High-Torque Density Design of Small Motors for Automotive Applications with Double Axial-Air-Gap Structures

Abstract

1. Introduction

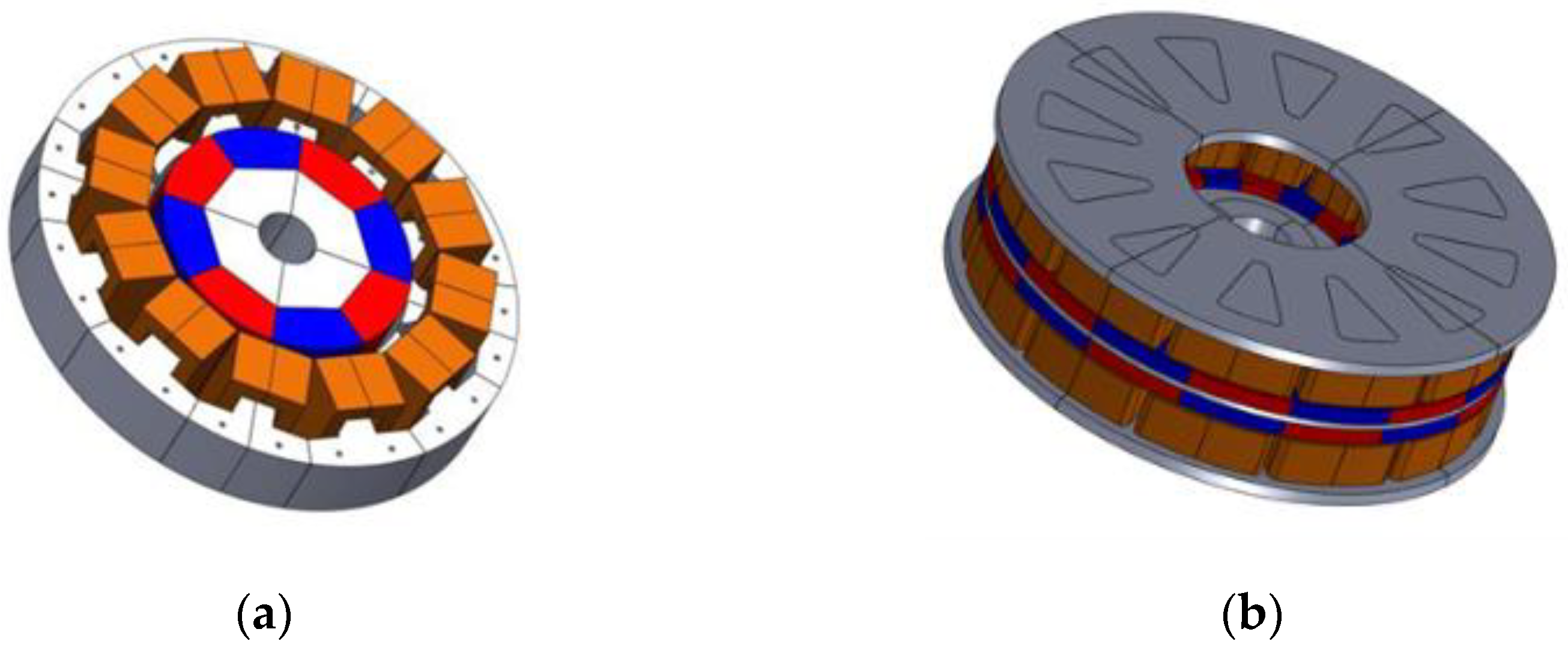

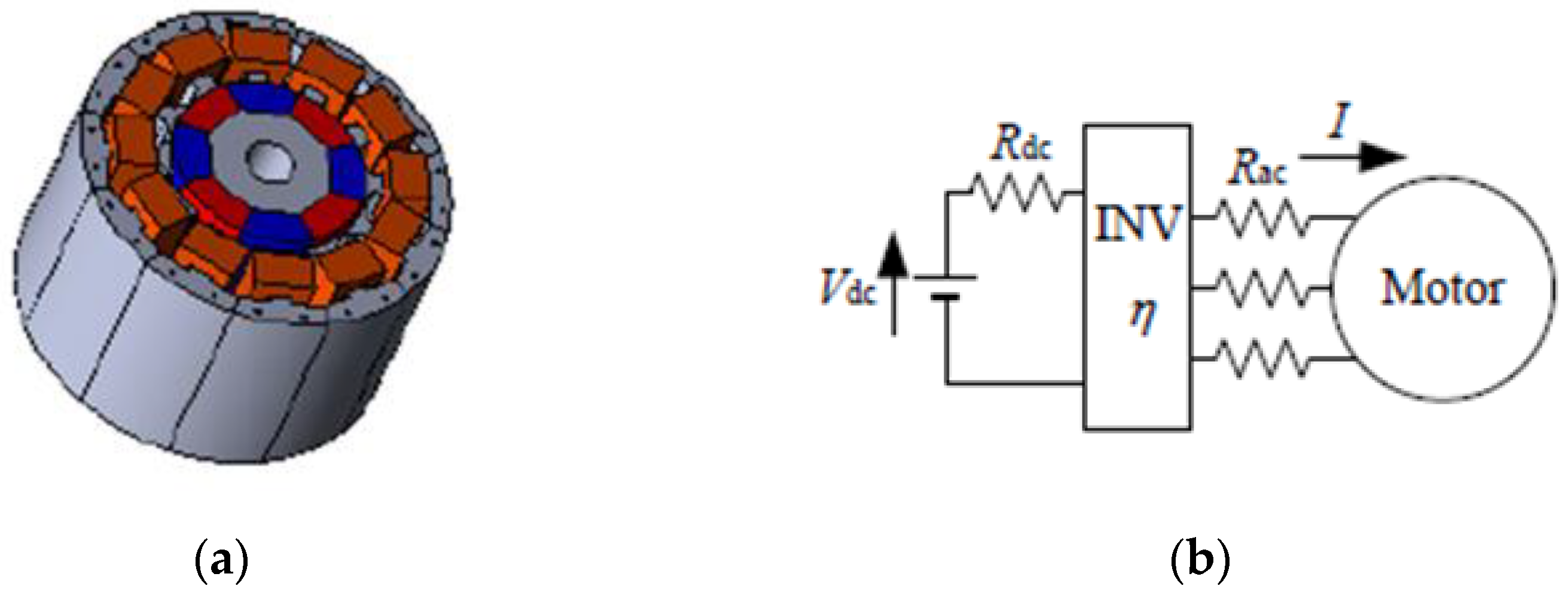

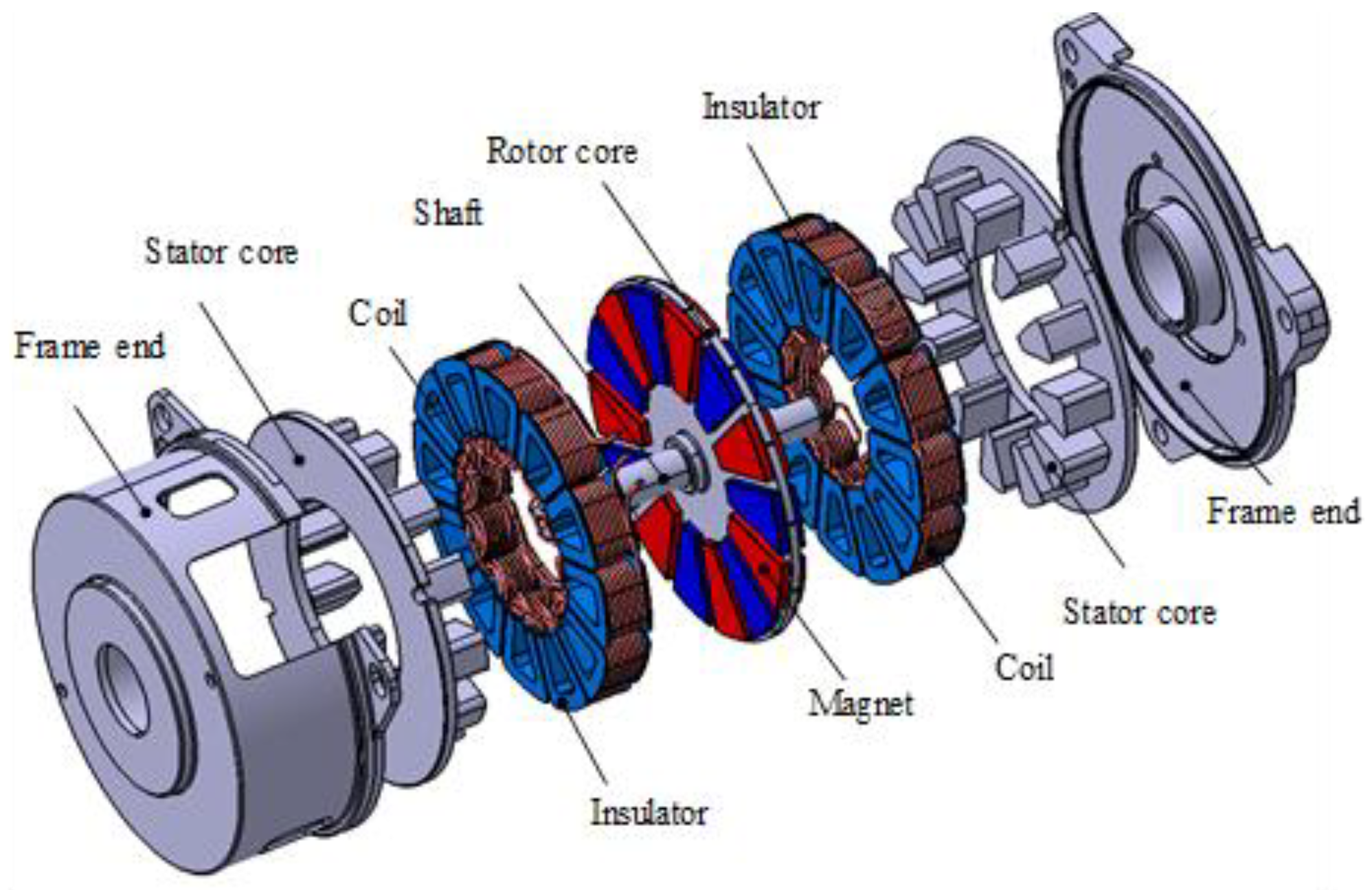

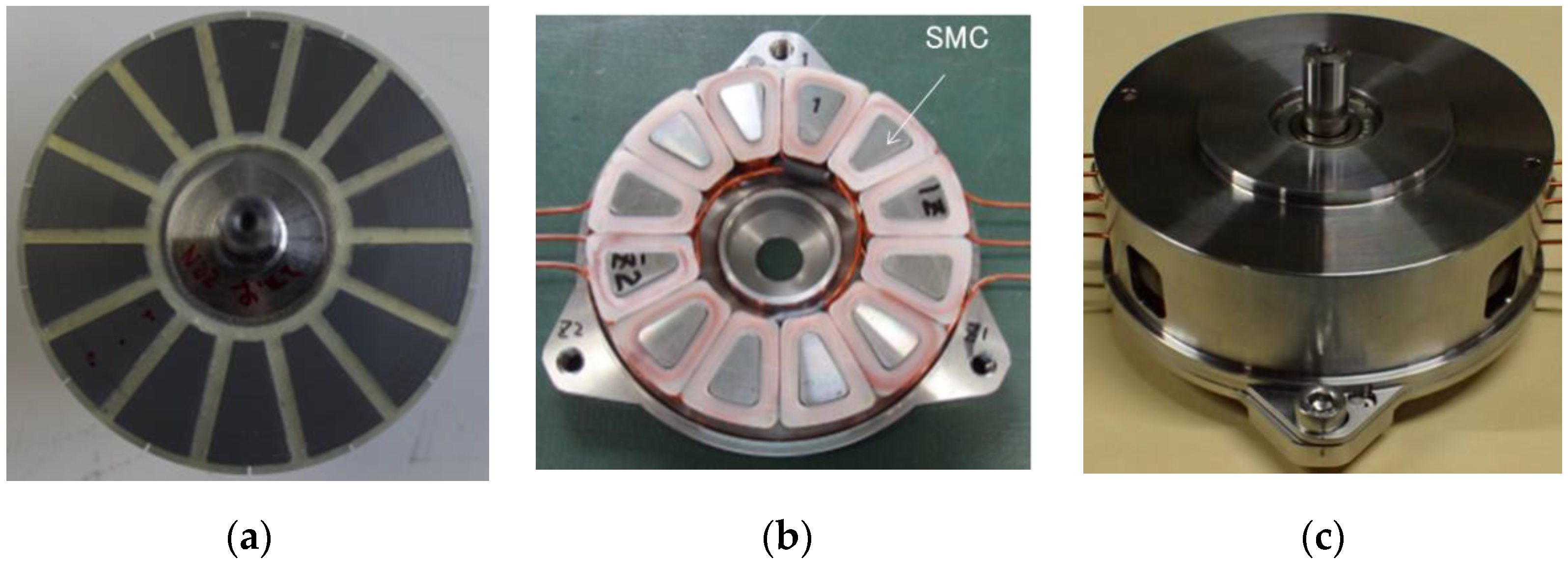

2. High Torque Density Design of Axial-Gap Motors

