Residual Damage, Its Consequences, and Remedial Measures on Post Hydrofrac Well Productivity: Learnt Lessons

Abstract

:1. Background

1.1. Fracture Orientation, Propagation, and Conductivity

1.2. Frac Fluids and Their Properties

1.2.1. Slick-Water-Frac or Water-Frac

1.2.2. Water-Based Gelled Fluids

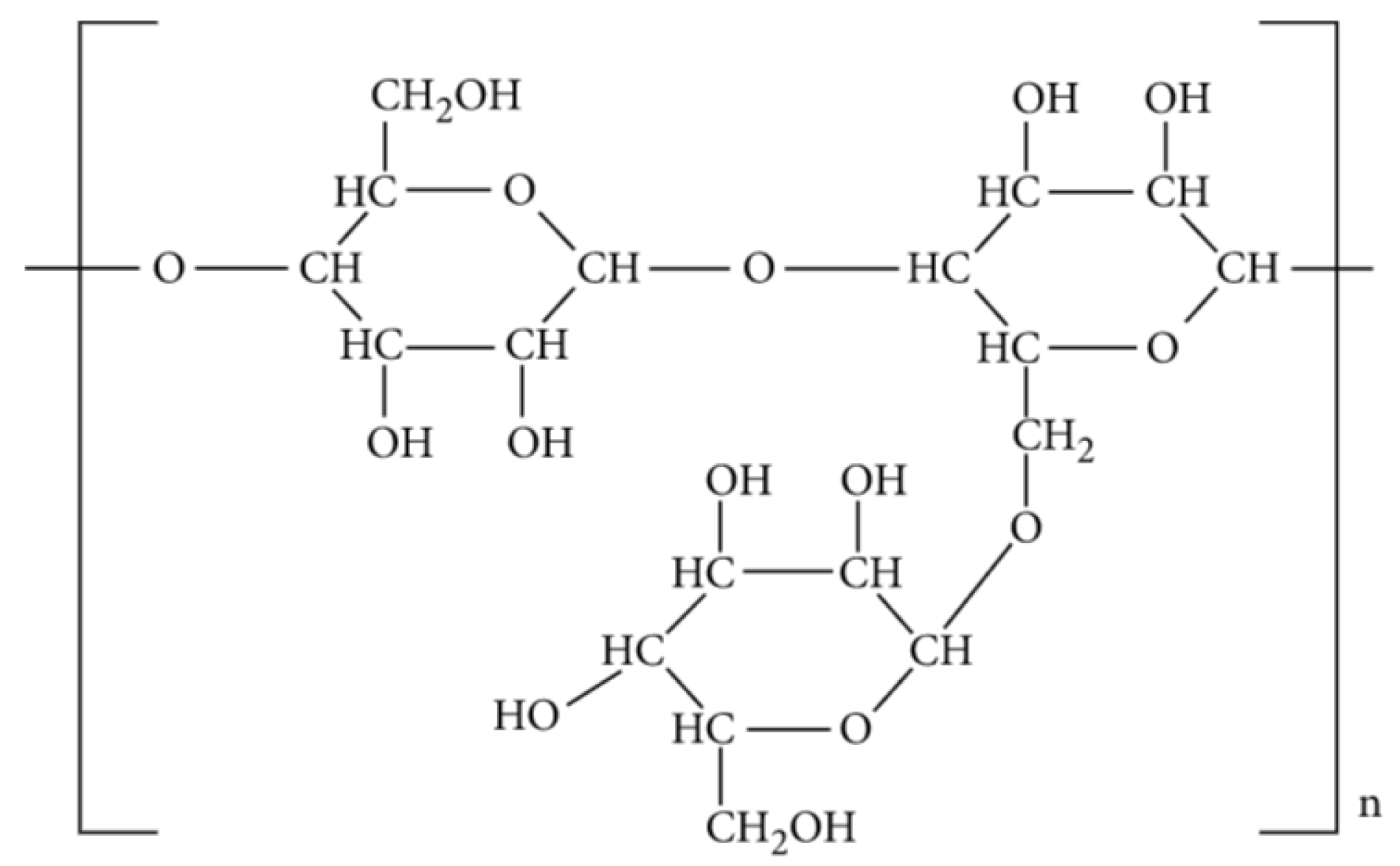

Natural Guar Gum

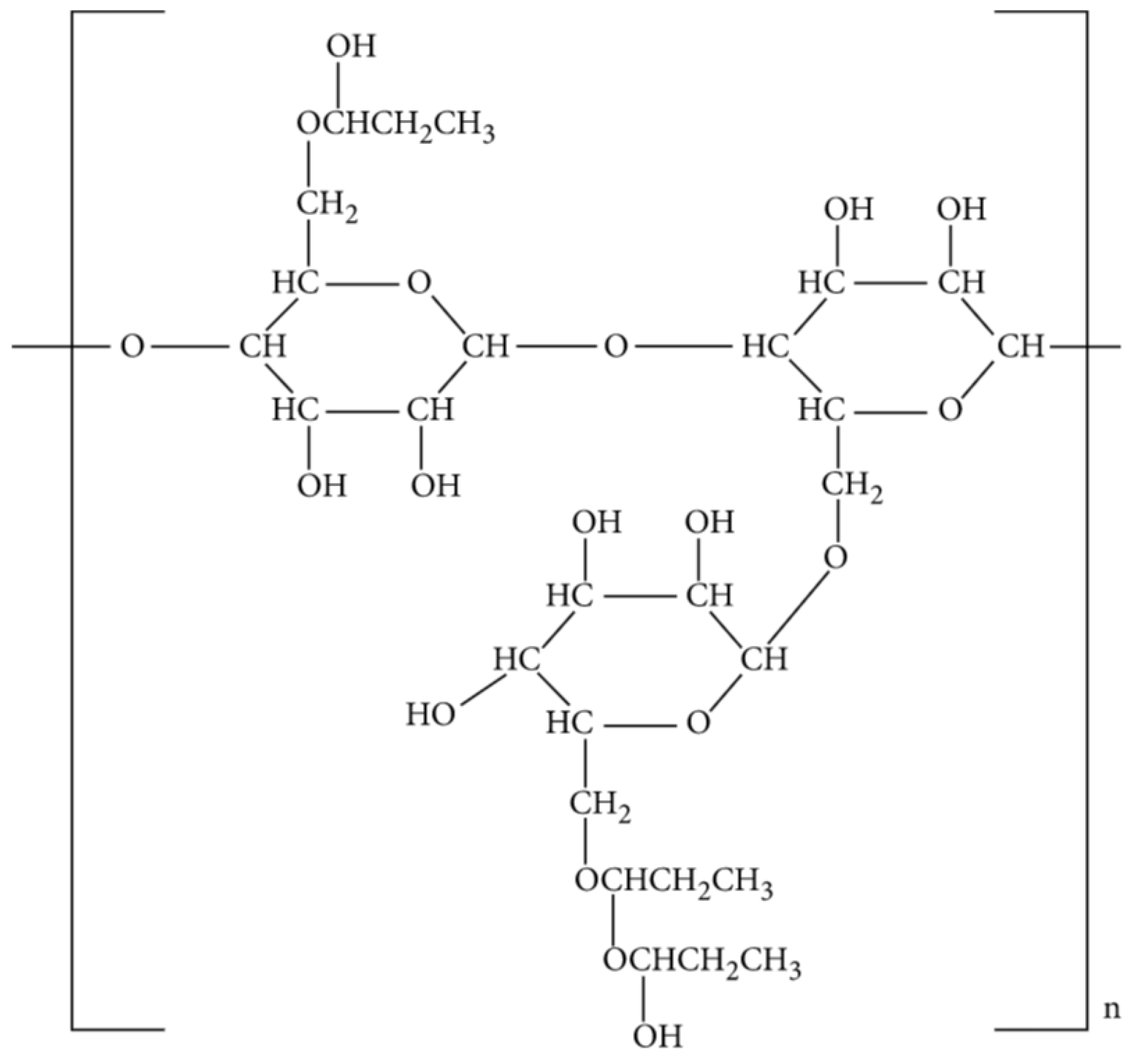

Hydroxypropyl Guar (HPG)

Carboxymethyl Hydroxypropyl Guar (CMHPG)

