Research Progress of Applying Distributed Fiber Optic Measurement Technology in Hydraulic Fracturing and Production Monitoring

Abstract

:1. Introduction

2. Principles of Distributed Fiber Optic Measurement Technology

2.1. Fundamentals

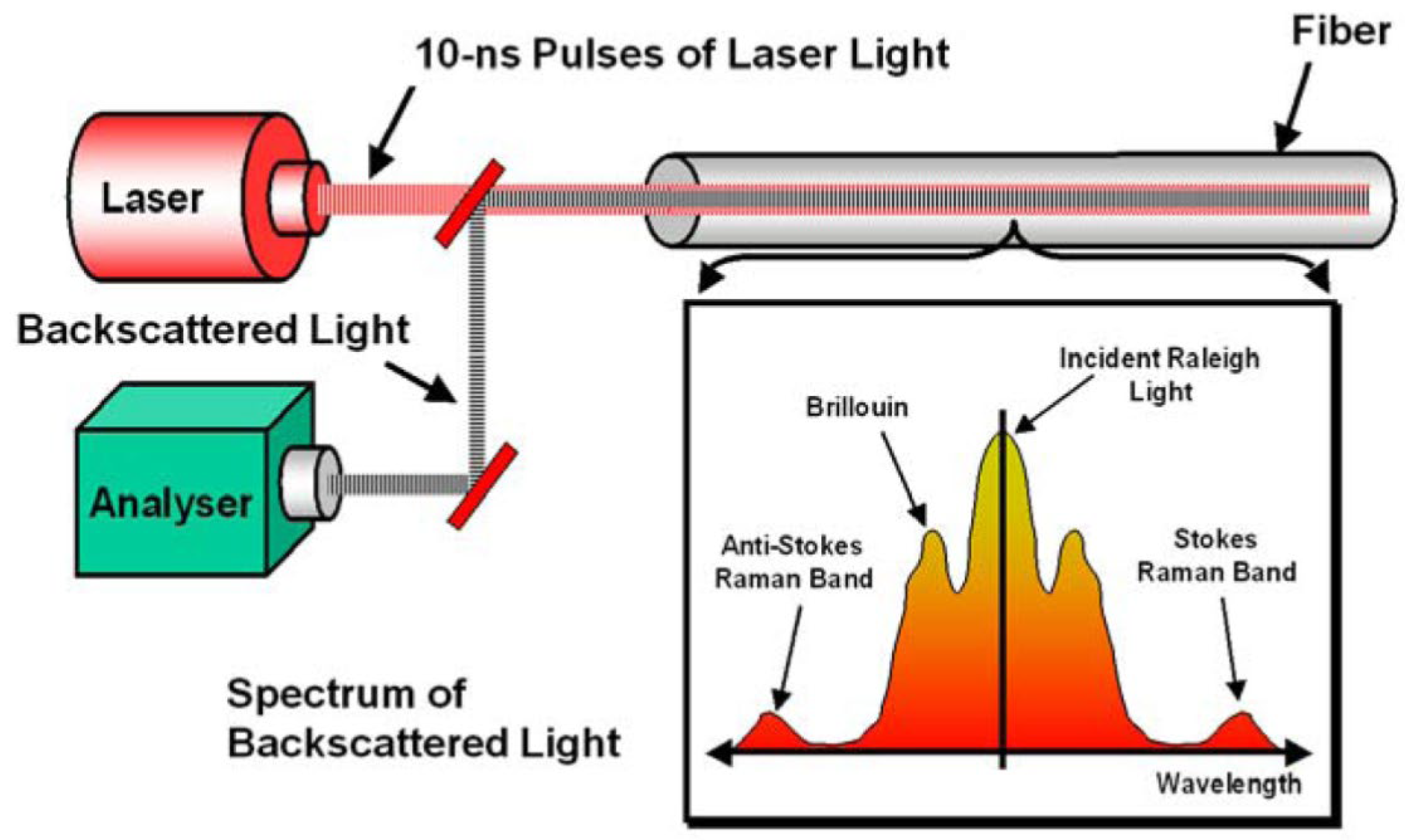

2.1.1. Fundamentals of DTS

2.1.2. Fundamentals of DAS

2.1.3. Fundamentals of DSS

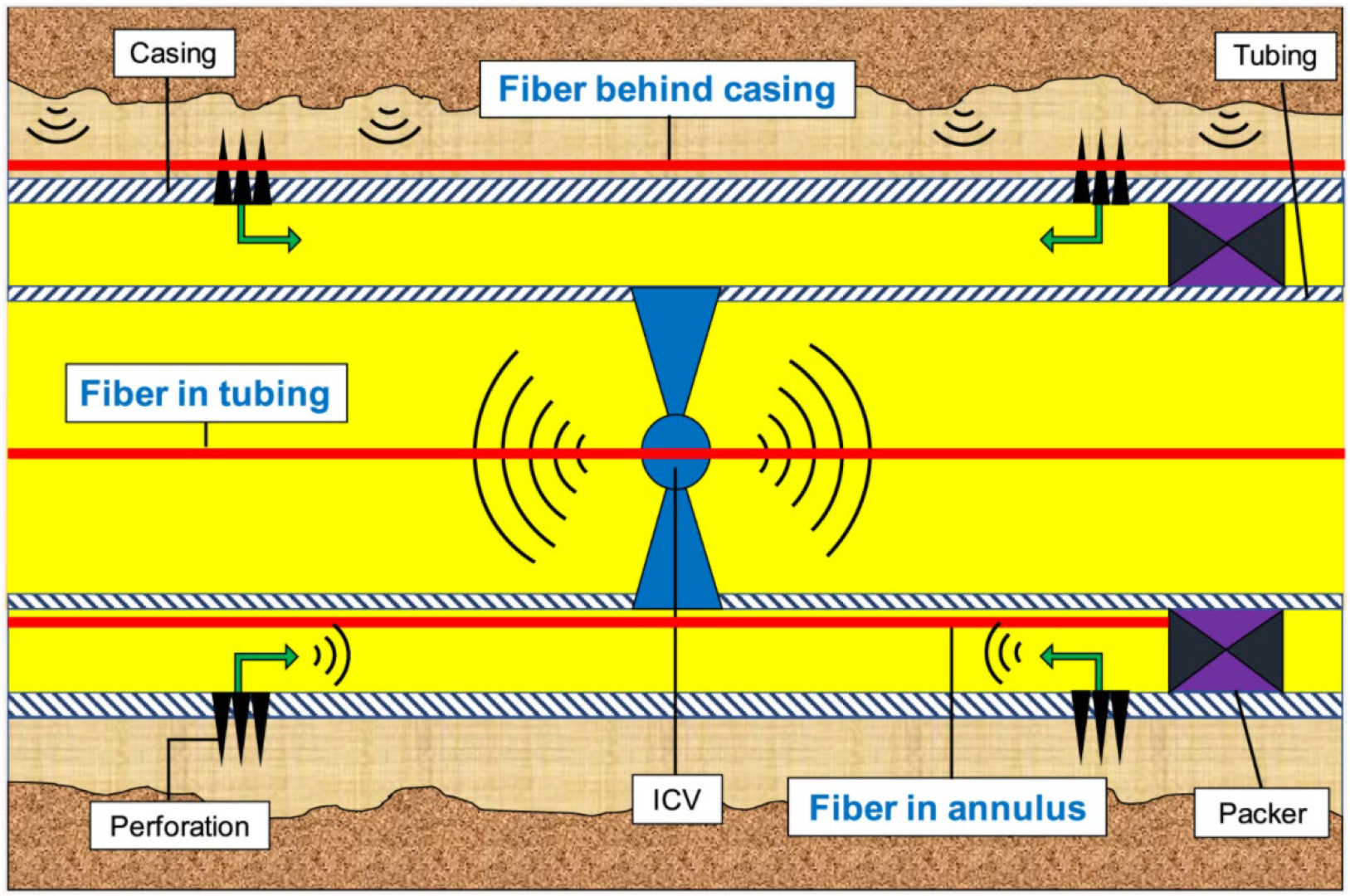

2.2. Installation Location

3. Application of Distributed Measurement Technology for Hydraulic Fracturing and Production Monitoring

