1. Introduction

There is a growing demand globally to find solutions to overcome the challenges presented by freshwater scarcity. The United Nations’ Sustainable Development Goal 6.1 (SDG 6.1), which is to ensure universal access to safe drinking water by 2030, requires an investment of USD 114 billion in 140 low- and middle-income countries [

1]. Globally, around 3.5 billion people live in areas with water scarcity; and this number is expected to increase to 5 billion by 2050 [

2]. For example, based on the population growth in the Gulf Cooperation Council (GCC) region, the per capita freshwater availability is going to be reduced by half by 2030 [

3]. The growing challenge of difficulty accessing freshwater poses more of a risk to the hundreds of millions of people living in developing regions along the coast who face the exacerbated threats of climate change, sea-level rise, high evaporation rates and seawater intrusion [

4].

Desalination is the main source of fresh water in coastal regions, and there are various desalination technologies employed ranging from reverse osmosis and multiple-effect distillation to multistage flash desalination. Technological development based on experience and research and geared to optimize current technologies and develop new ones is gaining momentum worldwide [

5]. Some of these studies focus on thermal and reverse osmosis processes, both of which are at the forefront of desalination at a large scale [

6,

7,

8]. Since desalination is an energy-intensive process and utilizing conventional energy increases the carbon footprint further, introducing renewable energy to desalination is essential.

Solar stills are simple devices that use solar irradiance to convert saline water into fresh water, essentially by phase transfer, from liquid to vapor, and subsequently condensation. The resulting water is low in salts and devoid of other impurities. Such systems have already been deployed in several coastal communities in many low- and middle-income countries [

9].

Solar stills are a comparatively simple and low-cost method of delivering clean drinking water to rural, arid and remote areas with a scarcity of fresh water. They can provide relief in challenging situations such as natural or water-related calamities, as well as in drought-stricken areas with no access to drinking water. In general, solar stills require less complicated expertise and can be built with locally available materials even in the most impoverished areas. Furthermore, the maintenance and operation of solar stills are relatively easy and inexpensive. The energy required for solar still is provided by the sun with little or no human intervention.

This work focuses on a micro solar still (MSS) technology that uses solar energy to generate fresh water. It is a multi-stage desalination method that uses solar heat collectors to evaporate and condense the supplied water. The innovative part of this research was that the tested MSS was simple, designed with low-cost materials as an all-in-one structure through a mass-production-friendly process. The parameters considered during design were the number of effects, the gap between evaporating and condensing surfaces, effect material, system sizing, the mass flow rate of feed water, the salinity of feed water and the climate conditions. Improvements to the origami structure were studied here to determine their effects on the distillate yield and quality with the goal of assessing the system’s capability of producing potable water in an arid beach environment, specifically in Kuwait [

10,

11,

12]. This paper serves as a pilot study for MSS technology in Kuwait. The following sections of the paper provide a review of the recently published literature related to the development of solar stills; their performance studies are discussed in

Section 2.

Section 3 presents the methodology followed for this research, followed by the results and discussions in

Section 4, and lastly, the conclusions in

Section 5.

2. Literature Review

A great deal of research and experimentation has been carried out in the recent past to improve the efficiency of solar stills. To date, the conventional solar still has low productivity and poor efficiency compared with other desalination methods. Hence, it has not been fully commercialized yet. However, further research and developments have been carried out in order to find more efficient designs that maximize the productivity of the solar still.

Yeo et al. [

10] proposed a prototype of a hybrid multiple-effect diffusion solar still (HMED) operating with various heat sources, such as solar thermal, electric heat and waste heat, and it was tested in Korea. The study found that the HMED can be operated with not only solar energy but also with waste heat or a combination of these. However, the performance ratio of the system was the lowest for solar heat (0.18–0.71) and the highest for waste heat (2.32), even though the amount of thermal energy supplied from waste heat was lower (6–9 MJ) than global solar radiation (11–23 MJ/m

2). Their research concluded that the optimum feed flow rate of seawater to the multiple-effect diffusion section (MED) increases with the thermal energy supplied. Nevertheless, its optimum ratio to the amount of evaporation in each effect plate of the MED stays within a range of 4.6–2.8, regardless of thermal energy input.

A theoretical parametric investigation was performed by Tanaka [

11] for a solar still consisting of a vertical multiple-effect unit (MEU) and a tilted-wick unit (TWU). This was followed by an outdoor experiment in Kurume, Japan, with a 4-effect MEU to validate the theoretical results. The experimental still was tested on a clear day in December with an average ambient air temperature of around 5 °C. The experiment indicated that the difference between the experimental and theoretical results was about 10%. The author also numerically analyzed the key parameters that affect the daily production of fresh water from a solar still combining a MEU and a TWU, and concluded that the inclination angle has an optimum value for each season, and it should be at a 30° fixed angle.

