Beeswax–EVA/Activated-Charcoal-Based Fuels for Hybrid Rockets: Thermal and Ballistic Evaluation

Abstract

1. Introduction

2. Experimental Setup

2.1. Materials and Fuel Grain Preparation

2.2. Thermogravimetric and Scanning Electron Microscope Analysis

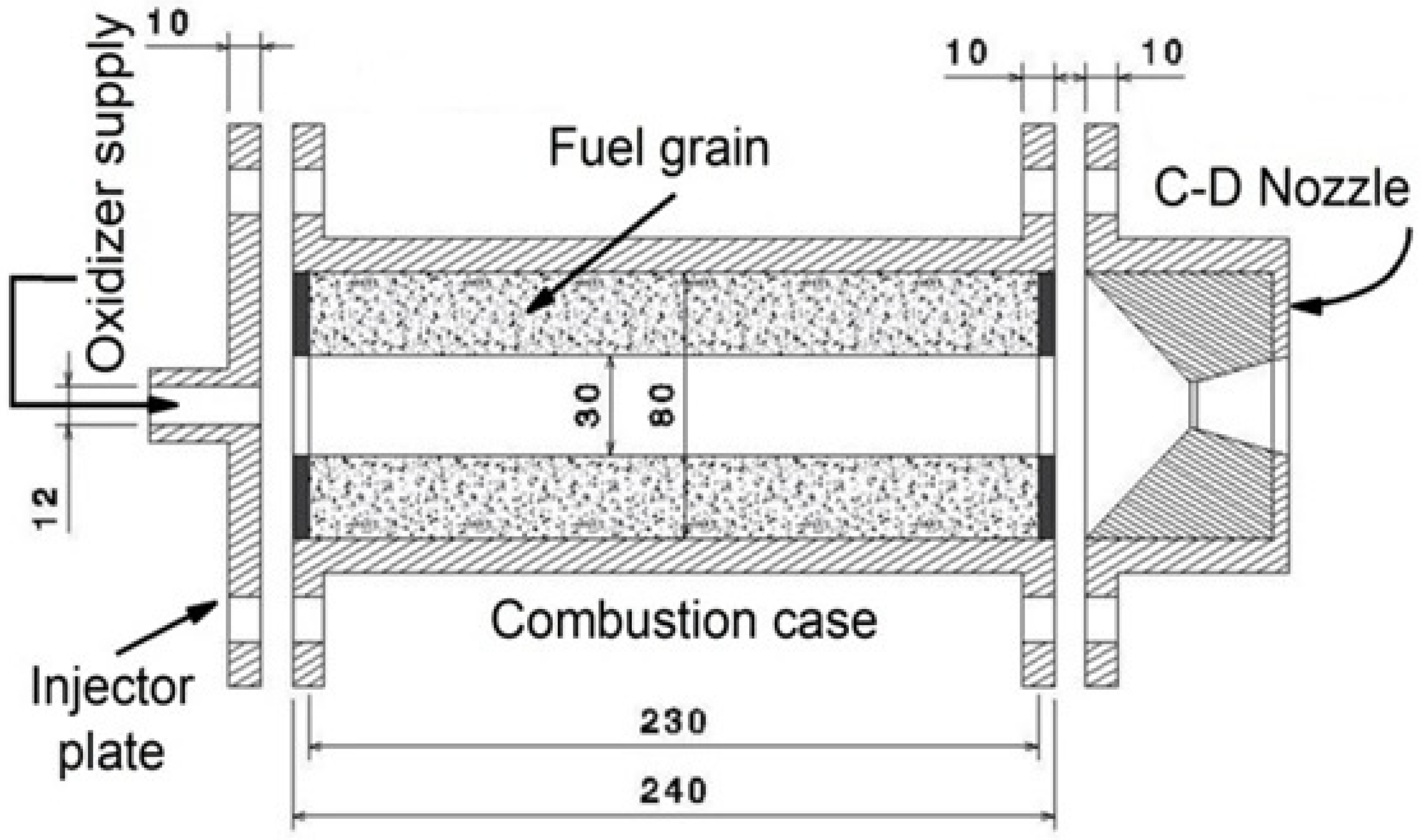

