Evaluation of Leachate Recirculation as a Stabilisation Strategy for Landfills in Developing Countries

Abstract

1. Introduction

2. Materials and Methods

2.1. Waste Source

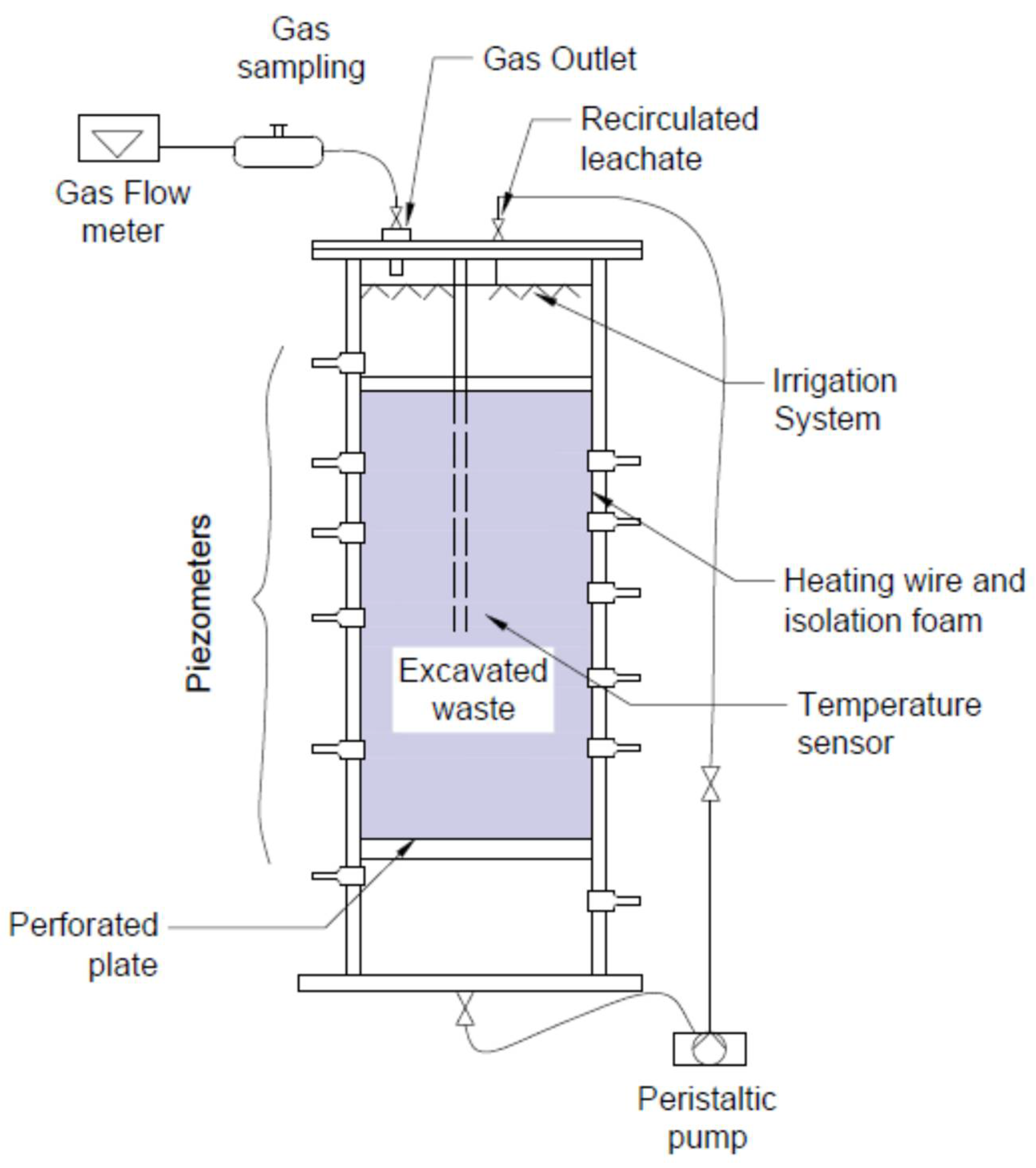

2.2. Landfill Simulation Bioreactors

2.3. Sampling and Analytical Methods

2.3.1. Leachate

2.3.2. Biogas

2.3.3. Solid Waste

2.3.4. Statistical Analysis

2.3.5. Mass Balance

3. Results and Discussion

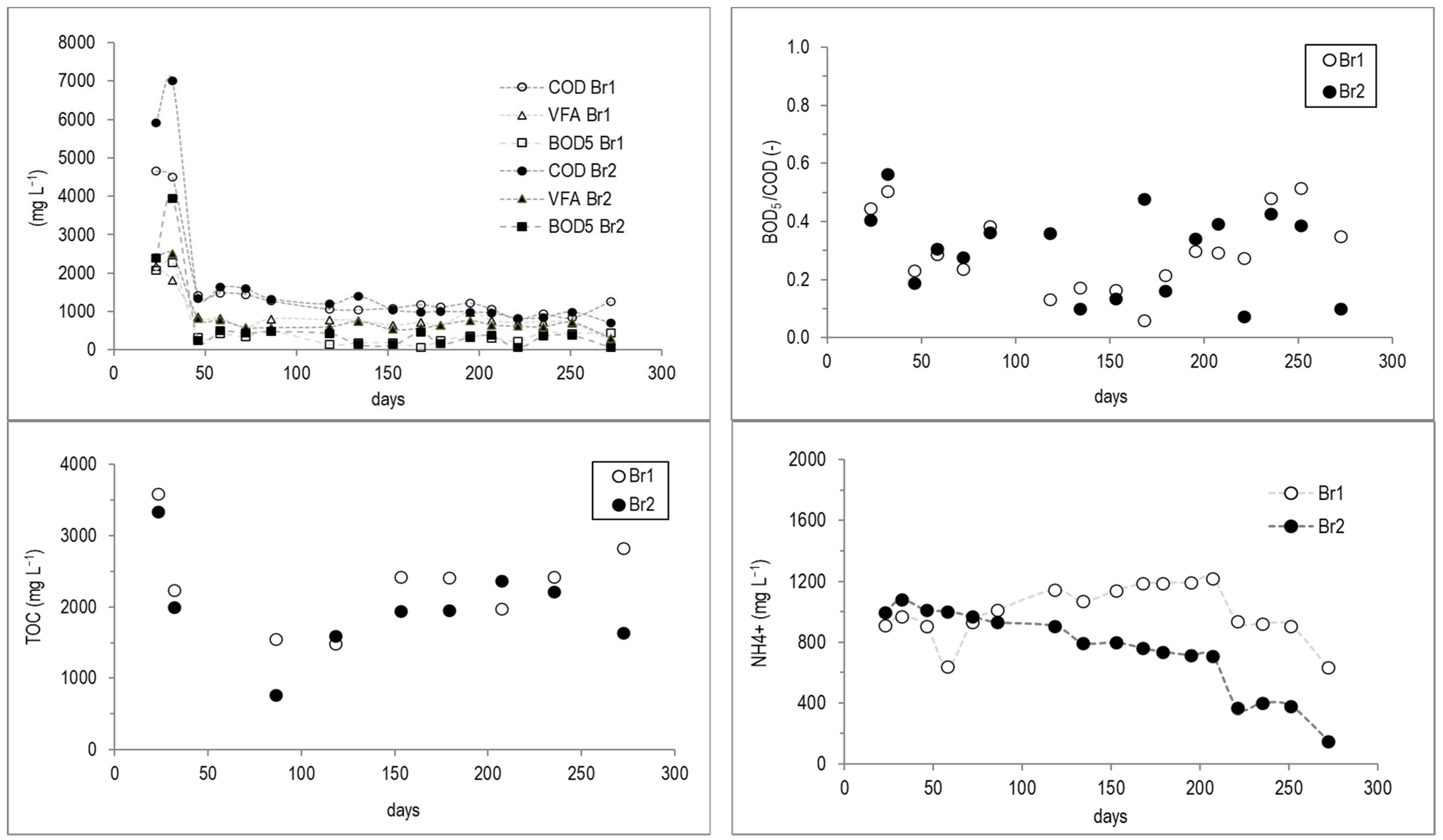

3.1. Leachate

LR Effect on Leachate Discharges

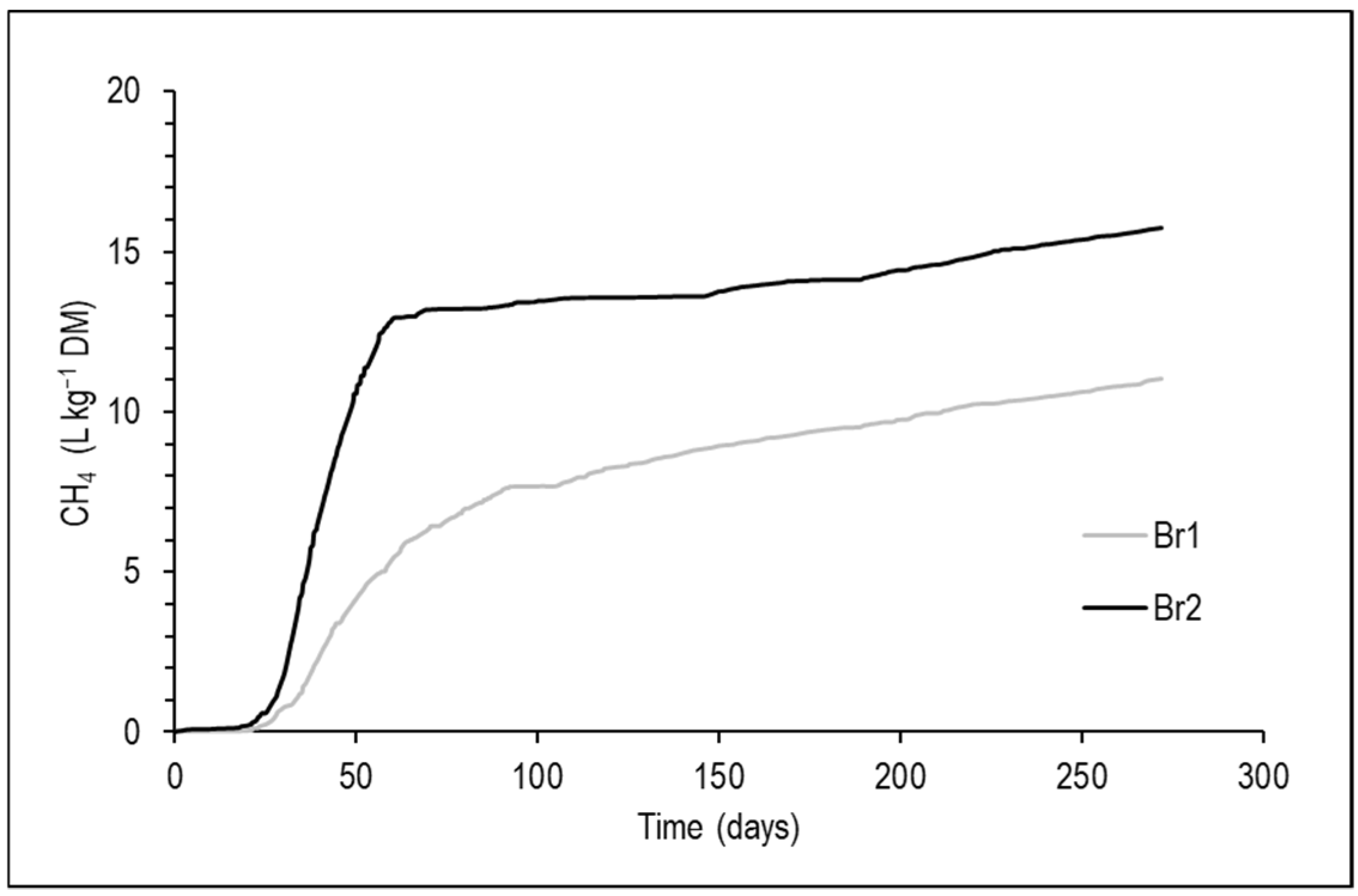

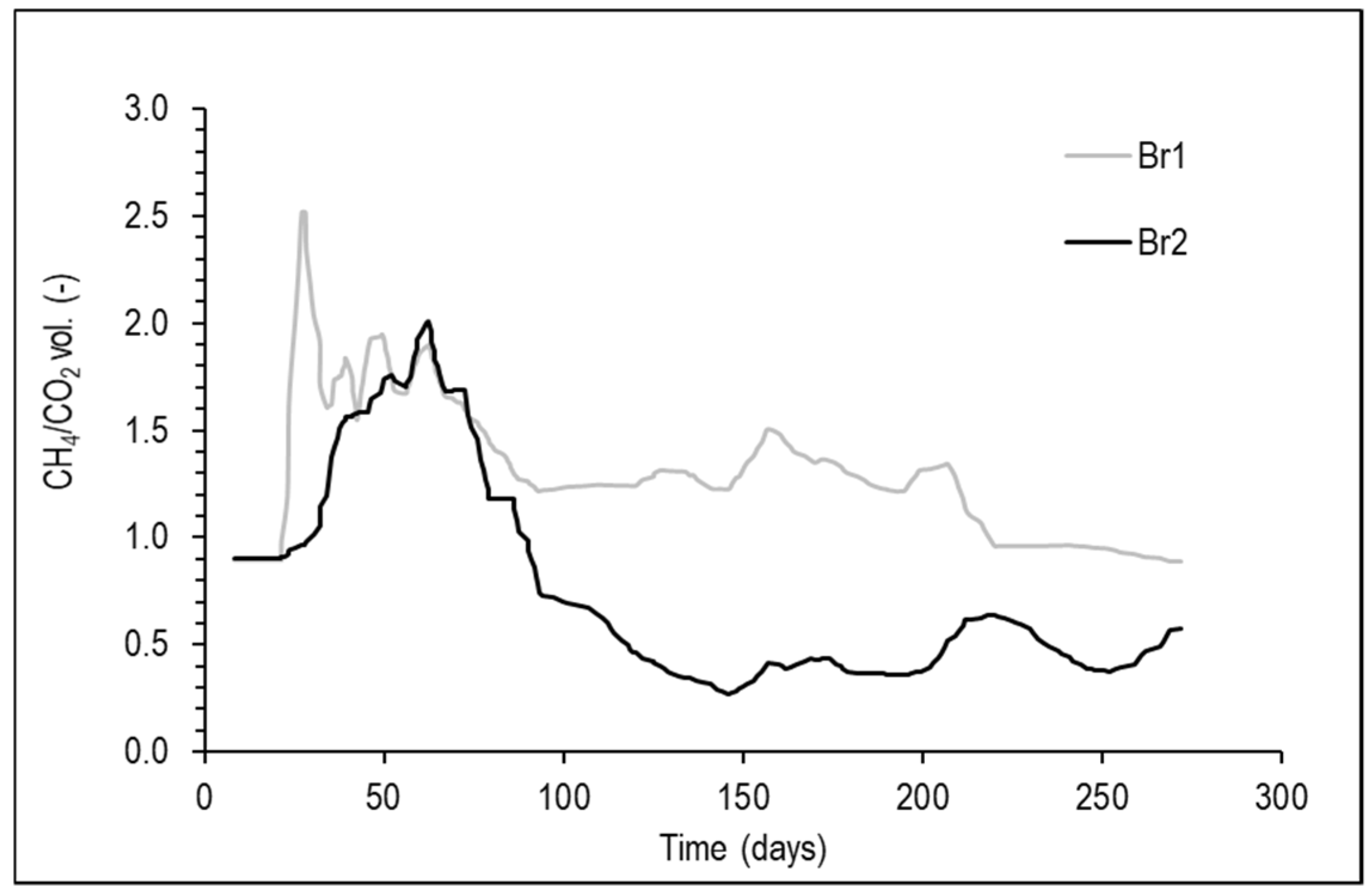

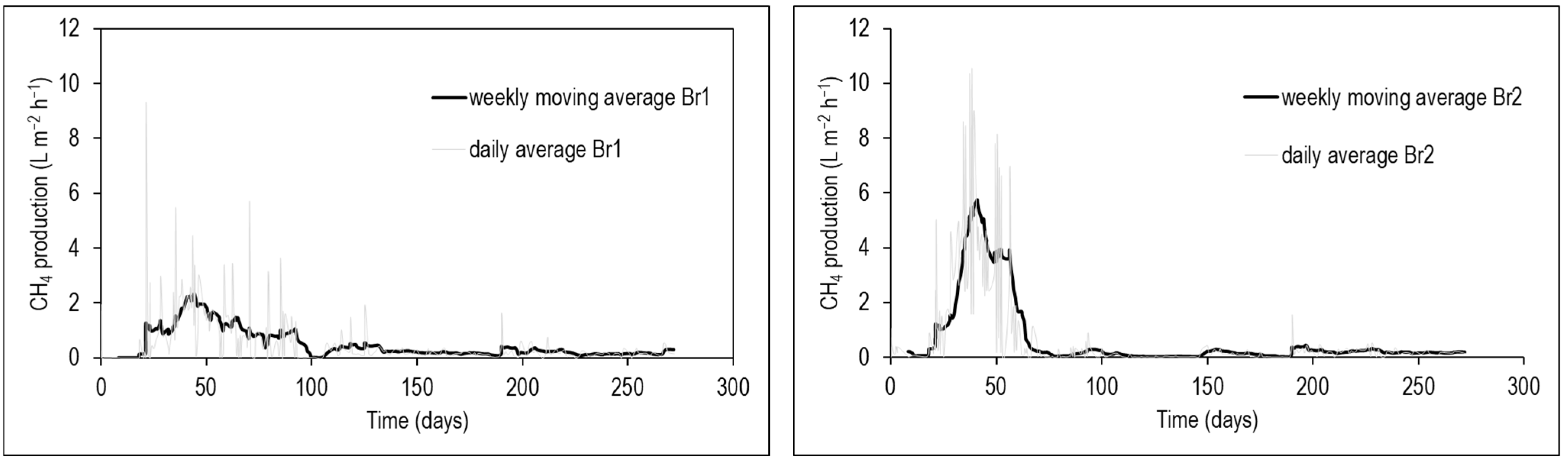

3.2. Biogas

3.3. Solid Waste

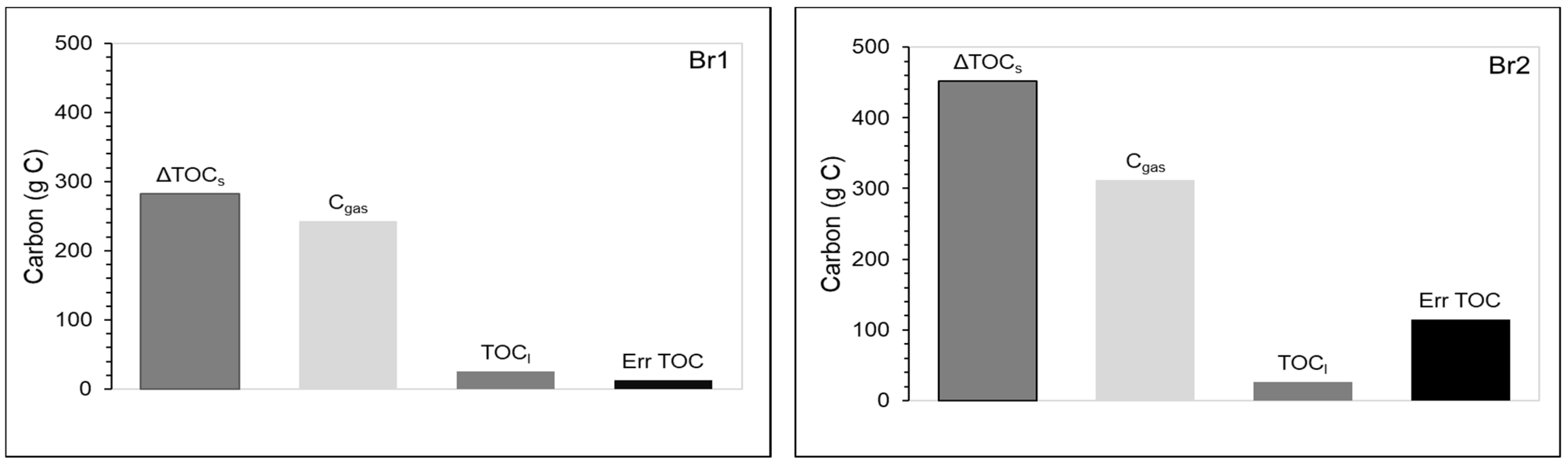

3.4. Mass Balance

3.5. Waste Stability Characteristics