The work presented by Maddah [

12], on a small, single-slope passive solar still using simple and inexpensive materials showed the highest efficiency of 18.3% with a freshwater production of 341 mL/day. However, the results also indicated that increasing the feed by another 120 mL/day can increase the product by 5.4 mL/day, but it lowered the efficiency to 6%.

Katekar et al. [

13] compared the productivity of wick-type, single-basin, single-slope solar stills using different types of wicks. The results indicated that jute is the most frequently used wick material in addition to sponge, cotton cloth and wool, which delivered the highest productivity of 85%. Agboola et al. [

14] reported a productivity of 3.25 kg/m

2 per day of distilled water with a daily efficiency of almost 40% through an inclined solar still with a wick.

Kuhe et al. [

15] studied the effect of using thermal storage in the solar still. The innovative design had a single-slope solar still integrated with a thermal energy storage system coupled with a parabolic concentrator to improve productivity. In addition, phase-change material (PCM) was used between the absorber plate and the bottom of the still in order to maintain continuous production even at sunset. Another solar still without PCM was also tested to compare its productivity and determine the effect of PCM. The experimental results showed that the daily productivity reached 5.24 kg/m

2, and it was increased up to 62% when using thermal storage. However, using thermal storage may increase the cost of the solar still system.

In addition, Rahman et al. [

16] developed a solar still integrated with an external water-cooled condenser to increase the rate of condensation. The effect of using such a condenser was studied in Rajshahi, Bangladesh. The team reported a maximum yield of 3.15 l/m

2 per day with a triangular channeled absorber plate. Moreover, productivity was increased by 24–30% as an effect of using a condenser. Balachandran et al. [

17] reported experimentally better productivity using a coating of micro and nano ferric oxide (Fe

2O

3) particles on the absorber plate of single-basin, single-slope solar still. They reported a cumulative yield of 3.23 kg/m

2 per day and 4.39 kg/m

2 per day for micro and nano coating, respectively.

Moreover, Jani and Modi [

18] evaluated the performance of a double-slope, single-basin solar still with circular and square cross-sectional hollow fins on the absorber plate experimentally under the climatic condition of Valsad, Gujarat, India. The maximum productivity of distilled water obtained was 1.49 kg/m

2 per day and 0.96 kg/m

2 per day for circular-finned and square-finned solar stills, respectively. Moreover, Assari et al. [

19] studied the performance of a solar still fitted with rotating, externally movable reflectors. The maximum productivity obtained for the rotating mode was 8.3 kg/m

2 of distilled water per day, and for the fixed mode it was 5.6 kg/m

2 per day. However, the results indicated that the productivity of the distilled water from the rotating mode was about 64% more than that from the fixed mode system.

Alternatively, a pyramid wick-type solar still was tested by Prakash et al. [

20] who concluded that integrating an inclined solar still with a pyramid solar still increased the yield of distilled water by 17.68% compared to the conventional still. The experimental results showed an average efficiency that equals 50.25% and a distilled water productivity of 5.25 kg/m

2 per day. Dhurwey et al. [

21] performed an experimental investigation of a double-basin, double-slope, stepped solar still integrated with PCM for thermal storage. They achieved a daily productivity of 4.6 kg/m

2 per day of distilled water and a thermal efficiency that equals 27.21%. In recent studies, a lot of researchers have focused on the ternary strategies involving organic photovoltaic cells which seized the attention of the research community [

22,

23,

24]. Some other works concentrated on donor-acceptor interactions, which were also found to be very interesting [

25,

26,

27].

3. Methodology

The multi-effect solar still (MES) has a stack of multiple layers for evaporation and condensation. The latent heat dissipated during condensation at the front layers is repeatedly recycled for evaporation at the back layers to increase the overall efficiency of the desalination process. Despite its proven efficiency and long history, the MES has not yet been widely used, because of its relatively high-capital cost. Here, the study presents a micro solar still (MSS) system that has a simplistic design, is lightweight and developed by integrating locally available cheaper materials. The design uses an effective latent heat transfer material made of black dyed polyester fabric laminated to a polyethylene terephthalate film (PET) in the shape of an origami structure. Two different prototypes were developed and tested outdoors in Kuwait under harsh climate conditions.

- (1)

