Residential Refrigeration MEPS in Colombia: A Review and a Comparative Analysis

Abstract

1. Introduction

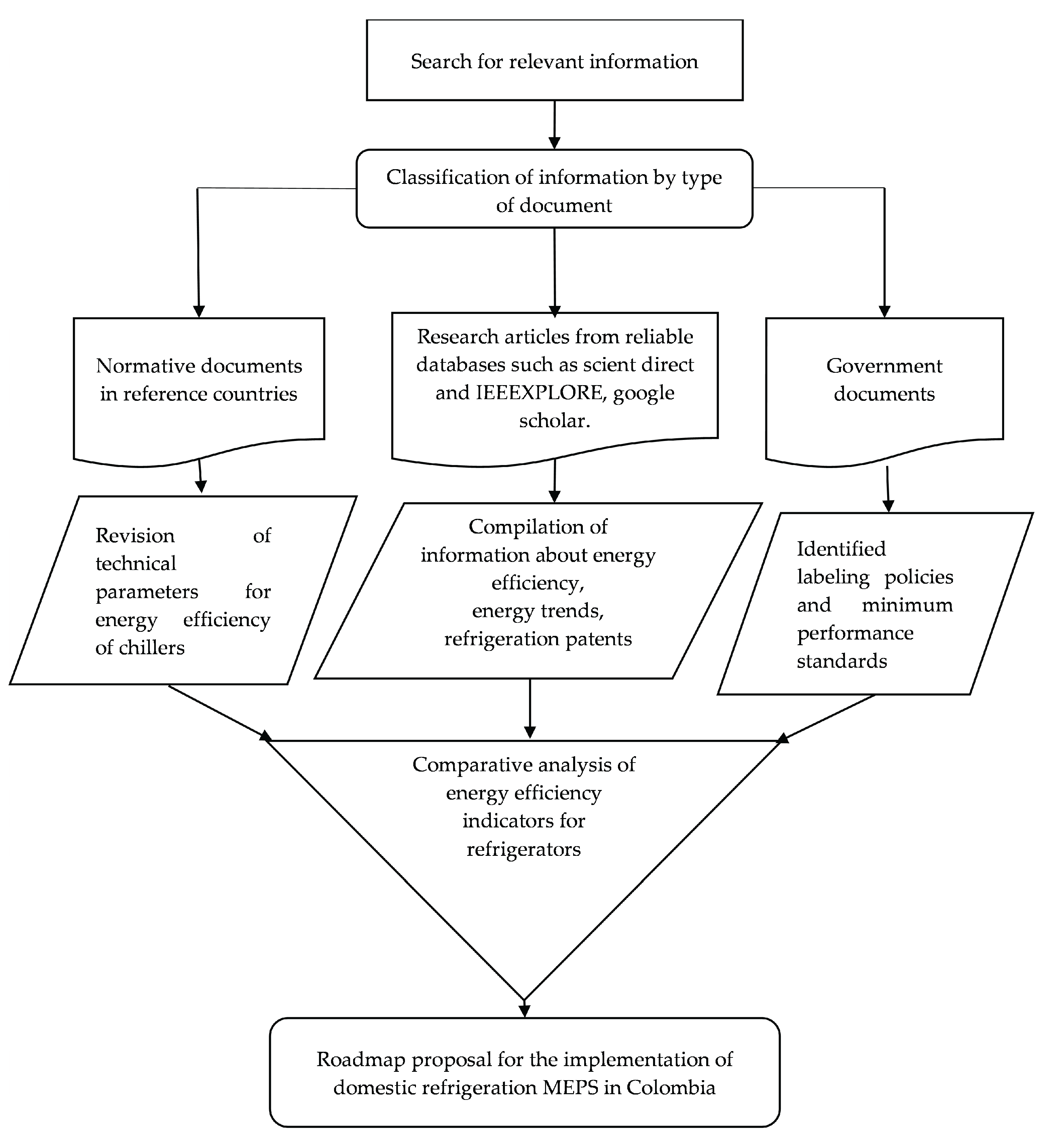

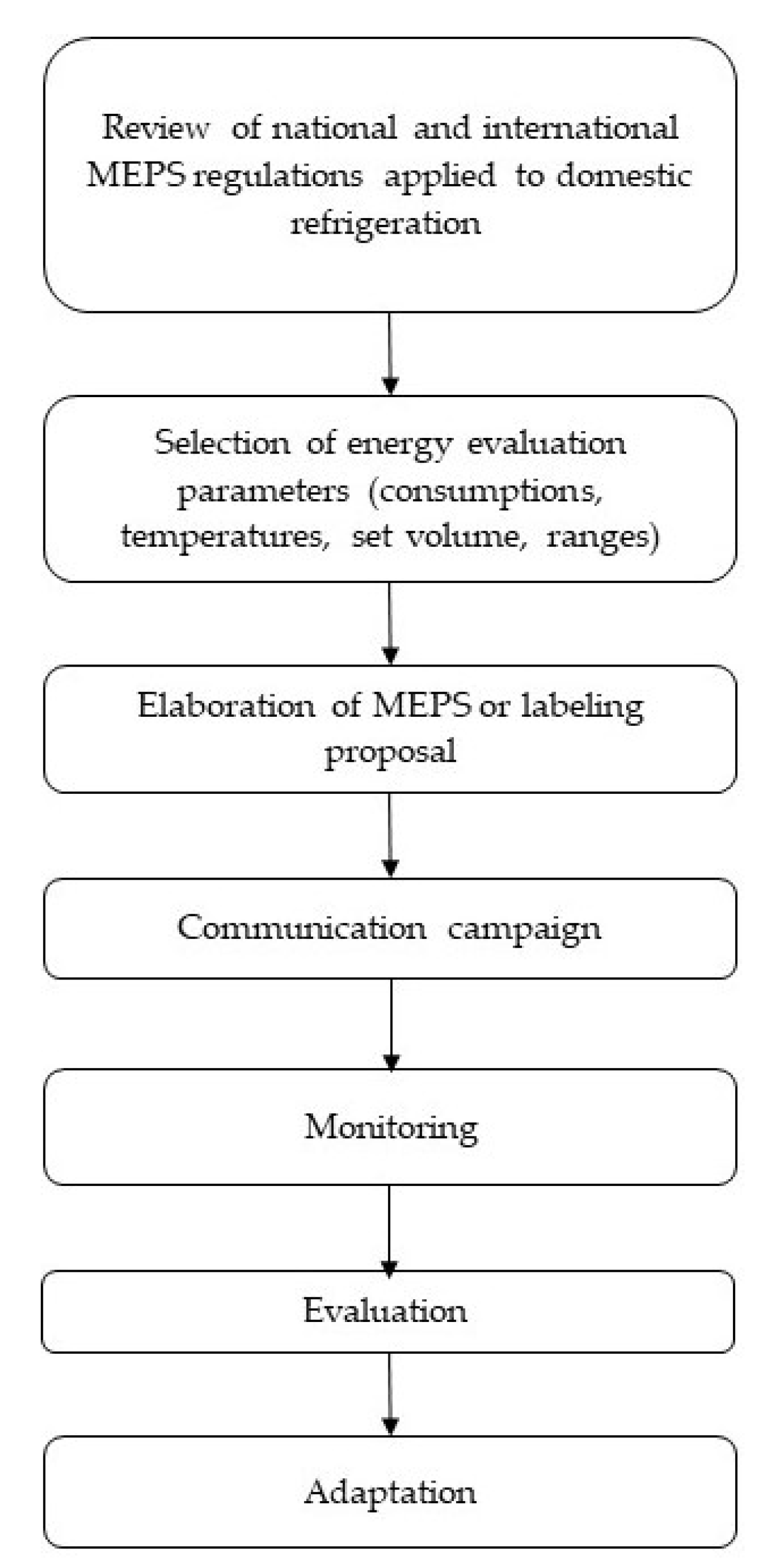

2. Reviewing & Comparison Methods

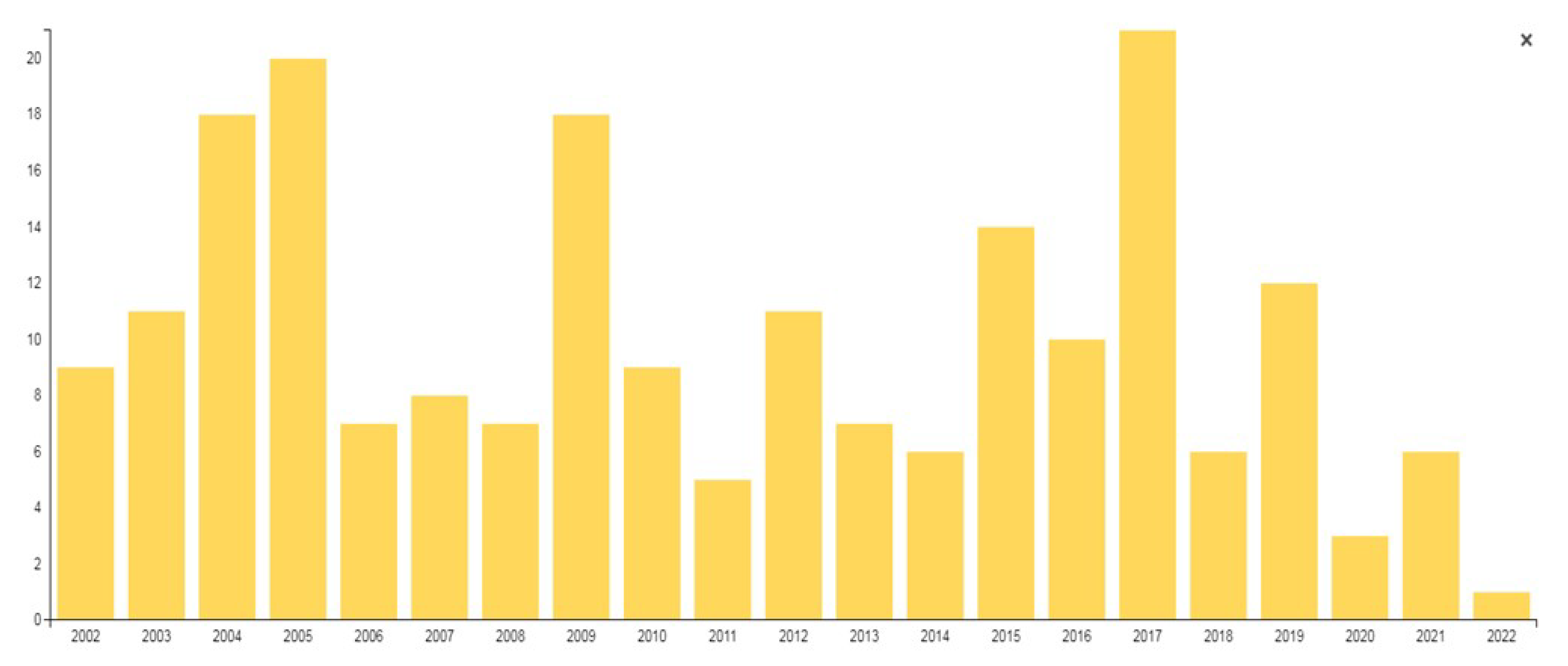

- Research articles from academic databases. The research focused on the energy efficiency issue and technological trends for domestic refrigeration in the period between 2005 and 2022 was consulted.

