A Comparative Analysis of Brake-by-Wire Smart Actuators Using Optimization Strategies

Abstract

:1. Introduction

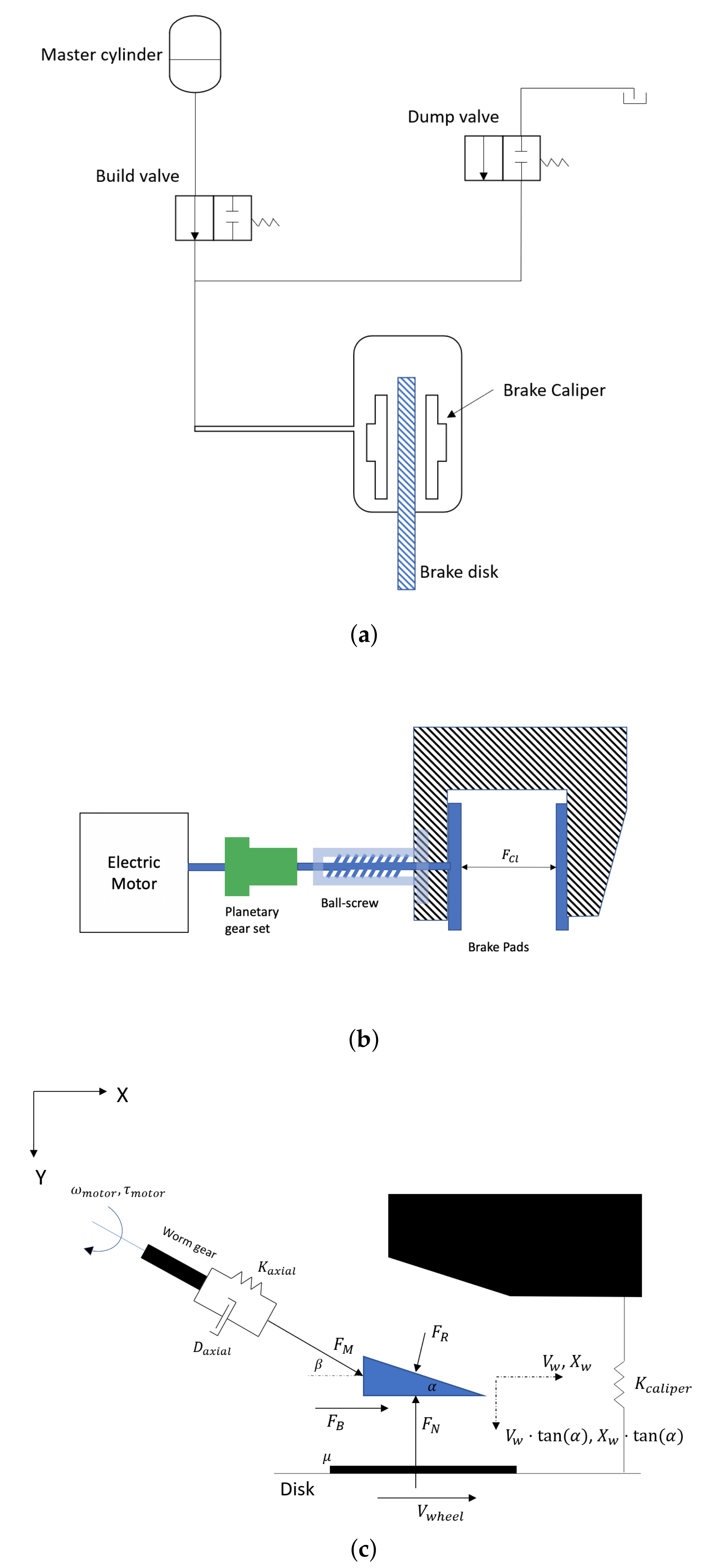

1.1. Brake-by-Wire Actuators

1.2. Objective Metrics for Brake-by-Wire Systems

1.3. Control Strategies for Brake-by-Wire Systems

1.4. Contribution and Paper Structure

- To the best of the authors’ knowledge, this is the first paper on the optimization and comparison of brake-by-wire actuators’ energy usage and responsiveness;

- Use of transfer functions as a way to optimize a nonlinear plant;

- The optimization of the brake-by-wire actuators operating in closed-loop (and following a target) has not been investigated before;

- The use of a robust control method (Youla parameterization) to control an EHB brake with build and dump valves (the use of Youla parameterization for EMB and EWB has already been investigated in another paper by the authors [31]);.