Prototype development

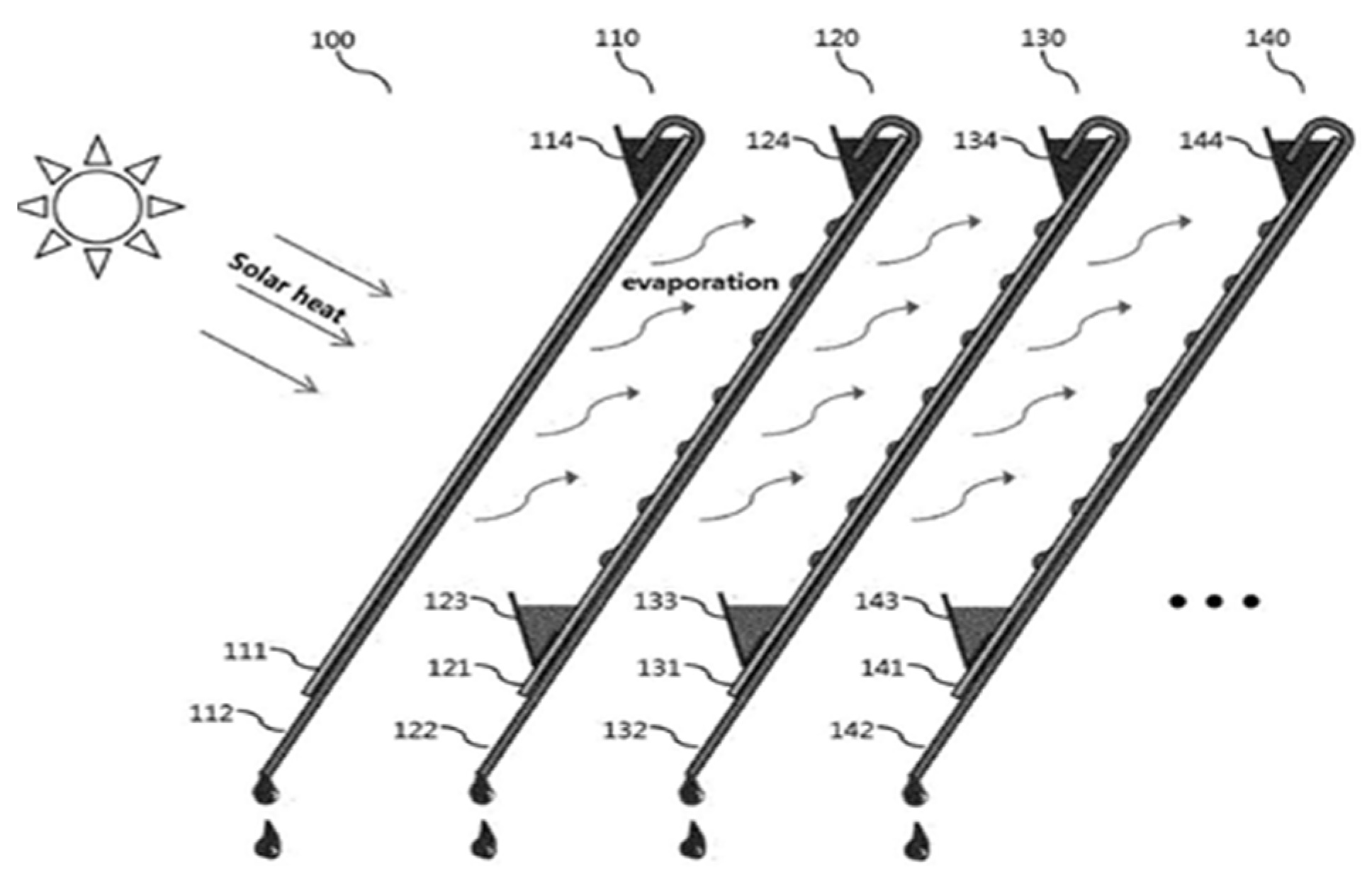

A multi-effect passive micro solar still (MSS) was developed, as shown in

Figure 1. It consists of multiple chambers or plates that are tilted at a certain angle for the distillation process. These plates are stacked one against the other, and are tightly packed in windows that receive passing sunlight; the structure is designed to prevent vapor leakage. The entire solar still unit was tilted at 55°, as shown in

Figure 1, to allow for optimum sunlight exposure based on a pyranometer to measure irradiance.The shading test was conducted using the Solmetric SunEye device at the location shown in

Figure 2, to maintain an appropriate level of water flow. The surface facing the glass solar collector of each plate serves as the evaporator, and the other surface, adjacent to the other plate, acts as the condenser. Each such evaporator–condenser element is considered as an effect, with respect to desalination processes, where each effect contributes to the overall recovery of the product. The MSS is typically fitted with the feed-water tank and feed trough at the top for allowing feed water to flow over the evaporating surface. The feed flow rate must be limited to avoid flooding the evaporating surface in order to maximize the efficiency of the device. The condenser surface is provided with a distillate trough at the bottom to collect the distillate. The evaporation of feed water occurs on the evaporating surface, and the movement of vapors toward the condensing surface occurs due to the partial pressure difference between the evaporator and condenser surface. The vapor generated is condensed over the condenser surface, such that the latent heat of the condensation is released to the next effect, which helps in the occurrence of enhanced evaporation in the next effect. The distillate is collected using distillate troughs; and the unevaporated brine exits the evaporator surface as waste.

The origami structure of the wick/condenser layer of the proposed MSS, which makes it unique, includes the evaporation wick (A), condensing surface (B), saline water feeding trough (or pocket) (C), condensed fresh water guiding channel (D), and draining guide that separates fresh water from waste water (F) (

Figure 3).

