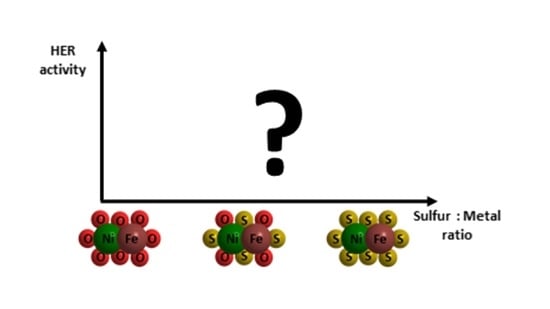

[NiFe]-(Oxy)Sulfides Derived from NiFe2O4 for the Alkaline Hydrogen Evolution Reaction

Abstract

:1. Introduction

2. Materials and Methods

2.1. Chemicals

2.2. Synthesis of Sulfidized NiFe2O4 (NFS) Materials

2.3. Characterization

2.3.1. Physical Characterization

2.3.2. Electrochemical Characterization

3. Results and Discussion

3.1. Synthesis and Physical Characterization

3.2. Electrochemical Hydrogen Evolution Reaction

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Siegmund, D.; Metz, S.; Peinecke, V.; Warner, T.E.; Cremers, C.; Grevé, A.; Smolinka, T.; Segets, D.; Apfel, U.-P. Crossing the Valley of Death: From Fundamental to Applied Research in Electrolysis. JACS Au 2021, 1, 527–535. [Google Scholar] [CrossRef] [PubMed]

- Chu, S.; Majumdar, A. Opportunities and challenges for a sustainable energy future. Nature 2012, 488, 294–303. [Google Scholar] [CrossRef] [PubMed]

- Greeley, J.; Stephens, I.E.L.; Bondarenko, A.S.; Johansson, T.P.; Hansen, H.A.; Jaramillo, T.F.; Rossmeisl, J.; Chorkendorff, I.; Nørskov, J.K. Alloys of platinum and early transition metals as oxygen reduction electrocatalysts. Nat. Chem. 2009, 1, 552–556. [Google Scholar] [CrossRef] [PubMed]

- Greeley, J.; Markovic, N.M. The road from animal electricity to green energy: Combining experiment and theory in electrocatalysis. Energy Environ. Sci. 2012, 5, 9246. [Google Scholar] [CrossRef]

- Amer, M.S.; Ghanem, M.A.; Al-Mayouf, A.M.; Arunachalam, P.; Khdary, N.H. Low-loading of oxidized platinum nanoparticles into mesoporous titanium dioxide for effective and durable hydrogen evolution in acidic media. Arab. J. Chem. 2020, 13, 2257–2270. [Google Scholar] [CrossRef]

- Boppella, R.; Tan, J.; Yun, J.; Manorama, S.V.; Moon, J. Anion-mediated transition metal electrocatalysts for efficient water electrolysis: Recent advances and future perspectives. Coord. Chem. 2021, 427, 213552. [Google Scholar] [CrossRef]

- Hu, C.; Zhang, L.; Gong, J. Recent progress made in the mechanism comprehension and design of electrocatalysts for alkaline water splitting. Energy Environ. Sci. 2019, 12, 2620–2645. [Google Scholar] [CrossRef]

- Li, A.; Sun, Y.; Yao, T.; Han, H. Earth-Abundant Transition-Metal-Based Electrocatalysts for Water Electrolysis to Produce Renewable Hydrogen. Chem. Eur. J. 2018, 24, 18334–18355. [Google Scholar] [CrossRef]

- Li, Y.H.; Liu, P.F.; Pan, L.F.; Wang, H.F.; Yang, Z.Z.; Zheng, L.R.; Hu, P.; Zhao, H.J.; Gu, L.; Yang, H.G. Local atomic structure modulations activate metal oxide as electrocatalyst for hydrogen evolution in acidic water. Nat. Commun. 2015, 6, 8064. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, L.; Zhang, T.; Yan, J.; Cai, X.; Liu, S.F. P Doped MoO3−x Nanosheets as Efficient and Stable Electrocatalysts for Hydrogen Evolution. Small 2017, 13, 1700441. [Google Scholar] [CrossRef]

