1. Introduction

When faced with increasingly severe environmental pollution, urban traffic congestion, and energy shortages, priority development of hybrid electric vehicles (HEVs) can effectively alleviate the current environmental pollution and energy crisis and, as such, is the main development trend of the automobile industry [

1,

2]. The key powertrain parameters and energy management strategies of hybrid electric vehicles determine the energy consumption and power performance. It is imperative that a particular set of layouts be taken into consideration when designing and matching the parameters of a hybrid electric vehicle powertrain system, since each of these layouts directly impacts the vehicle performance or design objectives, including fuel consumption and emissions [

3,

4]. For a given set of design layouts, identifying the appropriate design parameters that maximize the design objectives of a hybrid electric vehicle is necessary to solve the hybrid electric vehicle design problem [

5,

6]. The study of matching and optimizing the key powertrain parameters can effectively reduce the emissions and energy consumption of the vehicle, hence, in the face of the requirements of energy conservation and environmental protection, hybrid electric vehicles have gradually become a research focus [

7,

8]. Zhao et al. studied the parameter matching and configuration analysis of a fuel cell electric vehicle (EV) driving system. In their study, the hybrid, compensation, and full power type of the fuel EV powertrain were analyzed. Their results showed that the cost, performance, and portability were improved in the full-power type powertrain [

9].

Tran et al. designed a HEV powertrain configuration and components that can satisfy the performance criteria of acceleration, braking, driving range, fuel economy, and emissions given at the EcoCAR Mobility Challenge competition. Their design deduced a P4 powertrain system with a 2.5 L engine, a 150 kW electric motor, and a 133 kW battery pack [

10]. Multi-objective optimization of the HEV transmission system based on an immune genetic algorithm is proposed by Wang, Z. et al. The authors considered the powertrain components and the control strategy as the design variables, the fuel consumption and emissions as the design objectives, and the vehicle’s dynamic performance as the primary constraint condition [

11]. Verbruggen, F.J.R. et al. developed a nested optimization routine which is used to optimize the battery, electric machine size, and the gear ratio values in an outer loop with the particle swarm optimization algorithm and, in the inner loop, the gear shifting is optimized as a local minimization problem. The simulation results showed that electric machine size can be reduced −16% without compromising the vehicle’s top speed and acceleration performance, and with a moderate reduction in energy usage of 1.4% [

12]. Pengxiang et al. proposed a genetic algorithm based on a multi-objective optimization method for matching power sources for PHEV.

Fuel economy and a lightweight quality were considered as the objectives under the performance constraints. In their results, the fuel economy and lightweight quality were increased by 2.26 and 8.26%, respectively [

13]. Xu adopted a hybrid Toyota PRIUS for the optimization and performance analysis of the power system. The author built and optimized the hybrid power system with AVL Cruise, resulting in an optimized system with better performance [

14]. In order to solve the problems of the cumbersome calibration process and the inability of calibration parameters to meet the requirements of different driving cycles, Li et al. proposed an optimization method for calibration parameters for HEV [

15]. Hong et al. designed a parameter tuning-based co-optimization for the HEV powertrain system by leveraging V2V/V2I information to maximize fuel efficiency. The authors achieved an average of 9.22% fuel savings for a random driving cycle on a Toyota Prius test model [

16]. With the aim of guaranteeing the vehicle’s comprehensive performance, a parameter matching and optimization for the power system of range-extended EV based on PSO and sensitivity analysis was proposed by Liu et al. Their results showed a significant influence on the characteristic parameters and the coupling effect in the vehicle performance indicators [