2.1. Prerequisites

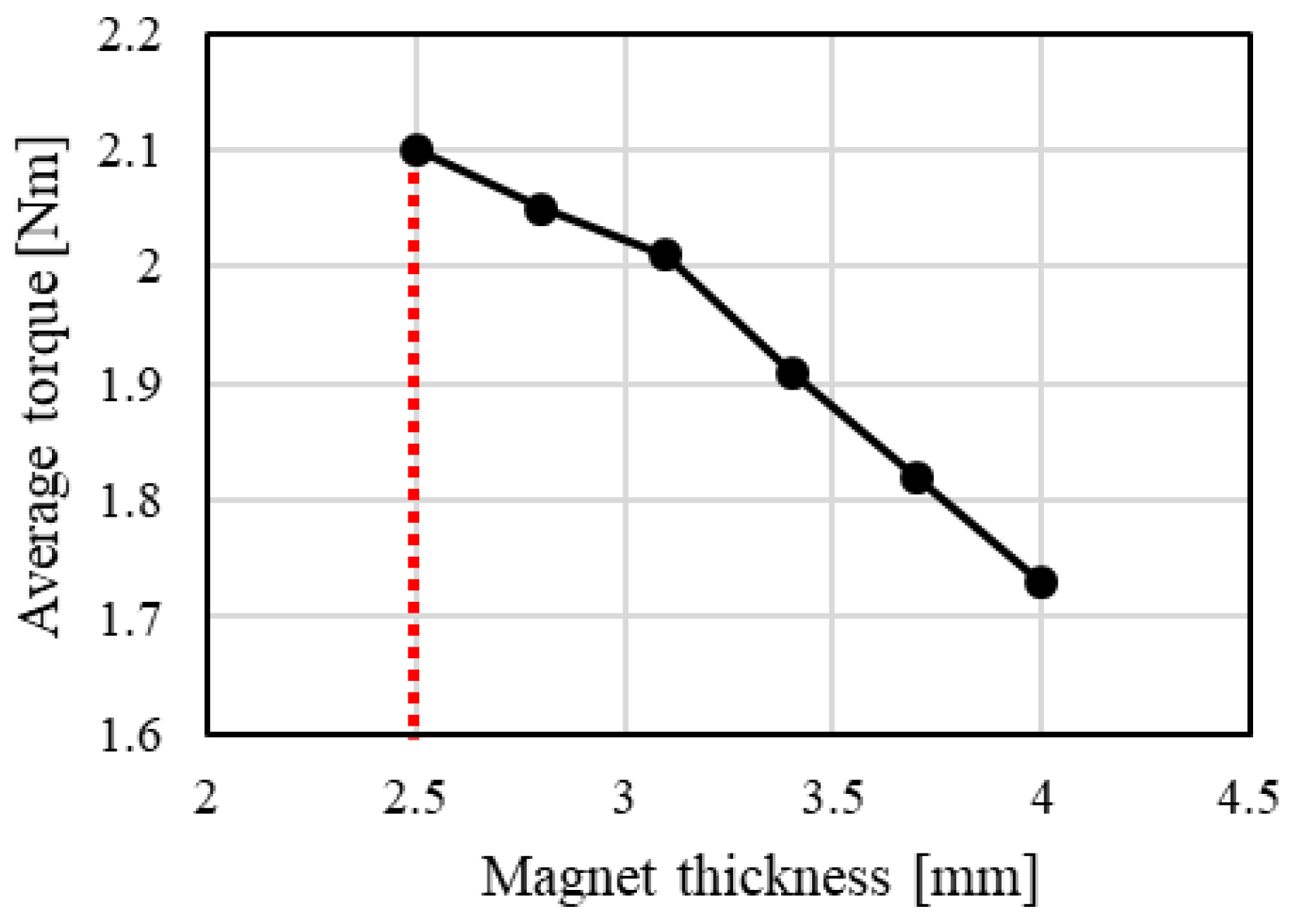

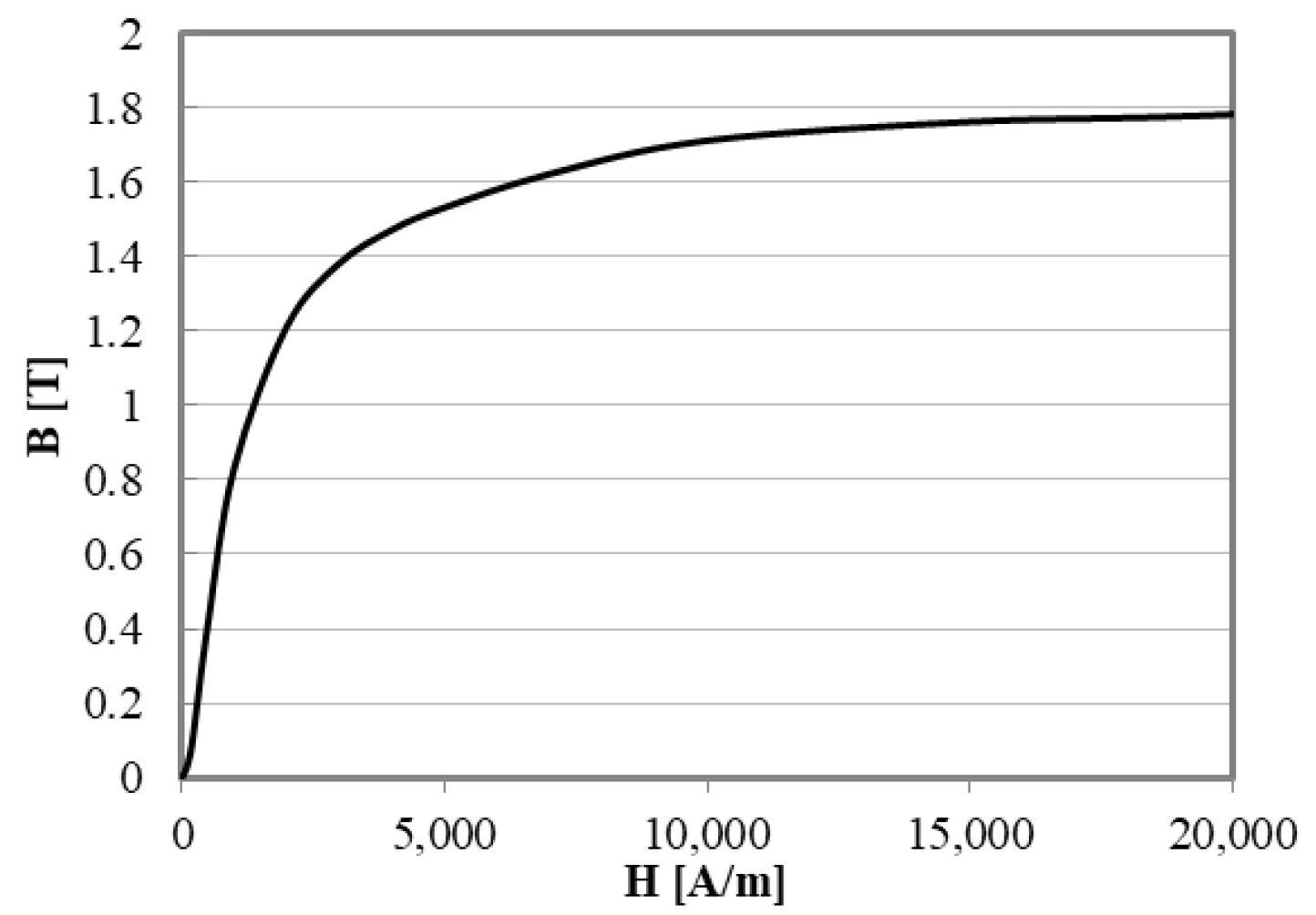

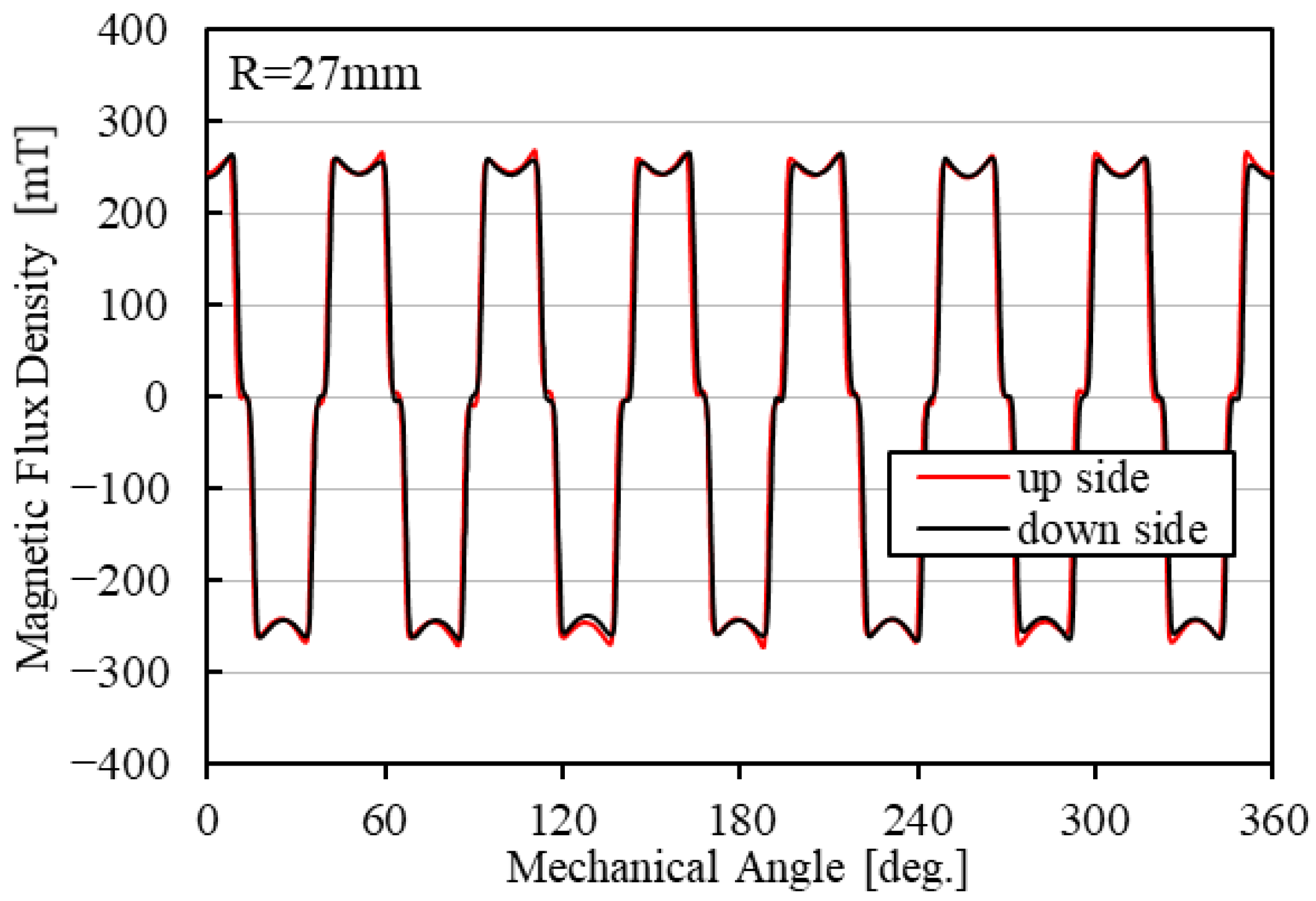

2.2. Magnetic Circuit Design of Axial-Gap Motor

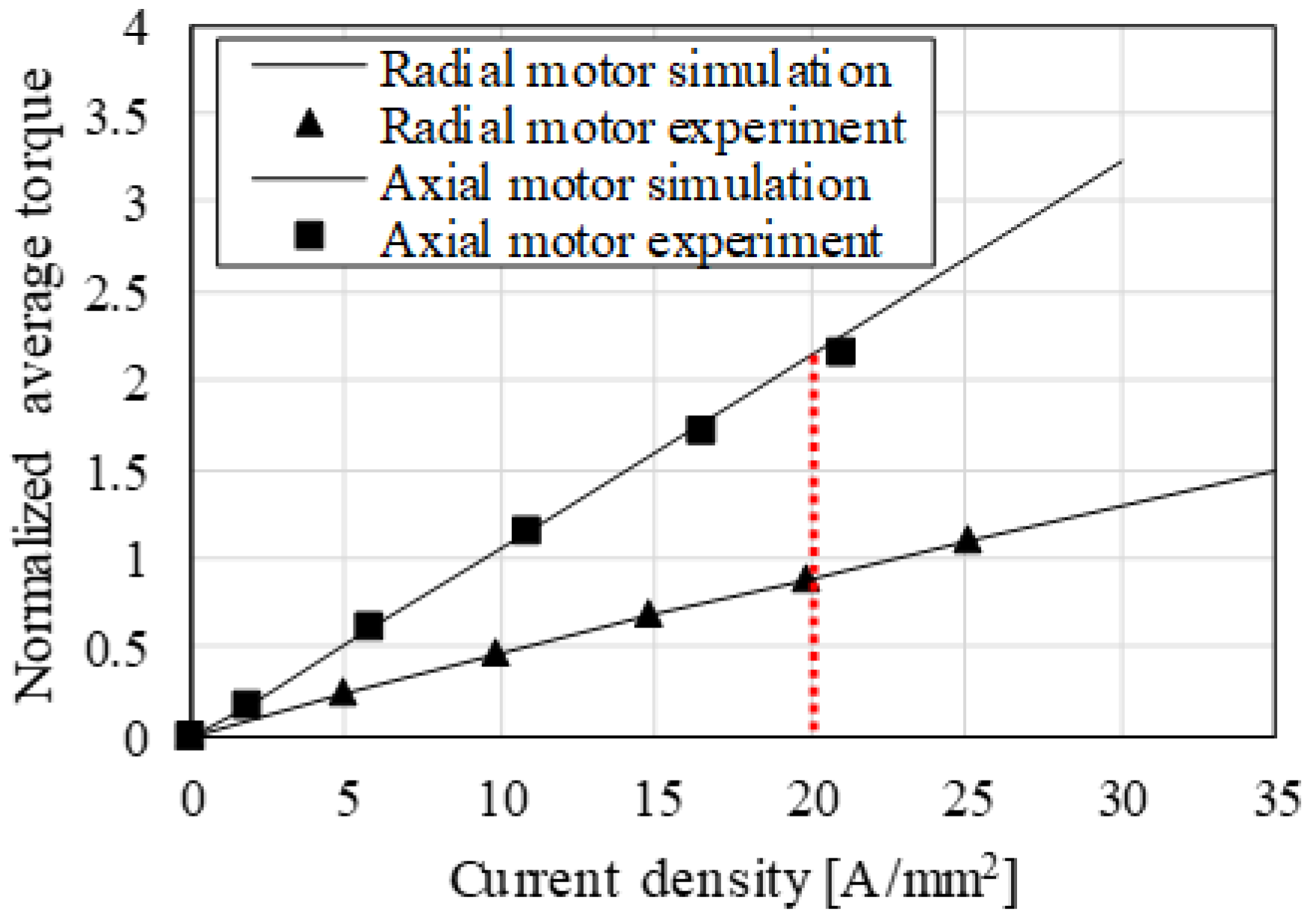

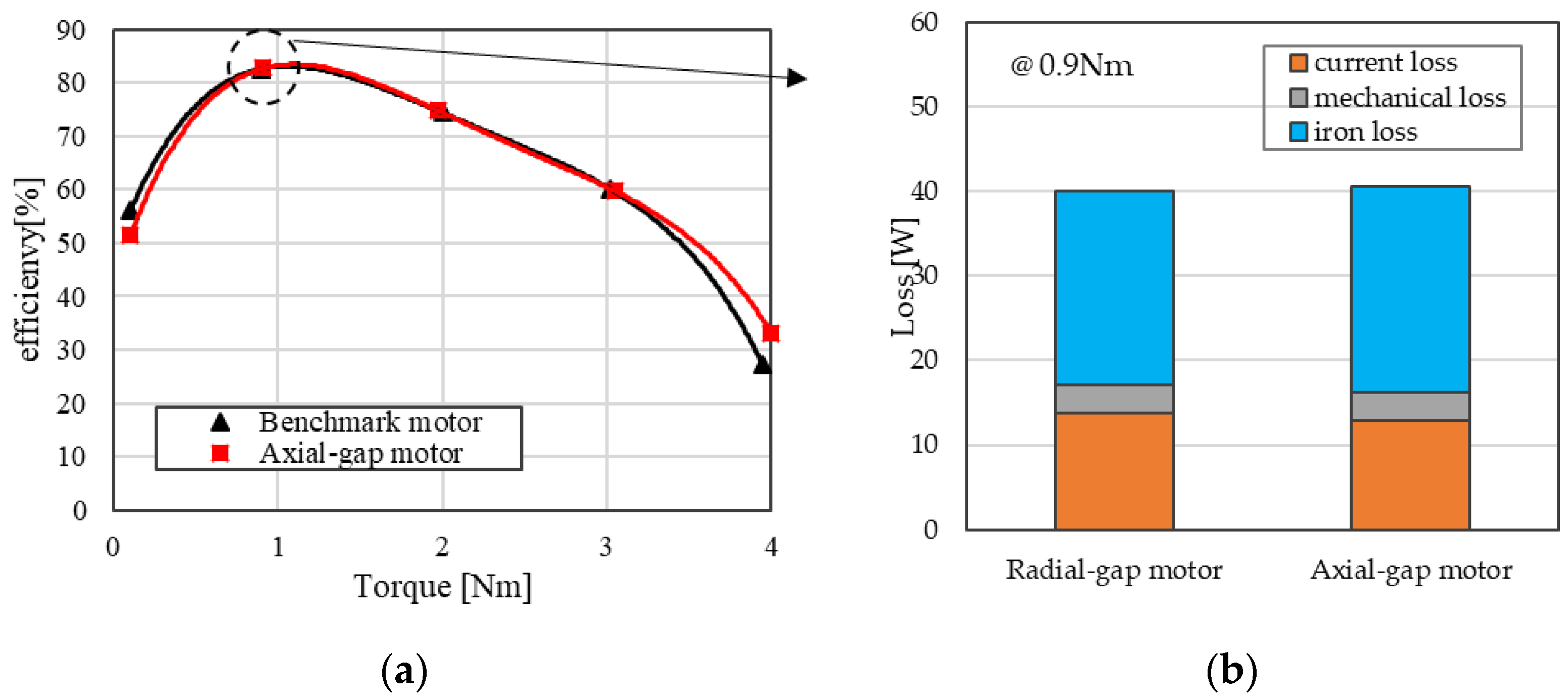

2.3. Experimental Results

3. High Torque Density of Axial-Gap Motor

