The Optimization of Parallel Resonance Circuit for Wear Debris Detection by Adjusting Capacitance

Abstract

1. Introduction

2. Determination of the Optimal Capacitance

2.1. The Impedance Variation in the Sensing Coil

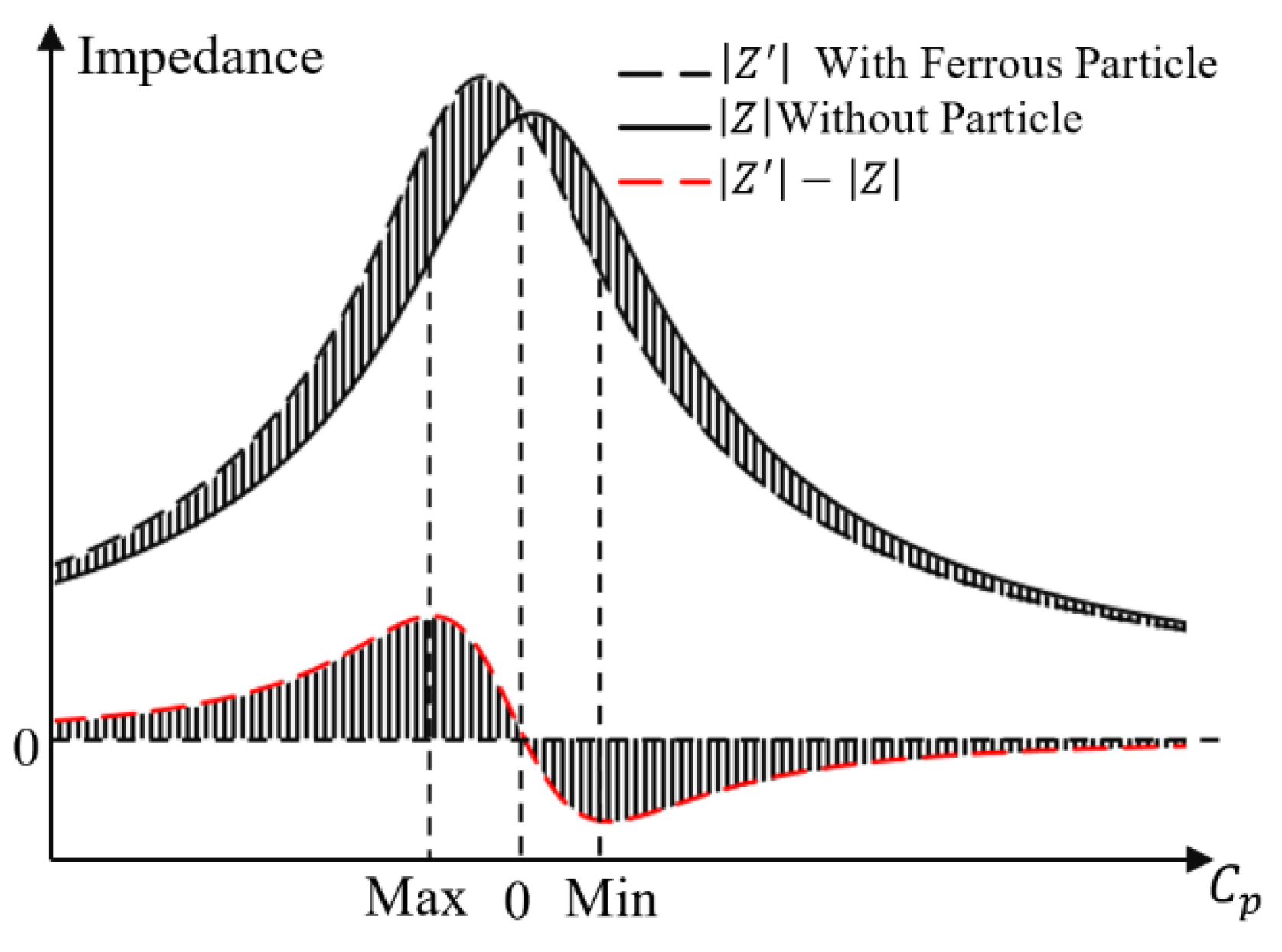

2.2. Relative Impedance Variation of Parallel LC Resonance Circuit

2.3. Estimation of the Optimal Capacitance

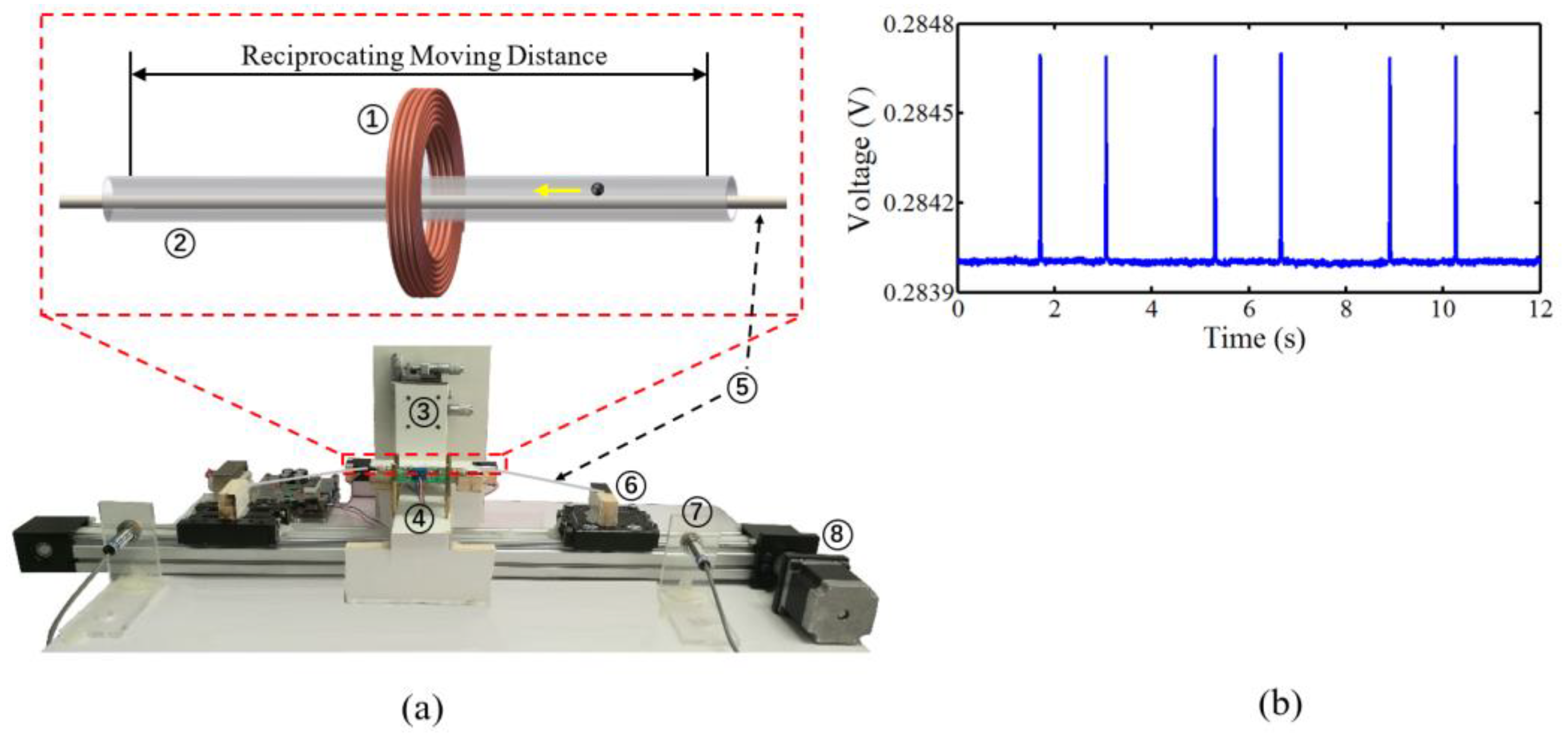

3. Experiment Method and Setup