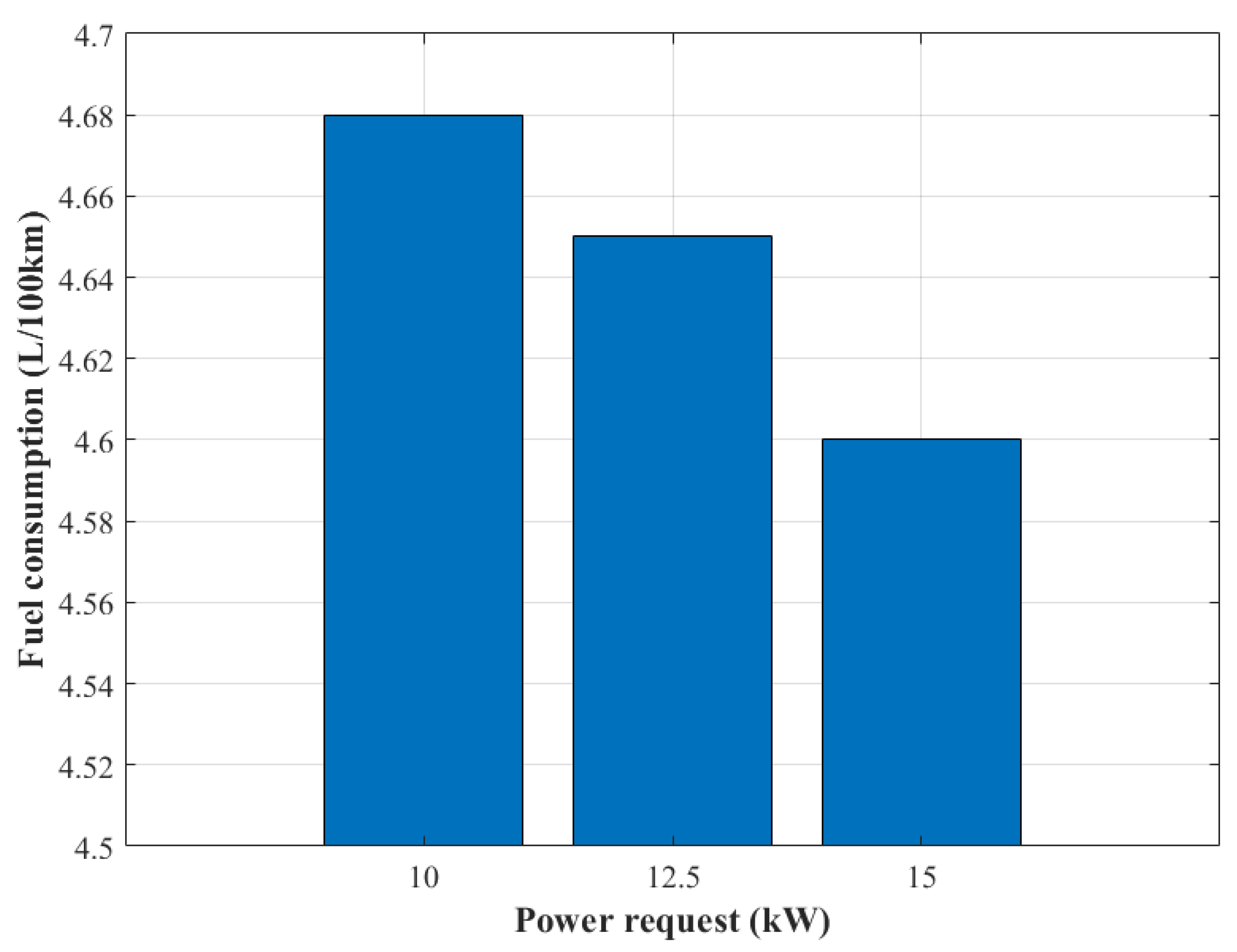

17]. He et al. put forward the parameter matching and simulation analysis of electromechanical coupling devices with the engine, motor, and generator as the characteristic parameters. They recorded fuel consumption of 4.6 L/100 km in NEDC, and the SOC battery was in line with the requirements of the control strategy [

18].