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Bareither, C.A.; Barlaz, M.A.; Doran, M.; Benson, C.H. Retrospective Analysis of Wisconsin’s Landfill Organic Stability Rule. J. Environ. Eng. 2017, 143, 04017001. [Google Scholar] [CrossRef]

- Reinhart, D.R.; McCreanor, P.T.; Townsend, T. The bioreactor landfill: Its status and future. Waste Manag. Res. J. Sustain. Circ. Econ. 2002, 20, 172–186. [Google Scholar] [CrossRef]

- Townsend, T.G.; Powell, J.; Jain, P.; Xu, Q.; Tolaymat, T.; Reinhart, D. Sustainable Practices for Landfill Design and Operation; Springer: Berlin/Heidelberg, Germany, 2015. [Google Scholar] [CrossRef]

- Benson, C.; Barlaz, M.; Lane, D.; Rawe, J. Practice review of five bioreactor/recirculation landfills. Waste Manag. 2007, 27, 13–29. [Google Scholar] [CrossRef]

- Kumar, S.; Chiemchaisri, C.; Mudhoo, A. Bioreactor landfill technology in municipal solid waste treatment: An overview. Crit. Rev. Biotechnol. 2010, 31, 77–97. [Google Scholar] [CrossRef]

- U.S. EPA. Bioreactor Performance. Report EPA530-R-07-007. 2007. Available online: https://www.epa.gov/sites/production/files/2016-03/documents/bio-perf.pdf (accessed on 1 July 2021).

- Hernández-Berriel, M.C.; Mañón-Salas, C.; Sánchez-Yáñez, J.; La Fuente, J.L.-D.; Marquez-Benavides, L. Influence of Recycling Different Leachate Volumes on Refuse Anaerobic Degradation. Open Waste Manag. J. 2010, 3, 155–166. [Google Scholar] [CrossRef][Green Version]

- Jain, P.; Ko, J.H.; Kumar, D.; Powell, J.; Kim, H.; Maldonado, L.; Townsend, T.; Reinhart, D.R. Case study of landfill leachate recirculation using small-diameter vertical wells. Waste Manag. 2014, 34, 2312–2320. [Google Scholar] [CrossRef]

- Wang, Y.; Pelkonen, M.; Kaila, J. Optimization of landfill leachate management in the aftercare period. Waste Manag. Res. J. A Sustain. Circ. Econ. 2012, 30, 789–799. [Google Scholar] [CrossRef] [PubMed]

- Cossu, R. The sustainable landfilling concept. In Eleventh International Waste Management and Landfill Symposium; Environmental Sanitary Engineering Centre: Sardinia, Italy, 2005. [Google Scholar]

- UNEP & ISWA. The Global Waste Management Outlook (GWMO). 2015. Available online: http://www.unep.org/ietc (accessed on 1 January 2021).