3.1. Advances in the Application of DTS for Hydraulic Fracturing and Production Monitoring

3.1.1. Gas-Lift Monitoring with DTS

3.1.2. Identification of the Fluid Type with DTS

3.1.3. Interpretation of Flow Profiles with DTS

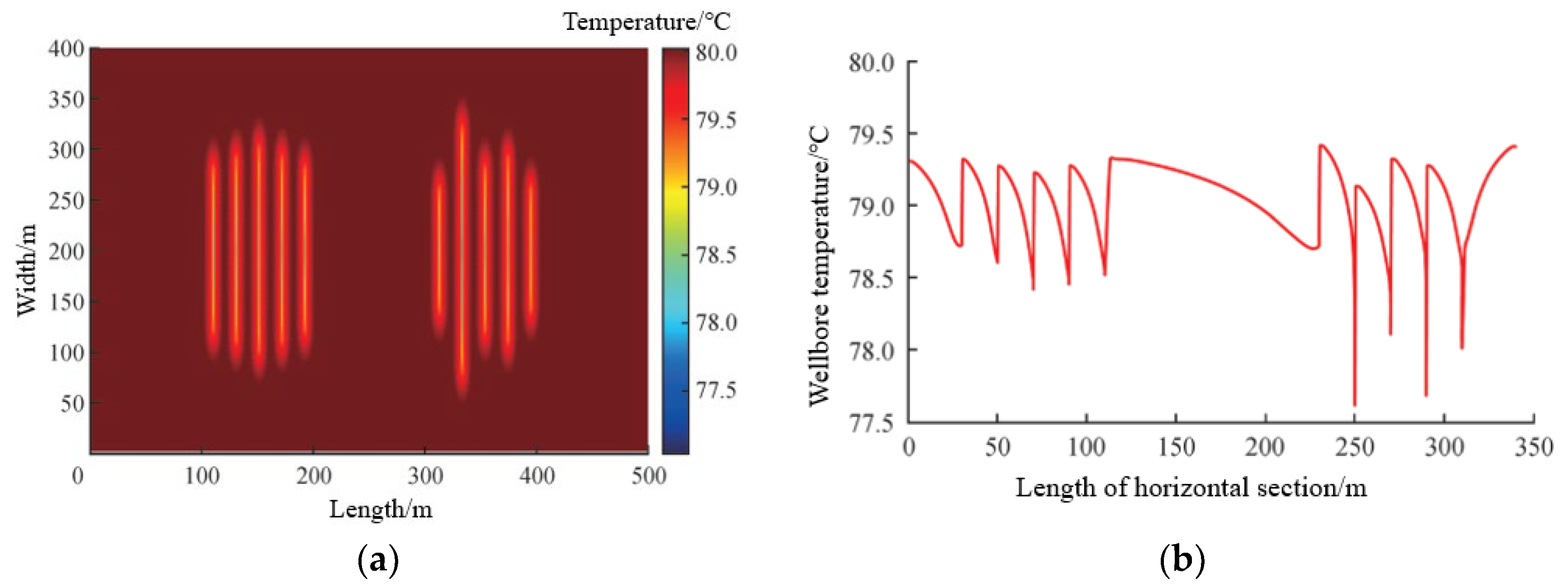

3.1.4. Application of DTS in Hydraulic Fracturing Monitoring

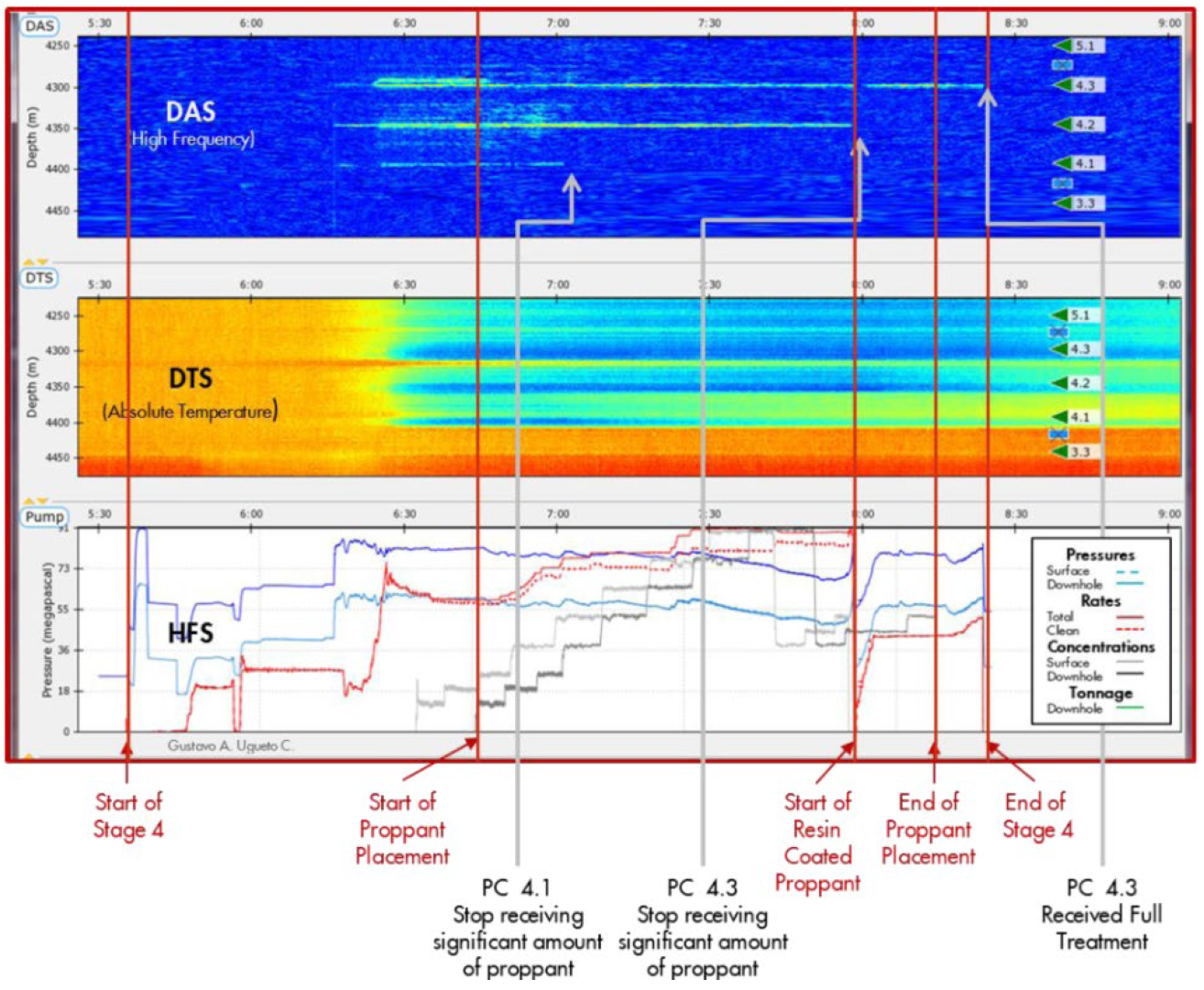

3.2. Advances in the Application of DAS for Hydraulic Fracturing and Production Monitoring

3.2.1. Monitoring the Distribution of Fracturing Fluid with DAS