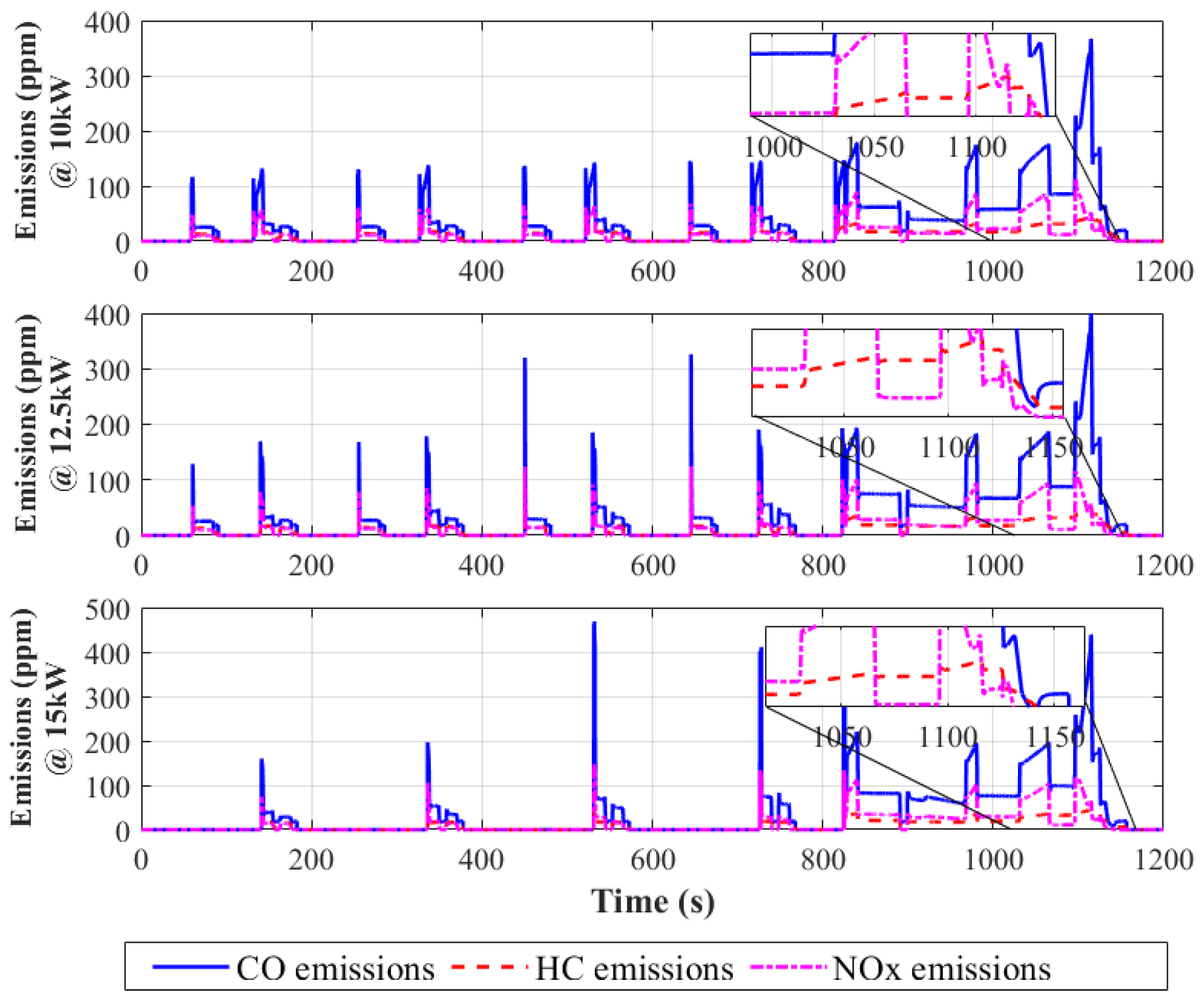

Aiming at problems of large computational complexity and poor reliability, Fu et al. proposed a multi-objective optimization (MOO) scheme for solving the parameter matching optimization of the HEV powertrain system. The authors streamlined the MOO problem for fuel consumption and emission with the weight coefficient method to analyze the parameter ranges of different components. Their results showed a significant reduction in fuel consumption and emissions of the vehicle [

19]. Cao et al. used the hybrid PSO method to solve the parameter matching of dual-clutch transmission for axle-split HEV [

20]. In order to improve the overall performance of EV, Wang and Sun used the quantum genetic intelligent algorithm to determine the parameter optimization of a dual-motor hybrid driving system for EV. According to their results, the quantum GA exhibited good global optimization capabilities, satisfying the design’s dynamic performance and economic requirements. A reduced energy consumption of 15.6% compared with conventional EV was reported in their study [

21]. Due to the fact that less attention is given to electric agricultural machinery, Chen et al. proposed a powertrain parameter matching and optimal design of a dual-motor electric tractor. A PSO algorithm based on a mixed penalty function was used for parameter optimization and designed in MATLAB [

22]. Zhang, Z., et al. proposed a master–slave hybrid electric vehicle (MSHEV) with multiple energy sources, selected the battery SOC of MSHEV as the optimization objective and optimized applicable parameters further. An approximate model was constructed based on the response surface model (RSM), and an optimization model was built based on the multi-island genetic algorithm (MIGA). Their results showed an enhanced SOC and a reasonably optimized MSHEV [

23]. Zhao, Z. et al. introduced a new method for optimizing the energy management strategy (EMS) for a fuel cell vehicle (FCV) to reduce fuel consumption.