- Kaza, S.; Yao, L.C.; Bhada-Tata, P.; Van Woerden, F. What A Waste 2.0: A Global Snapshot of Solid Waste Management to 2050; Urban Development Series; World Bank: Washington, DC, USA, 2018. [Google Scholar]

- Patil, B.; Singh, D. Study of Sustainable Engineereed Bioreactor Landfill (SEBL) for Small Communities. J. Solid Waste Technol. Manag. 2015, 41, 2–14. [Google Scholar] [CrossRef]

- Reinhart, D.R.; Townsend, T.G. Landfill Bioreactor Design and Operation; Routledge: New York, NY, USA, 2018. [Google Scholar] [CrossRef]

- Beaven, R.; Knox, K.; Powrie, W. A Technical Assesment of Leachate Recirculation; Report SC030144/R6; Environment Agency: Bristol, UK, 2009.

- Caicedo-Concha, D.M.; Sandoval-Cobo, J.J.; Whiting, K. An experimental study on the impact of two dimensional materials in waste disposal sites: What are the implications for engineered landfills? Sustain. Environ. Res. 2016, 26, 255–261. [Google Scholar]

- Liu, L.; Xiong, H.; Ma, J.; Ge, S.; Yu, X.; Zeng, G. Leachate Recirculation for Enhancing Methane Generation within Field Site in China. J. Chem. 2018, 2018, 9056561. [Google Scholar] [CrossRef]

- Zheng, W.; Lü, F.; Bolyard, S.C.; Shao, L.; Reinhart, D.R.; He, P. Evaluation of monitoring indicators for the post-closure care of a landfill for MSW characterized with low lignin content. Waste Manag. 2014, 36, 222–229. [Google Scholar] [CrossRef] [PubMed]

- Lohchab, R.; Singh, U. Performance evaluation of a landfill leachate recirculation treatment system using quadric model. J. Environ. Biol. 2017, 38, 1313–1320. [Google Scholar] [CrossRef]

- Ozkaya, B.; Demir, A.; Basturk, A.; Bilgili, M.S. Investigation of leachate recirculation effects in Istanbul Odayeri Sanitary Landfill. J. Environ. Sci. Health Part A Toxic/Hazard. Subst. Environ. Eng. 2004, 39, 873–883. [Google Scholar] [CrossRef] [PubMed]

- Patil, B.S.; Anto, C.A.; Singh, D.N. Simulation of municipal solid waste degradation in aerobic and anaerobic bioreactor landfills. Waste Manag. Res. J. Sustain. Circ. Econ. 2016, 35, 301–312. [Google Scholar] [CrossRef]

- Xu, Q.; Tian, Y.; Wang, S.; Ko, J.H. A comparative study of leachate quality and biogas generation in simulated anaerobic and hybrid bioreactors. Waste Manag. 2015, 41, 94–100. [Google Scholar] [CrossRef]

- Sandip, T.M.; Kanchan, C.K.; Ashok, H.B. Enhancement of methane production and bio-stabilisation of municipal solid waste in anaerobic bioreactor landfill. Bioresour. Technol. 2012, 110, 10–17. [Google Scholar] [CrossRef] [PubMed]

- Swati, M.; Karthikeyan, O.P.; Joseph, K.; Visvanathan, C.; Nagendran, R. Pilot-Scale Simulation of Landfill Bioreactor and Controlled Dumping of Fresh and Partially Stabilized Municipal Solid Waste in a Tropical Developing Country. J. Hazard., Toxic Radioact. Waste 2011, 15, 321–330. [Google Scholar] [CrossRef]

- Cossu, R.; Lai, T.; Piovesan, E. Proposal of a methodology for assessing the final storage quality of a landfill. In Proceedings of the 11th International Waste Management and Landfill Symposium, Sardinia, Italy, 1–5 October 2007. [Google Scholar]

- Knox, K.; Braithwaite, P.; Caine, M.; Croft, B. Brogborough landfill test cells: The final chapter. A study of landfill completion in relation to final storage quality (FSQ) criteria. In Sardinia 2005—10th International Waste Management and Landfill Symposium; Cossu, R., Diaz, L., Stegmann, R., Eds.; Environmental Sanitary Engineering Centre: Sardinia, Italy, 2005. [Google Scholar]

- Prantl, R.; Tesar, M.; Huber-Humer, M.; Lechner, P. Changes in carbon and nitrogen pool during in-situ aeration of old landfills under varying conditions. Waste Manag. 2006, 26, 373–380. [Google Scholar] [CrossRef]

- Ritzkowski, M.; Stegmann, R. Landfill aeration within the scope of post-closure care and its completion. Waste Manag. 2013, 33, 2074–2082. [Google Scholar] [CrossRef]

- Brandstätter, C.; Laner, D.; Fellner, J. Carbon pools and flows during lab-scale degradation of old landfilled waste under different oxygen and water regimes. Waste Manag. 2015, 40, 100–111. [Google Scholar] [CrossRef]

- Hrad, M.; Gamperling, O.; Huber-Humer, M. Comparison between lab- and full-scale applications of in situ aeration of an old landfill and assessment of long-term emission development after completion. Waste Manag. 2013, 33, 2061–2073. [Google Scholar] [CrossRef]

- Valencia, R.; van der Zon, W.; Woelders, H.; Lubberding, H.; Gijzen, H. Achieving “Final Storage Quality” of municipal solid waste in pilot scale bioreactor landfills. Waste Manag. 2009, 29, 78–85. [Google Scholar] [CrossRef]

- Shalini, S.S.; Karthikeyan, O.P.; Joseph, K. Biological stability of municipal solid waste from simulated landfills under tropical environment. Bioresour. Technol. 2010, 101, 845–852. [Google Scholar] [CrossRef]

