A Sensor-Based System for Dust Containment in the Construction Site

Abstract

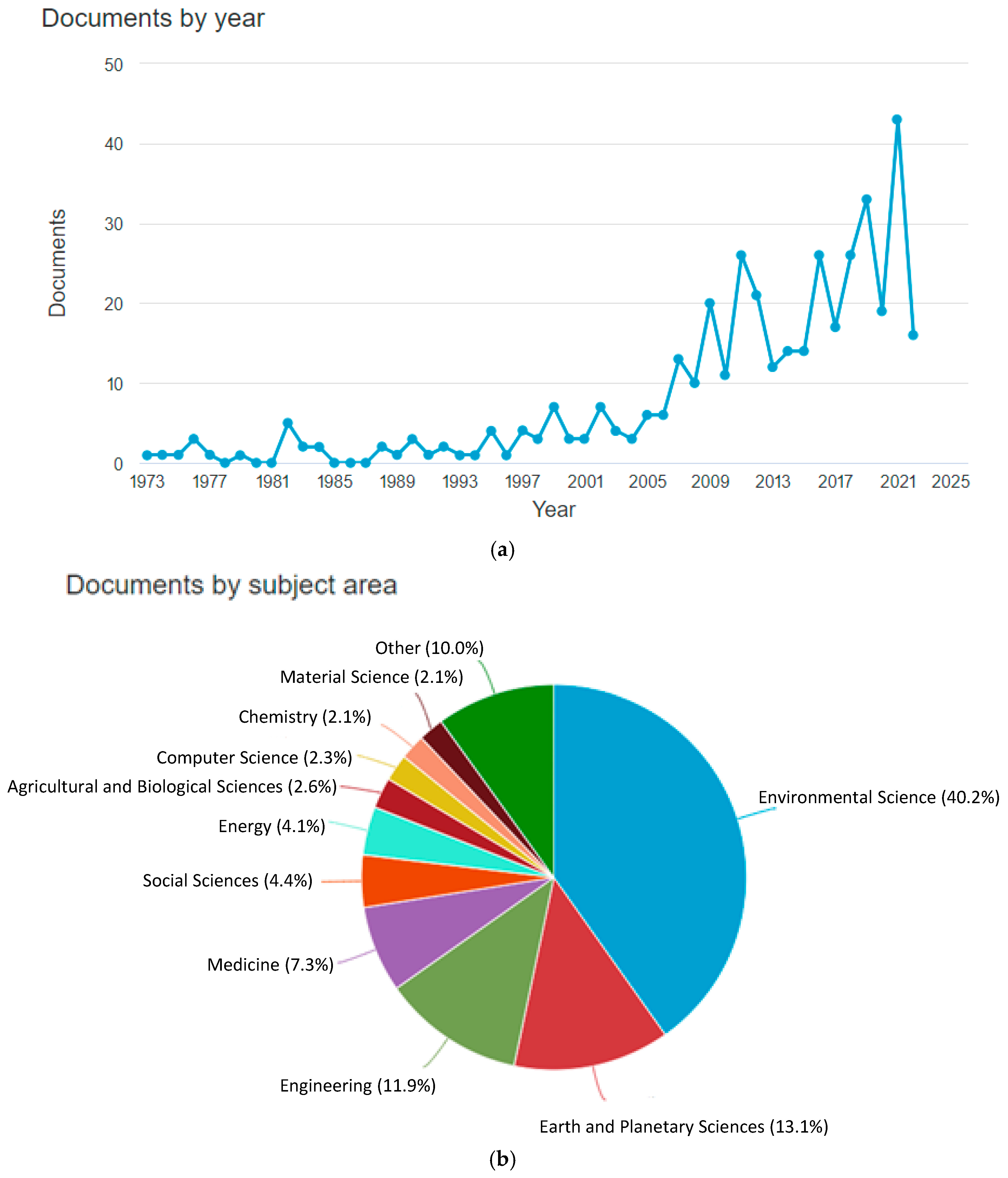

1. Introduction

- The continuous wetting of the work area;

- The coverage of deposits of dusty material (both deposited and transported);

- The use of dust shields.