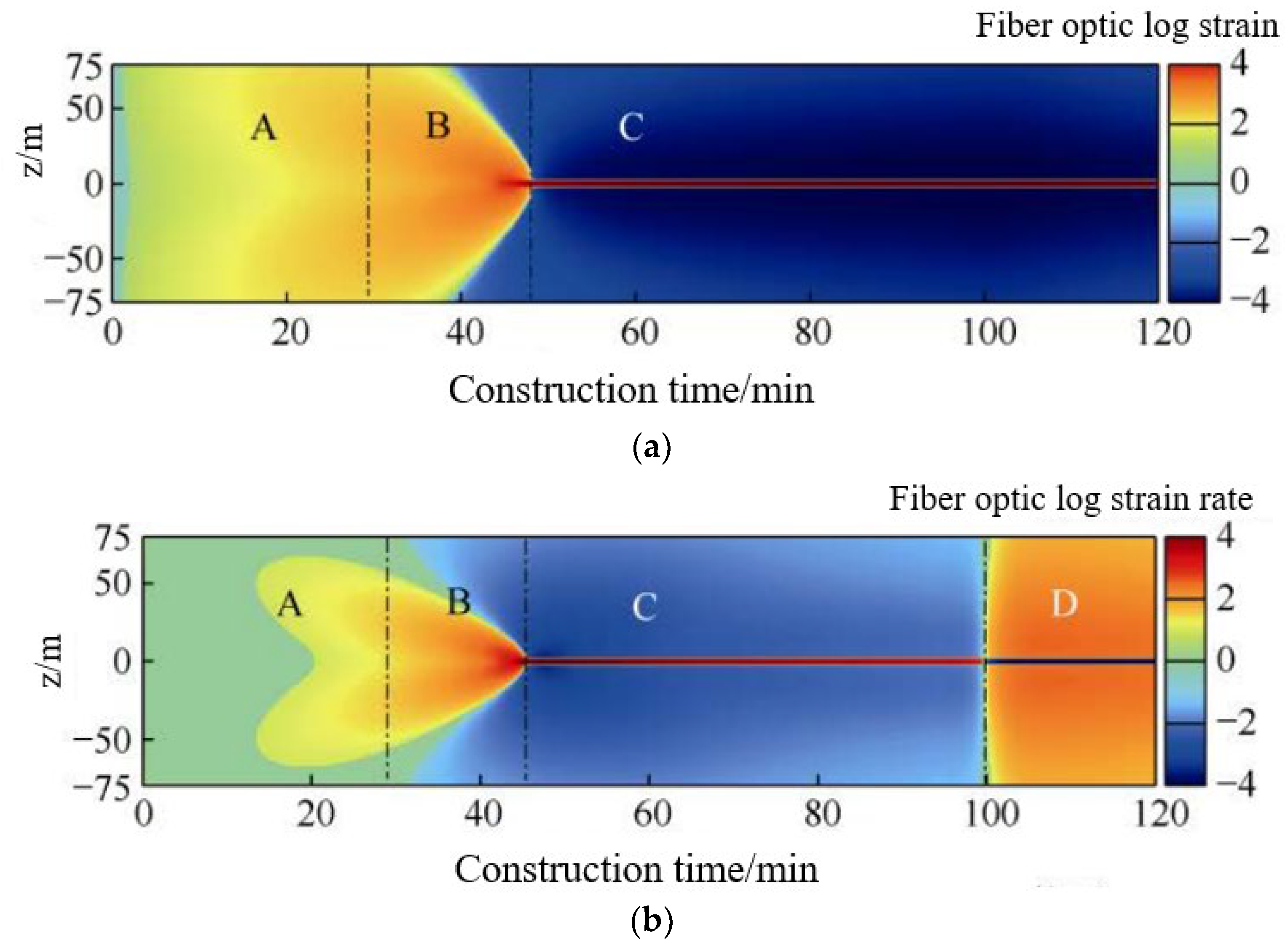

3.2.2. Strain Monitoring with DAS

3.2.3. Advances in the Application of DAS in Microseismic Monitoring

3.2.4. Production Monitoring with DAS

3.3. Advances in the Application of DSS for Hydraulic Fracturing and Production Monitoring

4. Advantages and Limitations of Distributed Fiber Optic Measurement Technology

- (1)

- Real-time monitoring of temperature, acoustic and strain information distributed along the length of the borehole by optical fibers throughout the life of the well.

