Abstract

The deepwater drilling riser is a very important and vulnerable connection between an offshore platform and subsea wellhead. Under some certain complex marine environment and operating conditions, the offshore platform may drift beyond the safe limitations or be driven away rapidly. In order to protect the safety of the platform, personnel and equipment, it is necessary to implement the emergency disconnection of the drilling riser. Since the riser is stretched under a normal connection, the riser will perform a recoil response under the combined effect of elastic potential energy and drilling fluid (mud) discharge frictional resistance after the emergency disconnection. There are complex mechanical mechanisms, influencing factors and difficult safety control problems in the recoil control process. Therefore, effectively controlling the recoil response of the deepwater drilling riser after emergency release has become one of the technical difficulties faced by deepwater drilling. The drilling mud discharge frictional resistance and tensioning force are important factors affecting the recoil response. It is necessary to develop a more general dynamic recoil model for the riser that considers the actual conditions of drilling mud discharge, floating platform motion and nonlinear tensioner factors. This paper introduces the research progress on the recoil analysis and control technology of the deepwater drilling riser, including the discharge, mechanical analysis model, the top tensioner system and control method of the recoil response, which provides a reference for future research on recoil response analyses and design of deepwater drilling risers.

1. Introduction

The deepwater drilling riser connecting the offshore platform and the subsea wellhead is a “borehole in water” and plays an important role in isolating seawater, guiding drilling tools, lowering and recovering the Blowout Preventer (BOP) and so on [1]. It is one important and indispensable piece of equipment for the development of deepwater oil and gas resources. Normally, the deepwater drilling riser consists of a tensioner system, buoyancy module, bare riser joints and other components [2]. During the whole service process, the riser involves a variety of working conditions, such as installation, normal connection, emergency disconnection and suspension, and is subject to environmental loads such as waves, currents and platform offset. It is one of the weakest links in a deepwater drilling system, since it is subject to fracture, wear, fatigue and other mechanical failures. Therefore, it is important to ensure the safety of the deepwater drilling riser system to guarantee the safe and efficient development of deepwater oil and gas resources [3,4].

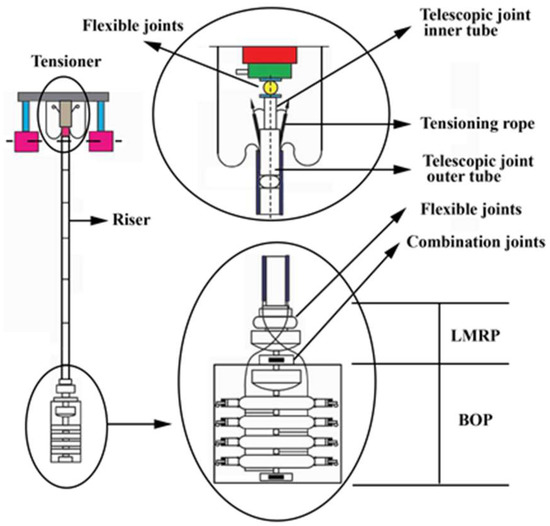

Under normal operating conditions, the floating platform is automatically controlled by the Dynamic Positioning system (DP) to ensure the operational safety of deepwater drilling risers under environmental loads [5,6]. However, in some harsh marine environments or DP failure conditions, the emergency disconnection of the Low Marine Riser Package (LMRP) will be carried out from the BOP. This is to ensure the safety of the deepwater drilling riser and the subsea wellhead [7]. During the normal connection process, the drilling riser is in a stretched state and stores a large amount of elastic potential energy. The stored elastic potential energy of the riser will be released a short time after the emergency disconnection. In this case, the riser will drive the LMRP to vibrate axially, which is called the recoil response [8]. A schematic diagram of the deepwater drilling riser system is shown as Figure 1. If the recoil response is not effectively controlled, there may be a collision between the top tensioner system and the moon pool of the platform or a collision between the LMRP and the BOP. This will result in damage of the riser system or the BOP or even irreversible and catastrophic consequences, such as platform capsizing [9,10]. As the emergency disconnection of the riser usually occurs under extreme conditions, the marine environment is very harsh, and the mechanical behavior is very complicated. Thus, how to ensure the safety of a deepwater drilling riser after emergency disconnection under complicated working conditions is the key and difficulty point of the safe operation of the deepwater drilling riser system [11,12,13].

Figure 1.

Schematic diagram of the deepwater drilling riser system [1].

In summary, the recoil response analysis of a deepwater drilling riser involves many factors, and the mechanical behavior is complex. The safe and reliable control of the recoil response of a deepwater drilling riser is necessary to ensure its safe operation. Therefore, this paper provides a comprehensive introduction to the new progress of the recoil response and control technology of deepwater drilling risers during emergency disconnection, from the point of view of providing scientific guidance for the riser recoil response and safety control of emergency disconnection.

2. Recoil Response Characteristics

Once the LMRP and BOP are disconnected, the elastic potential energy stored in the riser will be released rapidly, and the mud inside the riser will be discharged from the bottom of the LMRP. The riser will be lifted upward rapidly by the combined effect of top tension, mud frictional resistance and elastic potential energy. After the recoil response, the riser is suspended and evacuated together with the platform to avoid damage from the harsh marine environment. Therefore, the operating modes of the drilling riser, the operation of the top tensioner and antirecoil control system, the method of mud discharge and the external conditions of the marine environment are all main factors affecting the recoil behavior response of the riser when the riser is disconnected in case of severe weather.

2.1. Recoil Response Mechanism

The deepwater drilling riser is generally very long, up to several thousand meters, and the length is much greater than the diameter. Therefore, the influence of the riser joint can usually be ignored, and the riser is assumed to be a slender rod with an equal cross-section to analyze the recoil response problem [14,15]. During normal operations, the riser is connected to the top tensioner and in an elongation state. As the water depth becomes deeper, the length of the riser becomes longer, and the top tension force is correspondingly greater [16,17]. Before the emergency disconnection, the riser is deformed under the action of the top tensioner, which will do work to the riser column due to the displacement caused by the deformation, and this work is the strain energy stored in the column. After the disconnection, the riser gradually returns to its original length, and the strain energy stored in the riser is converted into kinetic energy, which is consumed by the frictional resistance of the riser itself, seawater and mud during the recoil response. In addition, there is not enough time for rapid resetting of the tensioner system during emergency disconnection, so the riser will experience large acceleration and axial displacement due to the top tensioning force and will lift rapidly in a relatively short period of time [18].

