Abstract

The aim of the study was to verify the impact of the location of a cyclically heated building on its energy needs and interaction with the environment. The model building was a large-scale broiler house located in southern Poland. In the examined facility, year-round measurements of selected parameters of the internal and external microclimate were carried out. The tests also covered the temperature of the soil in three measurement columns. The obtained measurement results were used for further computer analyses. A geometric model of the building was made and a calculation model specification was introduced, supported by specialized software for the physics of WUFI®plus structures. The numerical analysis included validation. The validation results were assessed on the basis of the Coefficient of Determination method (R2) and the Goodness of Fit (GOF) method. Due to the lack of normality of the data distribution, a Rang-Spearman correlation analysis was carried out, which showed a very strong data correlation (0.94). The analysis of the R2 coefficient of determination confirmed the high reliability of the model (83%). In the case of the GOF method, a compliance value of 87% was obtained. Differentiated locations were adopted for further analysis, while maintaining the structure of the examined building in reality. Six European locations were selected: Kraków (Poland), Málaga (Spain), Brest (France), Visby (Sweden), Umea (Sweden), and Kiruna (Sweden). The analysis included three variants, in which the length of the technological break was adopted accordingly. A technological break between production cycles was assumed, the three variants of which lasted 3, 7, and 14 days. The analysis of the obtained results showed that the external microclimate significantly determines the energy interaction between the building and the ground. The length of the technological break is very important in a climate dominated by low temperatures (Northern Scandinavia). The south-western part of Europe allows the technological break to be extended without significant differences for heating purposes. The length of the technological break in the range of 3 to 14 days does not significantly affect the intensity of heat exchange with the ground on a yearly basis, regardless of the location of the building. There were differences of no more than 2% between the technological break lasting 3 days and the 14-day break.

1. Introduction

The second decade of the 21st century has brought many challenges for the global economy. Frequently raised topics include the reduction of greenhouse gas emissions to the atmosphere, reduction of production costs, and reduction of water consumption [1,2,3,4]. The adoption of sensible solutions to these issues is extremely difficult, due to increasing energy consumption. According to recent research, the construction sector in Europe contributes to the emission of 30% of carbon dioxide to the atmosphere on a global scale, while in the United States alone, construction consumes over 40% of the energy produced there [5,6]. Energy expenditure in the livestock sector, aimed at intensive livestock production, can account for up to 48% of the total energy needed for animal husbandry [7]. In these types of buildings, there are many opportunities to improve energy efficiency. It is very important that the adopted material and construction solutions as well as the way the building is operated allow for minimizing heat losses and increasing potential gains from the external environment [8,9].

The thermal interaction between buildings and the surrounding environment is a very complex phenomenon. This subject is much more discussed in the case of residential buildings [10,11]. However, agricultural buildings require constant broadening of knowledge in this area. The nature of this phenomenon is influenced by a number of factors, such as the purpose of the building, the material and construction solutions used, soil and water conditions, and the way the building is used [12,13,14]. The location, which determines the nature of geographical climatic factors, is also very important for the course of interaction between the building and the external environment [15,16]. The interaction between the building and the external environment will therefore depend on: latitude, land and ocean distribution, elevation above sea level, terrain layout, and the type of land cover. With this in mind, it is extremely difficult to adopt universal material and construction solutions or a single method of using buildings which would be equally effective in various locations. It is even more difficult to precisely determine the operating parameters of a building that is heated cyclically. An example of such an object may be a large-scale broiler house, in which intensive animal production takes place most often in 6-week cycles. Between the cycles, a so-called technological break is respected, which is aimed at disinfecting and preparing the interior of the hall for the next production cycle. The research carried out so far has shown a significant impact of the length of the technological break on the energy demand of this type of building [17].

The continuous and rapid progress of computer technology and digitization has allowed for efficient execution of complex engineering calculations. New computer programs are constantly being developed and improved, enabling simulations in the field of building physics and HVAC systems. The results obtained using calculations in computer programs can be used, among others, to forecast the thermal load, as well as to accurately determine the power of devices operating in active building systems. Despite the high availability of computer programs enabling simulation of physical processes taking place in buildings and soil, it should be remembered that it is necessary to verify the obtained results of calculations with experimental research. The deviations of the obtained data may exceed as much as 35% between programs [18]. For this reason, it is very important to carry out a validation of the calculation model in order to carry out further analyses.

The article presents a comparative analysis of the energy demand of a cyclically heated building for different lengths of the technological break, taking into account different locations in Europe. The interaction between the building and the ground was also examined, determining the magnitude of the heat flux flowing between the floor of the building and the ground underneath it. The analysis was supported by a previously validated calculation model based on the numerical method of elementary balances (MEB).

2. Materials and Methods

2.1. Test Object-Experimental Tests, Measuring Equipment

Experimental research was carried out in a large-scale broiler house, located in the southern part of Poland. The building was built using traditional, brick technology, and was set on concrete foundations, the base level of which was 1.00 m below ground level. The structure of the floor was layered, consisting of a gravel and sand bedding with a thickness of 0.20 m, a substructure of concrete class C12/15, with a thickness of 15 cm, and a cement screed with a thickness of 10 cm. The floor of the building did not have thermal insulation. The external walls were made using two-layer technology. The construction material consisted of cellular concrete blocks, 0.24 m thick (type 600). The thermal insulation of external walls made use of EPS façade polystyrene, 0.10 m thick. The roof support structure consisted of UPN 140 steel u-channels, between which a layer of 0.10 mineral wool was laid. The ceiling was finished on the lower side using galvanized steel sheet. The roof structure consisted of steel cross frames made of UPN 120 (upper band) and UPN 100 (lower band) steel u-channels. The entire structure was reinforced with struts and L 50 × 50 × 5 posts. The roof covering was made of galvanized, trapezoidal sheet metal.

