500 |

| wm | 200 | 300 | 500 |

| ha | 100 | 100 | 100 |

| h0 | 100 | 100 | 100 |

| hm | 40 | 40 | 40 |

| l0 | 3000 | 3000 | 3000 |

| w0 | 100 | 100 | 100 |

| harc (µm) | ps (kPa) | δmax (µm) | γm | t (ms) |

|---|---|---|---|---|

| 60 | 18 | 60 | 0% | 2.84 |

| 52 | 60 | 0% | 1.54 | |

| 90 | 60 | 0% | 1.11 | |

| 120 | 60 | 0% | 0.74 | |

| 150 | 60 | 0% | 0.66 | |

| 100 | 18 | 76 | 24% | - |

| 52 | 100 | 0% | 8.81 | |

| 90 | 100 | 0% | 5.70 | |

| 120 | 100 | 0% | 4.78 | |

| 150 | 100 | 0% | 4.26 | |

| 150 | 18 | 76 | 49% | - |

| 52 | 108.24 | 28% | - | |

| 90 | 129.96 | 13% | - | |

| 120 | 143.04 | 5% | - | |

| 150 | - | 0% | 19.18 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, X.; Song, H.; Zuo, W.; Ye, G.; Jin, S.; Wang, L.; Li, S. Theoretical and Experimental Studies of a PDMS Pneumatic Microactuator for Microfluidic Systems. Energies 2022, 15, 8731. https://doi.org/10.3390/en15228731

Liu X, Song H, Zuo W, Ye G, Jin S, Wang L, Li S. Theoretical and Experimental Studies of a PDMS Pneumatic Microactuator for Microfluidic Systems. Energies. 2022; 15(22):8731. https://doi.org/10.3390/en15228731

Chicago/Turabian StyleLiu, Xuling, Huafeng Song, Wensi Zuo, Guoyong Ye, Shaobo Jin, Liangwen Wang, and Songjing Li. 2022. "Theoretical and Experimental Studies of a PDMS Pneumatic Microactuator for Microfluidic Systems" Energies 15, no. 22: 8731. https://doi.org/10.3390/en15228731

APA StyleLiu, X., Song, H., Zuo, W., Ye, G., Jin, S., Wang, L., & Li, S. (2022). Theoretical and Experimental Studies of a PDMS Pneumatic Microactuator for Microfluidic Systems. Energies, 15(22), 8731. https://doi.org/10.3390/en15228731