Foam-Based Fracturing Fluids

Viscoelastic Surfactant (VES) Fluids

Crosslinking of Guar and Guar Derivatives

Borate-Cross-Linked Guar Gel

Metal-Crosslinked Guar Fluids

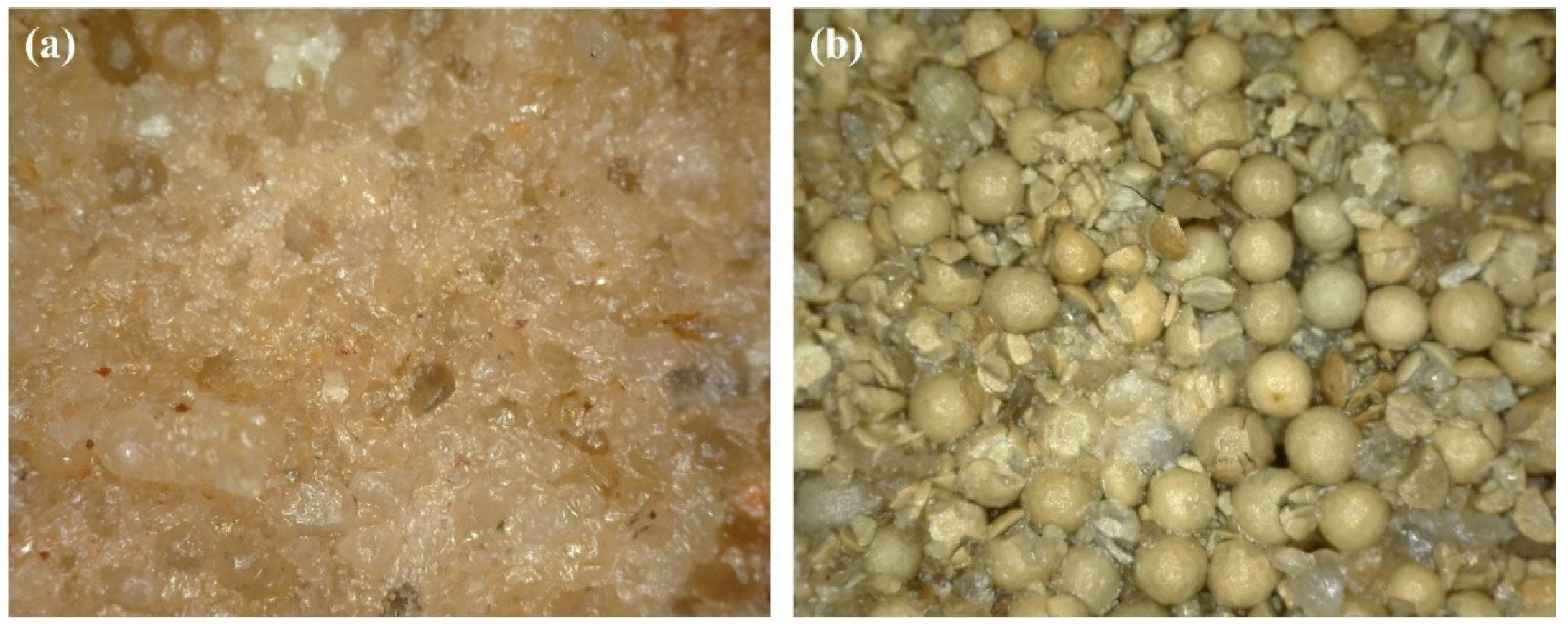

1.3. Proppants and Their Role in Fracturing

1.3.1. Sand

1.3.2. Ceramics

1.3.3. Resin Coated Proppant

1.3.4. Lightweight Proppant

1.3.5. Advanced Proppant Technology

1.4. Fracturing Fluids Rheology

1.5. Fracture Treatment Optimization

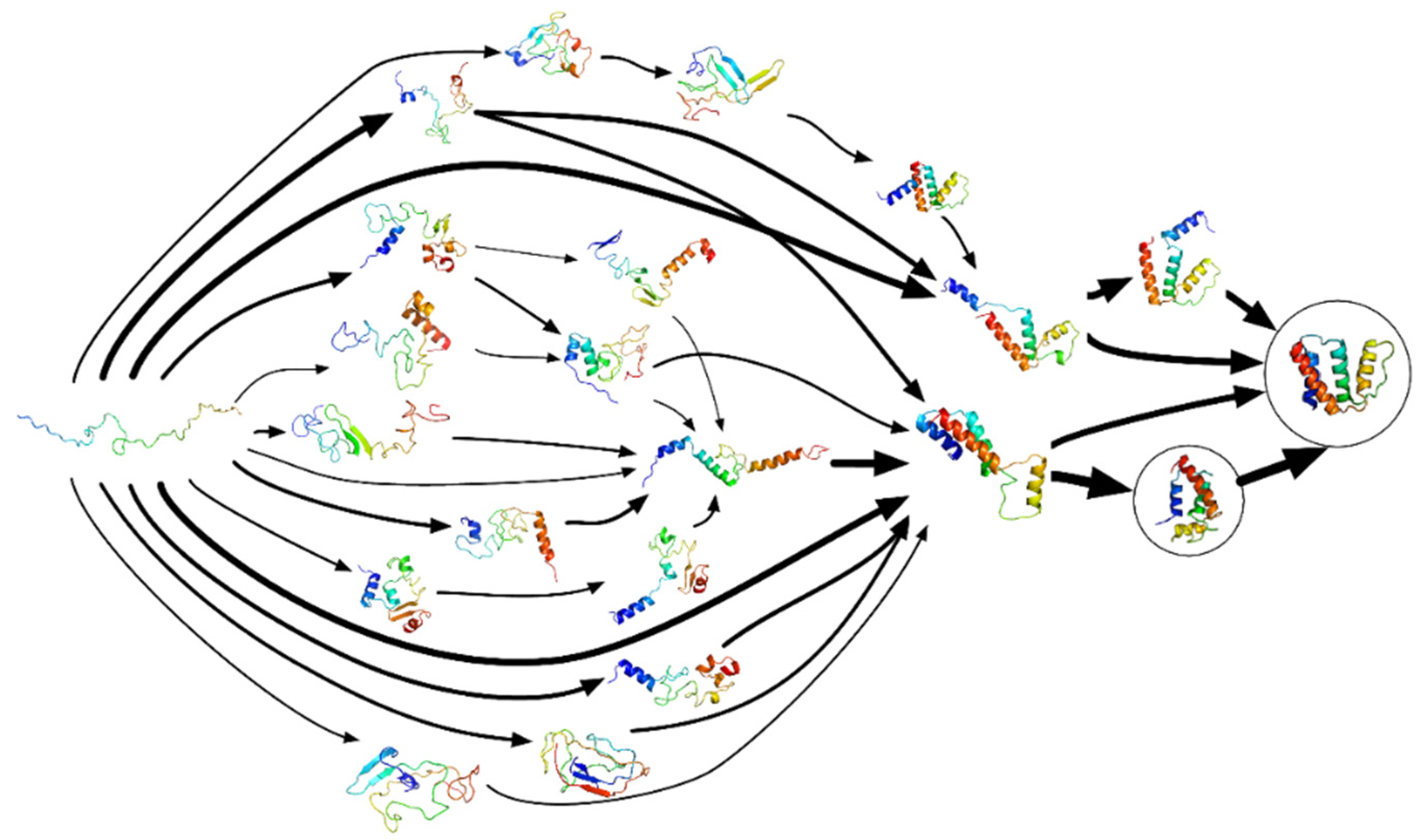

1.5.1. Fracturing Model Selection

1.5.2. Multi-Stage Fractures in Horizontal Well

1.5.3. Post-Fracture Well Behavior

2. Fracture Conductivity Damage

2.1. Guar Polymer Damage

2.2. Fracture Face Skin

2.3. Damage Due to Frac Fluid Invasion

2.4. Polymer Filter Cake Damage

2.5. Fracture Conductivity Damage Due to Proppant

2.6. Salt, Fines, and Water Phase Trap

2.7. Damage Mechanism and Quantification

3. Fracturing Fluids Damage Mitigation

3.1. Damage Mitigation through Microbes

3.2. Silica Nanoparticles (SNP)

3.3. Remediation through Foam

3.4. Remediation through Delayed Mechanisms

3.5. Remediation through Breakers

3.5.1. Enzyme Breakers

3.5.2. Breakers for Acid-Fracturing Gels

3.5.3. Delayed Breaker System and Carriers

3.5.4. Summary of Hydrofrac Damage Mitigation

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Aldhuhoori, M.; Belhaj, H.; Ghosh, B.; Fernandes, R.; Alkuwaiti, H.; Qaddoura, R. Unique Approach in Modelling Flow in Tight Oil Unconventional Reservoirs with Viscous, Inertial and Diffusion Forces Contributions. In Proceedings of the International Conference on Offshore Mechanics and Arctic Engineering, Cancún, Mexico, 5–6 April 2021. [Google Scholar]