In the broiler house, tubular and wall heating were used, supplied from the boiler house. In order to support the conventional heating system, four electric heaters were also used. The building was ventilated by exhaust fans. Fresh air was drawn through ventilation openings equipped with jet dampers, located on opposite walls to the fans. The building was also equipped with a misting system.

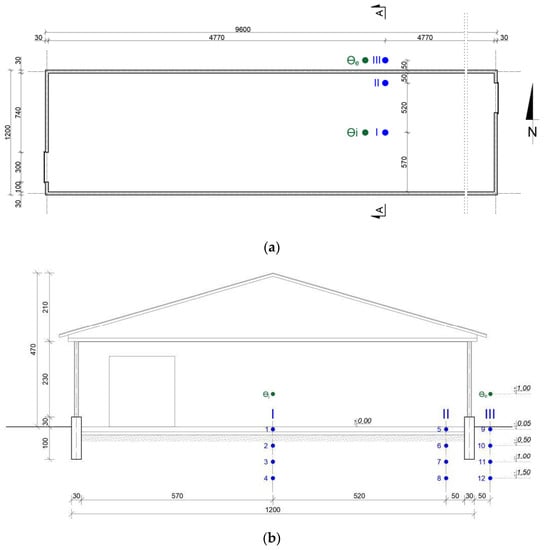

The research covered the area of the production hall located in the middle part of the building, between the longitudinal axis of the broiler house and its external wall (Figure 1).

Figure 1.

Horizontal plan (a), cross-section of the studied building (b) and arrangement of measurement points; Θe—point of measurement of the temperature of the external air; Θi—point of measurement of the temperature of the internal air; I, II, III—measurement columns; 1, 2…12—points of measurement of the temperature of the ground.

The temperature measurement points in the ground are located in 3 measurement columns. The set of measuring and control equipment included a multi-channel recorder from HP and 14 PT-100 sensors with a resolution of 0.1 °C and a measurement error of ±0.1 °C (12 sensors for measuring the ground temperature and 2 sensors for measuring the temperature of the external and internal air). The measurement frequency was 1 h. Field measurements were carried out in the period from 26 February 2018 to 3 June 2021. This article discusses the year-long period from 4 June 2020 to 3 June 2021, due to the modernization of the research facility at the beginning of 2020. During the period of the study, broiler chickens (Ross breed) did not experience bacterial or viral diseases that would have a significant impact on the rearing process and production results. The conducted research did not interfere with the welfare of animals and did not require the consent of the Veterinary Inspectorate.

The obtained measurement data were used for the validation of the calculation model and further numerical analyses.

2.2. Validation of the Calculation Model

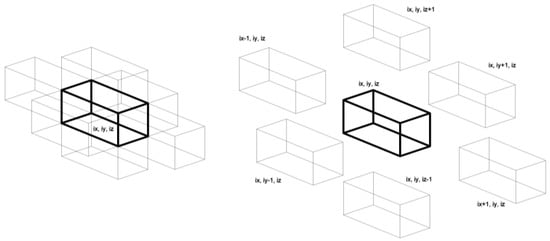

The validation of the computational model and the geometric model of the building and the ground were performed using specialized computer software WUFI®plus (Ver. 3.2.0.23, IBP Fraunhofer, Holzkirchen, Germany). The model takes into account the values of the physical parameters of the materials used to construct the building and the physical parameters of the soil (Table 1). Table 2 presents data on the heat transfer coefficient for the building envelope. Calculations were made on the basis of MEB. This method is currently one of a group of highly efficient and accurate numerical methods. It is especially recommended for calculations taking into account three-dimensional and non-stationary heat flow in the ground and in adjacent structural elements of a building. The idea of the elementary balance sheet method is to divide the complex area into rectangular balance-differential elements (Figure 2).

Table 1.

Physical parameters of the soil and construction materials used in the calculations.

Table 2.

The heat transfer coefficient of building partitions of the tested building.

Figure 2.

Balance and differential element with adjacent elements.

For each differential balance element, energy and temperature balance calculations were carried out assuming a time interval of 60 min. The heat flux flowing through the analyzed area is calculated on a non-stationary basis assuming the time interval Δτ Equation (1), where i—element number, Φixiyiz,…–heat flux (heat flows) flowing between the element ix iy iz and adjacent elements.

In the process of validation of the calculation model, a geometric model of the research object and the results of field measurements were used. The boundary condition of the external microclimate was the reference meteorological year (TRY) for Kraków (Poland). In order to meet the basic hygienic requirements of the interior of the modelled object, a minimum air exchange at the level of 1.0 h−1 was adopted. The indoor air temperature was maintained through a modelled heating system. The task of the heating system was to maintain the set internal air temperature based on the actual measurement data. The need to use actual measurement data results from the specificity of the building in which the heating takes place in accordance with the course of production cycles. During technological breaks, between production cycles, heating is switched off or its power drops significantly (in winter). If the set internal air temperature is exceeded, the model makes it possible to increase the ventilation efficiency to 5.0 h−1.