2.3. Hybrid Rocket Motor

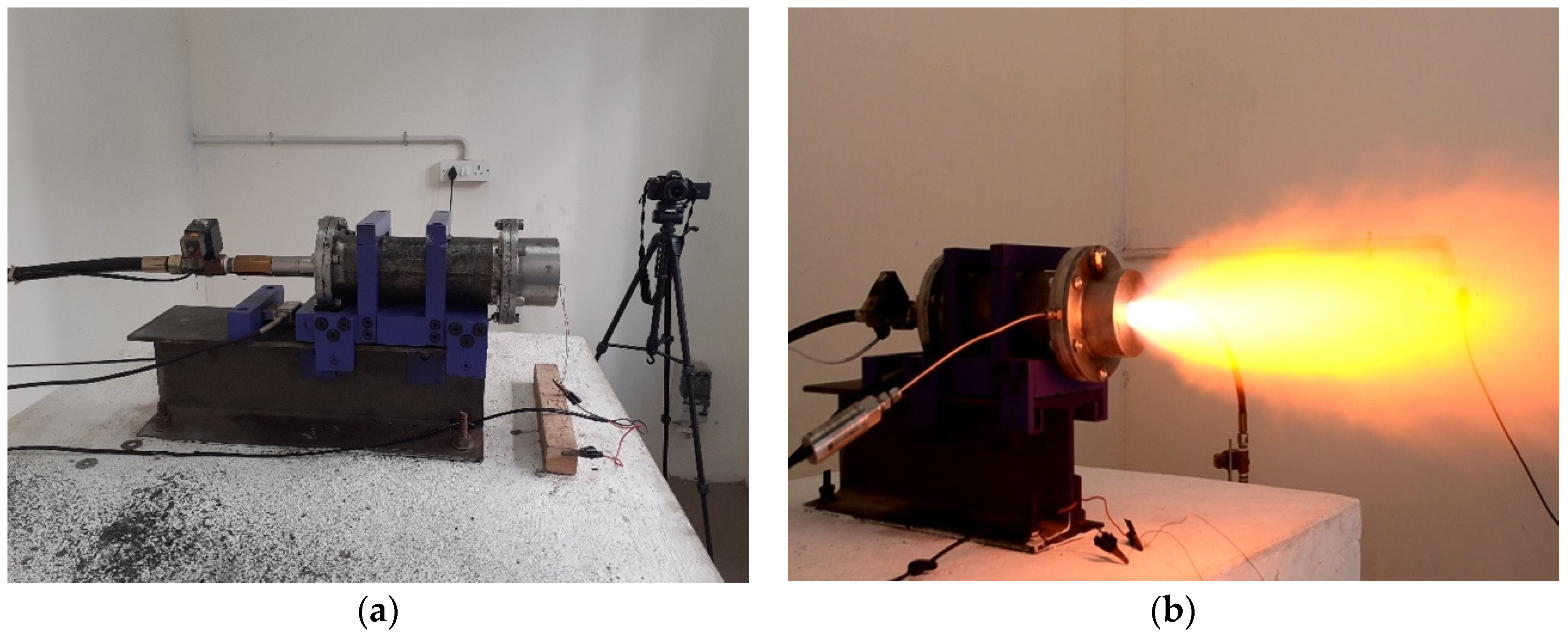

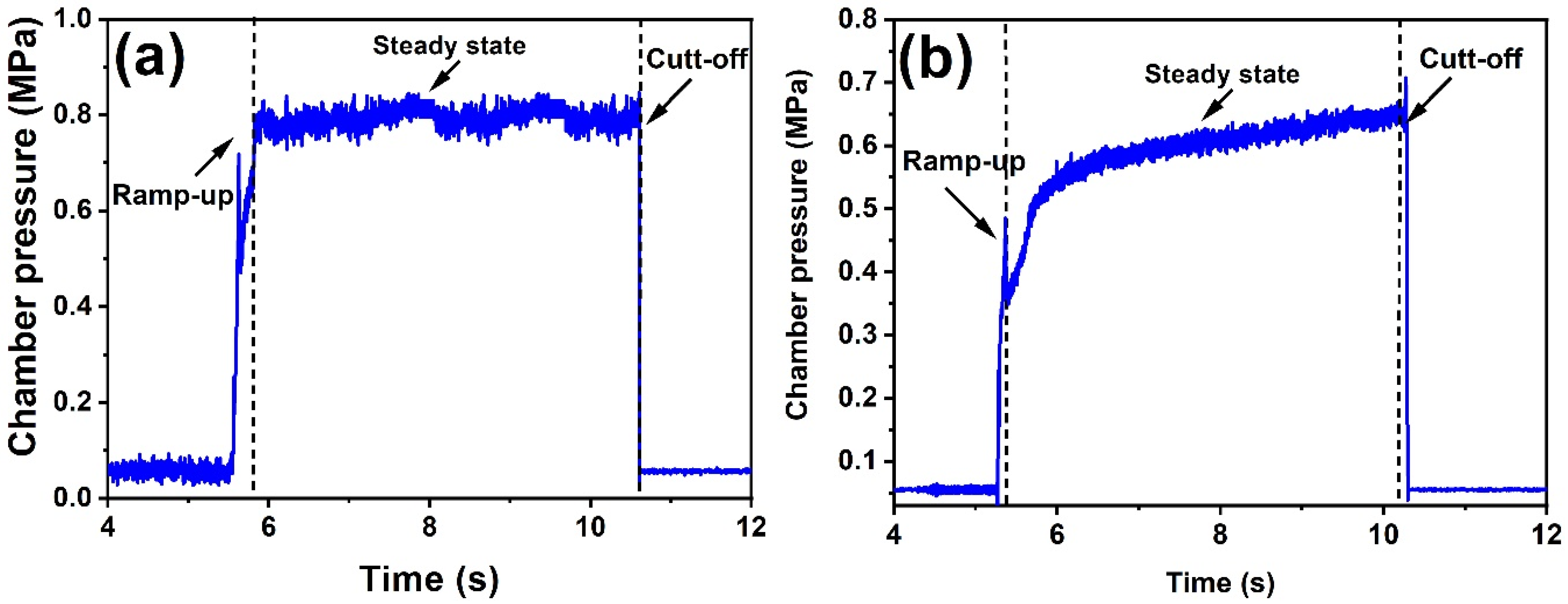

2.4. Ballistic Test Facility and Operating Procedure

2.5. Data Reduction Methodology

- i.

- Regression Rate Measurement

- ii.

- Combustion efficiency

- iii.