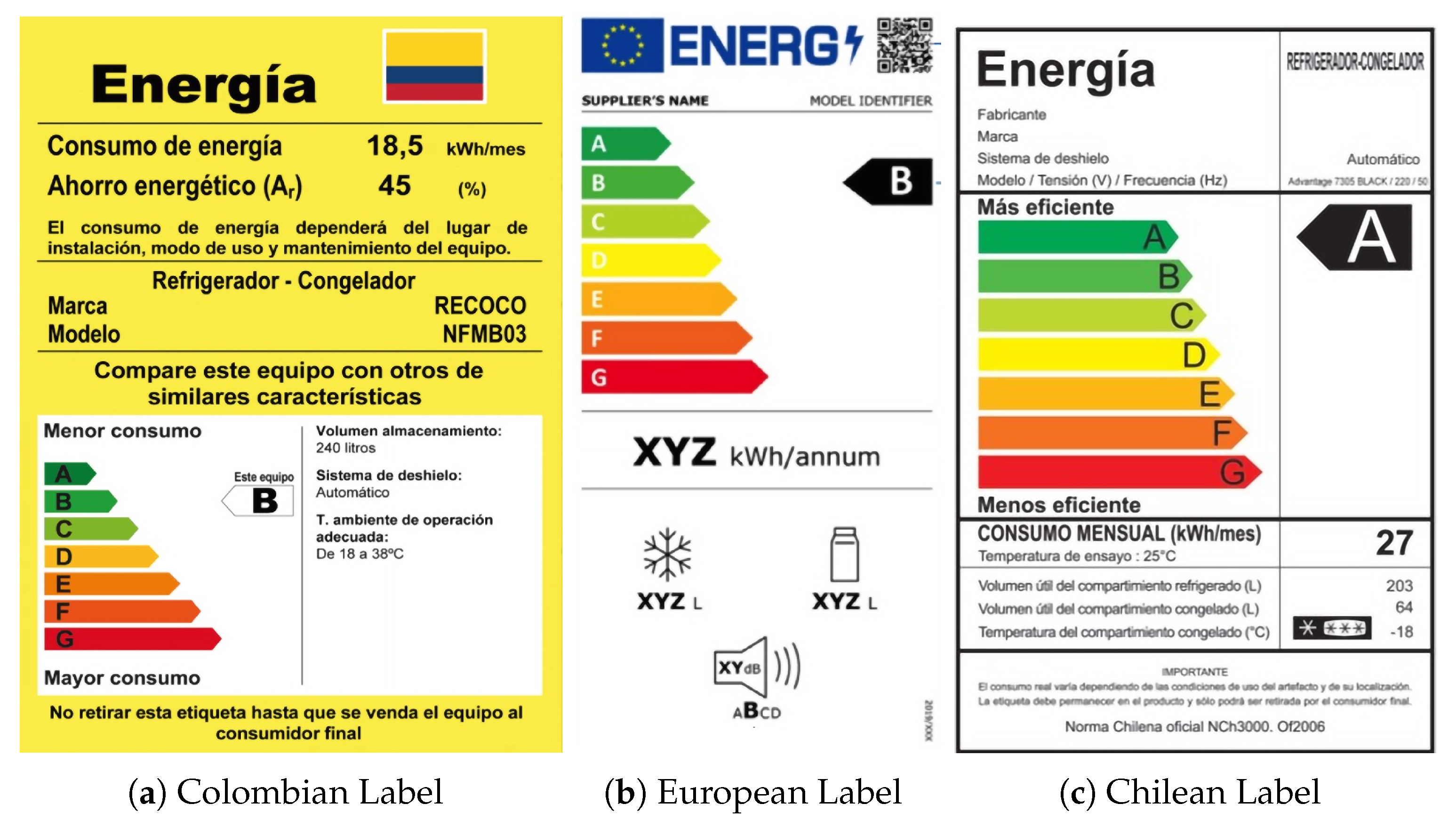

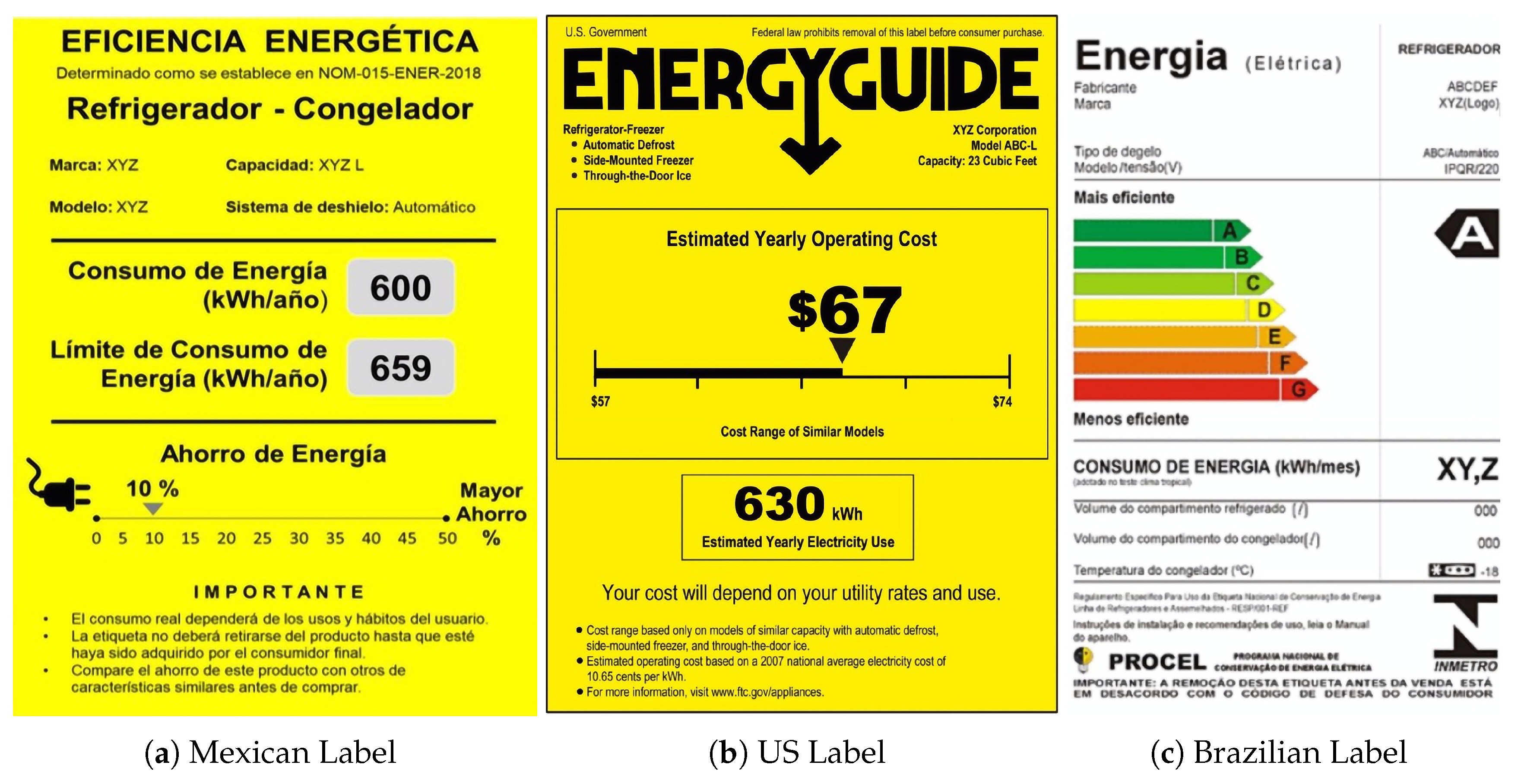

- Technical standards associated with calculating energy efficiency in domestic refrigerators in the countries considered for comparison, identifying the technical methodologies established by each country to determine energy consumption, and the refrigerator labeling for domestic use, according to Table 1.