2. Materials and Methods

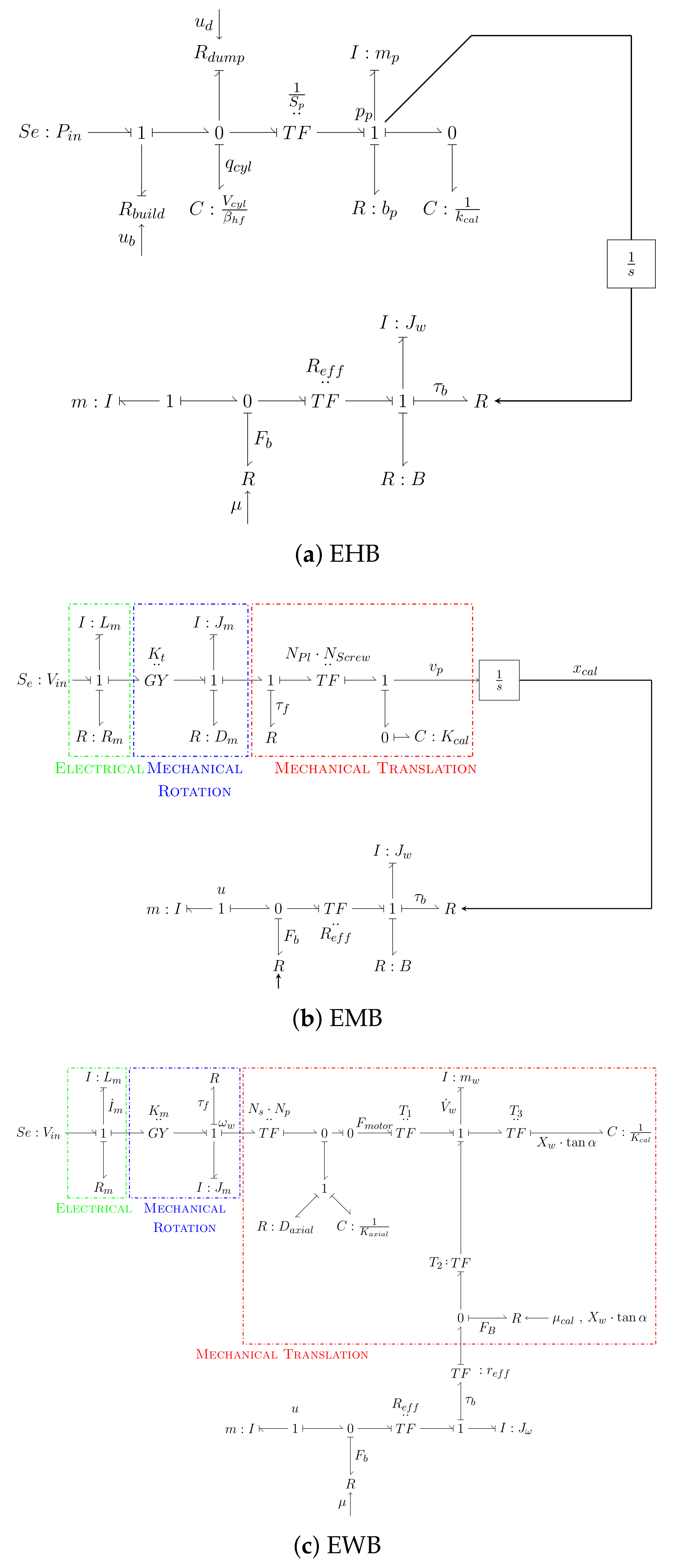

2.1. Actuator Modeling

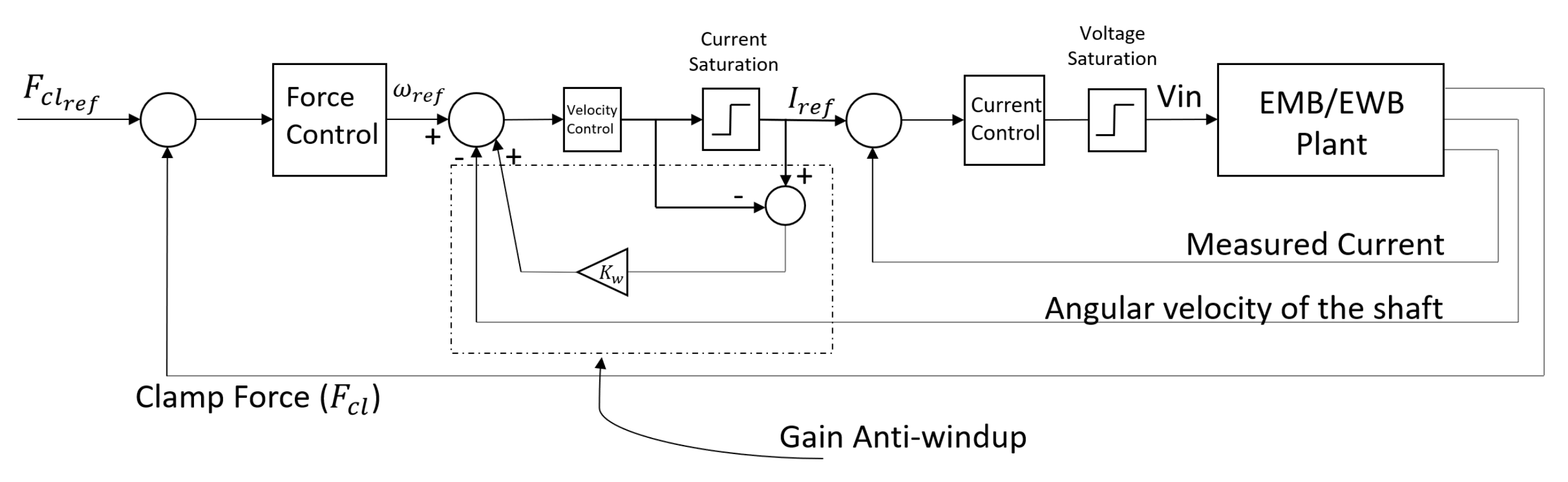

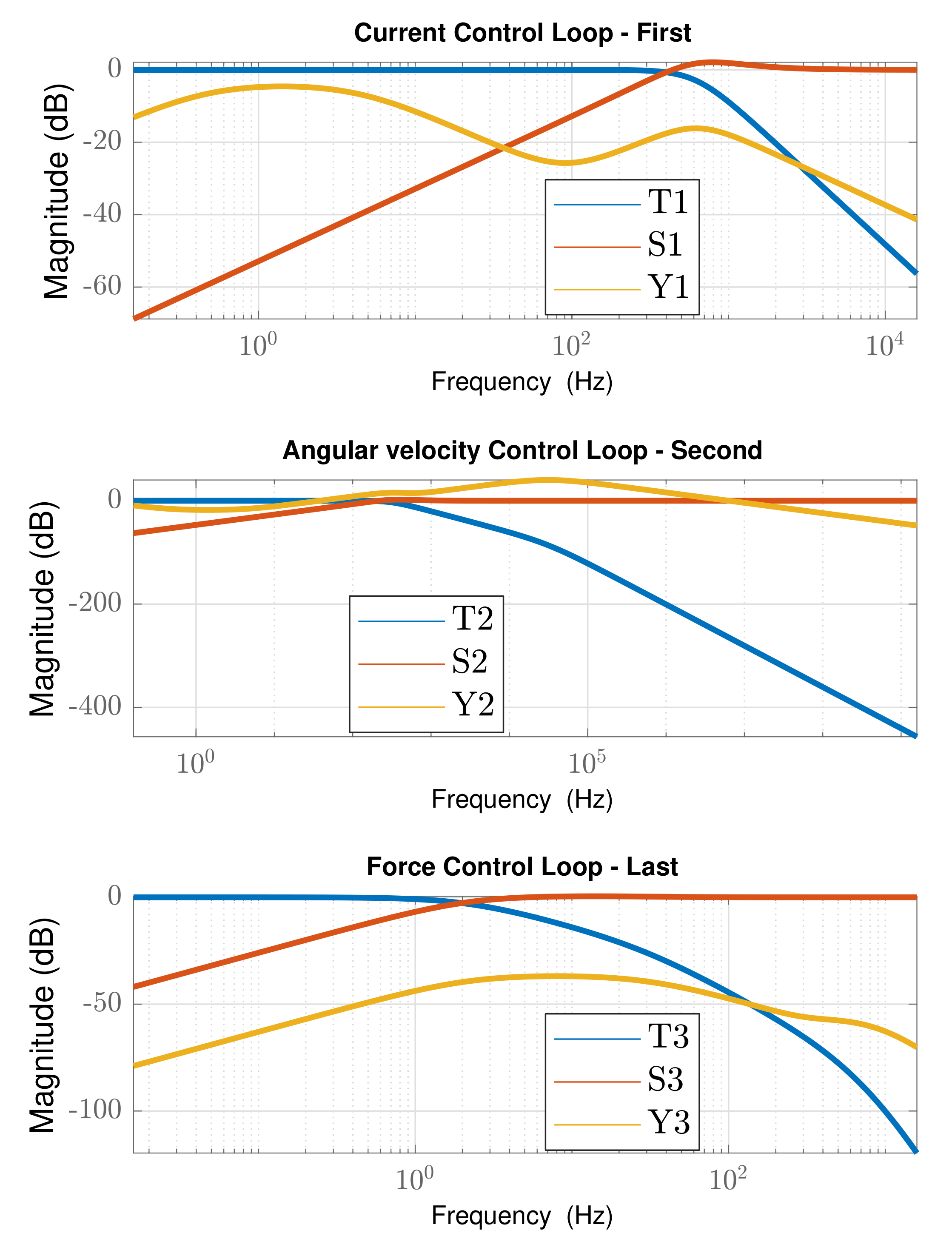

2.2. Model-Based Control Synthesis

Cascaded Control

2.3. Optimization

2.3.1. Linear Optimization: Using Transfer Functions

2.3.2. Nonlinear Optimization

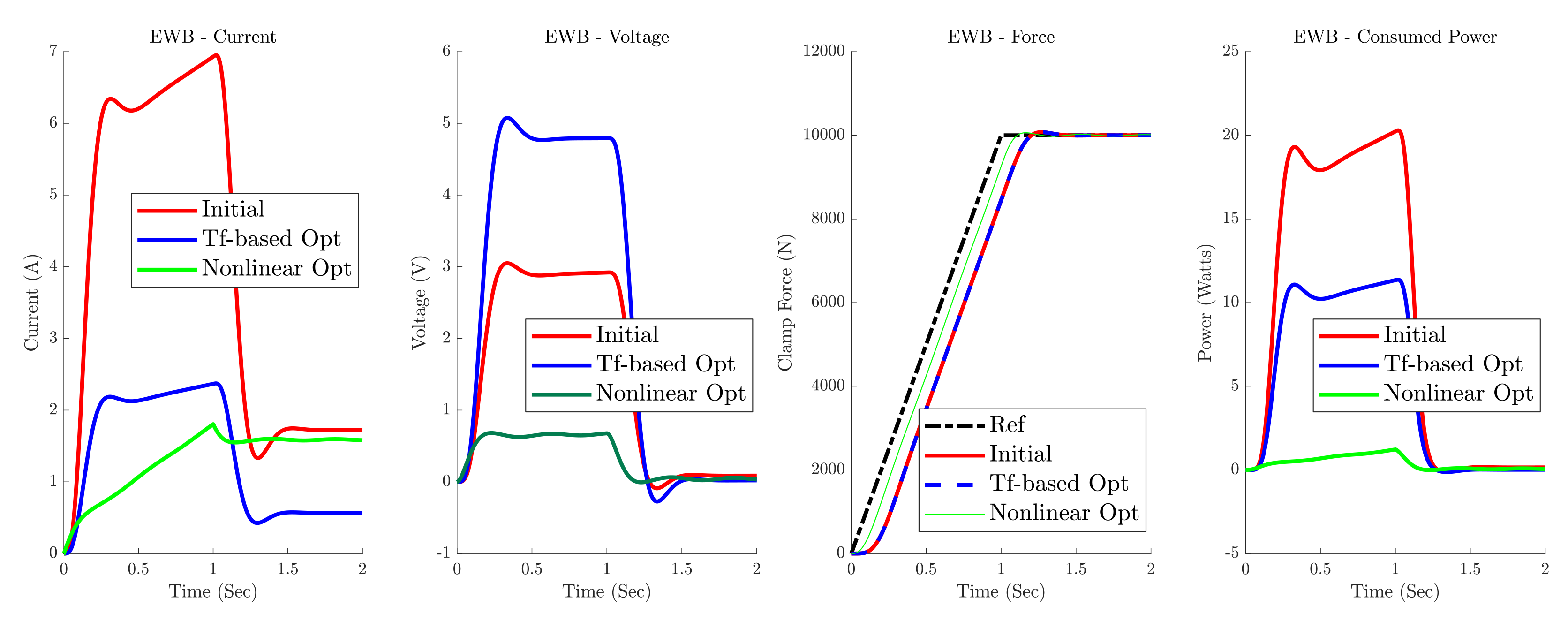

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| Notation | Definition |

| Clamping force | |

| Volumetric displacement of the cylinder fluid | |

| Momentum of the caliper | |

| Caliper displacement | |

| Pressure input | |

| Duty ratio of the build valve | |

| Duty ratio of the dump valve | |

| Maximum flow coefficient of valve | |

| Cross-sectional area of the build valve when fully open | |

| Cross-sectional area of the dump valve when fully open | |

| Density of the brake fluid | |

| Bulk modulus of the brake fluid | |

| Cylinder’s volume | |

| Cylinder’s cross-section surface | |

| Damping coefficient | |

| Brake pad’s mass | |

| Brake clearance | |

| Caliper stiffness | |

| Electric current | |

| Voltage input | |

| Angular velocity of the shaft | |

| Inductance of the electric motor | |

| Electrical resistance in the electric motor | |

| Electromotive force constant | |

| Total moment of inertia of the rotational parts | |

| Axial viscous friction | |

| Planetary gear reduction ratio | |

| Ball-screw gear reduction ratio | |

| N | Combined gear reduction () |

| Shaft axial displacement | |

| Shaft axial stiffness | |

| Shaft axial viscous resistance | |

| Wedge displacement | |

| Wedge velocity | |

| Motor force exerted to the wedge | |

| Wedge angle | |

| Friction coefficient between the pad and the wheel | |

| Lumped nonlinear frictions present in the actuator | |

| Contact (bristle) stiffness (Lugre friction model) | |

| Damping coefficient of the bristle (Lugre friction model) | |