- Zeng, H.; Chen, S.; Jin, Y.Q.; Li, J.; Song, J.; Le, Z.; Liang, G.; Zhang, H.; Xie, F.; Chen, J.; et al. Electron Density Modulation of Metallic MoO 2 by Ni Doping to Produce Excellent Hydrogen Evolution and Oxidation Activities in Acid. ACS Energy Lett. 2020, 5, 1908–1915. [Google Scholar] [CrossRef]

- Zhu, Y.; Lin, Q.; Zhong, Y.; Tahini, H.A.; Shao, Z.; Wang, H. Metal oxide-based materials as an emerging family of hydrogen evolution electrocatalysts. Energy Environ. Sci. 2020, 13, 3361–3392. [Google Scholar] [CrossRef]

- Guo, Y.; Park, T.; Yi, J.W.; Henzie, J.; Kim, J.; Wang, Z.; Jiang, B.; Bando, Y.; Sugahara, Y.; Tang, J.; et al. Nanoarchitectonics for Transition-Metal-Sulfide-Based Electrocatalysts for Water Splitting. Adv. Mater. 2019, 31, 1807134. [Google Scholar] [CrossRef] [PubMed]

- Siegmund, D.; Blanc, N.; Smialkowski, M.; Tschulik, K.; Apfel, U.-P. Metal-Rich Chalcogenides for Electrocatalytic Hydrogen Evolution: Activity of Electrodes and Bulk Materials. ChemElectroChem 2020, 7, 1514–1527. [Google Scholar] [CrossRef]

- Larquet, C.; Carenco, S. Metal Oxysulfides: From Bulk Compounds to Nanomaterials. Front. Chem. 2020, 8, 179. [Google Scholar] [CrossRef] [PubMed]

- Nelson, A.; Fritz, K.E.; Honrao, S.; Hennig, R.G.; Robinson, R.D.; Suntivich, J. Increased activity in hydrogen evolution electrocatalysis for partial anionic substitution in cobalt oxysulfide nanoparticles. J. Mater. Chem. A 2016, 4, 2842–2848. [Google Scholar] [CrossRef]

- Sarma, P.V.; Vineesh, T.V.; Kumar, R.; Sreepal, V.; Prasannachandran, R.; Singh, A.K.; Shaijumon, M.M. Nanostructured Tungsten Oxysulfide as an Efficient Electrocatalyst for Hydrogen Evolution Reaction. ACS Catal. 2020, 10, 6753–6762. [Google Scholar] [CrossRef]

- Vignais, P.M.; Billoud, B. Occurrence, classification, and biological function of hydrogenases: An overview. Chem. Rev. 2007, 107, 4206–4272. [Google Scholar] [CrossRef]

- Pandey, A.S.; Harris, T.V.; Giles, L.J.; Peters, J.W.; Szilagyi, R.K. Dithiomethylether as a ligand in the hydrogenase h-cluster. J. Am. Chem. Soc. 2008, 130, 4533–4540. [Google Scholar] [CrossRef]

- Möller, F.; Piontek, S.; Miller, R.G.; Apfel, U.-P. From Enzymes to Functional Materials-Towards Activation of Small Molecules. Chem. Eur. J. 2018, 24, 1471–1493. [Google Scholar] [CrossRef]

- Shang, X.; Chi, J.-Q.; Liu, Z.-Z.; Dong, B.; Yan, K.-L.; Gao, W.-K.; Zeng, J.-B.; Chai, Y.-M.; Liu, C.-G. Ternary Ni-Fe-V sulfides bundles on nickel foam as free-standing hydrogen evolution electrodes in alkaline medium. Electrochim. Acta 2017, 256, 241–251. [Google Scholar] [CrossRef]