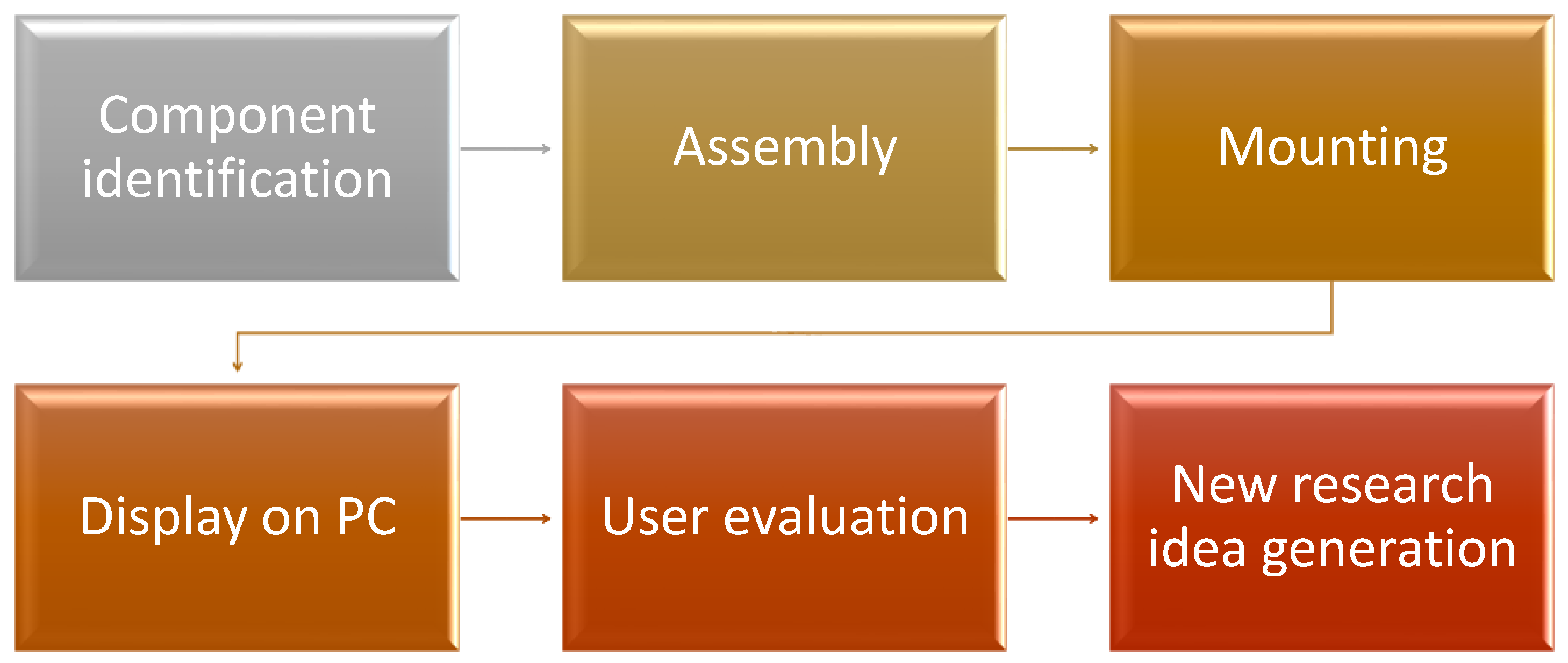

2. Materials and Methods

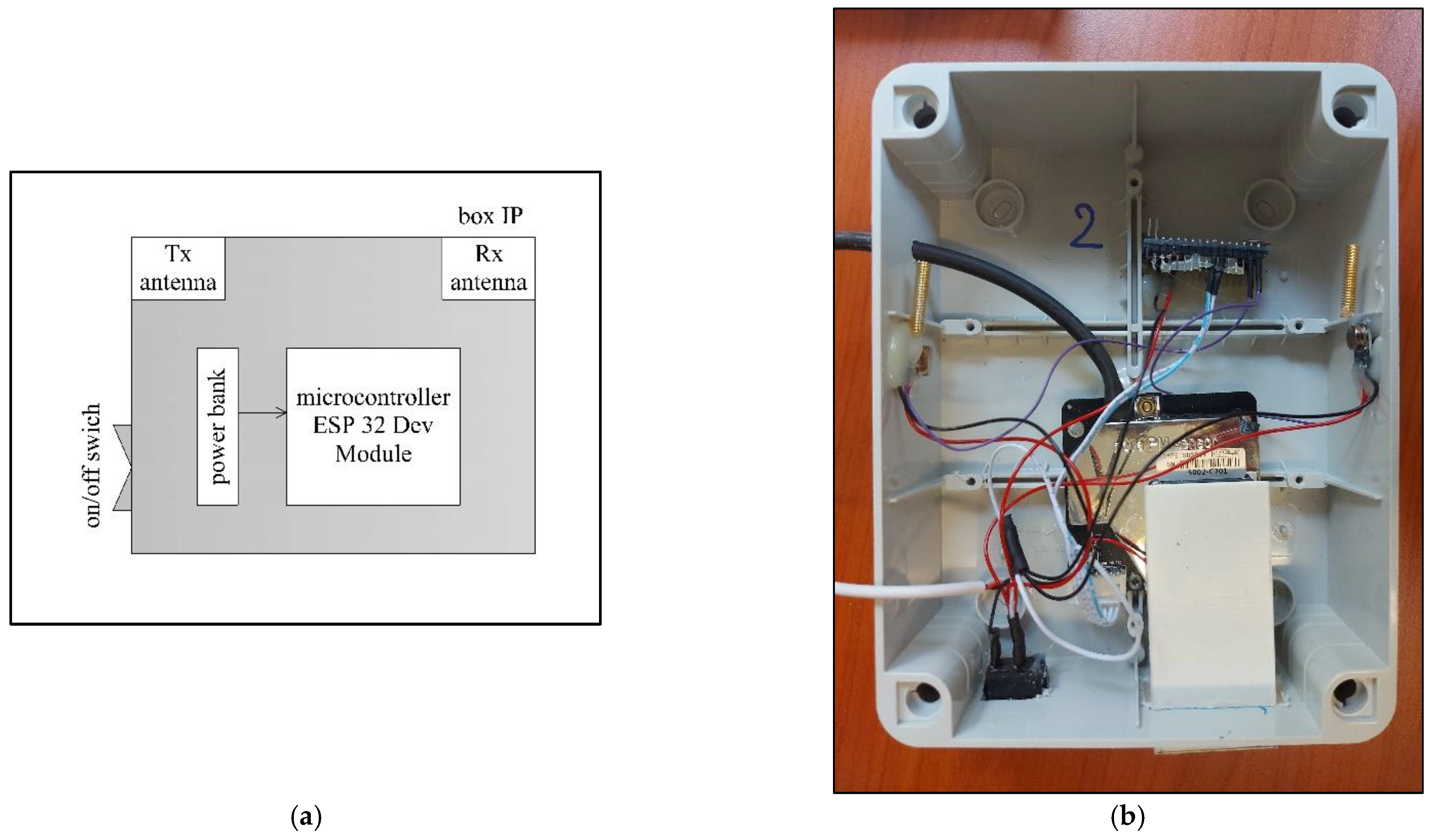

2.1. System Nodes

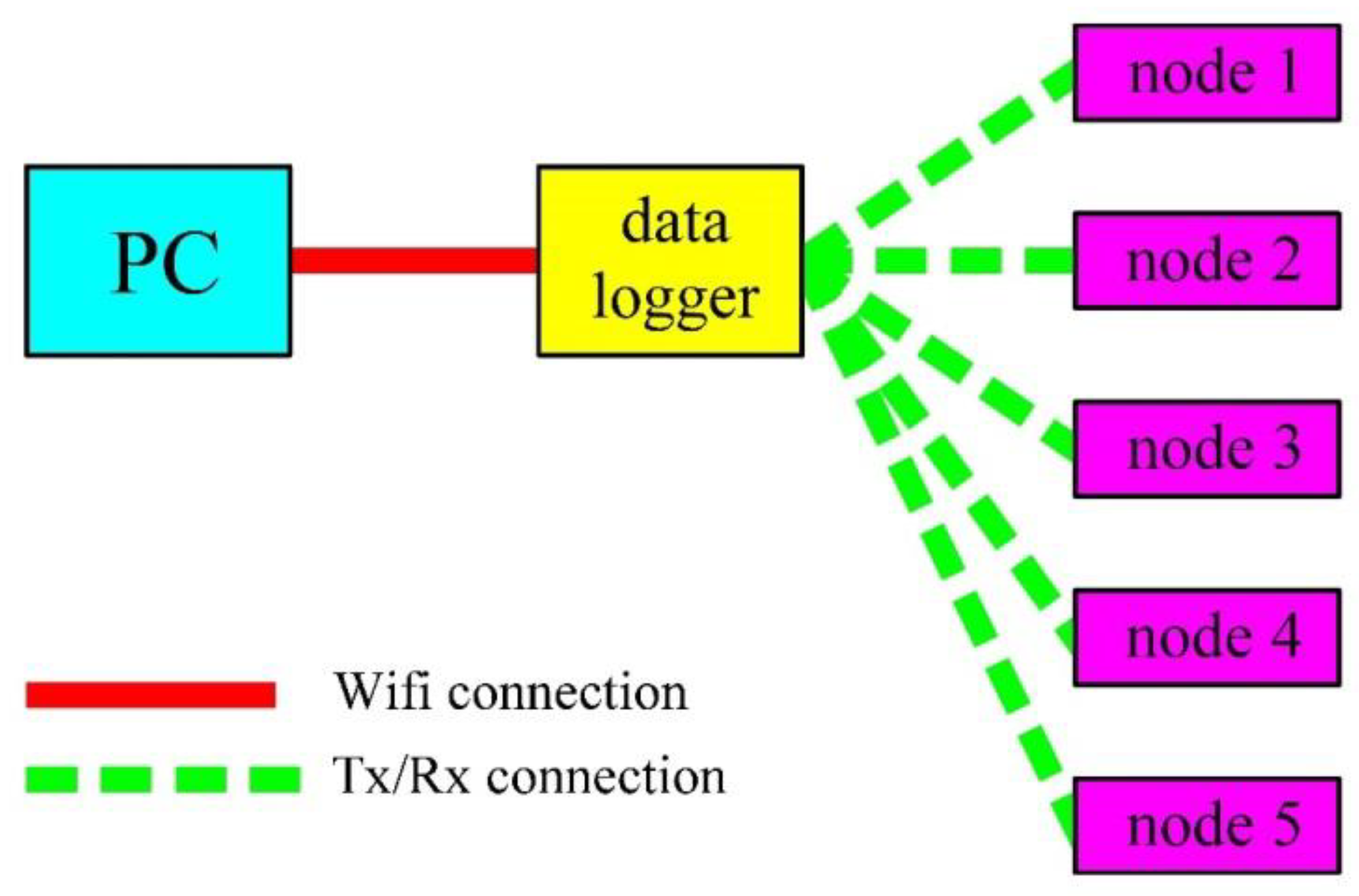

2.2. Data Logger

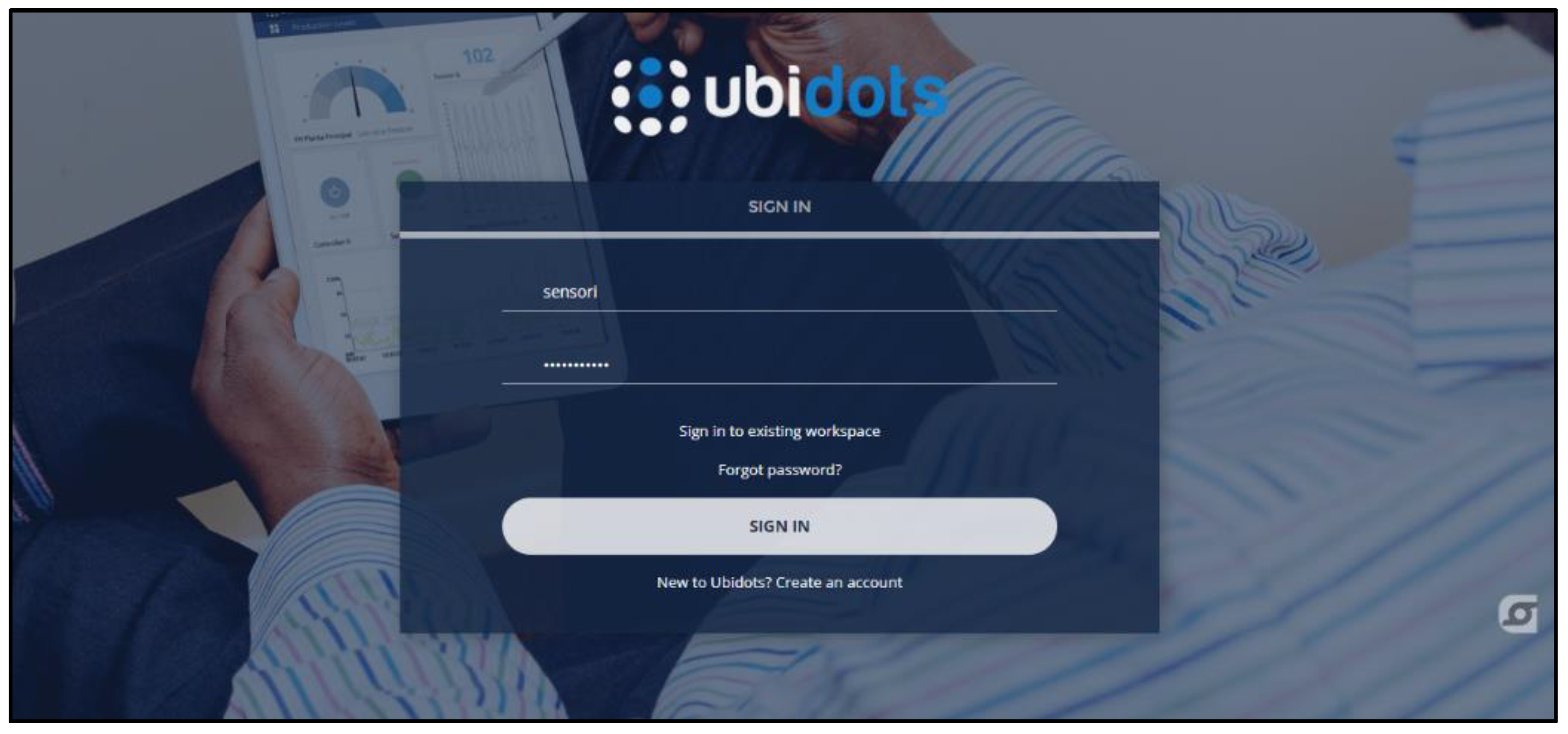