Generally, to prevent the safety of the tensioner system, telescopic joints, riser and other equipment, as well as platform personnel from being threatened by the recoil, an antirecoil control system will be installed. This system allows for safe emergency disconnection of the riser through reasonable emergency disconnection and recoil control. Up to now, many scholars have conducted extensive and in-depth research on the recoil response and achieved remarkable results. Young et al. [19] analyzed the causes and potential hazards of the deepwater drilling riser during emergency disconnection. Lang et al. [20,21] researched the criteria for safe emergency disconnection. The top tensioner telescopic joint is not beyond the stroke and not subjected to an excessive shock load [22,23]. The reason for that is that the sudden acceleration recoil of the riser may make the telescopic joint of the Direct Acting Tensioner (DAT) exceed the stroke, and the piston rod will break through the tensioner cylinder and transfer the impact force to the offshore platform, which will threaten the safety of the equipment and personnel on the platform. Avoiding a collision between the LMRP and BOP is one of the most important criteria to judge the safe operation of the emergency disconnection [24,25]. The distance between the LMRP and BOP is very short in the initial emergency disconnection, which may lead to a collision between the LMRP and the BOP or other subsea equipment if the offshore platform lifts and sinks at a small amplitude or at a large speed at this time [26]. The riser and attached pipeline cannot produce local compression or flexion [27]. Due to the long length of the riser, the lower column of the riser is the first to accelerate in the initial stage of the recoil response, while the upper column is relatively stationary. After the recoil control system is activated, the upper column will be the first to start braking, and the lower column will continue to move upward under the action of inertia force, which will lead to local compression or even buckling of the riser in the recoil process, causing damage to the riser or the attached pipeline. After the mud is discharged, the seawater can fill the upper column in time to prevent the collapse of the riser [28]. During the rapid discharge of the mud column from the LMRP, there is a risk that the riser may be partially collapsed by the seawater outside the riser if the seawater cannot flow into the riser at a sufficient velocity.

2.2. Mechanical Behavior of Recoil Response

After the emergency disconnection, the top of the riser is always connected to the floating platform by the tensioner system, and the complex motion of the platform is applied on the riser as the top boundary condition of the recoil response. However, unlike ordinary vibration problems, in order to avoid the lowest-order natural frequency of the riser filled with mud from falling into the frequency range of the wave, the mud stored inside the riser will be discharged through the LMRP during the emergency disconnection of the riser. At the same time, in order to prevent the riser from hydrostatic collapse, the filling valve at the top of the riser will automatically open to direct the seawater to fill the inside of the riser. On the other hand, the whole process of the recoil response of the riser is under the seawater, and the riser, buoyancy module and attached pipeline will also generate the damping force distributed along the riser axially and change over time. Therefore, the recoil analysis of the deepwater drilling riser involves the influence of many nonlinear factors, such as the offshore floating platform, top tensioner system, mud viscous resistance, seawater damping force, etc. The mechanical model is very complicated, and the accurate calculations are difficult.

A large number of researchers have researched the recoil response of the riser and have made considerable progress. Young et al. [29] analyzed the design, installation and testing of the recoil control system on the Sonat Discoverer 534 drillship, documented the actual emergency disconnection test process in a 1127.76-m water depth and simulated the recoil response after emergency disconnection of the riser in a 1828.80-m water depth using the RISTEN program. Peter et al. [20] used a finite element program to calculate the tension of the tensioner and the vibration variation of the LMRP during the emergency disconnection of a deepwater drilling riser at different wave phase angles under different water depths and also pointed out that the configuration of the riser system had an important influence on the distribution of the axial vibration load of the riser and the vibration displacement of the LMRP during the recoil response. Lang et al. [21] researched the recoil analysis of the riser in deeper waters, simulated the recoil response of the riser in the Gulf of Mexico at a water depth of 3048 m after emergency disconnection using a 3D nonlinear time domain finite element model and investigated the influence of key parameters. Miller et al. [24] simulated the downward flow of mud after the emergency disconnection of the deepwater drilling riser using the STARR program and pointed out that the process of mud discharge could be regarded as a “water strike problem with fast opening of the valve”. If the configuration of the filling valve at the top of the riser was not reasonable, the riser might be destroyed by the seawater pressure outside the pipe after the emergency disconnection. Rinaldi [30] researched two methods of mud discharge during the emergency release of a deepwater drilling riser and conducted theoretical and simulated experiments on the “water strike effect” generated by the LMRP discharge. It was pointed out that the “water strike effect” had a certain influence on the recoil response of a deepwater drilling riser. Therefore, it is necessary to consider the “water strike effect” during mud discharge. Brynestad [31] studied the mechanical response characteristics of the riser during emergency release, analyzed the weak points of the recoil response process and emphasized that the recoil response should be strictly controlled by the movement of the tensioner piston rod to prevent the tensioner telescopic joints from exceeding the stroke or being subjected to excessive shock loads. Zhang et al. [32] proposed a new method for judging the envelope of the emergency disconnection; simulated the recoil response of the 1500-m riser by using finite element software and studied the influence of the riser parameters, mud viscous resistance, tensioner and recoil control system on the recoil response. Li et al. [33,34] introduced the reasons for the recoil response; established a dynamic analysis method for the riser considering the nonuniform sea current, surface waves, internal isolated waves and platform motion and analyzed the viscous resistance generated by the mud discharge during the recoil response of the riser. They pointed out that the emergency release moment and the release phase angle of the lifting and sinking motion of the floating platform need to be considered while analyzing the recoil response. Wang et al. [35] established a coupled recoil model of the platform–riser–tensioner in a 1500-m water depth through ANSYS software with consideration of the platform motion and emphasized that the mud density and tensioner force were important factors affecting the recoil response. Meng et al. [36] analyzed the effect of the riser–mud coupling effect on the recoil response based on the concentrated mass method, with different tensioner top boundary conditions and mud models.

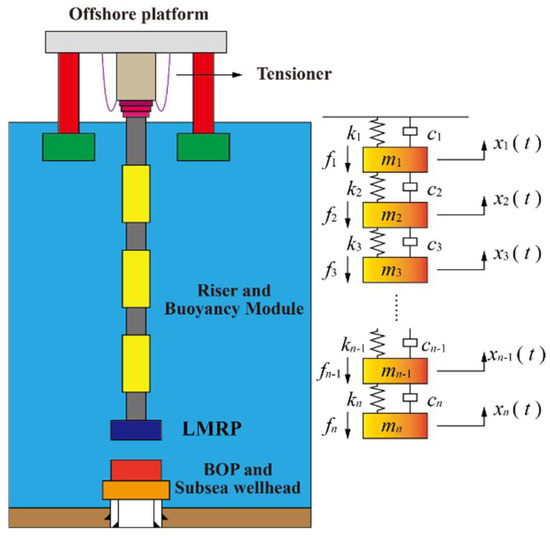

In recent years, the theoretical analysis methods of the recoil analysis have been gradually enriched and improved. Wang et al. [37,38,39] conducted a study on the recoil response using the principal coordinate analysis, complex modal method and subspace iteration method, respectively, based on a mass–spring–damping system with multi-degrees-of-freedom with consideration to the combined effect of the elastic potential energy stored in the riser and the viscous resistance of the mud discharge during normal drilling and also discussed the influence of mud discharge, the phase angle of emergency disconnection and the geometry size of the riser on the recoil response, where the mechanical model is shown in Figure 2.