- (2)

- Adaptability in harsh environments, with up to ten years of continuous operation in humid, high-temperature and high-pressure environments, and the fact that distributed fiber optic measurement technology is the only viable option for wells with polymer drives, where non-Newtonian fluids have a severe impact on most production-logging tools and the data obtained are not reliable;

- (3)

- The monitoring period can be regulated with the installation method and is easy to install: it can be installed before and during fracturing in just a few hours;

- (4)

- Low cost, averaging one dollar per measurement point, and reduced operational time for fault detection and well-stoppage testing compared to conventional measuring instruments, without delaying production time;

- (5)

- Stable nature, no electronic components, no interference with downhole information, and no interference from electromagnetic radiation;

- (6)

- With high data quality and a wide range of applications, fiber optic measurement systems can provide a variety of information, such as reservoir fracturing, leak detection, fluid injection and flow distribution.

- (1)

- The intensive sampling interval poses a challenge for storage and transmission, and current distributed fiber optic measurement technologies have autonomous data preliminary filtering and compression systems that can reduce the amount of data, but the filtered signals may contain events that lead to errors in the judgment of current conditions;

- (2)

- Installation of fiber optics in some wells, such as those with submerged electric pumps, is difficult to achieve;

- (3)

- The signal-to-noise ratio of DAS needs to be improved to match the geophone;

- (4)

- For microseismic detection, the sensitivity of DAS depends on the direction, which is generally lower than that of geophones, so the monitoring distance is limited and lacks multicomponent acquisition; otherwise it is difficult to locate the event;

- (5)

- DSS is sensitive to high-frequency vibration and cannot provide reliable measurement data in noisy environments. Due to its sensitivity to both temperature and strain, the measurement of stress relies on independent temperature measurements (e.g., DTS measurements are available to eliminate temperature effects). Beyond this, the accuracy of the measurements remains dependent on the coupling of the fiber to the ground;

- (6)

- Proving the integrity of the fiber optic sensing system is the technical basis for all successful monitoring. To avoid fiber damage, a series of shot-avoidance techniques have been carried out, such as directional shot, sliding casing, tube-delivered shotgun (TCP) outside the casing and a hydraulically controlled casing valve. However, once the fiber is damaged, subsequent measurements will be severely affected or even fail.

5. Outlook of Development Trends

- (1)

- To form a permanent distributed fiber optic measurement system, it is necessary to manage the explosive growth of data in the field. The huge data volume of real-time measurements poses a great challenge for data transmission and processing. The key to managing monitoring data is the hierarchical processing of the data. In the future, a database can be built to automatically generate the detection of fiber optic signal anomalies using machine learning algorithm construction. Data volume is reduced at the source by automatically identifying events in real time;

- (2)

- When monitoring hydraulic fracturing, the optical fiber needs to be fixed outside the casing and entered into the well together with the casing. In case of casing damage and perforation offset, it is difficult to ensure the integrity of the fiber. Ensuring that the fiber is not damaged is a prerequisite for successful monitoring. Although a number of techniques have been developed to avoid damage to the fiber during hole injection, they are not yet mature enough. Based on the technology of directional shot holes and junction-distributed fiber installation locations, we will continue to develop techniques to protect the fiber during the perforation process;

- (3)

- Distributed fiber optic measurement systems provide measurement data along the entire borehole and throughout the life of the well. With its unique advantages, it will definitely become a regular and important tool for fracture monitoring and evaluation. Among these, the DTS interpretation of flow profiles, DAS characterization of fracture parameters in hydraulic fracturing operations, optimization of fracture models, and joint monitoring and evaluation of hydraulic fracturing operations by DTS and DAS are a current theoretical research boom. In the future, reservoir parameter physical inversion and fracture monitoring and evaluation will continue to be hot research areas for DTS and DAS;

- (4)

- DAS is still limited by the directionality in microseismic monitoring. The technical difficulties, which are difficult to solve, are overcoming the dependence of DAS on direction and reducing the signal-to-noise ratio;

- (5)

- DTS has been very much studied in temperature-interpretation models for fractured horizontal wells, but DAS is still very much lacking in interpretation models for hydraulic fracturing. There are certain requirements for researchers if they want to translate the downhole information provided by DAS. Researchers need to have multidisciplinary knowledge, such as expertise in optics, logging, mathematics, acoustics and fracturing. The interpretation results of DAS and the monitoring data of DTS are combined with each other to reduce the multi-solution of the problem and to give a reasonable interpretation of the DAS data.

6. Summary

- (1)

- By establishing a three-dimensional fiber optic intelligent sensing network, the dynamic changes of hydraulic fracturing and production of oil and gas fields can be monitored in real time, and distributed fiber optic measurement technology can provide technical support and a theoretical basis for decision management and product development of oil and gas fields;

- (2)

- Real-time strain and microseismic data acquired by DAS monitor low-frequency strain and microseismics. These data can be used to observe the strain effect and fracturing-operation process in treatment wells. This includes stress disturbance, pump stopping time and fracture-extension dynamics. Based on the data provided by DAS, fracture length, height, width and density can be obtained, providing valuable data for fracture monitoring to constrain the fracture geometry and model to optimize fracturing and completion operations in real time;

- (3)

- DAS can monitor the core details of the fracturing process, such as bridge-plug sealing, ball seating, perforation and fracturing-fluid injection at different stages. DAS can monitor fracturing-fluid injection in clusters with a resolution of less than 3 m. This not only improves the monitoring capability from fracturing section to fracturing cluster but also achieves real-time dynamic and intuitive evaluation of the hydraulic fracturing effect;

- (4)

- The temperature variation is affected differently by formation permeability, fluid exchange rate and thermal properties of fluids and rocks. Based on the transient temperature data monitored by distributed fiber optic temperature sensors in real time and combined with downhole pressure-test data, reservoir property parameters (such as permeability, flow coefficient, skin coefficient, damage radius and damage permeability) are solved by establishing flow and thermodynamic models of reservoir and wellbore. The model is built to achieve the purpose of reservoir physical parameter inversion and flow-profile interpretation;

- (5)

- The data provided by the DSS strain based on the Rayleigh-frequency-shift principle are used to study the “pressure–strain variation path” of each fracture cluster, and their numerical simulation can not only explain and quantify the fracture characteristics and production in the near-well area but also provide important information about the fracture conductivity and reservoir fluid supply in the near-well area;

- (6)