The calculation model requires preliminary calculations, assuming the initial temperature of the soil. After a dozen or so calculation series, it was found that a period of 90 days allows for equalization of the initial conditions and such a period was adopted for further analysis. This allowed for the elimination of the occurrence of an initial error with a significant discrepancy between the measurement results and the simulation results. The initial temperature of the ground in the validation was assumed equal to the average annual temperature of the external air for each of the six locations studied (Kraków, Málaga, Brest, Visby, Umea, Kiruna). The validation process took place in the following stages:

- (1)

- Implementation of the results of actual measurements to the model;

- (2)

- Creation of a geometric model of the building and soil;

- (3)

- Declaration of physical parameters of materials used in the model;

- (4)

- Adoption of a 90-day period of initial simulation, a learning phase for the computational model to adapt to the real conditions;

- (5)

- Determination of the characteristics of the HVAC system;

- (6)

- Planning and implementation of control points corresponding to actual measurement points in the geometric model;

- (7)

- Conduct of the simulation; and

- (8)

- Verification of compliance of the theoretical results with the actual results.

After completing the validation process, an analysis of the reliability of the model and the possibility of its calibration was carried out using the Coefficient of Determination method (R2) and the Goodness of Fit (GOF) method, consisting in checking the fluctuation of measurement data and calculated by correlation of these two series of data [17,18]. Both methods are based on a monthly criterion. The method R2 can be described by the Equation (2), where mi—is the parameter measurement result, —the average from parameter measurement, si—the parameter simulation result, —the average from parameter simulation:

whereas the GOF method can be expressed using the Equation (3), where mi—the parameter measurement result, —the average from the parameter measurement, si—the parameter simulation result, —the average from the parameter simulation:

The calculation model subjected to validation and subsequent calibration should therefore yield results that are >75% for method R2 and >80% for the GOF method.

2.3. Calculations

Simulations of the interaction between the building under study and the external environment and the ground were carried out for 6 locations in Europe (Figure 3): Kraków (Poland), Málaga (Spain), Brest (France), Visby (Sweden), Umea (Sweden), and Kiruna (Sweden). The analysis included 3 variants, in which the length of the technological break was adopted accordingly. It was assumed that the technological break would last 3, 7, and 14 days.

Figure 3.

Locations were included in the simulation of the interaction between the tested building and the external environment.

3. Results

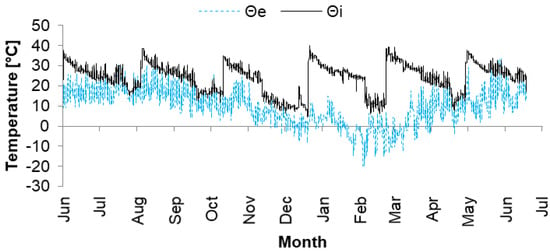

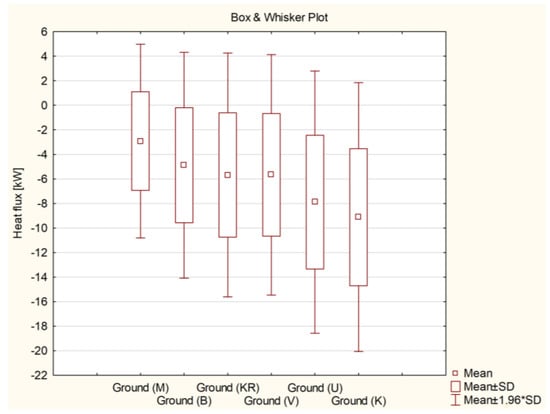

3.1. Field Measurement Results

The research was conducted from 4 June 2020 to 03 June 2021. During this period, 6 production cycles were recorded, separated by five technological breaks. In the early days of the cycle, the indoor air temperature (Θi) was in the range of 33–40 °C, which exceeded the recommended temperature. During the cycle, the indoor air temperature dropped to 17–20 °C by the end of the production cycles. The duration of the technological break in spring, summer and autumn was strongly varied and ranged from 6 to 24 days. In the winter, the technological break in February amounted to 16 days (Figure 4). During the break, the building was unheated.

Figure 4.

Indoor air temperature waveform Θi compared to outdoor air temperature Θe.

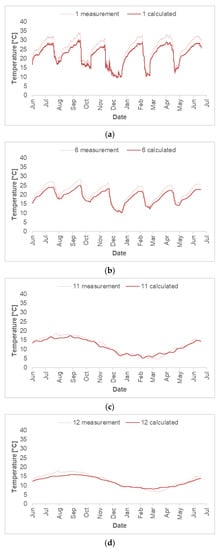

3.2. Validation

The validation process was carried out after prior preparation of the geometric model and specification of the calculation model. Validation was carried out for all measurement points located in the ground. For the purposes of the article, Figure 5 presents selected results from measurement and control points. The obtained results were subjected to a thorough analysis in terms of the significance of statistical differences and the R2 and GOF methods. Due to the lack of normality of the data distribution, a Rang–Spearman correlation analysis was carried out, which showed a very strong data correlation (0.94). The analysis of the R2 coefficient of determination confirmed the high reliability of the model (83%). In the case of the GOF method, a compliance value of 87% was obtained. Therefore, it was considered that the accuracy of the model and its calibration allowed for the conduct of the next step, consisting in simulating the interaction of the building, for different locations and different lengths of the technological break.