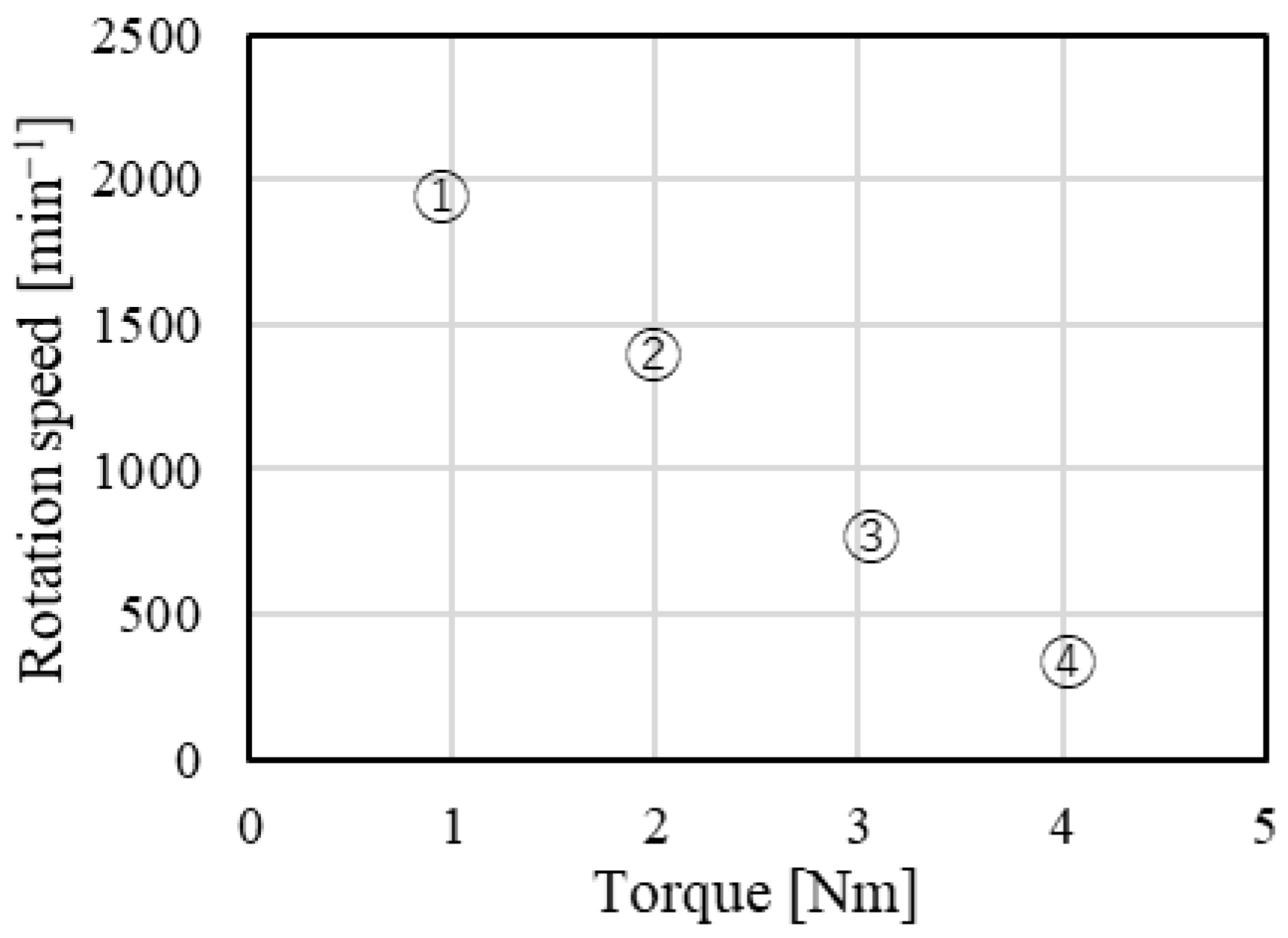

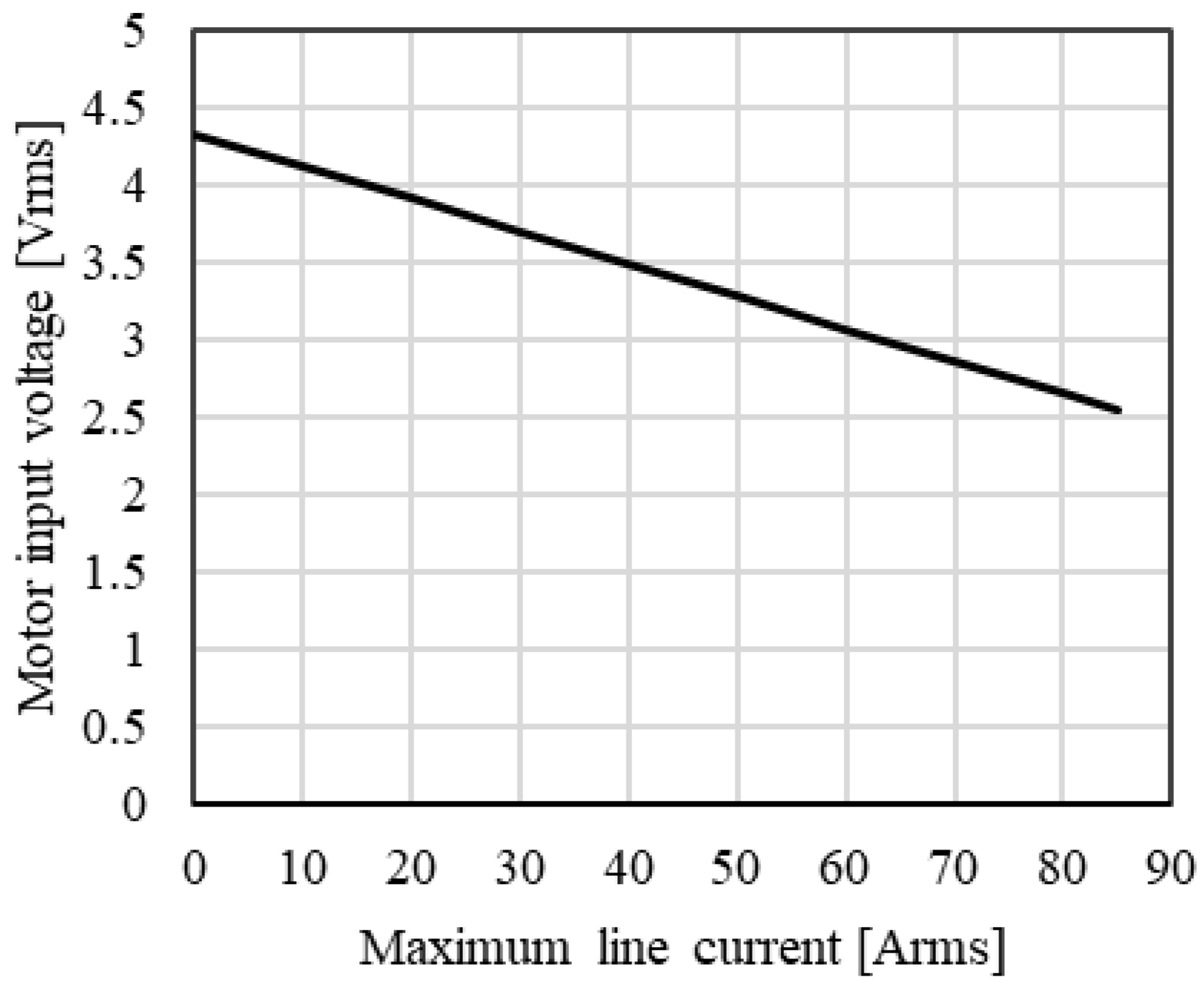

3.1. Preconditions and Target

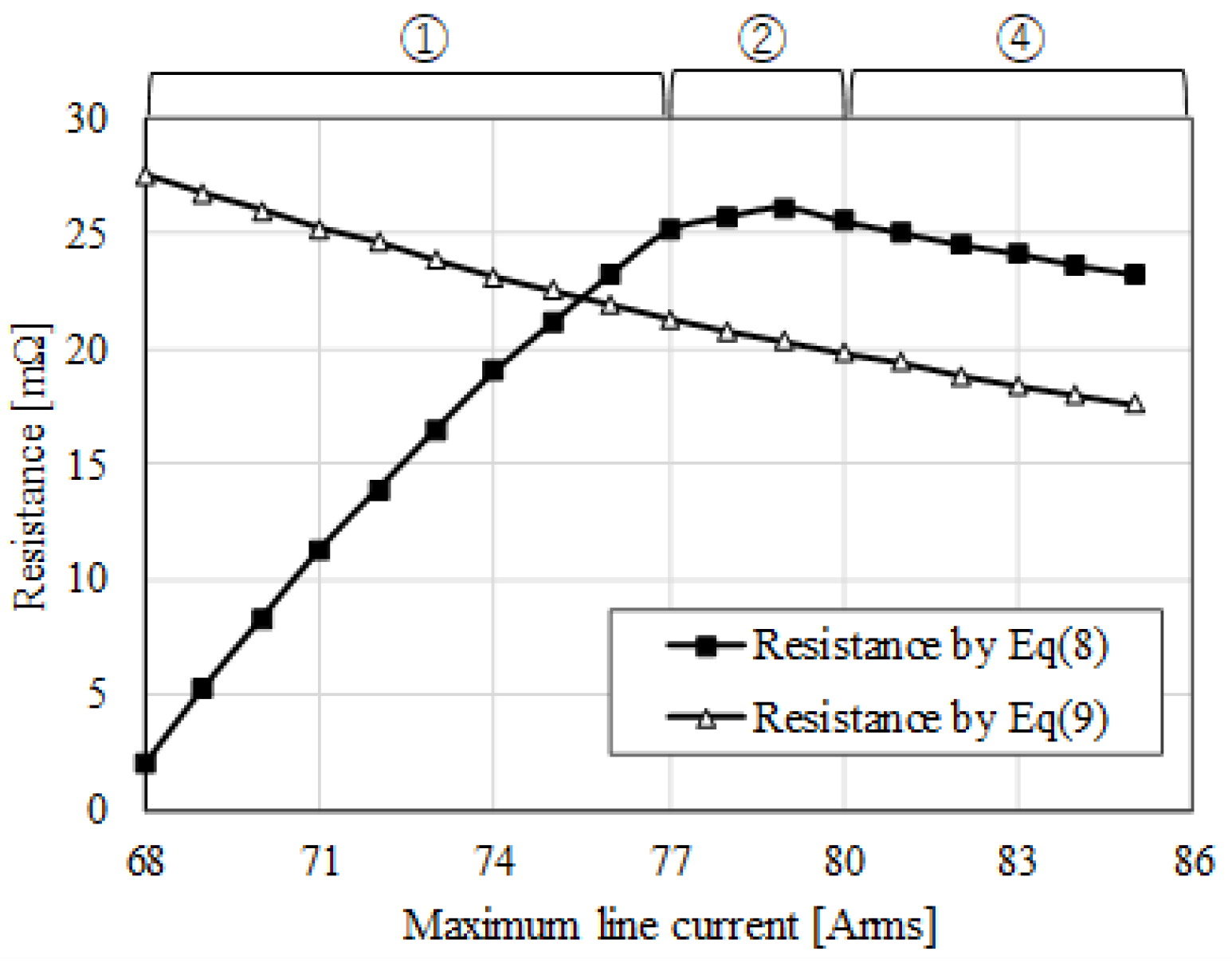

3.2. Design of Motor Constant for Maximum Output

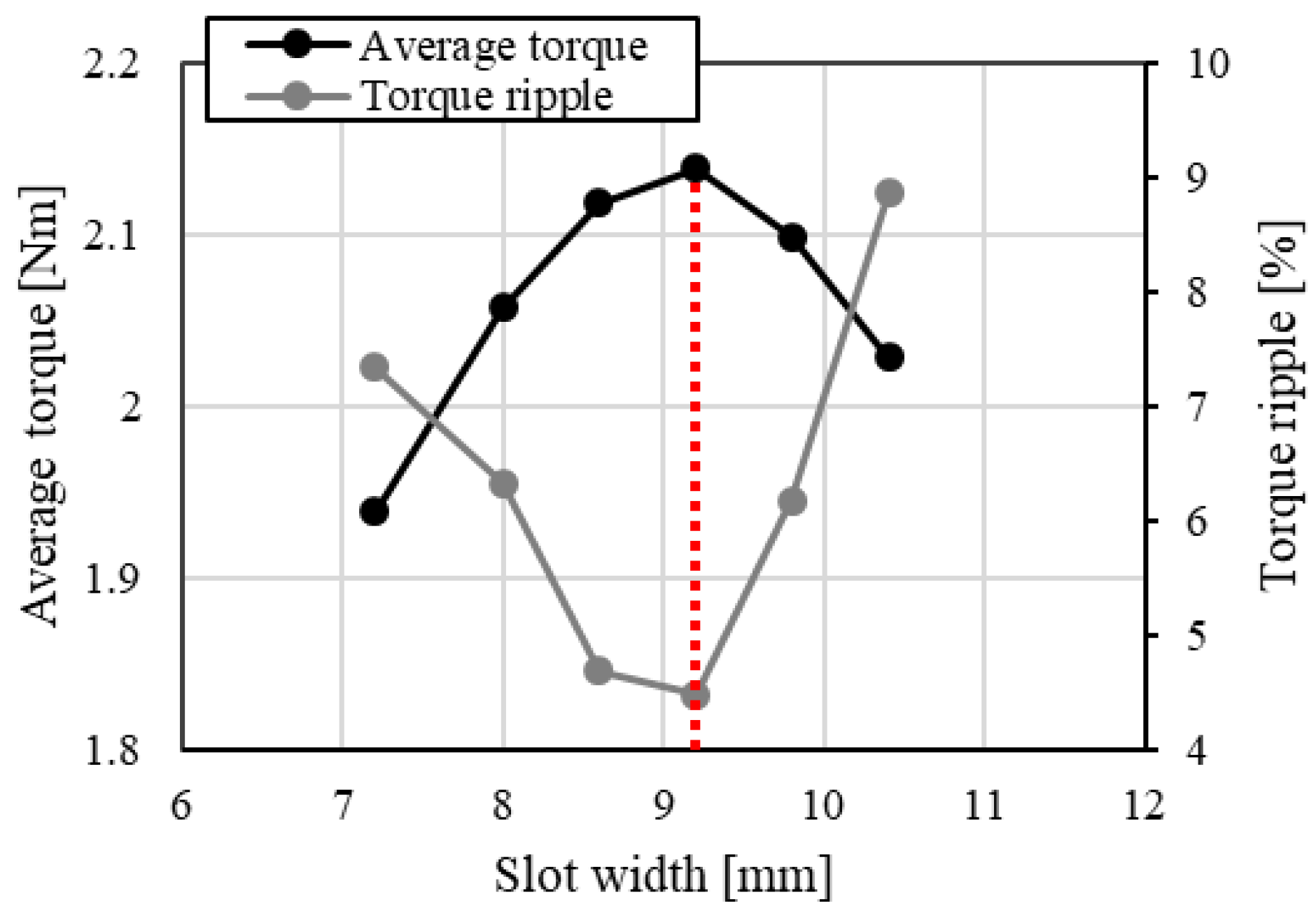

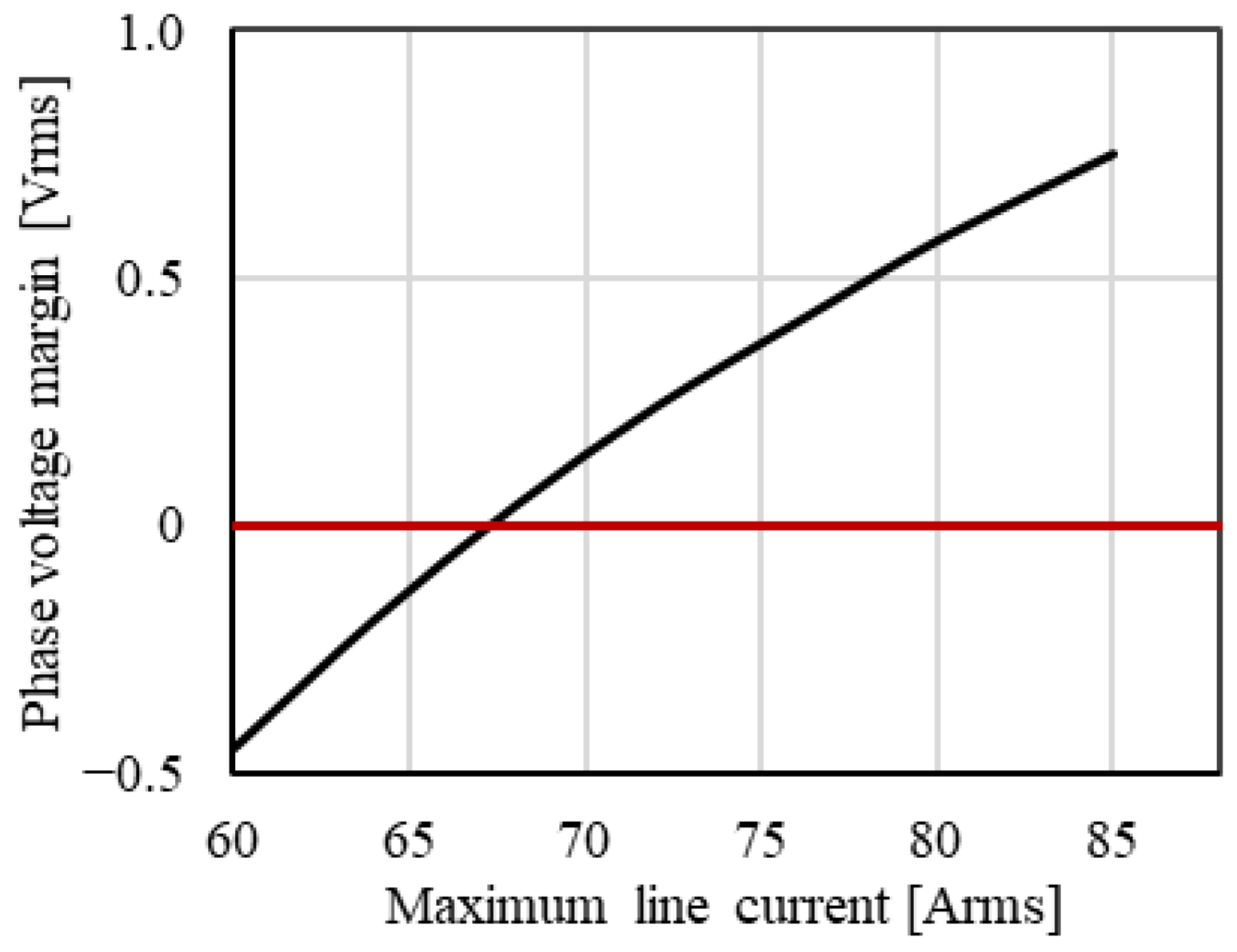

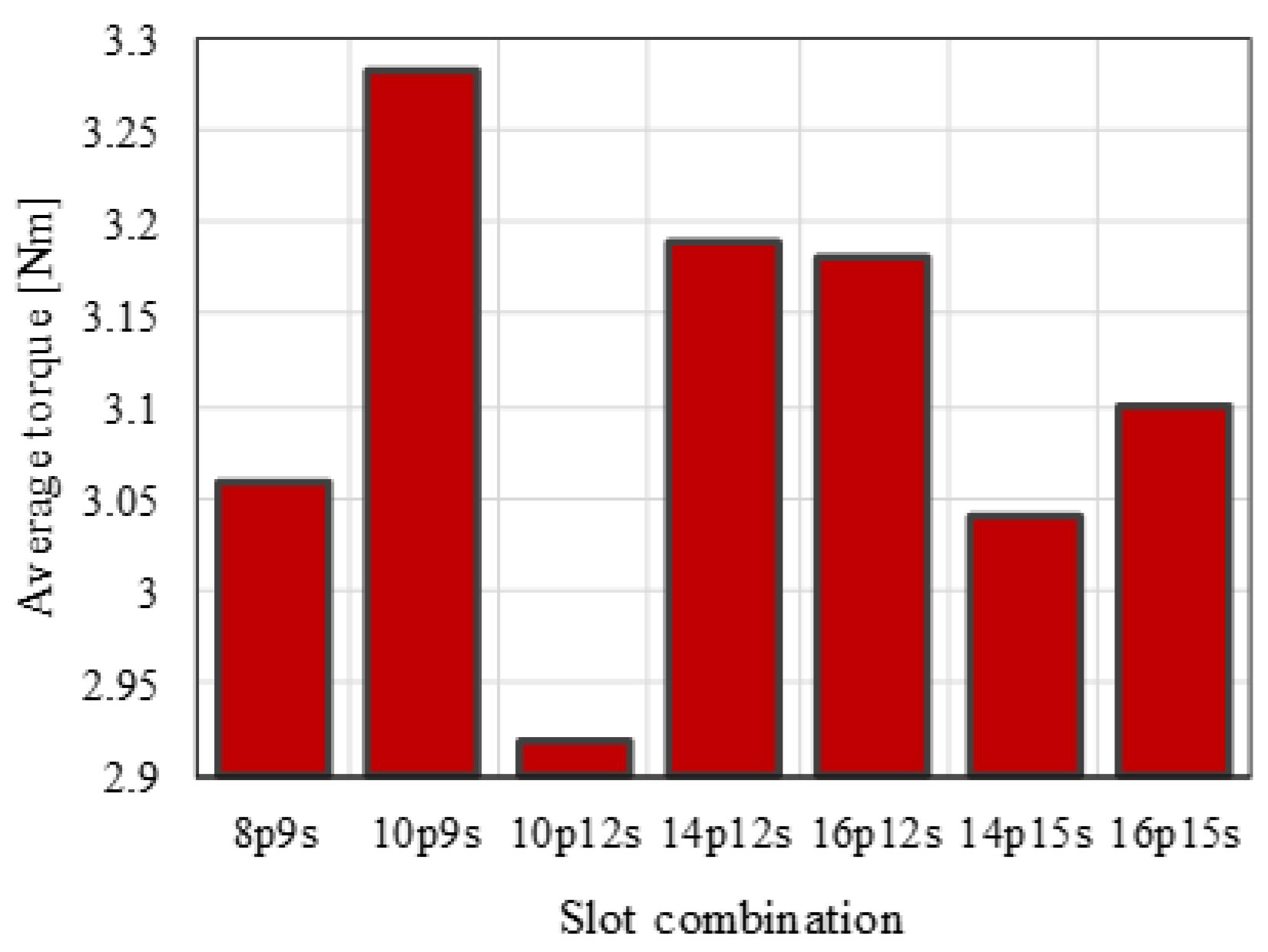