- Distributed fiber optic measurement technology is increasingly used in hydraulic fracturing and production monitoring. With the development of distributed fiber optic measurement technology and more in-depth research in related fields, a multi-component, multi-parameter, multi-channel composite instrument that integrates distributed fiber optic temperature, acoustic and strain sensors can be developed in the future. Distributed fiber optic measurement technology continues to be optimized toward improving measurement accuracy and operational efficiency and reducing system costs. Technicians also need to continuously improve the knowledge of the relationship between measurement data and reservoir physical properties.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| the distance from the incident end to the reflected end, m; | |

| speed of light in a vacuum, m/s; | |

| speed of light propagation in the fiber, , m/s; | |

| refractive index of the fiber; | |

| the time required for the incident light to be received as reflected light, s; | |

| absolute temperature, K; | |

| Raman translation, ; | |

| Planck’s constant, J/K; | |

| the temperature dependent coefficient is the temperature dependent coefficient; | |

| inverse Stokes light intensity, cd; | |

| Stokes light intensity, cd; | |

| the frequency shift of the Rayleigh scattering spectrum; | |

| and | depend on the nature and structure of the fiber material; |

| and | strain and temperature variations, respectively. |

| the flow rate, | |

| sound pressure level; (The sound pressure level is the intensity of the sound and is replaced by the acoustic energy in the calculation.) | |

| A and B | the correlation coefficients. |

References

- Zou, C.N.; Yang, Z.; Dong, D.Z.; Zhao, Q.; Chen, Z.H.; Feng, Y.L.; Li, J.R.; Wang, X.N. Formation, Distribution and Prospect of Unconventional Hydrocarbons in Source Rock Strata in China. Earth Sci. 2022, 47, 1517–1533. [Google Scholar]

- Khormali, A.; Sharifov, A.-R.; Torba, D.-I. The control of asphaltene precipitation in oil wells. Pet. Sci. Technol. 2018, 36, 443–449. [Google Scholar] [CrossRef]

- Tabatabaei, M.; Zhu, D. Fracture Stimulation Diagnostics in Horizontal Wells Through Use of Distributed Temperature Sensing Technology. SPE Prod. Oper. 2012, 37, 154–158. [Google Scholar] [CrossRef]

- Song, X. Research and application of real-time monitoring and interpretation technology for hydraulic fracturing. Inn. Mong. Petrochem. Petrochem. Petrochem. Ind. 2011, 37, 154–158. [Google Scholar]

- Liu, X. Research and Application of Real-Time Monitoring and Interpretation Technology for Hydraulic Fracturing; Southwest Petroleum University: Chengdu, China, 2003. [Google Scholar]

- Li, H.; Luo, H.; Xiang, Y.; Xiang, Y.; An, S.; Li, Y.; Jiang, B.; Xie, B.; Xin, Y. The Application Status and Prospect of DTS/DAS in Fracturing Monitoring of Horizontal Wells. Xinjiang Oil Gas 2021, 17, 62–73. [Google Scholar]

- Sui, W.; Liu, R.; Cui, K. Application and research progress of distributed optical fiber acoustic sensing monitoring for hydraulic fracturing. Sci. Sin. Tech. 2021, 51, 371–387. (In Chinese) [Google Scholar] [CrossRef]

- Sui, W.; Zhang, D.; Wang, M.; Wang, X. Review on application and theoretical models for temperature monitoring technology under intelligent well completion conditions in oil and gas field development. Pet. Geol. Recovery Effic. 2020, 27, 129–138. [Google Scholar]

- Zhu, G.; Wang, X. Fiber Optic Sensing for Improving Wellbore Surveillance. Well Logging Technol. 2014, 38, 251–256. [Google Scholar]

- Zhu, S.; Li, H.; Zhang, J.; Tang, C.; Yang, M. Potential of fiber optic distributed temperature sensing technology for oilfield development. Reserv. Eval. Dev. 2015, 5, 69–75. [Google Scholar]

- Costello, C.; Sordyl, P.; Hughes, C.; Figueroa, M.; Balster, E.; Brown, G. Permanent Distributed Temperature Sensing (DTS) Technology Applied In Mature Fields: A Forties Field Case Study. In Proceedings of the SPE Intelligent Energy International Conference and Exhibition, Utrecht, The Netherlands, 27–29 March 2012. [Google Scholar]

- MoSoroush, M.; Roostaei, M.; Fattahpour, V.; Mahmoudi, M.; Keough, D.; Cheng, L.; Moez, K. Prognostics thermal well management: A review on wellbore monitoring and the application of Distributed Acoustic Sensing DAS for steam breakthrough detection. In Proceedings of the SPE Thermal Well Integrity and Design Symposium 2019, Banff, AB, Canada, 19–21 November 2019. [Google Scholar]

- Zhou, X.; Chen, W.; Jiangfeng, Y.; Li, X. Application review of DAS technology in oil and gas geophysics. Prog. Geophys. 2021, 36, 338–350. [Google Scholar]

- Liang, G.; Shaohua, Z.; Gang, Y.; Ximing, W.; Shujie, A.; Junjun, W.; Yuanzhong, C. Optical Sensing Promotes Intelligence, Innovation and Development of Reservoir Geophysical Technology. Pet. Sci. Technol. Forum 2021, 40, 55–64. [Google Scholar]

- Parker, T.; Shatalin, S.; Farhadiroushan, M. Distributed Acoustic Sensing—A new tool for seismic applications. First Break 2014, 32. [Google Scholar] [CrossRef]

- Jin, G.; Ugueto, G.; Wojtaszek, M.; Guzik, A.; Jurick, D.; Kishida, K. Novel Near-Wellbore Fracture Diagnosis for Unconventional Wells Using High-Resolution Distributed Strain Sensing during Production. SPE J. 2021, 26, 3255–3264. [Google Scholar] [CrossRef]

- Ugueto, G.A.; Wojtaszek, M.; Mondal, S.; Guzik, A.; Jurick, D.; Jin, G. New Fracture Diagnostic Tool for Unconventionals: High-Resolution Distributed Strain Sensing via Rayleigh Frequency Shift during Production in Hydraulic Fracture Test 2. In Proceedings of the SPE/AAPG/SEG Unconventional Resources Technology Conference 2021, Online, 16–18 November 2021. [Google Scholar]

- Sierra, J.R.; Kaura, J.D.; Gualtieri, D.; Glasbergen, G.; Sarker, D.; Johnson, D. DTS Monitoring Data of Hydraulic Fracturing: Experiences and Lessons Learned. Presented at the SPE Annual Technical Conference and Exhibition, Denver, CO, USA, 21–24 September 2008. Paper SPE 116182. [Google Scholar]