Figure 2.

Mechanical analysis model of the recoil response of a deepwater drilling riser after emergency disconnection [38].

Li et al. [40,41] analyzed the mechanical behavior of a deepwater drilling riser under the superposition effects of the sea current, surface wave, internal isolated wave and platform longitudinal motion of the platform. Su et al. [42] analyzed the mud discharge model and evaluated the influence of the mud discharge model on the recoil response of the riser based on a two-degrees-of-freedom mass–spring–damping system. Liu et al. [43,44] established a coupled recoil model for deepwater drilling riser systems and discussed the influence of the recoil control system on the recoil response. The advantages and disadvantages of riser recoil models are given in Table 1.

Table 1.

The comparison of riser recoil models.

At present, RISTEN, SIMA RIFLEX, 2HRECOIL, OrcaFlex and other software can be used to analyze the recoil response of a deepwater drilling riser to some extent and calculate the effect of key parameters such as telescopic joints stroke, tensioner force and LMRP vibration displacement during emergency disconnection of the riser. Grønevik [45] introduced the heave compensation system and the procedure of emergency disconnection and analyzed the emergency disconnection of 500-m and 1500-m water depth risers using SIMA RIFLEX software. Pestana [46] researched the mechanical behavior of the top tensioner during the recoil process using a nonlinear spring–damping system in OrcaFlex software and also pointed out that the tensioning force of the top tensioner would fluctuate significantly after emergency disconnection of the riser. It is important to control the fluctuation of the tensioning force effectively for the safe emergency disconnection of the riser. Yang [47] simulated the influence of riser tension, heave movement of the floating platform and release moment on the riser recoil using OrcaFlex software and pointed out that the reasonable setting of the tensioner before disconnection is crucial to the safe disconnection of the riser. Sun et al. [48] summarized the reasons for emergency disconnection of the riser and established a mechanical analysis model of the riser system during emergency release using OrcaFlex software and also discussed the influence of the tensioning force, wave motion, mud density, platform drift and other factors on the recoil response.

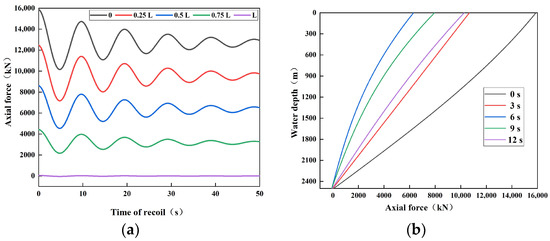

Although OrcaFlex software has a unique advantage in the simulation of marine engineering, which can simulate the water environment, and has a greater advantage in the simulation calculations of the riser system, mooring system, buoyancy module and slender rod, it cannot calculate the recoil response, which is influenced by the mud discharge. For example, the model and operational results simulated by OrcaFlex for the recoil response for a certain sea state and riser configuration are shown in Figure 3. Therefore, it can be widely used in the verification of the recoil model but cannot be directly used as an accurate result of the recoil.

Figure 3.

The results of OrcaFlex for the recoil response. (a) Variations of the axial forces at different water depths of the riser. (b) Global forces at different moments of the riser.

The theoretical models of Wang and Meng or simulations by OrcaFlex can be used to obtain sufficiently accurate recoil mechanical properties with fine-tuning of the safety factor in practice. However, considering the axial elongation of the riser during the normal connection process, the recoil response after the emergency disconnection belongs to a forced vibration problem of an elastic body with infinite degrees of freedom, kinematical top boundary conditions and initial displacement. Thus, the current theoretical model needs to be further improved. Therefore, based on Li’s theoretical model, further studies are still needed to systematically study the recoil response of deepwater drilling risers and establish a fully coupled model more in line with the actual conditions. The mechanical properties and key factors of the recoil response should be revealed, and professional recoil software that is more closely related to the actual working conditions should be developed, so that, in this way, more scientific guidance for the safe operation of deepwater drilling risers can be provided.

3. Drilling Mud Discharge Process

During the process of drilling operations, there are some complex and adverse sea conditions or human errors leading to dangerous situations, such as diffuse drift or rapid dispersal of the platform beyond the safety limits. In this case, the LMRP will be disconnected from the BOP in an emergency without recovering all the mud in the riser to protect the safety of the platform equipment and personnel to minimize pollution to the marine environment. After emergency disconnection, the riser is accelerated upward, and the mud discharges into the seawater through the LMRP, while seawater enters the riser through the filling valve at the top of the riser to prevent a “vacuum section” of the riser [49]. The frictional resistance generated by the relative motion between the riser and mud is one of the important influencing factors of the recoil response. Thus, the accurate calculation of the frictional resistance is of great significance for the study of the mechanical characteristics of the recoil response.

3.1. Mechanical Model of Drilling Mud Discharge

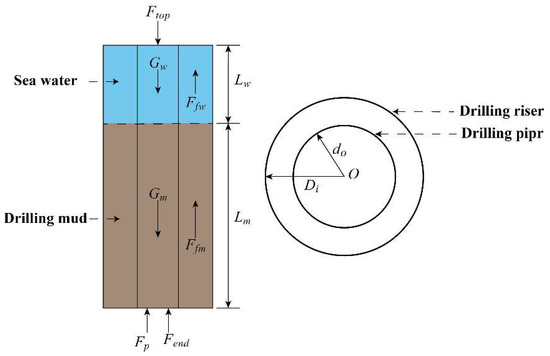

When the riser is disconnected from the BOP, the drilling riser accelerates upward. If the mud is retained inside the riser, the dynamic recoil response of the riser will increase. Actually, there is not enough time to recover the mud inside the riser during an emergency disconnection. Therefore, when the riser accelerates upward, the mud will usually discharge freely from the LMRP into the seawater, which is shown in Figure 4. In order to prevent a vacuum inside the riser, a filling valve is usually installed at the top of the riser. During the process of mud discharge, seawater will enter into the riser from the top filling valve, and finally, the pressure of the liquid column inside and outside the riser is balanced. The frictional resistance on the riser induced by the mud discharge is the important and basic parameter for the accurate calculations of the recoil response. Actually, the process of mud discharge is an unsteady flow process of non-Newtonian fluid, which is difficult to measure directly in actual working conditions, and it is also difficult to acquire more reliable test data through experiments. Thus, simplified theoretical calculations and numerical simulations are the common approach to study the mechanical behavior of the mud discharge.

Figure 4.

Mechanical model of the mud discharge [37].