A multi-island genetic algorithm was used to optimize the MFs and demonstrated optimized fuzzy control EMS in simulations of two EMSs under four driving cycles. The simulation results confirmed that the optimized fuzzy control EMS provided smoother and more stable output power from FCS, reducing hydrogen consumption by 8.4%, 1.1%, 5.1%, and 7.6%, respectively, compared to the original fuzzy control EMS [

24]. Jibin et al. proposed a parameter matching approach for a hybrid energy storage system based on a multi-objective optimization algorithm with a system simulation model in the loop designed by using an NSGA-II-type genetic algorithm. Considering the important indicator of capacity decay of hybrid energy storage systems in service life, a cumulative penalty factor was added. However, the adopted method did not consider the type of battery and supercapacitor monomer, meaning that the combined consideration of lifetime, price, and cost was highly constrained. Their results indicated a reduction in the performance degradation rate of battery by at least 31.1% when compared with the parameter matching result of the hybrid energy storage system based on the equivalent calculation approach [

25]. Zhang et al. proposed an improved genetic algorithm based on adaptive crossover probability and mutation probability; the algorithm solves the accuracy problem effectively, but the optimization process is complicated [

26].

In the field of classification and prediction, the support vector machine (SVM) based on the kernel method has been used as a powerful tool for solving practical binary classification problems [

27,

28,

29]; it is superior to other supervised learning methods, and the training time is short. Due to their good theoretical foundations and good generalization capacity, SVMs have become one of the most used classification methods. Decision functions are determined directly from the training data by using SVM in such a way that the existing separation (margin) between the decision borders is maximized in a highly dimensional space called the feature space [

30,

31]. This classification strategy minimizes the classification errors of the training data and obtains a better generalization ability, i.e., classification skills of SVMs and other techniques differ significantly, especially when the number of input data is small. Furthermore, SVMs are a powerful technique used in data classification and regression analysis [

32,

33]. Alimi, O.A. et al. presented a hybrid classification technique using support vector machine (SVM) with the evolutionary genetic algorithm (GA) model to detect and classify power system unwanted events in an accurate yet straightforward manner. The performance of the proposed GA-SVM model was evaluated and compared with other models using key classification metrics. In their experimental results, the proposed model improved the classification rate of unwanted events in power systems [

34].

As a popular machine learning algorithm, Jayadeva and Chandra designed two proximal class hyperplanes that theoretically reduce SVM’s training cost by one-fourth [

35]. The twin support vector machines (TSVM) have been developed as successful variants of support vector machines (SVM). They consist of nonparallel hyperplanes, where each hyperplane is either at least one distance from the other class or closer to one of the two classes. Compared to classical classifiers, non-parallel SVMs consider intra-class information and possess vital advantages. As a method of improving the generalization performance of twin-bounded support vector machines, Borah and Gupta proposed a truncated loss function-based algorithm with reduced sensitivity to noise and outliers and for handling class imbalance learning [

36]. The twin bounded support vector machine (TBSVM) was improved by Wang et al. by adding regularization terms to the objective functions [

37]. Using two non-parallel hyperplanes, Zhao adopted two methods to classify the diversity between classes, thereby boosting the performance of non-parallel support vector machine active learning [

38]. In a paper by Chen et al., they developed structural non-parallel support vector machines by using prior knowledge of data to improve generalization performance [

39]. According to Tian et al., non-parallel support vector machines were extended to large data learning by ν-nonparallel support vector machines and a divide-and-conquer method [

40,

41]. Additionally, Ju et al. [

42] proposed a divide-and-conquer method for large scale ν-non-parallel SVMs, similar to [

40].