- (2)

Instrumentation and lab testing

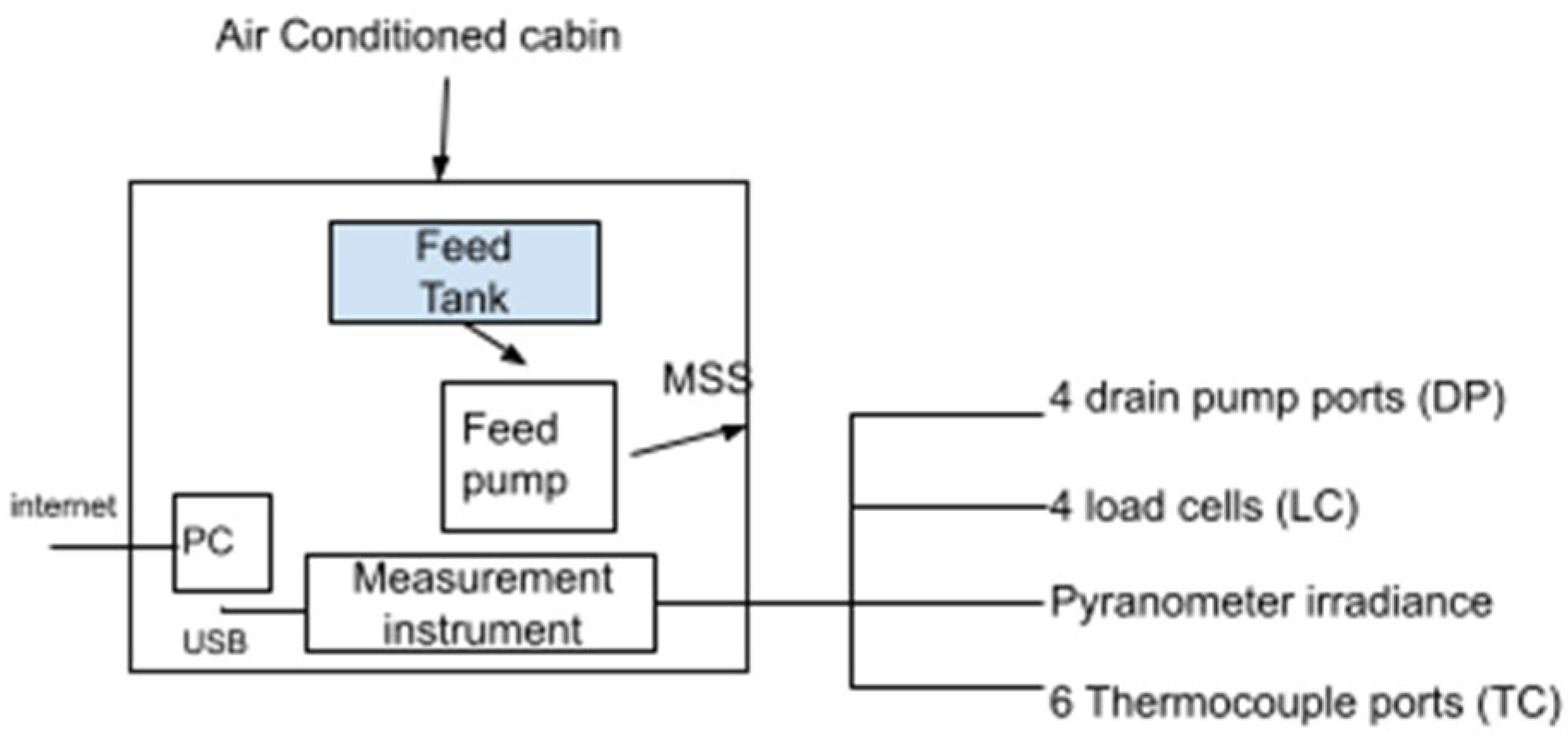

The assembled prototype along with other necessary equipment (i.e., sensors, data logger, etc.) was installed and tested in the laboratory of the Kuwait Institute for Scientific Research (KISR) prior to field deployment (

Figure 4). All the sensors and data-logging equipment were calibrated in the laboratory and for data acquisition during the field trials of the prototype.

Figure 5 shows the instrumentation and control drawings, while

Figure 6 and

Figure 7 show the side and front views of the prototype.

- (3)

Test site preparation

The test site for installing the MSS prototypes was located in the KISR premises, north of the main building, as shown in

Figure 2. The potential of any shading was measured using a Solmetric SunEye device [

28]. The location was physically prepared for installing the system, including the preparation of suitable foundations and the installation of feed water and discharge tanks, an electrical power supply and internet connectivity to ensure data acquisition.

Prototype deployment

- a.