- Viscosity Measurement

3. Results and Discussion

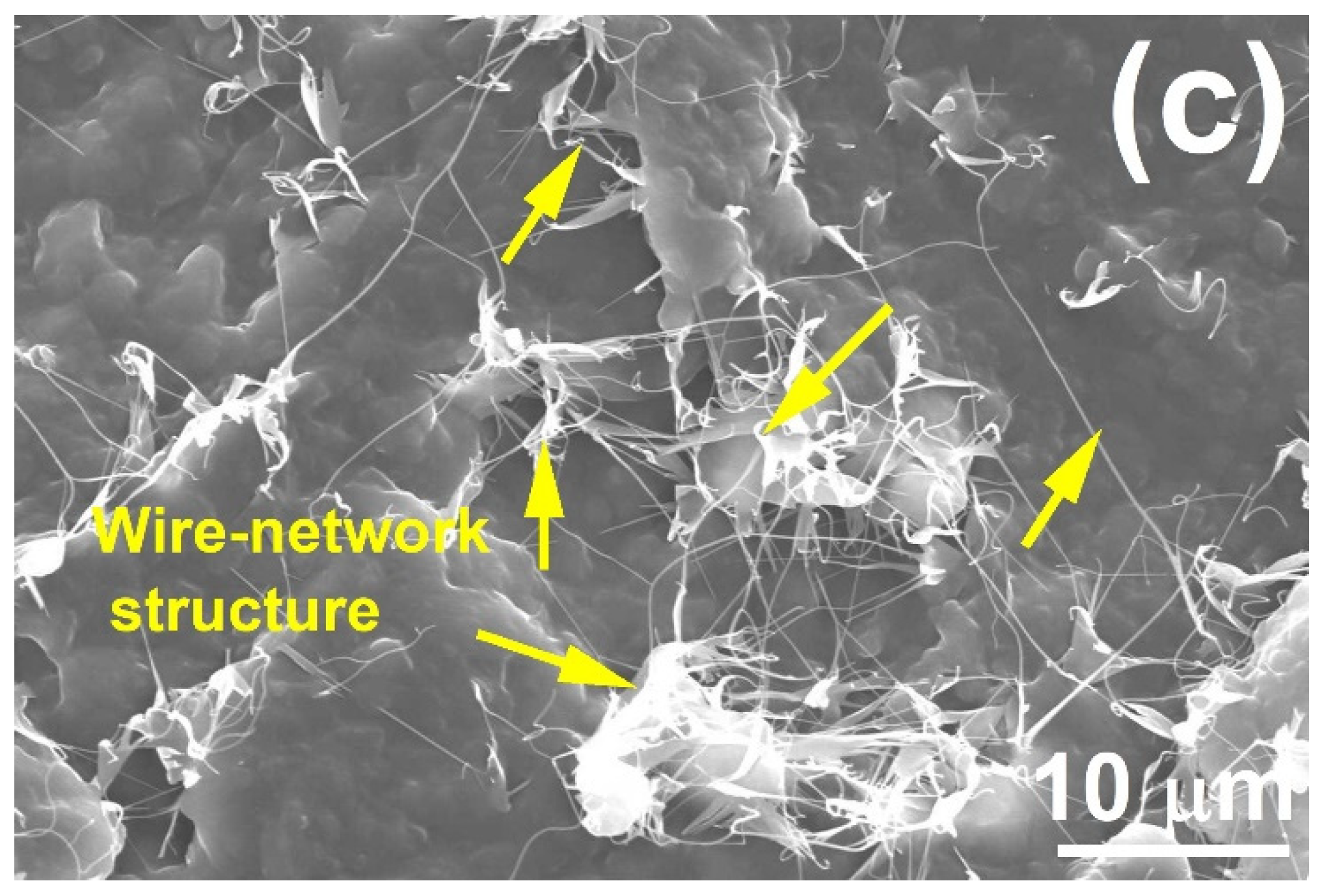

3.1. Surface Morphology of BW–EVA/AC-Based Samples

3.2. Thermal Stability of BW–EVA Based Solid Fuel Samples

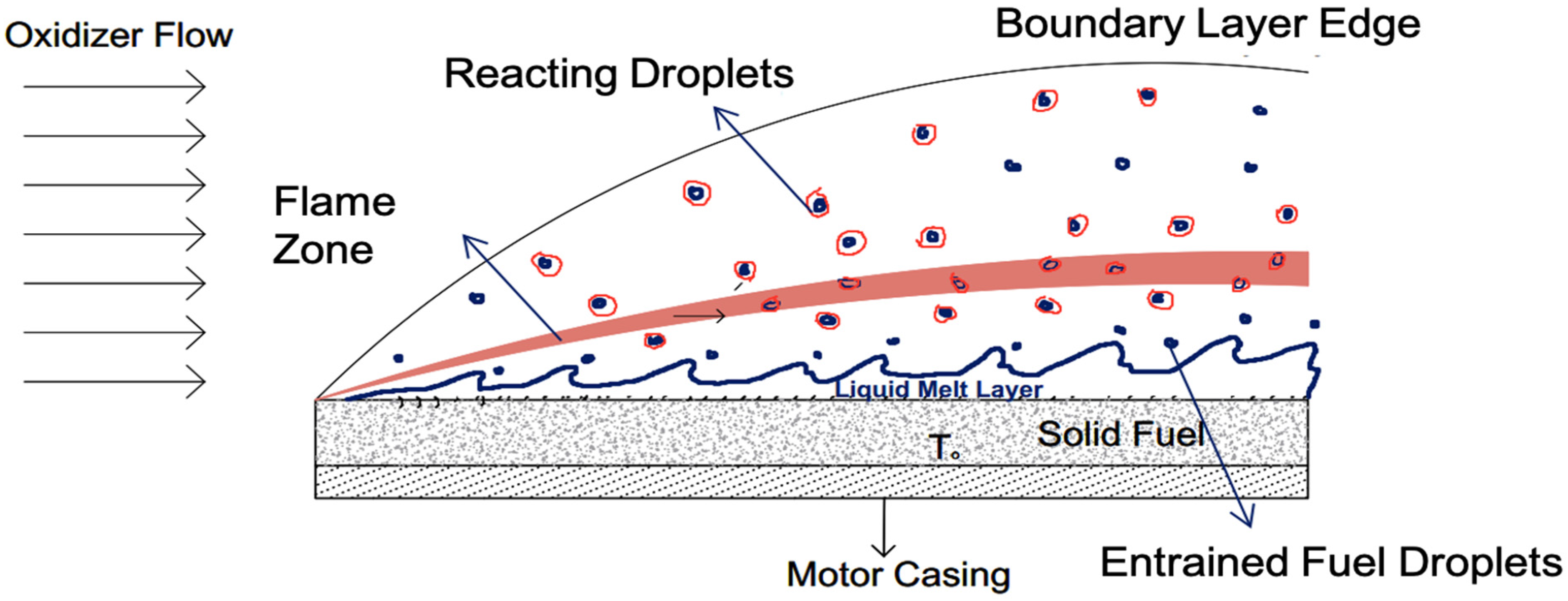

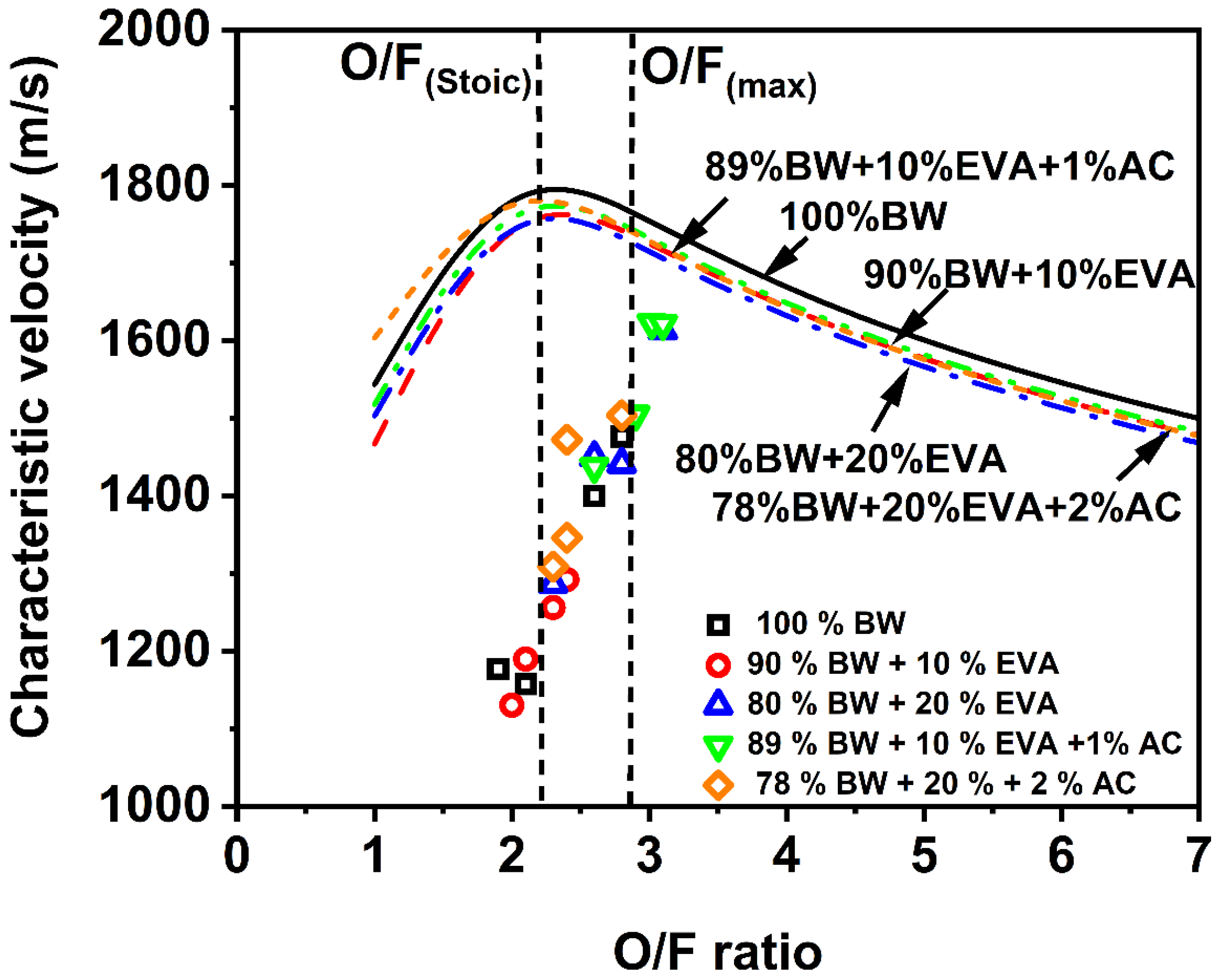

3.3. Regression Rate

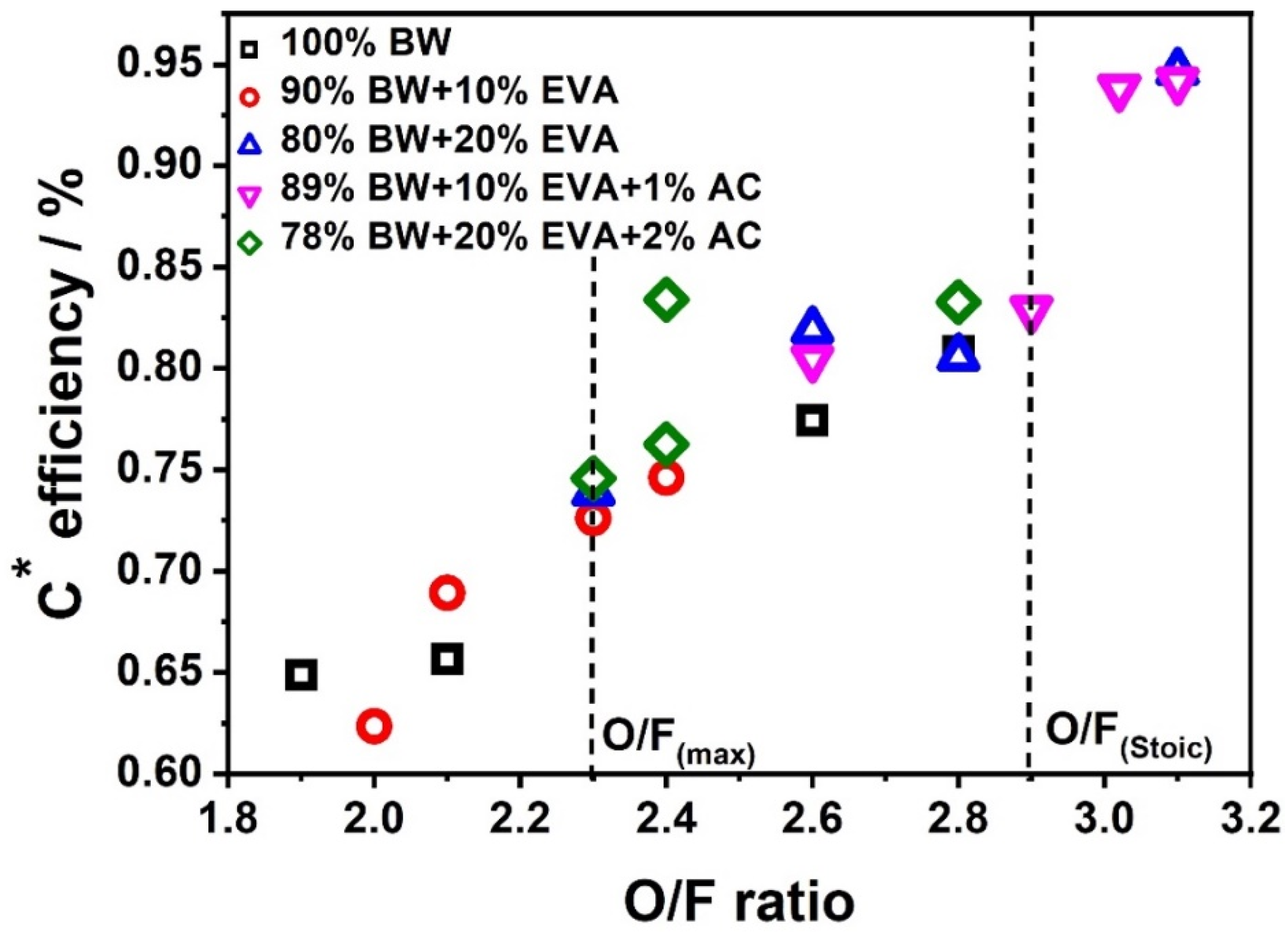

3.4. Combustion Efficiency Characterization

4. Conclusions

- The thermal stability of BW-based fuel was improved with the addition of EVA. The onset decomposition temperature increased from 205 °C to 227.3 °C when 20 wt.% EVA was added to BW.

- The thermal decomposition of BW–EVA samples was improved with the addition of AC. However, a marginal reduction in thermal stability was observed for the BW–EVA/AC-based fuel, which positively affected the regression rate performance.

- The viscosity of BW-based fuel formulations was increased significantly when EVA and AC were added to the BW matrix. The viscosity for pure BW was found to be 1.7 cp, which increased to 38.5 cp with the addition of EVA.

- Ballistic tests revealed that the pure BW displayed the highest regression rate among tested fuel formulations. The regression rate was reduced by adding EVA to BW matrix, which was attributed to the increased viscosity of the liquid melt layer. Furthermore, the regression rate was improved by adding AC to BW–EVA fuels.

