Abstract

Chemical flooding plays an important role in enhancing oil recovery due to many reasons, including the viscosity-increment effect of polymer, wettability alteration effect of surfactant, and the formation of emulsions, which have been known to effectively increase the swept area and oil displacement efficiency, hence increasing heavy oil recovery. Laboratory tests and pilot trials of alkali–surfactant–polymer (ASP) injection show that the oil recovery of the emulsified system is 5% more than the cases where no emulsions existed. Therefore, it is of great significance to study heavy oil emulsions and its field application for enhanced heavy oil recovery. This paper discusses a thorough overview of the most fundamental ASP flooding mechanisms, along with some examples of laboratory experiments and field trials. In addition, the formation conditions and the interfacial characteristics of heavy oil emulsions are also discussed, mainly ASP flooding, and then the seepage mechanisms of these emulsions are investigated. The relationship between the formation of heavy oil emulsions and the enhanced heavy oil recovery effect by chemical flooding is discussed through core flooding experiments at the reservoir temperature and some field pilots to reach the optimum heavy oil recovery.

1. Introduction

Unconventional reservoirs come in many different forms, such as heavy oil, bitumen, or oil sand reservoirs [1]. Many studies have proved that using the thermal EOR techniques acquired thus far, excellent results are to be expected for heavy oil recovery. However, there are also some unfavorable conditions, such as thin pay zone and deep reservoirs, which make it impossible to apply these techniques in some reservoirs due to significant heat losses [2]. The waterflooding technique has also been applied, but the large difference between the viscosity of heavy oil and water results in the appearance of viscous fingering [3], which causes early water breakthrough and a low oil recovery rate after breakthrough. Considering this, many researchers have turned to chemical EOR techniques as a viable substitute method to improve the swept area and the recovery of oil compared to water injection in heavy oil reservoirs [4,5,6,7].

Chemical flooding or chemical EOR (CEOR) is a nonthermal EOR [8] method that injects chemical agents diluted with water slug into the reservoir formation to change the interactions occurring among the injected solutions, reservoir fluids, and formation rocks and, hence, increase the overall recovery of crude oil. This technique is one of the most prominent EOR techniques due to its increased effectiveness and technical and economic viability (affordable cost). Polymer, surfactant, and alkaline flooding are the three traditional CEOR methods, also known as conventional CEOR methods, which, despite being cost-effective and having advantages in some cases, still have major demerits and several limitations, such as polymer’s low tolerance of high salinity and temperatures, which significantly affects its mechanism, increasing the viscosity of the displacing fluids to control the mobility and surfactant/alkali adsorption phenomena, which reduces the efficiency of the flow of these chemical agents during reservoir formation [9,10]. As a result, many studies have increasingly focused on different binary mixes, i.e., alkali–polymer (AP), alkali–surfactant (AS), and surfactant–polymer (SP), and ternary mixes, i.e., alkali–surfactant–polymer (ASP), of chemical agents as substitute solutions for traditional CEOR techniques [11,12]. Now, since ASP flooding is considered the most prominent CEOR method, which outperforms other A/S/P combinations due to its synergistic mechanisms of the combined chemical agents, we focus our study on the components of ASP flooding, individually and combined.

Alkaline–surfactant–polymer (ASP) flooding [12,13,14], which is one of the most viable chemical EOR techniques, has been widely studied in the last two decades. Based on the results of several tests and experiments, i.e., core flooding, pilot tests, and field-wide flooding, which were mostly conducted in China and the USA, the ASP method as an EOR for heavy oil is superior than alkaline–polymer (AP), polymer flooding, or any other chemical EOR method [15]. Several published studies indicate that many EOR mechanisms might be at work during ASP flooding, but only four main mechanisms have been widely used for design purposes and modeling as the reasons behind improving the heavy oil recovery [16]:

- Improving the mobility ratio between the heavy oil and the displacing phase.

- Lowering the interfacial tension between oil and water (IFT).

- Altering the rock wettability (oil-wet to water-wet).

- Emulsifying oil and water.

The constant development of new ASP EOR technologies [17] along with the advances in the production of new surfactant types (better and cheaper) have brought the attention back to chemical floodings as a very promising EOR method, especially to boost oil production in mature and water-flooded fields. Several research works are being carried out worldwide on the ASP flooding process simultaneously with numerous active ASP flooding projects, such as ASP flooding implementation at the Daqing field in China [18,19]. However, several disadvantages were identified during the implementation process of the ASP flooding technology, such as a low injectivity due to complete plugging of injection wells, polymer degradation, and unfavorable mobility control [20,21]. Laboratory tests and pilot trials of alkali–surfactant–polymer (ASP) injection showed that the oil recovery of the emulsified system is 5% more than the cases where no emulsions existed. Therefore, this research emphasizes how to enhance the results of emulsions in chemical injection [22,23]. Furthermore, the topic of stable emulsions, i.e., Pickering emulsions [24], has recently become a hot topic in which nanoparticles are used to enhance the stability of emulsions (better heat resistance and stable viscosity) so that heavy oil emulsions have greater applicability in optimizing the recovery of heavy oil [25]. On the other hand, unstable emulsions have a negative effect on oil recovery [26], but unfortunately, there is a lack of studies on this phenomenon. Therefore, it is necessary to conduct extensive research on the impacts of unstable emulsions on oil recovery, such as the type of emulsifiers. One of the main aspects that should be prioritized is highlighting the seepage mechanisms of heavy oil emulsions with various droplet sizes in pore throats, which play different roles in improving the oil recovery due to its complexity and the lack of attention given to it. Another aspect is the development of new chemical flooding technologies with environmental protection, i.e., low oil pollution and damage.

In this regard, the related literature on the seepage mechanisms of heavy oil emulations during chemical flooding is comprehensively reviewed to gain a wide understanding of the seepage mechanisms of heavy oil emulsions. Therefore, this paper focuses on reviewing the fundamental mechanisms of the three components of ASP flooding, individually and synergically, along with the results of some field trials using ASP flooding. This review also highlights the formation conditions, interfacial characteristics, and seepage mechanisms of heavy oil emulsions during ASP flooding. Additionally, the existence of heavy oil emulsions is connected with EOR chemical methods by identifying their impact on enhancing heavy oil recovery.

2. ASP Flooding Mechanisms

The alkaline–surfactant–polymer (ASP) flooding technology consists of a mixture of chemicals and methods that is used to optimize the recovery of heavy oil [10]. The scenario of how this technique works is manifested in the main mechanisms of ASP flooding. Therefore, before presenting the interactions and synergy of ASP, the main mechanisms of each component are first discussed individually.

2.1. Polymer Flooding Mechanisms

Polymer flooding is an EOR technique in which a high-viscosity polymer solution is injected into the formation to reduce the mobility ratio, increase the swept volume, and, hence, improve the oil recovery [27]. In other words, polymer injection is similar to waterflooding except that the polymer is diluted in water to increase the viscosity of the solution [28]. Consequently, increasing the viscosity of the polymer slug widens the swept area by preventing viscous fingering [29]. Over the past decade, many studies have focused on polymer flooding and how it works under different conditions. Through those studies, some common traits have been observed during and after polymer flooding, which were later considered the fundamental working mechanisms of polymer flooding.

The oil displacement mechanism of polymer flooding is directed more toward expanding the sweep efficiency [30,31,32,33] by reducing the mobility ratio M, the ratio of the mobility of the displacing fluid (mainly water) to the mobility of the displaced fluid (mainly oil). According to the definition of the mobility ratio, there are two ways to reduce the mobility ratio: (1) increasing the viscosity of the displacement agent and (2) decreasing the relative permeability of the displacement agent. Currently, an increase in the viscosity is most commonly used in laboratories and oilfields.

After many extensive types of research, it was found that polymer viscoelastic behavior results in some mechanisms that enhance heavy oil recovery. Sheng et al. [34]. summarized four recovery mechanisms related to polymer viscoelasticity: (1) the pulling mechanism, (2) oil-thread flow mechanism, (3) stripping mechanism and (4) shear-thickening mechanism.

In summary, Table 1 contains the mechanisms that are reported to enhance oil recovery due to polymer injection [35].

Table 1.

Overview of the mechanisms reported to enhance oil recovery due to polymer injection.