- Laner, D.; Crest, M.; Scharff, H.; Morris, J.W.; Barlaz, M.A. A review of approaches for the long-term management of municipal solid waste landfills. Waste Manag. 2012, 32, 498–512. [Google Scholar] [CrossRef]

- Ponsa, S.; Gea, T.; Alerm, L.; Cerezo, J.; Sánchez, A. Comparison of aerobic and anaerobic stability indices through a MSW biological treatment process. Waste Manag. 2008, 28, 2735–2742. [Google Scholar] [CrossRef]

- O’Donnell, S.T.; Caldwell, M.D.; Barlaz, M.A.; Morris, J.W. Case study comparison of functional vs. organic stability approaches for assessing threat potential at closed landfills in the USA. Waste Manag. 2018, 75, 415–426. [Google Scholar] [CrossRef]

- DNP. Pólítica Nacional para la Gestión Integral de Residuos Sólidos; CONPES 3874; DNP: Bogotá, Colombia, 2016. Available online: https://colaboracion.dnp.gov.co/CDT/Conpes/Econ%C3%B3micos/3874.pdf (accessed on 1 January 2022).

- Minvivienda. Ministerio de Vivienda Ciudad y Territorio de Colombia; Resolución No. 938 de 2019; Minvivienda: Bogotá, Colombia, 2019. [Google Scholar]

- Boulanger, A.; Pinet, E.; Bouix, M.; Bouchez, T.; Mansour, A.A. Effect of inoculum to substrate ratio (I/S) on municipal solid waste anaerobic degradation kinetics and potential. Waste Manag. 2012, 32, 2258–2265. [Google Scholar] [CrossRef]

- Francois, V.; Feuillade, G.; Skhiri, N.; Lagier, T.; Matejka, G. Indicating the parameters of the state of degradation of municipal solid waste. J. Hazard. Mater. 2006, 137, 1008–1015. [Google Scholar] [CrossRef]

- Kim, H.; Townsend, T.G. Wet landfill decomposition rate determination using methane yield results for excavated waste samples. Waste Manag. 2012, 32, 1427–1433. [Google Scholar] [CrossRef]

- Sandoval, J.J. Characterisation of Saturated & Unsaturated Flow of Liquids in Municipal Solid Waste. Master’s Thesis, University of Southampton, Southampton, UK, 2013. Available online: https://eprints.soton.ac.uk/466854/ (accessed on 1 January 2021).

- Caicedo, D. A Study of the Structure in Solid Wastes and Some Implications for Fluid Flow in Landfills. Ph.D. Thesis, University of Southampton, Southampton, UK, 2013. [Google Scholar]

- Minvivienda. Reglamento Técnico del Sector de Agua Potable y Saneamiento Básico—RAS; Minvivienda: Bogotá, Colombia, 2012. [Google Scholar]

- Hudson, A. Evaluation of the Vertical and Horizontal Hydraulic Conductivities of Household Wastes. Ph.D. Thesis, University of Southampton, Southampton, UK, 2007. [Google Scholar]

- Wang, Y.; Pelkonen, M. Impacts of temperature and liquid/solid ratio on anaerobic degradation of municipal solid waste: An emission investigation of landfill simulation reactors. J. Mater. Cycles Waste Manag. 2009, 11, 312–320. [Google Scholar] [CrossRef]

- Francois, V.; Feuillade, G.; Matejka, G.; Lagier, T.; Skhiri, N. Leachate recirculation effects on waste degradation: Study on columns. Waste Manag. 2007, 27, 1259–1272. [Google Scholar] [CrossRef]

- Wang, Y.-S.; Odle, W.S.; Eleazer, W.E.; Bariaz, M.A. Methane Potential of Food Waste and Anaerobic Toxicity of Leachate Produced During Food Waste Decomposition. Waste Manag. Res. J. Sustain. Circ. Econ. 1997, 15, 149–167. [Google Scholar] [CrossRef]

- Brandstätter, C.; Laner, D.; Fellner, J. Nitrogen pools and flows during lab-scale degradation of old landfilled waste under different oxygen and water regimes. Biogeochemistry 2015, 26, 399–414. [Google Scholar] [CrossRef]

- Ritzkowski, M.; Heyer, K.-U.; Stegmann, R. Fundamental processes and implications during in situ aeration of old landfills. Waste Manag. 2006, 26, 356–372. [Google Scholar] [CrossRef]

- Wu, C.; Shimaoka, T.; Nakayama, H.; Komiya, T.; Chai, X. Stimulation of waste decomposition in an old landfill by air injection. Bioresour. Technol. 2016, 222, 66–74. [Google Scholar] [CrossRef]

- Walker, M.; Zhang, Y.; Heaven, S.; Banks, C. Potential errors in the quantitative evaluation of biogas production in anaerobic digestion processes. Bioresour. Technol. 2009, 100, 6339–6346. [Google Scholar] [CrossRef]

- Ivanova, L. Quantification of Factors Affecting Rate and Magnitude of Secondary Settlement of Landfills. Ph.D. Thesis, University of Southampton, Southampton, UK, 2007. Available online: https://eprints.soton.ac.uk/466251/ (accessed on 1 July 2021).