| Viscous friction coefficient (Lugre friction model) | |

| Stribeck velocity (Lugre friction model) | |

| j | Shape factor (Lugre friction model) |

| Coulomb friction (Lugre friction model) | |

| Static friction (Lugre friction model) | |

| Complementary sensitivity transfer function | |

| Plant transfer function | |

| Sensitivity transfer function | |

| Youla transfer function | |

| Unstable pole | |

| Non-minimum phase zero | |

| Controller transfer function | |

| The operating point of (for the purpose of linearization) | |

| The operating point of u (for the purpose of linearization) | |

| Plant transfer function for the current loop () | |

| Plant transfer function for the omega loop () | |

| Plant transfer function for the Force loop () | |

| Plant transfer function of the second loop without the s in the numerator | |

| Youla transfer function for the i-th loop | |

| Closed-Loop transfer function of the i-th loop | |

| Constants of the first order transfer functions added to Youla | |

| Butterworth filters’ cut-off frequency | |

| Damping ratio of Butterworth filter | |

| Youla transfer function of the system () | |

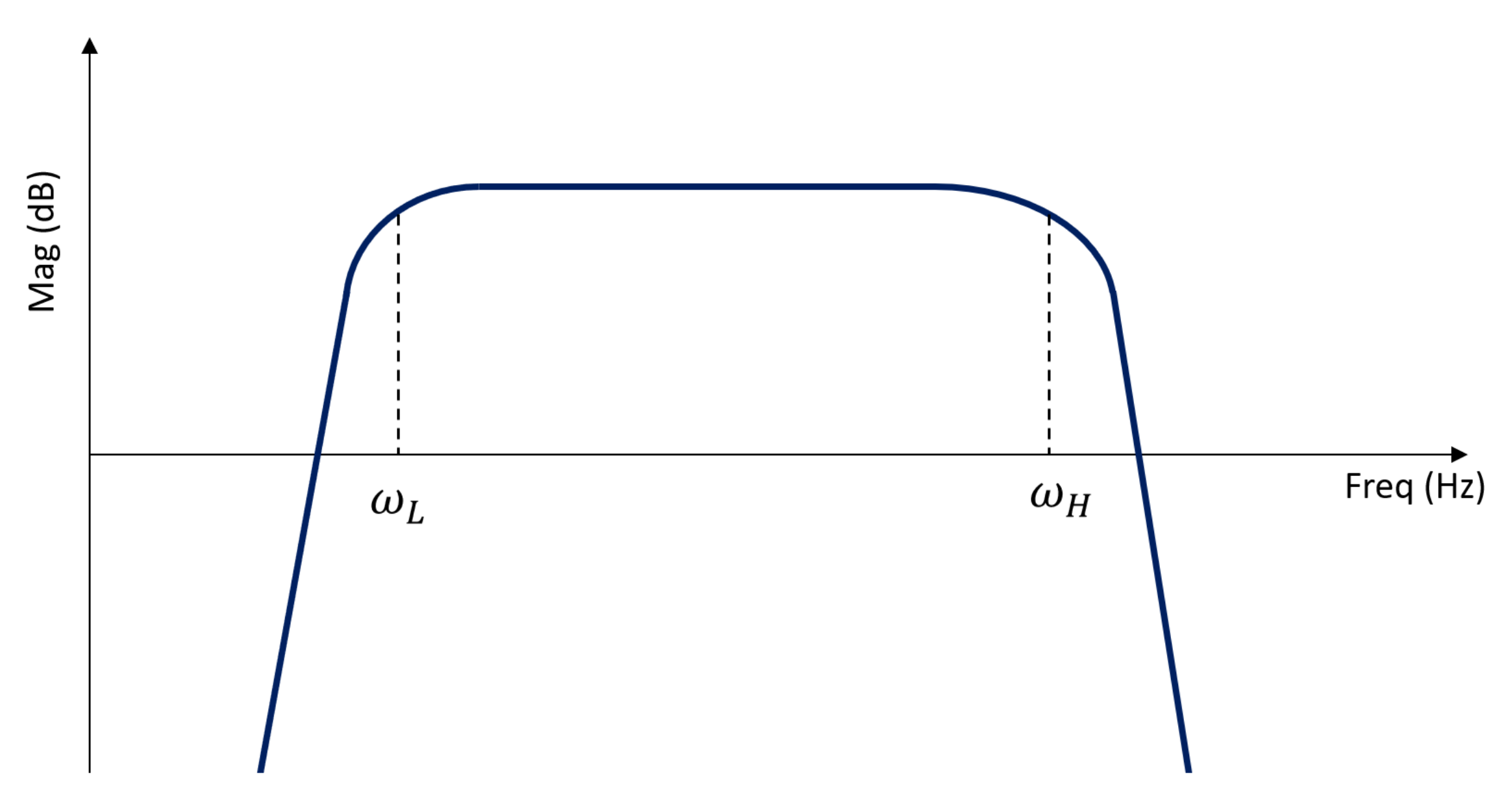

| Filter used to emphasize specific frequency region of in the H2 norm | |

| DC gain of plant tranfer function () | |

| Bandwidth of plant transfer function () | |

| Minimum of the parameter set | |

| Maximum of the parameter set | |

| Amount of power loss in the build valve | |

| Amount of power loss in the dump valve | |

| Effort in the build valve (refers to Figure 2a) | |

| Flow in the build valve (refers to Figure 2a) | |

| Effort in the dump valve (refers to Figure 2a) | |

| Effort in the dump valve (refers to Figure 2a) | |

| Power usage of the actuator | |

| Overshoot percentage | |

| Settling time |

References