- Aldhuhoori, M.; Belhaj, H.; Ghosh, B.; Fernandes, R.; Alkuwaiti, H.; Qaddoura, R. A Micro/Nano Scale Fluid Flow Model in Tight Unconventional Reservoirs. In Proceedings of the Abu Dhabi International Petroleum Exhibition & Conference, Abu Dhabi, United Arab Emirates, 9–12 November 2020. [Google Scholar]

- Belhaj, H.; Qaddoura, R.; Ghosh, B.; Saqer, R. Modeling Fluid Flow in Tight Unconventional Reservoirs: Nano-Scale Mobility/Trapability Mechanistic Approach. In Proceedings of the SPE Gas & Oil Technology Showcase and Conference, Dubai, United Arab Emirates, 21 October 2019. [Google Scholar]

- Wu, Z.; Cui, C.; Jia, P.; Wang, Z.; Sui, Y. Advances and challenges in hydraulic fracturing of tight reservoirs: A critical review. Energy Geosci. 2022, 3, 427–435. [Google Scholar] [CrossRef]

- Alklih, M.Y.; Ghosh, B.; Al-Shalabi, E.W. Tight Reservoir Stimulation for Improved Water Injection—A Novel Technique. In Proceedings of the International Petroleum Technology Conference, Doha, Qatar, 19–22 January 2014. [Google Scholar]

- Wang, D.B.; Zhou, F.; Li, Y.; Yu, B.; Martyushev, D.; Liu, X.; Wang, M.; He, C.; Han, D.; Sun, D. Numerical simulation of fracture propagation in Russia carbonate reservoirs during refracturing. Pet. Sci. 2022. [Google Scholar] [CrossRef]

- Al-Attar, H.; Alshadafan, H.; Al Kaabi, M.; Al Hassani, A.; Al Mheiri, S. Integrated optimum design of hydo-frac for tight hydrocarbon-bearing reservoirs. J. Pet. Exp. Prod. Tech. 2020, 10, 3347–3361. [Google Scholar] [CrossRef]

- Economides, M.J.; Hill, D.; Ehlig-Economides, C.; Zhu, D. Petroleum Production Systems; Prentice Hall: Hoboken, NJ, USA, 2013. [Google Scholar]

- Jennings, A.R., Jr. Fracturing fluids-then and now. J. Pet. Technol. 1996, 48, 604–610. [Google Scholar] [CrossRef]

- Xu, Y.; Dehghanpour, H.; Ezulike, O.; Virues, C. Effectiveness and time variation of induced fracture volume: Lessons from water flowback analysis. Fuel 2017, 210, 844–858. [Google Scholar] [CrossRef]

- Arshadi, M.; Zolfaghari, A.; Piri, M.; Al-Muntasheri, G.A.; Sayed, M. The effect of deformation on two-phase flow through proppant packed fractured shale samples: A micro-scale experimental investigation. Adv. Water Resour. 2017, 105, 108–131. [Google Scholar] [CrossRef]

- Zhou, W.; Dilmore, R.; Kleit, A.; Wang, J.Y. Evaluating fracking fluid flowback in Marcellus using data mining technologies. SPE Prod. Oper. 2016, 31, 133–146. [Google Scholar]

- You, L.; Xie, B.; Yang, J.; Kang, Y.; Han, H.; Wang, L.; Yang, B. Mechanism of fracture damage induced by fracturing fluid flowback in shale gas reservoirs. Natural Gas Ind. B 2019, 6, 366–373. [Google Scholar] [CrossRef]

- Nicot, J.-P.; Scanlon, B.R.; Reedy, R.C.; Costley, R.A. Source and fate of hydraulic fracturing water in the Barnett shale: A historical perspective. Environ. Sci. Technol. 2014, 48, 2464–2471. [Google Scholar] [CrossRef]

- Guo, J.; He, J. Microscopic mechanism of the damage caused by gelout process of fracking fluids. Acta Pet Sin. 2012, 33, 1018–1022. [Google Scholar]

- Xu, C.; Kang, Y.; You, Z.; Chen, M. Review on formation damage mechanisms and processes in shale gas reservoir: Known and to be known. J. Nat. Gas. Sci. Eng. 2016, 36, 1208–1219. [Google Scholar] [CrossRef]

- Wu, X.; Pu, H.; Zhu, K.; Lu, S. Formation damage mechanisms and protection technology for Nanpu nearshore tight gas reservoir. J. Pet. Sci. Eng. 2017, 158, 509–515. [Google Scholar] [CrossRef]

- King, G.E. Thirty years of gas shale fracturing: What have we learned? In Proceedings of the SPE Annual Technical Conference and Exhibition, Florence, Italy, 20–22 September 2010. [Google Scholar]

- Xu, W.; Thiercelin, M.J.; Walton, I.C. Characterization of hydraulically-induced shale fracture network using an analytical/semi-analytical model. In Proceedings of the SPE Annual Technical Conference and Exhibition, New Orleans, LA, USA, 4–7 October 2009. [Google Scholar]

- Rahman, M.M.; Rahman, S.S. Fully coupled finite-element-based numerical model for investigation of interaction between an induced and a preexisting fracture in naturally fractured poroelastic reservoirs: Fracture diversion, arrest, and breakout. Int. J. Geomech. 2013, 13, 390–401. [Google Scholar] [CrossRef]

- Zhang, J.; Zhu, D.; Hill, A.D. Water-Induced Fracture Conductivity Damage in Shale Formations. In Proceedings of the SPE Hydraulic Fracturing Technology Conference, The Woodlands, TX, USA, 3–5 February 2015. [Google Scholar]

- Wang, H.Y.; Sharma, M.M. Estimating Unpropped-Fracture Conductivity and Fracture Compliance from Diagnostic Fracture-Injection Tests. SPE J. 2018, 23, 1648–1668. [Google Scholar] [CrossRef]

- Abdelrahim, M.; Ghosh, B.; Belhaj, H.; Ghosh, D. High-Temperature Stable Specific Enzyme for Guar Polymer Based Fracturing Fluid Degradation. In Proceedings of the SPE/IATMI Asia Pacific Oil & Gas Conference and Exhibition, SPE-205569-MS, Virtually, 12–14 October 2021. [Google Scholar]

- Al-Taq, A.A.; Al-Khaldi, M.H.; Alfakher, B.M.; Mechkak, K. Successful Application of TSE-Based Fracturing Fluids in Proppant Fracturing for Unconventional Carbonate Source Rock. In Proceedings of the SPE International Hydraulic Fracturing Technology Conference and Exhibition, Muscat, Oman, 16–18 October 2018. [Google Scholar]

- Handren, P.J.; Palisch, T.T. Successful Hybrid Slickwater Fracture Design Evolution--An East Texas Cotton Valley Taylor Case History. SPE Prod. Oper. 2009, 24, 415–424. [Google Scholar] [CrossRef]

- Birdsell, D.; Rajaram, H.; Dempsey, D.; Viswanathan, H.S. Hydraulic fracturing fluid migration in the subsurface: A review and expanded modeling results. Water Resour. Res. 2015, 51, 7159–7188. [Google Scholar] [CrossRef]

- Wang, J.; Zhou, F.; Bai, H.; Li, Y.; Yang, H. A Comprehensive method to evaluate the viscous slickwater as fracturing fluids for hydraulic fracturing applications. J. Pet. Sci. Eng. 2020, 193, 107359. [Google Scholar] [CrossRef]

- Funkhouser, G.P.; Norman, L.R. Synthetic polymer fracturing fluid for high-temperature applications. In Proceedings of the International Symposium on Oilfield Chemistry, Houston, TX, USA, 5–8 February 2003. [Google Scholar]

- Palisch, T.T.; Vincent, M.C.; Handren, P.J. Slickwater fracturing: Food for thought. SPE Prod. Oper. 2010, 25, 327–344. [Google Scholar] [CrossRef]

- Kakadjian, S.; Thompson, J.; Torres, R.; Trabelsi, S.; Zamora, F. Stable fracturing fluids from waste water. In Proceedings of the SPE Unconventional Resources Conference Canada, Calgary, AB, Canada, 5–7 November 2013. [Google Scholar]

- Al-Muntasheri, G.A.; Nasr-El-Din, H.A.; Hussein, I.A. A rheological investigation of a high temperature organic gel used for water shut-off treatments. J. Pet. Sci. Eng. 2007, 59, 73–83. [Google Scholar] [CrossRef]