Prototype Installation

The device was set up on a metal frame with a 55° tilt to maximize solar irradiance. The device was fitted with an irradiance sensor along with three temperature sensors on each layer corresponding to the inlet, middle and outlet of the device. The feed volume was controlled by a small peristaltic pump with a feedback controller based on the temperature data. The brine and product outlets were each separately connected to a 20-l container placed upon a scale to collect weight data to evaluate the performance of the proposed solar stills, as the main performance indicator. High-resolution data ranging between 20 s and 30 s for different parameters of the prototype were collected using a data logger between 5:00 a.m. and 8:00 p.m. The prototypes were monitored regularly via the remote access software TeamViewer [

29]. A list of sensors and kits used for data acquisition is presented in

Table 1. The MSS setup is shown in

Figure 8.

- b.

Prototype operation

Feed water was provided from a beach well-designed to filter the seawater from large particulates as a pre-treatment. The feed was then fed to the peristaltic pump, and a control program was designed and initiated to control and monitor the process as well as record data.

The operation of the prototype is assumed to be fairly simple, as long as no problems occur within the device, because the production response lags an hour behind the temperature rise. The experiment was designed to test the MSS technology’s performance in the arid seaside conditions of Kuwait.

- (4)

Water quality testing

Three water samples (product, feed and brine) were taken from the two tested prototypes for laboratory analysis. The samples were analyzed following the methods described in APHA’s Standard Methods for the Examination of Water and Wastewater (APHA 2015). Four major cations and anions were analyzed using an ion chromatograph (ASTM D6919-09 and SMEWW Method No. 4110). The total coliform and E.coli were analyzed using an enzyme substrate technique, the most probable number (MPN) method (SMEWW Method No. 9222) [

30], in the Water Research Centre laboratory at KISR, and results were compared with the standards of the World Health Organization (WHO) [

31].

4. Results and Discussion

- (1)

Prototype development

A total of two prototypes were trialed, and the necessary improvements carried out in the first one informed the design and operation of the second one—with optimum performance. Prototype-1 held a new skid platform that was designed for this MSS by the KISR team. All components were assembled and mounted on the new skid. This prototype functioned well as expected for one month. After this period, it started failing as the data logger experienced a malfunction around noon. This may be attributed to the high temperature in the cabin. Spot sample checks revealed high total dissolved solid (TDS) content. The product, brine and feed channels were found to be damaged, resulting in fluid mixing. Furthermore, a sandstorm that occurred during the trial period caused more damage, particularly as dust accumulated in the prototype’s side apertures, making it difficult to clean them or remove the dust.

All the issues with prototype-1 and the lessons learned along with the solutions led to the design of prototype-2, which was installed on 5 June 2022. This prototype worked well except for on few occasions when air bubble accumulations occurred in the feed line. However, this problem was resolved, and the flow appeared to have improved once the line was cleared and straightened.

The data collected during these experiments in the harsh weather conditions in Kuwait indicated that raising the treatment capacity of the device posed a challenge to the current design of the prototype, and the device malfunction rate increased drastically in the summer, where peak temperatures ranged between 45 and 50 °C. The high temperatures and the high salinity of the seawater caused scaling and blockages within the device, which fouled the product by mixing it with the brine.

- (2)

Prototype performance

Prototype-1 was able to achieve recovery rates of up to 22%;