- Lamnabhi-Lagarrigue, F.; Annaswamy, A.; Engell, S.; Isaksson, A.; Khargonekar, P.; Murray, R.M.; Nijmeijer, H.; Samad, T.; Tilbury, D.; Van den Hof, P. Systems & Control for the future of humanity, research agenda: Current and future roles, impact and grand challenges. Annu. Rev. Control 2017, 43, 1–64. [Google Scholar] [CrossRef]

- Yuan, Y.; Zhang, J.; Li, Y.; Lv, C. Regenerative Brake-by-Wire System Development and Hardware-In-Loop Test for Autonomous Electrified Vehicle. 2017. Available online: https://www.researchgate.net/publication/315859566_Regenerative_Brake-by-Wire_System_Development_and_Hardware-In-Loop_Test_for_Autonomous_Electrified_Vehicle (accessed on 7 January 2022). [CrossRef]

- Sinha, P. Architectural design and reliability analysis of a fail-operational brake-by-wire system from ISO 26262 perspectives. Reliab. Eng. Syst. Saf. 2011, 96, 1349–1359. [Google Scholar] [CrossRef]

- Gombert, B.D.; Schautt, M.; Roberts, R.P. The Development of alternative brake systems. In Encyclopedia of Automotive Engineering; Crolla, D., Foster, D.E., Kobayashi, T., Vaughan, N., Eds.; John Wiley & Sons, Ltd.: Chichester, UK, 2014; pp. 1–11. [Google Scholar] [CrossRef]

- Cheon, J.S. Brake by Wire System Configuration and Functions using Front EWB (Electric Wedge Brake) and Rear EMB (Electro-Mechanical Brake). Actuators 2010. [Google Scholar] [CrossRef]

- Line, C.; Manzie, C.; Good, M. Electromechanical Brake Modeling and Control: From PI to MPC. IEEE Trans. Control Syst. Technol. 2008, 16, 446–457. [Google Scholar] [CrossRef]

- Line, C.; Manzie, C.; Good, M. Robust control of an automotive electromechanical brake. IFAC Proc. Vol. 2007, 40, 579–586. [Google Scholar] [CrossRef]

- Sakamoto, T.; Hirukawa, K.; Ohmae, T. Cooperative control of full electric braking system with independently driven four wheels. In Proceedings of the 9th IEEE International Workshop on Advanced Motion Control, Istanbul, Turkey, 27–29 March 2006; pp. 602–606. [Google Scholar] [CrossRef]

- Hartmann, H.; Schautt, M.; Pascucci, A.; Gombert, B. eBrake®—The Mechatronic Wedge Brake. SAE Trans. 2002, 2146–2151. [Google Scholar] [CrossRef]