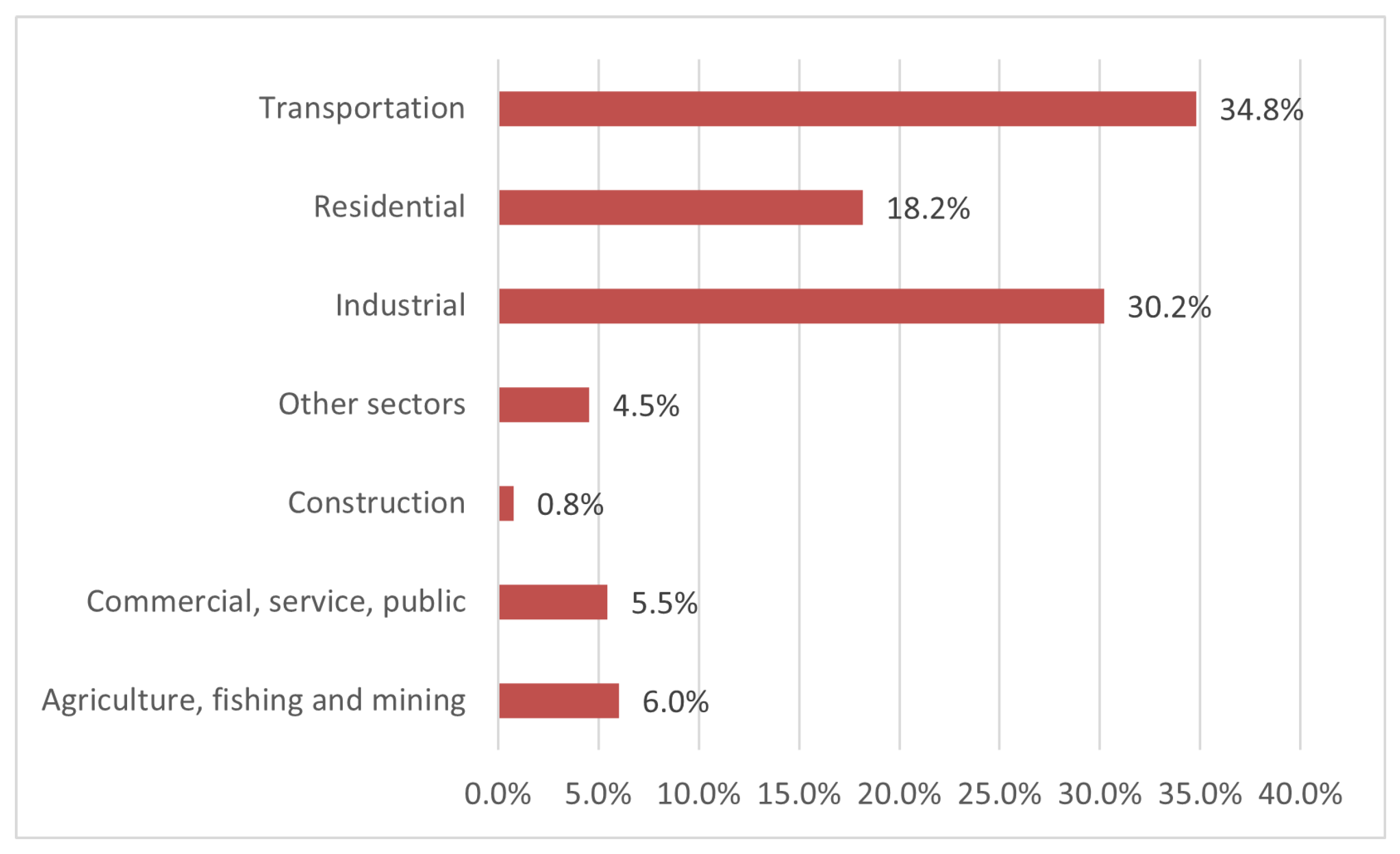

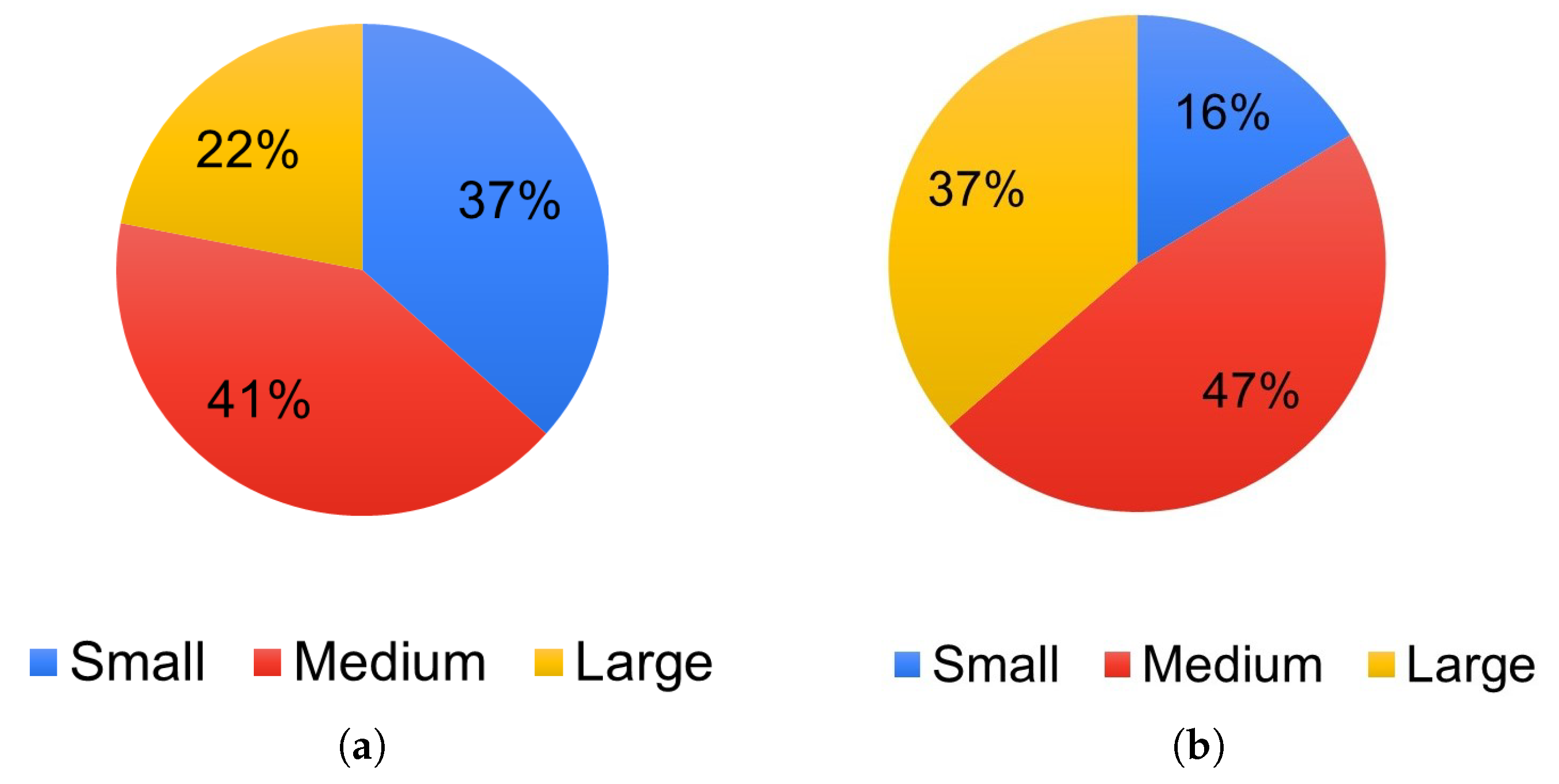

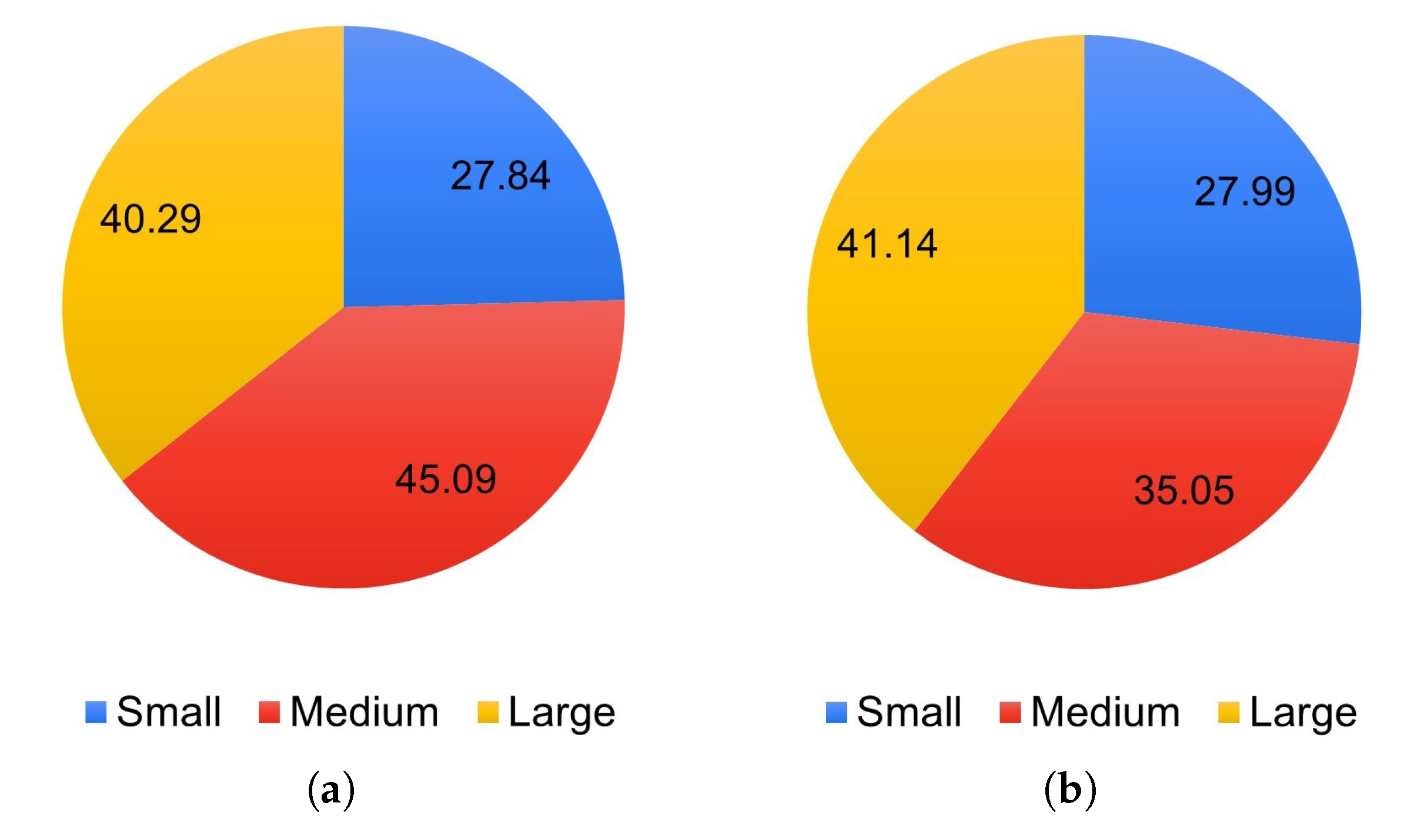

- Colombian Government Documents on energy efficiency for refrigeration. The First BEU of 2019, carried out by the UPME and the Ministry of Mines and Energy [30], was used.

- The RETIQ Regulation [29], and the Indicative Action Plan for Energy Efficiency prepared by UPME [26], the Final Report on Cost-Effectiveness Evaluation of Energy Efficiency Programs in the Residential, Tertiary, and Industrial Sectors presented by CORPOEMA [31], and in turn the National Energy Plan: Energy Ideario 2050 carried out by the UPME [32].

- Regulatory Documents of reference countries on energy efficiency in domestic refrigeration using an observation window of 20 years (2001–2021). They consulted the technical standards associated with the energy efficiency calculation in domestic refrigerators in the countries considered for comparison. And thus, managing to identify the technical methodologies established by each country to determine the energy consumption and the labeling of refrigeration equipment for domestic use according to Table 1.

3. MEPS & Labeling Policies

3.1. European Union

3.2. United States

3.3. Mexico

3.4. Chile

3.5. Brazil

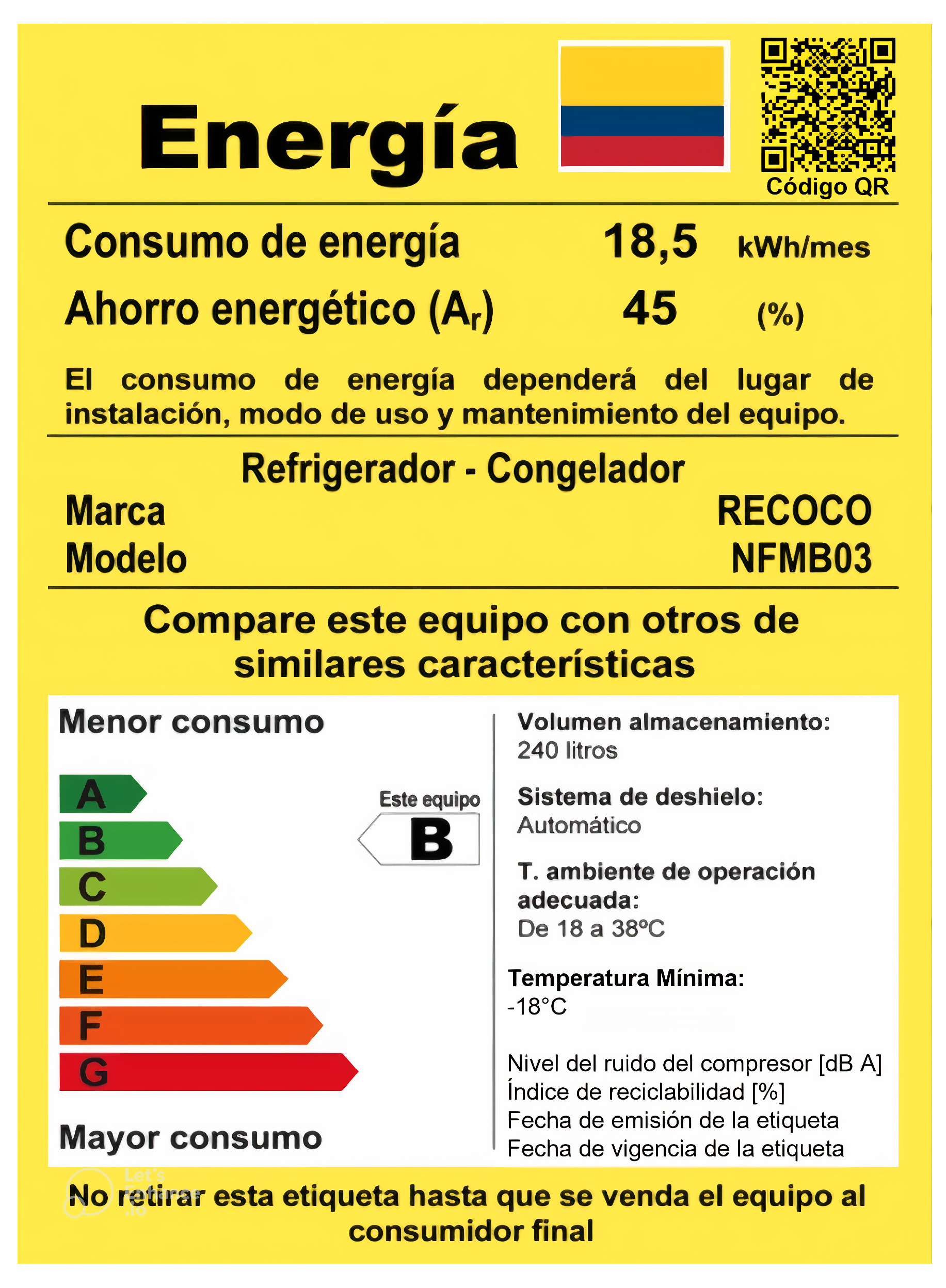

3.6. Colombia

4. State of the Art of Residential Refrigeration Efficiency

4.1. Thermal Insulation Efficiency

4.2. Refrigerant Efficiency

4.3. Compressor’s Efficiency

Compressor’s Noise Level

4.4. SPV Refrigerators Efficiency

4.5. New Patents on Refrigeration Efficiency Outlook

5. Methodologies for the Estimation of Energy Efficiency in Residential Refrigeration

5.1. Energy Consumption Calculation

5.1.1. Energy Consumption Calculation in Colombia

5.1.2. Energy Consumption Calculation in European Union

5.1.3. Energy Consumption Calculation in Brasil

5.1.4. Energy Consumption Calculation in the United States

- Refrigerators.

- Refrigerators-Freezers.

- Miscellaneous refrigeration products.