Figure 5.

Results of validation and calibration of the calculation model at measurement and control points: 1 (a), 6 (b), 11 (c) and 12 (d).

3.3. Simulation of External and Internal Microclimate

Simulations of the interaction between the building under study and the external environment and the ground were carried out for 6 locations in Europe: Kraków (Poland), Málaga (Spain), Brest (France), Visby (Sweden), Umea (Sweden), and Kiruna (Sweden). In order to facilitate the interpretation of the results and their presentation in graphical form, the following abbreviations have been assigned to individual locations: Kraków—KR, Málaga—M, Brest—B, Visby—V, Umea—U, Kiruna—K.

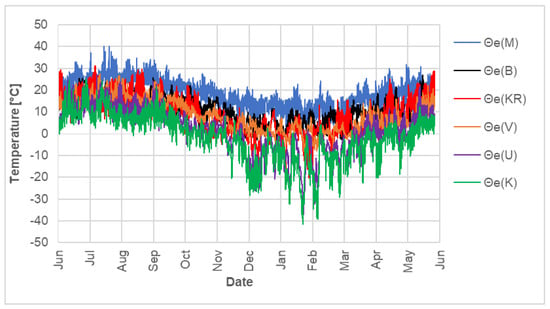

The analysis of the external microclimate (Figure 6) showed a significant differentiation between the adopted locations.

Figure 6.

Course of outside air temperature Θe in the analyzed locations: Kraków—KR, Málaga—M, Brest—B, Visby—V, Umea—U, Kiruna—K.

Table 3 shows the basic statistics of data Θe.

Table 3.

Characteristics of the external air temperature in the tested locations.

The computational model used allowed for the maintenance of a similar microclimate inside the discussed building, regardless of its location. The maximum indoor air temperature Θi did not exceed 40.0 °C, which corresponded to the actual measurement results. A minimum value of 4.5 °C was recorded in Brest (B), Visby (V), Kiruna (K), and Umea (U). In Kraków (KR), a minimum value of Θi was found, amounting to 4.8 °C, while in Málaga (M) this was 7.4 °C (Figure 7).

Figure 7.

Course of outside air temperature Θi in the analyzed locations: Kraków—KR, Málaga—M, Brest—B, Visby—V, Umea—U, Kiruna—K.

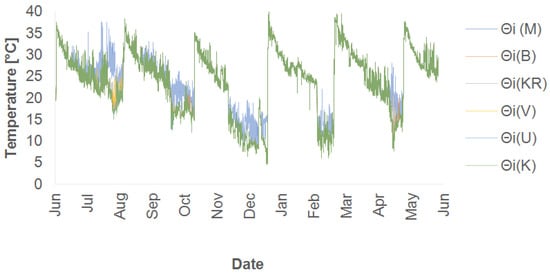

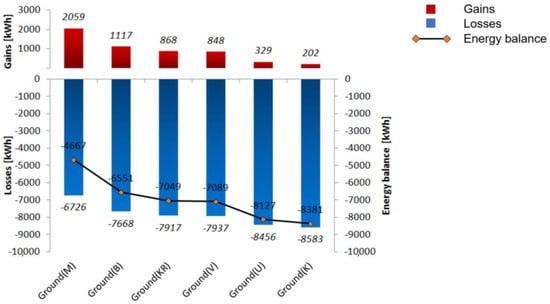

3.4. Heat Exchange with Ground and Energy Demand for Heating Purposes

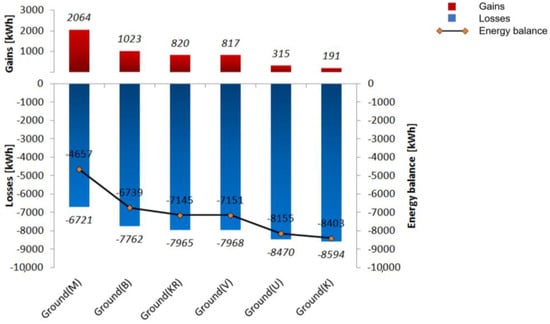

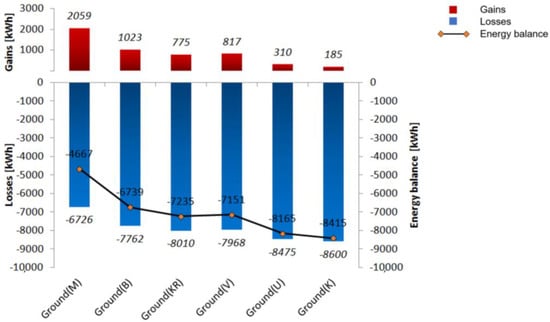

The analysis of the results between the tested building and the ground demonstrated the significant role of the ground in energy losses per year. The highest losses to ground were recorded in northern Sweden (Kiruna, 8583 kWh/a), while the lowest were in Málaga (6726 kWh/a). Due to the cold climate, for the buildings located in Visby, Umea and Kiruna, the lowest values of heat gains from the ground were found, in the range of 202–848 kWh/a (Figure 8 and Figure 9). Analysing all of the surveyed locations across the board, it was found that over the course of the year the energy balance shows only a tendency towards heat loss to the ground. The largest losses in the annual balance sheet were observed in Kiruna (8381 kWh/a) and the smallest in Málaga (4667 kWh/a).

Figure 8.