- Fox, J.; Roberts, R.; Baier-Welt, C.; Ho, L.M.; Lacraru, L.; Gombert, B. Modeling and Control of a Single Motor Electronic Wedge Brake. SAE Trans. 2007, 321–331. [Google Scholar] [CrossRef] [Green Version]

- Han, K.; Kim, M.; Huh, K. Modeling and control of an electronic wedge brake. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2012, 226, 2440–2455. [Google Scholar] [CrossRef]

- Che Hasan, M.H.; Khair Hassan, M.; Ahmad, F.; Marhaban, M.H. Modelling and design of optimized electronic wedge brake. In Proceedings of the 2019 IEEE International Conference on Automatic Control and Intelligent Systems (I2CACIS), Selangor, Malaysia, 29 June 2019; pp. 189–193. [Google Scholar] [CrossRef]

- Cheon, J.S.; Kim, J.; Jeon, J. New Brake By Wire Concept with Mechanical Backup. SAE Int. J. Passeng. Cars Mech. Syst. 2012, 5, 1194–1198. [Google Scholar] [CrossRef]

- Emam, M.A.A.; Emam, A.S.; El-Demerdash, S.M.; Shaban, S.M.; Mahmoud, M.A. Performance of Automotive Self Reinforcement Brake System. J. Mech. Eng. 2012, 1, 7. [Google Scholar]

- Ahmad, F.; Hudha, K.; Mazlan, S.; Jamaluddin, H.; Aparow, V.; Yunos, M.M. Simulation and experimental investigation of vehicle braking system employing a fixed caliper based electronic wedge brake. Simulation 2018, 94, 327–340. [Google Scholar] [CrossRef]

- Ho, L.M.; Roberts, R.; Hartmann, H.; Gombert, B. The Electronic Wedge Brake—EWB; SAE International: Warrendale, PA, USA, 2006. [Google Scholar] [CrossRef]

- Putz, M.H. VE Mechatronic Brake: Development and Investigations of a Simple Electro Mechanical Brake; SAE International: Warrendale, PA, USA, 2010. [Google Scholar] [CrossRef]

- De Castro, R.; Todeschini, F.; Araújo, R.E.; Savaresi, S.M.; Corno, M.; Freitas, D. Adaptive-robust friction compensation in a hybrid brake-by-wire actuator. Proc. Inst. Mech. Eng. Part I J. Syst. Control Eng. 2014, 228, 769–786. [Google Scholar] [CrossRef]