- The combustion efficiency of BW-based fuel was improved from 62% to 94% when 20 wt.% of EVA and 2 wt.% of AC were added to BW fuel.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mazzetti, A.; Merotto, L.; Pinarello, G. Paraffin-Based Hybrid Rocket Engines Applications: A Review and a Market Perspective. Acta Astronaut. 2016, 126, 286–297. [Google Scholar] [CrossRef]

- Mahottamananda, S.N.; Kadiresh, N.P.; Pal, Y. Regression Rate Characterization of HTPB-Paraffin Based Solid Fuels for Hybrid Rocket. Propellants Explos. Pyrotech. 2020, 45, 1755–1763. [Google Scholar] [CrossRef]

- Chiaverini, M.J. Review of Solid-Fuel Regression Rate Behavior in Classical and Nonclassical Hybrid Rocket Motors. In Fundamentals of Hybrid Rocket Combustion and Propulsion; Kuo, K.K., Chiaverini, M.J., Eds.; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2007; pp. 37–126. ISBN 978-1-56347-703-4. [Google Scholar]

- Mukunda, H.S.; Jain, V.K.; Paul, P.J. A Review of Hybrid Rockets: Present Status and Future Potential. Proc. Indian Acad. Sci. Sect. C Eng. Sci. 1979, 2, 215–242. [Google Scholar] [CrossRef]

- Pal, Y.; Mahottamananda, S.N.; Palateerdham, S.K.; Subha, S.; Ingenito, A. Review on the Regression Rate-Improvement Techniques and Mechanical Performance of Hybrid Rocket Fuels. FirePhysChem 2021, 1, 272–282. [Google Scholar] [CrossRef]

- Mahottamananda, S.N.; Kadiresh, P.N.; Pal, Y. A Study on Thermal Stability and Combustion Performance of Hydroxyl-Terminated Polybutadiene-Paraffin Blended Fuel. Energy Sources Part A Recovery Util. Environ. Eff. 2020. [Google Scholar] [CrossRef]