- Al Shoaibi, S.; Kechichian, J.; Mjeni, R.; Al Rajhi, S.; Bakker, G.G.; Hemink, G.; Freeman, F. Implementing fiber optics distributed sensing as a key surveillance tool. In Proceedings of the Abu Dhabi International Petroleum Exhibition & Conference 2016, Abu Dhabi, United Arab Emirates, 7–10 November 2016. [Google Scholar]

- Soroush, M.; Mohammadtabar, M.; Roostaei, M.; Hosseini, S.A.; Fattahpour, V.; Mahmoudi, M.; Keough, D.; Tywoniuk, M.; Mosavat, N.; Cheng, L.; et al. Downhole Monitoring Using Distributed Acoustic Sensing: Fundamentals and Two Decades Deployment in Oil and Gas Industries. In Proceedings of the SPE Conference at Oman Petroleum & Energy Show 2022, Muscat, Oman, 21–23 March 2022. [Google Scholar]

- Sanchez, A.; Brown, G.A.; Carvalho, V.L.; Wray, A.S.; Gutierrez Murillo, G. Slickline with fiber-optic distributed temperature monitoring for water-injection and gas lift systems optimization in Mexico. In Proceedings of the SPE Latin American and Caribbean Petroleum Engineering Conference 2005, Rio de Janeiro, Brazil, 20–23 June 2005. [Google Scholar]

- Weaver, M.A.; Kragas, T.K.; Burman, J.; Copeland, D.L.; Phillips, B.; Seagraves, R. Installation and Application of Permanent Downhole Optical Pressure/Temperature Gauges and Distributed Temperature Sensing in Producing Deepwater Wells at Marco Polo. In Proceedings of the SPE Annual Technical Conference and Exhibition 2005, Dallas, TX, USA, 9–12 October 2005. [Google Scholar]

- Ting, C.S.; Minggu, N.A.; Kamat, D.; Chaw, K.T.; Tan, C.S.; Kalidas, S.; Barretto, G.J. Production Enhancement Evaluation via Permanent Fiber Optics Distributed Temperature Sensing Interpretation for a Gas-Lifted Producer in Field B, Offshore Malaysia. In Proceedings of the Offshore Technology Conference Asia 2022, Kuala Lumpur, Malaysia, 22–25 March 2022. [Google Scholar]

- Bello, O.; Bale, D.S.; Yang, L.; Yang, D.; Kb, A.; Lajith, M.; Lazarus, S. Integrating downhole temperature sensing datasets and visual analytics for improved gas lift well surveillance. In Proceedings of the SPE Annual Technical Conference and Exhibition 2018, Dallas, TX, USA, 24–26 September 2018. [Google Scholar]

- Patel, D.; Wee, K.; Gorgi, S.; Ashraf, H. Success Story: 64 Wells with Hybrid Real Time DTS/DAS Monitoring and Permanent Downhole Gauges Installed in the United Arab Emirates. In Proceedings of the Abu Dhabi International Petroleum Exhibition & Conference 2020, Abu Dabi, United Arab Emirates, 9–12 November 2020. [Google Scholar]

- Li, Y. Production Profile Interpretation Model and Its Software Development Based on DTS Data for Horizontal Well in Bottom Production Profile Interpretation Model and Its Software Development Based on DTS Data for Horizontal Well in Bottom Water Gas Reservoir; Southwest Petroleum University: Chengdu, Chiana, 2018. [Google Scholar]

- Wu, M.; Zheng, Y.; Long, T.; Duan, Y.; Wei, M. Interpretation of gas well production profile based on distributed temperature sensing monitoring: A case study of multilayered exploration wells in Yongle, South China Sea. Sci. Technol. Eng. 2022, 22, 2245–2251. [Google Scholar]

- Fu, J.; Xiao, L.; Zhang, Y. Progress of permanent fiber-optic sensor applications to oil and gas well. Prog. Geophys. 2004, 19, 515–523. [Google Scholar]

- Ramey, H.J. Wellbore heat transmission. J. Pet. Technol. 1962, 14, 427–435. [Google Scholar] [CrossRef]

- Zhao, Z.; Yang, H.; Wu, J.; Chang, C.; Sun, H.; Sepehrnoori, K.; Yu, W.; Torres, F.; Xavier, M. Fracture Diagnosis with Distributed Temperature Sensing Using Thermal Embedded Discrete Fracture Model (EDFM). In Proceedings of the 55th US Rock Mechanics/Geomechanics Symposium 2021, Online, 18–25 June 2021. [Google Scholar]

- Yang, B. Successful Flow Profiling of Gas Wells Using Distributed Temperature Sensing Data. Inn. Mong. Petrochem. Petrochem. Ind. 2013, 39, 47–50. [Google Scholar]

- Hongwen, L.U.O.; Haitao, L.I.; Huibin, L.I.U. A novel method to interpret production profiles of fractured horizontal well in low-permeability gas reservoir by inversing DTS data. Nat. Gas Geosci. 2019, 30, 1639–1645. [Google Scholar]

- Li, H.; Luo, H.; Xiang, Y.; Li, Y.; Jiang, B.; Cui, X.; Gao, S.; Zou, S.; Xin, Y. DTS based hydraulic fracture identification and production profile interpretation method of horizontal well. Nat. Gas Ind. 2021, 41, 66–75. [Google Scholar] [CrossRef]

- Wang, X.; Bussear, T.R. Real time horizontal well monitoring using distributed temperature sensing (DTS) technology. In Proceedings of the OTC Brasil Conference, Rio de Janeiro, Brazil, 4–6 October 2011. [Google Scholar]

- Sookprasong, P.A.; Hurt, R.S.; Gill, C.C. Downhole monitoring of multicluster, multistage horizontal well fracturing with fiber optic distributed acoustic sensing (DAS) and distributed temperature sensing (DTS). In Proceedings of the International Petroleum Technology Conference 2014, Doha, Qatar, 19–22 January 2014. [Google Scholar]

- Ugueto, C.G.A.; Huckabee, P.T.; Molenaar, M.M.; Wyker, B.; Somanchi, K. Perforation cluster efficiency of cemented plug and perf limited entry completions; Insights from fiber optics diagnostics. In Proceedings of the Spe Hydraulic Fracturing Technology Conference 2016, The Woodlands, TX, USA, 9–11 February 2016. [Google Scholar]

- Tabatabaei, M.; Ding, Z. Fracture stimulation diagnostics in horizontal wells using DTS. In Proceedings of the Canadian Unconventional Resources Conference 2011, Calgary, AB, Canada, 15–17 November.