Due to the importance of mud discharge on the recoil response, many scholars have studied the analysis method of the frictional resistance during mud discharge. Young et al. [19] analyzed the frictional resistance by using a slug column model and discussed the discharge velocity and column length of the mud. Lang et al. [21] simulated the mud discharge process by the finite volume method (FVM) based on the one-dimensional Euler equation. Miller et al. [24] simulated the mud discharge using the method of characteristics (MOC) and a special program called “STARR”. Grytøyr et al. [50] modified the previous “segment plug column model” and simulated the mud discharge process by considering the overall weight of the riser system and the effect of friction during mud discharge. Li et al. [51] analyzed the flow state of mud in three states: laminar flow, transition flow and turbulent flow and evaluated the influence of mud discharge on the recoil response using 2HRECOIL software and the 3D finite element method. Zhang et al. [52,53] studied the problem of collapse caused by mud discharge and pointed out two reasons for riser collapse in deepwater and ultra-deepwater drilling operations. One is the “U-shaped pipe effect” caused by the massive loss of mud, and the other is the “water strike effect” caused by the emergency disconnection of the riser due to harsh weather or platform drift. Zhang et al. [54] calculated the frictional resistance during mud discharge by using the theory for fluid in a circular tube. Diao et al. [55] proposed a calculation method of the pressure drop and discharge force in the annulus of the riser. Wang et al. [56] established the mud discharge model, derived the frictional resistance and also discussed the main influence factors. Wang et al. [57,58] established the mathematical expression of the frictional resistance force of the riser in the process of mud discharge by the sum of a finite series of sinusoidal functions and gave the specific solution process and the difference of the calculation results of the two solution methods. The advantages and disadvantages of mud discharge models are given in Table 2.

Table 2.

The comparison of mud discharge models.

Although the segment plug column model can calculate the fluid performance parameters of the mud during the entire discharge process, it uses a constant set of discharge flow velocity and acceleration at each time step with the depth of the column. It cannot provide the detailed changes of mud fluctuation. The characteristic line method is able to simulate the flow velocity and fluid pressure at each depth as a function of time; however, the computational grid of the characteristic line method is fixed and cannot adapt to changed boundaries, nor can it calculate the interface between the top of the mud column and the bottom of the seawater that moves during the mud drainage process. The mathematical expression of mud discharge using the sum of a finite series of sinusoidal functions can accurately calculate the relevant parameters. However, it is difficult to calculate due to having many fitting parameters and cannot accurately simulate the frictional resistance due to the relative movement of seawater in the riser after the discharge process completes.

Thus, the author suggests establishing a nonlinear computational model with less fitting parameters of frictional resistance in mud discharge by combining exponential and polynomial functions. In summary, research on the mechanical model of mud discharge, the riser recoil response and the axial relative velocity of mud discharge should be further considered comprehensively. Lastly, the frictional resistance on the riser should be calculated by a coupled iterative solution.

3.2. Influence of Mud on Recoil Response

If the riser annulus is closed after the emergency disconnection, the total weight and inertial forces acting on the riser will increase due to the mud stored in the riser. In addition, the lowest natural frequency of the riser filled with mud may fall into the wave frequency range, which will result in a severe overhanging dynamic response. Meng et al. [36] analyzed the riser for recoil, pointed out that the mud in the riser would have some influence on the recoil response, studied the specific changes of mud discharge during recoil using two different models and emphasized that the significant influence of the coupling between mud and the riser during the recoil response should be considered. Wang et al. [58,59] evaluated the influence of the nondiagonal elements in the damping matrix on the recoil response, and pointed out that the frictional resistance of the mud is an important factor affecting the recoil response. Wang et al. [60] concluded that the segment plug flow model, slug fluid model (SFM) model and whole fluid column (WFC) model have shortcomings that neglected the radial motion of the mud and the influence of the interface between the mud and seawater. Thus, a more accurate three-dimensional model was established to study the radial velocity, axial velocity and the mixing interface characteristics between the two fluids during the mud discharge and also pointed out that mud density has a strong effect on the recoil response. Liu et al. [61] established a dynamic nonlinear model of the coupled drilling riser–tensioner system, with consideration of the coupling effect of the recoil response and mud discharge by regarding the riser as a beam with multi degrees of freedom and proposed a comprehensive analysis method for the recoil control method based on the fuzzy control theory.

The recoil behavior of a deepwater drilling riser during an emergency disconnection is a complex and sensitive phenomenon. There is a consensus that mud discharge-induced frictional resistance can significantly affect the recoil dynamics. Therefore, the discharging fluid column that follows the oscillation of the riser in the mud discharge and seawater refilling process must be considered in the study of the recoil analysis.

4. Recoil Response Control

After the emergency disconnection of the riser, the tensioner will generate a huge upward pull force on the riser system. Thus, the riser will recoil upward at a high speed and may have a collision with the floating platform or cause unpredictable accidents. For a floating platform with a DP system, in order to avoid the recoil of the riser against the platform, property damage and casualties, it is necessary to install the antirecoil control system to control the magnitude and fluctuation of the tension force exerted on the riser.

4.1. Mechanical Model of Top Tensioner System

The tensioner system is a high-tech piece of equipment integrating liquid, electricity and gas, which is used to connect the riser system and the offshore floating platform. Zhou et al. [62] studied the principle and the development trend of the tensioner system and analyzed the differences in the working principle and characteristics of the wire rope type (WRT) and DAT tensioner system. The WRT is characterized by mature technology, low cost and good stability and is widely used at present but limited to the problem of wear and fatigue of the wire rope. Additionally, the tensioning force provided by the WRT cannot be adapted to deeper waters. The DAT is characterized by its lighter mass, smaller occupation area and better compensation ability, which makes the deck more flexible and can provide a greater range of tensioning force and make the drilling operations safer. With the development of offshore oil and gas resources moving to deeper waters and the maturity of DAT tensioner technology, the application of a DAT tensioner will be used more extensively. Pestana et al. [46] established a tensioner model based on a nonlinear spring–damping model and investigated the mechanical behavior of the tensioner. Grytøyr et al. [50] established two simplified models of WRT and DAT tensioning systems and carried out a three-dimensional nonlinear simulation analysis of the recoil response at a 500-m water depth using the RIFLEX program and also discussed the operation window of the emergency disconnection of the riser. Liu et al. [63] analyzed the design and selection principle of the riser systems and pointed out that the tensioner system is an important limiting factor. Wang et al. [64,65] established a coupling model of the tensioner–riser system based on a user subroutine written by PYTHON script, implemented the tensioner model in ANSYS-AQWA and analyzed the influence of friction in the tensioner cylinder on the performance of the tensioner. They pointed out that the vertical relative displacement variation between the platform and the riser obtained by the hysteresis tensioner model was similar to the results obtained by the nonlinear tensioner model, while the tension force obtained by the hysteresis tensioner model had a larger range compared to the nonlinear tensioner model. In addition, the fatigue life of the riser and tensioner will be greatly affected due to the fact that the tensioning force will change abruptly several times in a short cycle under the actions of irregular waves. Zhao et al. [66] established a mechanical model of a riser tensioning system with consideration of the influence of the boundaries conditions through introducing the smooth hyperbolic tangent function, auxiliary system and Nussbaum function into the model. The problem of the tensioner in most of the current analysis models is simplified into a beam model or a spring with constant stiffness. Wang et al. [67] established a coupling dynamic model of a riser considering the riser motion and mud discharge; discussed the effects of fluids, platform and tensioner on the recoil response and also pointed out that the recoil response was more sensitive to the motion of a floating platform. The advantages and disadvantages of top tensioner models are given in Table 3.