- Natan, B.; Gany, A. Combustion Characteristics of a Boron-Fueled Solid Fuel Ramjet with Aft-Burner. J. Propuls. Power 1993, 9, 694–701. [Google Scholar] [CrossRef]

- Metals, Energetic Additives, and Special Binders Used in Solid Fuels for Hybrid Rockets. In Fundamentals of Hybrid Rocket Combustion and Propulsion; Progress in Astronautics and Aeronautics; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2007; pp. 413–456. ISBN 978-1-56347-703-4.

- Larson, D.; Boyer, E.; Wachs, T.; Kuo, K.; DeSain, J.; Curtiss, T.; Brady, B. Characterization of the Performance of Paraffin/LiAlH4 Solid Fuels in a Hybrid Rocket System. In Proceedings of the 47th AIAA/ASME/SAE/ASEE Joint Propulsion Conference & Exhibit, San Diego, CA, USA, 31 July–3 August 2011; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2022. [Google Scholar]

- Boiocchi, M.; Maggi, F.; Paravan, C.; Galfetti, L. Paraffin-Based Fuels and Energetic Additives for Hybrid Rocket Propulsion. In Proceedings of the 51st AIAA/SAE/ASEE Joint Propulsion Conference, Orlando, FL, USA, 27–29 July 2015; AIAA Propulsion and Energy Forum. American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2015. [Google Scholar]

- Galfetti, L.; Merotto, L.; Boiocchi, M.; Maggi, F.; DeLuca, L.T. Experimental Investigation of Paraffin-Based Fuels for Hybrid Rocket Propulsion. Prog. Propuls. Phys. 2013, 4, 59–74. [Google Scholar]