Heat exchange with soil on an annual basis for the tested locations, assuming 14 days of technological break: Kraków—KR, Málaga—M, Brest—B, Visby—V, Umea—U, Kiruna—K.

Figure 9.

Boxplot graph of heat exchange with soil, assuming 14 days of technological break: Kraków—KR, Málaga—M, Brest—B, Visby—V, Umea—U, Kiruna—K.

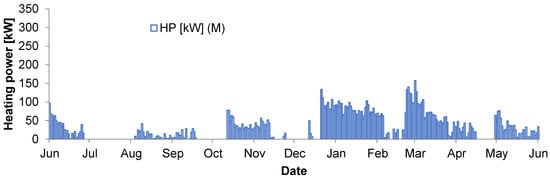

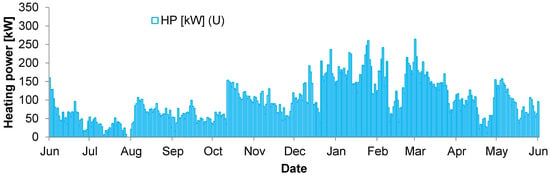

Numerical analysis allowed for the demonstration of how the location of the facility affects the energy demand for heating purposes. The facility located in Málaga (M) required a heating power of 157.4 kW. The tested building located in Spain showed an average daily energy demand for heating purposes at the level of 29.2 kW/day with a median of 17.4 kW/day. Due to the most favorable external microclimate conditions, it was found that the heating system in Málaga provided the least energy compared to the other locations (Figure 10).

Figure 10.

Characteristics of the heating power demand for the building located in Málaga, assuming a 14-day technological break.

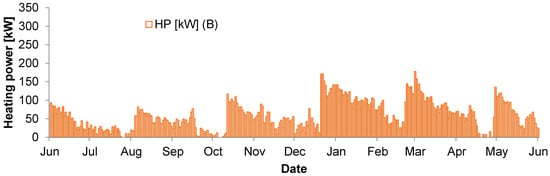

Based on the analysis of the results obtained for the facility located in Brest (France), demand was found to be increased by 20.2 kW (13%) for peak power for heating purposes compared to the building located in Málaga (Figure 11). The average heating power necessary to heat the broiler house in Brest was 57.2 kW/day (median 52.9 kW/day).

Figure 11.

Characteristics of the heating power demand for the building located in Brest, assuming a 14-day technological break.

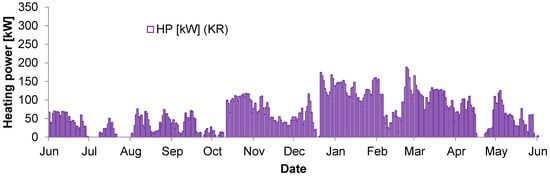

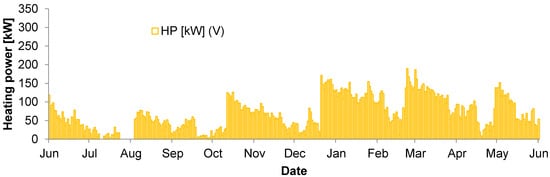

In terms of energy demand for heating purposes, the location of the buildings in Kraków and Visby gave comparable results. The maximum heating power in these locations was higher by 31.0–32.2 kW compared to Málaga, which was a difference of 20% of the peak heating power. The location of the building in Visby required an average daily heating capacity of 66.7 kW/day, whereas in Kraków this value was 62.4 kW/day (Figure 12 and Figure 13).

Figure 12.

Characteristics of the heating power demand for the building located in Kraków, assuming a 14-day technological break.

Figure 13.

Characteristics of the heating power demand for the building located in Visby.

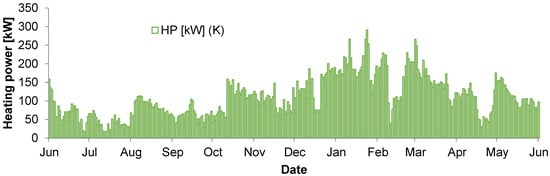

The facility located in Kiruna was characterized by the highest energy demand for heating purposes (291.1 kW). This was 85% higher than the building located in Spain. In addition, the average daily heating capacity necessary to maintain normal thermal conditions inside the building in Kiruna was 107.1 kW/day, which was 367% higher than the facility located in Málaga. The facility located in Umea was characterized by a lower demand for peak heating power compared to the broiler house in Kiruna, amounting to 264 kW. However, this was 68% higher compared to the results obtained for Málaga and 48% higher than the buildings located in Kraków and Visby (Figure 14 and Figure 15).

Figure 14.

Characteristics of the heating power demand for the building located in Umea, assuming a 14-day technological break.

Figure 15.

Characteristics of the heating power demand for the building located in Kiruna, assuming a 14-day technological break.

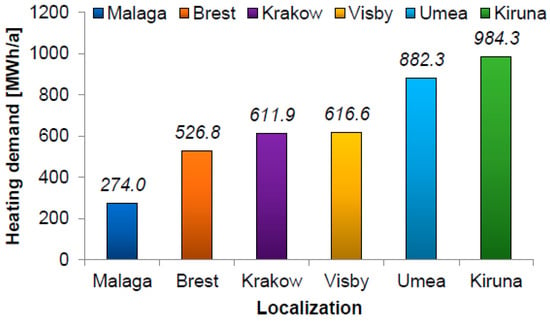

Computer simulations of thermal interaction between the building and the external environment allowed us to obtain precise values of the building’s energy demand throughout the year. The broiler plant located in Kiruna required the provision of 984.3 MWh/a of thermal energy. In the case of a building located in Málaga, this value was 3.5 times lower, amounting to 274 MWh/a. Analysing the other locations, it was also possible to notice a significant impact of the building’s location on its heating needs. In Kraków and Visby, 611.9–616.6 MWh/a of heating energy were needed in order to maintain the set internal microclimate conditions (Figure 16).