Table 3.

The comparison of top tensioner models.

The existing riser recoil analyses rarely include a hydro-pneumatic tensioner or the main nonlinear characteristics of the tensioner throughout the analysis, including, for instance, the internal friction, pressure loss of the hydraulic oil flow and the stroke limit, which are almost always ignored. However, the coupling effect of the tensioners, risers and mud discharge is increasingly important as drilling ventures into deepwater or ultra-deepwater. Therefore, the tensioner models should be further coupled with the riser and mud discharge models. More general dynamic recoil models should be established by exploring the coupled recoil response characteristics of nonlinear oil and gas tensioners.

4.2. Antirecoil Control System

For the top tensioner design, carrying out antirecoil control strategy research through simulation software to guide the creation of an antirecoil control system, the design of key parameter optimizations is important to improve the capability of the antirecoil control system. Puccio et al. [49] presented a test of a riser recoil control system in a water depth of 1889.76 m in the Gulf of Mexico and pointed out that riser recoil could be effectively controlled by controlling the form of motion of the top tensioner piston, but no specific equation of tensioner piston motion or control method was given. Chang et al. [68] proposed the strategy of antirecoil control by fuzzy Proportion Integral Differential (PID) and simulated the antirecoil control capability. Tian et al. [69,70] established a simulation model of an antirecoil control system consisting of a riser tensioner system, recoil valve, isolation valve and a programmable logic controller (PLC) automatic control system. Through research, they conducted simulation studies using PID and fuzzy PID control algorithms and pointed out that the recoil control can be achieved by controlling the hydraulic oil flow velocity and the system gas volume and developed an overall control scheme. He et al. [71] modeled and simulated an antirecoil control system and pointed out that a fuzzy PID controller can effectively improve the stability of the system. Liu et al. [72,73] established the riser tensioning system monitoring software on a distributed system platform and proposed a hardware implementation method for antirecoil control. Li et al. [74,75] proposed an antirecoil control model by AMESim simulation software. They also evaluated the influence of the control parameters and disconnection moment on the recoil response and analyzed the adaptation of the antirecoil control algorithm. Ren et al. [76,77] designed a setup to simulate the heave motion of the floating platform, conducted dynamic load tests on the riser tensioner and analyzed the velocity and tension of the WRT tensioner. Dong et al. [78,79,80] discussed the influence of high-pressure gas cylinder volume, hydraulic line pressure drop, tensioning force and stiffness of the system on the stability of the top tensioner system. Duan et al. [81] established a linkage simulation model of a gas–liquid loop and multibody mechanical system based on Simulation X and analyzed the dynamic response of the tensioner system under three different operating modes. Sun et al. [82] simulated an antirecoil control model and pointed out that the main valve opening control curve is the dominant factor for the recoil control. Fei et al. [83] designed an antirecoil control valve and verified its performance through applying the valve to a liquid–cylinder-type riser tensioner system. Wang et al. [84] designed an antirecoil control valve according to the actual working conditions, established a simulation model of the recoil control using AMESim software and verified the validity of the PID control algorithm.

Antirecoil control tests are costly and risky for sea tests, so most of the published papers remain at the stage of theoretical analysis and prototype tests. The current research has concentrated on DAT tensioner systems, where the system consists of two main components, hydraulic and electromagnetic control, and therefore, scholars have mostly used the internationally recognized AMESim and Simulation X. In the area of antirecoil control systems, further optimization of the main valve opening control curve and optimization of the control algorithm can be developed to optimize the antirecoil-related processes with consideration to the effect of the mud concentration and mud discharge on the recoil force.

5. Conclusions

This paper presents a comprehensive review and analysis of the research progress on the recoil response and control technology of deepwater drilling risers in three aspects: mechanical characteristics of the recoil response, influence of drilling mud discharge and recoil control system, which is of reference value for future related research and engineering practices.

A comprehensive understanding of the mechanical behavior of the recoil response of deepwater drilling risers is necessary for the safe implementation of emergency disconnection of a riser. Further analysis of the recoil response is needed with consideration of the service conditions and operation conditions of deepwater drilling risers. In addition, more accurate analytical models are necessary to propose to describe the recoil response and reveal the main influenced factors and provide scientific guidance for deepwater drilling operations.

The drilling mud discharge frictional resistance and tensioning force are important factors affecting the recoil response, and their accurate analysis is related to the accuracy of the mechanical model of the riser recoil and top tensioner system. Therefore, it is necessary to develop a more general dynamic recoil model for the riser that considers the actual conditions of the drilling mud discharge, floating platform motion and nonlinear tensioner factors.

For the recoil response in practical engineering calculations, the models and software of recent articles have been sufficiently accurate when being accompanied with the fine-tuning of the safety factors. However, it is still necessary to develop more research on the recoil response, from mathematizing and making software for floating platforms, tensioners, risers and drilling mud systems to integrating them as one. Finally, specialized software or enrichment submodules should be created to be used by the general public.

Author Contributions

Conceptualization and methodology, Y.W.; investigation, T.L. and J.W.; writing—original draft preparation, T.L. and J.W.; writing—review and editing, Y.W. and supervision, project administration and funding acquisition, D.G. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Natural Science Foundation of China (Grant No. 52074310) and Science Foundation of China University of Petroleum, Beijing (No. 2462021QNXZ006, 2462021QZDX001 and 2462020YXZZ031).