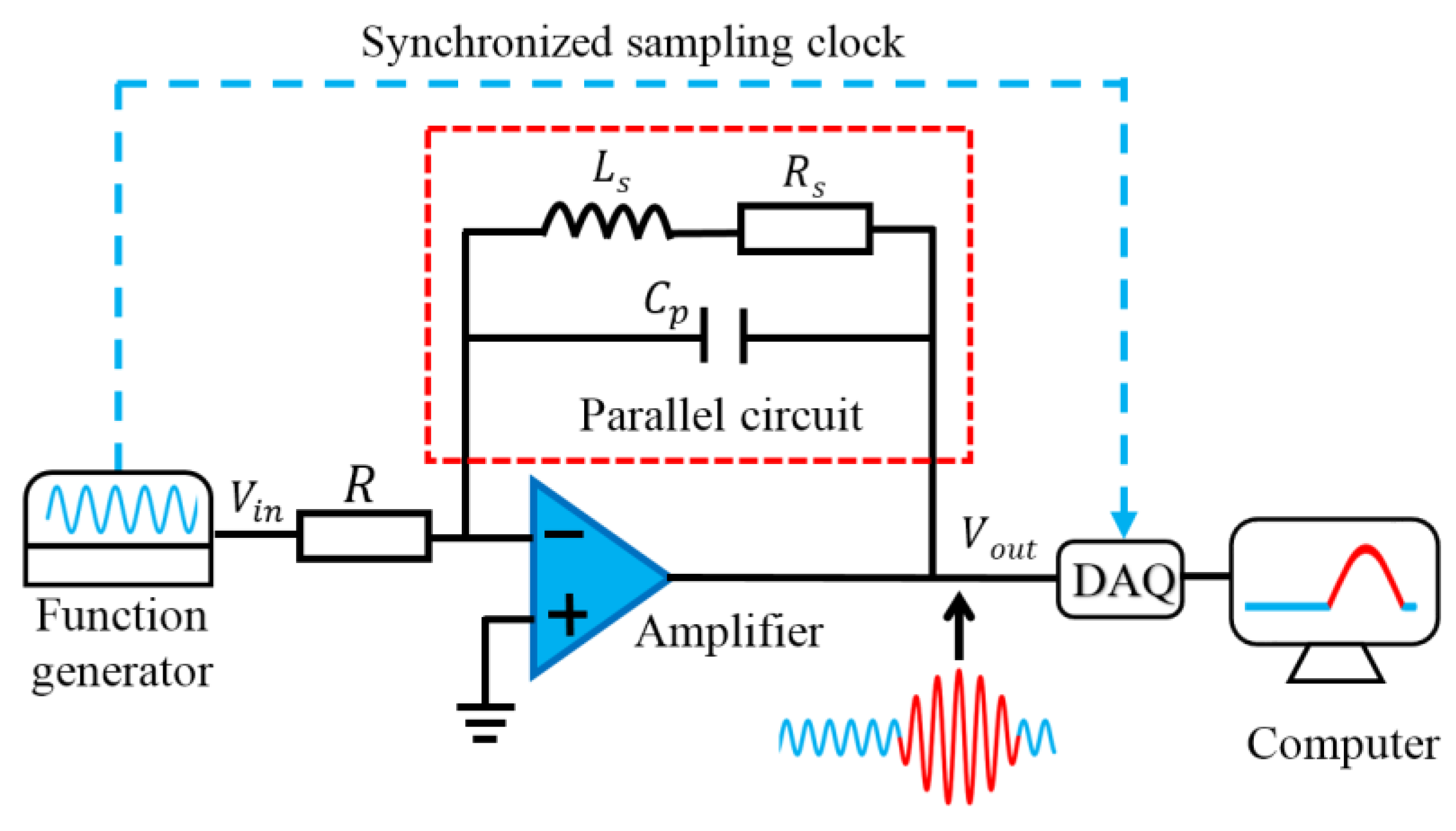

3.1. Signal Detection Method

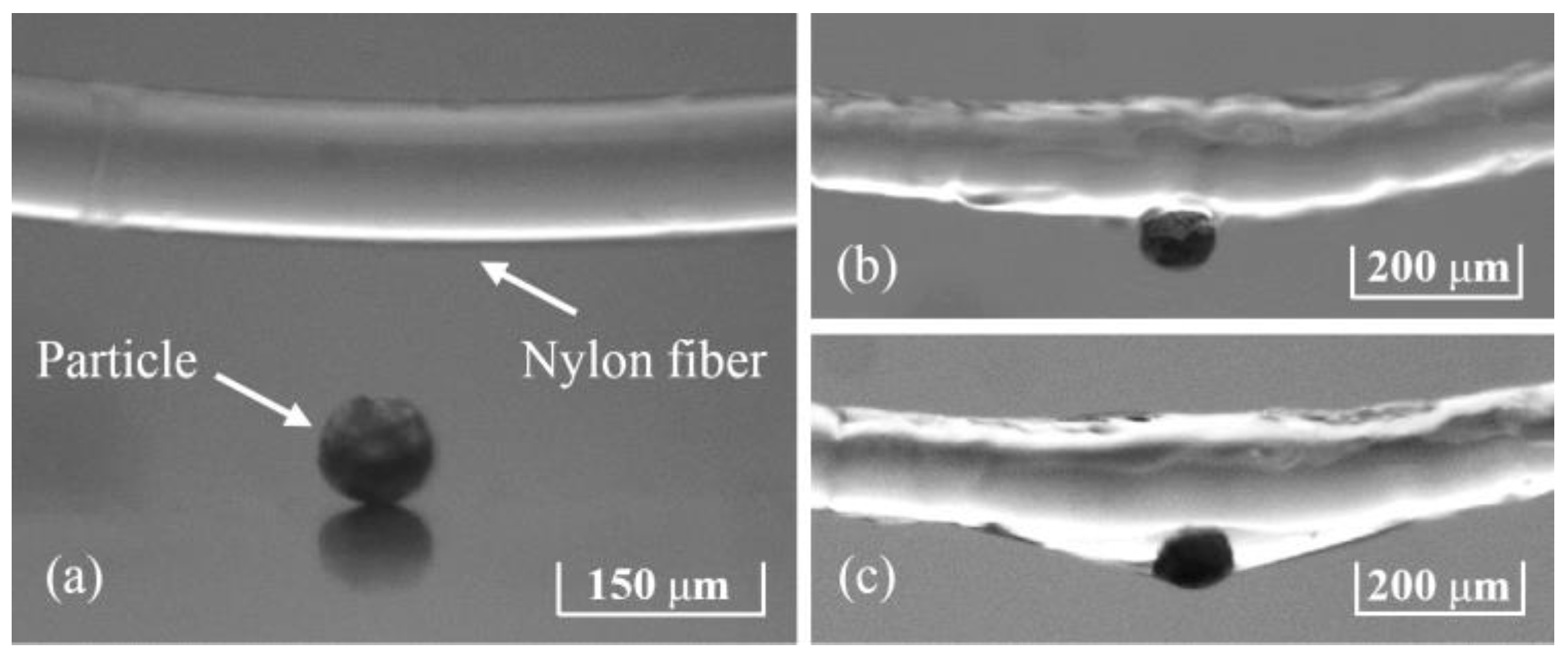

3.2. Particle Preparation

3.3. Setup and Testing

4. Results and Discussion

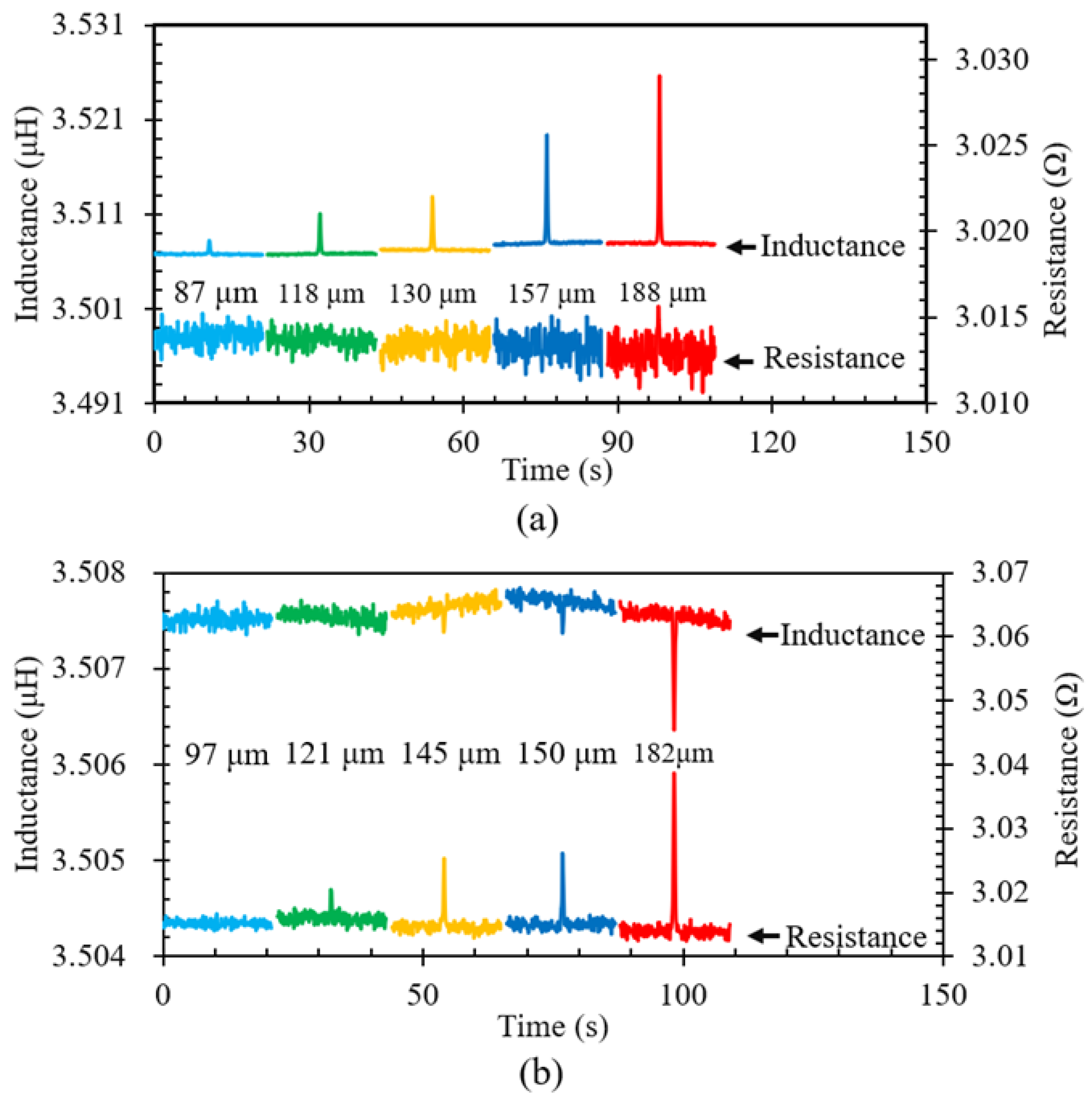

