Abstract

Building Information Modeling (BIM), as an auxiliary design platform, is increasingly adopted in construction projects. However, it is not widely applied in the collaborative design of zero energy buildings (ZEBs), due to the cross-discipline and complex features of ZEB projects and lack of research on the procedure and method of collaborative design in this field. This paper introduces a BIM-based collaborative design method for ZEBs. From the perspective of the technical requirements of ZEBs, the study elaborates the application of a BIM-based collaborative design method among specialists from different disciplines in passive design, renewable energy utilization and active design. The feasibility of this method is verified by the actual design and construction of the T&A House in Solar Decathlon China (SDC) competition. The research results show that the BIM-based collaborative design method can facilitate the completion of a construction project and achieve the expected goal of zero energy consumption in ZEBs.

1. Introduction

The energy issue is a major challenge facing the world today. The construction industry accounts for nearly 41% of the total global energy consumption and has surpassed transportation as the world’s largest energy-consuming industry [1]. In China, the energy consumption in the building process was 1 billion tce in 2018, accounting for 21.7% of the total national energy consumption, of which residential energy consumption accounted for 81% [2]. This figure is expected to double by 2050 as a result of China’s economic development and rapid urbanization [3]. In view of this situation, improving building performance is a possible solution to reduce building energy consumption. Zero energy buildings (ZEBs) have significant advantages in terms of energy conservation and consumption reduction by improving the utilization efficiency of renewable energy [4]. Studies have shown that ZEBs can save 60% to 75% of energy compared to traditional buildings [5]. Therefore, ZEBs are of great significance for reducing the energy consumption of Chinese buildings.

In China, the relevant practical research on ZEBs started relatively late. However, with the promotion of national policies and the demonstration effect of pilot projects, ZEBs have developed rapidly since 2017, showing an increasing trend year by year [6]. As of the beginning of 2022, the under-construction and constructed area of nearly zero energy buildings has exceeded 12 million m2 [7]. With the announcement of the dual carbon goals of China, ZEBs have gradually become an important way for the construction industry to reduce energy consumption and carbon emissions [8].

The development of ZEBs in China benefits from the policies and standards issued by the national and local governments [9], the excellent demonstration projects, solid theoretical research in other countries and the domestic exploration of ZEB design [10]. Against this backdrop, the Solar Decathlon China (SDC) was introduced to China in 2011, which is affiliated with the Solar Decathlon (SD) sponsored by the U.S. Department of Energy since 2002. In 2021, the third SDC competition was held in Zhangbei County, Zhangjiakou City, China, aiming at the three propositions of “sustainable development, intelligent interconnection, and healthy living”. Candidates are encouraged to design and construct solar-energy-powered ecological houses with demonstration effect and promotion value [11]. The case of T&A House in this study is a jointly designed ZEB by China University of Mining and Technology and AGH University of Science and Technology in Krakow, Poland. It has entered the final stage competition of SDC in 2021 for its excellent performance in zero energy consumption.

2. Literature Review

Building Information Modeling (BIM) can be applied in accurate modeling [12], envelope optimization [13], energy performance simulation [14,15], renewable energy utilization [16], building performance evaluation [17,18,19], smart management [20], etc. It has demonstrated great benefits in assisting the design of ZEBs in terms of saving time, improving coordination, reducing costs and reducing load on information exchange [21,22]. However, most studies on BIM-assisted ZEB projects focus on the design optimization of some stages [23] rather than the whole process from site design to energy simulation. In addition, most research on ZEBs is devoted to the evaluation and optimization of existing cases [24], so it is difficult to follow up the entire design stages of the project with BIM. The SDC competition requires the participating teams to build a low-energy green house within the specified time, providing ideal conditions for the application of BIM in the design and construction stages of ZEBs. Therefore, under the requirements of the SDC competition, this research uses BIM to carry out cross-discipline collaboration in designing a T&A House. After field construction, a T&A House that may achieve zero energy consumption is finally completed.

Owing to its comprehensiveness, the design of a ZEB project demands cross-disciplinary collaboration from a spectrum of fields including architecture, electricity, energy, the environment and so on. Jassawalla and Sashittal defined collaboration as people with different interests coming together to achieve a common goal through interaction, information sharing and coordination of activities, where various professionals collaborate on a common goal [25]. BIM is a modern platform enabling the collaboration of multiple disciplines on the same construction projects. Due to its potential ability to improve efficiency in design, procurement, prefabrication, construction and post-construction stages, BIM is being accepted by the construction industry [26,27] and is increasingly used in ZEB projects [28]. BIM provides a collaboration platform with which members in a ZEB project can exchange and update information about the model so as to facilitate decision-making.

In the collaborative design of ZEBs, BIM exerts multiple advantages. In terms of improving work efficiency, the application of BIM can significantly improve construction quality and efficiency [29]. Effective implementation of BIM can enhance high-level collaboration in a multidisciplinary work environment [30]. Research has shown that improved collaboration among project participants can increase the efficiency and effective outcomes of a project [31]. BIM can automate the process of modeling, increase the accuracy of construction documents and improve communication between all parties in the design and construction process [32]. These characteristics have greatly influenced the way architects and structural engineers work. In terms of reducing costs, Azhar et al. used data obtained from 10 specific case studies to demonstrate that BIM could improve collaboration and has the potential to reduce costs, increase profits and improve efficiency [33]. Bryde et al. assembled data from 35 case studies in the literature and concluded that cost reduction was one of the main benefits of BIM, in addition to improved project delivery time, quality, coordination and collaboration among different stakeholders [34]. In terms of reducing energy consumption, Hindavi et al. optimized the energy performance of a single-story urban house in a poor area in India by 13%, which was achieved by simulating the energy consumption in eight directions and seven masonry combinations of the house in BIM [35].

Previous research reveals that BIM-based collaboration can save the economic and time cost of ZEB projects and optimize energy structure and building performance through simulation. However, in practical application, some problems still exist in real collaboration in BIM-based ZEB projects.

An enhanced integration of BIM software does not always guarantee a high level of collaboration [36] because BIM users from different professions may possess different thinking styles, and their operating proficiency with BIM may also vary greatly. As a result, in real applications of BIM in ZEB projects, a wide range of risks, including misunderstandings, data-misinterpretation, increased reworking [37] and poor collaboration, are affecting project implementation [38]. Besides technical professionals, decision makers such as house-owners and contractors also reject the application of BIM for ZEBs, as the benefits of BIM have not been verified and quantified in previous studies, and there is a lack of metrics to support its incorporation into their workflows [39]. Existing literature and practical implementations do not demonstrate clearly why BIM facilitates collaboration in ZEB projects and why collaboration is crucial for the successful construction of ZEBs [40]. In addition, e-documents generated in the BIM-based management process are easier to forge than paper versions [40], and so legal disputes such as liability and copyright may arise.

In conclusion, BIM-based collaboration is difficult to achieve in ZEB projects, mainly due to the following three reasons. First, BIM standards and data exchange formats are complex, which, in turn, affects the data transmission efficiency in BIM applications. Second, BIM users may be slow to adjust to this new platform and have misunderstandings of data and insufficient understanding of their roles and responsibilities in ZEB projects. Third, there is not sufficient quantitative research and real cases to which to refer, and differences between BIM-based collaboration and non-BIM-based collaboration are still unclear, so the BIM collaborative process for ZEBs is not mature.

The SDC competition, however, provides ideal conditions for the application of BIM in ZEB projects and a good research environment for collaborative design as well. Guided by cross-disciplinary teachers, students, as mainstays of design and construction, all have the same goal, clear division of labor and a certain foundation in the operation of BIM software, which has created favorable conditions for BIM-based collaboration on ZEBs. On this basis, this study explores the BIM-based collaborative design method of ZEBs, with which we build a T&A House that fulfills the residential functions, is expected to achieve zero-energy consumption and provides a reliable case for related research.

Though this research describes a new method and has tested its feasibility, there is insufficient data to quantitatively support how well this project is completed compared with other projects. As the SDC competition has not officially entered the final stage, the relevant monitoring data of the building performance is not yet fully collected. We will fill this gap in the follow-up research.

3. T&A House’s Technical Strategies to Achieve Zero Energy Consumption

The design team of T&A House is from China University of Mining and Technology in Xuzhou, China, and AGH University of Science and Technology in Krakow, Poland. Participants from China University of Mining and Technology are teachers and students from seven majors, including architecture, environmental design, electrical engineering, energy and power engineering, environmental engineering, engineering management and civil engineering, while those from the AGH University of Science and Technology mainly contribute to the energy optimization of the project.