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Gao, D.L.; Wang, Y.B. Some research progress in deepwater drilling mechanics and control technology. Acta Pet. Sin. 2019, 40, 102–115. [Google Scholar] [CrossRef]

- Liu, S.Y.; Sun, M.Y. Discussion on design, selection and configuration of riser system in deep-water drilling. Chem. Enterp. Manag. 2021, 4, 132–133. [Google Scholar] [CrossRef]

- American Petroleum Institute. Recommended Practice for Design, Selection, Operation and Maintenance of Marine Drilling Riser System; API QP 16Q; American Petroleum Institute: Washington, DC, USA, 2017. [Google Scholar] [CrossRef]

- Gao, D.L.; Wang, Y.B. Progress in tubular mechanics and design control techniques for deep-water drilling. Pet. Sci. Bull. 2016, 1, 61–80. [Google Scholar] [CrossRef]

- American Bureau of Shipping. Guidance Notes on Drilling Riser Analysis; ABS; American Bureau of Shipping: Huston, TX, USA, 2017; p. 280. [Google Scholar]

- Chen, K.; Huang, J.; Han, X.Y.; Li, J.X.; Guo, L.L.; Xia, C.Y. Mechanical characteristics analysis of marine riser system. Ship Eng. 2021, 43, 6–13. [Google Scholar] [CrossRef]

- Li, C.W. Research on Overall Mechanical Properties of Deepwater Drilling Riser-Wellhead-Conductor System. Ph.D. Thesis, China University of Petroleum (Beijing), Beijing, China, 2018. [Google Scholar]

- Stahl, M.J.; Wishahy, M.; Brekke, J.N. Riser recoil analysis at a harsh environment. In Proceedings of the International Conference on Offshore Mechanics and Arctic Engineering, Vancouver, BC, Canada, 20–25 June 2004. [Google Scholar] [CrossRef]

- Meng, S.; Che, C.D.; Zhang, W.J. Discharging flow effect on the recoil response of a deep-water drilling riser after an emergency disconnect. Ocean Eng. 2018, 151, 199–205. [Google Scholar] [CrossRef]

- Li, C.W.; Fan, H.H.; Wang, Z.M.; Shen, W.G.; Wang, Y.Q. Recoil response of deepwater drilling riser during emergency disconnection. Ocean Eng. 2015, 4, 121–127. [Google Scholar] [CrossRef]

- Grytøyr, G.; Sharma, P.; Vishnubotla, S. Marine drilling riser disconnect and recoil analysis. In Proceedings of the National Technical Conference and Exhibition, Houston, TX, USA, 12–14 April 2011. [Google Scholar]

- Liao, M.L.; Zhou, Y.C.; Su, Y.N.; Lian, A.L.; Jiang, H.W. A study of the dynamic analysis and design method of deepwater drilling string systems. Pet. Drill. Technol. 2019, 47, 56–62. [Google Scholar] [CrossRef]

- Guo, M. Research on Vibration Law of Riser in Deep Water Drilling. Master’s Thesis, Northeastern Petroleum University, Heilongjiang, China, 2021. [Google Scholar] [CrossRef]

- Ding, T.H.; Li, C. Analysis of coupling axial vibrations between drilling fluids and drill string. Chinses J. Mech. Eng. 2007, 43, 215–219. [Google Scholar] [CrossRef]

- Young, R.; Hock, C.; Karlsen, G.; Miller, J. Analysis and design of anti-recoil system for emergency disconnect of a deepwater riser. In Proceedings of the Ocean Technology Conference, Houston, TX, USA, 4–7 May 1992. [Google Scholar] [CrossRef]

- Yang, H.Z.; Xiao, F. Instability analyses of a top-tensioned riser under combined vortex and multi-frequency parametric excitations. Ocean Eng. 2004, 81, 12–28. [Google Scholar] [CrossRef]

- Yang, J.; Meng, W.; Yao, M.B.; Gao, D.L.; Zhou, B.; Xu, Y.J. Calculation method of riser top tension in deep water drilling. Pet. Explor. Dev. 2015, 42, 107–110. [Google Scholar] [CrossRef]

- Brekke, J.N. Key elements in ultra-deep water drilling riser management. In Proceedings of the SPE/IADC Drilling Conference, Amsterdam, The Netherlands, 27 February–1 March 2001; p. 67812. [Google Scholar] [CrossRef]

- Young, R.; Hock, C.; Karlsen, G.; Albert, J. Comparison of analysis and full-scale testing of anti-recoil system for emergency disconnect of deepwater riser. In Proceedings of the Ocean Technology Conference, Houston, TX, USA, 4–7 May 1992. [Google Scholar] [CrossRef]

- Peter, M.; Pyke, J.; Vankadari, A.; Whooley, A. Ensuring safe riser emergency disconnect in harsh environments-experience and design requirements. In Proceedings of the International Offshore and Polar Engineering, Houston, TX, USA, 30 June–5 July 2013. [Google Scholar]

- Lang, D.W.; Real, J.; Lane, M. Recent developments in drilling riser disconnect and recoil analysis for deepwater applications. In Proceedings of the International Conference on Offshore Mechanics and Arctic Engineering, Honolulu, HI, USA, 31 May–5 June 2009. [Google Scholar] [CrossRef]

- Hock, C.J.; Young, R.D. A deepwater riser emergency disconnect anti-recoil system. J. Pet. Technol. 1993, 45, 744–751. [Google Scholar] [CrossRef]

- Ren, G.F.; Wang, D.Y.; Deng, P.; Niu, M.; Xin, X.G. Technological analysis of the riser tensioner in offshore drilling. China Pet. Mach. 2013, 41, 43–45. [Google Scholar] [CrossRef]

- Miller, J.E.; Stahl, M.J.; Matice, C.J. Riser collapse pressures resulting from release of deepwater mud columns. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 4–7 May 1998. [Google Scholar] [CrossRef]

- Stahl, M.J.; Hock, C.J. Design of a riser recoil control system and validation through full-scale testing. In Proceedings of the SPE Annual Technical Conference and Exhibition, Dallas, TX, USA, 1–4 October 2000. [Google Scholar] [CrossRef]

- Dupal, K.; Curtiss, J.P.; Noort, R.H.; Mack, C. LMRP Disconnect in deepwater, harsh environment conditions. In Proceedings of the IADC/SPE Drilling Conference, Fort Worth, TX, USA, 6–8 March 2018. [Google Scholar] [CrossRef]

- Sun, Y.Y. Strength Assessment for Deepwater Drilling Riser and Engineering Application. Ph.D. Thesis, China University of Petroleum (East China), Chengdu, China, 2009. [Google Scholar]

- Zhang, W.; Gao, D.L. Research on the Dynamic Behavior of Riser in Deepwater Drilling under the Condition of Disconnection Mode. Pet. Drill. Technol. 2010, 38, 7–9. [Google Scholar] [CrossRef]

- Karlsen, G.; Sikes, J.D. 6000-ft water depth upgrade of the sonat discoverer 534. In Proceedings of the SPE/IADC Drilling Conference, Amsterdam, The Netherlands, 11–14 March 1991. [Google Scholar] [CrossRef]

- Rinaldi, S.; Païdoussis, M.P. Dynamics of a cantilevered pipe discharging fluid, fitted with a stabilizing end-piece. Ocean Eng. 2010, 3, 517–525. [Google Scholar] [CrossRef]

- Brynestad, B.I. Disconnection of Workover Risers on Very Deep Water. Master’s Thesis, Norwegian University of Science and Technology, Trondheim, Norway, 2012. [Google Scholar]