- Gong, X.; Ge, W.; Yan, J.; Zhang, Y.; Gongye, X. Review on the Development, Control Method and Application Prospect of Brake-by-Wire Actuator. Actuators 2020, 9, 15. [Google Scholar] [CrossRef] [Green Version]

- Büchler, R. Future Brake Systems and Technologies-MK C1®-Continental’s brake system for future vehicle concepts. In 7th International Munich Chassis Symposium 2016; Pfeffer, P.D.P.E., Ed.; Springer Fachmedien Wiesbaden: Wiesbaden, Germany, 2017; pp. 717–723. [Google Scholar] [CrossRef]

- Shankar, R.; Marco, J.; Assadian, F. The Novel Application of Optimization and Charge Blended Energy Management Control for Component Downsizing within a Plug-in Hybrid Electric Vehicle. Energies 2012, 5, 4892–4923. [Google Scholar] [CrossRef]

- Yao, M.; Miao, J.; Cao, S.; Chen, S.; Chai, H. The Structure Design and Optimization of Electromagnetic-Mechanical Wedge Brake System. IEEE Access 2020, 8, 3996–4004. [Google Scholar] [CrossRef]

- Fengjiao, Z.; Minxiang, W. Multi-objective optimization of the control strategy of electric vehicle electro-hydraulic composite braking system with genetic algorithm. Adv. Mech. Eng. 2015, 7, 168781401456849. [Google Scholar] [CrossRef]

- Kwon, Y.; Kim, J.; Cheon, J.S.; Moon, H.; Chae, H.J. Multi-Objective Optimization and Robust Design of Brake By Wire System Components. SAE Int. J. Passeng. Cars Mech. Syst. 2013, 6, 1465–1475. [Google Scholar] [CrossRef]

- Hierlinger, T.; Dirndorfer, T.; Neuhauser, T. A method for the simulation-based parameter optimization of autonomous emergency braking systems. In Proceedings of the 25th International Technical Conference on the Enhanced Safety of Vehicles (ESV), Detroit, MI, USA, 5–8 June 2017; Available online: https://trid.trb.org/view/1483876 (accessed on 7 January 2022).

- Kelling, N.A.; Heck, W. The BRAKE Project—Centralized Versus Distributed Redundancy for Brake-by-WireSystems; SAE International: Warrendale, PA, USA, 2002. [Google Scholar] [CrossRef]

- Anwar, S. Anti-Lock Braking Control of a Hybrid Brake-by-Wire System. Proc. Inst. Mech. Eng. Part D: J. Automob. Eng. 2006, 220, 1101–1117. [Google Scholar] [CrossRef]

- Savaresi, S.M.; Tanelli, M. Active Braking Control Systems Design for Vehicles; Advances in Industrial Control; Springer: London, UK, 2010. [Google Scholar] [CrossRef]

- Khalil, H.K. Nonlinear control; Prentice Hall: Hoboken, NJ, USA, 2015. [Google Scholar]

- Soltani, A.; Assadian, F. New Slip Control System Considering Actuator Dynamics. SAE Int. J. Passeng. Cars Mech. Syst. 2015, 8, 512–520. [Google Scholar] [CrossRef] [Green Version]

- Arasteh, E.; Assadian, F. Advanced applications of hydrogen and engineering systems in the automotive industry. In New Robust Control Design of Brake-by-Wire Actuators; IntechOpen: London, UK, 2020. [Google Scholar] [CrossRef]

- Karnopp, D.; Margolis, D.L.; Rosenberg, R.C. System Dynamics: Modeling and Simulation of Mechatronic Systems, 5th ed.; Wiley: Hoboken, NJ, USA, 2012. [Google Scholar]

- Zhao, J.; Song, D.; Zhu, B.; Chen, Z.; Sun, Y. Nonlinear Backstepping Control of Electro-Hydraulic Brake System Based on Bond Graph Model. IEEE Access 2020, 8, 19100–19112. [Google Scholar] [CrossRef]

- Arasteh, E.; Assadian, F.; Filipozzi, L. Algorithm to Generate Target for Anti-Lock Braking System using Wheel Power. J. Mech. Aerosp. Eng. 2021, 2, 2–7. [Google Scholar]

- Wang, X.; Lin, S.; Wang, S. Dynamic Friction Parameter Identification Method with LuGre Model for Direct-Drive Rotary Torque Motor. Math. Probl. Eng. 2016, 2016, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Assadian, F.; Mallon, K.R. Robust Control: Youla Parameterization Approach; John Wiley: Hoboken, NJ, USA, 2021. [Google Scholar]

- Zaccarian, L.; Teel, A.R. A common framework for anti-windup, bumpless transfer and reliable designs. Automatica 2002, 38, 1735–1744. [Google Scholar] [CrossRef]

- Todeschini, F.; Formentin, S.; Panzani, G.; Corno, M.; Savaresi, S.M.; Zaccarian, L. Nonlinear Pressure Control for BBW Systems via Dead-Zone and Antiwindup Compensation. IEEE Trans. Control Syst. Technol. 2016, 24, 1419–1431. [Google Scholar] [CrossRef]

| Parameter | Units | Lower Bound | Upper Bound | Initial | TF-Based Opt. | Nonlinear Opt. | |