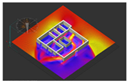

With respect to the design framework, the team refers to the SDC competition evaluation system and the zero energy evaluation standard (GB/T51350-2019) [41] and implements the requirements of both in establishing a zero energy residential optimization system. The SDC competition evaluation system includes 5 aspects—architectural design, energy, environmental comfort, social economy and design strategy—and on this basis, they are extended to cover 10 evaluation indexes (Table 1). With respect to the technology of ZEB, passive design and active design are two main technical measures (Figure 1). In the design process, specialists from different disciplines collaborate on the BIM platform to propose specific design strategies for active and passive design, which can meet the SDC evaluation requirements and achieve the final target of zero energy consumption.

Table 1.

Evaluation indices of the third SDC competition.

Figure 1.

T&A House’s technical measures.

Passive design mainly aims at an energy-saving effect in four aspects: creating good lighting and ventilation conditions, creating a beautiful and suitable landscape environment, improving the performance of the envelope structure and reducing the cooling and heating load. To reduce the dependence on traditional energy systems and initially achieve low energy consumption through the shape design and space utilization of the building itself, the design team proposes a series of architectural design practices, including optimizing the building orientation, controlling the shape coefficient (the ratio of the external surface area of a building in contact with the outdoor atmosphere to the volume it encloses [42]), guiding good natural lighting, enhancing natural ventilation, improving the thermal insulation performance of the envelope structure, assisting the convection of indoor/outdoor hot/cold airflow and setting buffer space for heat storage and release.

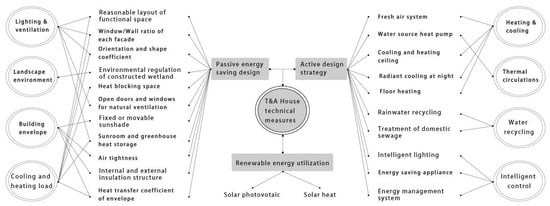

The active design, through the selection of mechanical energy-saving equipment, aims at reducing energy consumption in four aspects: heating and cooling, thermal cycle, water source recovery and intelligent control. Active technical measures focus on efficient energy-saving appliances such as fresh air integrated machines, air conditioning systems, cooling and heating ceilings, floor heating, rainwater recycling and intelligent lighting. Active design is based on passive design to further optimize the indoor living environment and improve energy-saving effects and smart home experience. In terms of renewable energy utilization, T&A House achieves energy balance by using technologies that integrate a solar photovoltaic, solar thermal energy and house photovoltaic system to meet the needs of indoor electricity, hot water and heating. Integrated zero energy technology and the intelligent control system of T&A House are shown in Figure 2.

Figure 2.

Integrated zero energy technology and intelligent control system of T&A House.

4. Collaborative Design Method for T&A House

4.1. Collaboration-Oriented Passive Design

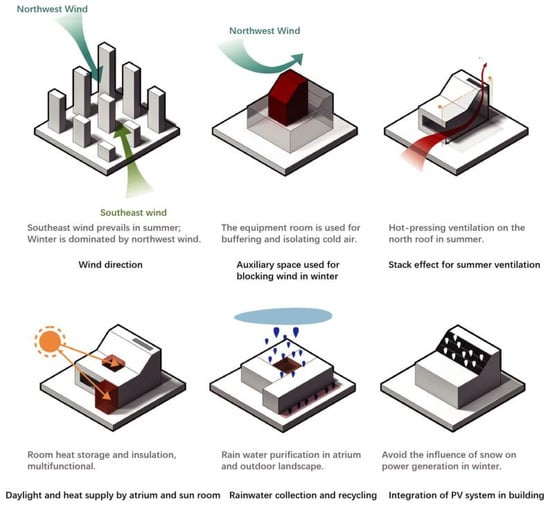

Zhangjiakou City (from 113°50′ E to 116°30′ E and 39°30′ N to 42°10′ N), where the project is located, belongs to the cold region in China. It features a temperate continental monsoon climate with four distinct seasons. The southeast wind prevails in summer, while the northwest wind, the dominant wind direction in this city, prevails in winter. The relationship between its climate and the choice of zero energy technologies is here described from the aspects of temperature, humidity, sunshine and wind conditions.

- (1)

- Temperature

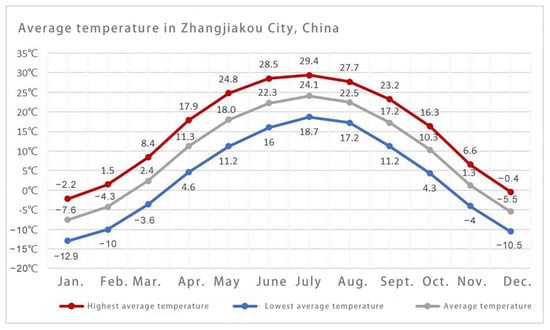

According to the data of a typical meteorological year in Zhangjiakou City, the average temperature is the highest in July (with the highest temperature not more than 29 °C) and the lowest in January (with the highest temperature below zero). More than 145 days in Zhangjiakou City have a daily average temperature below 5 °C (Figure 3). Therefore, thermal insulation in winter should be the primary focus following the passive design strategies of ZEB, including improving the thermal insulation performance of the building envelope, enhancing the air tightness of the building and controlling the energy consumption from the aspects of thermal insulation and heating.

Figure 3.

Monthly average temperature in Zhangjiakou City, China.

- (2)

- Humidity

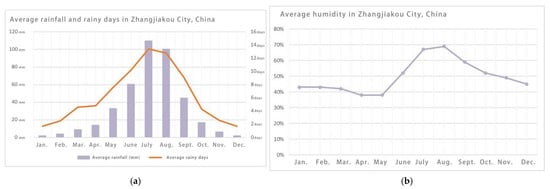

The average annual rainfall in Zhangjiakou is 403.6 mm, which is comparatively low in amount and mainly in summer. July takes the lead in the average rainfall and the number of rainy days. In contrast, it is the driest in spring, with the average humidity in April and May being only 38% (Figure 4). Considering the above condition, improving the indoor humidity in spring will improve indoor comfort and hygiene.

Figure 4.

Average rainfall, rainy days and humidity in Zhangjiakou City, China. (a) Average rainfall and rainy days in Zhangjiakou City, China; (b) average humidity in Zhangjiakou City, China.

- (3)

- Sunshine

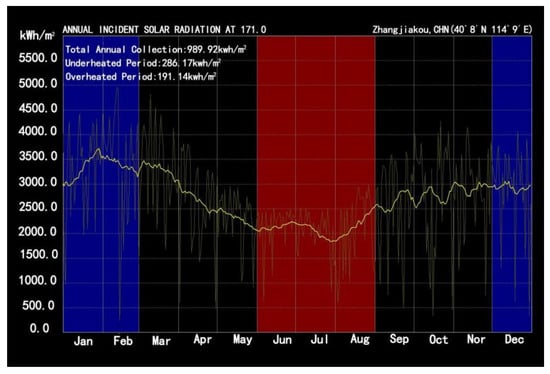

Zhangjiakou City receives an average of more than 9 sun-hours per day and reaches more than 12 sun-hours in 7 months of a year. The annual solar radiation in Zhangjiakou City is considered very high by importing the meteorological data of Zhangjiakou City into Weather Tool (Figure 5), which makes solar energy one of the most promising renewable energy sources in power generation and heating.

Figure 5.

Annual solar radiation in Zhangjiakou City.

- (4)

- Wind conditions

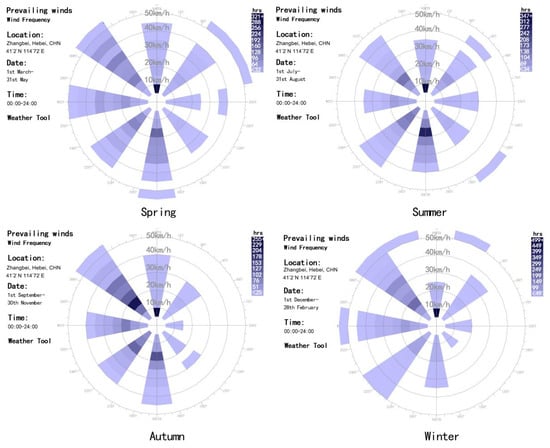

The northwest wind from Siberia prevails in Zhangjiakou City in winter, and the average wind speed in spring and autumn is very swift and can reach up to 3 m/s in April. In contrast, wind speed in summer is much slower. Under the prevailing northwest wind, air tightness measures should be taken in this region to prevent cold air penetration, which demands careful consideration of building structure and envelope materials in the preliminary designing stage. (Figure 6).