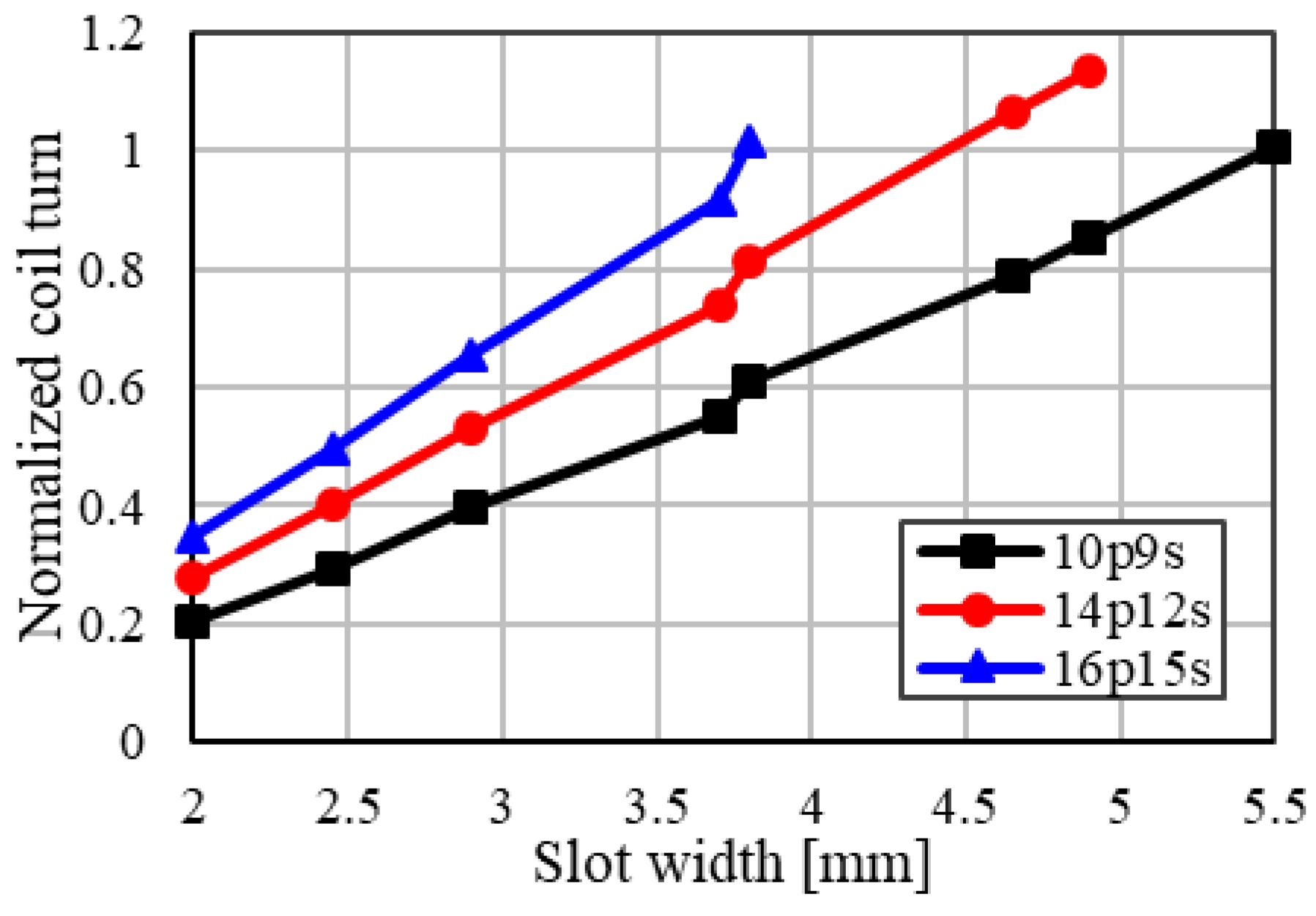

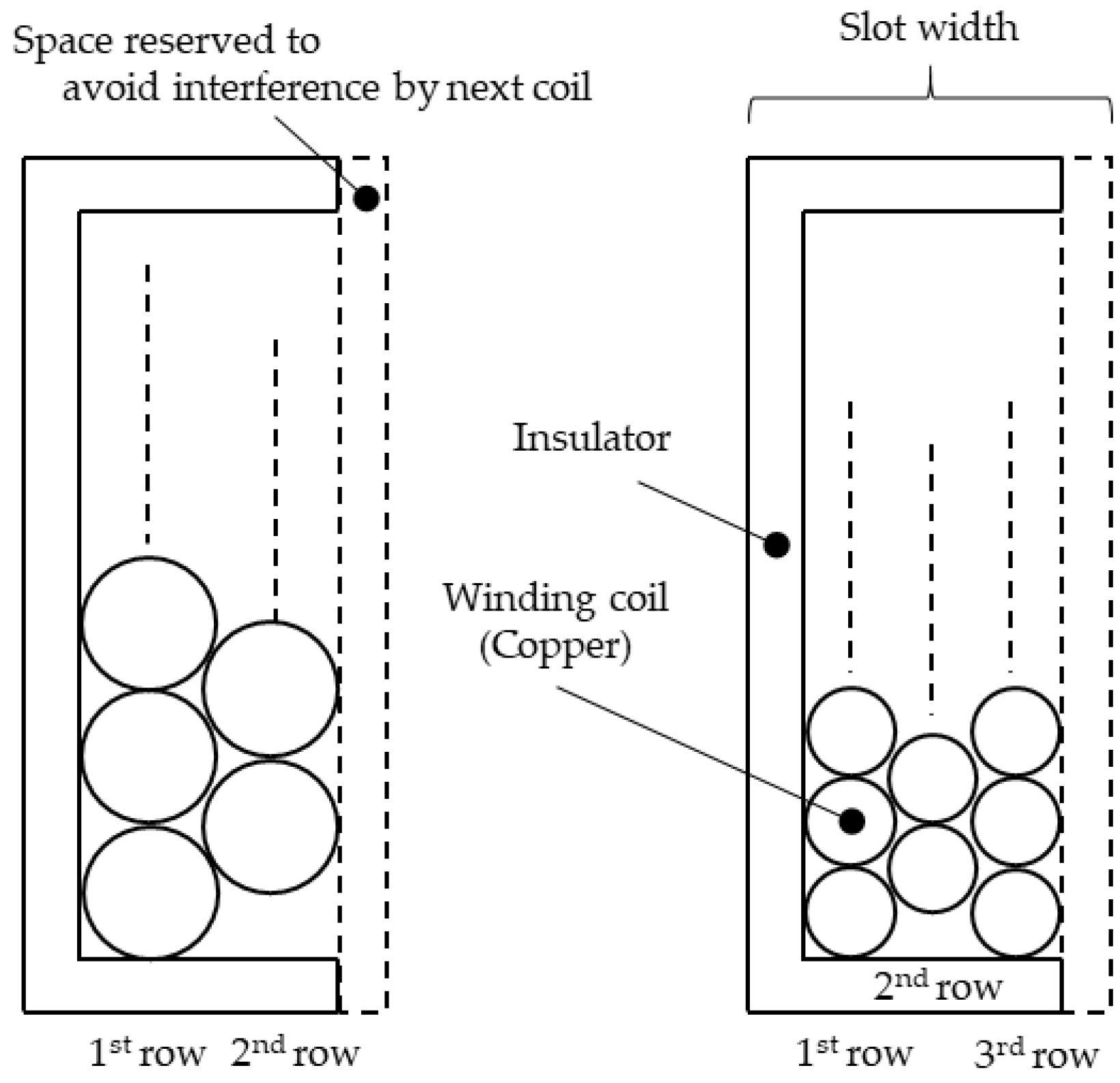

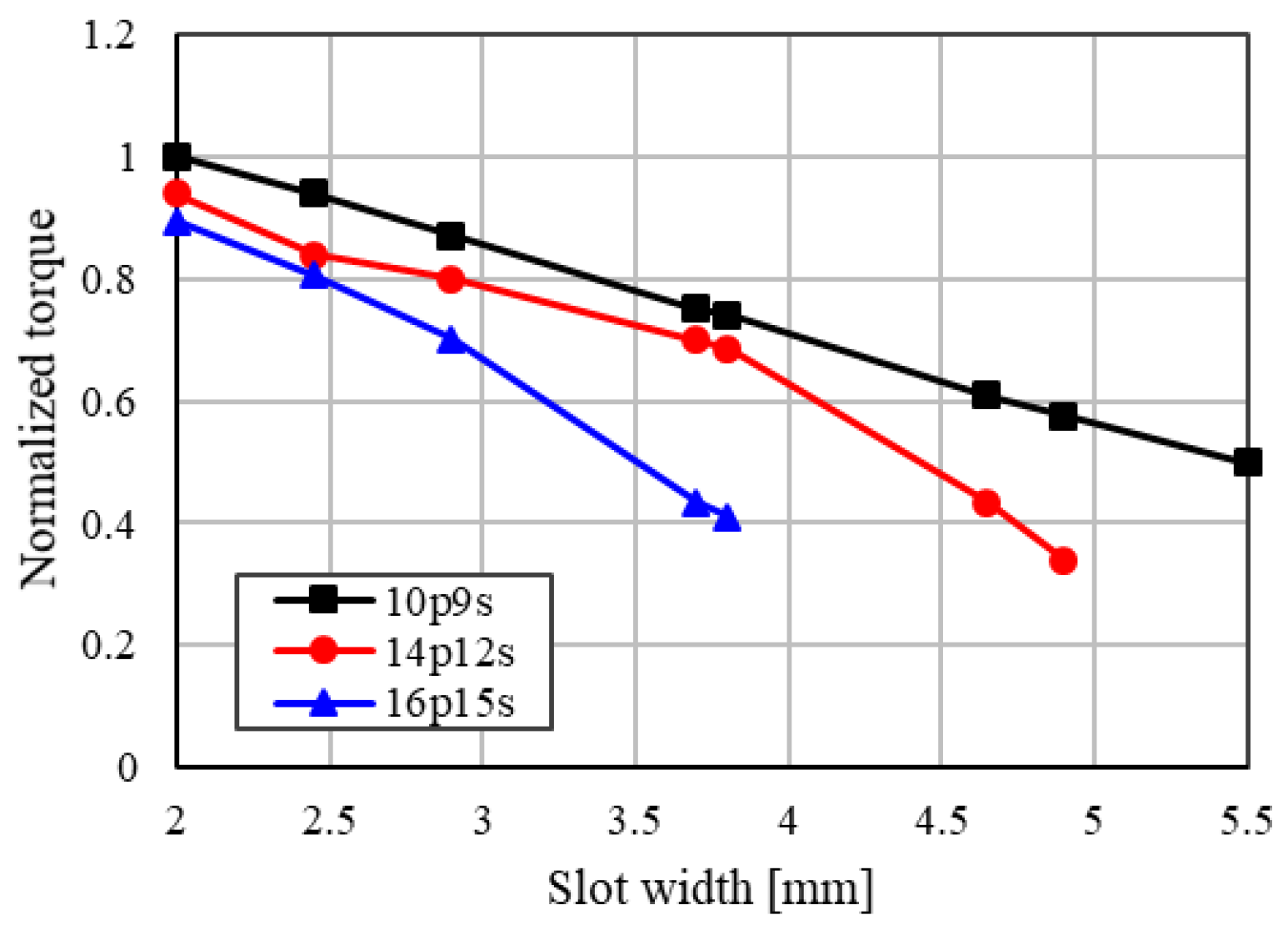

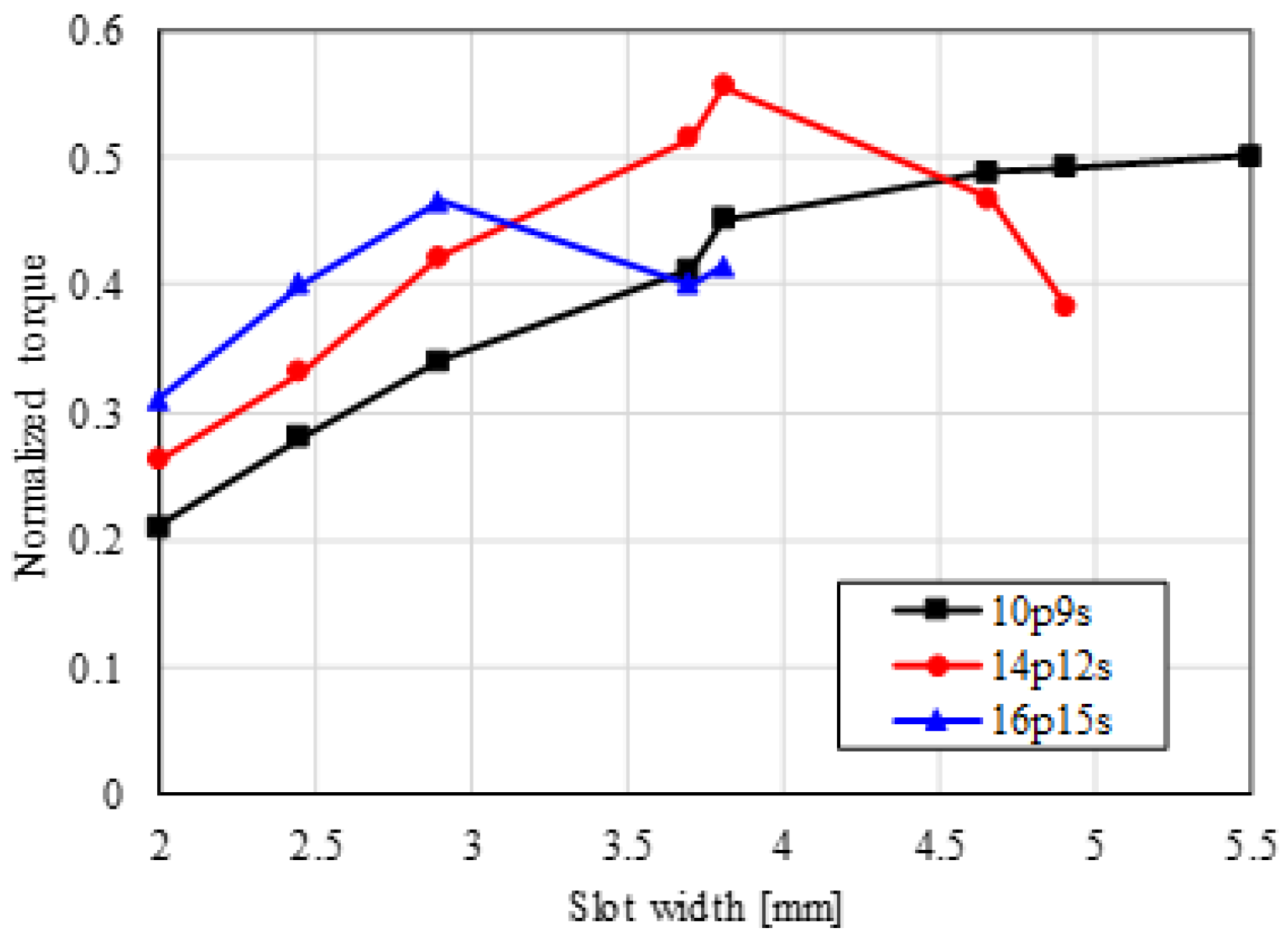

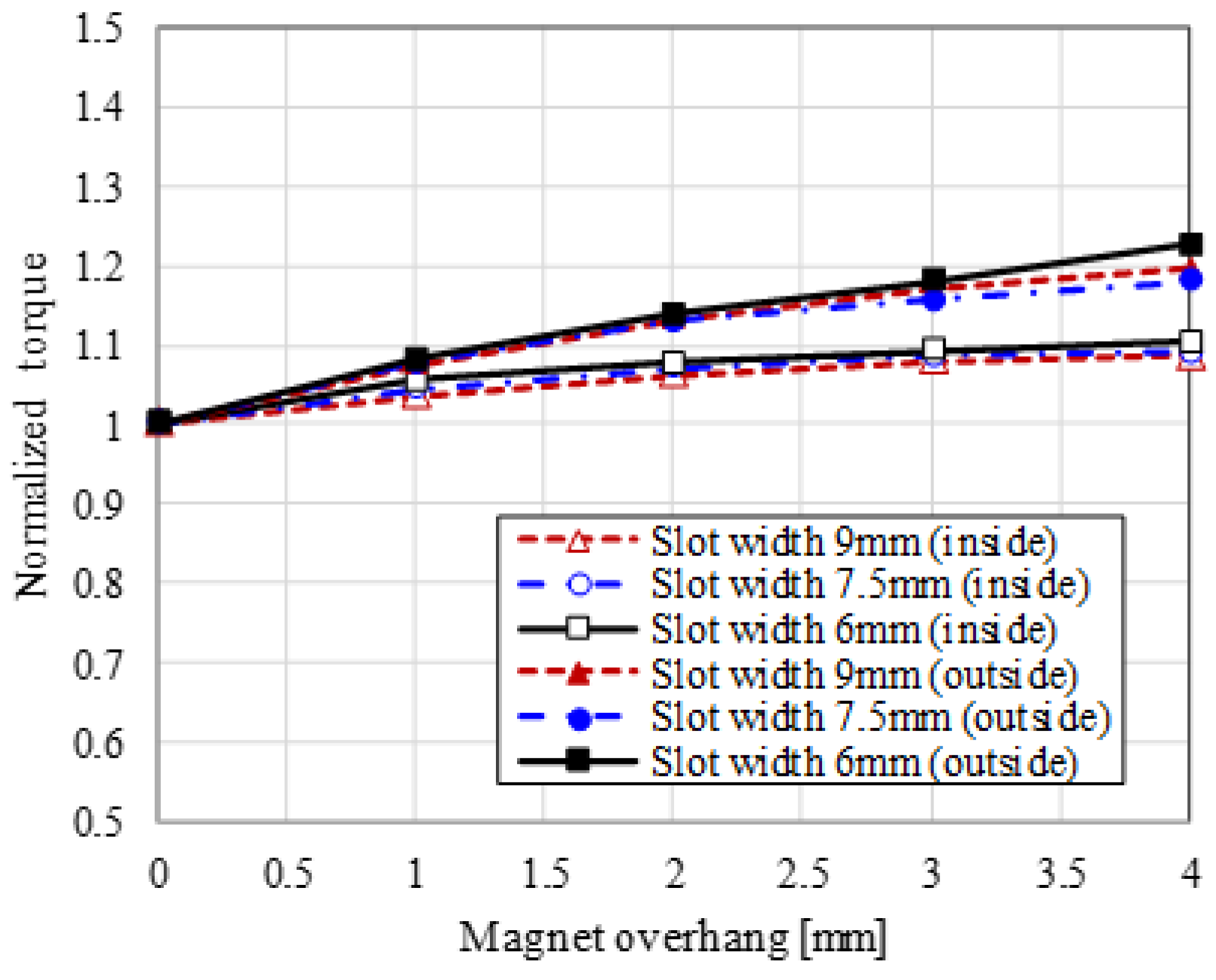

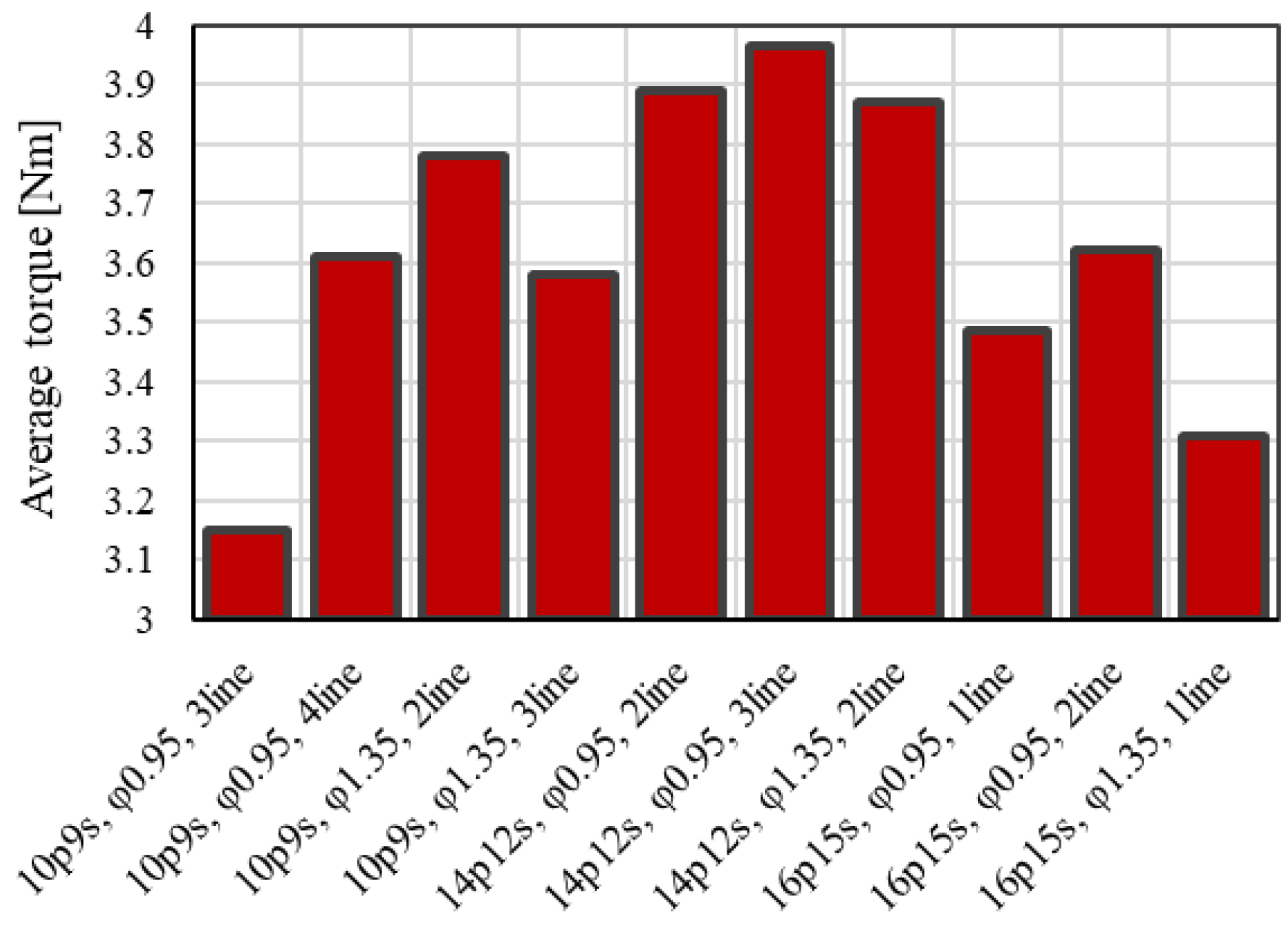

3.3. Magnetic Circuit Design (Structural Design)

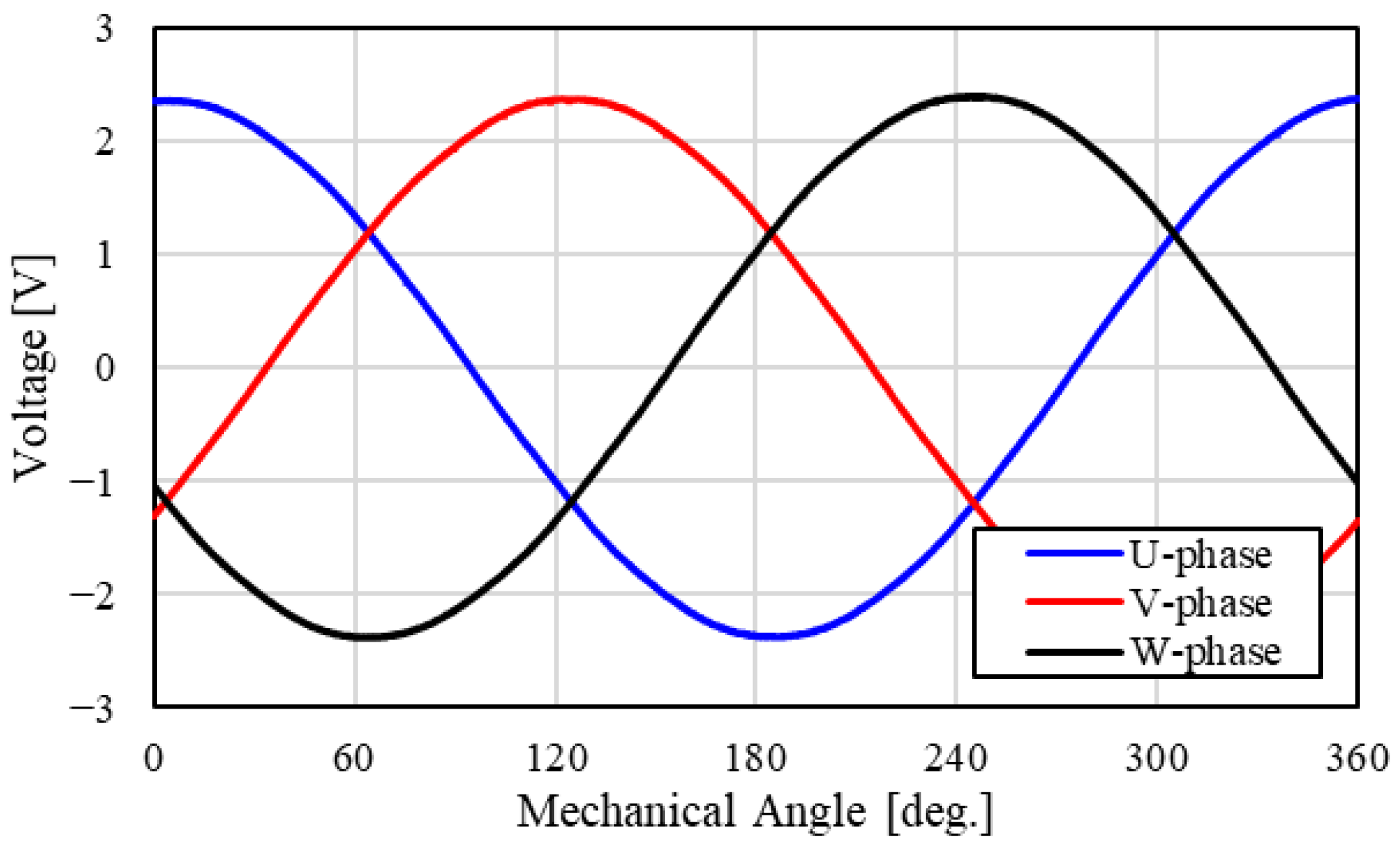