2.2. Surfactant Flooding Mechanisms

Surfactants are generally used to overcome the immiscibility between water and oil by reducing the interfacial tension (IFT) between them and changing the wettability of the reservoir rocks to water-wet so that the seepage and, eventually, the recovery of the residual oil in the formation are enhanced. According to the nature of the hydrophilic head, surfactants can be classified into four main categories: anionic surfactants, cationic surfactants, non-ionic surfactants, and zwitterionic (amphoteric) surfactants [36,37].

As stated by previous studies, surfactants play an important role in affecting the process of oil recovery, which means that they have significant potential for chemical EOR applications. The effects of surfactants are generally linked to four main mechanisms: reduction in the interfacial tension, alteration of the wettability, and emulsification and foam generation, through which surfactants prove to be beneficial as a CEOR method.

2.3. Alkali Flooding Mechanisms

Alkaline (or caustic) flooding is a chemical method that can be used to increase the oil displacement efficiency and, consequently, more of the remaining oil can be produced [38]. The benefits of this process are based on the reaction between sodium hydroxide (NaOH) with the naturally occurring organic acids in crude oil, which results in soap production at the oil–water interface. In situ production of this type of surfactant results in a reduction in the interfacial tension (IFT) between oil and water. Alkaline basicity (pH) ranges from 8 to 14, where 14 is considered to be a very strong alkaline agent. The use of a strong alkali does not necessarily provide incremental oil recovery because the use of strong alkalis is more likely to result in a loss in production capacity and scaling problems [39].

2.4. ASP Flooding Synergy and Its EOR Applications

ASP flooding is a mixture technique that injects alkali (A), surfactant (S), and polymer (S) solutions into the reservoir formation to improve the exploitation of crude oil. After carrying out extensive studies, it was proved that the integrated synergistic mechanism of each component of the injected alkali–surfactant–polymer slugs is the main reason for the significant success of ASP injection and why it is regarded as the most prominent CEOR technique [10]. Chen et al. [40] conducted a laboratory experiment on several core samples to investigate the impact of the synergistic mechanisms of injecting a multi-component chemical system (ASP) on improving crude oil recovery compared to single-component (polymer, alkali, surfactant) and double-component chemical systems (AS, AP, SP). The results of these experiments showed that the injection of the multi-component chemical system (ASP) achieved the highest recovery percentage of crude oil compared to the other systems, which proves the effects of the contribution of the synergistic mechanisms within the ASP flooding components.

Now, to provide a deeper insight into ASP synergy, which makes it more efficient than other CEOR techniques, we investigate the potential effects of ASP components on the solution viscosity, IFT, and the amount of A/S/P adsorption [41]:

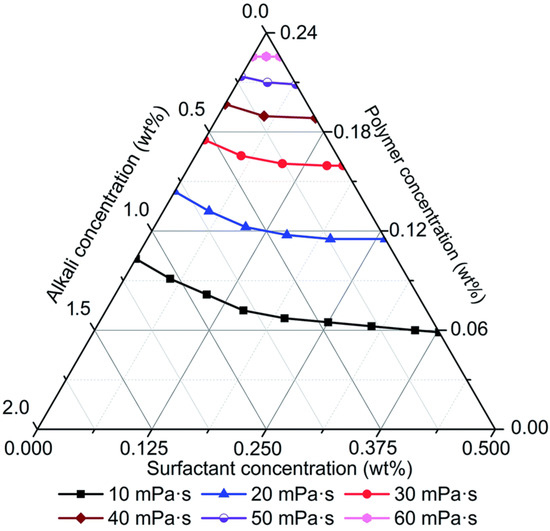

(1) The effects of ASP components on viscosity: The solution viscosity is primarily controlled by the amount of polymer followed by the alkali concentration and lastly, the surfactant concentration, as shown in Figure 1 [40].

Figure 1.

Effects of ASP components on viscosity.

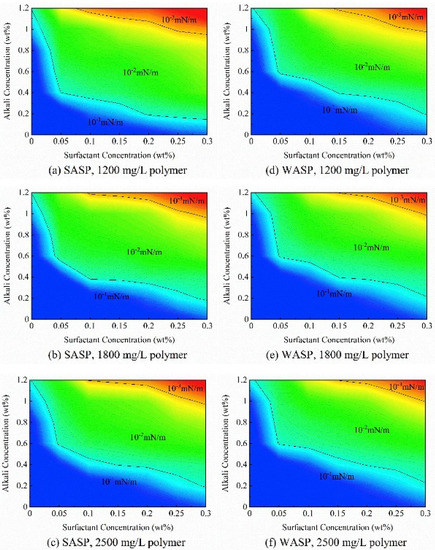

(2) The effects of ASP components on the interfacial tension (IFT): The surfactant is the primary component that controls the changes in IFT during ASP injection, followed by alkali and, finally, polymer, as shown in Figure 2.

Figure 2.

Effects of ASP components on IFT.

Field trials are considered to be essential for ASP flooding projects to move from the stage of laboratory experiments to the final stage of field applications. During the implementation of pilot tests, petroleum engineers should carry out proper measurements of the injection system, i.e., the injection mode and well pattern/spacing, to ensure the highest, most economic oil recovery is achieved under a certain set of conditions. According to several previous studies, 32 ASP flooding field trials have been reported so far worldwide, including 19 inshore projects in China, 7 inshore projects in the USA, 3 inshore projects in Canada, 2 inshore projects in India, and finally, one offshore project in Venezuela. The basic information of these projects is summarized in Table 2 [10,42,43,44,45,46,47,48,49,50,51,52,53,54].

Table 2.

Summary of recent ASP field trails.

3. Formation and Seepage Mechanism of Heavy Oil Emulsions

3.1. The Formation Conditions and Interfacial Characteristics of Heavy Oil Emulsions

The formation of heavy oil emulsions in a reservoir is a complicated physical and chemical process and is influenced by many factors, for instance, the structures of the formation’s pore throats, the reservoir wettability, the amount and distribution type of the residual oil, the properties of the reservoir’s crude oil, etc. Therefore, to obtain a better understanding of the formation of these emulsions and their stability factors, several studies and experiments, such as displacement experiments and microscopic visual core experiments, were used to analyze the flow behavior of heavy oil, especially residual oil, during waterflooding and chemical flooding and its relationship with the formation of emulsions, mainly O/W emulsions [55].

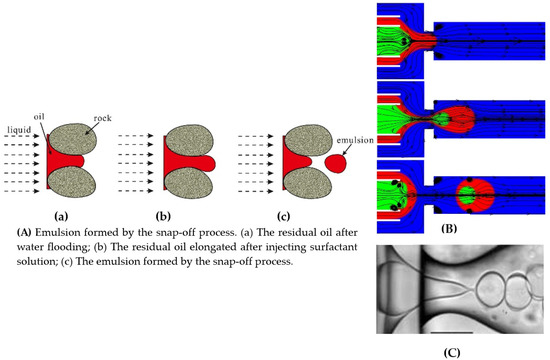

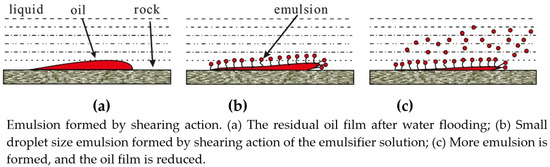

Based on the results of these studies and experiments, it can be concluded that the formation of O/W emulsions in reservoirs follows two mechanisms: the snap-off mechanism and the shearing mechanism, as shown in Figure 3 and Figure 4.

Figure 3.

The formation of O/W emulsions by the snap-off mechanism: (A) A schematic drawing of the snap-off mechanism. (B) Simulation of the snap-off mechanism by a ternary LBM. (C) An experiment image of the snap-off mechanism.

Figure 4.

The formation of O/W emulsions by the shearing mechanism.

Research on the interfacial features of heavy oil emulsion has mostly focused on IFT of heavy oil and its ingredients, such as the interfacial facial mask pressure, interfacial dilational viscoelasticity, and interfacial zeta potential of the simulated emulsion. Although IFT is one factor affecting heavy oil emulsion, it is not the main aspect controlling the stability of emulsions. The emulsion stability increases as IFT decreases. By adding a surfactant, IFT between water and oil can be reduced, the interfacial area can be maintained, the interfacial energy can be reduced, and the emulsion stability can be enhanced. When the surfactant and polymer exist at the same time, the time and speed of interfacial coalescence do not depend on the interfacial tension [56]. The oil–water interfacial film pressure is an important parameter that determines the stability of the crude oil emulsion and characterizes the properties of the interfacial film. The magnitude of the interfacial pressure can directly reflect the interfacial film toughness, that is, the greater the interfacial pressure, the more stable the emulsion. Research shows that the adsorption component of asphalt at the interface is mainly asphaltene, and the retention of asphaltene particles at the interface of water and oil is irreversible, which makes it one of the major elements that affects the stability of the crude oil emulsion [57]. In addition to the interfacial pressure, the interfacial viscosity can also be used as an important parameter to measure the properties of the interfacial film. Many studies have described the important role of the interfacial dilation viscoelasticity in the stability of an emulsion [58]. Additionally, the zeta potential is a key feature describing the emulsion stability. Its size reflects the electrification of oil beads. The greater the zeta potential, the steadier the emulsion [59].