Figure 6.

Wind roses in Zhangjiakou City.

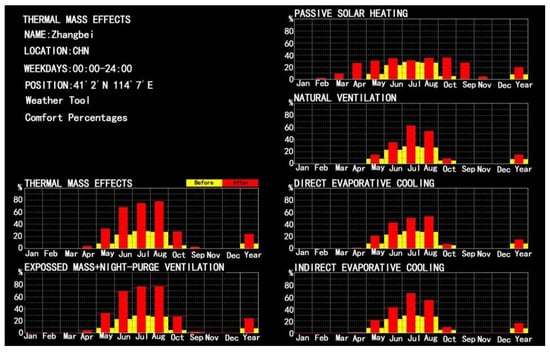

Prior to the design, architectural designers use ECOTECT(See Supplementary Materials) to analyze the climate of Zhangjiakou City and propose passive strategies for achieving zero energy consumption (Figure 7). The simulation analysis reveals that this design can minimize energy consumption by enhancing the heat storage capacity of the envelope structure and optimizing ventilation to cool down the house at night. The application of passive solar energy for heating has a certain effect throughout the year, of which the use of solar energy for heating in April, May, September and October has the greatest effect. In summer, direct and indirect evaporative cooling systems have certain effects, which are most significant in July and August. Furthermore, according to the psychrometric chart analysis, the passive design should focus on cold prevention and heat preservation in winter, where the design effect of passive solar heat gain and heat storage capacity of the envelope can be maximized. These measures need to be highlighted in design.

Figure 7.

Combination analysis of passive strategies.

4.2. Collaborative Design in the Scheme Generation Stage

The design of a ZEB is a process of collaboration of various specialties. In the passive design stage, architectural designers first pin down the goal of the optimal performance of a ZEB and chose the generation of the housing shape as the main line. Then, they carry out architectural design and passive performance-based design supported by specialties from environmental design, electrical engineering, energy and power engineering and environmental engineering. In fulfilling the energy performance and environmental comfort, the specific collaborative operation methods of each discipline are shown in Table 2.

Table 2.

Collaborative design in the preliminary design stage.

4.2.1. Collaborative Passive Design in the Stage of Environment Planning

In the stage of passive design, specialists from architecture and environmental engineering cooperate in the design of passive landscapes of the site. When dealing with waste treatment and rainwater utilization, they integrate the concept of the sponge courtyard (whose theory and concept are borrowed from those of Sponge City in [43]) into the site design.

In planning the site for storing water treatment equipment, environmental engineering specialists propose a set of water treatment schemes with small size, low energy consumption and eco-friendly features. Most of the water treatment equipment required in water processing is properly set in the northern part of the site and buried underground. The environmental engineering specialists provide the exact number and size of the equipment to the architecture specialists, who adjust and optimize the building plan in combination with the residential area and landscape design.

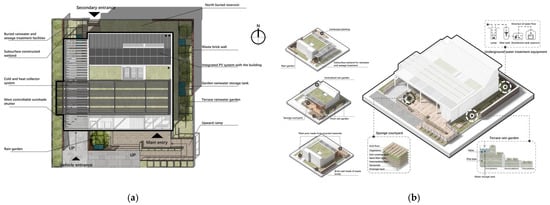

The terrace landscape in front of the house adopts the sponge courtyard, which combines the rainwater circulation system proposed by environmental engineering specialists. The multi-layer structure of the sponge courtyard can purify rainwater for landscape plant irrigation. In addition, the northwest area of the site is designed as a multi-stage subsurface constructed wetland, which can improve the phosphorus removal rate, ensure the water treatment effect and enhance the ornamental value. The final site design scheme is shown in Figure 8.

Figure 8.

BIM-based site design. (a) Site design; (b) site design analysis.

4.2.2. Collaborative Passive Design in the Stage of Shape Design

As the first step in the shape design, the orientation of the ZEB is determined by importing the climate data of Zhangjiakou City into Weather Tool of ECOTECT for analysis. The best orientation of thermal radiation is obtained as it will be conducive to the winter heating of the ZEB and the acquisition of more solar energy by photovoltaic (PV) modules and hence is used as the reference for the orientation of main rooms and the inclination of PV roof.

In the shape design of T&A House, the architectural designers adopt the compact layout based on the existing residential form in the new rural area of Zhangjiakou City, which is designed to actively respond to the local climatic characteristics (Figure 9). According to the prevailing wind direction, the northern side of the house is raised to counteract the impact of the northwest wind. A rectangular hole on the top of the raised house is opened to achieve the chimney effect for ventilation. In order to mitigate the adverse effects of the compact layout on the lighting and ventilation of the internal space, an atrium is placed in the middle of the house, which serves the functions of lighting and heating, rainwater collection, purification and reuse and microclimate regulation. A sloped roof is considered for the layout of PV panels and the integration of the PV system into buildings.

Figure 9.

Influence of climatic characteristics on shape design.

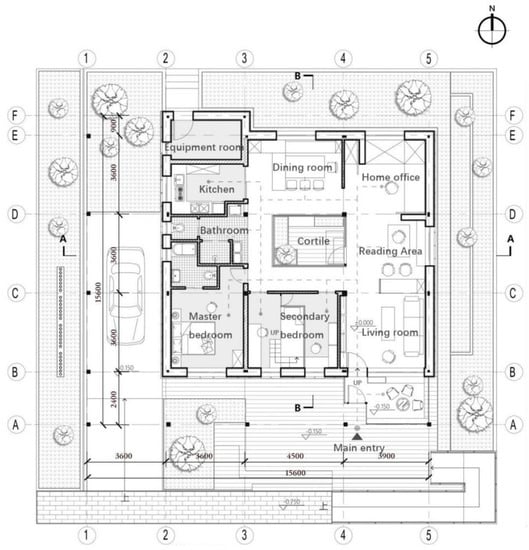

4.2.3. Collaboration Passive Design in the Stage of Functional Areas Layout Design

In designing the overall shape of the house, the architectural designers provide the layout design of functional areas and make corresponding adjustments to optimize the shape. As Zhangjiakou City is situated in the cold area of China, the compact layout can reduce the shape coefficient of the building and ensure better thermal comfort. Combined with the design of architectural shape and the analysis of ventilation and lighting, the prototype with a central courtyard is adopted. Considering the climate in Zhangjiakou City, the main principles for the layout of T&A House (Figure 10) are as follows: locating the main living space in the south and east, the secondary living space in the north, the auxiliary space in the northwest corner and the courtyard in the middle.

Figure 10.

BIM-based floor plan of T&A House.

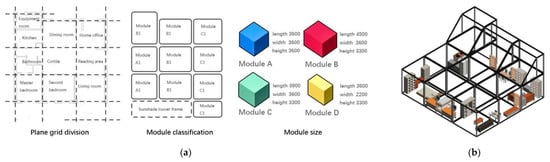

Another factor that affects the location of functional areas is the modular scale. Since the SDC competition requires the construction of a ZEB within 21 days, the building should be prefabricated in modules. In order to ensure the reasonable module division of the house, the structure specialists put forward the column grid size requirements when determining the column grid layout. Room width is used to define the column grid. Finally, four types of modules are shortlisted to divide different functional areas (Figure 11a). According to the final shape of the house, three independent slope modules are created for the northern raised part to meet the stability and safety requirements of the sloped roof. Next, the structural specialists establish a preliminary BIM model of the structure (Figure 11b) based on load and internal force and then design and select materials for the frame structure and form of connection of the modules.

Figure 11.

Module division form and BIM model for modular design. (a) Module division form; (b) modular BIM module.

4.2.4. Collaboration Design Process of Passive Design in the Stage of Performance-Based Design

The performance-based design of T&A House is implemented to improve the indoor comfort, mainly from the following three aspects: creating a passive design of the building facade to reduce building energy consumption, improving the performance of the envelope to reduce the heat load per unit area and using environmentally friendly and energy-saving materials with regional characteristics.