2.3. Data Consultation Platform

2.4. The Case Study—Experimental Set Up

3. Results

3.1. Results of 23 June 2022

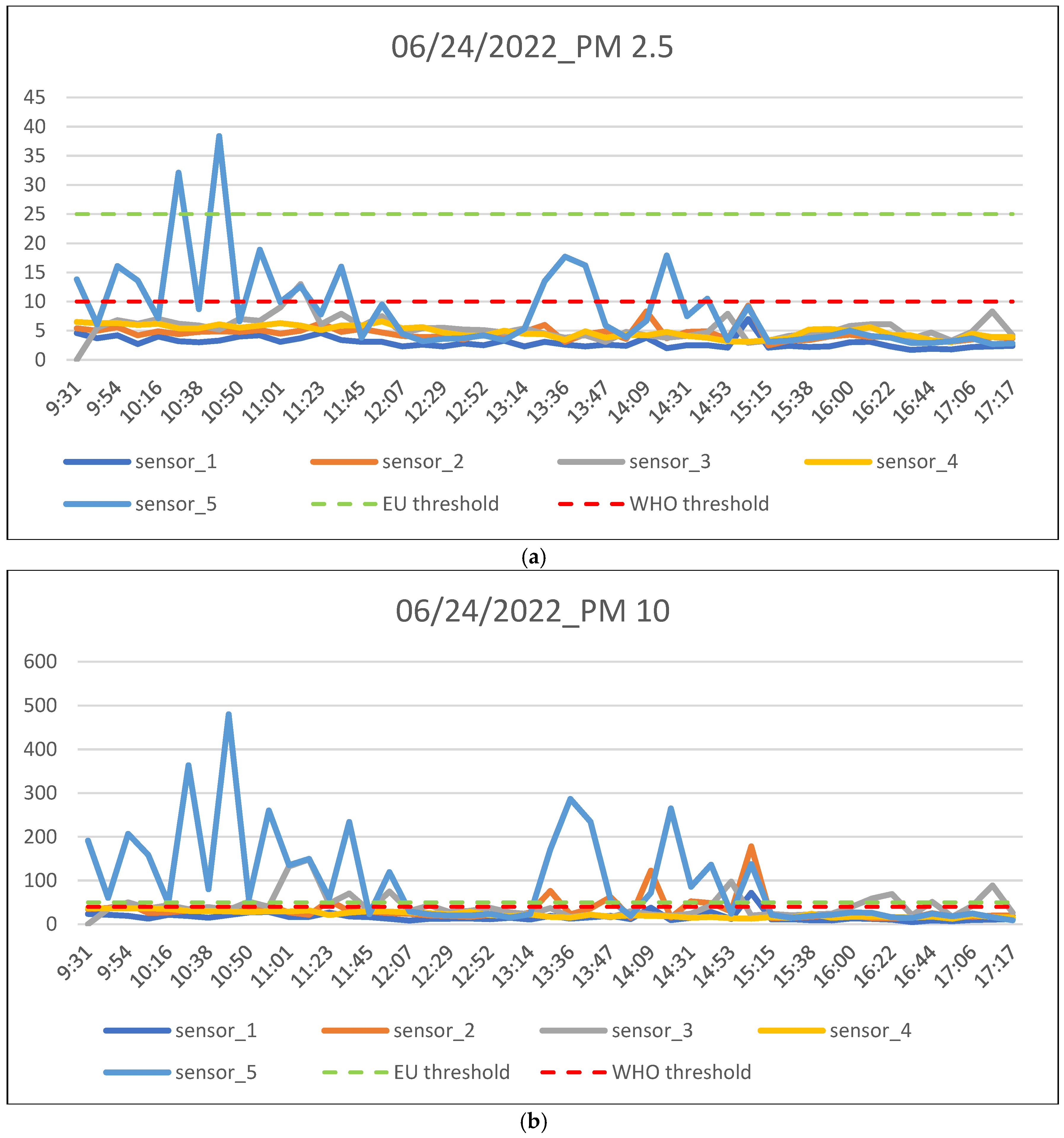

3.2. Results of 24 June 2022

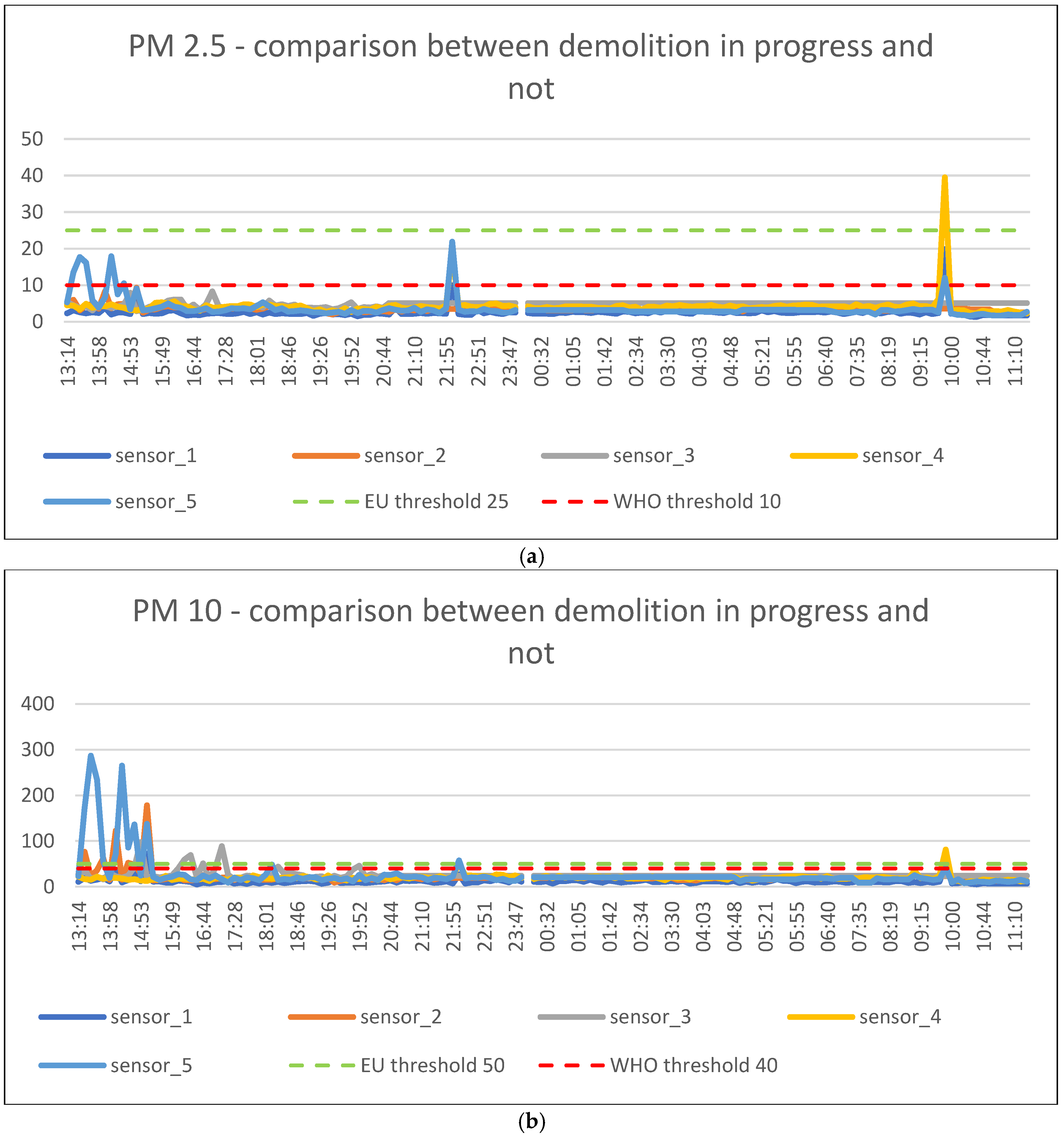