3.2. Types and Properties of Heavy Oil Emulsions

Emulsions can be categorized into different types based on various criteria. In this section, we only study the types of heavy oil emulsions based on the criteria of their structures. Therefore, heavy oil emulsions can be divided into water-in-oil (W/O) emulsions, oil-in-water (O/W) emulsions, and multiple emulsions (W/O/W or O/W/O) [60].

Studies have shown that heavy oil emulsion is difficult to demulsify because it contains a large number of natural active substances in heavy oil, such as colloid, asphaltene, fatty acid, and solid particles. These surface-active substances are adsorbed at the oil–water interface. They change the strength of the facial mask and form a stable film around the droplets, which hinders the coalescence of water droplets and leads to the formation of a stable crude oil emulsion. Among the natural interface active substances in heavy oil, asphaltene has the strongest emulsifying ability and has the greatest impact on the stability of heavy oil emulsion. Therefore, the effects on the stability of W/O emulsions have been studied [61]. We can conclude that the stability of W/O emulsions is affected by natural emulsifying substances in two ways. One way is to “impede the interfacial film drainage to maintain the stability of the emulsion”, which is reflected in three roles: spatial position resistance, electro-viscous effect, and interfacial viscosity [62,63,64]. The other way is to “affect the interfacial film strength”. A natural emulsifier that is contained in the crude oil is adsorbed at the oil–water interface, forming a viscoelastic film with a certain strength. As the concentration of the natural emulsifiers increases, the molecules of the emulsifiers adsorbed at the interface increase, and the number of emulsified molecules adsorbed at the interface increases, which increases the strength of the film. Thus, the water droplets in crude oil are less likely to break as they collide with each other and the stability of W/O emulsions is improved.

For O/W heavy oil emulsions, the stability can be divided into static stability and dynamic stability. Static stability is achieved when the emulsion remains dispersed while standing, without stratification, flocculation, or oil–water separation. The dynamic stability of O/W emulsion simulates the stability and non-phase transformation of emulsions after undergoing strong shear action in the wellbore, pipeline transportation, and pump passing [65].

Regarding the research on the stability of emulsions, predecessors have paid more attention to the water in oil emulsion of crude oil while less research has been conducted on O/W heavy oil emulsion, especially the influence of the components of heavy oil on the stability of emulsions. Study of the oil–water interface properties is the basis of emulsion stability research. When studying the stability factors of water-in-oil emulsions, predecessors have separated the components of crude oil according to the polarity; studied the interface properties of gum, asphaltene, and other components; and obtained many meaningful results regarding other that can also affect the stability of heavy oil O/W emulsions [66], including the interfacial tension, oil–water interfacial film, influence of the interface charge, effect of viscosity, effect of temperature, stabilizing effect of polymers, settlement, droplet size, and change in the oil:water ratio.

3.3. Seepage Mechanisms of Heavy Oil Emulsions

Heavy oil is usually mined in the form of an emulsion, which proves the significance of studying the formation of emulsions, emulsion types, and displacement mechanisms of emulsions. Since it is difficult to imitate the system of heavy oil emulsions in the reservoir’s porous media, currently, research on the seepage characteristics of heavy oil emulsions has mainly focused on two aspects: the experimental method and the use of mathematical models of the seepage mechanisms.

The size of emulsion droplets and their distribution have significant importance in the study of the stability of heavy oil emulsions and their seepage mechanisms in porous media. Cartmill and Dickey (1969) conducted a series of experiments with a stable oil in water emulsion in order to study the seepage of emulsion in underground rock. They found that in porous media with high heterogeneity, a significant number of emulsion droplets are captured. Moreover, in the area with low permeability, the amount of emulsion droplets captured is large, which reduces the permeability of porous media. Their analysis shows that the permeability reduction is due to the capillary resistance and electrostatic attraction [67]. To obtain a better understanding of the permeability reduction caused by capillary resistance, another concept called the resistance factor (f) was introduced. The resistance factor f is defined as the ratio of the pressure drop at the pore throat (∆Pp) with that of water flow ∆Pw and is calculated as . If the emulsion droplet size is slightly larger than the pore throat, the droplets are trapped at the entrance of this throat, with f being larger than 1. As the injection pressure increases, the emulsion droplets eventually enter the pore throat when the resistance factor approaches 1. On the other hand, when the emulsion droplets are significantly larger than the pore throat, the resistance factor is very high, which is impossible to overcome. Therefore, after the application of high pressure on these droplets, they will eventually break down into smaller droplets and the resistance factor will experience a rapid reduction, allowing the smaller emulsion droplets to seep through the pore throat [68].

Since the pore throat of the porous medium of the reservoir rock stratum is in the order of microns, the diameter of the emulsion droplets is generally about the same size as the pores in the formation rock. Therefore, the seepage mechanisms of emulsions in the rock cores are very different from that studied by the traditional “deep filtration” theory. In the same emulsion system, droplets of different sizes are present at the same time, and the large and small droplets have different trapping abilities in the pore medium so that the separation of the large and small droplets occurs during the flow process as the percolation process proceeds. This separation of small and large droplets has been observed in the laboratory, but quantitative calculations of this effect are lacking so far. A general quantitative theoretical calculation of the retention of unstable particles and the separation of particles of different sizes is very difficult because the trapping capacity of a given size of particles strongly depends on the trapping capacity of other sizes of particles in the suspension. McAuliffe (1973 a, b) [69] studied the seepage of emulsions in porous media in the laboratory. The experimental results indicated that the O/W emulsions can trap inside the large pores, make solutions penetrate the small pores, improve the swept volume, and improve the oil recovery. He assumed that if the emulsion injected into the rock core can first enter an area with a large core permeability, the emulsion will restrict the flow of water in the area with a large core permeability, which will force the displacement fluid to flow into the area with a small core permeability, thus improving the swept volume. Based on these trapping abilities of heavy oil emulsions, there are two main blocking mechanisms of heavy oil emulsions in which large O/W emulsions tend to be trapped in the inlet of small pore throats and increase the flow resistance.

Regarding mathematical models, currently, there are three classic mathematical models that describe heavy oil emulsion seepage, including the bulk viscosity model [68], droplet retardation model, and filtration flow model. The bulk viscosity model views emulsions as non-Newtonian liquids that exist in one phase and flow through the pores in a similar manner to that of the polymer solution. Although this model is known for its consideration of various shear rates, it neglects the relationship between the size of the emulsion droplets and their flow through the pore throat. So, it is usually only used to predict the seepage behavior of tiny emulsion droplets or flows with high velocities. Emulsion is regarded as a two-phase fluid in the droplet retardation model, describing the additional resistance of the migrating emulsion droplets due to the blockage of smaller pore throats by large emulsion droplets. This model succeeds in determining the reduction of the permeability of the reservoir formation, whereas it fails to come up with similar results to the experimental results in other aspects. The filtration flow model is currently the most widely used model and is based on the theory of deep-bed filtration. Even though this model succeeds in describing the phenomenon of the retention of emulsion droplets in the pore throat and blockage, it fails to describe the pressure gradient drop, which means that it is unable to mimic the restarting of emulsion particles under a large pressure drop.

3.4. Nonlinear Flow Mechanics of Heavy Oil Emulsions

High-viscosity heavy oil shows the characteristics of non-Newtonian fluid in porous media [70]. The intricacy of the microstructure in the heavy oil system reflects the complexity and diversity of the rheological characteristics at the macro level, making it challenging to accurately represent the flow law with constitutive equations [71]. to investigate heavy oil, two main non-Newtonian fluid models are used: (1) Bingham fluid, which begins to flow as the fluid achieves the starting pressure gradient; and (2) power–law fluid, which illustrates that the viscosity of a fluid is reduced as the shear rate increases due to shear thinning [72]. To sum up, subsurface creation of a nonlinear seepage process of heavy oil occurs due to three main reasons: (1) Crude oil viscoelasticity and pseudoplasticity and high viscosity have the same significant impact on seepage; (2) the interaction between a porous medium and heavy oil exerts a blockage impact on seepage, such as the flow resistance caused by the existence of the boundary layer; and (3) irreversibility of pore compression: when the pressure drops, the pore compresses, the seepage channel decreases, and the flow conditions of the crude oil are dynamically changed.