- Kim, S.; Kim, J.; Moon, H.; Sung, H.; Lee, J.; Kim, G.; Cho, J.; Park, S. Combustion Characteristics of the Cylindrical Multi-Port Grain for Hybrid Rocket Motor. In Proceedings of the 45th AIAA/ASME/SAE/ASEE Joint Propulsion Conference & Exhibit, Denver, CO, USA, 2–5 August 2009; ISBN 978-1-60086-972-3. [Google Scholar]

- Tian, H.; Li, X.; Peng, Z.; Yu, N.; Cai, G. Numerical and Experimental Studies of the Hybrid Rocket Motor with Multi-Port Fuel Grain. Acta Astronaut. 2014, 96, 261–268. [Google Scholar] [CrossRef]

- George, P.; Krishnan, S.; Varkey, P.M.; Ravindran, M.; Ramachandran, L. Fuel Regression Rate in Hydroxyl-Terminated-Polybutadiene/Gaseous-Oxygen Hybrid Rocket Motors. J. Propuls. Power 2001, 17, 35–42. [Google Scholar] [CrossRef]

- Frederick, R.A.; Whitehead, J.J.; Knox, L.R.; Moser, M.D. Regression Rates Study of Mixed Hybrid Propellants. J. Propuls. Power 2007, 23, 175–180. [Google Scholar] [CrossRef]

- Karabeyoglu, M.; Cantwell, B.; Altman, D. Development and Testing of Paraffin-Based Hybrid Rocket Fuels. In Proceedings of the 37th Joint Propulsion Conference and Exhibit, Salt Lake, UT, USA, 8–11 July 2001; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2001. [Google Scholar]

- Heydari, M.M.; Ghadiri Massoom, N. Experimental Study of the Swirling Oxidizer Flow in HTPB/N2O Hybrid Rocket Motor. Int. J. Aerosp. Eng. 2017, 2017, 3174140. [Google Scholar] [CrossRef]

- Kumar, C.P.; Kumar, A. Effect of Swirl on the Regression Rate in Hybrid Rocket Motors. Aerosp. Sci. Technol. 2013, 29, 92–99. [Google Scholar] [CrossRef]

- Chidambaram, P.K.; Kumar, A. Effect of Diaphragms on Regression Rate in Hybrid Rocket Motors. J. Propuls. Power 2013, 29, 559–572. [Google Scholar] [CrossRef]

- Kumar, R.; Ramakrishna, P.A. Effect of Protrusion on the Enhancement of Regression Rate. Aerosp. Sci. Technol. 2014, 39, 169–178. [Google Scholar] [CrossRef]

- Dinesh, M.; Rajput, S.S.; Kumar, R. Protrusion Effect on the Performance of Hybrid Rocket with Liquefying and Non-Liquefying Fuels. Acta Astronaut. 2021, 178, 536–547. [Google Scholar] [CrossRef]

- Dinesh, M.; Kumar, R. Utility of Multiprotrusion as the Performance Enhancer in Hybrid Rocket Motor. J. Propuls. Power 2019, 35, 1005–1017. [Google Scholar] [CrossRef]

- Dinesh, M.; Kumar, R. Effect of Protrusion on Combustion Stability of Hybrid Rocket Motor. Propellants Explos. Pyrotech. 2022, 47, e202100067. [Google Scholar] [CrossRef]

- Dinesh, M.; Kumar, R. Experimental Studies of Protrusion-Inserted Hybrid Rocket Motor with Varying L/D Ratio. J. Spacecr. Rocket. 2021, 58, 134–147. [Google Scholar] [CrossRef]

- Kumar, R.; Periyapatna, R. Enhancement of Hybrid Fuel Regression Rate Using a Bluff Body. J. Propuls. Power 2014, 30, 909–916. [Google Scholar] [CrossRef]

- Wu, Y.; Yu, X.; Lin, X.; Li, S.; Wei, X.; Zhu, C.; Wu, L. Experimental Investigation of Fuel Composition and Mix-Enhancer Effects on the Performance of Paraffin-Based Hybrid Rocket Motors. Aerosp. Sci. Technol. 2018, 82, 620–627. [Google Scholar] [CrossRef]

- Cai, G.; Cao, B.; Zhu, H.; Tian, H.; Ma, X. Parametric Investigation of Secondary Injection in Post-Chamber on Combustion Performance for Hybrid Rocket Motor. Acta Astronaut. 2017, 140, 427–438. [Google Scholar] [CrossRef]

- Sinha, Y.K.; Sridhar, B.T.N.; Kishnakumar, R. Study of Thermo-Mechanical Properties of HTPB–Paraffin Solid Fuel. Arab. J. Sci. Eng. 2016, 41, 4683–4690. [Google Scholar] [CrossRef]

- Jayapal, S.N.M.; Dubey, V.K.; Dinesh, S.; Wahab, A.; Abdul Khaleel, A.; Kadiresh, P.N. Thermal Stability and Kinetic Study of Blended Beeswax-Ethylene Vinyl Acetate Based Hybrid Rocket Fuels. Thermochim. Acta 2021, 702, 178989. [Google Scholar] [CrossRef]

- Kim, S.; Moon, H.; Kim, J. Thermal Characterizations of the Paraffin Wax/Low Density Polyethylene Blends as a Solid Fuel. Thermochim. Acta 2015, 613, 9–16. [Google Scholar] [CrossRef]

- Pal, Y.; Kumar, V.R. Thermal Decomposition Study of Paraffin Based Hybrid Rocket Fuel Containing Aluminum and Boron Additives. Thermochim. Acta 2017, 655, 63–75. [Google Scholar] [CrossRef]

- Tang, Y.; Chen, S.; Zhang, W.; Ruiqi, S.; DeLuca, L.; Ye, Y. Mechanical Modifications of Paraffin-Based Fuels and the Effects on Combustion Performance. Propellants Explos. Pyrotech. 2017, 42, 1268–1277. [Google Scholar] [CrossRef]

- Kim, S.; Moon, H.; Kim, J.; Cho, J. Evaluation of Paraffin–Polyethylene Blends as Novel Solid Fuel for Hybrid Rockets. J. Propuls. Power 2015, 31, 1750–1760. [Google Scholar] [CrossRef]