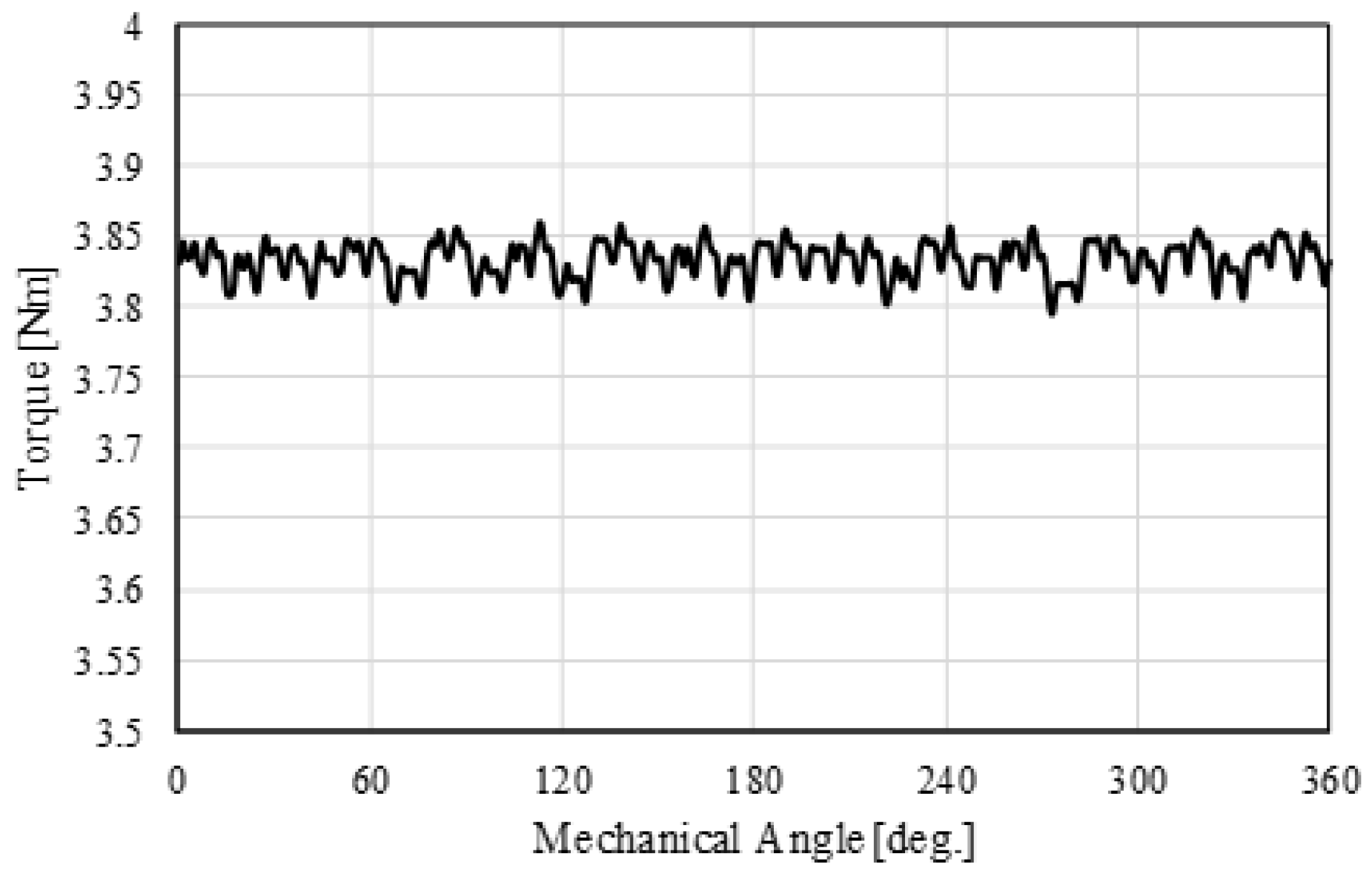

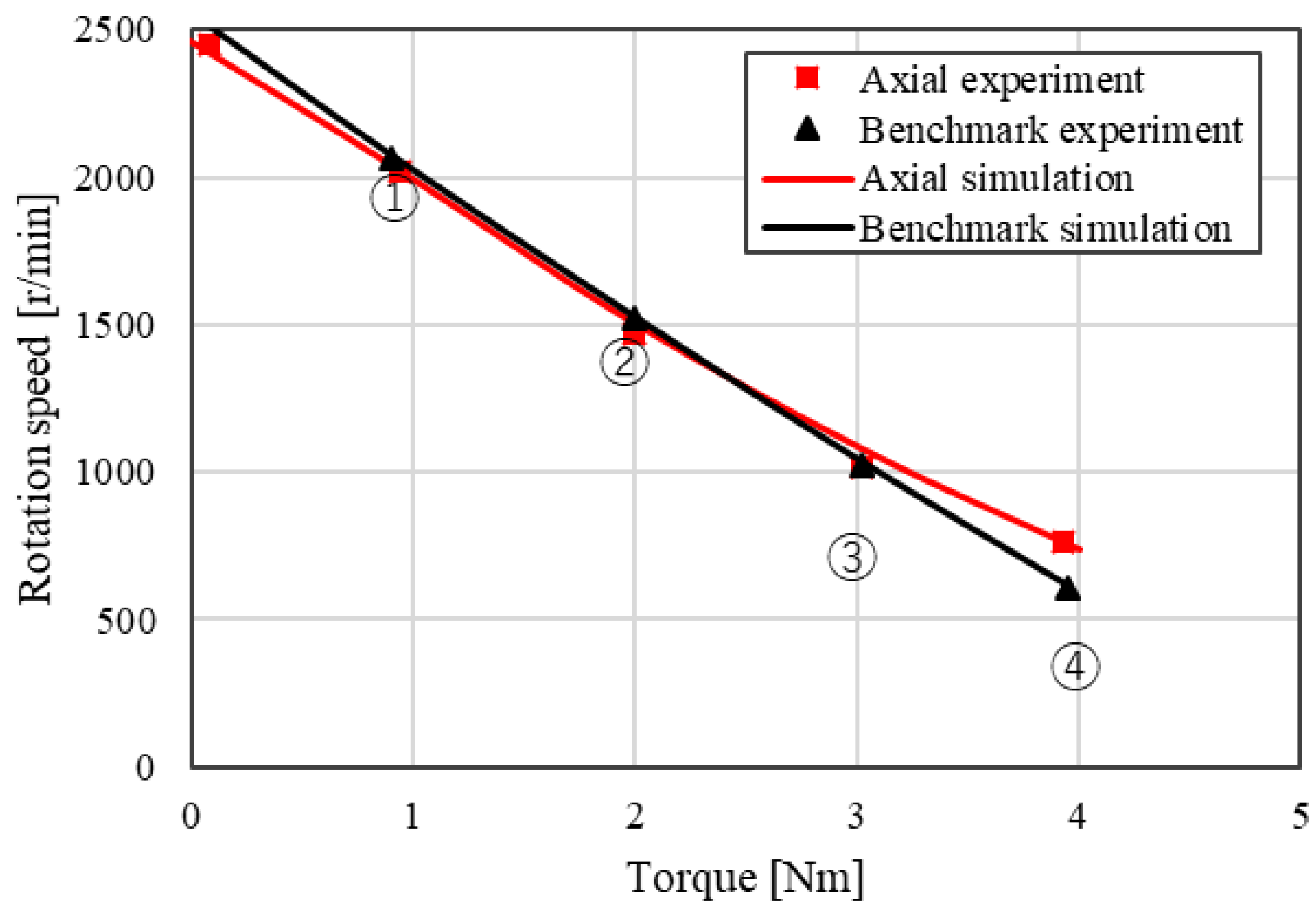

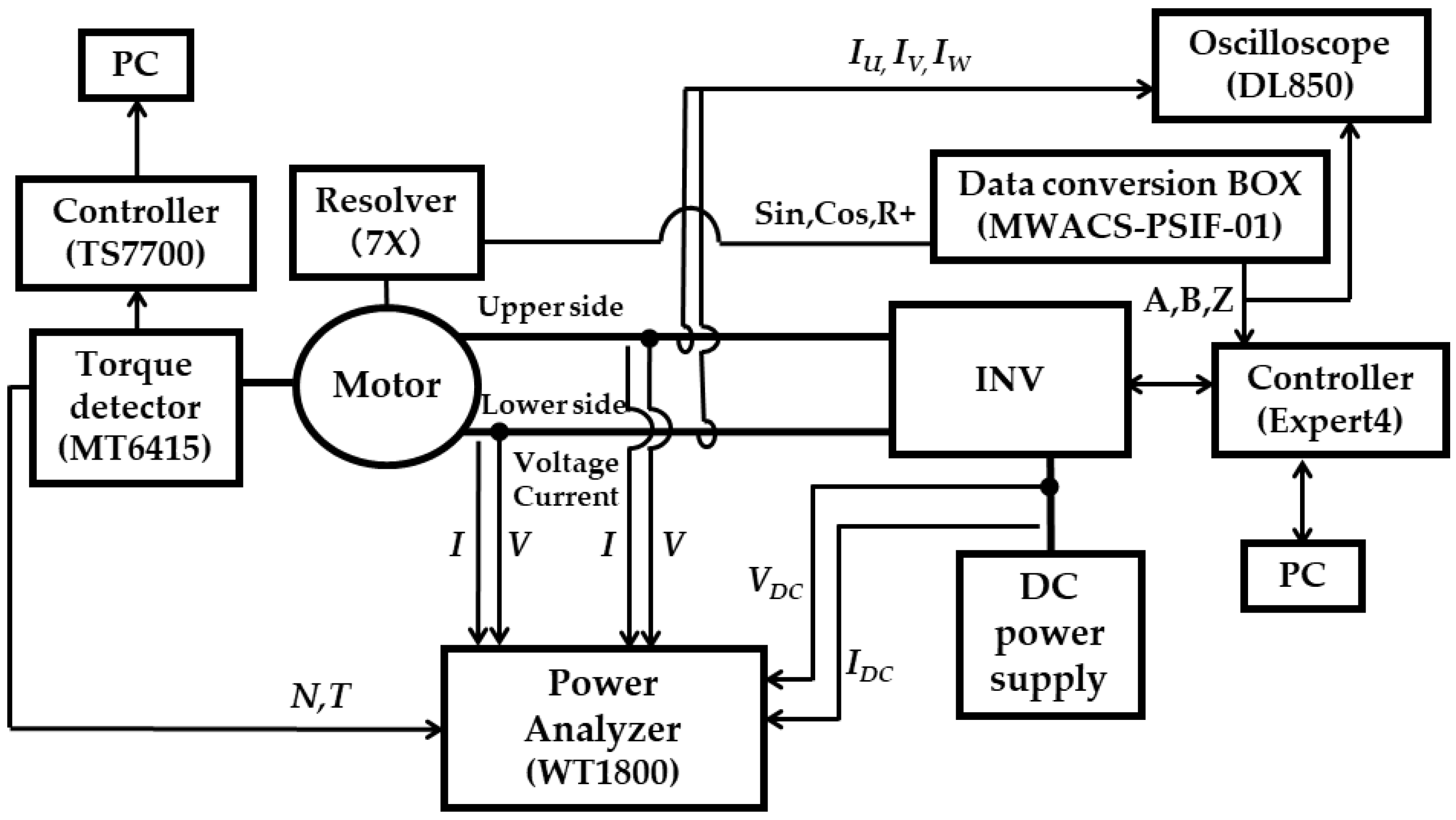

3.4. Results of Verification of Equipment

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yamamura, T.; Moroi, H.; Nakamura, Y.; Kawamura, R. Motor Technical Trend for Automotive. DENSO Tech. Rev. 2018, 23, 37–44. [Google Scholar]

- Investing R&D Committee on Elemental Technology Related to Electric Drive Assisted System for Mobility. Technical Trend of Electric Drive Assisted System for Mobility toward Creating Sustainable Society. IEEJ Tech. Rep. 2019, 1433, 49–63. [Google Scholar]

- Investing R&D Committee on Elemental Technology Related to Electric Drive Assisted System for Mobility. Development Trend and Prospect of Elemental Technology for Electric Drive Assisted System for Mobility. IEEJ Tech. Rep. 2022, 1528, 44–73. [Google Scholar]

- Tanaka, K.; Kawarai, H.; Mori, T.; Hara, K.; Koga, H.; Sunaga, Y. Brushless Blower Motor for Battery Cooling. Calsonic Kansei Tech. Rev. 2013, 10, 58–60. [Google Scholar]