In recent years, scholars have proposed many experimental methods for the development of heavy oil to measure the starting pressure gradient. Sun [73] showed that the flow characteristics of heavy oil depend on the critical temperature. The flow velocity of heavy oil above the critical temperature has a linear relationship with the pressure gradient, and the flow performance shows Darcy flow characteristics. The heavy oil below the critical temperature is characterized by a non-Darcy flow.

Based on the experimental research results, research on nonlinear seepage of heavy oil has also made some progress. Yun et al. [74] established a seepage model of Bingham fluid considering the starting pressure gradient based on the laws of heat transfer and material conservation. Luo et al. [75] studied the influence of the starting pressure gradient, viscosity, drainage radius, and other changes on the unsteady seepage of non-Newtonian fluid. Yao et al. [76] studied the seepage characteristics of heavy oil in pores, improved Hagen Poiseuille’s law, and clarified the role of seepage resistance. In 2015, many scholars established numerical simulation software to study the nonlinear seepage of heavy oil based on the above understanding and conducted targeted research on Bingham fluid power–law fluid and water drive heavy oil [77]. By deriving the well grid fluid dynamic coupling equation considering the variable starting pressure gradient, the stable simulation of non-Darcy seepage of heavy oil was realized. The existing research results on the nonlinear seepage law show that consideration of the starting pressure gradient of heavy oil produces additional seepage resistance in the water drive oil process, accelerates the formation of high-speed seepage channels, reduces the sweep efficiency of the water drive, intensifies the difference in the water oil mobility, makes the water phase fingering more serious, and, at the same time, in the longitudinal direction, the interlayer contradiction is more prominent. In general, the current research on the rheology of heavy oil is limited to non-Newtonian fluid models such as Bingham fluid, power–law fluid, and generalized Bingham fluid, and the nonlinear seepage law under the existence of starting pressure gradient has been studied.

4. The Impact of Heavy Oil Emulsions on Enhancing Heavy Oil Recovery

4.1. The Impact of Emulsion Formations and Properties on Heavy Oil Recovery

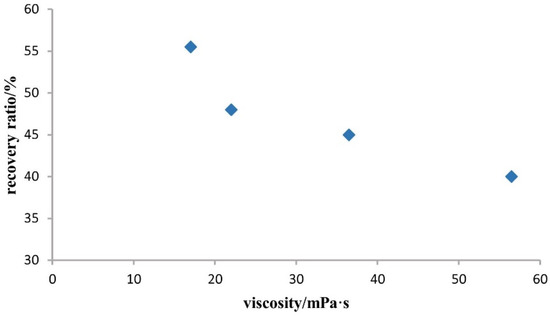

Wang et al. [78] experimentally studied the effect of emulsions on the viscosity of heavy oil. An experiment on the creation of heavy oil emulsions and viscosity reducers was carried out. The emulsification of different oil samples under different emulsifier volume fractions was investigated. As illustrated in Figure 5, it can be seen that the recovery factor differs under different oil viscosity, and the recovery factor tends to increase with the decrease in the oil viscosity.

Figure 5.

Heavy oil recovery under different viscosity.

The rheology of an emulsion affects its flow performance in the formation, production performance, and development effect. Most oil-in-water emulsions of crude oil are Newtonian fluid and a few are non-Newtonian fluid. The rheology of emulsions is related to the ambient temperature, internal phase volume fraction, internal phase particle size, and distribution, and the volume fraction of the internal phase is the main influencing factor. Pal [79] used a controlled-stress rheometer to experimentally investigate the rheology of high internal phase ration O/W emulsions. When the volume fraction of the inner phase is low, the pressure drop and flow velocity have a linear Darcy flow relationship. An increase in the volume fraction results in a deviation from the linear relationship and has the characteristics of shear thinning of non-Newtonian fluid. This critical rate is related to the volume percentage of the emulsions’ inner phase. Ali [80] studied the percolation law of oil-in-water emulsion in porous media. The oil-in-water emulsions with different internal phase concentrations were prepared by mixing crude oil and the surfactant system and then injecting it into cores with different permeability values (k = (90~1100) × 10−3 μm2) to conduct a seepage experiment. In the core samples with the same permeability values, the mobility gradually increased with the decrease in the internal phase concentration (heavy oil). Moreover, in the cores with the same permeability, the seepage viscosity decreased as the internal phase concentration decreased, and the reduction rate was more than 50%. The initial pressure gradient has a good power–law relationship with the permeability. With the decrease in the internal phase concentration, the power index gradually decreased, that is, the value of the initial pressure gradient gradually decreased, and the reduction rate was more than 60%. Therefore, it was concluded that the generation of O/W emulsion in the formation can reduce the initial pressure gradient of crude oil and reduce the seepage resistance to enhance the seepage rheology of formation crude oil and improve the recovery of heavy oil.

Different emulsion droplet sizes play different roles in the procedure of oil recovery. Small droplets increase the effective displacing force for all reservoirs (regardless of their wettability), whereas big droplets temporarily block the pore throat. It was proved that higher oil recovery in emulsions is due to the synergistic mechanism of small and big droplets. The emulsion droplets of locally generated crude oil emulsions become stuck in the pore medium, which can reduce the fluidity of water, improve the vertical or horizontal sweep area, and thus improve the crude oil recovery [81]. Early in the surfactant injection process, the volume fraction of the surfactant is high, and the generated emulsion is relatively stable. In the process of displacement, it preferentially enters the high-permeability zone. Because the inner-phase particles remain in the pore throats of the porous media, the absolute permeability of this area is reduced, the medium- and low-permeability layers can be started, and the swept volume of the displacement fluid is expanded. In addition, due to the loss of surfactant diffusion and adsorption, the volume fraction of the surfactant decreases, and the emulsion becomes unstable. The emulsified particles and the droplets of heavy oil come together to create an oil wall and are then recovered, which increases the seepage efficiency of the displacement fluid.

4.2. Parameter Design of ASP to Ensure Optimum Heavy Oil Recovery

For the optimization method, according to the orthogonal design method and the principle of fuzzy mathematics, on the basis of laboratory experiments and numerical simulation research, and comprehensively considering the influence of various technical and economic indexes, an optimization design model of the injection production parameters of composite flooding based on fuzzy comprehensive evaluation model is established. The key technologies involved in the optimization process include laboratory experimental research, orthogonal design, fuzzy comprehensive evaluation model, compound flooding numerical simulation, and compound flooding economic evaluation [82,83,84].

4.3. Studies of the Impact of Heavy Oil Emulsions on EOR

Table 3 shows many examples of the impact of heavy oil emulsions on improving the recovery of heavy oil, including experimental, numerical and field studies.

Table 3.

Studies on the effects of heavy oil emulsions on EOR [68,85,86,87,88,89,90,91,92,93,94].

With this, we prove that the emulsification phenomenon of heavy oil can increase heavy oil recovery as the heavy oil emulsion system improves the sweep efficiency by a combined set of actions carried out by the system solvent, when the emulsion droplets are much smaller than the pore throat, and the microemulsions (pore scale emulsions). Finally, even though emulsions can cause some issues, such as increasing the injection pressure and reducing the rate of liquid production, the merits of emulsions are still far greater than their demerits.

5. Field Application of Chemical Flooding in Heavy Oil Reservoirs

Currently, ASP flooding is still in the experimental laboratory stage. The design of field applications requires a full understanding of the above aspects. There are very few field test cases, and the most successful case is the field test at zone 7 of Gudong Oilfield. Therefore, to ensure optimum heavy oil recovery, the injection production parameters of composite flooding were optimized on the basis of laboratory experiment and numerical simulation research.

The test area is located at the Southern Ng54-61 layer of the West 7 Block of Gudong Oilfield. The oil layer depth is 1261~1294 m. There are three oil-bearing sublayers, with a pay zone area of 0.85 km2 and 218 × 104 t of geological reserves. The porosity and permeability are 34% and 1.32 μM2, respectively, with an effective pay thickness of 11.9 m. The coefficient of the variation of the permeability is 0.58, underground crude oil viscosity is 45 mPa·s, original oil saturation is 72%, and acid value of crude oil is 1.73 mg/g. At present, the salinity of the produced water is 7438 mg/L, pressure is 12.9 MPa, and temperature is 56 °C. There are nine injection wells, eighteen production wells, and one observation well in the test area. As of June 1998, the comprehensive water cut was 97.1%, recovery degree was 29.3%, remaining oil saturation was 47.6%, and ratio of injection production was 1.02. The water drive recovery was predicted to be 31.5% in the test area.