5.1.5. Energy Consumption Calculation in Mexico

5.2. Equivalent Volume Calculation

5.2.1. Equivalent Volume Estimation in Colombia

5.2.2. Equivalent Volume Estimation in the European Union

5.2.3. Equivalent Volume Estimation in Brazil

5.2.4. Equivalent Volume Estimation in United States

5.2.5. Equivalent Volume Estimation in Mexico

5.3. Efficiency Energy Index Calculation

5.3.1. Efficiency Energy Index Calculation in Colombia

5.3.2. Efficiency Energy Index Calculation in the European Union

5.3.3. Efficiency Energy Index Calculation in Brasil

5.3.4. Efficiency Energy Index Calculation in the United States

5.3.5. Efficiency Energy Index Calculation in Mexico

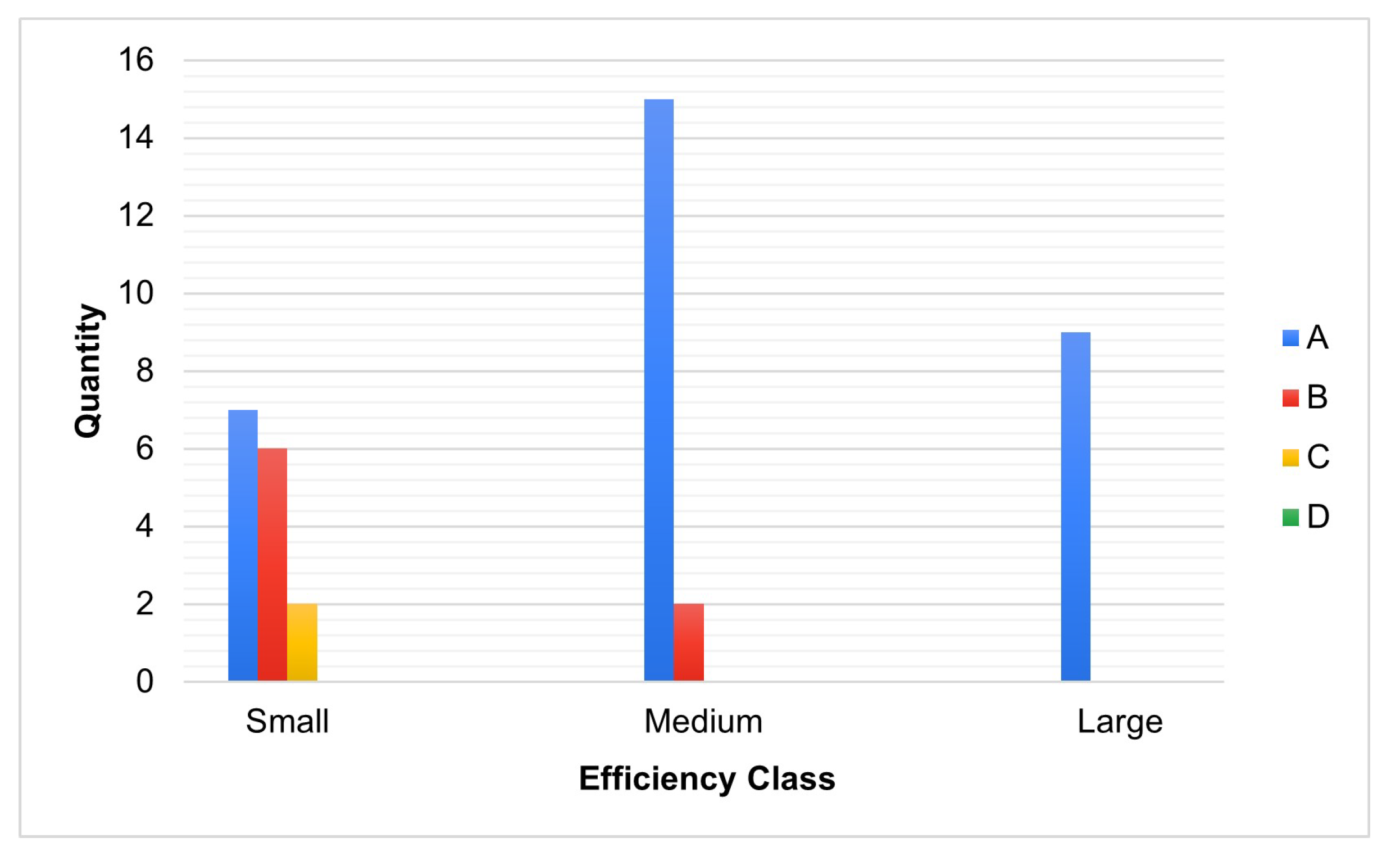

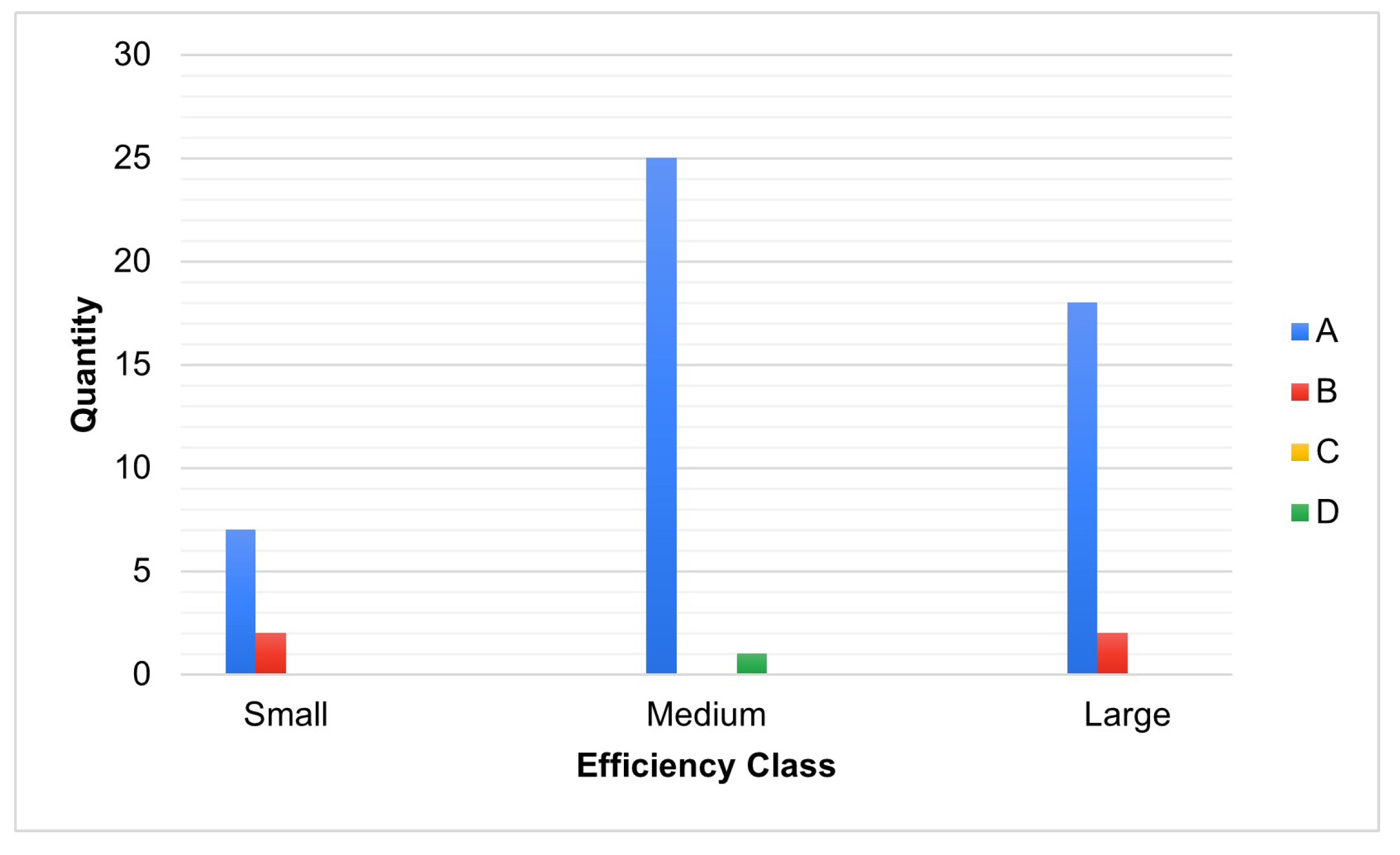

5.4. Efficiency Energy Categories Comparison

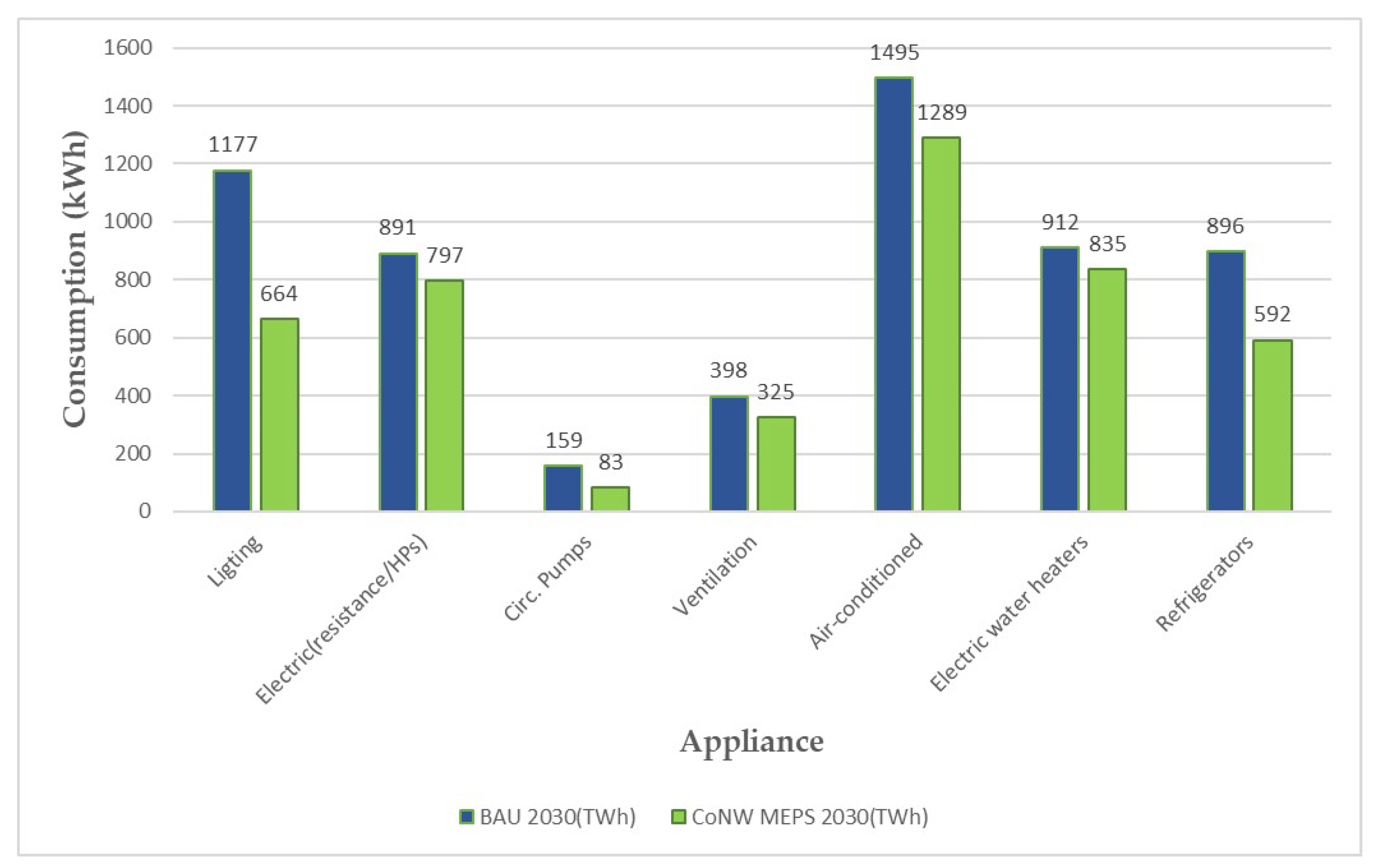

6. Discussion

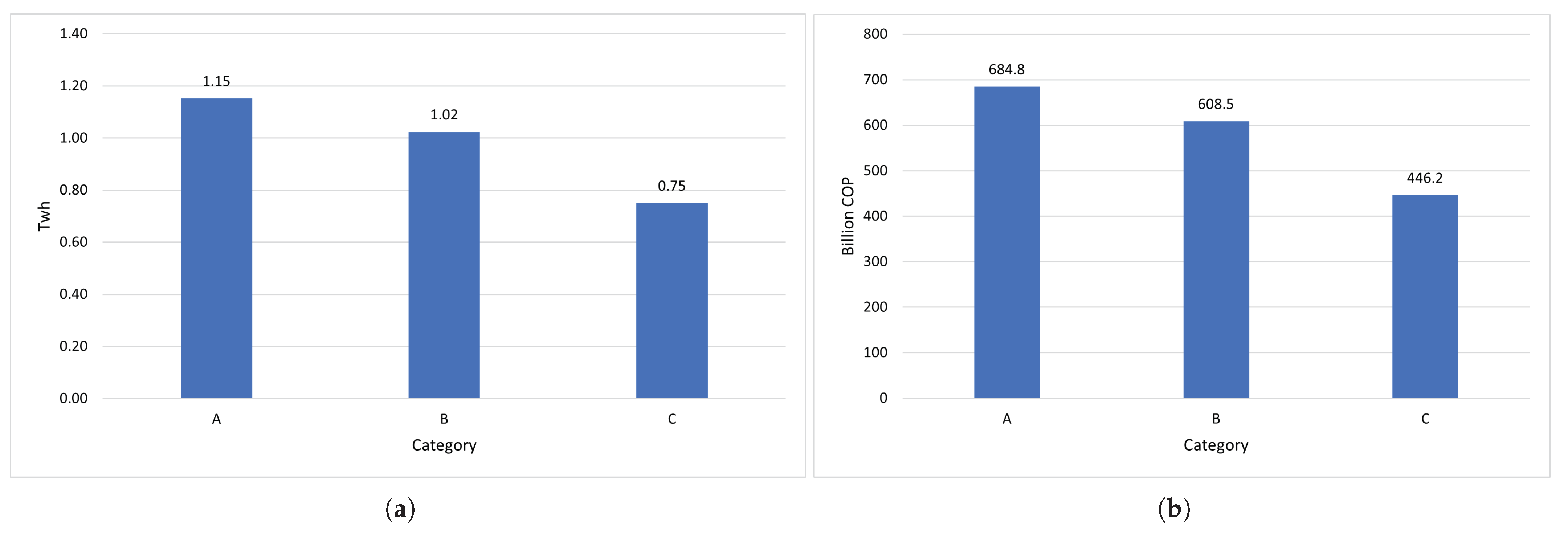

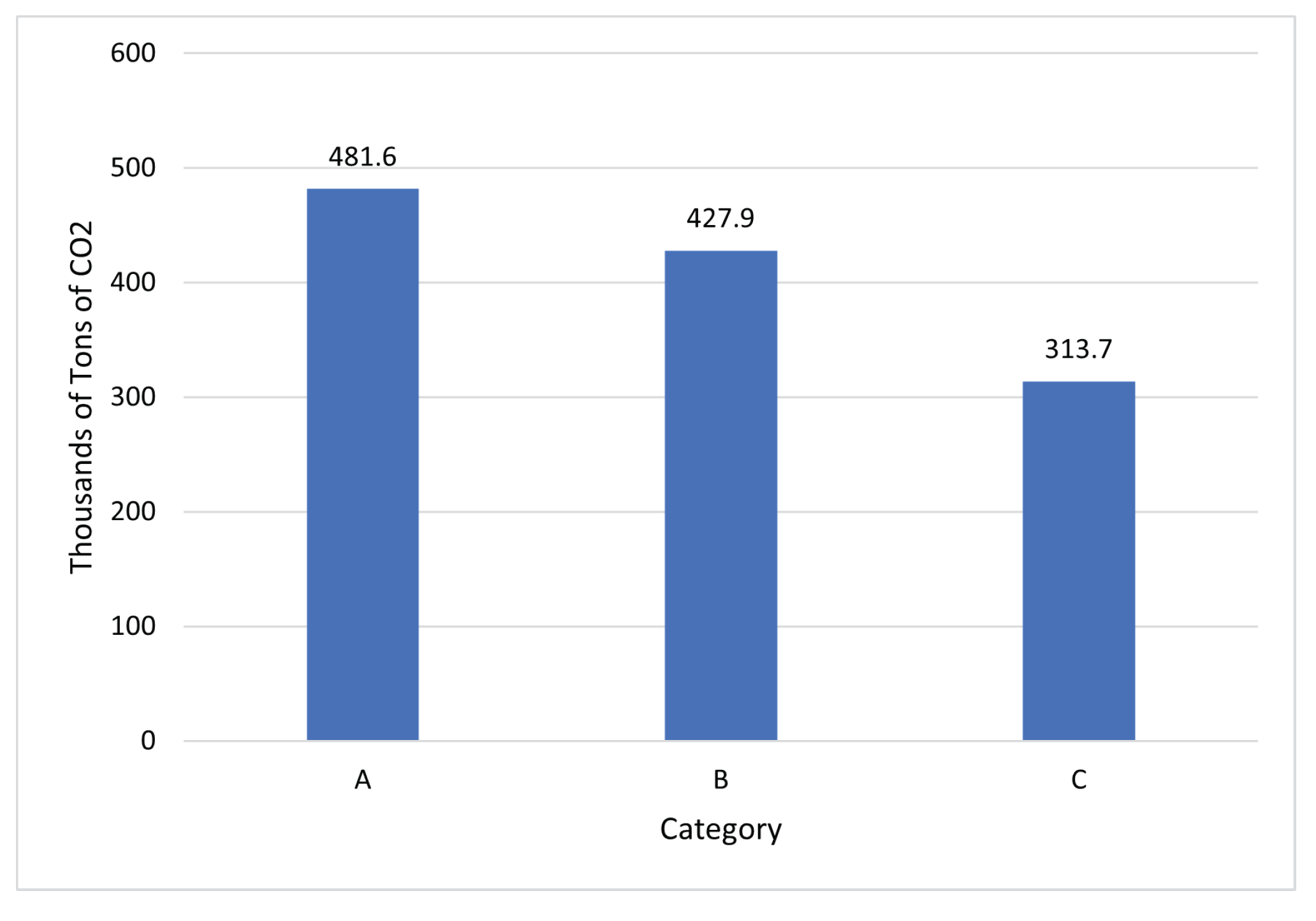

- Reference scenario: All available fridges are D category.

- Scenario 1: All available fridges are A category.

- Scenario 2: All available fridges are B category.

- Scenario 3: All available fridges are C category.

- Buy your fridge and pay only 5% VAT: Campaign led by Red Verde, the first post-consumer appliance program in Colombia. It is in charge of the administration, operation and financing of the selective collection system and environmental management of household refrigerators when they have completed their life cycle and are discarded by consumers. To access this benefit, the user of strata 1, 2, 3, and 4, must request through the network digital channels the fridge collection so that a certificate is issued with which they can later access the discount when buying a more efficient refrigerator.

- Efficient Caribbean: The PEECES was created in 2017 as a proposal for the Green Climate Fund—GCF, with technical support from the UPME and the collaboration of the DNP, foreseeing an estimated investment of 200 million dollars by the GCF and the Colombian State through FENOGE. To access this benefit, the user of strata 1 and 2 (with a consumption of less than 210 kWh/month) of the departments of Atlántico, Bolívar and Córdoba, must fill out the form where the refrigerator is delivered, complying with some characteristics like state, age and size of the fridge and a commitment to purchase a more efficient refrigerator is possible, being part of the program (for follow-up), and a training in energy efficiency. The benefit is granted through a discount bond of $400,000 COP pesos ($100 USD) by the Ministry of Mines and Energy and with the possibility of additional support of $200,000 COP, this is called «Air-e», and will be redeemed in stores allied to the program.

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Relative Savings | |

| Adjusted Volume | |

| Exajoule | |

| Maximum power consumption | |

| GWh | Gigawatt-hours |

| Maximum energy consumption index | |

| Energy Efficiency Index | |

| kWh | Kilowatt-hour |

| Picojoule | |

| TWh/year | Terawatt-hours per year |

| Equivalent Volume |

Acronyms & Abbreviations

| AC | Alternating Current |

| BAU | Business as Usual |

| BEU | Useful Energy Balance |

| CFC | Chlorofluorocarbon |

| CGIEE | Energy Efficiency Indicators Management Committee |

| CONUEE | National Commission for the Efficient Use of Energy |

| CoNW | Cost of Non World |

| COP26 | Conference of parties 26th edition |

| CORPOEMA | Corporation for Energy and the Environment |

| DANE | National Statistics Administrative Department |

| DC | Direct Current |

| DOE | Department of Energy |

| EPA | Environmental Protection Agency |

| ECV | Survey on Quality of Life |

| EU | European Union |