- McCullagh, C.L.; Tutuncu, A.N.; Song, T.H. Coupling distributed temperature sensing (DTS) based wellbore temperature models with microseismic data for enhanced characterization of hydraulic fracture stimulation. In Proceedings of the 48th US Rock Mechanics/Geomechanics Symposium 2014, Minneapolis, MN, USA, 1–4 June 2014. [Google Scholar]

- Li, H.; Guo, Z.; Luo, H.; Xiang, Y.; Liu, W.; Ai, Y. Physical simulation experiment on temperature profile of fractured horizontal well in gas reservoir. Sci. Technol. Eng. 2021, 21, 14133–14138. [Google Scholar]

- Ghosh, S.; Zhou, D.; App, J.; Jain, L.; Hughes, K.; Emery, D.; Fu, J.; Zhang, R. Insights into fracture fluid distribution and fracture geometry in hydraulically fractured horizontal wells through thermal simulations and fiber optics distributed temperature sensing (FO-DTS) measurements. In Proceedings of the Unconventional Resources Technology Conference (URTEC) 2020, Austin, TX, USA, 20–22 July 2020; pp. 3787–3796. [Google Scholar]

- He, S.; Yu, W.; Sepehrnoori, K. Fracture Characterization and Flow Profiling with Distributed Temperature Sensing. In Proceedings of the Unconventional Resources Technology Conference (URTEC) 2020, Austin, TX, USA, 20–22 July 2020; pp. 4213–4244. [Google Scholar]

- Molenaar, M.M.; Cox, B.-E. Field cases of hydraulic fracture stimulation diagnostics using fiber optic distributed acoustic sensing (DAS) measurements and Analyses. In Proceedings of the SPE Unconventional Gas Conference and Exhibition 2013, Muscat, Oman, 28–30 January 2013. [Google Scholar]

- Evans, S.; Holley, E.; Dawson, K.; Garrison, N.; Montes, M.; Preston, G.; Hudson, S. Eagle Ford Case History: Evaluation of Diversion Techniques to Increase Stimulation Effectiveness. In Proceedings of the SPE/AAPG/SEG Unconventional Resources Technology Conference, San Antonio, TX, USA, 1–3 August 2016. [Google Scholar]

- Wheaton, B.; Haustveit, K.; Deeg, W.; Miskimins, J.; Barree, R. A case study of completion effectiveness in the eagle ford shale using DAS/DTS observations and hydraulic fracture modeling. In Proceedings of the SPE Hydraulic Fracturing Technology Conference, The Woodlands, TX, USA, 9–11 February 2016. [Google Scholar]

- Pakhotina, J.; Zhu, D.; Hill, A.D. Evaluating Perforation Erosion and its Effect on Limited Entry by Distributed Acoustic Sensor DAS Monitoring. In Proceedings of the SPE Annual Technical Conference and Exhibition 2020, Online, 26–29 October 2022. [Google Scholar]

- Pakhotina, I.; Sakaida, S.; Zhu, D.; Hill, A.D. Diagnosing multistage fracture treatments with distributed fiber-optic sensors. SPE Prod. Oper. 2020, 35, 852–864. [Google Scholar]

- Sakaida, S.; Pakhotina, I.; Zhu, D.; Hill, A.D. Estimation of Fracture Properties by Combining DAS and DTS Measurements. In Proceedings of the SPE International Hydraulic Fracturing Technology Conference & Exhibition 2022, Muscat, Oman, 11–13 January 2022. [Google Scholar]

- Sherman, C.S.; Mellors, R.J.; Morris, J.P. Subsurface monitoring via physics-informed deep neural network analysis of DAS. In Proceedings of the 53rd US Rock Mechanics/Geomechanics Symposium 2019, New York, NY, USA, 23–26 June 2019. [Google Scholar]

- Liu, Y.; Wu, K.; Jin, G.; Moridis, G. Hydraulic fracture modeling of fracture-induced strain variation measured by low-frequency distributed acoustic sensing (LF-DAS) along offset wells. In Proceedings of the 54th US Rock Mechanics/Geomechanics Symposium, Online, 28 June–1 July 2020. [Google Scholar]

- Liu, Y.; Wu, K.; Jin, G.; Moridis, G.J.; Kerr, E.; Scofield, R.; Johnson, A. Strain and strain-rate responses measured by LF-DAS and corresponding features for fracture-hit detection during multiple-fracture propagation in unconventional reservoirs. In Proceedings of the Unconventional Resources Technology Conference (URTEC), Online, 20–22 July 2020; pp. 1134–1152. [Google Scholar]

- Ming, C.; Guo, T.; Xu, Y.; Qu, Z.; Zhang, Z.; Zhou, T.; Wang, Y. Evolution mechanism of optical fiber strain induced by multi-fracture growth during fracturing in horizontal well. Pet. Explor. Dev. 2022, 49, 183–193. [Google Scholar]

- Schumann, H.; Jin, G. Inferring near-well conductivity from DAS-recorded tube waves generated by perforation shots. In Proceedings of the SEG International Exposition and Annual Meeting 2020, Online, 11–16 October 2020. [Google Scholar]

- Ugueto, G.A.; Todea, F.; Daredia, T.; Wojtaszek, M.; Huckabee, P.T.; Reynolds, A.; Laing, C.; Chavarria, J.A. Can you feel the strain? DAS strain fronts for fracture geometry in the BC Montney, Groundbirch. In Proceedings of the SPE Annual Technical Conference and Exhibition 2019, Calgary, AB, Canada, 30 September–2 October 2019. [Google Scholar]

- Zhu, X.; Ge, J. Analysis of cross-well fracture hits in DJ Basin, Colorado using low-frequency DAS data. In Proceedings of the SEG/AAPG/SEPM First International Meeting for Applied Geoscience & Energy 2021, Denver, CO, USA, 26 September–1 October 2021. [Google Scholar]

- Holzhausen, G.-R.; Gooch, R.-P. Impedance of hydraulic fractures: Its measurement and use for estimating fracture closure pressure and dimensions. In Proceedings of the SPE/DOE Low Permeability Gas Reservoirs Symposium 1985, Denver, CO, USA, 19–22 May 1985. [Google Scholar]

- Wu, C. 3D finite-difference elastic modeling for DAS VSP and microseismic surveys. In Proceedings of the SEG/AAPG/SEPM First International Meeting for Applied Geoscience & Energy 2021, Denver, CO, USA, 26 September–1 October 2021. [Google Scholar]