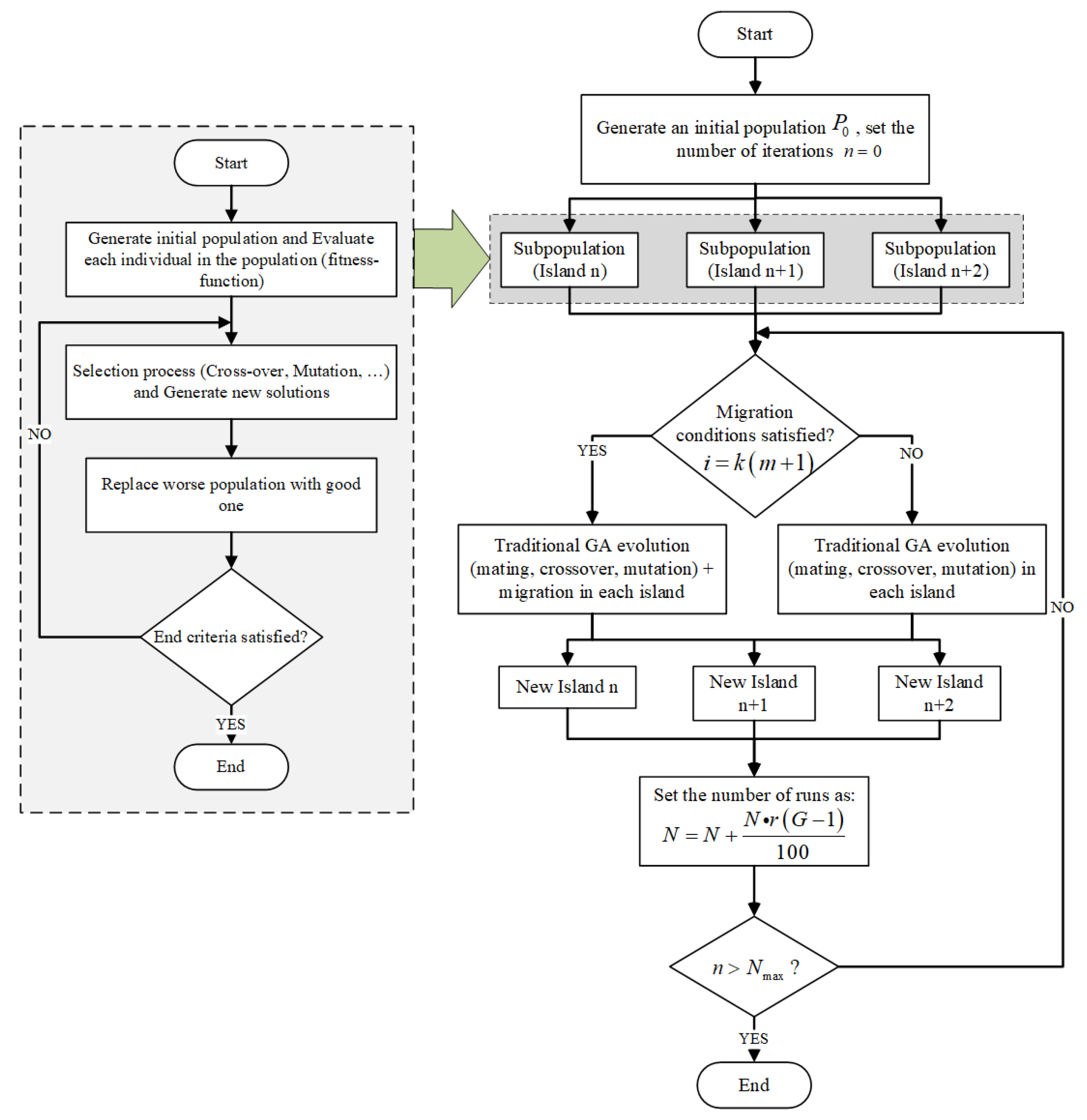

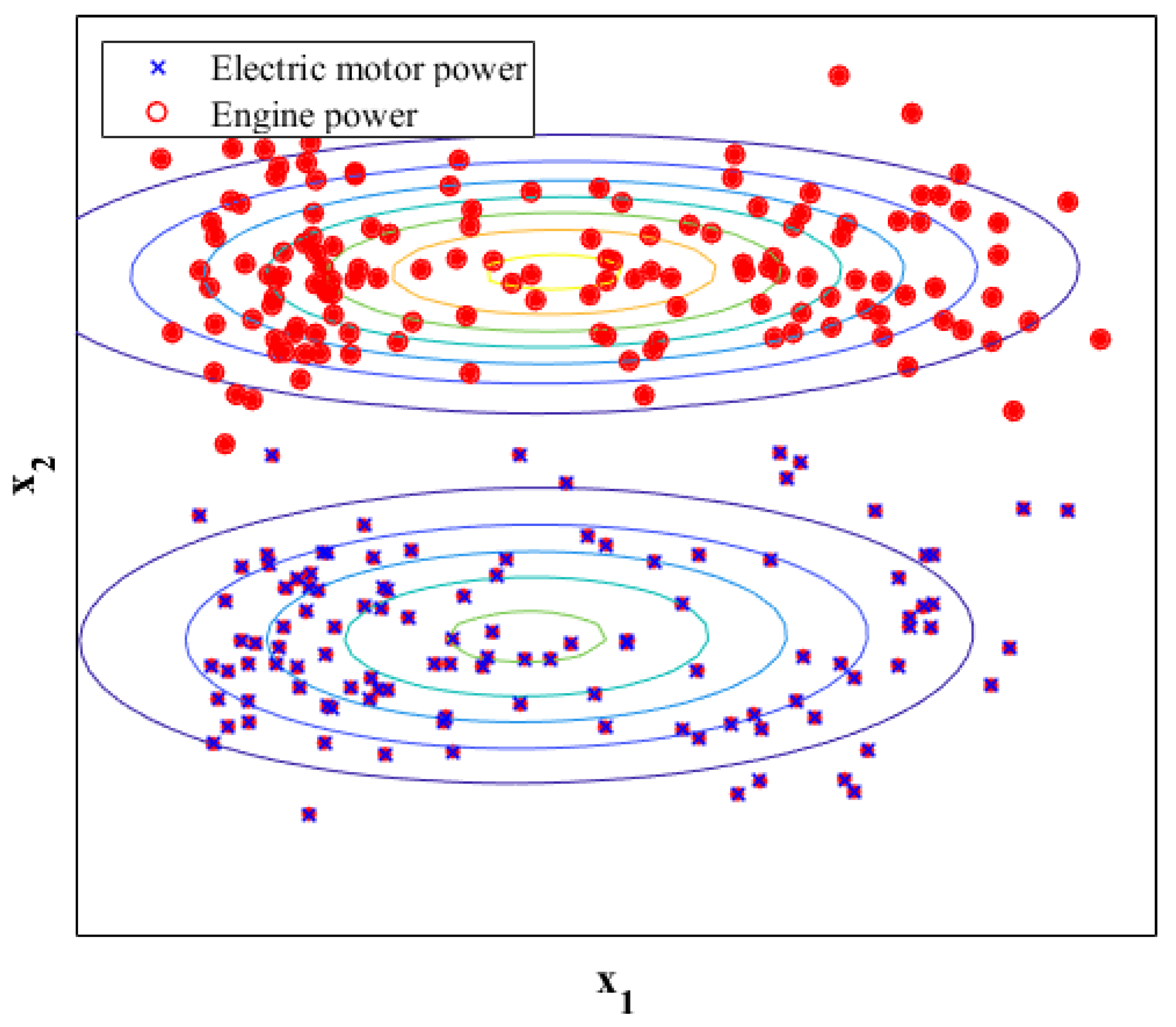

In this study, a foam fire truck hybrid electric emergency rescue vehicle is used as the research object. In summary, the contributions of this study are as follows: (1) Classifying and determining the particular type of emergency rescue vehicle from sets of optimized matched power source parameters of the hybrid electric emergency rescue vehicle using non-parallel SVM classification (NPSVM); (2) combinatorial optimization of theoretical analysis of matching parameters of hybrid electric emergency rescue vehicle using MIGA and NLPQL.