4.1. Verification of Optimal Capacitance for Ferrous Particle

4.2. Verification of Optimal Capacitance for Nonferrous Particle

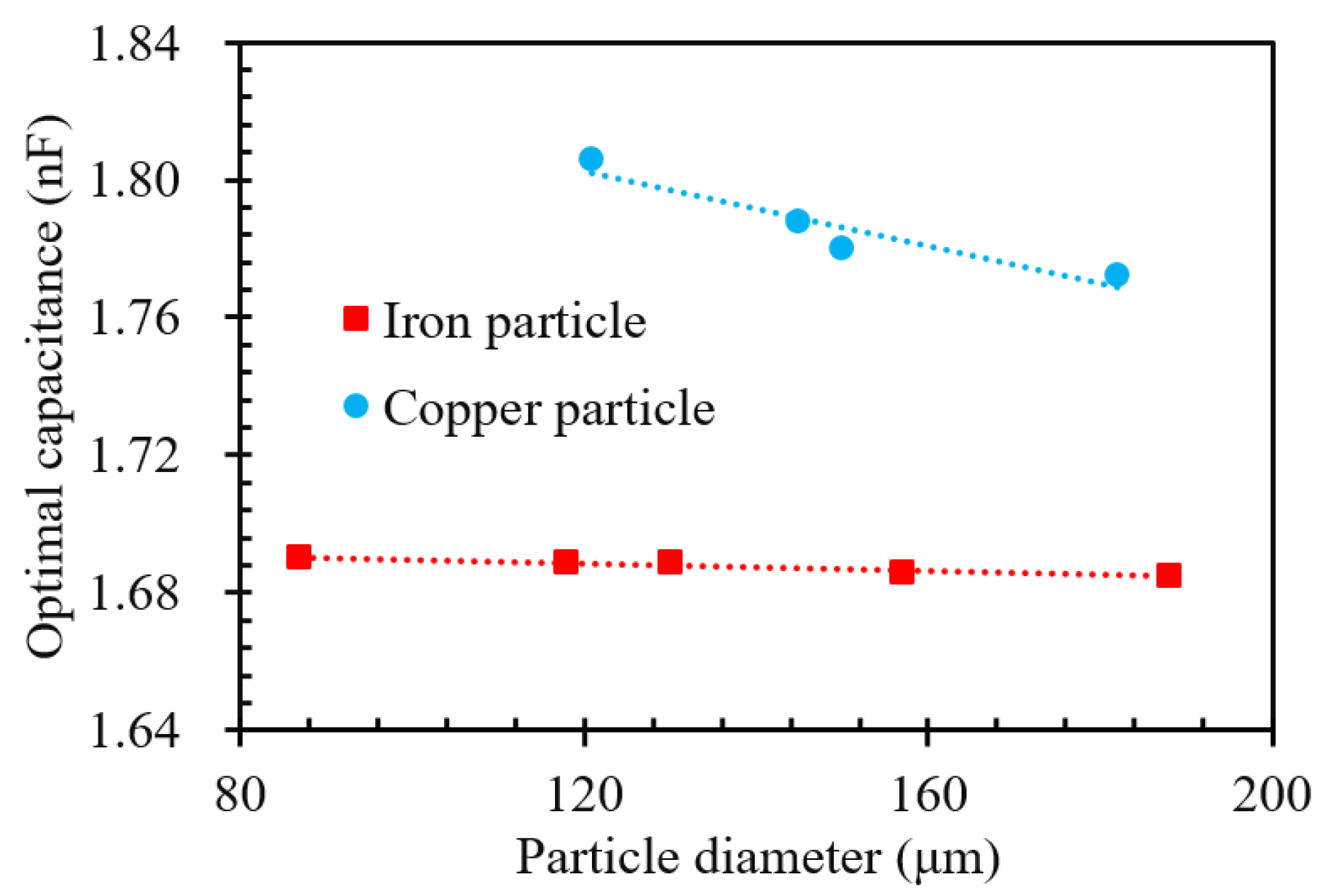

4.3. Sensitivity Testing for Iron and Copper Particles

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Jardine, A.K.S.; Lin, D.; Banjevic, D. A Review on Machinery Diagnostics and Prognostics Implementing Condition-Based Maintenance. Mech. Syst. Signal Process. 2006, 20, 1483–1510. [Google Scholar] [CrossRef]