3.3. Results of the Surveys with Standstill Activities

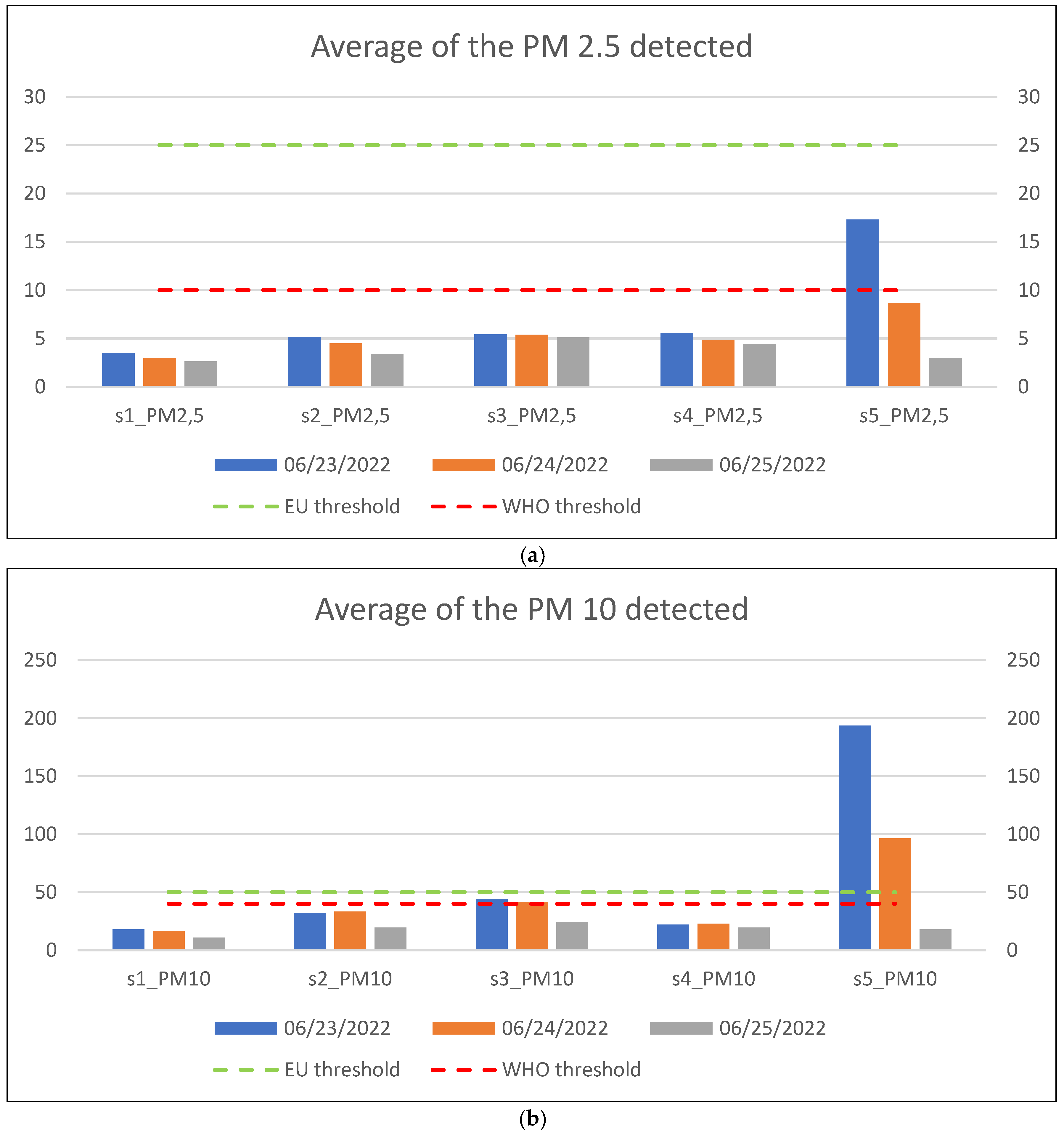

3.4. Final Comparisons

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Eun-Min, C.; Hyung Jin, J.; Dan Ki, Y.; Si Hyun, P.; Hyung Jin, H.; Kil Yong, C.; Heun Woo, C.; Hyo Chang, C.; Cheol Min, L. Reliability of Low-Cost, Sensor-Based Fine Dust Measurement Devices for Monitoring Atmospheric Particulate Matter Concentrations. Int. J. Environ. Res. Public Health 2019, 16, 1430. [Google Scholar] [CrossRef]