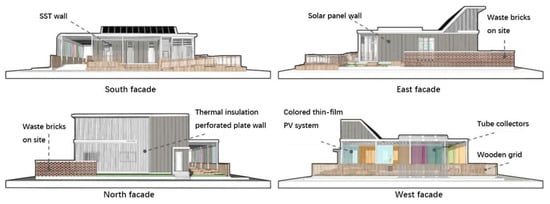

As the south and east facades of the house can harness solar energy for lighting and heating, while the west and north facades need to be designed to resist northwest wind and preserve heat, the architectural designers implement different designs for the four facades (Figure 12). The SST wall (a variant and optimized form of the Trombe wall) is adopted in the south facade to regulate the convection by opening and closing the top and bottom vents of the exterior wall to maintain a more comfortable indoor airflow. The east facade is equipped with the solar panel wall, another variant of the Trombe wall. The north facade adopts the thermal insulation perforated plate. The facade of the equipment room on the northwest side adopts the thermal insulation and wind resistance board, which contributes to heat preservation in winter. A wooden grid and colored thin-film PV system are arranged on the west side of the parking space on the west facade, which can be used as a small charging station because of its good power generation effect in low light.

Figure 12.

Facade design model.

In addition to different forms of facade design to reduce residential energy consumption, the location and size of windows on the facade are also one of the important aspects affecting energy consumption. Under the restriction of natural lighting, natural ventilation and other factors, the ECOTECT software is used to simulate and analyze the impact of different windows on the indoor environment to determine the range of window limits. After optimizing and adjusting the effect of the windows, ECOTECT software simulates and verifies the indoor natural lighting and ventilation under different window opening types, as shown in Table 3 and Table 4.

Table 3.

Natural lighting simulation.

Table 4.

Natural ventilation simulation.

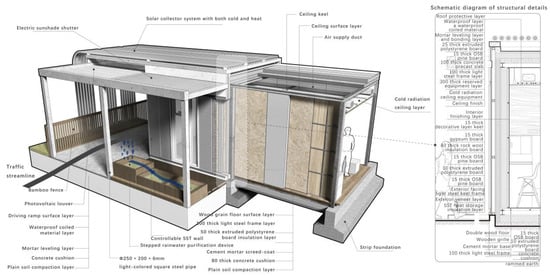

Under the existing facade modeling, architectural and structural specialists work together on the construction plan to improve the thermal insulation performance of exterior walls, roofs and floors and reduce the heat load per unit area. According to the common practice of external insulation in cold regions and the characteristics of module prefabrication, this scheme adopts a layer of 100 mm thick rock wool insulation board and oriented strand board (OSB) when prefabricating the frame, coupled with a layer of 100 mm thick extruded polystyrene board (XPS) and OSB during construction on site. The thick wall structure not only ensures the thermal insulation needs of the buildings but also enhances the sound insulation performance. The specific construction measures of the envelope structure are shown in Figure 13.

Figure 13.

Envelope construction model and practice.

4.3. Collaborative Design of Renewable Energy Utilization

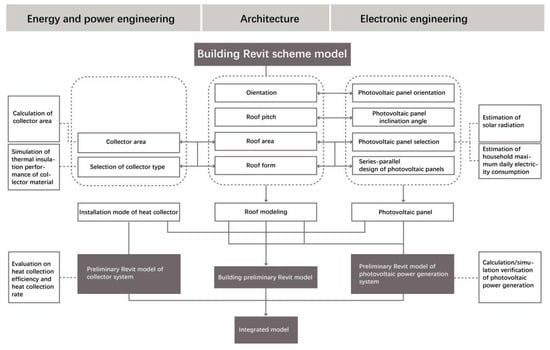

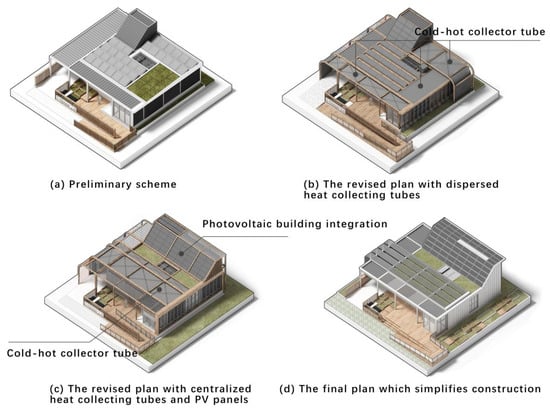

After the formation of the preliminary building shape, the electrical engineering specialists and the energy and power engineering specialists put forward the design ideas of the PV system and collector system according to the heating requirements of ZEB. Their suggestions for the modification of residential form according to the design requirements of the PV system and collector system provide conditions for the use of renewable energy. Specific collaborative design methods are shown in Figure 14.

Figure 14.

Collaborative design method in designing residential shape.

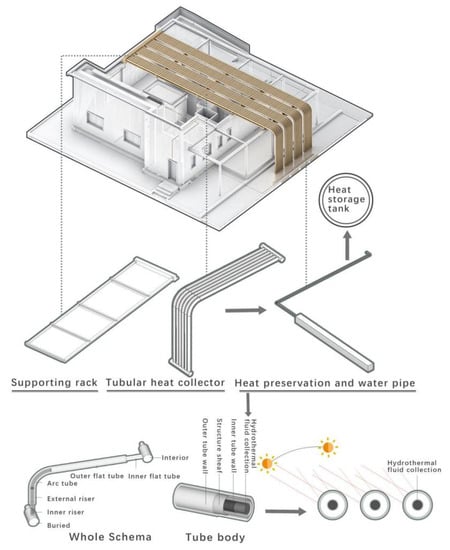

The collector system designers calculate that the required roof collector area is about 90 m2, which can meet the all-day indoor heating demand and domestic hot water supply in winter. For the selection of a collector, the designers propose a new type of tubular collector, which not only saves the collector area but also increases the effective collector surface and improves the collector efficiency. The designers simulate the collector tube with Fluent(See Supplementary Materials) and preliminarily select the heat pipe material.

Architectural designers modify the roof shape of the house according to the area requirements and the form of the tubular collector provided by the collector system designers. Due to the large volume of the collector tube, the first design adjustment is to decompose the volume of the collector tube into three discrete volumes, which are arranged in different positions of the roof in a woven shape to adapt to the building shape. However, the collector designers consider that this decentralized arrangement would greatly increase the heat loss of the collector tube and increase the difficulty of construction and installation, so they reject it. The second plan is to arrange the collector tube in the middle of the roof as a whole and connect the roof horizontal tube and the vertical tube through a section of arc tube. In order to avoid the overlapping of adjacent horizontal tubes and leave space for snow sliding, the collector designers calculate the minimum spacing according to the solar altitude angle and obtain the minimum spacing (40 mm) between two adjacent horizontal tubes. The designers calculate the volume of the heat storage water tank according to the area and performance of the collector tube and arrange it in series in the raised wind tower on the north side of the building. The arrangement can ensure that the working medium from the underground heat collecting tube can quickly reach the heat storage water tank after being heated, thereby reducing the heat loss along the way. This arrangement can basically realize the design effect of the integrated tubular collector in the building.

After determining the orientation and conceptual shape of the building, the designers in charge of the PV power generation system in electrical discipline begin to join the design. They propose firstly that the orientation of the PV modules should be consistent with the building orientation (south-facing), so that the PV modules can absorb more solar energy. Secondly, the inclined PV modules have higher energy efficiency than the horizontal PV modules. Thirdly, PV modules can be integrated in the prefabricated frame. Finally, the installation method of the single-sided inclined PV panel (inclination angle of 45°) installed directly on the roof slope is put forward.

By analyzing and calculating the amount of solar radiation in Zhangjiakou City and the maximum daily power consumption of households in the new countryside of Zhangjiakou City, the PV system designers determine that the PV power generation system of T&A House should adopt a non-dispatchable grid-connected power generation plan. With this guideline, they select PV modules, inverters, meters and other components. For the PV system of T&A House, the team first connects 10 pieces of 330 W PV modules in series, then connects these two modules in parallel and finally connects 20 PV modules to the inverter. PV system designers send this result to architectural designers. On the basis of the roof inclination of the northwest equipment room, the architectural designers extend the inclined roof eastward to form a completely inclined design of the northern roof. This inclined plane can hold 24 pieces of 300 W PV modules, which meets the requirements of PV module layout without destroying the collector tube layout and forms the building PV integrated design. The PV system designers establish the PV system model with the BIM building model, and the inverter and distribution box are placed in the equipment room (Figure 15). The optimization process of collectors and PV panels is revealed in Figure 16.

Figure 15.

BIM model of PV system. (a) BIM model of PV modules; (b) BIM model of inverter and distribution box.

Figure 16.

The optimization of building shape through the collector and PV panels design.