Based on this, laboratory tests and research were conducted, including interfacial tension tests, emulsification tests, adsorption loss tests, thermal stability tests, and oil displacement tests. The test oil was the simulated oil of Gudong 7-36-166 well (formation temperature 69 °C, crude oil viscosity 45 mPa·s). The test water was water produced from Gudong 7-36-135 well (Ca2+ and Mg2+ concentration is 148 mg/L, total salinity is 6871 mg/L) and the injected water was obtained from 44-1 metering station (Ca2+ and Mg2+ concentration is 276 mg/L, total salinity is 8246 mg/L). The test agents were Na2CO3 (alkali), 3530S (polymer), and petroleum sulfonate PS (surfactant). The oil displacement test model is the oil sand filling tubular model (the pipe diameter is 30 mm and the length is 300 mm). The composite system can reach ultra-low interfacial tension with the simulated oil, with a small adsorption capacity, good emulsification performance and thermal stability, and an obvious oil displacement effect. The optimization range of the concentration and dosage is as follows: the alkali concentration is 0.6~1.2%, surfactant concentration is 0.2~0.5%, polymer concentration is 0.11~0.17%, and pore volume multiple of the slug is 0.25~0.40.

In addition, optimization of the injection production parameters of composite flooding was conducted, mainly including optimization of the chemical agent combination mode, formula concentration, slug size, injection production speed, injection mode, and injection timing. Therefore, under the conditions of the other conditions being equal, seven schemes such as single alkali flooding(A), surfactant flooding (S), polymer flooding (P), alkali surfactant binary flooding (AS), alkali polymer binary flooding (AP), surfactant polymer binary flooding (SP), and alkali surfactant polymer ternary flooding (ASP) were compared and calculated. According to this comprehensive evaluation, it is concluded that ASP flooding is generally better than binary flooding while binary flooding is generally better than single chemical flooding. According to the laboratory test results, the horizontal value of the injection production parameters was obtained and the economic indexes of the L16 and l145 schemes were established, as shown in Table 4. As it can be seen from Table 4, 16 sets of economic simulation indexes were selected to evaluate the schemes. At the same time, the comprehensive evaluation value was obtained using the fuzzy comprehensive evaluation method.

Table 4.

Chemical concentration and slug optimization parameter values.

In order to investigate the sensitivity of various factors (injection production parameters) to the performance of oil recovery, a significance test (analysis of variance) was carried out to identify the sensitive factors. Comparison of the comprehensive evaluation values of the injection production parameters under different levels resulted in the following conclusions: The concentrations of the alkali, surfactant, polymer, and other chemical agents are compatible, and the optimal combination in the test area is 1.0% A + 0.3% S + 0.17% P. Considering the comprehensive factors of technology and economy, the slug size has an optimal value. The optimal value of the test area is 0.35 PV (PV is the pore volume). According to the optimization of the concentrations of the chemical agents and the slug size, 4 injection speeds of 1000~1300 m3/D were designed. The relationship between the injection time, water cut, and production volume was obtained according to the numerical simulation. By increasing the injection and production rate, the recovery degree was slightly increased, and the production time was significantly shortened. Therefore, an increase in the injection and production rate is conducive to enhancing the development effect and economic benefit. The preferred injection rate in this test area was 1300 m3/d. The injection mode of front (sacrificial) slug + main slug + rear (protective) slug was better than the single slug injection mode.

In summary, (1) the effects of the oil displacement of ASP injection are better than binary or single chemical flooding; (2) the composite flooding system has the best concentration ratio of alkali, surfactant, polymer, and slug size; (3) by increasing the injection and production rate, the economic benefit of the optimization scheme is improved, but it is limited by the injection capacity of the oilfield; (4) the three slug injection mode with a front sacrificial slug and rear protective slug is better than the single slug injection mode; (5) the injection timing should occur when the water cut stage is in the middle of block development. The optimal scheme is three slug injection (0.05 pv [1.2% a] + 0.3 pv [1% a + 0.3% s + 0.17% P] + 0.05 pv [0.13% P]), the predicted final recovery of which is 45.37%. The recovery increment is 13.87%, which is equivalent to the polymer injection utilization rate of 84.92 T/T, the average oil recovery rate is 1.32%, the internal rate of return after tax is 16.73%, the financial net present value after-tax is 13.13 million yuan, the investment payback period is 6.56 years, the investment profit rate is 31.29%, the investment profit and tax rate is 42.34%, and the comprehensive evaluation value is 0.9784 (the reagent cost is 74.8 million yuan when the crude oil price is 923 yuan/T).

6. Conclusions

This study presents a comprehensive review OF the seepage of heavy oil during chemical flooding, its mechanism for improving oil recovery, hybrid modes of injection that help to improve the sweep efficiency, laboratory experiments, and pilot and full-field applications. It was found that the synergistic mechanism of each component of the injected alkali–surfactant–polymer slugs is the major reason for the ASP injection’s significant success and why it is considered one of the most prominent CEOR techniques. Based on the structure of heavy oil emulsion, it can be categorized into three main types: W/O, O/W, and multi-emulsions, the stability of which relies on many factors, including IFT between heavy oil and water, the interface charges, heavy oil composition, viscosity, droplet size, and temperature. The emulsification phenomenon can increase heavy oil recovery as the heavy oil emulsion system improves the sweep efficiency by a combined set of actions carried out by the system solvent. Compared with crude oil, the rheology of emulsified heavy oil is significantly improved, and the mobility is more than two-fold higher than the mobility of heavy oil. With the decrease in the internal phase concentration, the increase in the mobility is greater, and the recovery efficiency of heavy oil is increased. The injection recovery parameters of the ASP composite injection can be enhanced using the orthogonal design method and fuzzy evaluation method. From other work, it was found that the time of injection is suitable for the middle water cut period of block development.

Author Contributions

Outline, structure, and guidance, X.W.; original draft preparation, F.W. and M.A.M.T.; Literature review, Z.W. and X.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

Abbreviations

| EOR | Enhanced Oil Recovery |

| CEOR | Chemical Enhanced Oil Recovery |

| ASP | Alkali–Surfactant–Polymer |

| AP | Alkali-Polymer |

| AS | Alkali-Surfactant |

| SP | Surfactant-Polymer |

| IFT | Interfacial Tension |

References

- Dastjerdi, A.M.; Ashoorian, S. Chemical enhanced oil recovery in unconventional reservoirs. Chem. Methods 2021, 433–459. [Google Scholar] [CrossRef]

- Popov, Y.; Chekhonin, E.; Parshin, A.; Law, D.H.-S.; Pissarenko, D.; Miklashevskiy, D.; Popov, E.; Spasennykh, M.; Safonov, S.; Romushkevich, R.; et al. Experimental investigations of spatial and temporal variations in rock thermal properties as necessary stage in thermal EOR. In Proceedings of the SPE Heavy Oil Conference, Calgary, AB, Canada, 11–13 June 2013; pp. 1135–1153. [Google Scholar] [CrossRef]

- Jamaloei, B.Y.; Kharrat, R.; Torabi, F. Analysis and Correlations of Viscous Fingering in Low-Tension Polymer Flooding in Heavy Oil Reservoirs. Energy Fuels 2010, 24, 6384–6392. [Google Scholar] [CrossRef]

- Fu, L.; Zhang, G.; Ge, J.; Liao, K.; Pei, H.; Jiang, P.; Li, X. Study on organic alkali-surfactant-polymer flooding for enhanced ordinary heavy oil recovery. Colloids Surf. A Physicochem. Eng. Asp. 2016, 508, 230–239. [Google Scholar] [CrossRef]

- Yu, Q.; Liu, Y.; Liang, S.; Tan, S.; Sun, Z.; Yu, Y. Experimental study on surface-active polymer flooding for enhanced oil recovery: A case study of Daqing placanticline oilfield, NE China. Pet. Explor. Dev. 2019, 46, 1206–1217. [Google Scholar] [CrossRef]