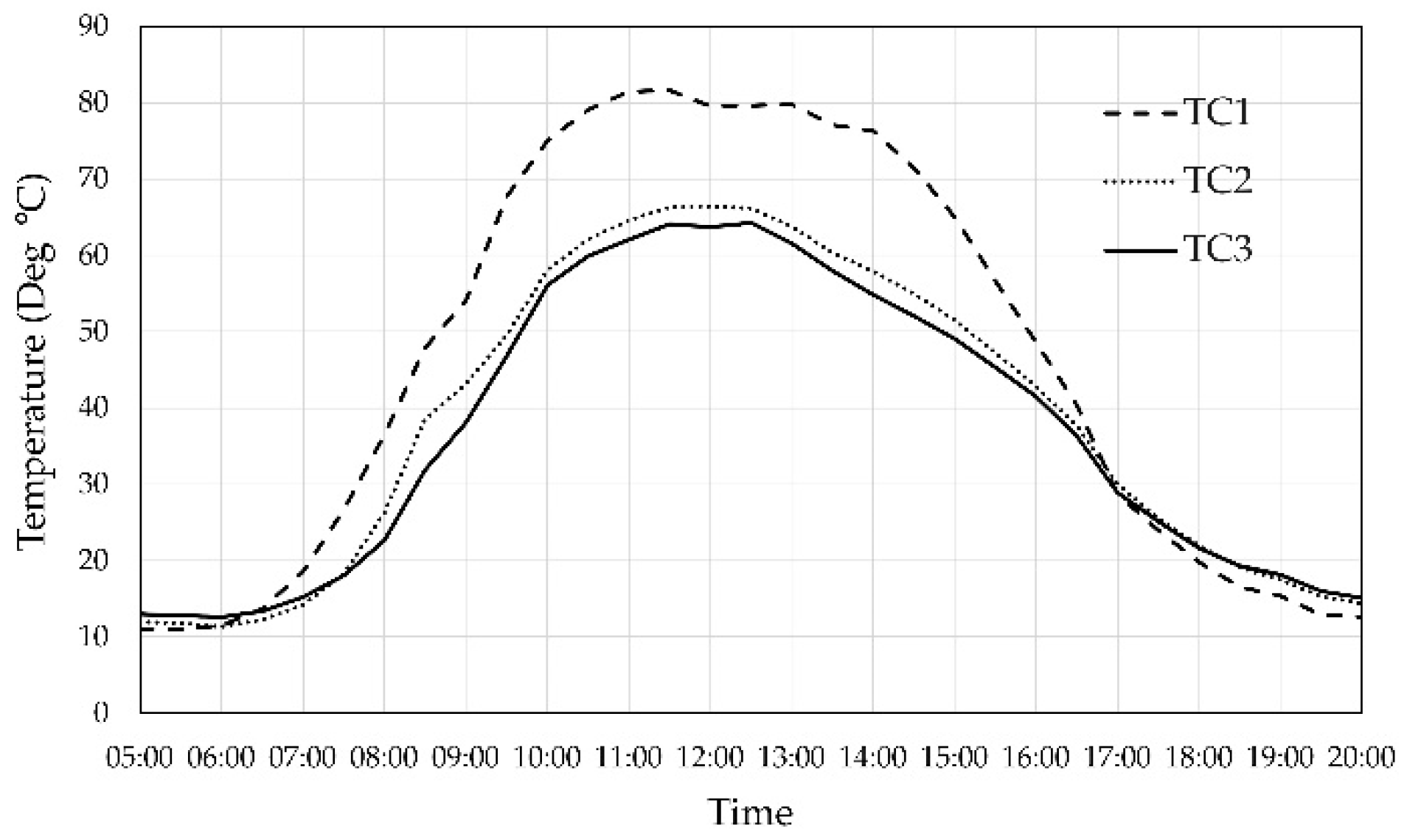

Figure 9 shows that the production rate reached its peak point in correlation with irradiance and temperature.

Figure 10 shows the temperature measured inside the device. The recovery rate was calculated at 15:30 p.m. by dividing the total product by the total feed. The production stopped at this time. However, the vapor inside the device needed time to condense, which caused the production to continue until 16:00 p.m. at which point production stopped completely. A total feed of 4 kg was used for the experiment to produce 900 g of product. The temperature inside the device was recorded, as shown in

Figure 9, as documented by Thermocouples 1, 2 and 3 (TC 1,2,3).

- 2.2.