- Xiaoling, Z.; Liyin, S.; Lei, Z. Life cycle assessment of the air emissions during building construction process: A case study in Hong Kong. Renew. Sustain. Energy Rev. 2015, 17, 160–169. [Google Scholar] [CrossRef]

- Ko, J.; Ni, Y. Technology developments in structural health monitoring of large-scale bridges. Eng. Struct. 2005, 27, 1715–1725. [Google Scholar] [CrossRef]

- Cigada, A.; Moschioni, G.; Vanali, M.; Caprioli, A. The measurement network of the San Siro Meazza stadium in Milan: Origin and implementation of a new data acquisition strategy for structural health monitoring. Exp. Tech. 2010, 34, 70–81. [Google Scholar] [CrossRef]

- Ni, Y.; Xia, Y.; Liao, W.; Ko, J. Technology innovation in developing the structural health monitoring system for Guangzhou New TV Tower. Struct. Control Health Monit. 2009, 16, 73–98. [Google Scholar] [CrossRef]

- Velmurugan, R.; Balaganesan, G. Modal analysis of pre and post impacted nano composite laminates. Lat. Am. J. Solids Struct. 2011, 8, 9–26. [Google Scholar] [CrossRef][Green Version]

- Muttillo, M.; Di Battista, L.; de Rubeis, T.; Nardi, I. Structural health continuous monitoring of buildings—A modal parameters identification system. In Proceedings of the 4th International Conference on Smart and Sustainable Technologies (SpliTech), Bol (Island of Brac) and Split, Croatia, 18–21 June 2019. [Google Scholar] [CrossRef]

- Lifshitz, J.; Rotem, A. Determination of Reinforcement Unbonding of Composites by a Vibration Technique. J. Compos. Mater. 1969, 3, 412–423. [Google Scholar] [CrossRef]

- Kim, J.; Ryu, Y.; Cho, H.; Stubbs, N. Damage identification in beam-type structures: Frequency-based method vs mode-shape-based method. Eng. Struct. 2003, 25, 57–67. [Google Scholar] [CrossRef]

- Gomes, G.; Ancelotti, A.; da Cunha, S. Residual stress prediction in porous cfrp using artificial neural networks. Compos. Mech. Comput. Appl. Int. J. 2018, 9, 27–40. [Google Scholar] [CrossRef]

- Cawley, P.; Adams, R. The location of defects in structures from measurements of natural frequencies. J. Strain Anal. Eng. Des. 1979, 14, 49–57. [Google Scholar] [CrossRef]

- Aloisio, A.; Di Battista, L.; Alaggio, R.; Antonacci, E.; Fragiacomo, M. Assessment of structural interventions using Bayesian updating and subspace-based fault detection methods: The case study of S. Maria di Collemaggio basilica, L’Aquila, Italy. Struct. Infrastruct. Eng. 2020, 17, 141–155. [Google Scholar] [CrossRef]

- Aloisio, A.; Di Battista, L.; Alaggio, R.; Fragiacomo, M. Sensitivity analysis of subspace-based damage indicators under changes in ambient excitation covariance, severity and location of damage. Eng. Struct. 2020, 208, 110235. [Google Scholar] [CrossRef]

- Khan, I.; Choi, S.; Kwon, Y. Earthquake Detection in a Static and Dynamic Environment Using Supervised Machine Learning and a Novel Feature Extraction Method. Sensors 2020, 20, 800. [Google Scholar] [CrossRef] [PubMed]

- Quqa, S.; Landi, L.; Diotallevi, P. Real time damage detection through single low-cost smart sensor. In Proceedings of the 7th International Conference on Computational Methods in Structural Dynamics and Earthquake Engineering (COMPDYN), Crete, Greece, 24–26 June 2019. [Google Scholar] [CrossRef]

- Valenti, S.; Conti, M.; Pierleoni, P.; Zappelli, L.; Belli, A.; Gara, F.; Carbonari, S.; Regni, M. A low cost wireless sensor node for building monitoring. In Proceedings of the IEEE Workshop on Environmental, Energy, and Structural Monitoring Systems (EESMS), Salerno, Italy, 21–22 June 2018. [Google Scholar] [CrossRef]

- Liu, L.; Zhang, Y. Design of greenhouse environment monitoring system based on Wireless Sensor Network. In Proceedings of the 3rd International Conference on Control, Automation and Robotics (ICCAR), Nagoya, Japan, 22–24 April 2017. [Google Scholar] [CrossRef]

- Barile, G.; Leoni, A.; Pantoli, L.; Stornelli, V. Real-Time Autonomous System for Structural and Environmental Monitoring of Dynamic Events. Electronics 2018, 7, 420. [Google Scholar] [CrossRef]

- Pantoli, L.; Muttillo, M.; Ferri, G.; Stornelli, V.; Alaggio, R.; Vettori, D.; Chinzari, L.; Chinzari, F. Electronic system for structural and environmental building monitoring. In Lecture Notes in Electrical Engineering; Springer: Cham, Switzerland, 2019; Volume 539, pp. 481–488. [Google Scholar] [CrossRef]

- Ghosh, A.; Raha, A.; Mukherjee, A. Energy-Encient IoT-Health Monitoring System using Approximate Computing. Internet Things 2020, 9, 100166. [Google Scholar] [CrossRef]