- Gbadamosi, A.O.; Junin, R.; Manan, M.A.; Yekeen, N.; Agi, A.; Oseh, J.O. Recent advances and prospects in polymeric nanofluids application for enhanced oil recovery. J. Ind. Eng. Chem. 2018, 66, 1–19. [Google Scholar] [CrossRef]

- Isaac, O.T.; Pu, H.; Oni, B.A.; Samson, F.A. Surfactants employed in conventional and unconventional reservoirs for enhanced oil recovery—A review. Energy Rep. 2022, 8, 2806–2830. [Google Scholar] [CrossRef]

- Mai, A.; Bryan, J.; Goodarzi, N.; Kantzas, A. Insights into Non-Thermal Recovery of Heavy Oil. J. Can. Pet. Technol. 2009, 48, 27–35. [Google Scholar] [CrossRef]

- Abidin, A.; Puspasari, T.; Nugroho, W. Polymers for Enhanced Oil Recovery Technology. Procedia Chem. 2012, 4, 11–16. [Google Scholar] [CrossRef]

- Olajire, A.A. Review of ASP EOR (alkaline surfactant polymer enhanced oil recovery) technology in the petroleum industry: Prospects and challenges. Energy 2014, 77, 963–982. [Google Scholar] [CrossRef]

- Kakati, A.; Bera, A.; Al-Yaseri, A. A review on advanced nanoparticle-induced polymer flooding for enhanced oil recovery. Chem. Eng. Sci. 2022, 262. [Google Scholar] [CrossRef]

- Kumar, D.; Lashari, N.; Ganat, T.; Abdalla Ayoub, M.; Ahmed Soomro, A.; Ali Chandio, T. A Review on Application of Nanoparticles in CEOR: Performance, Mechanisms, and Influencing Parameters. J. Mol. Liq. 2022, 353, 118821. [Google Scholar] [CrossRef]

- Nurxat, N.; Massachusetts Institute of Technology; Gussenov, I.; Tatykhanova, G.; Akhmedzhanov, T.; Kudaibergenov, S. Alkaline/Surfactant/Polymer (ASP) Flooding. Int. J. Biol. Chem. 2015, 8, 30–42. [Google Scholar] [CrossRef]

- Yang, P.; Li, Z.-A.; Xia, B.; Yuan, Y.-J.; Huang, Q.-T.; Liu, W.-L.; Cheng, C.-Y. Comprehensive review of Alkaline–Surfactant–Polymer (ASP)-Enhanced Oil Recovery (EOR). In Springer Series in Geomechanics and Geoengineering, Proceedings of the International Field Exploration and Development Conference 2017, Chengdu, China, 21–22 September 2017; Springer: Singapore, 2017; pp. 858–872. [Google Scholar] [CrossRef]

- Mandal, A. Chemical flood enhanced oil recovery: A review. Int. J. Oil Gas Coal Technol. 2015, 9, 241. [Google Scholar] [CrossRef]

- Numin, M.S.; Hassan, A.; Jumbri, K.; Ramli, A.; Borhan, N. Interfacial tension reduction mechanism by alkaline-surfactant-polymer at oil-water interface from experimental and molecular dynamics approaches. J. Mol. Liq. 2022, 356. [Google Scholar] [CrossRef]

- Ball, J.T.; Surkalo, H. A New Variation of Chemical EOR and its Economic Potential: The ASP Process. Energy Sources 1990, 12, 121–130. [Google Scholar] [CrossRef]

- Sun, L.; Wu, X.; Zhou, W.; Li, X.; Han, P. Technologies of enhancing oil recovery by chemical flooding in Daqing Oilfield, NE China. Pet. Explor. Dev. 2018, 45, 673–684. [Google Scholar] [CrossRef]

- Zhong, H.; He, Y.; Yang, E.; Bi, Y.; Yang, T. Modeling of microflow during viscoelastic polymer flooding in heterogenous reservoirs of Daqing Oilfield. J. Pet. Sci. Eng. 2021, 210, 110091. [Google Scholar] [CrossRef]

- Cheng, K. Chemical Consumption During Alkaline Flooding: A Comparative Evaluation. Soc. Pet. Eng. AIME 1986. [Google Scholar] [CrossRef]

- Dordzie, G.; Dejam, M. Enhanced oil recovery from fractured carbonate reservoirs using nanoparticles with low salinity water and surfactant: A review on experimental and simulation studies. Adv. Colloid Interface Sci. 2021, 293, 102449. [Google Scholar] [CrossRef]

- Guo, J.; Liu, Q.; Li, M.; Wu, Z.; Christy, A.A. The effect of alkali on crude oil/water interfacial properties and the stability of crude oil emulsions. Colloids Surf. A Physicochem. Eng. Asp. 2006, 273, 213–218. [Google Scholar] [CrossRef]

- Li, S.; Yang, Z.; Song, K.; Kang, W. Effect of Crude Oil Emulsion on Enhanced Oil Recovery in Alkaline Surfactant Polymer Flooding. Acta Pet. Sin. 2003, 24, 71–73. [Google Scholar] [CrossRef]

- Jiang, H.; Sheng, Y.; Ngai, T. Pickering emulsions: Versatility of colloidal particles and recent applications. Curr. Opin. Colloid Interface Sci. 2020, 49, 1–15. [Google Scholar] [CrossRef]

- Wei, B.; Ning, J.; Shang, J.; Pu, W. An experimental validation of a smart emulsion flooding for economic chemical EOR. In Proceedings of the SPE EOR Conference at Oil and Gas West Asia, Muscat, Oman, 21 March 2018. [Google Scholar] [CrossRef]

- Sarma, H.; Maini, B.; Jha, K. Evaluation of Emulsified Solvent Flooding for Heavy Oil Recovery. J. Can. Pet. Technol. 1998, 37. [Google Scholar] [CrossRef]

- Lu, X.; Cao, B.; Xie, K.; Cao, W.; Liu, Y.; Zhang, Y.; Wang, X.; Zhang, J. Enhanced oil recovery mechanisms of polymer flooding in a heterogeneous oil reservoir. Pet. Explor. Dev. 2021, 48, 169–178. [Google Scholar] [CrossRef]

- Asghari, K.; Nakutnyy, P. Experimental results of polymer flooding of heavy oil reservoirs. In Proceedings of the Canadian International Petroleum Conference, Calgary, AB, Canada, 17–19 June 2008. [Google Scholar] [CrossRef]

- Tang, M.; Zhang, G.; Ge, J.; Jiang, P.; Liu, Q.; Pei, H.; Chen, L. Investigation into the mechanisms of heavy oil recovery by novel alkaline flooding. Colloids Surf. A Physicochem. Eng. Asp. 2013, 421, 91–100. [Google Scholar] [CrossRef]

- Ping, P.; Shi, Y.; Bao, R.; Jie, S.; Kui, Y. Influence Factors of Oil Displacement Efficiency and Sweep Efficiency in Chemical Flooding. Pet. Explor. Dev. 2004, 31, 1–4. [Google Scholar] [CrossRef]

- Lan, Y.; Yang, Q.; Li, B. Experimental Research on Sweep Efficiency and Oil-Displacement Efficiency of Polymer Flooding. Acta Pet. Sin. 2006, 27, 64. [Google Scholar] [CrossRef]

- Zhu, Y.; Hou, Q.; Jian, G.; Ma, D.; Wang, Z. Current development and application of chemical combination flooding technique. Pet. Explor. Dev. 2013, 40, 96–103. [Google Scholar] [CrossRef]

- Tan, F.-Q.; Ma, C.-M.; Qin, J.-H.; Li, X.-K.; Liu, W.-T. Factors influencing oil recovery by surfactant–polymer flooding in conglomerate reservoirs and its quantitative calculation method. Pet. Sci. 2022, 19, 1198–1210. [Google Scholar] [CrossRef]

- Sheng, J.; Leonhardt, B.; Al Azri, N.S. Status of Polymer-Flooding Technology. J. Can. Pet. Technol. 2015, 54, 116–126. [Google Scholar] [CrossRef]

- Rock, A.; Hincapie, R.E.; Tahir, M.; Langanke, N.; Ganzer, L. On the Role of Polymer Viscoelasticity in Enhanced Oil Recovery: Extensive Laboratory Data and Review. Polymers 2020, 12, 2276. [Google Scholar] [CrossRef]

- Kume, G.; Gallotti, M.; Nunes, G. Review on Anionic/Cationic Surfactant Mixtures. J. Surfactants Deterg. 2007, 11, 1–11. [Google Scholar] [CrossRef]