| FENOGE | Fund for Non-Conventional Energies and Efficient Energy Management |

| FIDE | Fund for Electric Energy Savings |

| FTC | Federal Trade Commission |

| GHG | Greenhouse Gases |

| HC | Hydrocarbons |

| HCFC | Hydrochlorofluorocarbon |

| HFC | Hydrofluorocarbon |

| IEC | International Electrotechnical Commission |

| LATIPAT | Latin America and Spain |

| LBNL | Lawrence Berkeley National Laboratory |

| MEPS | Minimum Energy Performance Standards |

| MME | Ministry of Mines and Energy |

| NAEWG | North American Energy Working Group |

| NCh | Chilean Standard |

| NECPA | National Energy Conservation Policy Act |

| NOM-ENER | National Consultative Committee for Official Mexican Energy Efficiency Standards |

| PAI PROURE | Indicative Action Plan for Energy Efficiency |

| PEB | Brazilian Labeling Program |

| PEECES | Sustainable Energy Caribbean Energy Efficiency Program |

| PROCEL | National Energy Conservation Program |

| RETIQ | Technical Labeling Regulation |

| SICEX | Colombian market research company owned by the Quintero Bros. |

| SPV | Solar Photovoltaic |

| SUI | Unique System of Information |

| SDG | Sustainable Development Goals |

| UPME | Energy Mining Planning Unit |

| URE | Efficient Use of Energy |

| VAT | Value Added Tax |

| VFD | Variable Frequency Driver |

References

- Secretaria del Ozono. Manual del Protocolo de Montreal relativo a las Sustancias que Agotan la Capa de Ozono; Secretaria del Ozono: Nairobi, Kenya, 2016. [Google Scholar]

- Naciones Unidas. Protocolo de Kyoto de la Convención Marco de las Naciones Unidas Sobre el Cambio Climático; Technical Report; Naciones Unidas: Santiago, Chile, 1998. [Google Scholar] [CrossRef]

- Naciones Unidas. Convención Marco sobre el Cambio Climático; Naciones Unidas: Santiago, Chile, 2015. [Google Scholar]

- Schloss, M. COP 26: ¿Hacia dónde se va? In Proceedings of the Conferencia de la Nacionaes Unidas Sobre el Cambio Climático cop26, Glasgow, UK, 31 October–13 November 2021. [Google Scholar]

- University of Birmingham. A Cool World Defining the Energy Conundrum of Cooling for All; Technical Report; University of Birmingham: Birmingham, UK, 2018. [Google Scholar]

- Statista.com. Global: Refrigerator Sales 2012–2025; Statista.com: New York, NY, USA, 2021. [Google Scholar]

- Unidad de planeación minero energtica (UPME). Proyección Demanda Energéticos ante el COVID-19; UPME: Bogotá, Colombia, 2020. [Google Scholar]

- Cheshmehzangi, A. COVID-19 and household energy implications: What are the main impacts on energy use? Heliyon 2020, 6, e05202. [Google Scholar] [CrossRef] [PubMed]

- Rosin, A.; Auvaart, A.; Lebedev, D. Analysis of Operation Times and Electrical Storage Dimensioning for Energy Consumption Shifting and Balancing in Residential Areas. Electron. Electr. Eng. 2012, 120, 15–20. [Google Scholar] [CrossRef]

- Schleich, J.; Durand, A.; Brugger, H. How effective are EU minimum energy performance standards and energy labels for cold appliances? Energy Policy 2021, 149, 112069. [Google Scholar] [CrossRef]

- International Energy Agency (IEA). Energy Efficiency 2020; IEA: Paris, France, 2020; p. 105.

- International Energy Agency (IEA). Achievements of Energy Efficiency Appliance and Equipment Standards and Labelling Programmes; IEA: Paris, France, 2021. [Google Scholar] [CrossRef]

- Naciones Unidas. La Agenda 2030 y los Objetivos de Desarrollo Sostenible una Oportunidad para América Latina y el Caribe; Technical Report; Economic Commission for Latin America and the Caribbean: Santiago, Chile, 2018. [Google Scholar]

- Carta internacional de la energia. In Proceedings of the Conferencia Ministerial sobre la Carta Internacional de la Energía, The Hague, The Netherlands, 20 May 2015; 2015; p. 44.