4.4. Collaboration-Oriented Active Design

The energy consumption of residential buildings is mainly from heating, cooling, hot water, lighting, etc. In the design of T&A House, in addition to the use of passive design to reduce building energy consumption, the use of active technology is also a critical part. Active design reduces energy consumption by increasing the energy efficiency of systems and equipment. The design of active equipment requires the collaboration of various disciplines, and the specific collaboration methods are shown in Table 5.

Table 5.

The collaboration-oriented active design in the refining design stage.

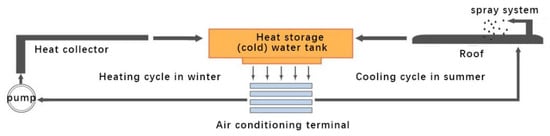

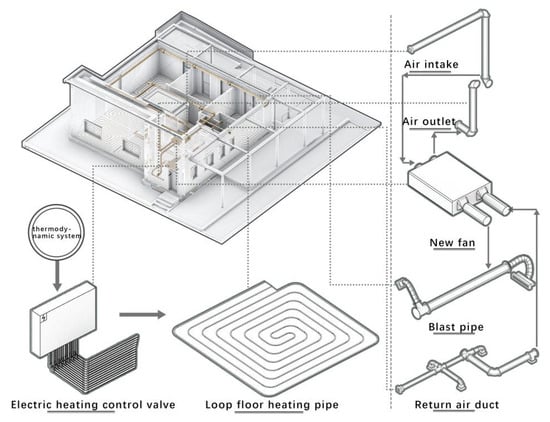

4.4.1. Collaboration in Designing Thermal System

The thermal system is important but rather complex in the design of ZEB. After considering the climate data of Zhangjiakou City, the requirements of SDC competition and relevant design specifications, the energy and power engineering specialists finally selected the solar water source HP system from five alternative schemes. This thermal system mainly includes three parts: the heat collector system, central control unit and heating, ventilation and air conditioning (HVAC) system.

The heat collector system, as an active solar energy utilization system, can avoid the use of electric energy for heating, thereby reducing energy consumption and improving the efficiency of energy use. The working principle of the heat collector system is shown in Figure 17. In summer, cold water collected at night from the roof sprinkler is supplemented to the cold water storage tank and circulates through the thermal system. In winter, hot water obtained from the heat collector is pumped through the thermal system for residential heating.

Figure 17.

Working principle of heat collector in winter and summer.

In the preliminary design stage, the heat collector system designers collaborated with the architectural designers to optimize the roof form of the house in terms of collector size, preliminary selection and arrangement. In the refining stage, their priority was to refine the size, composition materials, installation and connection methods of the collector. By using Fluent, the collector designers obtained the influence of wall thickness, pipe diameter, insulation layer thickness, different materials and ambient temperature changes on the insulation performance of collector tubes. By using WORKBENCH(See Supplementary Materials) to analyze and compare variables, they further verified the calculation results and finalized the material scheme. The total size of the horizontal row of collector tubes on the roof is 5100 mm × 1620 mm. According to the relevant parameter information in the BIM model of the collector, the structural designers calculate the uniform load, moment of inertia and allowable deformation of the collector tube. In order to meet the stiffness requirements of the horizontal tube, the structural designers set seven collector supports on the roof to hold the casing, with a maximum interval of 2.7 m. The vertical pipe of the collector tube is made of stainless steel to achieve the required rigidity and strength with no supporting structure being provided. The 90° elbow is selected to smoothly connect the horizontal tube and the vertical tube, which can not only reduce the flow resistance but also has a certain aesthetic value to meet the integration requirements of the collector tube and the building shape. The BIM model of the collector system is shown in Figure 18, and specifications of the heat collector tube are shown in Table 6.

Figure 18.

BIM model of collector system.

Table 6.

Specifications of heat collector tube.

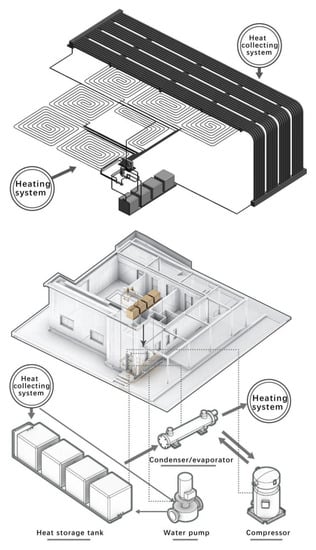

After the heat collector area and system performance are determined by the collector system designers, the designers responsible for the central control unit of the thermal system calculate the volume of the storage water tank and select other equipment components in the system, such as compressors, condensers, evaporators, throttling mechanisms and auxiliary equipment. After this step, the central control unit designers build models in Revit(See Supplementary Materials) (Figure 19) for connecting the solar collector with the indoor terminal equipment so that the water can circulate in the collector tube, the water tank and the HVAC equipment and transmit the energy obtained by the solar collector to the indoor equipment for heating. During this design process, the central control unit designers constantly coordinate with the designers of the collector system and HVAC system to modify the design of the entire thermal system.

Figure 19.

BIM model of central control unit system.

4.4.2. Coordination in Designing HVAC System

In HVAC system design, the energy and power engineering specialists who take the leading role need to produce the BIM of the HVAC system, collaborate with the designers of the collector system and central control system from the same discipline and cooperate with designers from other disciplines.

Based on the refinement of the specific composition and heat transfer coefficient of the envelope structure by the architectural and structural specialists, HVAC designers calculate the heat input from the building envelope, the solar radiation through the external windows and the heat dissipation generated by indoor equipment, lighting systems, human movement, etc. According to the obtained initial cooling and heating load of T&A House, it is determined that T&A House should adopt a floor heating system in winter, radiant cooling ceiling system in summer and independent indoor fresh air system in winter and summer.

Low-temperature hot water in the floor heating system is regulated by the central control unit to provide heat uniformly by heat radiation and convection. The heat dissipation area is about 105 m2, including the master bedroom, the secondary bedroom, the large open space and the dining room. Considering the climatic characteristics and heating needs of Zhangjiakou City, the indoor temperature of T&A House in winter is set to 20 °C and the humidity to 50% to meet the design standards and energy consumption requirements. As regards the layout of floor heating, rather than accommodating the traditional room layout, the heating region is divided into seven parts according to the division of the house modules. Each floor heating module has an independent water inlet and return pipe, which can be controlled separately according to actual needs.

The air conditioning system, composed of an independent fresh air system and radiant cooling ceiling panels, can avoid moisture condensation on the radiant ceiling, save energy from the ventilator and improve the cooling effect of the ceiling by 15~20%.

Before the design and selection of a fresh air system, the designers calculate the fresh air volume and exhaust air volume according to the relevant specifications and further calculate the fresh air load, moisture load and sensible load. According to the calculation results, the cooling and dehumidification configuration scheme of the fresh air system is selected.

The heat transfer of the radiant cooling ceiling and the required area are calculated, and the results suggest that the thin pipe of the radiant cooling ceiling should be embedded into the gypsum radiant panels. After completing the design of the floor heating system, fresh air system and radiant cooling ceiling, the design of the HVAC system is basically completed. The BIM model is shown in Figure 20.

Figure 20.

BIM model of HVAC system.

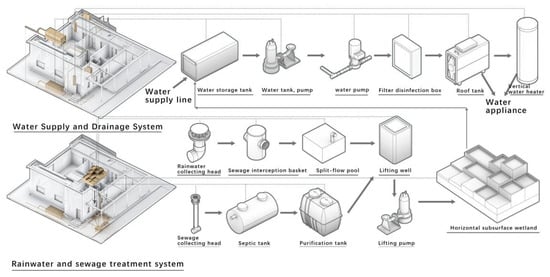

4.4.3. Coordination in Designing Water Treatment System

The water treatment system of T&A House mainly includes two parts: the water supply/drainage system and the rainwater/sewage treatment system. The above two parts are inseparable in the design and are jointly completed by environmental engineering designers and architectural, indoor and electrical specialists.

Rainwater is treated in T&A House in two ways: natural filtration and purification and recycling. The first method is mainly realized through rainwater gardens, which are mainly combined with site design in the preliminary design stage to achieve functional and aesthetic synergy. The second method—recycling—is achieved by collecting rainwater on the roof. It is the environmental engineering designers who recommend that the architectural and structural designers use the roof slope to collect rainwater so as to reduce the use of equipment and save energy. After confirming the inclined roof scheme, the structural designers tilt the roof of the south module slightly to the north to guide the rainwater to the rainwater collecting head arranged on the west side of the rainwater channel.