|---|---|---|---|---|---|---|---|

| 4.48 | 5 | 5.6 | 6.36 | 2.8 | |||

| 2.50 | 1 | 5 | 2.5 | 3.76 | |||

| 6.0 | 5.8 | 2.9 | 7.19 | 1.03 | |||

| 2.0 | 1.5 | 9 | 2.02 | 9.0 | |||

| EMB | - | 7.96 | 1.3 | 6.37 | 1.3 | 1.2 | |

| - | 6/266 | 18/266 | 4.14 | 6.74 | 6.26 | ||

| 2.3 | 4.3 | 3.35 | 4.3 | 4.19 | |||

| 5.0 | 5.2 | 6.97 | 1.59 | 4.3 | |||

| 4.48 | 5 | 5.6 | 4.7 | 4.48 | |||

| 2.50 | 1 | 5 | 2.5 | 2.6 | |||

| 6.0 | 5.8 | 2.9 | 5.8 | 9.26 | |||

| 2.0 | 1.5 | 9 | 2.0 | 2.1 | |||

| EWB | - | 7.96 | 7.96 | 4.77 | 7.96 | 7.89 | |

| - | 6/266 | 18/266 | 4.17 | 6.77 | 6.76 | ||

| 2.3 | 4.3 | 3.35 | 4.3 | 4.29 | |||

| 5.0 | 5.2 | 6.97 | 5.0 | 5.88 | |||

| degrees | 10 | 24.5 | 10 | 24.5 | 24 | ||

| 0.1 | 0.5 | 0.3 | 2.9 | 3.15 | |||

| 1.6 | 1.28 | 1.6 | 1.6 | 7.93 | |||

| 1 | 4 | 4.0 | 4.0 | 2.16 | |||

| EHB | 6.38 | 1.02 | 1.6 | 1.7 | 3.7 | ||

| 5 | 2 | 1.973 | 1.967 | 1.25 | |||

| 2.3 | 4.3 | 4.3 | 4.3 | 3.69 |

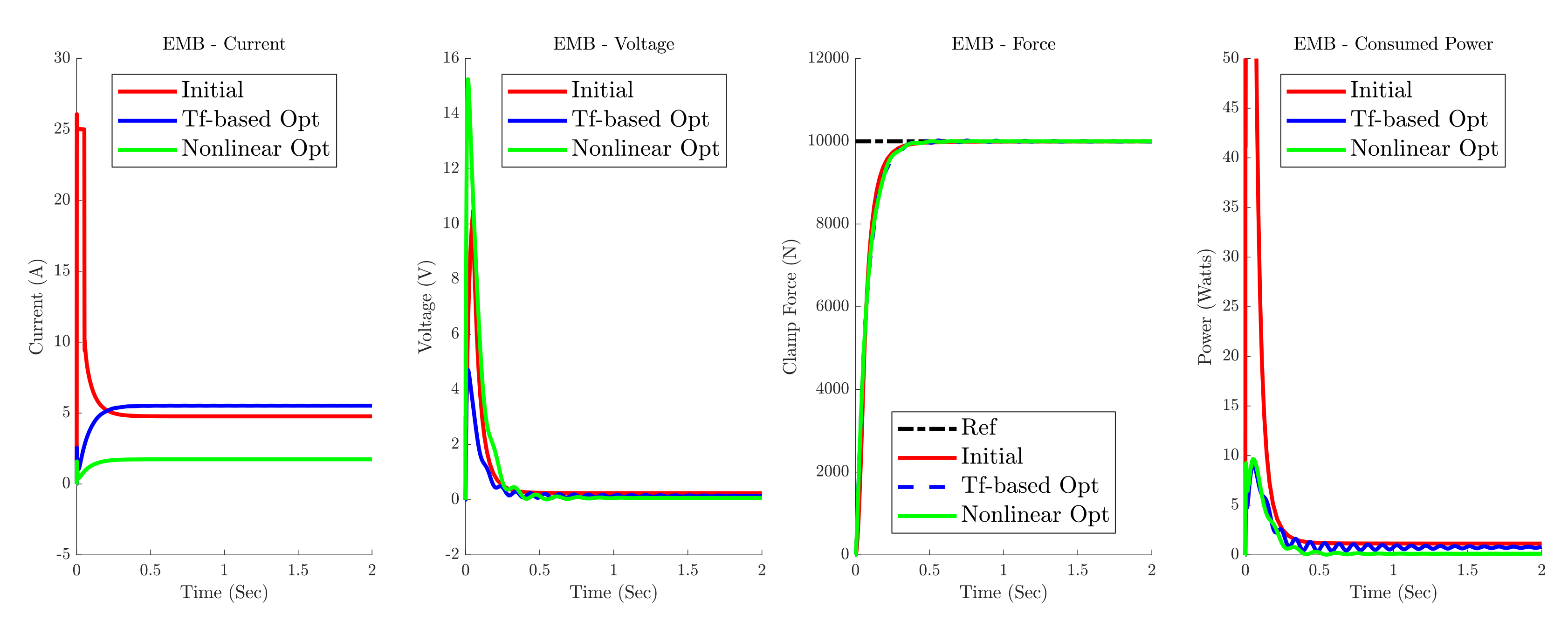

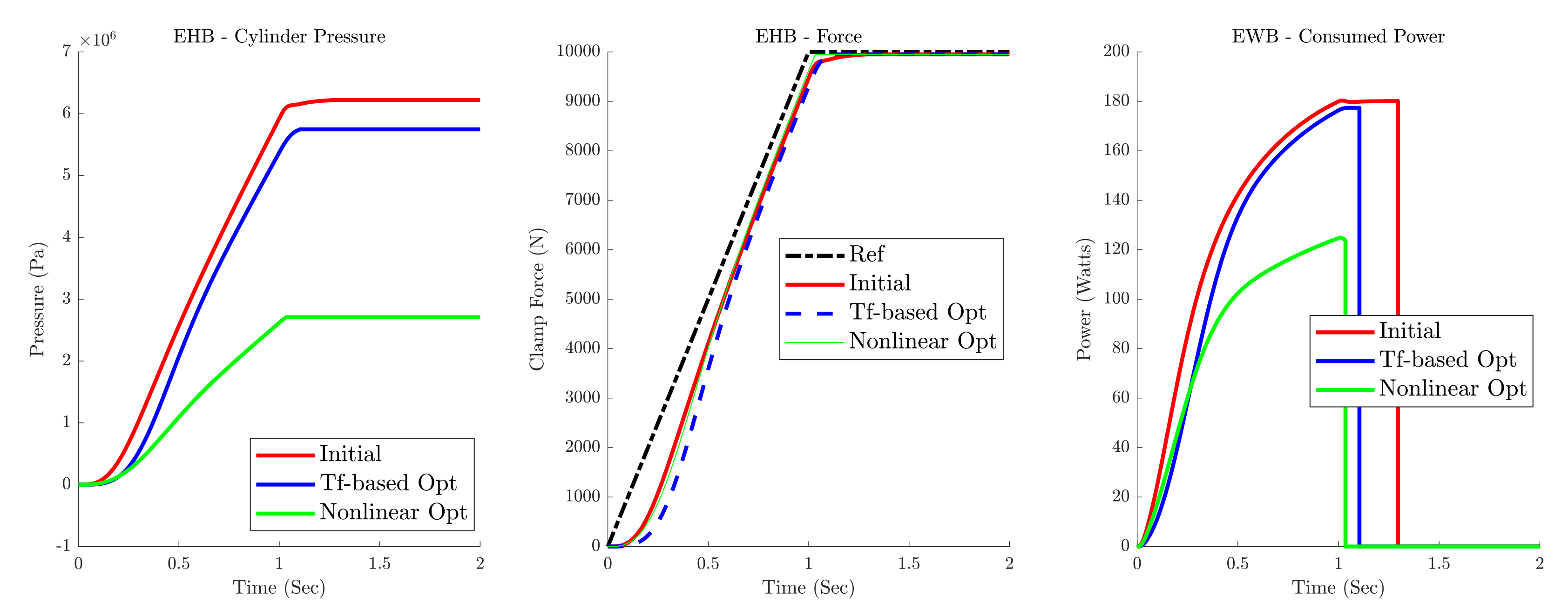

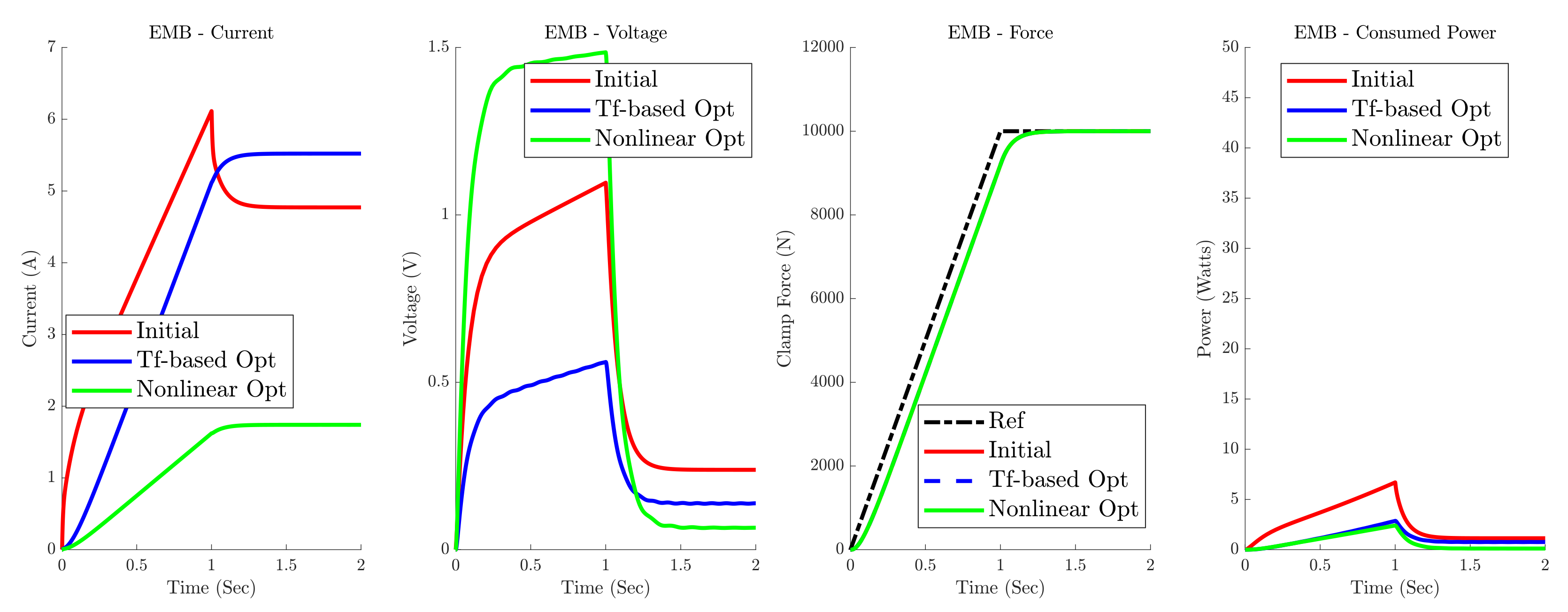

| EMB | EWB | EHB | |

|---|---|---|---|