- McGlynn, S.E.; Kanik, I.; Russell, M.J. Peptide and RNA contributions to iron-sulphur chemical gardens as life’s first inorganic compartments, catalysts, capacitors and condensers. Phil. Trans. R. Soc. A 2012, 370, 3007–3022. [Google Scholar] [CrossRef] [Green Version]

- Konkena, B.; Junge Puring, K.; Sinev, I.; Piontek, S.; Khavryuchenko, O.; Dürholt, J.P.; Schmid, R.; Tüysüz, H.; Muhler, M.; Schuhmann, W.; et al. Pentlandite rocks as sustainable and stable efficient electrocatalysts for hydrogen generation. Nat. Commun. 2016, 7, 12269. [Google Scholar] [CrossRef]

- Piontek, S.; Andronescu, C.; Zaichenko, A.; Konkena, B.; Junge Puring, K.; Marler, B.; Antoni, H.; Sinev, I.; Muhler, M.; Mollenhauer, D.; et al. Influence of the Fe:Ni Ratio and Reaction Temperature on the Efficiency of (FexNi1−x)9S8 Electrocatalysts Applied in the Hydrogen Evolution Reaction. ACS Catal. 2018, 8, 987–996. [Google Scholar] [CrossRef]

- Zhang, W.; Li, D.; Zhang, L.; She, X.; Yang, D. NiFe-based nanostructures on nickel foam as highly efficiently electrocatalysts for oxygen and hydrogen evolution reactions. J. Energy Chem. 2019, 39, 39–53. [Google Scholar] [CrossRef] [Green Version]

- Wang, X.; Zong, X.; Liu, B.; Long, G.; Wang, A.; Xu, Z.; Song, R.; Ma, W.; Wang, H.; Li, C. Boosting Electrochemical Water Oxidation on NiFe (oxy) Hydroxides by Constructing Schottky Junction toward Water Electrolysis under Industrial Conditions. Small 2021, 7, e2105544. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.; Wu, Y.; Zhang, D. Potentiostatic electrodeposition of cost-effective and efficient Ni–Fe electrocatalysts on Ni foam for the alkaline hydrogen evolution reaction. Int. J. Hydrogen Energy 2021, 47, 1425–1434. [Google Scholar] [CrossRef]

- Li, B.-Q.; Zhang, S.-Y.; Tang, C.; Cui, X.; Zhang, Q. Anionic Regulated NiFe (Oxy)Sulfide Electrocatalysts for Water Oxidation. Small 2017, 13, 1700610. [Google Scholar] [CrossRef]

- Liu, J.; Zhu, D.; Ling, T.; Vasileff, A.; Qiao, S.Z. Anthony Vasileff; Shi-Zhang Qiao. S−NiFe2O4 ultra-small nanoparticle built nanosheets for efficient water splitting in alkaline and neutral pH. Nano Energy 2017, 40, 264–273. [Google Scholar] [CrossRef]

- Simon, C.; Zakaria, M.B.; Kurz, H.; Tetzlaff, D.; Blösser, A.; Weiss, M.; Timm, J.; Weber, B.; Apfel, U.-P.; Marschall, R. Magnetic NiFe2O4 Nanoparticles Prepared via Non-Aqueous Microwave-Assisted Synthesis for Application in Electrocatalytic Water Oxidation. Chem. Eur. J. 2021, 27, 16990–17001. [Google Scholar] [CrossRef]

- Bezverkhyy, I.; Danot, M.; Afanasiev, P. New Low-Temperature Preparations of Some Simple and Mixed Co and Ni Dispersed Sulfides and Their Chemical Behavior in Reducing Atmosphere. Inorg. Chem. 2003, 42, 1764–1768. [Google Scholar] [CrossRef] [PubMed]

- Wyckoff, R.W.G. The structure of crystals. J. Chem. Technol. Biotechnol. 1931, 50, 877. [Google Scholar] [CrossRef]