- Luan, H.; Leng, J. Design of energy monitoring system based on IOT. In Proceedings of the 28th Chinese Control and Decision Conference (CCDC), Yinchuan, China, 28–30 May 2016. [Google Scholar] [CrossRef]

- De Rubeis, T.; Muttillo, M.; Nardi, I.; Pantoli, L.; Stornelli, V.; Ambrosini, D. Integrated Measuring and Control System for Thermal Analysis of Buildings Components in Hot Box Experiments. Energies 2019, 12, 2053. [Google Scholar] [CrossRef]

- Paolucci, R.; Muttillo, M.; Di Luzio, M.; Alaggio, R.; Ferri, G. Electronic Sensory System for Structural Health Monitoring Applications. In Proceedings of the 5th International Conference on Smart and Sustainable Technologies (SpliTech), Virtual, 23–26 September 2020. [Google Scholar] [CrossRef]

- Tao, G.; Feng, J.; Feng, H.; Feng, H.; Zhang, K. Reducing Construction Dust Pollution by Planning Construction Site Layout. Buildings 2022, 12, 531. [Google Scholar] [CrossRef]

- Rönnberg, N.; Ringdahl, R.; Fredriksson, A. Measurement and sonification of construction site noise and particle pollution data. Smart Sustain. Built Environ. 2020. [Google Scholar] [CrossRef]

- Jiang, Q.; Zhang, K. Research on construction site dust detection based on prior knowledge MinMax k-Means. In Proceedings of the 2nd IEEE International Conference on Artificial Intelligence and Industrial Design (AIID), Virtual, 28–30 May 2021. [Google Scholar] [CrossRef]

- Manzhilevskaya, S.; Petrenko, L.; Azarov, V. Monitoring Methods for Fine Dust Pollution During Construction Operations. In Proceedings of the International Scientific Conference Energy Management of Municipal Facilities and Sustainable Energy Technologies (EMMFT), Voronezh, Russia, 10–13 December 2019. [Google Scholar] [CrossRef]

- Luo, Q.; Huang, L.; Xue, X.; Chen, Z.; Zhou, F.; Wei, L.; Hua, J. Occupational health risk assessment based on dust exposure during earthwork construction. J. Build. Eng. 2021, 44, 103186. [Google Scholar] [CrossRef]

- Manzhilevskaya, S.; Petrenko, L.; Azarov, V. Vertical Distribution of Fine Dust During Construction Operations. In Proceedings of the International Scientific Conference Energy Management of Municipal Facilities and Sustainable Energy Technologies (EMMFT), Voronezh, Russia, 10–13 December 2019. [Google Scholar] [CrossRef]

- Zhang, D.; Ji, H.; Li, Z.; Ge, H. Design of Building Environment Detection System for Architectures Based on Internet of Things. Comput. Intell. Neurosci. 2022, 2022, 5438305. [Google Scholar] [CrossRef]

- United Nation, Department of Economic and Social Affairs Sustainable Development. Available online: https://sdgs.un.org/goals (accessed on 30 August 2022).

- Rotilio, M. Strategies for overcoming critical post-disaster reconstruction: A case study. In Proceedings of the 4th International Conference on Preservation, Maintenance and Rehabilitation of Historical Buildings and Structures (REHAB), Barcelos, Portugal, 17–19 July 2019; pp. 539–551, ISBN 978-989-8734-41-9. [Google Scholar]

- Rotilio, M.; Laurini, E.; Lucarelli, M.; De Berardinis, P. The maximization of the 4th dimension of the building site. Int. Arch. Photogramm. Remote Sens. Spat. Inf. Sci. 2019, XLII-4/W17, 15–20. [Google Scholar] [CrossRef]

- Alicandro, M.; Rotilio, M. UAV photogrammetry for resilience management in reconstruction plan of urban historical centres after seismic events. A case study. Int. Arch. Photogramm. Remote Sens. Spat. Inf. Sci. 2019, XLII-2/W11, 55–61. [Google Scholar] [CrossRef]

- Tagle, M.; Rojas, F.; Vásquez, Y.; Hallgren, F.; Lindén, J.; Kolev, D.; Watne, Å.K.; Oyola, P. Field performance of a low-cost sensor in the monitoring of particulate matter in Santiago, Chile. Environ. Monit. Assess. 2020, 192, 171. [Google Scholar] [CrossRef] [PubMed]

- Candia, A.; Represa, S.N.; Giuliani, D.; Luengo, M.A.; Porta, A.A.; Marrone, L.A. Solutions for SmartCities: Proposal of a monitoring system of air quality based on a LoRaWAN network with low-cost sensors. In Proceedings of the Congreso Argentino de Ciencias de la Informática y Desarrollos de Investigación (CACIDI), Buenos Aires, Argentina, 28–30 November 2018. [Google Scholar] [CrossRef]

- Kurnia, D.; Hadisantoso, F.S.; Suprianto, A.A.; Nugroho, E.A.; Janizal, J. Real-Time Air Quality Index Monitoring Experiments Using SDS011 Sensors and Raspberry Pi. In Proceedings of the 5th Annual Applied Science and Engineering Conference (AASEC), Virtual, 21–22 April 2020. [Google Scholar] [CrossRef]

- Paolucci, R.; Rotilio, M.; De Berardinis, P.; Ferri, G.; Cucchiella, F.; Stornelli, V. Electronic System for Monitoring of Dust on Construction Sites for the Health of Workers. In Proceedings of the 15th International Conference on Advanced Technologies, Systems and Services in Telecommunications (TELSIKS), Nis, Serbia, 20–22 October 2021. [Google Scholar] [CrossRef]

- Budde, M.; Schwarz, A.D.; Müller, T.; Laquai, B.; Streibl, N.; Schindler, G.; Köpke, M.; Riedel, T.; Dittler, A.; Beigl, M. Potential and Limitations of the Low-Cost SDS011 Particle Sensor for Monitoring Urban Air Quality. In Proceedings of the 3rd International Conference on Atmospheric Dust, Bari, Italy, 29–31 May 2018. [Google Scholar] [CrossRef]