- Zhang, L. Recoil Analysis for Deepwater Drilling Riser System. Master’s Thesis, China University of Petroleum (East China), Chengdu, China, 2014. [Google Scholar]

- Li, C.W.; Fan, H.H.; Wang, Z.M.; Shen, W.G.; Feng, X.; Deng, S. Numerical simulation of mud discharge after drilling riser emergency disconnection. In Proceedings of the International Society of Offshore and Polar Engineers, Kona, HI, USA, 21–26 June 2015. [Google Scholar]

- Li, C.W.; Wang, J.S.; Zhou, J.L.; Xu, L.B.; Wu, W.B. Analysis on the flow field characteristics around a drilling riser considering auxiliary lines. China Offshore Oil Gas 2019, 31, 133–139. [Google Scholar] [CrossRef]

- Wang, T.; Wang, K. Analysis of resilient response of emergently disentangled drilling risers. China Offshore Oil Gas 2018, 30, 120–125. [Google Scholar] [CrossRef]

- Meng, S.; Chen, Y.; Che, C.D. Coupling effects of a deep-water drilling riser and the platform and the discharging fluid column in an emergency disconnect scenario. China Ocean Eng. 2020, 34, 21–29. [Google Scholar] [CrossRef]

- Wang, Y.B.; Gao, D.L. Recoil analysis of deepwater drilling riser after emergency disconnection. Ocean Eng. 2019, 189, 106406. [Google Scholar] [CrossRef]

- Wang, Y.B.; Gao, D.L. Recoil response of deepwater drilling riser during emergency disconnection based on a multi-degrees-of-freedom system. Acta Pet. Sin. 2020, 41, 1259–1265. [Google Scholar] [CrossRef]

- Wang, Y.B.; Gao, D.L. Mechanical analysis on recoil response of deepwater drilling riser based on a complex mode method. J. China Univ. Pet. (Ed. Nat. Sci.) 2020, 44, 58–63. [Google Scholar] [CrossRef]

- Li, C.W.; Fan, H.H.; Wang, Z.M.; Shen, W.G.; Wang, Y.Q. Quasi-static analysis of a drilling riser under combined loads of non-uniform currents, surface waves and internal solitary waves. China Offshore Oil Gas 2015, 2, 78–86. [Google Scholar] [CrossRef]

- Li, C.W.; Xu, L.B.; Sheng, L.X.; Li, M.B.; Jiang, Z.B. Application of the preconditioned GMRES(m) algorithm in dynamic calculation of a drilling riser. J. Jiangsu Univ. Sci. Technol. (Nat. Sci. Ed.) 2018, 32, 765–773. [Google Scholar] [CrossRef]

- Su, W.; Meng, S.; Wang, J.X.; Wang, Z. Coupling effect of a deep-water drilling riser in recoil after emergency disconnection. Equip. Environ. Eng. 2018, 15, 40–44. [Google Scholar] [CrossRef]

- Liu, X.; Liu, Z.; Wang, X.; Zhang, N.; Qiu, N.; Chang, Y.; Chen, G. Recoil control of deepwater drilling riser system based on optimal control theory. Ocean Eng. 2021, 220, 108473. [Google Scholar] [CrossRef]

- Liu, X.Q.; Li, J.Y.; Ren, K.R.; Xu, L.B.; Chang, Y.J.; Song, Q. A calculation method for the top tension of deepwater drilling risers based on recoil response. Pet. Drill. Technol. 2016, 44, 47–51. [Google Scholar] [CrossRef]

- Grønevik, A. Simulation of Drilling Riser Disconnection-Recoil Analysis. Master’s Thesis, Norwegian University of Science and Technology, Trondheim, Norway, 2013. [Google Scholar] [CrossRef]

- Pestana, R.G.; Roveri, F.E.; Franciss, R.; Ellwanger, G.B. Marine riser emergency disconnection analysis using scalar elements for tensioner modelling. Ocean Eng. 2016, 59, 83–92. [Google Scholar] [CrossRef]

- Yang, Y.X. Research on Recoil Mechanism and Control Strategy of Emergency Release of Deepwater Drilling Riser. Master’s Thesis, China University of Petroleum (Beijing), Beijing, China, 2020. [Google Scholar] [CrossRef]

- Sun, M.; Zhang, M.; Liu, S.; Huang, F.; Yang, Y. Emergency release analysis of the riser on semi-submersible drilling rig. Drill. Eng. 2021, 48, 82–87. [Google Scholar] [CrossRef]

- Puccio, W.F.; Nuttall, R.-V. Riser recoil during unscheduled lower marine riser package disconnects. In Proceedings of the IADC/SPE Drilling Conference, Dallas, TX, USA, 3–6 March 1998. [Google Scholar] [CrossRef]

- Grytøyr, G. Improving operating window for disconnect operations of CWO risers. In Proceedings of the International Conference on Ocean, Offshore and Arctic Engineering, Shanghai, China, 6–11 June 2010. [Google Scholar] [CrossRef]

- Li, C.; Fan, H.; Wang, Z.; Ji, R.; Ren, W.; Feng, X. Two methods for simulating mud discharge after emergency disconnection of a drilling riser. Ocean Eng. 2016, 28, 142–152. [Google Scholar] [CrossRef]

- Zhang, W.; Gao, D.L.; Fan, C.Y. Hydrostatic collapse analysis of marine drilling riser. Drill. Technol. 2010, 33, 74–76. [Google Scholar] [CrossRef]

- Sun, Y.Y.; Chen, G.M.; Chang, Y.J. Axial direction dynamic analysis on ultra deep-water drilling riser under setting down and recovery operations. China Offshore Oil Gas 2009, 21, 116–119. [Google Scholar] [CrossRef]

- Zhang, L.; Chang, Y.J.; Liu, X.Q.; Liu, K.; Chen, L.M. Recoil analysis for deepwater drilling riser after emergency disconnection with blowout preventer. Pet. Drill. Technol. 2013, 41, 25–30. [Google Scholar] [CrossRef]

- Diao, Y.; Sun, B.L.; Wang, C.S.; Kang, J.; Pang, B.X.; Feng, Z.S. High pressure casing annulus well fracturing oil pressure drop calculation. Oil Field Equip. 2014, 43, 26–29. [Google Scholar] [CrossRef]

- Wang, K. Recoil Analysis for Drilling Riser for Emergency Disconnection. Master’s Thesis, China University of Petroleum (East China), Chengdu, China, 2020. [Google Scholar] [CrossRef]

- Wang, Y.B.; Gao, D.L.; Fang, J. Study on lateral vibration analysis of marine riser in installation-via variational approach. Ocean Eng. 2015, 22, 523–529. [Google Scholar] [CrossRef]