- Alsén, N. Röntgenographische Untersuchung der Kristallstrukturen von Magnetkies, Breithauptit, Pentlandit, Millerit und verwandten Verbindungen. Geol. Fören. Stock. Förh. 1925, 47, 19–72. [Google Scholar] [CrossRef]

- Baylis, P. Crystal structure refinement of a weakly anisotropic pyrite. Am. Mineral. 1977, 62, 1168–1172. [Google Scholar]

- McCrory, C.C.L.; Jung, S.; Ferrer, I.M.; Chatman, S.M.; Peters, J.C.; Jaramillo, T.F. Benchmarking hydrogen evolving reaction and oxygen evolving reaction electrocatalysts for solar water splitting devices. J. Am. Chem. Soc. 2015, 137, 4347–4357. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| Material | Fe:Ni Ratio | S:M Ratio | Sum Formula |

|---|---|---|---|

| NFO | 2.46 ± 0.10 | 0 | Ni0.30Fe0.74Ox |

| NFS100−N2 | 1.93 ± 0.96 | 1.09 ± 0.09 | Ni0.3Fe0.52S0.87Ox |

| NFS150−N2 | 2.47 ± 0.30 | 1.29 ± 0.22 | Ni0.3Fe0.74S1.29Ox |

| NFS200−N2 | 2.18 ± 0.41 | 1.34 ± 0.10 | Ni0.3Fe0.64S1.26Ox |

| NFS250−N2 | 2.50 ± 0.33 | 1.49 ± 0.06 | Ni0.3Fe0.74S1.54Ox |

| NFS300−N2 | 2.33 ± 0.31 | 1.98 ± 0.26 | Ni0.3Fe0.71S1.99 |

| NFS100−H2 | 2.43 ± 0.49 | 0.79 ± 0.26 | Ni0.3Fe0.71S0.80Ox |

| NFS150−H2 | 2.58 ± 0.45 | 1.09 ± 0.34 | Ni0.3Fe0.76S1.14Ox |

| NFS200−H2 | 2.41 ± 0.33 | 1.20 ± 0.08 | Ni0.3Fe0.71S1.21Ox |

| NFS250−H2 | 2.35 ± 0.37 | 1.11 ± 0.15 | Ni0.3Fe0.70S1.04Ox |

| NFS300−H2 | 2.18 ± 0.31 | 1.15 ± 0.06 | Ni0.3Fe0.64S1.07 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tetzlaff, D.; Alagarasan, V.; Simon, C.; Siegmund, D.; junge Puring, K.; Marschall, R.; Apfel, U.-P. [NiFe]-(Oxy)Sulfides Derived from NiFe2O4 for the Alkaline Hydrogen Evolution Reaction. Energies 2022, 15, 543. https://doi.org/10.3390/en15020543

Tetzlaff D, Alagarasan V, Simon C, Siegmund D, junge Puring K, Marschall R, Apfel U-P. [NiFe]-(Oxy)Sulfides Derived from NiFe2O4 for the Alkaline Hydrogen Evolution Reaction. Energies. 2022; 15(2):543. https://doi.org/10.3390/en15020543

Chicago/Turabian StyleTetzlaff, David, Vasanth Alagarasan, Christopher Simon, Daniel Siegmund, Kai junge Puring, Roland Marschall, and Ulf-Peter Apfel. 2022. "[NiFe]-(Oxy)Sulfides Derived from NiFe2O4 for the Alkaline Hydrogen Evolution Reaction" Energies 15, no. 2: 543. https://doi.org/10.3390/en15020543

APA StyleTetzlaff, D., Alagarasan, V., Simon, C., Siegmund, D., junge Puring, K., Marschall, R., & Apfel, U.-P. (2022). [NiFe]-(Oxy)Sulfides Derived from NiFe2O4 for the Alkaline Hydrogen Evolution Reaction. Energies, 15(2), 543. https://doi.org/10.3390/en15020543