- Zhang, R.; Fu, Y. Technological progress effects on energy efficiency from the perspective of technological innovation and technology introduction: An empirical study of Guangdong, China. Energy Rep. 2022, 8, 425–437. [Google Scholar] [CrossRef]

- Rahman, K.; Leman, A.; Mansor, L.; Salleh, M.; Yusof, M.; Mahathir, M. Energy Efficiency: The Implementation of Minimum Energy Performance Standard (MEPS) Application on Home Appliances for Residential. In Proceedings of the 2nd International Conference on Green Design and Manufacture 2016 (IConGDM 2016), Phuket, Thailand, 1–2 May 2016; Volume 78. [Google Scholar] [CrossRef]

- Molenbroek, E.; Smith, M.; Surmeli, N.; Schimschar, S.; Waide, P.; Tait, J.; Mcallister, C. European Commission Savings and Benefits of Global Regulations for Energy Efficient Products; Technical Report; European Commission: Brussels, Belgium, 2015. [Google Scholar]

- Mukhopadhyay, P.; Chawla, H. Approach to make smart grid a reality. In Proceedings of the 2014 International Conference on Advances in Energy Conversion Technologies—Intelligent Energy Management: Technologies and Challenges, ICAECT 2014, Manipal, India, 23–25 January 2014; pp. 77–82. [Google Scholar] [CrossRef]

- McNeil, M.; della Cava, M.; Blanco, J.; Quiros, K.; Lutz, W.F. Introducción a la Normalización y Etiquetado de Eficiencia Energética en Centroamérica; Diseño Editorial SA: San Jose, Costa Rica, 2008; p. 36. [Google Scholar]

- Lutz, W.F. Energy Efficiency Standards and Labelling in Latin AMERICA—The Issue of Alignment and Harmonisation; EEDAL: Lucerne, Switzerland, 2015. [Google Scholar]

- Sasaki, H.; Sakata, I.; Wangjiraniran, W.; Phrakonkham, S. Appliance diffusion model for energy efficiency standards and labeling evaluation in the capital of lao PDR. J. Sustain. Dev. Energy Water Environ. Syst. 2015, 3, 269–281. [Google Scholar] [CrossRef][Green Version]

- Mcmahon, J.E. Lawrence Berkeley National Energy-Efficiency Labels and Standards: A Guidebook for Appliances, Equipment, and Lighting, 2nd ed.; Lawrence Berkeley National Lab (LBNL): Berkeley, CA, USA, 2005. [Google Scholar] [CrossRef]

- Ministerio de Industria Turismo y Comercio de España. Etiquetado Energético de los Electrodomésticos. Situación del Sector y Planes de Renovación de Electrodomésticos (2006–2007); Ministerio de Industria Turismo y Comercio de España: Madrid, Spain, 2007.

- Ministerio de Energias de Bolivia; Deutsche Gesellschaft fur Internationale. Estudio: Etiquetado Energético para Artefactos Electrodomésticos. September 2019. Available online: https://www.google.com.hk/url?sa=t&rct=j&q=&esrc=s&source=webampersandtag|cd=&ved=2ahUKEwiXlLynq_j5AhVZZd4KHUgVB3MQFnoECA0QAQ&url=https%3A%2F%2Fenergypedia.info%2Fimages%2Fa%2Fa7%2F19-09-19-ETIQUETADO_ELECTRODOMESTICOS.pdf&usg=AOvVaw218gukcV_OivvGgFoqdx6R (accessed on 25 July 2022).

- Romero, J. Regulación de la eficiencia energética: El caso del etiquetado. Rev. Derecho Adm. Económico 2005, 73, 73–94. [Google Scholar] [CrossRef][Green Version]

- Unidad de Planeación Minero Energética (UPME). Plan de Acción Indicativo de Eficiencia Energética 2017–2022. Available online: https://www1.upme.gov.co/Paginas/Plan-de-Acci,%C3%B3n-Indicativo-de-Eficiencia-Energ%C3%A9tica-PAI-PROURE-2017—2022.aspx (accessed on 25 July 2022).

- Departamento Administrativo Nacional de Estadisiticas (DANE). Comunicado de Prensa, Encuenta Nacional de Calidad de Vidad 2021; Technical Report; Departamento Administrativo Nacional de Estadisiticas: Bogotá, Colombia, 2021.

- Ríos, J.; Olaya, Y. A dynamic analysis of strategies for increasing energy efficiency of refrigerators in Colombia. Energy Effic. 2018, 11, 733–754. [Google Scholar] [CrossRef]

- Ministerio de Minas y Energia. Reglamento Técnico de Etiquetado; RETIQ: Bogotá, Colombia, 2015.

- Unidad de Planeación Minero Energética (UPME). Primer Balance de Energía Útil para Colombia y Cuantificación de las Perdidas Energéticas Relacionadas y la Brecha de Eficiencia Energética Resumen Ejecutivo BEU Sector Residencial y Terciario; UPME: Bogotá, Colombia, 2019.

- Corporación para la Energia y el Medio Ambiente (CORPOEMA). Informe Final Evaluación Costo Efectividad de Programas de Eficiencia Energética en los Sectores Residencial; Terciario e Industrial (Subsectores codigo ciiu 10–18); CORPOEMA: Bogotá, Colombia, 2014. [Google Scholar]

- Unidad de Planeación Minero Energética (UPME). Plan Energetico Nacional Colombia: Ideario Energético 2050. Available online: https://www1.upme.gov.co/Paginas/Plan-Energetico-Nacional-Ideario-2050.aspx (accessed on 30 May 2022).

- OVTT LATIPAT: Base de datos de patentes en español y portugués. Available online: https://www.ovtt.org/recursos/latipat-base-de-datos-de-patentes-en-espanol-y-portugues/ (accessed on 19 July 2022).

- Jara, N. Impacto de las Políticas Energéticas en la Industria de la Fabricación de Refrigeradores Domésticos en Latinoamérica: Caso México, Colombia y Ecuador. Ph.D. Thesis, Universidad Pontificia Bolivariana, Medellín, Colombia, 2018. [Google Scholar]

- Jara, N.; Isaza-Roldan, C. Programas de Eficiencia Energética y Etiquetado en el Ecuador—Revisión del Estado Actual. Institución Universitaria Pascual Bravo: Medellin, Colombia, 2014. [Google Scholar]

- Organización lationamericana de energia (OLADE). Situación del Consumo energético a Nivel Mundial y para América Latina y el Caribe (ALC) y sus Perspectivas; OLADE: Quito, Ecuador, 2020. [Google Scholar]

- Ren, H.; Tibbs, M.; McLauchlan, C.; Ma, Z.; Harrington, L. Refrigerator cost trap for low-income households: Developments in measurement and verification of appliance replacements. Energy Sustain. Dev. 2021, 60, 1–14. [Google Scholar] [CrossRef]

- Bolaji, B.O. Exergetic performance of a domestic refrigerator using R12 and its alternative refrigerants. J. Eng. Sci. Technol. 2010, 5, 435–446. [Google Scholar]

- Goeschl, T. Cold Case: The forensic economics of energy efficiency labels for domestic refrigeration appliances. Energy Econ. 2019, 84, 104468. [Google Scholar] [CrossRef]

- Ing Liang, W.; Krüger, E. Comparing energy efficiency labelling systems in the EU and Brazil: Implications, challenges, barriers and opportunities. Energy Policy 2017, 109, 310–323. [Google Scholar] [CrossRef]

- Diario Oficial de la Unión Europea. Reglamento Delegado (UE) N o 1060/2010 de la Comision de 28 de Septiembre de 2010 por; Diario Oficial de la Unión Europea: Brussels, Belgium, 2010. [Google Scholar]

- Parlamento Europeo. Reglamento Delegado (UE) 2017/1926 de la Comision de 31 de Mayo de 2017; Parlamento Europeo: Strasbourg, France, 2017. [Google Scholar]

- Michel, A.; Attali, S.; Bush, E. Energy Efficiency of White Goods in Europe: Monitoring the Market with Sales Data; Technical Report June; Association for the Development of Monfragüe and Its Environment: Hamburg, Germarny, 2015. [Google Scholar]

- Schubert, T.; Breitschopf, B.; Plötz, P. Energy efficiency and the direct and indirect effects of energy audits and implementation support programmes in Germany. Energy Policy 2021, 157, 112486. [Google Scholar] [CrossRef]

- Parlamento Europeo y Consejo Europeo. Directiva 2018/2002/UE Por la que se Modifica la Directiva 2012/27/UE Relativa a la Eficiencia Energética; Parlamento Europeo y Consejo Europeo: Strasbourg, France, 2018. [Google Scholar]

- Faure, C.; Guetlein, M.; Schleich, J. Effects of rescaling the EU energy label on household preferences for top-rated appliances. Energy Policy 2021, 156, 112439. [Google Scholar] [CrossRef]

- European Commission. Reducing the Price of Development: The Global Potential of Efficiency Standards in the Residential Electricity Sector; European Commission: Brussels, Belgium, 2006; p. 464. [Google Scholar]

- Kelly, G. Sustainability at home: Policy measures for energy-efficient appliances. Renew. Sustain. Energy Rev. 2012, 16, 6851–6860. [Google Scholar] [CrossRef]

- Bertoldi, P.; Mosconi, R. The Impact of Energy Efficiency Policies on Energy Consumption in the EU Member States: A New Approach Based on Energy Policy Indicators; Technical Report; Publications Office: Brussels, Belgium, 2015. [Google Scholar]

- Bertoldi, P.; Mosconi, R. Do energy efficiency policies save energy? A new approach based on energy policy indicators (in the EU Member States). Energy Policy 2020, 139, 111320. [Google Scholar] [CrossRef]

- Harrington, L.; Aye, L.; Fuller, B. Energy impacts of defrosting in household refrigerators: Lessons from field and laboratory measurements. Int. J. Refrig. 2018, 86, 480–494. [Google Scholar] [CrossRef]

- Stadelmann, M.; Schubert, R. How Do Different Designs of Energy Labels Influence Purchases of Household Appliances? A Field Study in Switzerland. Ecol. Econ. 2018, 144, 112–123. [Google Scholar] [CrossRef]

- The Ecodesign Directive for Energy-Related Products. Available online: https://www.eceee.org/ecodesign/ (accessed on 19 July 2022).

- Foelster, A.; Andrew, S.; Kroeger, L.; Bohr, P.; Dettmer, T.; Boehme, S.; Herrmann, C. Electronics recycling as an energy efficiency measure—A Life Cycle Assessment (LCA) study on refrigerator recycling in Brazil. J. Clean. Prod. 2016, 129, 30–42. [Google Scholar] [CrossRef]

- European Commission. Simpler EU Energy Labels for Lighting Products Applicable from 1 September; Technical Report; European Commission: Brussels, Belgium, 2021. [Google Scholar]

- Marques, A.; Gomez-Agustina, L.; Dance, S.; Hammond, E.; Wood, I. Noise reduction in commercial refrigerators—A practical approach. In Proceedings of the 20th International Congress on Sound and Vibration 2013, ICSV 2013, Bangkok, Thailand, 7–11 July 2013; Volume 1, pp. 753–760. [Google Scholar]

- He, Z.; Li, D.; Han, Y.; Zhou, M.; Xing, Z.; Wang, X. Noise control of a twin-screw refrigeration compressor. Int. J. Refrig. 2021, 124, 30–42. [Google Scholar] [CrossRef]

- Héroux, M.; Babisch, W.; Belojevic, G.; Brink, M.; Janssen, S.; Lercher, P.; Paviotti, M.; Pershagen, G.; Waye, K.; Preis, A.; et al. Who environmental noise guidelines for the European Region. In Proceedings of the Euronoise 2015, Maastricht, The Netherlands, 31 May–3 June 2015; pp. 2589–2593. [Google Scholar]

- Licitra, G. Differences between the principles of the European national noise laws and those of the environmental noise directive. In Proceedings of the Euronoise 2015, Maastricht, The Netherlands, 31 May–3 June 2015; pp. 1045–1048. [Google Scholar]

- Bansal, P.; Vineyard, E.; Abdelaziz, O. Advances in household appliances- A review. Appl. Therm. Eng. 2011, 31, 3748–3760. [Google Scholar] [CrossRef]

- Zainudin, N.; Siwar, C.; Choy, E.; Chamhuri, N. Evaluating the Role of Energy Efficiency Label on Consumers’ Purchasing Behaviour. APCBEE Procedia 2014, 10, 326–330. [Google Scholar] [CrossRef]

- Vieira de Carvalho, A.; Rojas, L.; Mendez, P.; Flam, S.; Couture-Roy, M.; Langlois, P.; Dufresne, V. Guía E: Programas de Normalización y Etiquetado de Eficiencia energética; Inter-America Developement: Washington, DC, USA, 2015; p. 64. [Google Scholar] [CrossRef]

- Boyd, G.; Dutrow, E.; Tunnessen, W. The evolution of the Energy Star® energy performance indicator for benchmarking industrial plant manufacturing energy use. J. Clean. Prod. 2008, 16, 709–715. [Google Scholar] [CrossRef]

- Murray, A.; Mills, B. Read the label! Energy Star appliance label awareness and uptake among U.S. consumers. Energy Econ. 2011, 33, 1103–1110. [Google Scholar] [CrossRef]

- Hirayama, S.; Nakagami, H.; Murakoshi, C.; Nakamura, M. International Comparison of Energy Efficiency Standard and Labels: Development Process and Implementation Phase; Stanford University: Stanford, CA, USA, 2008; pp. 110–122. [Google Scholar]

- Wiel, S.; Van, L.; Lloyd, H. Energy Efficiency Standards and Labels in North America: Opportunities for Harmonization; Technical Report; Lawrence Berkeley National Laboratory: Berkeley, CA, USA; Available online: https://escholarship.org/uc/item/0gj43170 (accessed on 30 July 2022).