| Initial set | 15.5 | 60.13 | 109.73 |

| TF-Based optimized set | 2.73 | 1.91 | 44.36 |

| Nonlinear optimized set | 1.69 | 2.14 | 29.70 |

| EMB | EWB | EHB | |

|---|---|---|---|

| Initial set | 5.14 | 18.06 | 174.42 |

| TF-Based optimized set | 2.17 | 0.83 | 128.67 |

| Nonlinear optimized set | 1.41 | 0.82 | 89.72 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Arasteh, E.; Assadian, F. A Comparative Analysis of Brake-by-Wire Smart Actuators Using Optimization Strategies. Energies 2022, 15, 634. https://doi.org/10.3390/en15020634

Arasteh E, Assadian F. A Comparative Analysis of Brake-by-Wire Smart Actuators Using Optimization Strategies. Energies. 2022; 15(2):634. https://doi.org/10.3390/en15020634

Chicago/Turabian StyleArasteh, Ehsan, and Francis Assadian. 2022. "A Comparative Analysis of Brake-by-Wire Smart Actuators Using Optimization Strategies" Energies 15, no. 2: 634. https://doi.org/10.3390/en15020634

APA StyleArasteh, E., & Assadian, F. (2022). A Comparative Analysis of Brake-by-Wire Smart Actuators Using Optimization Strategies. Energies, 15(2), 634. https://doi.org/10.3390/en15020634