- Pakhotina, J.; Zhu, D.; Hill, A.D.; Santos, R. Characterization of production through a fracture cell using acoustic data. In Proceedings of the SPE Annual Technical Conference and Exhibition 2017, San Antonio, TX, USA, 9–11 October 2017. [Google Scholar]

- Mestayer, J.; Cox, B.; Wills, P.; Kiyashchenko, D.; Lopez, J.; Costello, M.; Bourne, S.; Ugueto, G.; Lupton, R.; Solano, G.; et al. Field trials of distributed acoustic sensing for geophysical monitoring. In SEG Technical Program Expanded Abstracts; Society of Exploration Geophysicists: Houston, TX, USA, 2011; pp. 4253–4257. [Google Scholar]

- Mateeva, A.; Mestayer, J.; Cox, B.; Kiyashchenko, D.; Wills, P.; Lopez, J.; Grandi, S.; Hornman, K.; Lumens, P.; Franzen, A.; et al. Advances in distributed acoustic sensing (DAS) for VSP. In SEG Technical Program Expanded Abstracts 2012; Society of Exploration Geophysicists: Houston, TX, USA, 2012; pp. 1–5. [Google Scholar]

- Zhou, R.; Willis, M.E.; Cheng, D.; Green, K. Characterization of a Fractured Reservoir Using DAS VSP—A Model-Based Reflection Amplitude Study. In Proceedings of the Fourth EAGE Borehole Geophysics Workshop, Abu Dhabi, United Arab Emirates, 19–22 November 2017; European Association of Geoscientists & Engineers: Utrecht, The Netherlands, 2017; pp. 1–5. [Google Scholar]

- Cole, S.; Karrenbach, M.; Boone, K.; Ridge, A.; Kahn, D.; Rich, J.; Silver, K.; Langton, D. Effective diffusivity estimates from distributed fiber-optic strain and microseismic measurements. In Proceedings of the 2017 SEG International Exposition and Annual Meeting, Houston, TX, USA, 24–29 September 2017. [Google Scholar]

- Chen, K.; Zhu, D.; Hill, A.D. Acoustic signature of flow from a fractured wellbore. In Proceedings of the SPE Annual Technical Conference and Exhibition 2015, Houston, TX, USA, 28–30 September 2015. [Google Scholar]

- Binder, G.; Titov, A.; Tamayo, D.; Simmons, J.; Tura, A.; Byerley, G.; Monk, D. Time delays from stress-induced velocity changes around fractures in a time-lapse DAS VSP. In Proceedings of the 2018 SEG International Exposition and Annual Meeting, Anaheim, CA, USA, 14–19 October 2018. [Google Scholar]

- Molenaar, M.M.; Hill, D.J.; Webster, P.; Fidan, E.; Birch, B. First downhole application of distributed acoustic sensing for hydraulic-fracturing monitoring and diagnostics. SPE Drill. Complet. 2012, 27, 32–38. [Google Scholar] [CrossRef]

- Gale, J.F.; Elliott, S.J.; Laubach, S.E. Hydraulic fractures in core from stimulated reservoirs: Core fracture description of HFTS slant core, Midland Basin, West Texas. In Proceedings of the Unconventional Resources Technology Conference, Houston, TX, USA, 23–25 July 2018; pp. 1340–1357. [Google Scholar]

- Zakhour, N.; Jones, M.; Zhao, Y.; Orsini, K.; Sahni, V. HFTS-2 Completions Design and State-of-the-Art Diagnostics Results. In Proceedings of the Unconventional Resources Technology Conference (URTeC), Houston, TX, USA, 26–28 July 2021; pp. 1162–1185. [Google Scholar]

- Liu, Y.; Jin, G.; Wu, K. New Insights on Near-Wellbore Fracture Characteristics from High-Resolution Distributed Strain Sensing Measurements. In Proceedings of the Unconventional Resources Technology Conference (URTeC), Houston, TX, USA, 26–28 July 2021; pp. 3366–3383. [Google Scholar]

- Liu, Y.; Jin, G.; Wu, K. New Insights on Characteristics of the Near-Wellbore Fractured Zone from Simulated High-Resolution Distributed Strain Sensing Data. SPE Reserv. Eval. Eng. 2022, 25, 99–112. [Google Scholar] [CrossRef]

- Berghmans, F. Reliability of optical fibers and components. In Proceedings of the 17th International Conference on Optical Fibre Sensors 2005, Bruges, Belgium, 23–27 May 2005; pp. 20–23. [Google Scholar]

- Van Der Horst, J.; Lopez, J.L.; Berlang, W.; Potters, H. In-well distributed fiber optic solutions for reservoir surveillance. In Proceedings of the Offshore Technology Conference 2013, Houston, TX, USA, 6–9 May 2013. [Google Scholar]

| Installation Location | Monitoring Time | Advantages | Disadvantages | Monitoring Events |

|---|---|---|---|---|

| Outside of the casing | Permanent | 1. Coupling with reservoirs 2. No production delays 3. Can be deployed post-production | 1. One must consider the outer diameter of the casing and plan the installation clearance 2. Damage to fiber when perforation occurs | Monitoring near the wellbore or of cement quality |

| Outside of the tubing | Permanent/ Semi- Permanent | 1. Can be installed in existing wells 2. Can be deployed post-production | 1. No coupling to reservoirs 2. Damage to fiber when perforation occurs 3. Once removed it needs to be reinstalled | Monitoring of various types of leaks |

| Inside of the tubing | Semi- Permanent | 1. High benefits 2. Can be installed in horizontal wells with large inclination | 1. One must consider erosion resistance and avoid fiber damage 2. Interference conductivity material | Monitor stimulation and production |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Wu, Z.; Wang, F. Research Progress of Applying Distributed Fiber Optic Measurement Technology in Hydraulic Fracturing and Production Monitoring. Energies 2022, 15, 7519. https://doi.org/10.3390/en15207519

Wang Y, Wu Z, Wang F. Research Progress of Applying Distributed Fiber Optic Measurement Technology in Hydraulic Fracturing and Production Monitoring. Energies. 2022; 15(20):7519. https://doi.org/10.3390/en15207519

Chicago/Turabian StyleWang, Yilin, Zhuoping Wu, and Fuyong Wang. 2022. "Research Progress of Applying Distributed Fiber Optic Measurement Technology in Hydraulic Fracturing and Production Monitoring" Energies 15, no. 20: 7519. https://doi.org/10.3390/en15207519

APA StyleWang, Y., Wu, Z., & Wang, F. (2022). Research Progress of Applying Distributed Fiber Optic Measurement Technology in Hydraulic Fracturing and Production Monitoring. Energies, 15(20), 7519. https://doi.org/10.3390/en15207519