- Budde, M.; Muller, T.; Laquai, B.; Streibl, N. Suitability of the Low-Cost SDS011 Particle Sensor for Urban PM-Monitoring. In Proceedings of the 3rd International Conference on Atmospheric Dust, Bari, Italy, 29–31 May 2018. [Google Scholar]

- Alfano, B.; Barretta, L.; Del Giudice, A.; De Vito, S.; Di Francia, G.; Esposito, E.; Formisano, F.; Massera, E.; Miglietta, M.L.; Polichetti, T. A Review of Low-Cost Particulate Matter Sensors from the Developers’ Perspectives. Sensors 2020, 20, 6819. [Google Scholar] [CrossRef] [PubMed]

- Chen, M.; Yuan, W.; Cao, C.; Buehler, C.; Gentner, D.R.; Lee, X. Development and Performance Evaluation of a Low-Cost Portable PM2.5 Monitor for Mobile Deployment. Sensors 2022, 22, 2767. [Google Scholar] [CrossRef]

- SDS011 Sensor Data Sheet. Available online: http://inovafitness.com/en/a/chanpinzhongxin/95.html (accessed on 22 March 2021).

| Reference, Year | Aim of the Research | Results |

|---|---|---|

| [24], 2022 | - To propose a new method of reducing construction dust pollution through a reasonable site layout plan | - Average dust concentration exposed to workers and total transportation cost were significantly reduced by 60.62% and 44.3%, respectively, thanks to the new method |

| [25], 2022 | - To explore how sonification can support visualization in construction planning to decrease construction transport disturbances | - The low-cost sensors used could capture “good enough” data; - The use of sonification for representing these data is interesting and a possible useful tool in urban and construction transport planning |

| [26], 2021 | - To propose a construction site dust detection method based on prior knowledge min-max k-means clustering algorithm | - Timely detect construction site dust could improve the ability of government supervision departments to monitor construction dust pollution |

| [27], 2021 | - To discusse a method for suppressing dust emission on a construction site | - The amount of fine dust PM 2.5–PM 10 pollution reduced under the influence of a water fog gun with a magnetic nozzle equipment; - The concentration of particles in the air reduced by almost 2 times, depending on the height of the equipment’s impact |

| [28], 2021 | - To establish a health risk evaluation system based on the measured data and difference in the working contents of the works in the earthwork construction phase; - To base the health risk evaluation system on both measurements of dust exposure and the quantification of health risks | - The protective mask and spray dust control system reduced the health risk by 67.54% and 38.56%, respectively; - The health risks for the use of both measures could be reduced by 76.89%; - Effective dust control measures were proposed according to the results of this study, which provides references for workers to strengthen dust-proof works |

| [29], 2021 | - To summarize the results of the study of fine dust distribution and concentration released during construction production | - The functional analysis of the amount of fine dust PM 2.5 and PM 10 released during the local construction; - Data knowledge allows us to determine the most dangerous construction works that affect the total environmental pollution in the working and sanitary protection areas |

| [30], 2022 | - To develop a new integrated system for monitoring the environment. The system uses a wireless sensor network environment monitoring system IoT platform with embedded internal processors | - Real-time supervision through a mobile terminal and computer terminal management platform; - Subsequent online guidance and regulation |

| Measurement Parameters | PM 2.5,PM 10 |

|---|---|

| Range | 0.0–999.9 μg/m3 |

| Rated voltage | 5V |

| Rated current | 70 mA ± 10 mA |

| Sleep current | <4 mA |

| Temperature range | Storage environment: −20~+60 °C |

| Work environment: −10~+50 °C | |

| Humidity range | Storage environment: Max 90% |

| Work environment: Max 70% | |

| Air pressure | 86 KPa~110 KPa |

| Corresponding time | 1 s |

| Serial data output frequency | 1 Hz |

| Minimum resolution of particle | 0.3 μm |

| Relative error | Maximum of ±15% and ±10 μg/m3 |

| DATA | s1_PM2.5 (μg/m3) | s2_PM2.5 (μg/m3) | s3_PM2.5 (μg/m3) | s4_PM2.5 (μg/m3) | s5_PM2.5 (μg/m3) |

|---|---|---|---|---|---|

| 23 June 2022 | 3,51219513 | 5.13414634 | 5.399999933 | 5.573170767 | 17.29268293 |

| 24 June 2022 | 2.94893614 | 4.50638302 | 5.387234008 | 4.855319165 | 8.648936211 |

| 25 June 2022 | 2.615 | 3.40249998 | 5.099999905 | 4.398749968 | 2.951249999 |

| DATA | s1_PM 10 (μg/m3) | s2_PM 10 (μg/m3) | s3_PM 10 (μg/m3) | s4_PM 10 (μg/m3) | s5_PM 10 (μg/m3) |

|---|---|---|---|---|---|

| 23 June 2022 | 17.8097561 | 31.995122 | 43.9975622 | 21.91219502 | 193.551216 |

| 24 June 2022 | 16.6021277 | 33.374468 | 41.30851068 | 22.72978718 | 96.28297777 |

| 25 June 2022 | 10.7487499 | 19.4174999 | 24.20000076 | 19.44249994 | 17.88250021 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Paolucci, R.; Rotilio, M.; Ricci, S.; Pelliccione, A.; Ferri, G. A Sensor-Based System for Dust Containment in the Construction Site. Energies 2022, 15, 7272. https://doi.org/10.3390/en15197272

Paolucci R, Rotilio M, Ricci S, Pelliccione A, Ferri G. A Sensor-Based System for Dust Containment in the Construction Site. Energies. 2022; 15(19):7272. https://doi.org/10.3390/en15197272

Chicago/Turabian StylePaolucci, Romina, Marianna Rotilio, Stefano Ricci, Andrea Pelliccione, and Giuseppe Ferri. 2022. "A Sensor-Based System for Dust Containment in the Construction Site" Energies 15, no. 19: 7272. https://doi.org/10.3390/en15197272

APA StylePaolucci, R., Rotilio, M., Ricci, S., Pelliccione, A., & Ferri, G. (2022). A Sensor-Based System for Dust Containment in the Construction Site. Energies, 15(19), 7272. https://doi.org/10.3390/en15197272