- Jia, R.; Wang, L.; Zheng, C.; Chen, T. Online Wear Particle Detection Sensors for Wear Monitoring of Mechanical Equipment—A Review. IEEE Sens. J. 2022, 22, 2930–2947. [Google Scholar] [CrossRef]

- Dong, X.T.; Nguyen, M.H.; Lee, D. Algorithm Development for Acoustic Emission Measurement in High-Frequency Ranges and Its Application on a Large Two-Stroke Marine Diesel Engine. Measurement 2020, 162, 107907. [Google Scholar] [CrossRef]

- Nithin, S.K.; Hemanth, K.; Shamanth, V. A Review on Combustion and Vibration Condition Monitoring of IC Engine. Mater. Today Proc. 2021, 45, 65–70. [Google Scholar] [CrossRef]

- Bagavathiappan, S.; Lahiri, B.B.; Saravanan, T.; Philip, J.; Jayakumar, T. Infrared Thermography for Condition Monitoring—A Review. Infrared Phys. Technol. 2013, 60, 35–55. [Google Scholar] [CrossRef]

- Edmonds, J.; Resner, M.S.; Shkarlet, K. Detection of Precursor Wear Debris in Lubrication Systems. In Proceedings of the 2000 IEEE Aerospace Conference. Proceedings (Cat. No.00TH8484), Big Sky, MT, USA, 18–25 March 2000; Volume 6, pp. 73–77. [Google Scholar]

- Wang, Z.; Xue, X.; Yin, H.; Jiang, Z.; Li, Y. Research Progress on Monitoring and Separating Suspension Particles for Lubricating Oil. Complexity 2018, 2018, 9356451. [Google Scholar] [CrossRef]

- Ahn, H.S.; Yoon, E.S.; Sohn, D.G.; Kwon, O.K.; Shin, K.S.; Nam, C.H. Practical Contaminant Analysis of Lubricating Oil in a Steam Turbine-Generator. Tribol. Int. 1996, 29, 161–168. [Google Scholar] [CrossRef]

- Varenberg, M.; Halperin, G.; Etsion, I. Different Aspects of the Role of Wear Debris in Fretting Wear. Wear 2002, 252, 902–910. [Google Scholar] [CrossRef]

- Iwai, Y.; Honda, T.; Miyajima, T.; Yoshinaga, S.; Higashi, M.; Fuwa, Y. Quantitative Estimation of Wear Amounts by Real Time Measurement of Wear Debris in Lubricating Oil. Tribol. Int. 2010, 43, 388–394. [Google Scholar] [CrossRef]

- Zhu, X.; Zhong, C.; Zhe, J. Lubricating Oil Conditioning Sensors for Online Machine Health Monitoring—A Review. Tribol. Int. 2017, 109, 473–484. [Google Scholar] [CrossRef]

- Wu, T.; Wu, H.; Du, Y.; Peng, Z. Progress and Trend of Sensor Technology for On-Line Oil Monitoring. Sci. China Technol. Sci. 2013, 56, 2914–2926. [Google Scholar] [CrossRef]

- Hong, W.; Cai, W.; Wang, S.; Tomovic, M.M. Mechanical Wear Debris Feature, Detection, and Diagnosis: A Review. Chin. J. Aeronaut. 2018, 31, 867–882. [Google Scholar] [CrossRef]

- Du, L.; Zhu, X.; Han, Y.; Zhao, L.; Zhe, J. Improving Sensitivity of an Inductive Pulse Sensor for Detection of Metallic Wear Debris in Lubricants Using Parallel LC Resonance Method. Meas. Sci. Technol. 2013, 24, 075106. [Google Scholar] [CrossRef]

- Du, L.; Zhe, J. Parallel Sensing of Metallic Wear Debris in Lubricants Using Undersampling Data Processing. Tribol. Int. 2012, 53, 28–34. [Google Scholar] [CrossRef]

- Yu, Z.; Zeng, L.; Zhang, H.; Yang, G.; Wang, W.; Zhang, W. Frequency Characteristic of Resonant Micro Fluidic Chip for Oil Detection Based on Resistance Parameter. Micromachines 2018, 9, 344. [Google Scholar] [CrossRef]

- Xie, Y.; Shi, H.; Zhang, H.; Yu, S.; Llerioluwa, L.; Zheng, Y.; Li, G.; Sun, Y.; Chen, H. A Bridge-Type Inductance Sensor With a Two-Stage Filter Circuit for High-Precision Detection of Metal Debris in the Oil. IEEE Sens. J. 2021, 21, 17738–17748. [Google Scholar] [CrossRef]