- American Public Health Association. Standard Methods for the Examination of Water and Wastewater; American Public Health Association: Washington, DC, USA, 2012. [Google Scholar]

- Van Soest, P.J.; Robertson, J.B.; Lewis, B.A. Methods for dietary fiber, neutral detergent fiber, and nonstarch polysaccharides in relation to animal nutrition. J. Dairy Sci. 1991, 74, 3583–3597. [Google Scholar] [CrossRef]

- Sandoval-Cobo, J.J.; Casallas-Ojeda, M.R.; Carabalí-Orejuela, L.; Muñoz-Chávez, A.; Caicedo-Concha, D.M.; Marmolejo-Rebellón, L.F.; Torres-Lozada, P. Methane potential and degradation kinetics of fresh and excavated municipal solid waste from a tropical landfill in Colombia. Sustain. Environ. Res. 2020, 30, 7. [Google Scholar] [CrossRef]

- Wang, B.; Björn, A.; Strömberg, S.; Nges, I.A.; Nistor, M.; Liu, J. Evaluating the influences of mixing strategies on the Biochemical Methane Potential test. J. Environ. Manag. 2017, 185, 54–59. [Google Scholar] [CrossRef]

- El-Fadel, M.; Bou-Zeid, E.; Chahine, W.; Alayli, B. Temporal variation of leachate quality from pre-sorted and baled municipal solid waste with high organic and moisture content. Waste Manag. 2002, 22, 269–282. [Google Scholar] [CrossRef]

- Jun, D.; Yong-Sheng, Z.; Mei, H.; Wei-Hong, Z. Influence of alkalinity on the stabilization of municipal solid waste in anaerobic simulated bioreactor. J. Hazard. Mater. 2009, 163, 717–722. [Google Scholar] [CrossRef] [PubMed]

- Gibbons, R.D.; Morris, J.W.; Prucha, C.P.; Caldwell, M.D.; Staley, B.F. Longitudinal data analysis in support of functional stability concepts for leachate management at closed municipal landfills. Waste Manag. 2014, 34, 1674–1682. [Google Scholar] [CrossRef]

- Kjeldsen, P.; Barlaz, M.A.; Rooker, A.P.; Baun, A.; Ledin, A.; Christensen, T.H. Present and Long-Term Composition of MSW Landfill Leachate: A Review. Crit. Rev. Environ. Sci. Technol. 2002, 32, 297–336. [Google Scholar] [CrossRef]

- Cossu, R.; Raga, R. Test methods for assessing the biological stability of biodegradable waste. Waste Manag. 2008, 28, 381–388. [Google Scholar] [CrossRef]

- Bolyard, S.C.; Reinhart, D.R. Application of landfill treatment approaches for stabilization of municipal solid waste. Waste Manag. 2016, 55, 22–30. [Google Scholar] [CrossRef] [PubMed]

- Berge, N.D.; Reinhart, D.R.; Dietz, J.; Townsend, T. In situ ammonia removal in bioreactor landfill leachate. Waste Manag. 2006, 26, 334–343. [Google Scholar] [CrossRef] [PubMed]

- Heyer, K.-U.; Hupe, K.; Stegmann, R. Methane emissions from MBT landfills. Waste Manag. 2013, 33, 1853–1860. [Google Scholar] [CrossRef]

- Xu, S.Y.; Karthikeyan, O.P.; Selvam, A.; Wong, J.W. Microbial community distribution and extracellular enzyme activities in leach bed reactor treating food waste: Effect of different leachate recirculation practices. Bioresour. Technol. 2014, 168, 41–48. [Google Scholar] [CrossRef]

- Tchobanoglous, G.; Theisen, H.; Vigil, S.A. Integrated Solid Waste Management: Engineering Principles and Management Issues; McGraw-Hill: New York, NY, USA, 1993. [Google Scholar]

- Capaccioni, B.; Caramiello, C.; Tatàno, F.; Viscione, A. Effects of a temporary HDPE cover on landfill gas emissions: Multiyear evaluation with the static chamber approach at an Italian landfill. Waste Manag. 2011, 31, 956–965. [Google Scholar] [CrossRef]

- Hrad, M.; Huber-Humer, M. Performance and completion assessment of an in-situ aerated municipal solid waste landfill—Final scientific documentation of an Austrian case study. Waste Manag. 2017, 63, 397–409. [Google Scholar] [CrossRef]

- U.S. EPA. Inventory of U.S. Greenhouse Gas Emissions and Sinks: 1990–2016. EPA 430-R-18-003. Washington, DC, USA, 2016. Available online: https://www.epa.gov/ghgemissions/inventory-us-greenhouse-gas-emissions-and-sinks-1990-2011 (accessed on 1 July 2021).

- Mahar, R.B.; Liu, J.; Li, H.; Nie, Y. Bio-Pretreatment of municipal solid waste prior to landfilling and its kinetics. Biogeochemistry 2008, 20, 319–330. [Google Scholar] [CrossRef]

- Council of the European Union. European Council Decision 2003/33/EC establishing criteria and procedures for the acceptance of waste at landfills pursuant to Article 16 of and Annex II to Directive 1999/31/EC. Off. J. Eur. Communities 2003, L11, 27–49. [Google Scholar]

- Kelly, R.J.; Shearer, B.D.; Kim, J.; Goldsmith, C.D.; Hater, G.R.; Novak, J.T. Relationships between analytical methods utilized as tools in the evaluation of landfill waste stability. Waste Manag. 2006, 26, 1349–1356. [Google Scholar] [CrossRef] [PubMed]

- Bilgili, M.S.; Demir, A.; Varank, G. Evaluation and modeling of biochemical methane potential (BMP) of landfilled solid waste: A pilot scale study. Bioresour. Technol. 2009, 100, 4976–4980. [Google Scholar] [CrossRef] [PubMed]

- Federal Government of Germany. Ordinance on Environmentally Compatible Storage of Waste from Human Settlements and on Biological Waste Treatment Facilities (AbfAblV); Federal Government of Germany: Berlin, Germany, 2001.

- U.S. EPA. Federal Register, 40 CFR Part 445, Subpart B: RCRA Subtitle D Non-Hazardous Waste Landfill; Landfills Point Source Category; Office of Federal Register: Washington, DC, USA, 2000.