- Inaguma, Y. Mathmatical Model for Characteristics of Oil Pump Driven by Electric Motor. JTECT Eng. J. 2009, 1006, 59–65. [Google Scholar]

- Jounokuchi, H.; Hamasaki, Y.; Yoshihara, Y. Technical Trends of Hydraulic-Electric Power Steering Systems. Koyo Eng. J. 2004, 166, 13–18. [Google Scholar]

- Okasaka, M. Electrification of the Automobile and Module Products of NTN. NTN Tech. Rev. 2015, 83, 16–19. [Google Scholar]

- Nagasawa, K.; Uemura, A.; Ohnishi, K.; Saito, Y. Study on Motor Drive Method in the Steer By Wire of the Redundancy. In Proceedings of the Japan Society for Precision Engineering, Nagoya, Japan, 27–29 September 2010; Volume D61, pp. 247–248. [Google Scholar]

- Takahashi, T.; Takemoto, M.; Ogasawara, S.; Arita, H.; Ogawa, T.; Daikoku, A. Examination of a Ferrite PM Axial Gap Motor with Field Windings. In Proceedings of the IEEJ Industry Applications Society Conference, Tokyo, Japan, 26–28 August 2014; pp. 213–216. [Google Scholar]

- Chino, S.; Miura, T.; Takemoto, M.; Ogasawara, S.; Chiba, A.; Hoshi, N. Load Test Results of a Ferrite Permanent Magnet Axial Gap Motor with Segmented Rotor Structure for the HEV. In Proceedings of the IEEJ Technical Meeting on Vehicle Technology, Nagoya, Japan, 24 May 2011; pp. 47–52. [Google Scholar]

- Miura, T.; Chino, S.; Takemoto, M.; Ogasawara, S.; Chiba, A.; Hoshi, N. A Proposal of a Ferrite Permanent Magnet Axial Gap Motor for the Next Generation Hybrid Vehicle. In Proceedings of the IEEJ Technical Meeting on Semiconductor Power Conversion, Nagasaki, Japan, 28 November 2009; pp. 59–64. [Google Scholar]

- Arakawa, T.; Takemoto, M.; Ogasawara, S.; Inoue, K.; Ozaki, O.; Hojo, H.; Mitani, H. Examination of an Interior Permanent Magnet Type Axial Gap Motor for the Hybrid Electric Vehicle. IEEE Trans. Magn. 2011, 47, 3602–3605. [Google Scholar] [CrossRef]

- Wang, X.; Wan, Z.; Tang, L.; Xu, W.; Zhao, M. Electromagnetic Performance Analysis of an Axial Flux Hybrid Excitation Motor for HEV Drives. IEEE Trans. Appl. Supercond. 2021, 31, 5205605. [Google Scholar] [CrossRef]

- Bruzinga, G.R.; Filho, S.J.A.; Pelizari, A. Analysis and Design of 3 kW Axial Flux Permanent Magnet Synchronous Motor for Electric Car. IEEE Lat. Am. Trans. 2022, 20, 855–863. [Google Scholar] [CrossRef]

- Zhao, W.; Lipo, A.T.; Kwon, B. Comparative Study on Novel Dual Stator Radial Flux and Axial Flux Permanent Magnet Motors With Ferrite Magnets for Traction Application. IEEE Trans. Magn. 2014, 50, 1–4. [Google Scholar] [CrossRef]

- Credo, A.; Tursini, M.; Villani, M.; Lodoxico, D.C.; Orlando, M.; Frattari, F. Axial Flux PM In-Wheel Motor for Electric Vehicles: 3D Multiphysics Analysis. Energies 2021, 14, 2107. [Google Scholar] [CrossRef]

- Takahashi, T.; Takemoto, M.; Ogasawara, S.; Hino, W.; Takezaki, K. Size and Weight Reduction of an In-Wheel Axial-Gap Motor Using Ferrite Permanent Magnets for Electric Commuter Cars. IEEE Trans. Ind. Appl. Appl. 2017, 53, 3927–3935. [Google Scholar] [CrossRef]

- Winterborne, D.; Stannard, N.; Sjoberg, L.; Atkinson, G. An Air-Cooled YASA Motor for in-Wheel Electric Vehicle Applications. IEEE Trans. Ind. Appl. 2020, 56, 6448–6455. [Google Scholar] [CrossRef]

- Kong, X.; Hua, Y.; Zhang, Z.; Wang, C.; Liu, Y. Analytical Modeling of High-Torque-Density Spoke-Type Permanent Magnet In-Wheel Motor Accounting for Rotor Slot and Eccentric Magnetic Pole. IEEE Trans. Transp. Electrif. 2021, 7, 2683–2693. [Google Scholar] [CrossRef]

- Shin, D.; Jung, M.; Lee, K.; Lee, K.; Kim, W. A Study on the Improvement of Torque Density of an Axial Slot-Less Flux Permanent Magnet Synchronous Motor for Collaborative Robot. Energies 2022, 15, 3464. [Google Scholar] [CrossRef]

- Tsunata, R.; Takemoto, M.; Ogasawara, S.; Watanabe, A.; Ueno, T.; Yamada, K. Investigation of Enhancing Efficiency and Acceleration in a Flat Shape Axial Gap Motor Having High Torque Characteristic. In Proceedings of the 2017 IEEE International Conference on Mechatronics (ICM), Churchill, VIC, Australia, 13–15 February 2017. [Google Scholar]

- Hattori, A.; Noguchi, T. Torque Density Comparison between Axial-Gap Motors and Radial-Gap Motors Using Simple High-Torque Design Based on Permeance Method. In Proceedings of the 2021 IEEE 24th International Conference on Electrical Machines and Systems (ICEMS), Gyeongju, Korea, 31 October–3 November 2021. [Google Scholar]

- Zhigang Li, Z.; Noguchi, T.; Kamiyama, H.; Hattori, A.; Yamada, Y.; Yokoyama, S. Experimental Verification of High-Torque-Density Axial-Gap PM Motor for Automotive Applications. In Proceedings of the IEEJ Annual National Conference, Nagoya, Japan, 28–29 September 2016; pp. 29–30. [Google Scholar]

- Hattori, A.; Yamada, Y.; Yokoyama, S.; Kamiyama, H.; Noguchi, T. Loss Analysis and Efficiency Enhancement of High-Torque Density Axial-Gap PM Motor for Automotive Applications. In Proceedings of the IEEJ Industry Applications Society Conference, Gunma, Japan, 30 August–1 September 2016; pp. 311–312. [Google Scholar]

- Kamiyama, H.; Noguchi, T.; Hattori, A.; Yamada, Y.; Yokoyama, S. Development of High-Torque Density Double-Axial-Air-Gap PM Motor for Automotive Applications. In Proceedings of the IEEJ Technical Meeting on Motor drive, Home and Consumer Appliances, Tokyo, Japan, 2 March 2017; pp. 67–72. [Google Scholar]

- Echle, A.; Pecha, U.; Parspour, N.; Gruner, C. Design of a Novel High Power Density Single Sided Axial Flux Motor Using SMC Materials. In Proceedings of the 2020 IEEE 13th International Conference on Electrical Machines (ICEM), Gothenburg, Sweden, 23–26 August 2020. [Google Scholar]

- Tokoi, H.; Kawamata, S.; Enomoto, Y. Study of High-Efficiency Motors Using Soft Magnetic Core. IEEJ Trans. Ind. Appl. 2015, 132, 574–580. [Google Scholar] [CrossRef]

- Cheng, B.; Pan, G.; Mao, Z. Analytical Calculation and Optimization of the Segmented-Stator Dual-Rotor Axial Flux Permanent Magnet Motors. IEEE Trans. Magn. 2020, 56, 8101709. [Google Scholar] [CrossRef]

- Huang, C.; Kou, B.; Zhao, X.; Niu, X.; Zang, I. Multi-Objective Optimization Design of a Stator Coreless Multidisc Axial Flux Permanent Magnet Motor. Energies 2022, 15, 4810. [Google Scholar] [CrossRef]

- Arakawa, T.; Hiramoto, K.; Nakai, H.; Tajima, S.; Inaguma, Y. Development of Axial Gap Motor by using High-Density Magnetic Composites. In Proceedings of the IEEJ Industry Applications Society Conference, Osaka, Japan, 20–22 August 2007; pp. 283–284. [Google Scholar]

- Tsunata, R.; Takemoto, M.; Ogasawara, S.; Watanabe, T.; Ueno, T.; Yamada, K. Development and Evaluation of an Axial Gap Motor Using Neodymium Bonded Magnet. IEEE Trans. Ind. Appl. 2018, 54, 254–262. [Google Scholar] [CrossRef]

- Tsunata, R.; Takemoto, M.; Ogasawara, S.; Saito, T.; Ueno, T. SMC Development Guidelines for Axial Flux PM Machines Employing Coreless Rotor Structure for Enhancing Efficiency Based on Experimental Results. IEEE Trans. Ind. Appl. Appl. 2022, 58, 3470–3485. [Google Scholar] [CrossRef]

- Morimoto, S.; Sanada, M. Principle and Design Method of Energy-Saving Motor; Kagakujyoho Shuppan Co. Ltd.: Ibaraki, Japan, 2013. [Google Scholar]

| Items | Value |

|---|---|

| Motor outer diameter | 84 mm |

| Stack length | 25 mm |

| Maximum current density | 30 Arms/mm2 |

| Volume of PM | constant |

| Kind of PM | Ferrite magnet |

| Magnet arrangement | SPM |

| Winding method | Concentrated windings |

| Winding connection method | Star configuration |

| Motor driving system | Three-phase sinusoidal AC drive |

| Items | Radial-Gap Motor | Axial-Gap Motor | |

|---|---|---|---|

| number of poles and slots | 8 poles, 12 slots | 16 poles, 12 slots | |

| Motor outer diameter | 84 mm | ||

| stack length | 25 mm | ||

| Air gap length | 1.0 mm | 0.5 mm (one side) | |

| stator | stator outer diameter | 84 mm | 84 mm |

| stator inner diameter | 45.4 mm | 44.2 mm | |

| width of tooth/width of slots | 7.2 mm/− | −/8.3 mm | |

| width of backyoke | 5 mm | 2 mm | |

| rotor | rotor outer diameter | 43.4 mm | 82 mm |

| thickness of PM | 9.4 mm | 2.5 mm | |

| outer diameter of PM | 43.4 mm | 80 mm | |

| inner diameter of PM | 24.6 mm | 32 mm | |

| Items | Value |

|---|---|

| Motor outer diameter | 80 mm |

| Supply voltage Vdc | 11 V |

| Maximum current density | 30 Arms/mm2 |

| Volume of magnet | less than benchmark |

| Slot | 6 | 9 | 12 | 15 | 18 | Torque Ripple |

|---|---|---|---|---|---|---|

| Pole | ||||||

| 4 | 0.866 | 0.617 | 0.433 | 0.389 | 0.328 | 12 |

| 6 | 0.866 | 0.38 | 0.433 | 18 | ||

| 8 | 0.866 | 0.946 | 0.866 | 0.711 | 0.616 | 24 |

| 10 | 0.5 | 0.946 | 0.933 | 0.866 | 0.735 | 30 |

| 12 | 0.866 | 0.91 | 0.866 | 36 | ||

| 14 | 0.5 | 0.617 | 0.933 | 0.952 | 0.902 | 42 |

| 16 | 0.866 | 0.328 | 0.866 | 0.952 | 0.946 | 48 |

| 18 | 0.91 | 54 | ||||

| 20 | 0.866 | 0.328 | 0.433 | 0.866 | 0.946 | 60 |

| 22 | 0.5 | 0.902 | 0.711 | 0.617 | 0.902 | 66 |

| Items | Value | |

|---|---|---|

| Number of Poles and Slots | 14poles, 12slots | |

| motor diameter | 80 mm | |

| axial length | 34.8 mm | |

| stator | winding method | Concentrated windings |

| winding connection method | Star connection 2 series, 4 parallel | |

| wire diameter | 0.95 mm | |

| stator core material | Soft Magnetic Composite (SMC) | |

| rotor | slot width | 3.8 mm |

| rotor frame material | SUS303 | |

| material of magnets | SmFeN | |

| magnet arrangement | SPM type | |

| thickness of magnets | 5.7 mm | |

| volume of magnets | 15,349 mm3 | |

| drive system | Three-phase sinusoidal voltage | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hattori, A.; Noguchi, T.; Kamiyama, H. High-Torque Density Design of Small Motors for Automotive Applications with Double Axial-Air-Gap Structures. Energies 2022, 15, 7341. https://doi.org/10.3390/en15197341

Hattori A, Noguchi T, Kamiyama H. High-Torque Density Design of Small Motors for Automotive Applications with Double Axial-Air-Gap Structures. Energies. 2022; 15(19):7341. https://doi.org/10.3390/en15197341

Chicago/Turabian StyleHattori, Akihisa, Toshihiko Noguchi, and Hiromu Kamiyama. 2022. "High-Torque Density Design of Small Motors for Automotive Applications with Double Axial-Air-Gap Structures" Energies 15, no. 19: 7341. https://doi.org/10.3390/en15197341

APA StyleHattori, A., Noguchi, T., & Kamiyama, H. (2022). High-Torque Density Design of Small Motors for Automotive Applications with Double Axial-Air-Gap Structures. Energies, 15(19), 7341. https://doi.org/10.3390/en15197341