- Kobald, M.; Schmierer, C.; Ciezki, H.; Schlechtriem, S.; Toson, E.; DeLuca, L. Viscosity and Regression Rate of Liquefying Hybrid Rocket Fuels. J. Propuls. Power 2017, 33, 1245–1251. [Google Scholar] [CrossRef]

- Veale, K.; Adali, S.; Pitot, J.; Brooks, M. A Review of the Performance and Structural Considerations of Paraffin Wax Hybrid Rocket Fuels with Additives. Acta Astronaut. 2017, 141, 196–208. [Google Scholar] [CrossRef]

- Nakagawa, I.; Nikone, S. Study on the Regression Rate of Paraffin-Based Hybrid Rocket Fuels. J. Propuls. Power 2011, 27, 1276–1279. [Google Scholar] [CrossRef]

- Karabeyoglu, M.A.; Altman, D.; Cantwell, B.J. Combustion of Liquefying Hybrid Propellants: Part 1, General Theory. J. Propuls. Power 2002, 18, 610–620. [Google Scholar] [CrossRef]

- Karabeyoglu, M.A.; Cantwell, B.J. Combustion of Liquefying Hybrid Propellants: Part 2, Stability of Liquid Films. J. Propuls. Power 2002, 18, 621–630. [Google Scholar] [CrossRef]

- Pal, Y.; Kumar, K.H.; Li, Y.-H. Ballistic and Mechanical Characteristics of Paraffin-Based Solid Fuels. CEAS Space J. 2019, 11, 317–327. [Google Scholar] [CrossRef]

- Kumar, R.; Ramakrishna, P.A. Studies on EVA-Based Wax Fuel for Launch Vehicle Applications. Propellants Explos. Pyrotech. 2016, 41, 295–303. [Google Scholar] [CrossRef]

- Evans, B.; Boye, E.; Kuo, K.; Risha, G.; Chiaverini, M. Hybrid Rocket Investigation at Penn State University’s High-Pressure Combustion Laboratory: Overview and Recent Results. In Proceedings of the 45th AIAA/ASME/SAE/ASEE Joint Propulsion Conference and Exhibit, Denver, CO, USA, 2–5 August 2009. AIAA Paper 2009-5349. [Google Scholar]

- Hashim, S.A.; Islam, M.; Kangle, S.M.; Karmakar, S.; Roy, A. Performance Evaluation of Boron/Hydroxyl-Terminated Polybutadiene-Based Solid Fuels Containing Activated Charcoal. J. Spacecr. Rocket. 2021, 58, 363–374. [Google Scholar] [CrossRef]

- Verma, S.; Periyapatna, R. Investigations on Activated Charcoal, a Burn-Rate Enhancer in Composite Solid Propellant. J. Propuls. Power 2013, 29, 1214–1219. [Google Scholar] [CrossRef]

- Putnam, S.G. Investigation of Non-Conventional Bio-Derived Fuels for Hybrid Rocket Motors. Ph.D. Thesis, The University of Tennessee, Knoxville, TN, USA, 2017; 145p. [Google Scholar]

- Scholes, J. Bio-Derived Fuels for Hybrid Rocket Motors. Master’s Thesis, University of Tennessee, Knoxville, TN, USA, 2005. [Google Scholar]

- Makled, E.-S.M. Beeswax Material: Non-Conventional Solid Fuel for Hybrid Rocket Motors. Adv. Mil. Technol. 2019, 14, 99–113. [Google Scholar] [CrossRef]

- Stober, K.J.; Sanchez, A.; Wanyiri, J.; Jiwani, S.; Wood, D. Centrifugal Casting of Paraffin and Beeswax for Hybrid Rockets. In Proceedings of the AIAA Propulsion and Energy 2020 Forum, Virtual Event, 24–28 August 2020; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2020. [Google Scholar]

- Naoumov, V.; Al-Masoud, N.; Butt, J.; Correa, C.; Parmelee, D.; Couillard, M.; Nguyen, H.; Ampofo, J.; Patel, K. Student-Faculty Research on the Combustion of Non-Conventional Fuels in Hybrid Propellant Rocket Engine in a Wide Range of Oxidizer-to-Fuel Ratios. In Proceedings of the AIAA SciTech 2020 Forum, Orlando, FL, USA, 6–10 January 2020. [Google Scholar] [CrossRef]

- Dubey, V.K.; Mahottamananda, S.N.; Khaleel, A.A.; Kadiresh, P.N.; Thirumurugan, M. Mechanical Characteristics of Paraffin Wax, Beeswax and HTPB as Rocket Propellant—A Comparative Study. In Advances in Design and Thermal Systems; Ganippa, L., Karthikeyan, R., Muralidharan, V., Eds.; Springer: Singapore, 2021; pp. 243–252. [Google Scholar] [CrossRef]

- Sri Nithya Mahottamananda, J.; Vanchhit Kumar, D.; Afreen, A.K.; Dinesh, S.; Ashiq, W.; Kadiresh, P.N.; Thirumurugan, M. Mechanical Characteristics of Ethylene Vinyl Acetate Mixed Beeswax Fuel for Hybrid Rockets. In Advances in Design and Thermal Systems; Ganippa, L., Karthikeyan, R., Muralidharan, V., Eds.; Lecture Notes in Mechanical Engineering; Springer: Singapore, 2021. [Google Scholar] [CrossRef]

- Kumar, R.; Ramakrishna, P.A. Issues Related to the Measurement of Regression Rate of Fast-Burning Hybrid Fuels. J. Propuls. Power 2013, 29, 1114–1121. [Google Scholar] [CrossRef]

- Paul, P.J.; Mukunda, H.S.; Narahari, H.K.; Venkataraman, R.; Jain, V.K. Regression Rate Studies in Hypergolic System. Combust. Sci. Technol. 1981, 26, 17–24. [Google Scholar] [CrossRef]

- Gordon, S.; Mcbride, B.J. Computer Program for Calculation of Complex Chemical Equilibrium Compositions and Applications. Part 1: Analysis; NASA: Washington, DC, USA, 1994; pp. 1–61.