- Du, L.; Zhe, J. A High Throughput Inductive Pulse Sensor for Online Oil Debris Monitoring. Tribol. Int. 2011, 44, 175–179. [Google Scholar] [CrossRef]

- Du, L. A Multichannel Oil Debris Sensor for Online Health Monitoring of Rotating Machinery. Ph.D. Thesis, Department of Mechanical Engineering, University of Akron, Akron, OH, USA, 2012. [Google Scholar]

- Zhang, H.; Zeng, L.; Teng, H.; Zhang, X. A Novel On-Chip Impedance Sensor for the Detection of Particle Contamination in Hydraulic Oil. Micromachines 2017, 8, 249. [Google Scholar] [CrossRef]

- Li, W.; Bai, C.; Wang, C.; Zhang, H.; Ilerioluwa, L.; Wang, X.; Yu, S.; Li, G. Design and Research of Inductive Oil Pollutant Detection Sensor Based on High Gradient Magnetic Field Structure. Micromachines 2021, 12, 638. [Google Scholar] [CrossRef]

- Zhu, X.; Zhong, C.; Zhe, J. A High Sensitivity Wear Debris Sensor Using Ferrite Cores for Online Oil Condition Monitoring. Meas. Sci. Technol. 2017, 28, 075102. [Google Scholar] [CrossRef]

- Hong, W.; Wang, S.; Tomovic, M.; Han, L.; Shi, J. Radial Inductive Debris Detection Sensor and Performance Analysis. Meas. Sci. Technol. 2013, 24, 125103. [Google Scholar] [CrossRef]

- Hong, W.; Wang, S.; Tomovic, M.M.; Liu, H.; Wang, X. A New Debris Sensor Based on Dual Excitation Sources for Online Debris Monitoring. Meas. Sci. Technol. 2015, 26, 095101. [Google Scholar] [CrossRef]

- Feng, S.; Yang, L.; Qiu, G.; Luo, J.; Li, R.; Mao, J. An Inductive Debris Sensor Based on a High-Gradient Magnetic Field. IEEE Sens. J. 2019, 19, 2879–2886. [Google Scholar] [CrossRef]

- Bai, C.; Zhang, H.; Zeng, L.; Zhao, X.; Ma, L. Inductive Magnetic Nanoparticle Sensor Based on Microfluidic Chip Oil Detection Technology. Micromachines 2020, 11, 183. [Google Scholar] [CrossRef]

- Wang, C.; Bai, C.; Yang, Z.; Zhang, H.; Li, W.; Wang, X.; Zheng, Y.; Ilerioluwa, L.; Sun, Y. Research on High Sensitivity Oil Debris Detection Sensor Using High Magnetic Permeability Material and Coil Mutual Inductance. Sensors 2022, 22, 1833. [Google Scholar] [CrossRef]

- Ren, Y.J.; Zhao, G.F.; Qian, M.; Feng, Z.H. A Highly Sensitive Triple-Coil Inductive Debris Sensor Based on an Effective Unbalance Compensation Circuit. Meas. Sci. Technol. 2019, 30, 015108. [Google Scholar] [CrossRef]

- Hong, W.; Wang, S.; Liu, H.; Tomovic, M.M.; Chao, Z. A Hybrid Method Based on Band Pass Filter and Correlation Algorithm to Improve Debris Sensor Capacity. Mech. Syst. Signal Process. 2017, 82, 1–12. [Google Scholar] [CrossRef]

- Hong, W.; Li, T.; Wang, S.; Zhou, Z. A General Framework for Aliasing Corrections of Inductive Oil Debris Detection Based on Artificial Neural Networks. IEEE Sens. J. 2020, 20, 10724–10732. [Google Scholar] [CrossRef]

- Li, C.; Peng, J.; Liang, M. Enhancement of the Wear Particle Monitoring Capability of Oil Debris Sensors Using a Maximal Overlap Discrete Wavelet Transform with Optimal Decomposition Depth. Sensors 2014, 14, 6207–6228. [Google Scholar] [CrossRef]

- Li, C.; Liang, M. Enhancement of Oil Debris Sensor Capability by Reliable Debris Signature Extraction via Wavelet Domain Target and Interference Signal Tracking. Measurement 2013, 46, 1442–1453. [Google Scholar] [CrossRef]

- Zhu, X.; Du, L.; Zhe, J. An Integrated Lubricant Oil Conditioning Sensor Using Signal Multiplexing. J. Micromechanics Microengineering 2015, 25, 015006. [Google Scholar] [CrossRef]

- Du, L.; Zhu, X.; Han, Y.; Zhe, J. High Throughput Wear Debris Detection in Lubricants Using a Resonance Frequency Division Multiplexed Sensor. Tribol. Lett. 2013, 51, 453–460. [Google Scholar] [CrossRef]