- Liang, F.; Sayed, M.; Al-Muntasheri, G.A.; Chang, F.F.; Li, L. A comprehensive review on proppant technologies. Petroleum 2016, 2, 26–39. [Google Scholar] [CrossRef]

- Reinicke, A.; Rybacki, E.; Stanchits, S.; Huenges, E.; Dresen, G. Hydraulic fracturing stimulation techniques and formation damage mechanisms—Implications from laboratory testing of tight sandstone–proppant systems. Geochemistry 2010, 70, 107–117. [Google Scholar] [CrossRef]

- Lam, K.S. New aspects of natural products in drug discovery. Trends Microbiol. 2007, 15, 279–289. [Google Scholar] [CrossRef] [PubMed]

- Blamble, E.A.; Pyncheon, J. Guar Replacement with Synthetic Polymers-Utica Shale Case Histories. In Proceedings of the SPE International Conference and Exhibition on Formation Damage Control, Lafayette, LA, USA, 19–21 February 2016. [Google Scholar]

- McCleary, B.V.; Clark, A.H.; Dea, I.C.M.; Rees, D.A. The fine structures of carob and guar galactomannans. Carbohydr. Res. 1985, 139, 237–260. [Google Scholar] [CrossRef]

- Hasan, A.M.; Abdel-Raouf, M.E. Applications of guar gum and its derivatives in petroleum industry: A review. Egypt. J. Pet. 2018, 27, 1043–1050. [Google Scholar] [CrossRef]

- Dressler, M.; Fischer, P.; Windhab, E.J. Rheological characterization and modeling of aqueous guar gum solutions. In Proceedings of the 3rd International Symposium on Food Rheology and Structure, Zurich, Switzerland, 9–13 February 2003; pp. 249–253. [Google Scholar]

- Lapasin, R.; De Lorenzi, L.; Pricl, S.; Torriano, G. Flow properties of hydroxypropyl guar gum and its long-chain hydrophobic derivatives. Carbohydr. Polym. 1995, 28, 195–202. [Google Scholar] [CrossRef]

- Institute of Chemistry of CAS. Thermally Stable Guar Gum Aqueous Solution and Preparation Method and Application Thereof. Chinese Patent No. CN104449645A, 25 August 2017. [Google Scholar]

- Shanmukha, M.C.; Usha, A.; Siddiqui, M.K.; Fufa, S.A.; Praveen, B.M. Degree-Based Molecular Descriptors of Guar Gum and Its Chemical Derivatives. J. Chem. 2022, 2022, 7371538. [Google Scholar] [CrossRef]

- Fink, J. Hydraulic Fracturing Chemicals and Fluids Technology; Gulf Professional Publishing: Oxford, UK, 2013. [Google Scholar]

- Li, L.; Tan, J.; Wood, D.A.; Zhao, Z.; Becker, D.; Lyu, Q.; Shu, B.; Chen, H. A review of the current status of induced seismicity monitoring for hydraulic fracturing in unconventional tight oil and gas reservoirs. Fuel 2019, 242, 195–210. [Google Scholar] [CrossRef]

- Ma, X.; Lei, G.; Wang, Z.; Da, Q.; Song, P.; Zhang, X.; Yao, C. Microbial Remediation of Guar-Based Fracturing Fluid Damage. In Proceedings of the SPE International Conference and Exhibition on Formation Damage Control, Lafayette, LA, USA, 7–9 February 2018. [Google Scholar]

- Wanniarachchi, W.A.M.; Ranjith, P.G.; Perera, M.S.A. Shale gas fracturing using foam-based fracturing fluid: A review. Environ. Earth Sci. 2017, 76, 91–99. [Google Scholar] [CrossRef]

- Ahmed, A.; Murtada, S.; Aljawad, Z.; Muhammad, M.A. A review of foam-based fracturing fluids applications: From lab studies to field implementations. J. Nat. Gas Sci. Eng. 2021, 95, 104236. [Google Scholar] [CrossRef]

- Pankaj, P.; Phatak, A.; Verma, S. Evaluating Natural Gas-Based Foamed Fracturing Fluid Application in Unconventional Reservoirs. In Proceedings of the SPE Asia Pacific Oil and Gas Conference and Exhibition, Brisbane, Australia, 25 October 2018. [Google Scholar]

- Kang, W.; Mushi, S.J.; Yang, H.; Wang, P.; Hou, X. Development of smart viscoelastic surfactants and its applications in fracturing fluid: A review. J. Pet. Sci. Eng. 2020, 190, 107107. [Google Scholar] [CrossRef]

- Zana, R. Dimeric and oligomeric surfactants. Behavior at interfaces and in aqueous solution: A review. Adv. Colloid Interface Sci. 2002, 97, 205–253. [Google Scholar] [CrossRef]

- Mao, J.; Yang, X.; Wang, D.; Li, Y.; Zhao, J. A novel gemini viscoelastic surfactant (VES) for fracturing fluids with good temperature stability. RSC Adv. 2016, 6, 88426–88432. [Google Scholar] [CrossRef]

- Kabir-ud-Din; Fatma, W.; Khan, Z.A.; Dar, A.A. 1H NMR and Viscometric Studies on Cationic Gemini Surfactants in Presence of Aromatic Acids and Salts. J. Phys. Chem. 2007, 111, 8860–8867. [Google Scholar] [CrossRef]

- Samuel, M.; Card, R.J.; Nelson, E.B.; Brown, J.E.; Vinod, P.S.; Temple, H.L.; Qu, Q.; Fu, D.K. Polymer-free fluid for hydraulic fracturing. In Proceedings of the SPE Annual Technical Conference and Exhibition, San Antonio, TX, USA, 5–8 October 1997. [Google Scholar]

- Huang, T.; Crews, J.B.; Agrawal, G. Nanoparticle Pseudocrosslinked Micellar Fluids: Optimal Solution for Fluid-Loss Control with Internal Breaking. In Proceedings of the SPE International Symposium and Exhibition on Formation Damage Control, Lafayette, LA, USA, 10–12 February 2010. [Google Scholar]

- Sullivan, P.F.; Gadiyar, B.; Morales, R.H.; Holicek, R.; Sorrells, D.; Lee, J.; Fischer, D. Optimization of a Visco-Elastic Surfactant (VES) Fracturing Fluid for Application in High-Permeability Formations. In Proceedings of the SPE International Symposium and Exhibition on Formation Damage Control, Lafayette, LA, USA, 15 February 2006. [Google Scholar]

- Fontana, C.; Muruaga, E.; Perez, D.R.; Cavazzoli, G.D.; Krenz, A. Successful Application of a High temperature VES Fracturing Fluids under extreme conditions in Patagonian Wells San Jorge Basin. In Proceedings of the EUROPEC/EAGE Conference and Exhibition, London, UK, 11–14 June 2007. [Google Scholar]

- Al-Muntasheri, G.A. A Critical Review of Hydraulic Fracturing Fluids over the Last Decade. In Proceedings of the SPE Western North American and Rocky Mountain Joint Meeting, Denver, CO, USA, 17–18 April 2014. [Google Scholar]

- Weaver, J.; Parker, M.; Slabaugh, B.; Walters, H.; Haley, W.; Bone, G.; Hensley, J.; Vashler, J. Application of new viscoelastic fluid technology results in enhanced fracture productivity. In Proceedings of the SPE Annual Technical Conference and Exhibition, New Orleans, LA, USA, 30 September 2001. [Google Scholar]

- Weaver, J.D.; Liang, F.; Schultheiss, N.C. Fracturing fluid conductivity damage and recovery efficiency. In Proceedings of the SPE European Formation Damage Conference & Exhibition, Noordwijk, The Netherlands, 5 June 2013. [Google Scholar]

- Mahdaviara, M.; Rostami, A.; Shahbazi, K. Smart learning strategy for predicting viscoelastic surfactant (VES) viscosity in oil well matrix acidizing process using a rigorous mathematical approach. SN Appl. Sci. 2021, 3, 815. [Google Scholar] [CrossRef]

- Thombare, N.; Mishra, S. Borax cross-linked guar gum hydrogels as potential adsorbents for water purification. Carbohydr. Polym. 2017, 168, 274–281. [Google Scholar] [CrossRef] [PubMed]

- Ihejirika, B.; Dosunmu, A.; Eme, C. Performance Evaluation of Guar Gum as a Carrier Fluid for Hydraulic Fracturing. In Proceedings of the SPE Nigeria Annual International Conference and Exhibition, Lagos, Nigeria, 4–6 August 2015. [Google Scholar]

- Holtmyer, M.D.; Hunt, C.V.; Laramay, M.A.H.; Rahimi, A.B.; Clark, M.G. Method of Crosslinking Cellulose and Guar Derivatives for Treating Subterranean Formations. U.S. Patent 5,304,620, 19 April 1994. [Google Scholar]