- Buchwald, R.; Breed, M.D.; Greenberg, A.R. The Thermal Properties of Beeswaxes: Unexpected Findings. J. Exp. Biol. 2008, 211, 121–127. [Google Scholar] [CrossRef]

- DeSain, J.; Brady, B.; Metzler, K.; Curtiss, T.; Albright, T. Tensile Tests of Paraffin Wax for Hybrid Rocket Fuel Grains. In Proceedings of the 45th AIAA/ASME/SAE/ASEE Joint Propulsion Conference & Exhibit; Joint Propulsion Conferences, Denver, CO, USA, 2–5 August 2009; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2009. [Google Scholar]

- Mengu, D.; Kumar, R. Development of EVA-SEBS Based Wax Fuel for Hybrid Rocket Applications. Acta Astronaut. 2018, 152, 325–334. [Google Scholar] [CrossRef]

- Carmicino, C.; Scaramuzzino, F.; Russo Sorge, A. Trade-off between Paraffin-Based and Aluminium-Loaded HTPB Fuels to Improve Performance of Hybrid Rocket Fed with N2O. Aerosp. Sci. Technol. 2014, 37, 81–92. [Google Scholar] [CrossRef]

| Chemical | Chemical Formula | Density, kg/m3 | Supplier |

|---|---|---|---|

| Beeswax (BW) | C46H92O | 970 | Unicorn Petroleum Industries Private Limited, Mumbai |

| Ethylene-vinyl acetate (EVA) | (C2H4)4(C4H6)2 | 950 | Happy Plastics, Mumbai |

| Activated charcoal (AC) | C | 1480 | Sigma Aldrich |

| Sample | Composition | Beeswax (wt.%) | EVA (wt.%) | Activated Charcoal (wt.%) |

|---|---|---|---|---|

| B1 | 100% BW | 100 | - | - |

| B2 | 90% BW + 10% EVA | 90 | 10 | - |

| B3 | 80% BW + 20% EVA | 80 | 20 | - |

| B4 | 89% BW + 10% EVA + 1% AC | 89 | 10 | 1 |

| B5 | 78% BW + 20% EVA + 2% AC | 78 | 20 | 2 |

| Fuel Sample | Chamber Pressure (MPa) | Mass of Fuel Consumed (kg) | Oxidizer Mass Flux Gox, (kg/m2-s) * | Regression Rate (mm/s) | Regression Rate Exponents | |

|---|---|---|---|---|---|---|

| a | n# | |||||

| 100% BW | 0.33 | 0.065 | 43.51 | 0.845 | 0.218 | 0.41 |

| 0.41 | 0.073 | 65.96 | 0.991 | |||

| 0.52 | 0.084 | 85.66 | 1.162 | |||

| 0.81 | 0.107 | 96.49 | 1.303 | |||

| 90% BW + 10% EVA | 0.21 | 0.058 | 48.97 | 0.766 | 0.094 | 0.56 |

| 0.25 | 0.066 | 70.46 | 0.904 | |||

| 0.28 | 0.070 | 87.37 | 1.011 | |||

| 0.38 | 0.088 | 95.84 | 1.118 | |||

| 80% BW + 20% EVA | 0.34 | 0.039 | 48.93 | 0.534 | 0.072 | 0.59 |

| 0.42 | 0.050 | 68.71 | 0.671 | |||

| 0.58 | 0.059 | 88.71 | 0.779 | |||

| 0.64 | 0.070 | 95.06 | 0.907 | |||

| 89% BW + 10% EVA + 1% AC | 0.25 | 0.059 | 45.45 | 0.781 | 0.154 | 0.41 |

| 0.43 | 0.068 | 71.08 | 0.935 | |||

| 0.52 | 0.071 | 84.73 | 1.043 | |||

| 0.79 | 0.90 | 91.19 | 1.132 | |||

| 78% BW + 20% EVA + 2% AC | 0.38 | 0.047 | 47.43 | 0.637 | 0.334 | 0.53 |

| 0.42 | 0.056 | 69.41 | 0.747 | |||

| 0.57 | 0.064 | 87.09 | 0.842 | |||

| 0.59 | 0.074 | 97.91 | 0.957 | |||

| Fuel Sample | Viscosity (Cp) at 90 °C, 22 S−1 | Reduction in Regression Rate (%) * |

|---|---|---|

| 100% BW | 1.7 | - |

| 90% BW + 10% EVA | 18.1 | 25 |

| 80% BW + 20% EVA | 38.5 | 32 |

| 89% BW + 10% EVA + 1% AC | 29.4 | 15 |

| 78% BW + 20% EVA + 2% AC | 48.7 | 30 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mahottamananda, S.N.; Pal, Y.; Dinesh, M.; Ingenito, A. Beeswax–EVA/Activated-Charcoal-Based Fuels for Hybrid Rockets: Thermal and Ballistic Evaluation. Energies 2022, 15, 7578. https://doi.org/10.3390/en15207578

Mahottamananda SN, Pal Y, Dinesh M, Ingenito A. Beeswax–EVA/Activated-Charcoal-Based Fuels for Hybrid Rockets: Thermal and Ballistic Evaluation. Energies. 2022; 15(20):7578. https://doi.org/10.3390/en15207578

Chicago/Turabian StyleMahottamananda, Sri Nithya, Yash Pal, Mengu Dinesh, and Antonella Ingenito. 2022. "Beeswax–EVA/Activated-Charcoal-Based Fuels for Hybrid Rockets: Thermal and Ballistic Evaluation" Energies 15, no. 20: 7578. https://doi.org/10.3390/en15207578

APA StyleMahottamananda, S. N., Pal, Y., Dinesh, M., & Ingenito, A. (2022). Beeswax–EVA/Activated-Charcoal-Based Fuels for Hybrid Rockets: Thermal and Ballistic Evaluation. Energies, 15(20), 7578. https://doi.org/10.3390/en15207578