- Borchardt, J.; Bright, D.; Dickson, M.; Wellington, S. Surfactants for CO2 foam flooding. In Proceedings of the SPE Annual Technical Conference and Exhibition, Las Vegas, NV, USA, 22–26 September 1985. [Google Scholar] [CrossRef]

- Khlaifat, A.L.; Dakhlallah, D.; Sufyan, F. A Critical Review of Alkaline Flooding: Mechanism, Hybrid Flooding Methods, Laboratory Work, Pilot Projects, and Field Applications. Energies 2022, 15, 3820. [Google Scholar] [CrossRef]

- Guo, H.; Li, Y.; Wang, F.; Gu, Y. Comparison of Strong-Alkali and Weak-Alkali ASP-Flooding Field Tests in Daqing Oil Field. SPE Prod. Oper. 2017, 33, 353–362. [Google Scholar] [CrossRef]

- Chen, F.; Gu, J.; Jiang, H.; Yao, X.; Li, Y. Laboratory evaluation and numerical simulation of the alkali–surfactant–polymer synergistic mechanism in chemical flooding. RSC Adv. 2018, 8, 26476–26487. [Google Scholar] [CrossRef]

- Li, J.; Niu, L.; Lu, X. Performance of ASP compound systems and effects on flooding efficiency. J. Pet. Sci. Eng. 2019, 178, 1178–1193. [Google Scholar] [CrossRef]

- Vargo, J.; Turner, J.; Vergnani, B.; Pitts, M.J.; Wyatt, K.; Surkalo, H.; Patterson, D. Alkaline-Surfactant-Polymer Flooding of the Cambridge Minnelusa Field. SPE Reserv. Eval. Eng. 2000, 3, 552–558. [Google Scholar] [CrossRef]

- Pitts, M.J.; Dowling, P.; Wyatt, K.; Surkalo, H.; Adams, K.C. Alkaline-surfactant-polymer flood of the tanner field. In Proceedings of the SPE/DOE Symposium on Improved Oil Recovery, Tulsa, OK, USA, 20 April 2006. [Google Scholar] [CrossRef]

- Seyler, B.; Grube, J.; Huff, B.; Webb, N.; Damico, J.; Blakley, C.; Madhavan, V.; Johanek, P.; Frailey, S. Reservoir Characterization of Bridgeport and Cypress Sandstones in Lawrence Field Illinois to Improve Petroleum Recovery by Alkaline-Surfactant-Polymer Flood; DOE Project DE-NT0005664; University of Illinois: Champaign, IL, USA, 2012. [Google Scholar] [CrossRef]

- Meyers, J.; Pitts, M.; Wyatt, K. Alkaline-Surfactant-Polymer flood of the West Kiehl, Minnelusa Unit. In Proceedings of the SPE/DOE Enhanced Oil Recovery Symposium, Tulsa, OK, USA, 22–24 April 1992. [Google Scholar] [CrossRef]

- French, T. Evaluation of the Sho-Vel-Tum Alkali-Surfactant-Polymer (ASP) Oil Recovery Project; DOE/SW/45030-1; National Petroleum Technology Office (NPTO): Tulsa, OK, USA, 1999. [Google Scholar]

- Charest, M. Alkaline-Surfactant-Polymer (ASP) Flooding in Alberta: Small Amounts of the Right Chemicals Can Make a Big Difference. Can. Discov. Dig. 2013, 1, 20–52. [Google Scholar]

- Pratap, M.; Gauma, M.S. Field implementation of Alkaline-Surfactant-Polymer (ASP) flooding: A maiden effort in India. In Proceedings of the SPE Asia Pacific Oil and Gas Conference and Exhibition, Perth, Australia, 18–20 October 2004. [Google Scholar] [CrossRef]

- Chang, H.; Zhang, Z.; Wang, Q.; Xu, Z.; Guo, Z.; Sun, H.; Cao, X.; Qiao, Q. Advances in Polymer Flooding and Alkaline/Surfactant/Polymer Processes as Developed and Applied in the People’s Republic of China. J. Pet. Technol. 2006, 58, 84–89. [Google Scholar] [CrossRef]

- Qi, Q.; Gu, H.; Li, D.; Dong, L. The pilot test of ASP combination flooding in Karamay oil field. In Proceedings of the International Oil and Gas Conference and Exhibition in China, Beijing, China, 7–10 November 2000. [Google Scholar] [CrossRef]

- Wang, C.; Wang, B.; Cao, X.; Li, H. Application and design of Alkaline-Surfactant-Polymer system to close well spacing pilot Gudong oilfield. In Proceedings of the SPE Western Regional Meeting, Long Beach, CA, USA, 25–27 June 1997. [Google Scholar] [CrossRef]

- Sheng, J.J. A comprehensive review of alkaline-surfactant-polymer (ASP) flooding. Asia-Pac. J. Chem. Eng. 2014, 9, 471–489. [Google Scholar] [CrossRef]

- Clara, H.; Larry, C.; Lorenzo, A.; Reinaldo, A.; Eduardo, M.; Eucario, R.; De Audemard, N.; Charles, C.; Hernández, C.; Chacon, L.; et al. Single well chemical tracer test to determine ASP injection efficiency at Lagomar VLA-6/9/21 Area, C4 Member, Lake Maracaibo, Venezuela. In Proceedings of the SPE/DOE Improved Oil Recovery Symposium, Tulsa, OK, USA, 14–18 April 2002. [Google Scholar] [CrossRef]

- Jiang, J.; Guo, D.; Li, X.; Zhao, P.; Wang, X.; Wu, X.; Li, G. Pilot Field Trial of Natural Mixed Carbox-ylates/Xanthan Flood at Well H5-15 Block in Huzhuangli Oil Field. Oilfield Chem. 2003, 1, 58–60. [Google Scholar] [CrossRef]

- Liu, J.; Zhong, L.; Ren, L.; Hao, T.; Wang, C.; Liu, Y.; Jiang, Y.; Zhou, Y. Laboratory Evaluation of Fluidity of Heavy Oil Emulsions in Formation Pores Medium. ACS Omega 2020, 6, 623–632. [Google Scholar] [CrossRef]

- Zhou, Y.; Wang, D.; Wang, Z.; Cao, R. The formation and viscoelasticity of pore-throat scale emulsion in porous media. Pet. Explor. Dev. 2017, 44, 111–118. [Google Scholar] [CrossRef]

- Izuchukwu, O.; Ayodele, T.O.; Abdullahi, G.S.B.; Joshua, D.; Olalekan, O. Visualization of heavy oil recovery processes using Hele-Shaw cell. In Proceedings of the Society of Petroleum Engineers SPE Nigeria Annual International Conference, Lagos, Nigeria, 5–7 August 2018. [Google Scholar] [CrossRef]

- Zhang, H.J. The Influence Faction to the Crude Oil Emulsion Stability. Adv. Mater. Res. 2012, 502, 330–334. [Google Scholar] [CrossRef]

- Dai, C.; Zhao, G.; You, Q.; Zhao, M.; Liu, Y.; Zhao, F. DPG soft heterogeneous combination flooding technology. In Theory and Technology of Multiscale Dispersed Particle Gel for In-Depth Profile Control; Elsevier: Amsterdam, The Netherlands, 2022; pp. 155–257. [Google Scholar] [CrossRef]

- Akbari, S.; Nour, A.H. Emulsion types, stability mechanisms and rheology: A review. Int. J. Innov. Res. Sci. Stud. 2018, 1, 11–17. [Google Scholar] [CrossRef]

- Da Silva, M.; Sad, C.M.; Pereira, L.B.; Corona, R.R.; Bassane, J.F.; dos Santos, F.D.; Neto, D.M.; Silva, S.R.; Castro, E.V.; Filgueiras, P.R. Study of the stability and homogeneity of water in oil emulsions of heavy oil. Fuel 2018, 226, 278–285. [Google Scholar] [CrossRef]

- Li, Y.; Chen, X.; Liu, Z.; Liu, R.; Liu, W.; Zhang, H. Effects of molecular structure of polymeric surfactant on its physico-chemical properties, percolation and enhanced oil recovery. J. Ind. Eng. Chem. 2021, 101, 165–177. [Google Scholar] [CrossRef]

- Kundu, P.; Kumar, V.; Mishra, I.M. Study the electro-viscous effect on stability and rheological behavior of surfactant-stabilized emulsions. J. Dispers. Sci. Technol. 2017, 39, 384–394. [Google Scholar] [CrossRef]