For the treatment of domestic sewage from toilets, kitchen and laundry, besides the set of equipment used in rainwater treatment, septic tank, purification tank and lifting pump are added. Therefore, rainwater and sewage system designers need to constantly coordinate and communicate with designers from other disciplines to confirm the size, quantity and layout of structures to avoid repeated design and collision during model design (Figure 21).

Figure 21.

BIM model of water treatment system.

The water supply and drainage system of T&A House is the responsibility of the water supply and drainage specialists from environmental engineering. Through comparative analysis of the advantages and disadvantages of different water supply types and the water demand of T&A House, the plan of using the municipal water supply system and tank water supply was selected. Water from the municipal water supply system is mainly used in washing and showering, while the supply from the water tank, mainly the treated rainwater, is used for the cleaning of toilets, garages and PV panels. After communicating with the PV system designers, the water supply and drainage specialists determined that the water tank should be located on the roof and placed higher than the PV panels, which by gravity can avoid the use of power. The water tank is equipped with an automatic control system. When the water tank cannot meet the demand, it can be supplemented by the municipal pipe network. Through the calculation and verification of the hydraulic capacity from municipal water supply system and waste of the water supply network, the water pressure can meet the daily water supply demand of T&A House.

4.4.4. Coordination in Designing Intelligent Control System

The hardware components of the intelligent control system in T&A House include sensors for induction detection, a tablet computer for core control and WIFI for real-time monitoring. In terms of software, the design and program selection of three monitoring modules of indoor environment, sewage treatment and temperature control are selected through Matlab (See Supplementary Materials) simulation. The design of intelligent systems requires the collaboration of electrical engineering specialists with indoor, environmental engineering, energy and power engineering specialists.

In terms of indoor environmental monitoring, according to the requirements of the SDC competition and the ZEB, indoor temperature and humidity, CO2 concentration and PM2.5 are monitored. Before the intelligent control designers design the specific monitoring system, interior specialists should provide space division and furniture layout, on the basis of which the hardware can be selected. According to the floor plan, three I/O modules and four sensors are selected to monitor the master bedroom, the secondary bedroom and the public area. I/O devices in Kingview software are set up by intelligent control designers to complete the hardware connection of monitoring modules and set relevant parameter variables.

The monitoring of a sewage treatment system requires the cooperation of intelligent control designers and sewage treatment designers. Based on the detailed water treatment process and component size provided by the water treatment specialists, the intelligent control designers monitor the level of the reservoir, lifting shaft and roof water tank in the process. According to the monitoring results, the intelligent controllers select the type and quantity of the monitoring hardware and connect the monitoring system to the corresponding process of the water treatment system to realize the intelligent monitoring of the water treatment system.

The temperature control in T&A House has two types: passive and active. The passive temperature control includes four modes: landscape microclimate, SST wall adjustment, sunshine room and atrium adjustment. The active type mainly uses the intelligent temperature control system to adjust the heating and cooling temperature of mechanical equipment. Therefore, the temperature control of T&A House needs to be coordinated and designed by intelligent control and thermal system specialists. Intelligent control specialists monitor the outlet water temperature of collector tubes and add intelligent three-way valves to select different water supply routes for different water temperatures in heating and cooling cycles, thus forming a dual-purpose system for heating and cooling. In winter, when the outlet water temperature of the collector tube reaches 55 °C, hot water can be supplied directly. When the set value is not reached, it needs to be heated to the specified temperature through the heat exchange device. In summer, when the temperature of cold water obtained from roof spraying is below 17 °C, it can be directly supplied to the radiant cooling ceiling. When the water temperature exceeds 17 °C, it needs to be cooled by the heat exchange system first and then supplied.

4.5. Functions of BIM in Collaborative Design of T&A House

The design process of T&A House involves many disciplines. In order to solve the problem of collaboration in the design process of T&A House, a unified BIM working platform is established to ensure timely and effective multi-disciplinary communication and real-time sharing of model information. It can integrate the concept of zero energy consumption and performance-based design into architectural design. The BIM-based collaborative design of T&A House includes two aspects: multi-disciplinary interactive collaborative modeling and energy consumption simulation and analysis.

4.5.1. Multi-Discipline Interactive Collaborative Modeling

In the design phase of T&A House, the elevation grid for the project, which serves as the basic standard of the design modeling for all disciplines, was established in Revit by the leader of architecture discipline. Following this, a preliminary BIM based on the conceptual model was built by the architectural designers. The details of the conceptual design, preliminary design and refining stage reached LOD100, LOD200 and LOD300 respectively.

Owing to the small size of T&A House and the simple overall structure, the structure specialists could proceed with structural modeling on the BIM model provided by the architecture specialists. Then, the model was imported into YJK (See Supplementary Materials) software through the YJK–Revit conversion interface for structural analysis and calculation and then reloaded into Revit to form structural analysis model automatically. The design load and other information were added to complete the load calculation of the structure. After that, the YJK model and the designed structure were imported into ANSYS (See Supplementary Materials) for elastic–plastic dynamic time-history analysis and construction simulation analysis. Finally, the models were merged in Navisworks for professional reviewing.

The electrical engineering specialists created and refined the BIM model of the solar PV system. After establishing the e-template, they linked the existing documents of the architectural discipline to the current project and imported information such as elevation and grid to ensure synchronous updating. The calculation of illuminance and load was carried out in Revit to determine the dimensions of the inverter, distribution box and other related equipment.

The energy and power engineering specialists were responsible for the modeling of the collector system, thermal central control system and HVAC system in the T&A House, including the layout of equipment, terminals, pipelines and pipeline accessories. In this process, they made constant adjustments and refinements on the shared model by incorporating information from other specialists. The BIM tools that the energy and power engineering specialists used could simulate the energy consumption and estimate the cooling and heating load according to the building size. Then, they adjusted the model according to the calculation results to achieve the goal of zero energy consumption.

The environmental engineering specialists established a BIM model based on the one created by the architectural designers, but they also developed a BIM project template for their own discipline to model the rain and sewage system and the water supply and drainage system (mainly including models of various water pipes and corresponding valves). The selection and layout of water pumps and water tanks was completed with BIM plug-ins. Since different disciplines collaborate in an interlinking pattern, environmental engineering specialists can use the filter function in BIM to select all the equipment requiring the cooperation of the environmental engineering discipline and import any changes into the environmental engineering model with the copy/monitoring function. In this way, when the upstream disciplines modify the model, the environmental engineering discipline can receive the modification prompt and make relevant adjustments.

Figure 22.

Collaborative modeling contents across disciplines.

Table 7.

Collaborative modeling contents across disciplines.

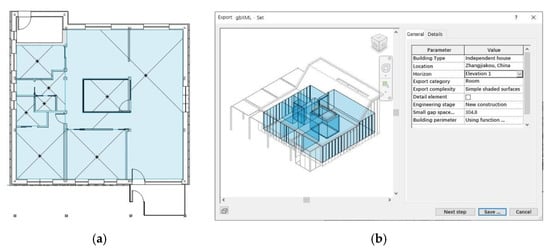

4.5.2. Simulation Analysis of Energy Consumption of T&A House

During the design process of T&A House, Hongye software (HY-EP) (See Supplementary Materials) is used to simulate the main load and energy consumption. Based on the full information model system of BIM, each discipline optimizes and adjusts its own design according to the results of residential energy consumption simulation.

When carrying out load calculation and energy consumption simulation for T&A House with HY-EP, the model was first simplified in Revit, with unnecessary equipment deleted. The rooms were then divided into eight regions (master bedroom, secondary bedroom, primary bathroom, secondary bathroom, shower room, atrium, kitchen and public area) and simulated accordingly (Figure 23a). After that, the elevation of the rooms was modified and confirmed. Some further configurations, such as building location and building type, could be set when exporting the model in GBXML format (Figure 23b).

Figure 23.

BIM space model export. (a) Room division; (b) exporting in GBXML format.

In HY-EP, the gbXML file could be imported through the BIM interface. The spatial data in the Revit model were synchronized to the software so that the load could be calculated and the results could be viewed directly. Then, the air conditioning system was established in HY-EP by specifying parameters including cold/heat source, cooling system, fresh air system, HP system and heating system, which could be used to simulate residential energy consumption.