Figure 16.

Demand for energy for heating throughout the year, for various locations of the facility, assuming a 14-day technological break.

The analysis of the results of the interaction between the building and the ground in the variants of the 3- and 7-day technological break showed that the length of the break does not significantly affect the variability of the value of heat gains and losses to the ground. Changing the length of the technological break in the range of 3–14 days contributed to the variability of heat exchange with the ground with a difference of 1–1.5% (Figure 17 and Figure 18).

Figure 17.

Heat exchange with ground on an annual basis for the tested locations, assuming 7 days of technological break: Kraków—KR, Málaga—M, Brest—B, Visby—V, Umea—U, Kiruna—K.

Figure 18.

Heat exchange with ground on an annual basis for the tested locations, assuming 3 days of technological break: Kraków—KR, Málaga—M, Brest—B, Visby—V, Umea—U, Kiruna—K.

The length of the technological break also did not affect the demand for maximum heating power, the values of which were maintained for each location. The biggest differences were obtained for the building located in Kiruna, where shortening the winter break from 14 to 3 days resulted in the need to provide 5.8 kW less heating power. This represents a decrease of 2% compared to a 14-day break. Shortening the technological break creates opportunities to use the accumulated heat in the ground at the beginning of the next production cycle. This is the reason for the decrease in the demand for peak heating power, especially at the beginning of production cycles.

4. Discussion

The assessment of thermal interaction between buildings and the environment is a difficult task and requires a number of factors to be taken into account. A helpful tool in this aspect is undoubtedly the use of digital techniques based on a model numerical analysis [19,20]. Buildings of an agricultural character exhibit very specific operational features and strongly diverse material and construction solutions. This implies the need for an individual analysis of the technical parameters for a given type of building, as they have specific energy characteristics and energy demands [21]. The tested building is characterized by a cyclic production mode, during which there are technological breaks necessary to carry out cleaning and disinfection works. Such a character of the building opens up opportunities for some optimization of the duration of individual production stages. Particularly susceptible to change is the break period, which can be extended or shortened [17]. It should be noted, however, that this optimization is strongly dependent on the location of the facility. Numerical analysis allows us to carry out simulations taking into account the specificity of the building and the aforementioned location [22,23,24]. However, the simulation results must be validated against the measurement data to verify the reliability of the calculations. Without this process, simulations carried out only on initially assumed assumptions may give unacceptable results to draw substantive and true conclusions [25]. The obtained research results showed the impact of the technological break on the energy use of the building and its impact on the environment, which confirms the earlier results of the authors’ research [17]. The length of the technological break is particularly important in the winter period, because switching off the heating causes a very fast cooling of the building, in particular the floor and the ground under it. An excessively long technological break may therefore lead to unnecessarily high energy expenditure for heating purposes, in order to ensure the temperature required at the beginning of the cycle [26]. In the event of excessive cooling of the floor in the first days of rearing, thermal stress may occur. Stress associated with an unfavorable thermal environment in the early development of broiler chickens has a very negative impact through physiological mechanisms. The first weeks of life of broilers are the most critical, and the errors made in this phase cannot be corrected in a satisfactory way in the future, which may affect final production efficiency [27,28]. The assessment of the internal environment is necessary to explain its negative impact on the production of broilers. The poultry industry is constantly working to reduce the impact of indoor environment parameters such as temperature, humidity, air velocity, gases and others on animal welfare. All these parameters are regulated by the operation of active systems, including the heating system [29]. It should be noted, however, that shortening the technological break can significantly reduce the demand for heat in the first days of the cycle. Due to the complexity of phenomena occurring in the internal environment of the broiler house, field experiments of shortening the break are very difficult to implement and time-consuming. The amount of information required to fully quantify environmental variables depends on both advanced building physics and the level of precision associated with analytical tools. Therefore, computational techniques using numerical methods can be used as an alternative to determine indoor environmental conditions [30,31,32]. It should also be emphasized that it is not possible to apply universal recommendations in the field of material and construction solutions of the broiler house and the operation of its active systems for various locations. To this end, local guidelines for the design and operation of such facilities should be sought, in which numerical models can be used to a large extent.

5. Conclusions

The construction sector, and in particular the agricultural construction sector, requires increasingly larger inputs in terms of reducing energy consumption and optimizing the exploitation process. Undoubtedly, computer simulations are a very valuable tool that can be successfully used to address this topic, allowing for the impact of a number of factors on the shaping of the microclimate in a building to be taken into account in real time. Determining the values of the output parameters for the simulation is very important in order to validate the calculation results. Nevertheless, numerical analyses should be compared with the results of field tests in order to validate computational models.