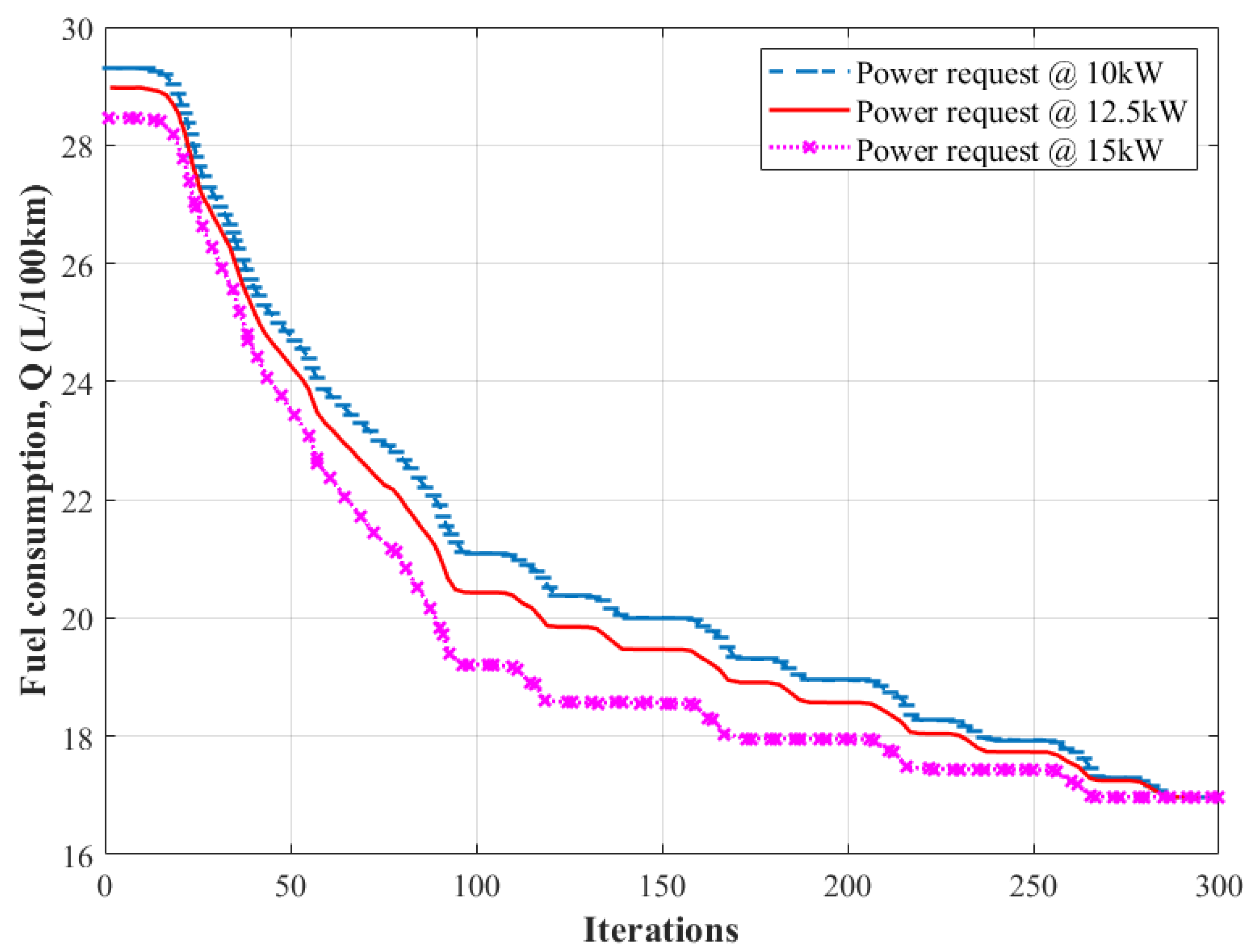

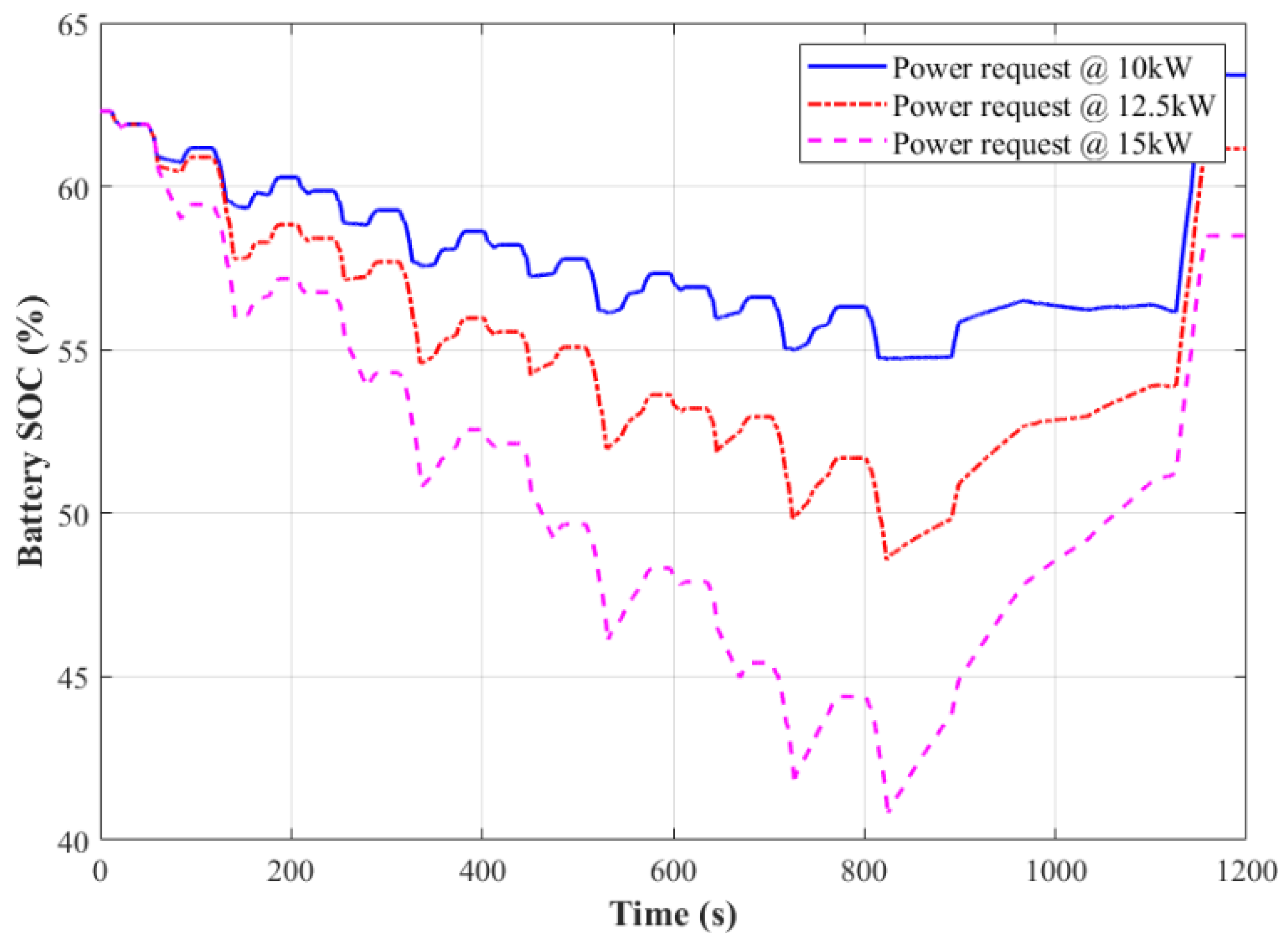

The following methodology was used in the study. Firstly, the matching parameters of the emergency rescue vehicle is achieved by theoretical analysis. Secondly, the matched parameters are optimized using a combined optimization methods of multi-island genetic algorithm (MIGA) and non-linear programming quadratic Lagrangian (NLPQL) methods to determine the dynamic performance of the energy source power output and the battery SOC according to the power request from the driver input. Finally, the optimized matched parameters are classified into different types of emergency rescue vehicles. The proposed method adopted in this study is comprised of the discriminant and Gaussian mixture methods to distinctly classify the optimized matched parameters with a linear kernel function in SVM classification.

The research organization is summarized as follows.

Section 2 presents the parameter matching theoretical analysis of the HE-ERV powertrain system. In

Section 3, MIGA and NLPQL optimization methods are applied to the power source matched parameters. In

Section 4, the support vector machines classification is presented and discussed for the optimized matched parameters. The optimization and classification results are presented and analyzed in

Section 5. Finally, in

Section 6, the conclusion is presented.