- Cao, C.; Gu, S.; Song, Z.; Xie, Z.; Chang, X.; Shen, P. The viscosifying behavior of W/O emulsion and its underlying mechanisms: Considering the interfacial adsorption of heavy components. Colloids Surf. A Physicochem. Eng. Asp. 2021, 632, 127794. [Google Scholar] [CrossRef]

- Griffith, C.; Daigle, H. A comparison of the static and dynamic stability of Pickering emulsions. Colloids Surf. A Physicochem. Eng. Asp. 2019, 586, 124256. [Google Scholar] [CrossRef]

- Sousa, A.M.; Matos, H.A.; Pereira, M.J. Properties of Crude Oil-in-Water and Water-in-Crude Oil Emulsions: A Critical Review. Ind. Eng. Chem. Res. 2021, 61, 1–20. [Google Scholar] [CrossRef]

- Chen, D.; Zhao, H.; Liu, K.; Huang, Y.; Li, B. The effect of emulsion and foam on anti-water coning during nitrogen foam injection in bottom-water reservoirs. J. Pet. Sci. Eng. 2020, 196, 107766. [Google Scholar] [CrossRef]

- Zhou, Y.; Yin, D.; Chen, W.; Liu, B.; Zhang, X. A comprehensive review of emulsion and its field application for enhanced oil recovery. Energy Sci. Eng. 2019, 7, 1046–1058. [Google Scholar] [CrossRef]

- Mandal, A.; Bera, A. Modeling of flow of oil-in-water emulsions through porous media. Pet. Sci. 2015, 12, 273–281. [Google Scholar] [CrossRef]

- Savins, J. Generalized Newtonian (Pseudoplastic) Flow in Stationary Pipes and Annuli. Trans. AIME 1958, 213, 325–332. [Google Scholar] [CrossRef]

- Bhatnagar, P.L. Comparative study of some constitutive equations characterising non-Newtonian fluids. Proc.-Math. Sci. 1967, 66, 342–352. [Google Scholar] [CrossRef]

- Wu, Y.-S.; Pruess, K. A numerical method for simulating non-Newtonian fluid flow and displacement in porous media. Adv. Water Resour. 1998, 21, 351–362. [Google Scholar] [CrossRef]

- Sun, J. Experimental Study on Single Phase Flow in Block Zheng 411 of Shengli Ultra Heavy Oil Reservior. Pet. Drill. Tech. 2011, 39, 86–90. [Google Scholar] [CrossRef]

- Wang, S.; Yu, B.; Zheng, Q.; Duan, Y.; Fang, Q. A fractal model for the starting pressure gradient for Bingham fluids in porous media embedded with randomly distributed fractal-like tree networks. Adv. Water Resour. 2011, 34, 1574–1580. [Google Scholar] [CrossRef]

- Luo, Y.; Cheng, L.; Huang, S. Mathematical Model for Transient Flow of Non-Newtonian Heavy Oil with Dynamic Radius and Variable Viscosity. Chin. J. Comput. Phys. 2011, 28, 869. [Google Scholar] [CrossRef]

- Yao, T.; Huang, Y.; Li, J. Nonlinear Flow Equations for Heavy Oil in Porous Media. Chin. J. Theor. Appl. Mech. 2012, 44, 106–110. [Google Scholar] [CrossRef]

- Liu, W.; Shi, G. Numerical Simulation Study of Heavy Oil Reservoir Steam Flooding Influencing Factors. Pet. Geol. Eng. 2014, 28, 106–109. [Google Scholar] [CrossRef]

- Wang, X.; Wang, X.; Lei, L.; Guo, Y.; Yang, Y.; Xu, Y.; Hao, H. Effect of in Situ Formed Emulsions on Enhanced Extra-Heavy Oil Recovery by Surfactant Flooding. IOP Conf. Ser. Earth Environ. Sci. 2021, 702, 012046. [Google Scholar] [CrossRef]

- Pal, R. Rheology of high internal phase ratio emulsions. Food Hydrocoll. 2006, 20, 997–1005. [Google Scholar] [CrossRef]

- Thomas, S.; Ali, S.F. Flow of emulsions in porous media, and potential for enhanced oil recovery. J. Pet. Sci. Eng. 1989, 3, 121–136. [Google Scholar] [CrossRef]

- Romero, L.; Ziritt, J.; Marín, A.; Rojas, F.; Mogollón, J.; Paz, E.M. Plugging of high permeability-fractured zones using emulsions. In Proceedings of the SPE/DOE Improved Oil Recovery Symposium, Tulsa, Oklahoma, 21–24 April 1996. [Google Scholar] [CrossRef]

- Guo, H.; Li, Y.; Li, Y.; Kong, D.; Li, B.; Wang, F. Lessons learned from ASP flooding tests in China. In Proceedings of the SPE Reservoir Characterization and Simulation Conference and Exhibition, Abu Dhabi, United Arab Emirates, 8–10 May 2017. [Google Scholar] [CrossRef]

- He, H.; Chen, Y.; Yu, Q.; Wen, X.; Liu, H. Optimization Design of Injection Strategy for Surfactant-Polymer Flooding Process in Heterogeneous Reservoir under Low Oil Prices. Energies 2019, 12, 3789. [Google Scholar] [CrossRef]

- Chen, G.; Tian, Y.; Zhao, X.; Li, X. Optimization of the ASP Flooding Injection Pattern for Sub-Layers in Daqing Oilfield. Acta Pet. Sin. 2012, 33, 459–464. [Google Scholar] [CrossRef]

- McAuliffe, C.D. Crude-Oil-Water Emulsions to Improve Fluid Flow in an Oil Reservoir. J. Pet. Technol. 1973, 25, 721–726. [Google Scholar] [CrossRef]

- Jiecheng, C.; Dianping, X.; Wenguang, B. Commercial ASP flood test in daqing oil field. In Proceedings of the Society of Petroleum Engineers 13th Abu Dhabi International Petroleum Exhibition and Conference, ADIPEC, Abu Dhabi, United Arab Emirates, 3–6 November 2008. [Google Scholar] [CrossRef]

- Ma, D.S.; Liu, W.L.; Wang, Q.; Sun, Y.Y. Mathematic Model of Alkali-Surfactant-Polymer (ASP) Flooding with Consideration of Oil-in-Water Emulsion. J. China Univ. Pet. 2013, 37, 100–105. [Google Scholar] [CrossRef]

- Lei, Z.; Yuan, S.; Song, J.; Yuan, J.; Wu, Y.-S. A mathematical model for emulsion mobilization and its effect on EOR during ASP flooding. In Proceedings of the SPE Symposium on Improved Oil Recovery, Tulsa, OK, USA, 24–28 April 2008. [Google Scholar] [CrossRef]

- Ponce, F.; Carvalho, M.; Alvarado, V. Oil recovery modeling of macro-emulsion flooding at low capillary number. J. Pet. Sci. Eng. 2014, 119, 112–122. [Google Scholar] [CrossRef]

- Demikhova, I.I.; Likhanova, N.V.; Perez, J.R.H.; Falcon, D.A.L.; Olivares-Xometl, O.; Berthier, A.E.M.; Lijanova, I.V. Emulsion flooding for enhanced oil recovery: Filtration model and numerical simulation. J. Pet. Sci. Eng. 2016, 143, 235–244. [Google Scholar] [CrossRef]

- Karambeigi, M.S.; Abbassi, R.; Roayaei, E.; Emadi, M.A. Emulsion flooding for enhanced oil recovery: Interactive optimization of phase behavior, microvisual and core-flood experiments. J. Ind. Eng. Chem. 2015, 29, 382–391. [Google Scholar] [CrossRef]

- Xu, K.; Zhu, P.; Tatiana, C.; Huh, C.; Balhoff, M. A microfluidic investigation of the synergistic effect of nanoparticles and surfactants in macro-emulsion based EOR. In Proceedings of the SPE Improved Oil Recovery Symposium, Tulsa, OK, USA, 11–13 April 2016. [Google Scholar] [CrossRef]

- Kang, W.; Liu, S.; Meng, L.; Wwang, Z.; Zhou, Y. Microscopic Mechanism of Spontaneous Emulsification Displacement. J. Pet. Nat. Gas 2009, 31, 99–102. [Google Scholar] [CrossRef]

- Zhou, Y.; Yin, D.; Cao, R.; Zhang, C. The mechanism for pore-throat scale emulsion displacing residual oil after water flooding. J. Pet. Sci. Eng. 2018, 163, 519–525. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).