- Wang, Y.B.; Gao, D.L. Influence of the damping matrix and mud discharge on the recoil response of deepwater drilling riser after emergency disconnection. Ocean Eng. 2021, 222, 108591. [Google Scholar] [CrossRef]

- Wang, Y.B.; Gao, D.L.; Wang, J.D. Methodology for recoil analysis of emergency disconnection drilling riser in a deepwater environment. In Proceedings of the Abu Dhabi International Petroleum Exhibition & Conference, Abu Dhabi, United Arab Emirates, 11–14 November 2019. [Google Scholar] [CrossRef]

- Wang, X.; Liu, X.; Zhang, S.; Chen, G.; Chang, Y. Study on mud discharge after emergency disconnection of deepwater drilling risers. Ocean Eng. 2022, 190, 107105. [Google Scholar] [CrossRef]

- Liu, X.; Liu, Z.; Wang, X.; Qiu, N.; Zhang, N.; Chang, Y.; Chen, G. An intelligent recoil controller for riser system based on fuzzy control theory. Ocean Eng. 2022, 14, 100439. [Google Scholar] [CrossRef]

- Zhou, R.; Lai, L. Performance analysis of riser tensioner for drilling vessel. Mar. Technol. 2019, 1, 32–35. [Google Scholar] [CrossRef]

- Liu, S.Y.; Sun, M.Y. Discussion on key factors of deep-water drilling unit design. Chem. Enterp. Manag. 2021, 4, 142–143. [Google Scholar] [CrossRef]

- Liu, Y.J. Analysis of Deepwater Drilling Riser Tensioner System and Recoil Control. Master’s Thesis, China University of Petroleum (East China), Chengdu, China, 2019. [Google Scholar] [CrossRef]

- Wang, T.; Liu, Y.J. Dynamic response of platform-riser coupling system with hydro-pneumatic tensioner. Ocean Eng. 2018, 166, 172–181. [Google Scholar] [CrossRef]

- Zhao, Y.-D.; Sun, Y.-T.; Zhang, B.-L.; Han, Q.-L.; Zhang, X.-M. Recoil control of deepwater drilling riser systems via optimal control with feedforward mechanisms. Ocean Eng. 2022, 257, 111690. [Google Scholar] [CrossRef]

- Wang, X.; Liu, X.; Liu, Z.; Qiu, N.; Hu, P.; Chang, Y.; Chen, G.; Li, C. Dynamic recoil response of tensioner and riser coupled in an emergency disconnection scenario. Ocean Eng. 2022, 247, 110730. [Google Scholar] [CrossRef]

- Zhang, L.; Chang, Y.J.; Liu, X.Q.; Liu, K.; Yang, H.L. AMESim-based modeling and simulation of platform riser tensioner. China Pet. Mach. 2013, 41, 38–42. [Google Scholar] [CrossRef]

- Zhang, F.F. The Countermeasure and Application Research of Anti-Recoil Control about Deepwater Drilling Riser Device. Master’s Thesis, China University of Petroleum (East China), Chengdu, China, 2015. [Google Scholar]

- Tian, X.J. Research on Recoil Control of Deepwater Drilling Riser Tensioning System. Master’s Thesis, China University of Petroleum (East China), Chengdu, China, 2013. [Google Scholar]

- He, X.; Zhang, F.; Tian, X.; Liu, X.Q. Modeling and simulation for recoil control system of deepwater drilling riser. China Pet. Mach. 2016, 44, 63–67. [Google Scholar] [CrossRef]

- Liu, Q.M.; Zhang, R.S.; Sun, C.X.; Ren, G.F.; Li, H. Design of monitoring system for cable-type riser tensioner. China Pet. Mach. 2014, 42, 124–128. [Google Scholar] [CrossRef]

- Liu, Q.M. Off-Line Programming and Simulation Control of New Mechanized Workover System. Master’s Thesis, Daqing Petroleum Institute, Daqing, China, 2009. [Google Scholar]

- Li, H.; Li, P.; Fan, S.; Fu, J.; Zhang, C.Y. Amesim-based research on anti-recoil control of riser tensioner. China Pet. Mach. 2019, 47, 84–89. [Google Scholar] [CrossRef]

- Li, H.; Fan, C.M.; Li, P.; Zheng, W.L.; Liu, Q.M. Research and development suggestions of floating heave compensator. China Pet. Mach. 2022, 2, 53–58. [Google Scholar] [CrossRef]

- Ren, G.F.; Wang, D.Y.; Gou, Y.F.; Niu, M.; Li, Y.P.; Xin, X.G. Research on key equipment of deepwater drilling bop system. Oil Field Mach. 2014, 43, 95–98. [Google Scholar] [CrossRef]

- Zhou, T.M.; Gou, Y.F.; Liu, Y.B.; Niu, M.; Hou, X.D.; Ren, G.F.; Li, H. Testing on dynamic load of 200k wire rope type riser tensioner. China Pet. Mach. 2017, 45, 38–42. [Google Scholar] [CrossRef]

- Dong, X.L.; Yang, X.P.; Zhao, X.; Zhang, C.L.; Zheng, L.; Fei, L. Modeling and performance analysis of liquid cylinder type riser tensioning system. Chin. Hydraul. Pneum. 2019, 8, 39–48. [Google Scholar] [CrossRef]

- Dong, X.L. Research on Anti-Backlash Control Technology of the Floating Drilling Fluid Cylinder Riser Tension System. Master’s Thesis, Xihua University, Chengdu, China, 2020. [Google Scholar] [CrossRef]

- Liao, J.M.; Dong, X.L.; Zhao, X.; Fei, L. Research on the tensioning system of offshore drilling spacer pipe. Mach. Tools Hydraul. 2020, 48, 74–79. [Google Scholar] [CrossRef]

- Duan, M.X.; Wan, B.; Yang, Q.X.; Wang, S.F.; Ge, F. Multidisciplinary simulation analysis and study for direct acting riser tensioner system. Mach. Tools Hydraul. 2019, 47, 123–127. [Google Scholar] [CrossRef]

- Sun, Z.G.; Wu, Z.; Wu, A.P.; Wei, S.H.; Wang, Y.Z.; Pang, S.Q. Recoil control analysis of deepwater drilling riser tension system. China Pet. Mach. 2020, 48, 50–55. [Google Scholar] [CrossRef]

- Fei, L.; Zhao, X.; Zhang, C.L.; Dong, X.L.; Zheng, L.; Li, L.; Li, H. Research on anti-backlash control valve of hydraulic cylinder riser tensioning system. J. Xihua Univ. Nat. Sci. Ed. 2020, 39, 36–41. [Google Scholar] [CrossRef]

- Wang, B.; He, D.S.; Xie, X.L.; Dai, H.; Li, C. Design and simulation of anti recoil valve of riser tensioner. Chin. Hydraul. Pneum. 2021, 45, 108–121. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).