Prototype-2

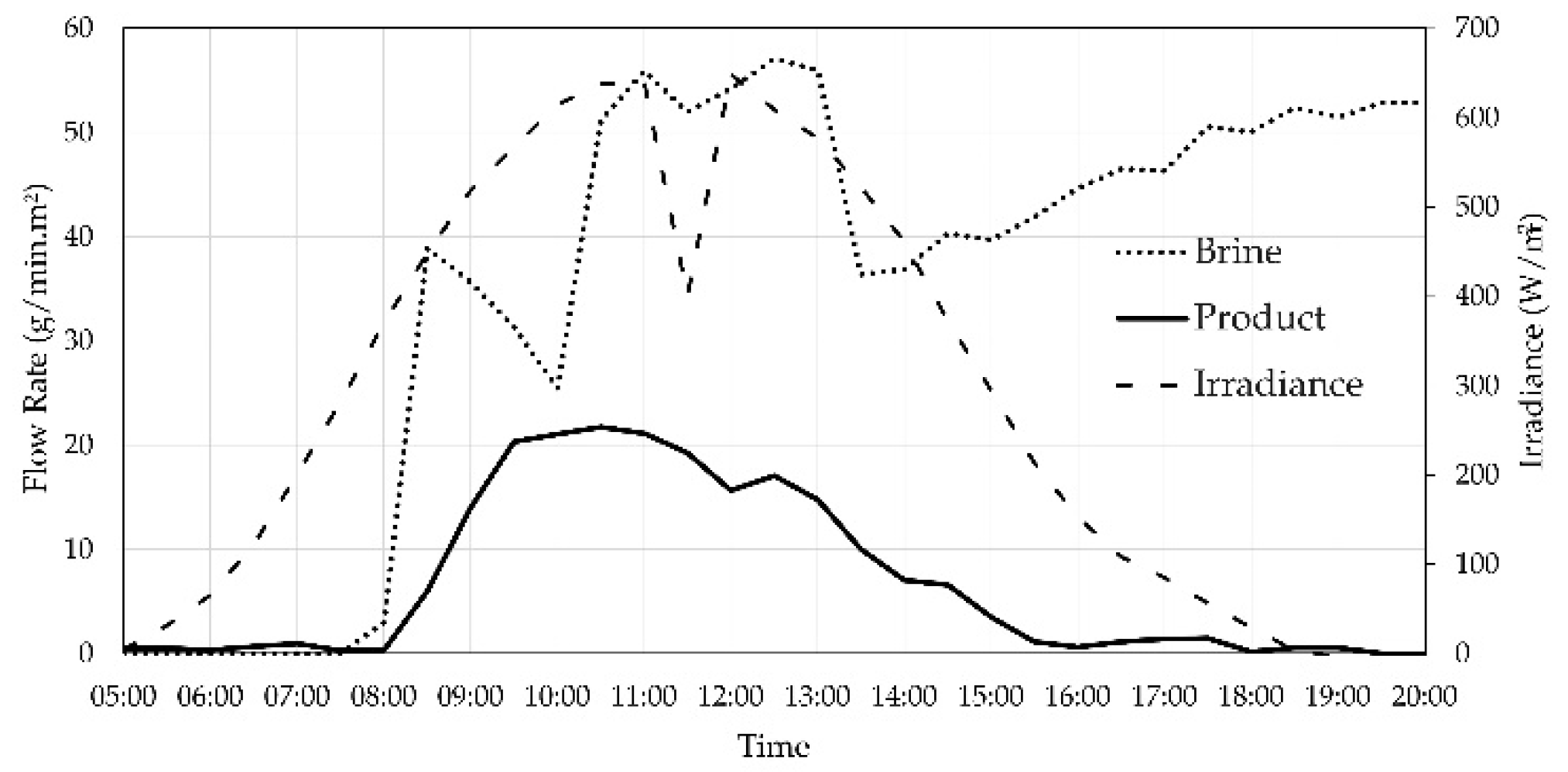

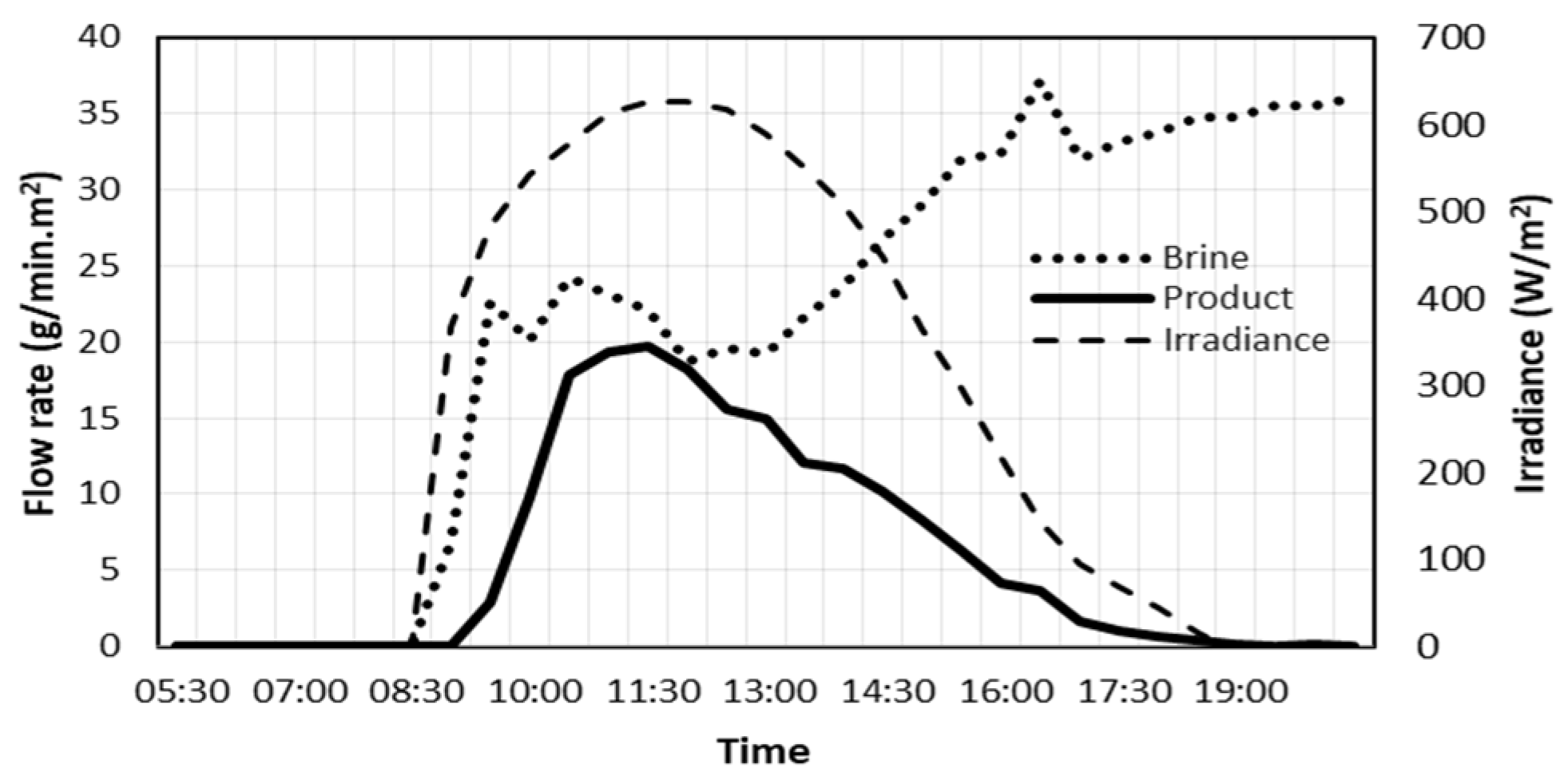

Prototype-2 was able to achieve a recovery rate of up to 25%, as shown in

Figure 11. The data suggests an operating window between 9 a.m. and 15:00 p.m., where the device had a capacity of 5 kg, and produced 1.2 kg of fresh water (

Figure 11). The trend displayed is typical of the device during a clear summer day. Water production stopped at roughly 15:00 p.m., which coincides with irradiance dropping below 250 W/m

2. However, the product continued to condense until 17:00 due to the vapor trapped inside. Production peaked in the period between 9:00 and 13:00 p.m., which coincided with peak irradiance periods for the device (

Figure 11). The feed flow rate increased to compensate for the elevation in temperatures at peak irradiance (

Figure 12).

The irradiance data (

Figure 9 and

Figure 11) showed that the peak irradiance during April was higher than that in June. However, prototype-2 produced more water at a higher recovery rate, indicating the increase in efficiency and productivity of the MSS prototype. This is attributed to the improved sealing of the device, as well as an improved origami structure for the wicking material, which allowed for the increase in feed rate. The increase in the available wicking surface contributes to an increase in vapor production.

Figure 11 represents an average day for prototype-2. The best operational results are represented in

Figure 13 and

Figure 14.

- (3)

Water quality results

From prototype-1, two batches of samples were collected on 22 March 2022, and 26 May 2022. The results of the first batch sample indicated that the newly installed prototype produced fresh water with a TDS level of 470 mg/L (

Table 2). The latter sample illustrated some issues with the product water; it showed a very high TDS value of 2920 mg/L (

Table 3). Moreover, upon the collection of the sample, it was noted that the color of the brine water was yellowish, which was unusual.

The water quality analysis from prototype-2 was performed with samples collected on 14 June 2022. The results showed an acceptable level of TDS 348 mg/L (

Table 4). Later, a portable conductivity meter was used to ensure the quality of the product. The quality of the product started to deteriorate on 18 July 2022. This indicated that the experiment had to be terminated due to the device being unable to produce an acceptable quality of product water.