- Du, L.; Zhe, J.; Carletta, J.; Veillette, R.; Choy, F. Real-Time Monitoring of Wear Debris in Lubrication Oil Using a Microfluidic Inductive Coulter Counting Device. Microfluid. Nanofluidics 2010, 9, 1241–1245. [Google Scholar] [CrossRef]

- Wu, S.; Liu, Z.; Yu, K.; Fan, Z.; Yuan, Z.; Sui, Z.; Yin, Y.; Pan, X. A Novel Multichannel Inductive Wear Debris Sensor Based on Time Division Multiplexing. IEEE Sens. J. 2021, 21, 11131–11139. [Google Scholar] [CrossRef]

- Wu, S.; Liu, Z.; Yuan, H.; Yu, K.; Gao, Y.; Liu, L.; Pan, X. Multichannel Inductive Sensor Based on Phase Division Multiplexing for Wear Debris Detection. Micromachines 2019, 10, 246. [Google Scholar] [CrossRef] [PubMed]

- Ren, Y.J.; Li, W.; Zhao, G.F.; Feng, Z.H. Inductive Debris Sensor Using One Energizing Coil with Multiple Sensing Coils for Sensitivity Improvement and High Throughput. Tribol. Int. 2018, 128, 96–103. [Google Scholar] [CrossRef]

- Qian, M.; Ren, Y.J.; Feng, Z.H. Interference Reducing by Low-Voltage Excitation for a Debris Sensor with Triple-Coil Structure. Meas. Sci. Technol. 2020, 31, 025103. [Google Scholar] [CrossRef]

- Du, L.; Zhe, J.; Carletta, J.E.; Veillette, R.J. Inductive Coulter Counting: Detection and Differentiation of Metal Wear Particles in Lubricant. Smart Mater. Struct. 2010, 19, 057001. [Google Scholar] [CrossRef]

- Wu, Y.; Yang, C. Ferromagnetic Metal Particle Detection Including Calculation of Particle Magnetic Permeability Based on Micro Inductive Sensor. IEEE Sens. J. 2021, 21, 447–454. [Google Scholar] [CrossRef]

- Wang, X.; Chen, P.; Luo, J.; Yang, L.; Feng, S. Characteristics and Superposition Regularity of Aliasing Signal of an Inductive Debris Sensor Based on a High-Gradient Magnetic Field. IEEE Sens. J. 2020, 20, 10071–10078. [Google Scholar] [CrossRef]

- Zhu, X.; Du, L.; Zhe, J. A 3×3 Wear Debris Sensor Array for Real Time Lubricant Oil Conditioning Monitoring Using Synchronized Sampling. Mech. Syst. Signal Process. 2017, 83, 296–304. [Google Scholar] [CrossRef]

| Particle | Diameter/μm | Inductance Variation (ΔL)/nH | Resistance Variation (ΔR)/Ω |

|---|---|---|---|

| Iron | 87 | 1.529 | 0 |

| 118 | 4.307 | 0 | |

| 130 | 5.553 | 0 | |

| 157 | 11.518 | 0 | |

| 188 | 18.057 | 0.00222 | |

| Copper | 97 | 0 | 0 |

| 121 | 0 | 0.00409 | |

| 145 | −0.241 | 0.01032 | |

| 150 | −0.417 | 0.01185 | |

| 182 | −1.259 | 0.02624 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Z.; Wu, S.; Raihan, M.K.; Zhu, D.; Yu, K.; Wang, F.; Pan, X. The Optimization of Parallel Resonance Circuit for Wear Debris Detection by Adjusting Capacitance. Energies 2022, 15, 7318. https://doi.org/10.3390/en15197318

Liu Z, Wu S, Raihan MK, Zhu D, Yu K, Wang F, Pan X. The Optimization of Parallel Resonance Circuit for Wear Debris Detection by Adjusting Capacitance. Energies. 2022; 15(19):7318. https://doi.org/10.3390/en15197318

Chicago/Turabian StyleLiu, Zhijian, Sen Wu, Mahmud Kamal Raihan, Diyu Zhu, Kezhen Yu, Feng Wang, and Xinxiang Pan. 2022. "The Optimization of Parallel Resonance Circuit for Wear Debris Detection by Adjusting Capacitance" Energies 15, no. 19: 7318. https://doi.org/10.3390/en15197318

APA StyleLiu, Z., Wu, S., Raihan, M. K., Zhu, D., Yu, K., Wang, F., & Pan, X. (2022). The Optimization of Parallel Resonance Circuit for Wear Debris Detection by Adjusting Capacitance. Energies, 15(19), 7318. https://doi.org/10.3390/en15197318