- Bayard, R.; Benbelkacem, H.; Gourdon, R.; Buffière, P. Characterization of selected municipal solid waste components to estimate their biodegradability. J. Environ. Manag. 2018, 216, 4–12. [Google Scholar] [CrossRef] [PubMed]

- Machado, S.; Karimpour-Fard, M.; Shariatmadari, N.; Carvalho, M.; do Nascimento, J. Evaluation of the geotechnical properties of MSW in two Brazilian landfills. Waste Manag. 2010, 30, 2579–2591. [Google Scholar] [CrossRef]

- Berge, N.D.; Reinhart, D.R.; Batarseh, E.S. An assessment of bioreactor landfill costs and benefits. Waste Manag. 2009, 29, 1558–1567. [Google Scholar] [CrossRef]

- EPA/ISWA. International Best Practices Guide for Landfill Gas Energy Project; Global Methane Initiative: Washington, DC, USA, 2012. [Google Scholar]

| Unit | Br1 | Br2 | |

|---|---|---|---|

| Initial waste mass | (kg DM) | 27.7 | 26.1 |

| Initial waste volume | (L) | 47.6 | 45.4 |

| Initial bulk density | (kg m−3) | 0.94 | 0.93 |

| Temperature | (°C) | 37.0 | 36.7 |

| Liquid to solid ratio (L/S) a | (L kg−1 DM) | 0.34 | 0.40 |

| Total recirculated leachate | (L) | 0 | 172.5 |

| Recirculation rate | (L day−1) | 0 | 0.73 |

| Operation time | (days) | 272 | 272 |

| Equation | Description | |

|---|---|---|

| (1) a | water vapour pressure (kPa) T: experiment temperature (°C) | |

| (2) | : biogas volume at standard conditions (mL) : measured volume (mL) Pa: atmospheric pressure (kPa) | |

| (3) | : CH4 volume at standard conditions (mL) %CH4: CH4 percentage in biogas (%) | |

| (4) | : CH4 volume at standard conditions (mL) %CO2: CH4 percentage in biogas (%) |

| Time Frame (Days) | L/S (L kg−1 DM) | LR (L Day−1) | COD Emission (mg kg−1 DM) | NTK Emission (mg kg−1 DM) | EW Age (Years) | VS (%) | |

|---|---|---|---|---|---|---|---|

| This research (Br2) | 272 | 0.4 | 0.73 | 694 | 331 a | 5 | 13.0 |

| [27] | 531 | 2.0 | 0.04 | 2000 | 635 a | 8–17 | 12.2 |

| [45] | 1050 | 1.5–1.8 | 2.2–4.5 | 4800 | 1348 | 3.5 | 45.0 |

| Beginning | Final Br1 | Statistical Test a | Final Br2 | Statistical Test a | |

|---|---|---|---|---|---|

| Moisture (%) b | 38.2 (0.3) | 33.4 (0.12) | * | 37.9 (0.1) | * |

| VS (% DM) | 13.0 (1.0) | 10.1 (0.5) | * | 8.8 (0.5) | * |

| TOC (% DM) | 12.8 (0.9) | 12.6 (1.2) | ns | 11.9 (0.5) | ns |

| Cellulose (% DM) | 47.7 (18.6) | 49.4 (31.3) | ns | 45.2 (32.0) | ns |

| Lignin (% DM) | 9.8 (0.9) | 10.9 (4.8) | ns | 11.9 (6.3) | ns |

| BMP (mL CH4 g−1 DM) | 17.5 (1.4) | 2.4 (0.4) | ** | 1.0 (0.6) | ** |

| Parameter | Units | Objective Value | Reactor Performance | |

|---|---|---|---|---|

| Br1 | Br2 | |||

| Solid waste | ||||

| VS | (% DM) | ≤25 (a) | Achieved | Achieved |

| TOC | (% DM) | ≤3 (b),(1) | Not achieved | Not achieved |

| ≤5 (b),(2) | Not achieved | Not achieved | ||

| ≤18 (c),(3) | Achieved | Achieved | ||

| BMP | (ml CH4 g−1 DM) | ≤2 (a) | Not achieved | Not achieved |

| ≤10 (d),(e) | Achieved | Achieved | ||

| (ml biogas g−1 DM) | ≤20 (c),(4) | Achieved | Achieved | |

| Cellulose | (% DM) | ≤1.5 (f) | Not achieved | Not achieved |

| C/L | (-) | ≤0.2 (a),(g) | Not achieved | Not achieved |

| Leachate | ||||

| COD | (mg L−1) | <200 (d) | Not achieved | Not achieved |

| BOD5 | (mg L−1) | <140 (h) | Not achieved | Achieved |

| <100 (i) | Not achieved | Achieved | ||

| BOD/COD | (-) | <0.1(d),(g) | Not achieved | Achieved |

| NH4+ | (mg L−1) | <300 (d) | Not achieved | Achieved |

| (mg L−1) | <70 (j) | Not achieved | Not achieved | |

| Biogas | ||||

| Emission rate | (L CH4 m−2 h−1) | <1.0 (a) | Achieved | Achieved |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sandoval-Cobo, J.J.; Caicedo-Concha, D.M.; Marmolejo-Rebellón, L.F.; Torres-Lozada, P.; Fellner, J. Evaluation of Leachate Recirculation as a Stabilisation Strategy for Landfills in Developing Countries. Energies 2022, 15, 6494. https://doi.org/10.3390/en15176494

Sandoval-Cobo JJ, Caicedo-Concha DM, Marmolejo-Rebellón LF, Torres-Lozada P, Fellner J. Evaluation of Leachate Recirculation as a Stabilisation Strategy for Landfills in Developing Countries. Energies. 2022; 15(17):6494. https://doi.org/10.3390/en15176494

Chicago/Turabian StyleSandoval-Cobo, John J., Diana M. Caicedo-Concha, Luis F. Marmolejo-Rebellón, Patricia Torres-Lozada, and Johann Fellner. 2022. "Evaluation of Leachate Recirculation as a Stabilisation Strategy for Landfills in Developing Countries" Energies 15, no. 17: 6494. https://doi.org/10.3390/en15176494

APA StyleSandoval-Cobo, J. J., Caicedo-Concha, D. M., Marmolejo-Rebellón, L. F., Torres-Lozada, P., & Fellner, J. (2022). Evaluation of Leachate Recirculation as a Stabilisation Strategy for Landfills in Developing Countries. Energies, 15(17), 6494. https://doi.org/10.3390/en15176494