The examined building was characterized by a specific internal microclimate due to production cyclicality, interrupted by technological breaks. After obtaining the results of the measurement tests of selected parameters of the internal and external microclimate and the temperature of the soil, these were implemented into the calculation model. A model based on the MEB method was used for the calculations, using specialized software for the physics of WUFI®plus structures. After a number of validation simulations, a satisfactory compliance of calculations with theoretical research was obtained. The validation results were assessed on the basis of the Coefficient of Determination method (R2) and the Goodness of Fit (GOF) method. Due to the lack of normality of the data distribution, a Rang–Spearman correlation analysis was carried out, which showed a very strong data correlation (0.94). The analysis of the R2 coefficient of determination confirmed the high reliability of the model (83%). In the case of the GOF method, a compliance value of 87% was obtained.

The numerical analysis carried out for the building located in different locations in Europe showed that the external microclimate very strongly determines the energy interaction between the building and the ground. The length of the technological break is very important in a climate dominated by low temperatures (Northern Scandinavia). The south-western part of Europe allows the technological break to be extended without significant differences for heating purposes, thanks to a milder and more favorable external climate. The length of the technological break in the range of 3 to 14 days does not significantly affect the intensity of heat exchange with the ground on a yearly basis, regardless of the location of the building. There were differences of no more than 2% between the technological break lasting 3 days and the 14-day break. It should also be emphasized that it is not possible to apply universal recommendations in the field of material and construction solutions of the broiler house and the operation of its active systems for various locations. Using numerical analyses, the authors plan to extend the research to indicate the optimization of the characteristics of objects of this type in various climatic zones, taking into account the actual climate and production factors.

Author Contributions

Conceptualization, G.N. and P.S.; methodology, G.N. and P.S.; software, P.S.; validation, P.S.; formal analysis, G.N. and P.S.; investigation, G.N.; resources, G.N.; data curation, G.N. and P.S.; writing—original draft preparation, G.N. and P.S.; writing—review and editing, G.N. and P.S.; visualization, G.N. and P.S.; supervision, G.N. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Faculty of Environmental Engineering, University of Agriculture in Krakow, through project “Subvention 030001-D014 Environmental Engineering, Mining and Energy”.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Thornton, P.K.; Gerber, P. Climate Change and the Growth of the Livestock Sector in Developing Countries. Mitig. Adapt. Strateg. Glob. Chang. 2010, 15, 3185–3198. [Google Scholar] [CrossRef]

- Deutsch, L.; Kalkenamrk, M.; Gordon, L.; Rockstrom, J.; Folke, K. Water-mediated ecological consequences of intensification and expansion of livestock production. In Livestock in a Changing Landscape: Drivers, Consequences and Responses; Steinfeld, H., Mooney, H., Schneider, F., Neville, L., Eds.; Island Press: Washington, DC, USA, 2010; Volume 1, pp. 8182–8194. [Google Scholar]

- Thornton, P.K. Livestock production: Recent trends, future prospects. Philos. Trans. R. Soc. 2010, 365, 2853–2867. [Google Scholar] [CrossRef] [PubMed]

- United Nations Framework Convention on Climate Change, Challenges and Opportunities for Mitigation in the Agricultural Sector: Technical Paper; United Nation Framework Convention on Climate Change: New York, NY, USA, 2008.

- Perez-Lombard, L.; Ortiz, J.; Pout, C. A review on buildings energy consumption information. Energy Build. 2008, 40, 394–398. [Google Scholar] [CrossRef]

- Chastas, P.; Theodosiou, T.; Bikas, D. Embodied energy in residential buildings- towards the nearly zero energy building: A literature review. Build. Environ. 2016, 105, 267–282. [Google Scholar] [CrossRef]

- Costantino, A.; Fabrizio, E.; Biglia, A.; Cornale, P.; Battaglini, L. Energy use for climate control of animal houses: The state of the art in Europe. Energy Procedia 2016, 101, 184–191. [Google Scholar] [CrossRef]

- Costantino, A.; Fabrizio, E.; Ghiggini, A.; Bariani, M. Climate control in broiler houses: A thermal model for the calculation of the energy use and indoor environmental conditions. Energy Build 2018, 169, 110–126. [Google Scholar] [CrossRef]

- Rossi, P.; Gastaldo, A.; Riva, G.; de Carolis, C. Progetto Re Sole (Final Draft); Centro Ricerche Produzioni Animali (CRPA): Reggio Emilia, Italy, 2013. [Google Scholar]

- Alimohammadisagvand, B. Influence of Demand Response Actions on Thermal Comfort and Electricity Cost for Residential Houses. Ph.D. Dissertation, Aalto University, Aalto, Finland, 2018. Available online: https://aaltodoc.aalto.fi/handle/123456789/33143 (accessed on 7 May 2018).

- Alimohammadisagvand, B.; Jokisalo, J.; Sirén, K. The potential of predictive control in minimizing the electricity cost in a heat-pump heated residential house. In Proceedings of the 3rd IBPSA-England Conference BSO 2016, Great North Museum, Newcastle, UK, 12–14 September 2016; Available online: http://www.ibpsa.org/proceedings/BSO2016/p1049.pdf (accessed on 7 May 2018).