- Wiskofske, M.; Wiggins, M.; Yaritz, J. Low-polymer borate frac fluid cleans up thoroughly. Oil Gas J. 1997, 95. [Google Scholar]

- Li, Y.; Guo, J.; Wang, S.; Yang, R.; Lu, Q. Reducing hydroxypropyl guar gum adsorption on rock by silica nanoparticles for tight reservoir damage remediation. In Proceedings of the International Petroleum Technology Conference, Beijing, China, 26–28 March 2019. [Google Scholar]

- Hurnaus, T.; Plank, J. Crosslinking of Guar and HPG Based Fracturing Fluids Using ZrO2 Nanoparticles. In Proceedings of the SPE International Symposium on Oilfield Chemistry, The Woodlands, TX, USA, 13–15 April 2015. [Google Scholar]

- Bankole, K.S.; Blauch, M. Applications of oilfield produced formation water for fracturing fluid. Res. J. Appl. Sci. Eng. Technol. 2014, 7, 2208–2216. [Google Scholar] [CrossRef]

- Li, L.; Ezeokonkwo, C.I.; Lin, L.; Eliseeva, K.E.; Kallio, W.; Boney, C.L.; Howard, P.; Samuel, M.M. Well Treatment Fluids Prepared with Oilfield Produced Water: Part II. In Proceedings of the SPE Annual Technical Conference and Exhibition, Florence, Italy, 20–22 September 2010. [Google Scholar]

- Li, L.; Al-Muntasheri, G.A.; Liang, F. A review of crosslinked fracturing fluids prepared with produced water. Petroleum 2016, 2, 313–323. [Google Scholar] [CrossRef]

- Fan, F.; Li, F.-X.; Tian, S.-C.; Sheng, M.; Khan, W.; Shi, A.-P.; Zhou, Y.; Xu, Q. Hydrophobic epoxy resin coated proppants with ultra-high self-suspension ability and enhanced liquid conductivity. Pet. Sci. 2021, 18, 1753–1759. [Google Scholar] [CrossRef]

- Vincent, M. Coating and/or Treating Hydraulic Fracturing Proppants to Improve Wettability, Proppant Lubrication, and/or to Reduce Damage by Fracturing Fluids and Reservoir Fluids. U.S. Patent 11/103,777, 3 November 2015. [Google Scholar]

- Osiptsov, A.A. Fluid Mechanics of Hydraulic Fracturing: A Review. J. Pet. Sci. Eng. 2017, 156, 513–535. [Google Scholar] [CrossRef]

- Cooke, C.E.J. Conductivity of fracture proppants in multiple layers. J. Pet. Technol. 1973, 25, 1101–1107. [Google Scholar] [CrossRef]

- Gu, M.; Dao, E.; Mohanty, K. Investigation of ultra-light weight proppant application in shale fracturing. Fuel 2015, 150, 191–201. [Google Scholar] [CrossRef]

- Palisch, T.T.; Duenckel, R.; Wilson, B.A. New Technology Yields Ultrahigh-Strength Proppant. SPE Prod. Oper. 2015, 30, 76–81. [Google Scholar] [CrossRef]

- Pangilinan, K.D.; de Leon, A.C.C.; Advincula, R.C. Polymers for proppants used in hydraulic fracturing. J. Petrol. Sci. Eng. 2016, 145, 154–160. [Google Scholar] [CrossRef]

- Yang, J.; Liu, X.-H.; Meng, Q.-N. (Eds.) Development and Application of Double-Layer Coated Hydrophobic Proppant; Springer: Berlin/Heidelberg, Germany, 2019; pp. 2487–2495. [Google Scholar]

- Balhoff, M.; Miller, M.J. Modeling fracture fluid cleanup in hydraulic fractures. In Proceedings of the SPE Annual Technical Conference and Exhibition, San Antonio, TX, USA, 29 September 2002. [Google Scholar]

- Yin, Z.; Wang, Y. Reduced the Adsorption of Guar-Based Hydraulic Fracturing Fluids in the Formation. In Proceedings of the SPE Kingdom of Saudi Arabia Annual Technical Symposium and Exhibition, Dammam, Saudi Arabia, 23–26 April 2018. [Google Scholar]

- May, E.A.; Britt, L.K.; Nolte, K.G. The Effect of Yield Stress on Fracture Fluid Cleanup. In Proceedings of the SPE Annual Technical Conference and Exhibition, San Antonio, TX, USA, 5–8 October 1997. [Google Scholar]

- Wigwe, M.; Kolawole, O.; Watson, M.; Ispas, I.; Li, W. Influence of Fracture Treatment Parameters on Hydraulic Fracturing Optimization in Unconventional Formations. In Proceedings of the ARMA-CUPB Geothermal International Conference, Beijing, China, 5–8 August 2019. [Google Scholar]

- Rahman, M.M.; Rahman, M.K. Optimizing Hydraulic Fracture to Manage sand Production by Predicting Critical Drawdown Pressure in Gas Well. J. Energy Res. Technol. 2012, 134, 13101–13109. [Google Scholar] [CrossRef]

- Ashena, R.; Aminzadeh, F.; Khoramchehr, A. Production Improvement via Optimization of Hydraulic Acid Fracturing Design Parameters in a Tight Carbonate Reservoir. Energies 2022, 15, 1947. [Google Scholar] [CrossRef]

- Cheng, L.; Wang, D.; Cao, R.; Xia, R. The influence of hydraulic fractures on oil recovery by water flooding processes in tight oil reservoirs: An experimental and numerical approach. J. Pet. Sci. Eng. 2020, 185, 106572. [Google Scholar] [CrossRef]

- Jamaloei, B.Y. A critical review of common models in hydraulic-fracturing simulation: A practical guide for practitioners. Theor. Appl. Fract. Mech. 2021, 113, 102937. [Google Scholar] [CrossRef]

- Belyadi, H.; Fathi, E.; Belyadi, F. Hydraulic Fracturing in Unconventional Reservoirs: Theories, Operations, and Economic Analysis, Second Edition; Elsevier Inc.: Amsterdam, The Netherlands, 2019. [Google Scholar]

- Valko, P.; Economides, M.J. Hydraulic Fracture Mechanics; John Wiley & Sons: Hoboken, NJ, USA, 1995. [Google Scholar]

- Rahman, M.M.; Rahman, M.K. A Review of Hydraulic Fracture Models and Development of Pseudo-3D Model for Stimulating Tight Oil/Gas Sand. Energy Sources Part A 2010, 32, 416–1436. [Google Scholar] [CrossRef]

- Hossain, M.M. Reservoir Stimulation by Hydraulic Fracturing: Complexities and Remedies with Reference to Initiation and Propagation of Induced and Natural Fractures. Ph.D. Thesis, The University of New South Wales, Sydney, Australia, 2001. [Google Scholar]

- Warpinski, N.R.; Smith, M.B. Rock mechanics and fracture geometry. In Recent Advances in Hydraulic Fracturing; SPE: Richardson, TX, USA, 1989. [Google Scholar]

- Rahman, M.M. Productivity prediction for fractured wells in tight sand gas reservoirs accounting for non-darcy effects. In Proceedings of the SPE Russian Oil and Gas Technical Conference and Exhibition, Moscow, Russia, 28–30 October 2008. [Google Scholar]

- Rahman, M.M.; Rahman, S.S.; Rahman, M.K. Multicriteria Hydraulic Fracturing Optimization for Reservoir Stimulation. Pet. Sci. Technol. 2003, 21, 1721–1758. [Google Scholar] [CrossRef]

- Lei, Q.; Xu, Y.; Cai, B.; Guan, B.; Wang, X.; Bi, G.; Li, H.; Li, S.; Ding, B.; Fu, H.; et al. Progress and prospects of horizontal well fracturing technology for shale oil and gas reservoirs. Petrol. Explor. Develop. 2022, 49, 191–199. [Google Scholar] [CrossRef]

- Brown, M.L.; Ozkan, E.; Raghavan, R.S.; Kazemi, H. Practical Solutions for Pressure Transient Responses of Fractured Horizontal Wells in Unconventional Reservoirs. SPE Reserv. Eval. Eng. 2011, 14, 663–676. [Google Scholar] [CrossRef]

- Zhao, K.; Du, P. Performance of horizontal wells in composite tight gas reservoirs considering stress sensitivity. Adv. Geo-En. Res. 2019, 3, 287–303. [Google Scholar] [CrossRef]