The comprehensive energy consumption value is the total energy consumption from heating, cooling, lighting, domestic hot water and elevator systems (excluding renewable energy power generation) minus the renewable energy power generation. The simulated energy consumption of T&A House is shown in Table 8. Compared with the official technical standard for nearly zero energy buildings in China (GB/T51350-2019) [41] which stipulates that “ZEB is an advanced form of Nearly Zero Energy Building, which makes full use of the renewable energy resources of the building and its surrounding areas, so that the annual productivity of renewable energy is greater than or equal to the total energy consumption of the building throughout the year, and the comprehensive energy consumption value of Nearly Zero Energy Building should be ≤55 kWh/m2·a”, the comprehensive energy consumption value of T&A House (52.26 kWh/m2·a) meets the requirements. The annual power consumption of T&A House is 6961 kWh, and the annual power generation of PV power generation system is 7820 kWh, which indicates that “the annual capacity of renewable energy is greater than the total annual energy consumption of buildings”. In theory, T&A House meets the standards and requirements of a ZEB. However, the software simulation has certain limitations, and the results can only be used as reference. The real energy consumption data were measured on site after the construction of T&A House.

Table 8.

Simulation results of energy consumption in T&A House.

5. Actual Effect of the Project

This project was completed in September 2021 in Zhangjiakou City, China. T&A House aimed to achieve zero energy consumption, highlighting its advantages of reducing energy consumption, improving living comfort and intelligent control and providing reference and ideas for the design of new rural housing in Zhangjiakou City and ZEBs in China in the future. The actual effect of the project is shown in Figure 24. On the basis of the original scheme, the T&A House was further optimized during the construction process.

Figure 24.

Photos of T&A House. (a) Project construction base; (b) southwest view of T&A House; (c) horizontal view of T&A House.

6. Discussion and Conclusions

The experience of applying BIM to the collaborative design of ZEBs is summarized through method research and verification in the actual design and construction of the T&A House in the Solar Decathlon China (SDC) competition.

(1) BIM-based collaborative design can expand participants’ knowledge and facilitate a collaborative process. Professionals who collaborate with each other should take the initiative to acquire knowledge from other disciplines to promote collaboration. Otherwise, due to the lack of understanding across disciplines, repeated revisions may surface when dealing with design conflicts, such as the conflict between architectural design and structural design. This would greatly reduce the efficiency of cooperation.

(2) The leading professionals, who can guide the collaborative process, should be determined in each stage. In the passive design, the collaborative process is led by professionals from architectural discipline, but in active design, the collaboration is dominated by those from other disciplines. When conflicting opinions in the collaborative process appear, the leading professionals make the final decision. In addition, architectural professionals, as the process-control staff, should master the overall process and the completion status of each stage and manage the models and data of each discipline.

(3) The collaborative process should be refined to optimize collaborative design. Due to the fact that the entire collaborative design lacks a detailed BIM collaboration flowchart and has only a rough specification of the collaboration stages and collaboration content, problems frequently occur in the actual design. For example, some individual disciplines cannot keep up with the collaborative progress or modify the design multiple times. In the collaborative design of the T&A home, the architectural designers first produce the shape scheme and then cooperate with PV collector designers to optimize the scheme. As a result, the architectural designers have to undertake double workload in terms of design and refinement. The ideal procedure is that before the design of the residential shape, the PV collector designers need to synchronize the PV panel area, installation location, collector area and other information with the architectural designers, who can use this information to generate the residential shape in one step.

(4) The optimization standard should be set to assist decision-making. In the collaborative process, architectural professionals start by providing the initial design which will be verified by related disciplines and then receive feedback from them to refine the design. Theoretically, this process is a loop with continued refinement followed by each modification. Therefore, a standard (such as the Energy Consumption Index) needs to be set to evaluate whether subsequent refinement is required.

(5) Project files should be created to store data backup. Process data should be retained as a reference due to multi-rounds of feedback and revisions from various disciplines. Specific project files should be created to manage these data.

This paper aims to explore the BIM-based collaborative design method of ZEBs. Through a literature review, the advantages of BIM technology and BIM collaborative design are expounded, and the difficulties in the collaborative design of ZEBs are pointed out. On this basis, a BIM-based collaborative design method of ZEBs is proposed, and the technical strategy is illustrated. Finally, the effectiveness of the method is verified in the real case of T&A house.

Based on the literature research, this study makes the following contributions to the BIM-based collaborative design of ZEBs.

(1) While other research adopts BIM in individual stages, this study has fully applied BIM in every stage from preliminary design, collaborative optimization and simulation verification to construction.

(2) Based on the analysis of the conditions and feasibility collaborative design with BIM in other studies, this study proposes a BIM-based collaborative design method for ZEBs. This approach not only requires a combination of passive design, active design and renewable energy technologies but also challenges the limitations of traditional collaborative design approaches. It is a complex design process that requires collaboration between architecture, energy, electromechanical and other professional disciplines

(3) The practical value of BIM collaborative design method for ZEBs is verified in the case of T&A House. The six disciplines of architecture, interior design, structure, energy and power, electrical engineering and environmental engineering collaborate on BIM in the stages of preliminary planning, scheme generation and equipment-refining and successfully achieve better results in reducing energy consumption and improving indoor comfort in the T&A House.

Supplementary Materials

The following supporting information can be found at: https://www.mdpi.com/article/10.3390/en15197185/s1, software: Ecotect, software: Fluent, software: Revit, software: Matlab, software: YJK, software: ANSYS & WORKBENCH, software: HYMEP for Revit.

Author Contributions

Conceptualization, G.Y. and P.L.; Data curation, W.X.; Formal analysis, N.C.; Funding acquisition, P.L.; Investigation, Y.R.; Methodology, G.Y.; Project administration, P.L.; Resources, Y.C.; Software, N.C.; Supervision, P.L.; Validation, G.Y., P.L. and W.X.; Visualization, Y.C.; Writing—original draft, Y.R.; Writing—review & editing, G.Y. and Y.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by National Key R&D Program of China, grant number 2018YFD1100900.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

Nomenclature

| T&A House | China University of Mining and Technology and Akademia Górniczo-Hutnicza House |

| SDC | Solar Decathlon China |

| BIM | Building Information Modeling |

| SST wall | Selective sun tunnel wall |

| LOD | Level of detail |

| HVAC | Heating, Ventilation and Air Conditioning |

| ZEB VMS | Zero energy building VELUX modular system |

References

- He, B.; Yang, L.; Ye, M.; Mou, B.; Zhou, Y. Overview of rural building energy efficiency in China. Energy Policy 2014, 69, 385–396. Available online: https://iopscience.iop.org/article/10.1088/1755-1315/410/1/012073 (accessed on 10 January 2022). [CrossRef]

- China Building Energy Consumption Research Report. 2020. Available online: https://www.cabee.org/site/content/24020.html (accessed on 4 January 2021).

- Rhodes, C.J. The 2015 Paris Climate Change Conference: Cop21. Sci. Prog. 2016, 99, 97–104. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.; Liu, Y.; He, B.-J.; Xu, W.; Jin, G.; Zhang, X. Application and suitability analysis of the key technologies in nearly zero energy buildings in China. Renew. Sustain. Energy Rev. 2019, 101, 329–345. [Google Scholar] [CrossRef]

- Zhang, S.-C.; Yang, X.-Y.; Xu, W.; Fu, Y.-J. Contribution of nearly-zero energy buildings standards enforcement to achieve carbon neutral in urban area by 2060. Adv. Clim. Chang. Res. 2021, 12, 734–743. [Google Scholar] [CrossRef]

- Xu, W.; Yang, X.; Zhang, S. Key Issues and Solutions for the Development of Near-Zero Energy Buildings in China. Build. Sci. 2018, 34, 165–173. [Google Scholar]

- Nearly Zero Energy Buildings Are Highly Anticipated. Available online: http://paper.people.com.cn/zgnyb/html/2022-01/10/content_25898332.htm (accessed on 10 January 2022).

- Wang, J.; Yu, C.W.; Cao, S.-J. Technology pathway of efficient and climate-friendly cooling in buildings: Towards carbon neutrality. Indoor Built Environ. 2021, 30, 1307–1311. [Google Scholar] [CrossRef]

- Zhang, Y.; Kang, J.; Jin, H. A review of green building development in China from the perspective of energy saving. Energies 2018, 11, 334. [Google Scholar] [CrossRef]

- Liu, Z.; Zhou, Q.; Tian, Z.; He, B.-J.; Jin, G. A comprehensive analysis on definitions, development, and policies of nearly zero energy buildings in China. Renew. Sustain. Energy Rev. 2019, 114, 109314. [Google Scholar] [CrossRef]

- Solar Decathlon China. Available online: https://scoring.sdchina.org.cn/ (accessed on 8 August 2022).