- Karkova, M. Energy Star. Available online: https://www.ecolabelindex.com/ecolabel/energy-star-usa (accessed on 1 June 2022).

- Morillon, G.; Rosas, A.; Floresa, D. What goes up: Recent trends in Mexican residential energy use. Energy 2010, 35, 2596–2602. [Google Scholar]

- Bansal, P.K. Developing new test procedures for domestic refrigerators: Harmonisation issues and future R&D needs—A review. Int. J. Refrig. 2003, 26, 735–748. [Google Scholar] [CrossRef]

- Comisión Nacional para el Uso Eficiente de la Energia. Nom-015-ener-2002; Comisión Nacional para el Uso Eficiente de la Energia: Mexico City, Mexico, 2003.

- Lutz, W.F. Eficiencia Energética y Desarrollo Sustentable en Europa y América Latina. In Proceedings of the Foro Nacional “Promoviendo la Eficiencia Energética”, Caracas, Venezuela, 4 October 2002; Available online: https://energy-strategies.nl/files-all/eficiencia-energetica-y-desarrollo-sustentable-en-europa-y-america-latina/ (accessed on 3 May 2022).

- Comisión Nacional para el Uso Eficiente de la Energía. NOM-015-ENER-2012; Comisión Nacional para el Uso Eficiente de la Energía: Mexico City, Mexico, 2012.

- Fideicomiso para el Ahorro de Energia Electrica (FIDE). Retos, Logros y Desafios 2013–2018; Technical Report; Fideicomiso para el Ahorro de Energia Electrica: Mexico City, Mexico, 2018. [Google Scholar]

- Secretaría de Energía (SENER). Fondo para la Transición Energética y el Aprovechamiento Sustentable de la Enegía (FOTEASE); Technical Report; Secretaría de Energía: Mexico City, Mexico, 2018. [Google Scholar]

- Comisión Nacional para el Uso Eficiente de la Energía. NOM-015-ENER-2018; Comisión Nacional para el Uso Eficiente de la Energía: Mexico City, Mexico, 2018.

- Arroyo, G.; Aguillon, J.; Ambriz, J.; Canizal, G. Electric energy saving potential by substitution of domestic refrigerators in Mexico. Energy Policy 2009, 37, 4737–4742. [Google Scholar] [CrossRef]

- Hancevic, P.; Lopez, J. Energy efficiency programs in the context of increasing block tariffs: The case of residential electricity in Mexico. Energy Policy 2019, 131, 320–331. [Google Scholar] [CrossRef]

- Onofri Salinas, A.M. Análisis del Impacto en el Consumo Eléctrico de la Implementación en Chile de la Política Pública de Estándares Mínimos de Eficiencia Energética para Lámparas Incandescentes; Universidad de Chile: Santiago, Chile, 2020. [Google Scholar]

- ISO 15502; Household refrigerating appliances - Characteristics and test methods. International Organization for Standardization (ISO): Geneva, Switzerland, 2007.

- IEC 60335-2-24; Household and similar electrical appliances—Safety—Part 2-24: Particular requirements for refrigerating appliances, ice-cream appliances and ice makers. Standardization International for Organization (ISO): Geneva, Switzerland, 2002.

- Letschert, V.E.; Mcneil, M.A.; Pavon, M.; Lutz, W.F. Design of Standards and Labeling programs in Chile: Techno-Economic Analysis for Refrigerators. In Proceedings of the 4th ELAEE Montevideo, Montevideo, Uruguay, 8–9 April 2013; p. 18. [Google Scholar]

- Organización Latinoamericana de Energía (OLADE). Eficiencia energética en América Latina y el Caribe: Avances y oportunidades; OLADE: Quito, Ecuador, 2017. [Google Scholar] [CrossRef]

- Kigali Cooling Performance Program. National Cooling Plan Proposal-Chile; Technical Report; National Cooling Plan Proposal (NCPP): Kigali, Ruanda, 2020. [Google Scholar]

- Ministerio de Energía Gobierno de Chile. Energia 2050. Política Energética de Chile. Informe de Seguimiento 2016; Technical Report; Ministerio de Energía Gobierno de Chile: Santiago, Chile, 2016.

- Volker, K.; Hirsch, M.; Delgado, F. Analisis de la Gestion Ambientalmente Responsable de Refrigeradores y Congeladores de uso Domestico en Chile; Technical Report; Fundacion de Chile: Santiago, Chile, 2021. [Google Scholar]

- Programa de Estudios e Investigaciones en Energia. Estudio de Bases para la Elaboración de un Plan Nacional de Acción de Eficiencia Energética 2010–2020; Technical Report; Universidad de Chile: Santiago, Chile, 2010. [Google Scholar]

- Nogueira, L.; Cardoso, R.B.; Cavalcanti, C.; Leonelli, P. Evaluation of the energy impacts of the Energy Efficiency Law in Brazil. Energy Sustain. Dev. 2015, 24, 58–69. [Google Scholar] [CrossRef]

- Huse, C.; Lucinda, C.; Cardoso, A. Consumer response to energy label policies: Evidence from the Brazilian energy label program. Energy Policy 2020, 138, 111207. [Google Scholar] [CrossRef]

- Sanches, A.; Tudeschini, L.; Coelho, S. Evolution of the Brazilian residential carbon footprint based on direct energy consumption. Renew. Sustain. Energy Rev. 2016, 54, 184–201. [Google Scholar] [CrossRef]

- Conrado, A.; de Martino Jannuzzi, G. Energy efficiency standards for refrigerators in Brazil: A methodology for impact evaluation. Energy Policy 2010, 38, 6545–6550. [Google Scholar] [CrossRef]

- Ministério da Economia/Instituto Nacional de Metrologia. Q.e.T. Portaria Nº 332, de 2 de Agosto de 2021. Available online: https://www.in.gov.br/en/web/dou/-/portaria-n-332-de-2-de-agosto-de-2021-336061973 (accessed on 20 May 2022).

- Cardoso, R.; Nogueira, L.; Haddad, J. Economic feasibility for acquisition of efficient refrigerators in Brazil. Appl. Energy 2010, 87, 28–37. [Google Scholar] [CrossRef]

- Gonzalez, R.; Lucena, A.; Garaffa, R.; Mir, A.R.; Chavez, M.; Cruz, T.; Bezerra, P.; Rathmann, R. Greenhouse gas mitigation potential and abatement costs in the Brazilian residential sector. Energy Build. 2019, 184, 19–33. [Google Scholar] [CrossRef]

- Agencia Internacional de Energia; Ministerio de Minas y Energia de Brasil. Atlas of Energy Efficiency Brazil 2019; Technical Report; International Energy Agency: Paris, France, 2019.

- International Energy Agency (IEA). E4 Country Profile: Energy Efficiency in Brazil; International Enerrgy Agency: Paris, France, 2021. [Google Scholar]

- Minestiro de Minas y Energia. Decreto 2143 de 2017; Technical Report; Departamento Administrativo de la Función Pública: Bogotá, Colombia, 2017.

- Unidad de planeación minero energética (UPME ). Comunicado de Prensa no. 009-2018; Technical Report; Unidad de planeación minero energética (UPME): Bogotá, Colombia, 2018.

- IEC 62552-1; Household Refrigerating Appliances—Characteristics and Test Methods—Part 1: General Requirements. International Electrotechnical Commission (IEC): Geneva, Switzerland, 2015.

- IEC 62552-2; Household Refrigerating Appliances—Characteristics and Test Methods—Part 2: Performance Requirements. International Electrotechnical Commission (IEC): Geneva, Switzerland, 2020.

- IEC 62552-3; Household Refrigerating Appliances—Characteristics and Test Methods—Part 3: Energy Consumption and Volume. International Electrotechnical Commission (IEC): Geneva, Switzerland, 2015.

- Xia, Y.; Liu, Y.; Liu, Y.; Ma, Y.; Xiao, C.; Wu, T. Experimental study on reducing the noise of horizontal household freezers. Appl. Therm. Eng. 2014, 68, 107–114. [Google Scholar] [CrossRef]

- Instituto colombiano de normas técnicas (ICONTEC). Norma Tecnica NTC 2252.Seguridad de Artefactos Electrodomésticos y Artefactos Similares. Parte 2: Requisitos Particulares para Refrigeradores, Fabricadores de Helado y Fabricadores de Hielo; ICONTEC: Bogotá, Colombia, 2016. [Google Scholar]

- Kapici, E.; Kutluay, E.; Izadi, R. A Novel Intelligent Control Method for Domestic Refrigerators Based on User Behavior. Int. J. Refrig. 2022, 136, 209–218. [Google Scholar] [CrossRef]

- Escuela de Ingenieria Electrica and Universidad de Costa Rica. Eficiencia Energética: El Refrigerador; Escuela de Ingenieria Electrica and Universidad de Costa Rica: San Pedro, Costa Rica, 2008. [Google Scholar]

- Hossieny, N.; Owusu, O.; Shrestha, S.; Desjarlais, A. Improved performance of polyurethane foam insulation using polylactide biopolymer liners and its impact on energy efficiency of refrigerator and freezers. In Proceedings of the Antec 2019 the Plastics Technology Conference, Detroit, MI, USA, 18–21 March 2019. [Google Scholar]

- Kumar, K.; Reddy, B.; Chandra, M. Experimental Investigation on the Performance of Refrigerator with Nitrile Rubber and Glass Wool as Insulating Material. In Advances in Industrial Automation and Smart Manufacturing; Springer: Singapore, 2021; Volume 23, pp. 1013–1019. [Google Scholar] [CrossRef]

- Calm, J.M. Comparative efficiencies and implications for greenhouse gas emissions of chiller refrigerants. Int. J. Refrig. 2006, 29, 833–841. [Google Scholar] [CrossRef]

- Isaza, C.; Jara, N. Análisis comparativo de sistemas de refrigeración doméstica utilizando refrigerantes R600a y R134a. Investig. Tecnol. Y Cienc. 2015, 1, 7–15. [Google Scholar]

- Bolaji, B.; Huan, Z. Ozone depletion and global warming: Case for the use of natural refrigerant—A review. Renew. Sustain. Energy Rev. 2013, 18, 49–54. [Google Scholar] [CrossRef]

- Maclaine-Cross, I.; Leonardi, E. Comparative Performance of Hydrocarbon Refrigerants; Commissions Report; The University of South Wales: Melbourne, Australia, 1996. [Google Scholar]

- Sánchez, D.; Andreu-Nácher, A.; Calleja-Anta, D.; Llopis, R.; Cabello, R. Energy impact evaluation of different low-GWP alternatives to replace R134a in a beverage cooler. Experimental analysis and optimization for the pure refrigerants R152a, R1234yf, R290, R1270, R600a and R744. Energy Convers. Manag. 2022, 256, 115388. [Google Scholar] [CrossRef]

- Corte, E.; Flores, C.; Jara, N.; Isaza, C. Sistemas de refrigeración doméstica—Estado del arte de las mejoras en la eficiencia energética. Rev. De La Fac. De Cienc. Químicas De La Univ. De Cuenca Ecuad. 2014, 9, 19–40. [Google Scholar]

- Binneberg, P.; Kraus, E.; Quack, H. Reduction In Power Consumption Of Household Refrigerators By Using Variable Speed Compressors. In Proceedings of the International Refrigeration and Air Conditioning Conference, West Lafayette, IN, USA, 16–19 July 2002; p. 9. [Google Scholar]

- Jang, Y.; Kang, M.; Oh, Y. A Study on the Sound Insulation and Absorption Design Plan which Affect the Noise Propagation from Household Appliances and Facilities in a House Using Room Acoustic Simulation. J. Korean Inst. Archit. Sustain. Environ. Build. Syst. 2020, 14, 767–778. [Google Scholar] [CrossRef]

- Park, K.; Kim, W.; Won, J. High-Frequency Noise Reduction in Mechanical Compartment of a Household Refrigerator via Dynamic Absorber Design. J. Vib. Eng. Technol. 2021, 9, 477–490. [Google Scholar] [CrossRef]

- Cingiz, Z.; Katircioğlu, F.; Saridemir, S.; Yildiz, G.; Cay, Y. Experimental investigation of the effects of different refrigerants used in the refrigeration system on compressor vibrations and noise. Int. Adv. Res. Eng. J. 2021, 5, 152–162. [Google Scholar] [CrossRef]