- Gao, Y.; Rahman, M.M.; Lu, J. Novel Mathematical Model for Transient Pressure Analysis of Multi-Fractured Horizontal Well in Naturally-Fractured Oil Reservoir. ACS Omega 2021, 6, 15205–15221. [Google Scholar] [CrossRef] [PubMed]

- Smith, M.B.; Montgomery, C.T. Hydraulic Fracturing; CRC Press, Taylor and Francis: Boca Raton, FL, USA, 2015; pp. 777–779. [Google Scholar]

- Miskimins, J. Hydraulic Fracturing—Fundamentals and Advancements; Society of Petroleum Engineers: Richardson, TX, USA, 2019; p. 797. [Google Scholar]

- Escobar, F.H. Well Test Analysis for Hydraulically-Fractured Wells. In Exploitation of Unconventional Oil and Gas Resources-Hydraulic Fracturing and Other Recovery and Assessment Techniques; Intechopen: Rijeka, Croatia, 2018; p. 80996. [Google Scholar]

- Weaver, J.D.; Nguyen, P.D.; Parker, M.A.; van Batenburg, D. Sustaining Fracture Conductivity. In Proceedings of the SPE European Formation Damage Conference, Sheveningen, The Netherlands, 25 May 2005. [Google Scholar]

- Nguyen, P.D.; Weaver, J.D.; Rickman, R.D. Prevention of Geochemical Scaling in Hydraulically Created Fractures: Laboratory and Field Studies. In Proceedings of the SPE Eastern Regional/AAPG Eastern Section Joint Meeting, Pittsburgh, PA, USA, 11–15 October 2008. [Google Scholar]

- Palisch, T.T. How to use and misuse proppant crush tests: Exposing the top 10 myths. SPE Prod. Oper. 2010, 25, 345–354. [Google Scholar] [CrossRef]

- Barati, R.; Liang, J.-T. A review of fracturing fluid systems used for hydraulic fracturing of oil and gas wells. J. Appl. Polym. Sci. 2014, 131. [Google Scholar] [CrossRef]

- Yao, E.; Bai, H.; Zhou, F.; Zhang, M.; Wang, J.; Li, F. Performance Evaluation of the Multifunctional Variable-Viscosity Slick Water for Fracturing in Unconventional Reservoirs. ACS Omega 2021, 6, 20822–20832. [Google Scholar] [CrossRef]

- Li, X.; Zhang, Q.; Liu, P.; Li, T.; Liu, G.; Liu, Z.; Zhao, H. Investigation on the microscopic damage mechanism of fracturing fluids to low-permeability sandstone oil reservoir by nuclear magnetic resonance. J. Pet. Sci. Eng. 2022, 209, 109821. [Google Scholar] [CrossRef]

- Holditch, S.A. Factors affecting water blocking and gas flow from hydraulically fractured gas wells. J. Pet. Technol. 1997, 31, 511–515. [Google Scholar] [CrossRef]

- Tannich, J.D. Liquid removal from hydraulically fractured gas wells. J. Can. Pet. Technol. 1975, 27, 301–309. [Google Scholar] [CrossRef]

- Gdanski, R.D.; Weaver, J.; Slabaugh, B.; Walters, H.; Parker, M. Fracture Face Damage-It Matters. In Proceedings of the SPE European Formation Damage Conference, Sheveningen, The Netherlands, 25–27 May 2005. [Google Scholar]

- Cinco-Ley, H. Transient pressure analysis: Finite conductivity fracture case versus damaged fracture case. In Proceedings of the SPE Annual Technical Conference and Exhibition, San Antonio, TX, USA, 4 October 1981. [Google Scholar]

- Lolon, E.P.; McVay, D.A.; Schubarth, S.K. Effect of Fracture Conductivity on Effective Fracture Length. In Proceedings of the SPE Annual Technical Conference and Exhibition, Denver, CO, USA, 5–8 October 2003. [Google Scholar]

- Bostrom, N.; Chertov, M.; Pagels, M.; Willberg, D.; Chertova, A.; Davis, M.; Zagorski, W. The time-dependent permeability damage caused by fracture fluid. In Proceedings of the SPE International Symposium and Exhibition on Formation Damage Control, Lafayette, LA, USA, 26–28 February 2014. [Google Scholar]

- Ghosh, B.; Abdelrahim, M.; Ghosh, D.; Belhaj, H. Delayed Breaker Systems to Remove Residual Polymer Damage in Hydraulically Fractured Reservoirs. ACS Omega 2021, 6, 31646–31657. [Google Scholar] [CrossRef] [PubMed]

- Conway, M.W.; Penny, G.S.; Schraufnagel, R.A. Fracturing fluid leakoff and damage mechanisms in coalbed methane reservoirs. In Proceedings of the Low Permeability Reservoirs Symposium, Denver, CO, USA, 26 April 1993. [Google Scholar]

- Al-Muntasheri, G.A.; Li, L.; Liang, F.; Gomaa, A.M. Concepts in cleanup of fracturing fluids used in conventional reservoirs: A literature review. SPE Prod. Oper. 2018, 33, 196–213. [Google Scholar] [CrossRef]

- Ghalambor, A.; Guo, B. How Much Can Fracturing Fluid Damage Productivity of Oil Wells? In Proceedings of the SPE International Symposium and Exhibition on Formation Damage Control, Lafayette, LA, USA, 10–12 February 2010. [Google Scholar]

- You, L.; Wang, F.; Kang, Y.L.; Fang, C.; Chen, Q. Evaluation and scale effect of aqueous phase damage in shale gas reservoir. Nat. Gas Geosci. 2016, 27, 2023–2029. [Google Scholar]

- Fink, J. Fracturing Fluids in Petroleum Engineer’s Guide to Oil Field Chemicals and Fluids; Gulf Professional Publishing: Oxford, UK, 2021. [Google Scholar]

- Pagels, M.; Willberg, D.M.; Edelman, E.; Zagorski, W.; Frantz, J. Quantifying fracturing fluid damage on reservoir rock to optimize production. In Proceedings of the SPE/AAPG/SEG Unconventional Resources Technology Conference, Denver, CO, USA, 12–14 August 2013; pp. 1766–1774. [Google Scholar]

- Civan, F. Analyses of Processes, Mechanisms, and Preventive Measures of Shale-Gas Reservoir Fluid, Completion, and Formation Damage. In Proceedings of the SPE International Symposium and Exhibition on Formation Damage Control, Lafayette, LA, USA, 26–28 February 2014. [Google Scholar]

- Li, J.; Guo, B.; Gao, D.; Ai, C. The effect of frac-face matrix damage on prod of fractures with infinite and finite conductivities in shale-gas reservoirs. SPE Drill. Compl. 2012, 27, 347–353. [Google Scholar] [CrossRef]

- Guo, J.; Li, Y.; Wang, S. Adsorption damage and control measures of slick-water fracturing fluid in shale reservoirs. Pet. Explor. Dev. 2018, 45, 336–342. [Google Scholar] [CrossRef]

- Bennion, D.B. An Overview of Formation Damage Mechanisms Causing a Reduction in the Productivity and Injectivity of Oil and Gas Producing Formations. J. Can. Pet. Technol. 2002, 41, 29–36. [Google Scholar] [CrossRef]

- Liang, X. Experimental study on fracture conductivity in high temperature and high pressure tight gas formation: A case of Tarim basin in China. Gondwana Res. 2022, 107, 49–58. [Google Scholar] [CrossRef]

- Liu, Q. An Assessment of Water Impact in Shale Gas Development: A Case Study of the Horn River Basin. Ph.D. Thesis, University of Waterloo, Waterloo, ON, Canada, 2014. [Google Scholar]

- Chen, M.; Kang, Y.; Zhang, X.; Lai, Z.; Li, P.; Chen, Z. Evaluation of Aqueous Phase Trapping in Shale Gas Reservoirs Based on Analytic Hierarchy Process. Energy Fuels 2021, 35, 1389–1397. [Google Scholar] [CrossRef]

- Volk, L.; Gall, B.; Raible, C.; Carroll, H. A method for evaluation of formation damage due to fracturing fluids. In Proceedings of the SPE/DOE Low Permeability Gas Reservoirs Symposium, Denver, CO, USA, 14 March 1983. [Google Scholar]

- Qu, X.; Zhang, Y.; Liu, F.; He, J.; Dyskin, A.V.; Qi, C. An Experimental Analysis of Microcrack Generation during Hydraulic Fracturing of Shale. Coatings 2022, 12, 483. [Google Scholar] [CrossRef]