- Khosakitchalert, C.; Yabuki, N.; Fukuda, T. Automated modification of compound elements for accurate BIM-based quantity takeoff. Autom. Constr. 2020, 113, 103142. [Google Scholar] [CrossRef]

- Uddin, M.N.; Wei, H.H.; Chi, H.L.; Ni, M. An Inquisition of Envelope Fabric for Building Energy Performance Using Prominent BIM-BPS Tools-A Case Study in Sub-Tropical Climate. IOP Conf. Ser. Earth Environ. Sci. 2019, 354, 012129. [Google Scholar] [CrossRef]

- Bonomolo, M.; Di Lisi, S.; Leone, G. Building Information Modelling and Energy Simulation for Architecture Design. Appl. Sci. 2021, 11, 2252. [Google Scholar] [CrossRef]

- El Sayary, S.; Omar, O. Designing a BIM energy-consumption template to calculate and achieve a net-zero-energy house. Sol. Energy 2021, 216, 315–320. [Google Scholar] [CrossRef]

- Gumbarević, S.; Burcar Dunović, I.; Milovanović, B.; Gaši, M. Method for Building Information Modeling Supported Project Control of Nearly Zero-Energy Building Delivery. Energies 2020, 13, 5519. [Google Scholar] [CrossRef]

- Abouhamad, M.; Abu-Hamd, M. Life Cycle Assessment Framework for Embodied Environmental Impacts of Building Construction Systems. Sustainability 2021, 13, 461. [Google Scholar] [CrossRef]

- Singh, P.; Sadhu, A. Multicomponent Energy Assessment of Buildings using Building Information Modelin. Sustain. Cities Soc. 2019, 49, 101603. [Google Scholar] [CrossRef]

- Feng, H.; Liyanage, D.R.; Karunathilake, H.; Sadiq, R.; Hewage, K. BIM-based life cycle environmental performance assessment of single-family houses: Renovation and reconstruction strategies for aging building stock in British Columbia. J. Clean. Prod. 2019, 250, 119543. [Google Scholar] [CrossRef]

- Liu, H.; Abudayyeh, O.; Liou, W. BIM-Based Smart Facility Management: A Review of Present Research Status, Challenges, and Future Needs. In Proceedings of the Construction Research Congress 2020: Computer Applications. Construction Research Congress (CRC) on Construction Research and Innovation to Transform Society, Tempe, AZ, USA, 8–10 March 2020; Available online: https://ascelibrary.org/doi/10.1061/9780784482865.115 (accessed on 20 May 2022).

- Guo, K.; Li, Q.; Zhang, L.; Wu, X. BIM-based green building evaluation and optimization: A case study. J. Clean. Prod. 2021, 320, 128824. [Google Scholar] [CrossRef]

- Kamel, E.; Memari, A.M. Review of BIM’s application in energy simulation: Tools, issues, and solutions. Autom. Constr. 2019, 97, 164–180. [Google Scholar] [CrossRef]

- Bracht, M.K.; Melo, A.P.; Lamberts, R. A metamodel for building information modeling-building energy modeling integration in early design stage. Autom. Constr. 2021, 121, 103422. [Google Scholar] [CrossRef]

- Gao, H.; Koch, C.; Wu, Y. Building information modelling based building energy modelling: A review. Appl. Energy 2019, 238, 320–343. [Google Scholar] [CrossRef]

- Jassawalla, A.R.; Sashittal, H.C. An examination of collaboration in high-technology new product development processes. J. Prod. Innov. Manag. 1998, 15, 237–254. [Google Scholar] [CrossRef]

- Cao, D.; Li, H.; Wang, G.; Huang, T. Identifying and contextualising the motivations for BIM implementation in construction projects: An empirical study in China. Int. J. Proj. Manag. 2016, 35, 658–669. [Google Scholar] [CrossRef]

- He, Q.; Wang, G.; Luo, L.; Shi, Q.; Xie, J.; Meng, X. Mapping the managerial areas of Building Information Modeling (BIM) using scientometric analysis. Int. J. Proj. Manag. 2016, 35, 670–685. [Google Scholar] [CrossRef]

- Chen, S.Y. Use of Green Building Information Modeling in the Assessment of Net Zero Energy Building Design. J. Environ. Eng. Landsc. Manag. 2019, 27, 174–186. [Google Scholar] [CrossRef]

- Wu, K.; Tang, S. BIM-Assisted Workflow Enhancement for Architecture Preliminary Design. Buildings 2022, 12, 601. [Google Scholar] [CrossRef]

- Grilo, A.; Jardim-Goncalves, R. Value proposition on interoperability of BIM and collaborative working environments. Autom. Constr. 2010, 19, 522–530. [Google Scholar] [CrossRef]

- Ozturk, G.B. The Relationship Between BIM Implementation and Individual Level Collaboration in Construction Projects. IOP Conf. Ser. Mater. Sci. Eng. 2019, 471, 022042. [Google Scholar] [CrossRef]

- Lin, Y.-C.; Yang, H.-H. A Framework for Collaboration Management of BIM Model Creation in Architectural Projects. J. Asian Arch. Build. Eng. 2018, 17, 39–46. [Google Scholar] [CrossRef]

- Azhar, S. Building Information Modeling (BIM): Trends, Benefits, Risks, and Challenges for the AEC Industry. Leadersh. Manag. Eng. 2011, 11, 241–252. [Google Scholar] [CrossRef]

- Bryde, D.; Broquetas, M.; Volm, J.M. The project benefits of Building Information Modelling (BIM). Int. J. Proj. Manag. 2014, 31, 971–980. [Google Scholar] [CrossRef]

- Gavali, H.R.; Ralegaonkar, R.V. Application of Information Modelling for Sustainable Urban-Poor Housing. In Proceedings of the Institution of Civil Engineers-Engineering Sustainability; Ice Publishinginst Civil Engineers: Westminister, England, 2018; pp. 1–29. [Google Scholar] [CrossRef]

- Oraee, M.; Hosseini, M.R.; Edwards, D.J.; Li, H.; Papadonikolaki, E.; Cao, D. Collaboration barriers in BIM-based construction networks: A conceptual model. Int. J. Proj. Manag. 2019, 37, 839–854. [Google Scholar] [CrossRef]

- Nikas, A.; Poulymenakou, A.; Kriaris, P. Investigating antecedents and drivers affecting the adoption of collaboration technologies in the construction industry. Autom. Constr. 2007, 16, 632–641. [Google Scholar] [CrossRef]

- Zhao, X. Modelling risk paths for BIM adoption in Singapore. Life-Cycle Analysis and Assessment in Civil Engineering: Towards an Integrated Vision. In Proceedings of the 6th International Symposium on Life-Cycle Civil Engineering (IALCCE), Ghent, Belgium, 28–31 October 2018; Available online: https://acquire.cqu.edu.au/articles/conference_contribution/Modelling_risk_paths_for_BIM_adoption_in_Singapore/13447877 (accessed on 10 January 2022).

- Eadie, R.; Browne, M.; Odeyinka, H.; Mckeown, C.; Mcniff, S. BIM implementation throughout the UK construction project lifecycle: An analysis. Autom. Constr. 2013, 36, 145–151. [Google Scholar] [CrossRef]

- Andriamamonjy, A.; Saelens, D.; Klein, R. A combined scientometric and conventional literature review to grasp the entire BIM knowledge and its integration with energy simulation. J. Build. Eng. 2018, 22, 513–527. [Google Scholar] [CrossRef]

- Ministry of Housing and Urban-Rural Development of China. Terms. In Technical Standard for Nearly Zero Energy Buildings, 1st ed.; Ministry of Housing and Urban-Rural Development of China; China Architecture & Building Press: Beijing, China, 2019; p. 2. Available online: https://www.mohurd.gov.cn/gongkai/fdzdgknr/tzgg/201905/20190530_240712.html (accessed on 4 June 2021).

- Ministry of Housing and Urban-Rural Development of China. Terms. In Design Standard for Energy Efficiency of Residential Buildings in Severe Cold and Cold Zones, 1st ed.; Ministry of Housing and Urban-Rural Development of China; China Architecture & Building Press: Beijing, China, 2019; p. 2. Available online: https://www.mohurd.gov.cn/gongkai/fdzdgknr/tzgg/201909/20190910_241751.html (accessed on 4 June 2021).

- Hamidi, A.; Ramavandi, B.; Sorial, G.A. Sponge City—An emerging concept in sustainable water resource management: A scientometric analysis. Resour. Environ. Sustain. 2021, 5, 100028. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).