The results were also compared with WHO standards and found to be acceptable (

Figure 15).

- (4)

Discussion

Prototype-1 functioned as expected, achieving a recovery percentage comparable to other MSS designs documented in the literature (22% recovery). The flow rate was manipulated to correlate with solar irradiance. The experimental setup malfunctioned at a high frequency due to the high salinity and flow rate of the feed. This caused the scales to stop functioning as multiple pumps designed to empty the waste tanks failed repeatedly. Although this caused challenges in the operation and in data acquisition, it provided ample learning to upgrade the experiment and improve the maintenance routine for the next prototype.

- 4.2.

Prototype-2

Prototype-2 had improved sealing to prevent dust from entering the device, an improved experimental setup (larger waste tanks and more regular maintenance) and an additional layer of wicking material in the origami structure. This prototype achieved a higher recovery percentage of 25% on average. The prototype was capable of achieving a recovery rate of 33% using a similar operation window. However, if the operation window is extended an extra hour, as shown in

Figure 13, the recovery rate could be maintained at 30% and the capacity increased to treat 3.7 L of water, producing 1.1 L of potable water. The flow rate was manipulated to increase at peak temperatures to improve production (

Figure 11). It was found that increasing the feed flow rate at peak irradiance increased the capacity of the device and improved the recovery rate (

Figure 13). However, if the flow rate was increased too drastically, the wick flooded and was unable to perform its desired function. The maximum limit was found to be 20 mL/min of feed. Prototype-2 was exposed to a lower peak irradiance than Prototype-1 and yet achieved consistently higher recovery rates. The device was perfectly operational until the middle of July and then deformed, resulting in a product of lower quality. The lifetime of this prototype device during the summer season was drastically shortened. The increase in recovery is attributed mainly to the added layer to the origami structure, which increased the surface area of the wick. It was also found that providing a continuous flow of feed water, even during the downtime of the device, extended the lifetime of the device due to the origami structure maintaining function for a longer duration.