- Alkouh, A.; Wattenbarger, R.A. New Advances in Shale Reservoir Analysis Using Flowback Data. In Proceedings of the SPE Eastern Regional Meeting, Pittsburgh, PA, USA, 20 August 2013. [Google Scholar] [CrossRef]

- Liu, Y.; Leung, J.Y.W.; Chalaturnyk, R.J.; Virués, C.J.J. New Insights on Mechanisms Controlling Fracturing-Fluid Distribution and Their Effects on Well Performance in Shale-Gas Reservoirs. SPE Prod. Oper. 2019, 34, 564–585. [Google Scholar] [CrossRef]

- Shaoul, J.; Park, J.; Bakhtiyarov, A.; Fekkai, S.; Jeffs, P.; Mandiwall, D. Clipper south field: Fracturing operations and production matching in a low permeability, sandstone gas reservoir in the North Sea. In Proceedings of the EAGE Annual Conference & Exhibition Incorporating SPE Europe, London, UK, 10 June 2013. [Google Scholar]

- Civan, F. Reservoir Formation Damage; Gulf Professional Publishing: Oxford, UK, 2015. [Google Scholar]

- Mahadevan, J.; Sharma, M.M.; Yortsos, Y.C. Capillary wicking in gas wells. SPE J. 2007, 12, 429–437. [Google Scholar] [CrossRef]

- Bazin, B.; Bekri, S.; Vizika, O.; Herzhaft, B.; Aubry, E. Fracturing in tight gas reservoirs: Application of special-core-analysis methods to investigate formation-damage mechanisms. SPE J. 2010, 15, 975–982. [Google Scholar] [CrossRef]

- Bahrami, H.; Rezaee, M.R.; Asadi, M.S. Stress anisotropy, long-term reservoir flow regimes and production performance in tight gas reservoirs. In Proceedings of the SPE Eastern Regional Meeting, Morgantown, WV, USA, 13 October 2010. [Google Scholar]

- Xu, Z.; Li, Z.; Wang, C.; Adenutsi, C.D. Experimental study on microscopic formation damage of low permeability reservoir caused by HPG fracturing fluid. J. Nat. Gas Sci. Eng. 2016, 36, 486–495. [Google Scholar] [CrossRef]

- McDaniel, G.A.; Abbott, J.; Mueller, F.A.; Mokhtar, A.; Pavlova, S.; Nevvonen, O.; Parias, T.; Alary, J.A. Changing the Shape of Fracturing: New Proppant Improves Fracture Conductivity. In Proceedings of the SPE Annual Technical Conference and Exhibition, Florence, Italy, 20–22 September 2010. [Google Scholar]

- Yeten, B.; Castellini, A.; Guyaguler, B.; Chen, W.H. A Comparison Study on Experimental Design and Response Surface Methodologies. In Proceedings of the SPE Reservoir Simulation Symposium, The Woodlands, TX, USA, 31 January 2005. [Google Scholar]

- Xiaodong, K.; Baozhen, L.; Jian, Z. Optimization of the SAGP Process in Oil-Sand Field with Response Surface Methodology. In Proceedings of the Abu Dhabi International Petroleum Exhibition & Conference, Abu Dhabi, United Arab Emirates, 11–14 November 2019. [Google Scholar]

- Shusei, T.; Tsubasa, O.; Dongjae, K. Application of Combined Streamline Based Reduced-Physics Surrogate and Response Surface Method for Field Development Optimizaion. In Proceedings of the International Petroleum Technology Conference, Dhahran, Saudi Arabia, 13 January 2020. [Google Scholar]

- Pan, Y.; Yang, Z.; Pan, Y.; Xu, Y.; Liao, R. Research on Conductivity Damage Based on Response Surface Analysis. Energies 2022, 15, 2818. [Google Scholar] [CrossRef]

- Bunger, A.P.; Kear, J.; Dyskin, A.V.; Pasternak, E. Interpreting post-injection acoustic emission in laboratory hydraulic fracturing experiments. In Proceedings of the 48th US Rock Mechanics/Geomechanics Symposium, Minneapolis, MN, USA, 1–4 June 2014. [Google Scholar]

- Mogi, K. Experimental Rock Mechanics; Taylor & Francis: Abingdon, UK, 2007; pp. 361–363. [Google Scholar]

- Moradian, Z.; Ballivy, G.; Rivard, P.; Gravel, C.; Rousseau, B. Evaluating damage during shear tests of rock joints using acoustic emissions. Int. J. Rock. Mech. Min. Sci. 2010, 1, 590–598. [Google Scholar] [CrossRef]

- Mayr, S.I.; Stanchits, S.; Langenbruch, C.; Dresen, G.; Shapiro, S. Acoustic emission induced by pore-pressure changes in sandstone samples. Geophysics 2011, 76, 21–32. [Google Scholar] [CrossRef]

- Graham, C.C.; Stanchits, S.; Main, I.G.; Dresen, G. Comparison of polarity and moment tensor inversion methods for source analysis of acoustic emission data. Int. J. Rock Mech. Min. Sci. 2010, 47, 161–169. [Google Scholar] [CrossRef]

- Stoeckhert, F.; Molenda, M.; Brenne, S.; Alber, M. Fracture propagation in sandstone and slate—Laboratory experiments, acoustic emissions and fracture mechanics. J. Rock Mech. Geotech. Eng. 2015, 7, 237–249. [Google Scholar] [CrossRef]

- Hampton, J.; Gutierrez, M.; Matzar, L.; Hu, D.; Frash, L. Acoustic emission characterization of microcracking in laboratory-scale hydraulic fracturing tests. J. Rock Mech. Geotech. Eng. 2018, 10, 805–817. [Google Scholar] [CrossRef]

- McCutchen, C.M.; Duffaud, G.D.; Leduc, P.; Petersen, A.R.H.; Tayal, A.; Khan, S.A.; Kelly, R.M. Characterization of extremely thermostable enzymatic breakers (α-1,6-galactosidase and β-1,4-mannanase) from the hyperthermophilic bacterium Thermotoga neapolitana 5068 for hydrolysis of guar gum. Biotechnol. Bioeng. 1996, 52, 332–339. [Google Scholar] [CrossRef]

- Liebl, W.; Wagner, B.; Schellhase, J. Properties of an α-galactosidase, and structure of its gene galA, within an α-and β-galactoside utilization gene cluster of the hyperthermophilic bacterium Thermotoga maritima. Syst. Appl. Microbiol. 1998, 21, 1–11. [Google Scholar] [CrossRef]

- Politz, O.; Krah, M.; Thomsen, K.K.; Borriss, R. A highly thermostable endo-(1,4)-β-mannanase from the marine bacterium Rhodothermus marinus. Appl. Microbiol. Biotechnol. 2000, 53, 715–721. [Google Scholar] [CrossRef] [PubMed]

- Ma, X.; Wang, Z.; Da, Q.; Cheng, M.; Yao, C.; Lei, G. Application of Guar Gum Degrading Bacteria in Microbial Remediation of Guar-Based Fracturing Fluid Damage. Energy Fuels 2017, 31, 7894–7903. [Google Scholar] [CrossRef]

- Ma, X.; Wang, H.; Boyd, W.W.; Cheng, M.; Yao, C.; Lei, G. Thermal stability enhancement of guar-based hydraulic fracturing fluids by phosphate treatment. J. Appl. Pol. Sci. 2018, 136, 47119. [Google Scholar] [CrossRef]

- Tjon-Joe-Pin, R.M. Enzyme Breaker for Galactomannan Based Fracturing Fluids. U.S. Patent 5806597-A, 13 April 1993. [Google Scholar]

- Liu, S.; Zhao, M.; Wu, Y.; Gao, Z.; Dai, C.; Liu, P. Fracturing Fluid with High Temperature and Shear Resistance Ability. Energy Fuels 2022, 36, 7177–7185. [Google Scholar] [CrossRef]

- Murtada, S.A.; Olalekan, S.A.; Amjed, H.; Mahmoud, M.; Muhammad, S.K. Application of Nanoparticles in Stimulation: A Review. Energy Fuels 2022, 36, 4276–4296. [Google Scholar]

- Yekeen, N.; Padmanabhan, E.; Idris, A.K. A review of recent adv in foam-based frac fluid application in unconventional reservoirs. J. Ind. Eng. Chem. 2018, 66, 45–71. [Google Scholar] [CrossRef]

- Zhou, J.; Legemah, M.; Beall, B.; Sun, H.; Qu, Q. Alternative polysaccharide fracturing fluids for harsh reservoir conditions. In Proceedings of the SPE Unconventional Resources Conference and Exhibition-Asia Pacific, Brisbane, Australia, 11–13 November 2013. [Google Scholar]