- Sokolowski, P.; Nawalany, G. Experimental study of the impact of the vegetable cold store floor location on heat exchange with the soil. Appl. Ecol. Environ. Res. 2019, 17, 8179–8189. [Google Scholar] [CrossRef]

- Sokolowski, P.; Nawalany, G. Numerical Analysis of the Impact of the Cooling Cycle Length in Vegetable Cold Stores on the Heat Exchange with Soil. J. Ecol. Eng. 2019, 20, 162–170. [Google Scholar] [CrossRef]

- Nawalany, G.; Sokołowski, P. Numerical Analysis of the Effect of Ground Dampness on Heat Transfer between Greenhouse and Ground. Sustainability 2021, 13, 3084. [Google Scholar] [CrossRef]

- Borrallo-Jimenez, M.; de Asiain, M.L.; Esquivias, P.M.; Delgado-Trujillo, D. Comparative study between the Passive House Standard in warm climates and Nearly Zero Energy Buildings under Spanish Technical Building Code in a dwelling design in Seville, Spain. Energy Build. 2022, 254, 111570. [Google Scholar] [CrossRef]

- Nawalany, G.; Lendelova, J.; Sokolowski, P.; Zitnak, M. Numerical Analysis of the Impact of the Location of a Commercial Broiler House on Its Energy Management and Heat Exchange with the Ground. Energies 2021, 14, 8565. [Google Scholar] [CrossRef]

- Nawalany, G.; Sokołowski, P. Improved Energy Management in an Intermittently Heated Building Using a Large Broiler House in Central Europe as an Example. Energies 2020, 13, 1371. [Google Scholar] [CrossRef]

- Andolsun, S.; Culp, C.H.; Heberl, J.; Witte, M. EnergyPlus vs DOE-2.1e: The effect of ground coupling on cooling/heating requirements of weak-on grade code houses in four climates of the US. Energy Build. 2012, 52, 189–206. [Google Scholar] [CrossRef]

- Ruiz, G.R.; Bandera, C.F. Validation of calibrated energy models: Common errors. Energies 2017, 10, 1587. [Google Scholar] [CrossRef]

- Radoń, J.; Wąs, K.; Flaga-Maryanczyk, A.; Schnotale, J. Experimental and theoretical study on hygrothermal long-term performance of outer assemblies in lightweight passive house. J. Build. Phys. 2018, 41, 299–320. [Google Scholar] [CrossRef]

- Liu, Y.J.; Li, J.D.; Misra, R.D.K.; Wang, Z.D.; Wang, G.D. A numerical analysis of weak heating characteristics in a rolling type reheating furnace with pulse combustion. Appl. Therm. Eng. 2016, 107, 1304–1312. [Google Scholar] [CrossRef]

- Snow, S.; Clerc, C.; Horrocks, N. Energy audits and eco-feedback: Exploring the barriers and facilitators of agricultural energy efficiency improvements on Australian farms. Energy Res. Soc. Sci. 2021, 80, 102–113. [Google Scholar] [CrossRef]

- Bambara, J.; Athienitis, A.K. Energy and Economic Analysis for greenhouse Ground Insulation Design. Energies 2018, 11, 3218. [Google Scholar] [CrossRef]

- Dong, C. Heat Loss via Concrete Slab Floors in Australian Houses. Procedia Eng. 2017, 205, 108–115. [Google Scholar]

- Starodubtseva, I.P.; Pavlenko, A.N.; Surtaev, A.S. Heat transfer during quenching of high temperature surface by the falling cryogenic liquid film. Int. J. Therm. Sci. 2017, 114, 196–204. [Google Scholar] [CrossRef]

- Akkurt, G.G.; Aste, N.; Borderon, J.; Buda, A.; Calzolari, M.; Chung, D.; Costanzo, V.; Del Pero, C.; Evola, G.; Huerto-Cardenas, H.E.; et al. Dynamic thermal and hygrometric simulation of historical buildings: Critical factors and possible solutions. Renew. Sustain. Energy Rev. 2020, 118, 109509. [Google Scholar] [CrossRef]

- Ferraz, P.F.P.; Yanagi, T.; Lima, R.R.D.; Ferraz, G.A.; Xin, H. Performance of chicks subjected to thermal challenge. Agropecuária Bras. 2017, 52, 113–120. [Google Scholar] [CrossRef]

- Olfati, A.; Mojtahedin, A.; Sadeghi, T.; Akbari, M.; Martínez-Pastor, F. Comparison of growth performance and immune responses of broiler chicks reared under heat stress, cold stress and thermoneutral conditions. Span. J. Agric. Res. 2018, 16, 307–321. [Google Scholar] [CrossRef]

- Cordeiro, M.B.; Tinôco, I.D.F.F.; Silva, J.N.D.; Vigoderis, R.B.; Pinto, F.D.A.D.C.; Cecon, P.R. Conforto térmico e desempenho de pintos de corte submetidos a diferentes sistemas de aquecimento no período de inverno. Rev. Bras. De Zootec. 2010, 39, 217–224. [Google Scholar] [CrossRef][Green Version]

- Goel, A.; Ncho, C.M.; Choi, Y.H. Regulation of gene expression in chickens by heat stress. J. Anim. Sci. Biotechnol. 2021, 12, 1–13. [Google Scholar] [CrossRef]

- Norton, T.; Sun, D.W.; Grant, J.; Fallon, R.; Dodd, V. Applications of computational fluid dynamics (CFD) in the modelling and design of ventilation systems in the agricultural industry: A review. Bioresour. Technol. 2007, 98, 2386–2414. [Google Scholar] [CrossRef]

- Seo, I.H.; Lee, I.B.; Moon, O.K.; Kim, H.T.; Hwang, H.S.; Hong, S.W.; Han, J.W. Improvement of the ventilation system of a naturally ventilated broiler house in the cold season using computational simulations. Biosyst. Eng. 2009, 104, 106–117. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).