- Han, H.; Jeong, W.; Kim, M.; Kim, T.H. Analysis of the root causes of refrigerant-induced noise in refrigerators. J. Mech. Sci. Technol. 2009, 23, 3245–3256. [Google Scholar] [CrossRef]

- Son, Y.; Choi, J.; Lee, S. Noise source identification of the hermetic reciprocating compressor for refrigerator. J. Mech. Sci. Technol. Vol. 2021, 35, 4849–4858. [Google Scholar] [CrossRef]

- McCarney, S.; Robertson, J.; Arnaud, J.; Lorenson, K.; Lloyd, J. Using solar-powered refrigeration for vaccine storage where other sources of reliable electricity are inadequate or costly. Vaccine 2013, 31, 6050–6057. [Google Scholar] [CrossRef]

- Ekren, O.; Celik, S.; Noble, B.; Krauss, R. Performance evaluation of a variable speed DC compressor. Int. J. Refrig. 2013, 36, 745–757. [Google Scholar] [CrossRef]

- Sabry, A.; Shallal, A.; Hameed, H.; Ker, P. Compatibility of household appliances with DC microgrid for PV systems. Heliyon 2020, 6, e05699. [Google Scholar] [CrossRef]

- Rajkumar, M.; Rathinam, A. Effective power sharing between Solar Refrigerator and DC Micro Grid. In Proceedings of the 2018 International Conference on Power Electronics (IEEE), Drives and Energy Systems (PEDES), Chennai, India, 18–21 December 2018; pp. 1–4. [Google Scholar] [CrossRef]

- Park, W.; Shah, N.; Phadke, A. Enabling access to household refrigeration services through cost reductions from energy efficiency improvements. Energy Effic. 2019, 12, 1795–1819. [Google Scholar] [CrossRef]

- Ouali, M.; Djebiret, M.; Ouali, R.; Mokrane, M.; Merzouk, N.; Bouabdallah, A. Thermal control influence on energy efficiency in domestic refrigerator powered by photovoltaic. Int. J. Hydrogen Energy 2017, 42, 8955–8961. [Google Scholar] [CrossRef]

- Su, P.; Ji, J.; Cai, J.; Gao, Y.; Han, K. Dynamic simulation and experimental study of a variable speed photovoltaic DC refrigerator. Renew. Energy 2020, 152, 155–164. [Google Scholar] [CrossRef]

- Modi, A.; Chaudhuri, A.; Vijay, B.; Mathur, J. Performance analysis of a solar photovoltaic operated domestic refrigerator. Appl. Energy 2009, 86, 2583–2591. [Google Scholar] [CrossRef]

- Espacenet. Espacenet—Página Inicial. Espacenet. Available online: https://lp.espacenet.com/ (accessed on 25 April 2022).

- Electronic Code of Federal Regulations (CFR). Federal Trade Commission Part 305—Energy and Water Use Labeling for Consumer Products Under the Energy Policy and Conservation Act (‘‘ENERGY LABELING”); CFR: New York, NY, USA, 2021. [Google Scholar]

- Encuesta de Consumo de Energía Residencial (RECS)—Administración de Información Energética. Available online: https://www.eia.gov/consumption/residential/ (accessed on 5 April 2022).

- Diario oficial de la Unión Europea. Reglamento Delegado (UE) 2019/2016 de la Comisión de 11 de Marzo de 2019; Diario Oficial de la Unión Europea: Brussels, Belgium, 2019. [Google Scholar]

- Camarinha-Matos, L.; Afsarmanesh, H. A Roadmapping Methodology for Strategic Research on VO. In Collaborative Networked Organizations; Kluwer Academic Publishers: Boston, MA, USA, 2004; pp. 275–288. [Google Scholar] [CrossRef]

| Country | Labeling Regulation or MEPS | Technical Rules |

|---|---|---|

| Colombia | RETIQ | NTC-IEC 62552 |

| Brazil | RTAC 002813 | IEC 62552 |

| Chile | NCh 3000:2006 | IEC 62552 |

| Mexico | Mexican Official Standard Nom-015-Ener-2018 | The same labeling regulation |

| European Union | Delegated Regulation (UE) 2016/2019 from the commission of march 2019 | The same labeling regulation |

| USA | Part 305- Energy and Water Use Labeling for Consumer Products Under the Energy Policy and Conservation Act («Energy Labeling Rule»). Appendix A to Subpart B of Part 430 | The same labeling regulation |

| Energy Efficiency Range | Relative Saving (%) | Relative Saving (%) | Relative Saving (%) |

|---|---|---|---|

| Validity | Until 31 August 2021 | From 1 September 2021 | From 1 September 2023 |

| A | |||

| B | |||

| C | |||

| D | REMOVED | ||

| E | REMOVED | REMOVED | |

| F | REMOVED | REMOVED | |

| G | REMOVED | REMOVED |

| Refrigerator Type | Energy Consumption Calculation | Definitions |

|---|---|---|

| Equipment with manual and automatic defrosting | test cycle energy expended in kilowatt-hours per day. energy expended in kilowatt-hours during the test period. T duration of the trial period in minutes. 1440 conversion factor to adjust to a 24-h period in minutes per day. K dimensionless correction factor of 1.0 for chillers and chiller-freezers; and 0.55 for chillers and combined refrigeration products for chillers to adjust for average household use. | |

| Equipment with automatic long time defrosting | energy expended in kilowatt-hours during the first part of the test. energy expended in kilowatt-hours during the second part of the test. and time in minutes of the first and second test parts respectively defrost timer run time or compressor run time between defrosts in hours required to cycle the compressor through a complete cycle, rounded to the nearest tenth of an hour. 12 factor to adjust for 50% compressor running time in hours per day. | |

| Equipment with variable defrost control | shortest compressor run time between defrost used in the variable defrost control algorithm (greater than or equal to 6 but less than or equal to 12 h). maximum compressor run time between defrosts in hours rounded to the nearest tenth of an hour (greater than but not more than 96 h. F ratio of energy consumption per day in excess of the least amount of energy and the maximum difference in energy consumption per day y is equal to 0.20. For the variable defrost models with no values for and in the algorithm, the default values of 6 and 96, respectively, will be used. |

| Mexico | |

|---|---|

| Maximum Energy Consumption for Household Refrigerators, Refrigerator-Freezers and Freezers | |

| Description of the Device | Maximum Energy Consumption per Year (Emax) |

| 1. Refrigerator-freezers and refrigerators efrigerators other than refrigerators appliances with manual defrost only | |

| 1A. Only refrigerators with manual defrost. | |

| 2. Refrigerator-freezer with partially automatic defrost. | |

| 3. Refrigerator-freezer with automatic defrost, with top-mounted freezer, without automatic icemaker. | |

| 3-BI. Built-in refrigerator-freezer with automatic defrost, with top-mounted freezer without automatic icemaker. | |

| 3I. Refrigerator-freezer with automatic defrost, with top-mounted freezer with automatic ice maker without ice inlet through outside door. | |

| 3I-BI. Built-in refrigerator-freezer, with automatic defrost with top-mounted freezer with automatic icemaker without outside door ice delivery. | |

| Colombia | Annual energy consumption of the device, determined as is the Energy Consumption in a test period of 24 h * 365 days | |

| European Union | is the annual energy consumption given in kWh/year. L Heat load factor of the food used in the test Daily energy in kWh/ 24 h Energy used by an environmentally controlled anti-condensation heater (kWh/year) | |

| United States | test cycle energy expended in kilowatt-hours per day. energy expended in kilowatt-hours during the test period. T test period duration in minutes1440 conversion factor to adjust to a 24-h period in minutes per day. K dimensionless correction factor of 1.0 for chillers and chiller-freezers; and 0.55 for chillers and refrigeration products combined for chillers to adjust for average household usage | |

| Brazil | declared monthly energy consumption is the energy consumption in Wh per 24 h, based on the ambient temperature determined at 32 °C. | |

| Mexico | Maximum power consumption adjusted volume and correlation coefficients dependent on the type of cooler |

| Maximum Temperature Obtained in the Freezer Compartment or in Its Section () | Nominal Temperature Rating °C) | Number of Stars |

|---|---|---|

| 0 | 0 | |

| 1 (*) | ||

| 2 (**) | ||

| 3 (***) |

| Colombia | n is the total number of compartments of the equipment. is the useful volume of the compartment(s), in liters. is the nominal compartment temperature in °C. , and are correction factors | |

| European Union | is the net volume of a given type of compartment in the apparatus. is the weighting coefficient for different compartment types (equal to 1 for the fresh food compartment (5 ℃) and equal to 2. for the nonfresh food compartment. is a factor equal to 1.2 for frost-free compartments and 1 for other compartments. | |

| United States | freezer compartment volume in liters. volume of the fresh food compartment in liters cooler compartment volume in liters. adjustment factor | |

| Brazil | Refrigerator compartment volume (liters). Freezer compartment volume (liters). f Equivalent value of the classification of each compartment. | |

| Mexico | freezer compartment volume in liters. volume of the fresh food compartment in liters cooler compartment volume in liters. and adjustment factor |

| USA | ||

|---|---|---|

| Product Class | Annual Energy Consumption Base Allowance, AECBASE (kWh/year) | % Less Energy Than Measured Energy Use |

| Full-Size Refrigerators and Refrigerator-Freezers | ||

| 1. Refrigerator-freezers and refrigerators other than all refrigerators with manual defrost. | 10% | |

| 1A. All Refrigerators refrigerators with manual defrost | 10% | |

| 2. Refrigerator-freezers partial automatic defrosts. | 10% | |

| 3. Refrigerator-freezers automatic defrost with top-mounted freezer without an automatic icemaker | 10% | |

| 3-BI. Built-in refrigerator-freezer automatic defrost with top mounted freezer without an automatic icemaker. | 10% | |

| 3I. Refrigerator-freezers-autmatic defrost with top mounted freeser with an automatic icemaker without through-the-door ice service | 10% | |

| Energy Efficiency Range | Colombia | EU | Chile | Brazil | |||

|---|---|---|---|---|---|---|---|

| Relative Saving (%) | Relative Saving (%) | Relative Saving (%) | Energy Efficiency Index IEE | Energy Efficiency Index Refrigerator IEE | Maximun Efficiency Rates (% in relation to Cp) (Valid until 29 June 2022 | ||

| Validity | Until 31 August 2021 | From 1 September 2021 | From 1 September 2023 | Refrigerator Freezer (RC) | Refrigerator-Freezer Frost-Free (RC FF) | ||

| – | – | – | – | – | – | ||

| – | – | – | – | – | – | ||

| A | 85.50% | 84.60% | |||||

| B | 93.10% | 92.10% | |||||

| C | 97.20% | 97.20% | |||||

| D | REMOVED | – | – | ||||

| E | REMOVED | REMOVED | – | – | |||

| F | REMOVED | REMOVED | – | – | |||

| G | REMOVED | REMOVED | – | – | |||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ramírez Sánchez, A.F.; Solís-Chaves, J.S.; Rodríguez-Muñoz, A.d.P.; Arias Barragán, L.A.; Serna-Pérez, D.X.; Prías Caicedo, O.F. Residential Refrigeration MEPS in Colombia: A Review and a Comparative Analysis. Energies 2022, 15, 6483. https://doi.org/10.3390/en15176483

Ramírez Sánchez AF, Solís-Chaves JS, Rodríguez-Muñoz AdP, Arias Barragán LA, Serna-Pérez DX, Prías Caicedo OF. Residential Refrigeration MEPS in Colombia: A Review and a Comparative Analysis. Energies. 2022; 15(17):6483. https://doi.org/10.3390/en15176483

Chicago/Turabian StyleRamírez Sánchez, Andrés Felipe, Juan Sebastián Solís-Chaves, Andrea del Pilar Rodríguez-Muñoz, Luis Alejandro Arias Barragán, Diana Ximena Serna-Pérez, and Omar Fredy Prías Caicedo. 2022. "Residential Refrigeration MEPS in Colombia: A Review and a Comparative Analysis" Energies 15, no. 17: 6483. https://doi.org/10.3390/en15176483

APA StyleRamírez Sánchez, A. F., Solís-Chaves, J. S., Rodríguez-Muñoz, A. d. P., Arias Barragán, L. A., Serna-Pérez, D. X., & Prías Caicedo, O. F. (2022). Residential Refrigeration MEPS in Colombia: A Review and a Comparative Analysis. Energies, 15(17), 6483. https://doi.org/10.3390/en15176483