- Putzig, D.E.; St Clair, J.D. A new delay additive for hydraulic fracturing fluids. In Proceedings of the SPE Hydraulic Fracturing Technology Conference, College Station, TX, USA, 29 January 2007. [Google Scholar]

- Kalgaonkar, R.A.; Patil, P.R. Performance Enhancements in Metal-Cross-linked Fracturing Fluids. In Proceedings of the North Africa Technical Conference and Exhibition, Cairo, Egypt, 14–17 February 2012. [Google Scholar]

- Meng, Y.; Zhao, F.; Jin, X.; Feng, Y.; Sun, G.; Lin, J.; Jia, B.; Li, P. Performance Evaluation of Enzyme Breaker for Fracturing Applications under Simulated Reservoir Conditions. Molecules 2021, 26, 3133. [Google Scholar] [CrossRef]

- Kyaw, A.; Azahar, B.S.B.N.; Tunio, S.Q. Frac fluid degradation study by using oxidative and enzyme breaker. Res. J. Appl. Sci. Eng. Technol. 2012, 4, 1167–1671. [Google Scholar]

- Mehtar, M.A.; Kasam, Y.; Al-Aleeli, A.; Ghosh, B.; Ghosh, D.; Chaudhuri, B. Derivation of kinetic rate constant of enzyme-buffer mud cake clean up systems—Laboratory investigation and verification in high temperature fractured carbonate reservoir. In Proceedings of the Abu Dhabi International Petroleum Conference and Exhibition, Abu Dhabi, United Arab Emirates, 11–14 November 2012. [Google Scholar]

- Kitany, N.A.; Ghosh, B.; Eldin, Y.F.; Al-Bemani, A.S.; Al-Hadhrami, H. Evaluation of wellbore clean up fluids by comparing laboratory test results with field production data. In Proceedings of the Abu Dhabi International Petroleum Exhibition and Conference, Abu Dhabi, United Arab Emirates, 6 November 2008. [Google Scholar]

- Al-Khaldi, M.H.; Ghosh, B.; Ghosh, D. A Novel Enzyme Breaker for Mudcake Removal in High Temperature Horizontal and Multi-lateral Wells. In Proceedings of the SPE Asia Pacific Oil & Gas Conference and Exhibition, Jakarta, Indonesia, 20 September 2011. [Google Scholar]

- Vengosh, A.; Jackson, R.B.; Warner, N.; Darrah, T.H.; Kondash, A. A Critical Review of the Risks to Water Resources from Unconventional Shale Gas Development and Hydraulic Fracturing in the United States. Environ. Sci. Technol. 2014, 48, 8334–8348. [Google Scholar] [CrossRef]

- Sarwar, M.U.; Cawiezel, K.E.; Nasr-El-Din, H.A. Gel Degradation Studies of Oxidative and Enzyme Breakers to Optimize Breaker Type and Concentration for Effective Break Profiles at Low and Medium Temperature Ranges. In Proceedings of the SPE Hydraulic Fracturing Technology Conference, The Woodlands, TX, USA, 24–26 January 2011. [Google Scholar]

- Wang, Z.; Bai, B.; Zhou, E.; Pu, J.; Schuman, T.P. Experimental Evaluation of Oxidizing Breakers for a Polyacrylamide-Based Re-Crosslinkable Preformed Particle Gel. Energy Fuels 2019, 33, 5001–5010. [Google Scholar] [CrossRef]

- Fogang, L.; Kamal, M.; Sultan, A. Viscosity-Reducing Agents (Breakers) for Viscoelastic Surfactant Gels for Well Stimulation. Energy Fuels 2020, 34, 15686–15700. [Google Scholar] [CrossRef]

- Sumner, A.J.; Plata, D.L. Oxidative Breakers Can Stimulate Halogenation and Competitive Oxidation in Guar-Gelled Hydro-Frac Fluids. Environ. Sci. Technol. 2019, 53, 8216–8226. [Google Scholar] [CrossRef] [PubMed]

- Peterson, M.; Daniel, R.M.; Danson, M.J.; Eisenthal, R. The dependence of enzyme activity on temperature: Determination and validation of parameters. Biochem. J. 2007, 403, 615. [Google Scholar] [CrossRef]

- Groitl, B.; Horowitz, S.; Makepeace, K.A.T.; Petrotchenko, E.V.; Borchers, C.H.; Bardwell, J.C.A.; Jakob, U. Protein unfolding as a switch from self-recognition to high-affinity client binding. Nat Commun. 2016, 20, 10357. [Google Scholar] [CrossRef] [PubMed]

- Shaanxi Yanchang Petroleum Group Co., Ltd. Bio-Enzyme Gel Breaker and Technique for Water-Based Guargum Fracturing Gel Breaking with the Same. Chinese Patent No. CN101781552B, 7 November 2012. [Google Scholar]

- Yin, L.J. Characterization of Mannanase from a Novel Mannanase-Producing Bacterium. J. Agric. Food Chem. 2012, 60, 6425–6431. [Google Scholar] [CrossRef]

- Mohapatra, B.R. Characterization of β-mannanase extracted from a novel Streptomyces species Alg-S25 immobilized on chitosan nanoparticles. Biotech. Biotechnol. Equipm. 2021, 35, 150–161. [Google Scholar] [CrossRef]

- Barati, R.; Johnson, S.J.; McCool, S.; Green, D.W.; Willhite, G.P.; Liang, J.-T. Polyelectrolyte complex nanoparticles for protection and delayed release of enzymes in alkaline pH and at elevated temperature during hydraulic fracturing of oil wells. J. Appl. Polym. Sci. 2012, 126, 587–592. [Google Scholar] [CrossRef]

- Zhang, B.; Huston, A.; Whipple, L.; Urbina, H.; Barrett, K.; Wall, M.; Hutchins, R.D.; Mirakyan, A.L. A Superior, High-Performance Enzyme for Breaking Borate Cross-linked Fracturing Fluids Under Extreme Well Conditions. SPE Prod. Oper. 2013, 28, 210–216. [Google Scholar]

- Barati, R.; Johnson, S.J.; McCool, S.; Green, D.W.; Willhite, G.P.; Liang, J.T. Fracturing fluid cleanup by controlled release of enzymes from polyelectrolyte complex nanoparticles. J. Appl. Polym. Sci. 2011, 121, 1292–1298. [Google Scholar] [CrossRef] [Green Version]

| Component/Category | Function/Remark |

|---|---|

| Water-based polymers | Thickener, transport proppant, reduces leak off information |

| Friction reducers | Limits drag in the tubing |

| Fluid loss additives | Filter cake formation, reduce leak off |

| Breakers | Disable cross-linkers |

| Cross-linkers | Improves the viscosity of the thickener |

| Gel stabilizers | Keep gels active longer |

| Defoamers | Breakdown foam |

| Crosslinked gel systems | Increase viscosity |

| Oil-based systems | Applied in water-sensitive formations |

| Breakers | Metal-Crosslinked Bipolymers | Borate-Crosslinked Bipolymers | Metal-Crosslinked Synthetic Polymers | Phosphate Esters (Gelled Hydrocarbons) |

|---|---|---|---|---|

| Oxidizers | Applicable | Applicable | Applicable | x |

| Weak acids | x | Applicable | x | x |

| Decrosslinking agent | Applicable | x | Applicable | x |

| Calcium and magnesium oxides | x | x | x | Applicable |

| Enzymes | Applicable | Applicable | x | x |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ghosh, B.; Abdelrahim, M.; Belhaj, H. Residual Damage, Its Consequences, and Remedial Measures on Post Hydrofrac Well Productivity: Learnt Lessons. Energies 2022, 15, 7194. https://doi.org/10.3390/en15197194

Ghosh B, Abdelrahim M, Belhaj H. Residual Damage, Its Consequences, and Remedial Measures on Post Hydrofrac Well Productivity: Learnt Lessons. Energies. 2022; 15(19):7194. https://doi.org/10.3390/en15197194

Chicago/Turabian StyleGhosh, Bisweswar, Mumin Abdelrahim, and Hadi Belhaj. 2022. "Residual Damage, Its Consequences, and Remedial Measures on Post Hydrofrac Well Productivity: Learnt Lessons" Energies 15, no. 19: 7194. https://doi.org/10.3390/en15197194

APA StyleGhosh, B., Abdelrahim, M., & Belhaj, H. (2022). Residual Damage, Its Consequences, and Remedial Measures on Post Hydrofrac Well Productivity: Learnt Lessons. Energies, 15(19), 7194. https://doi.org/10.3390/en15197194