Improved Frequency Control Strategy for Offshore Wind Farm Integration via VSC-HVDC

Abstract

:1. Introduction

- (1)

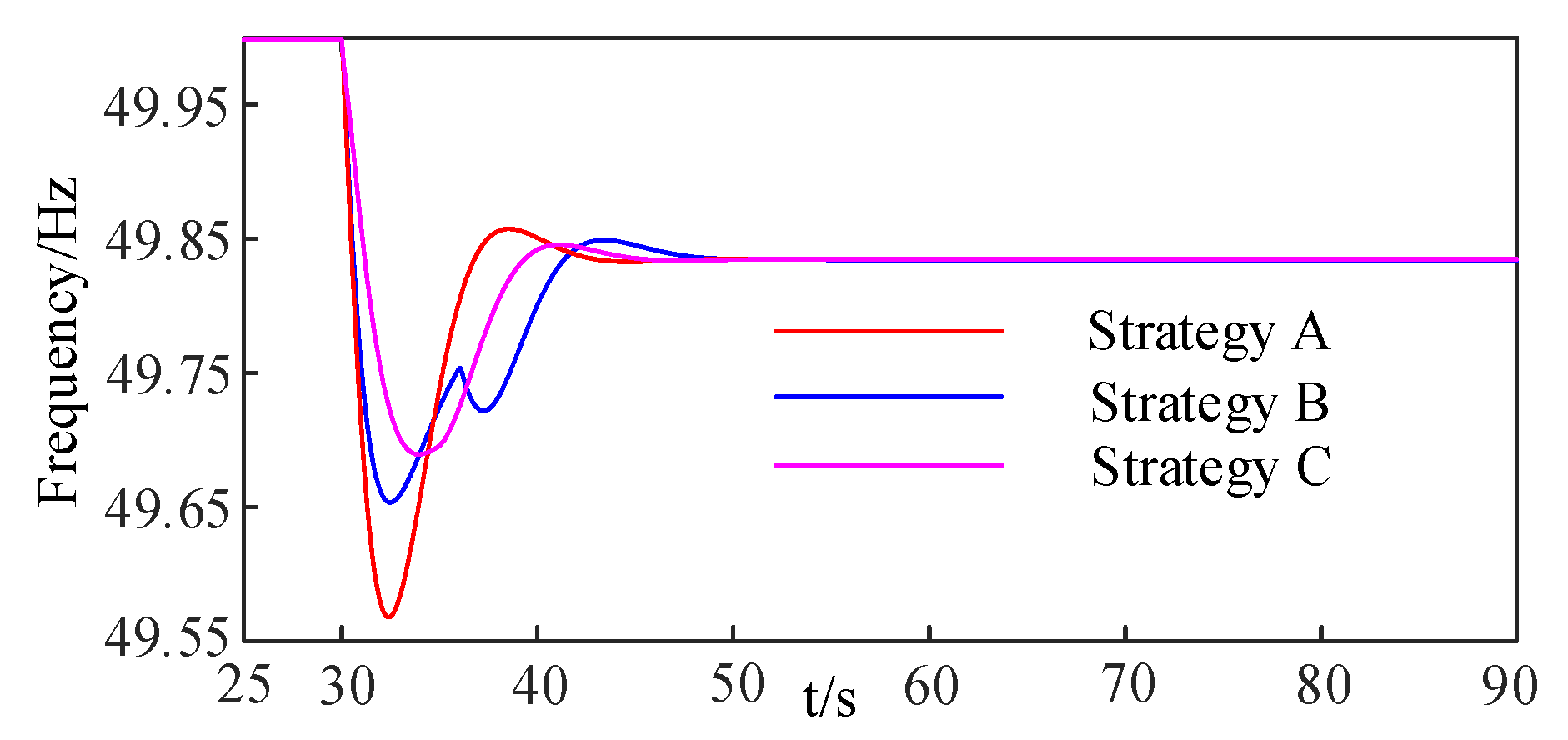

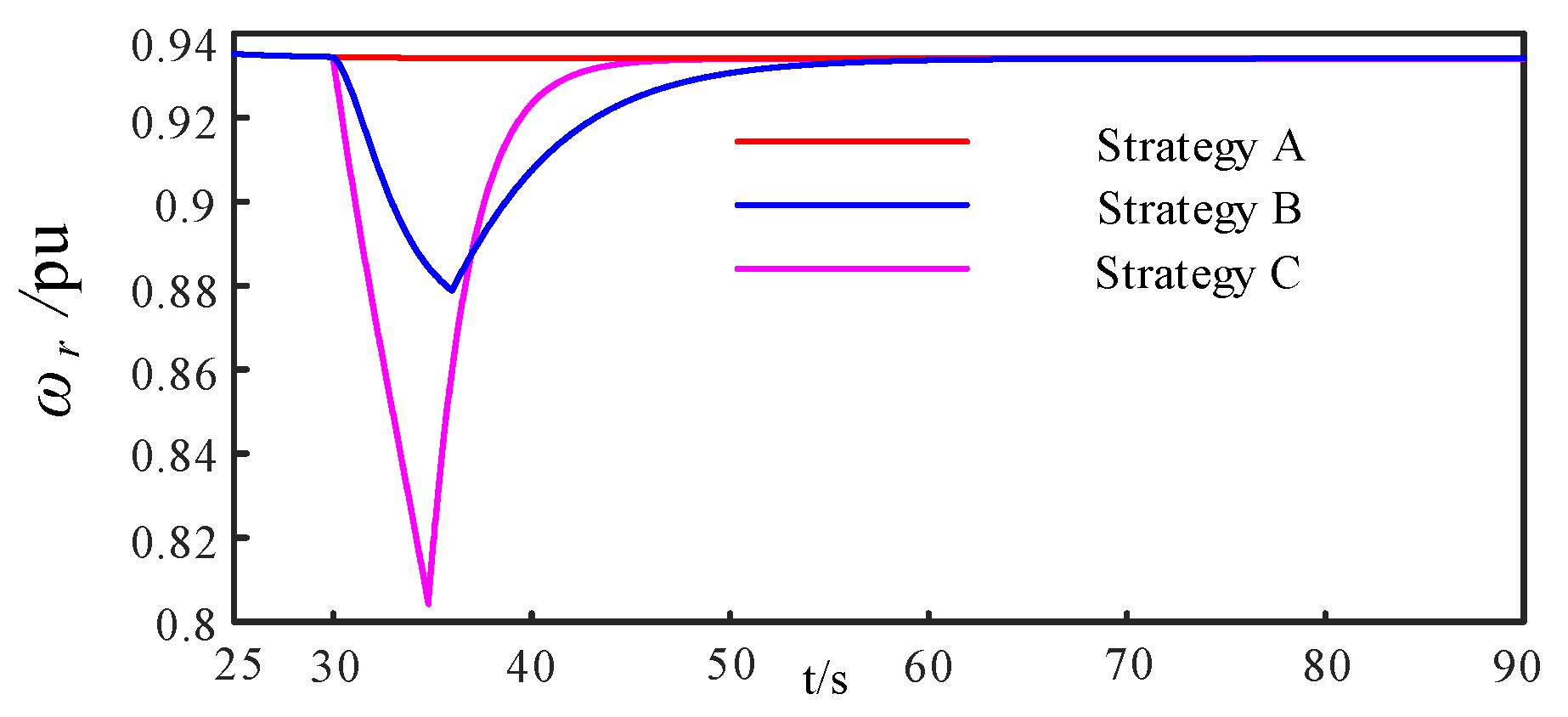

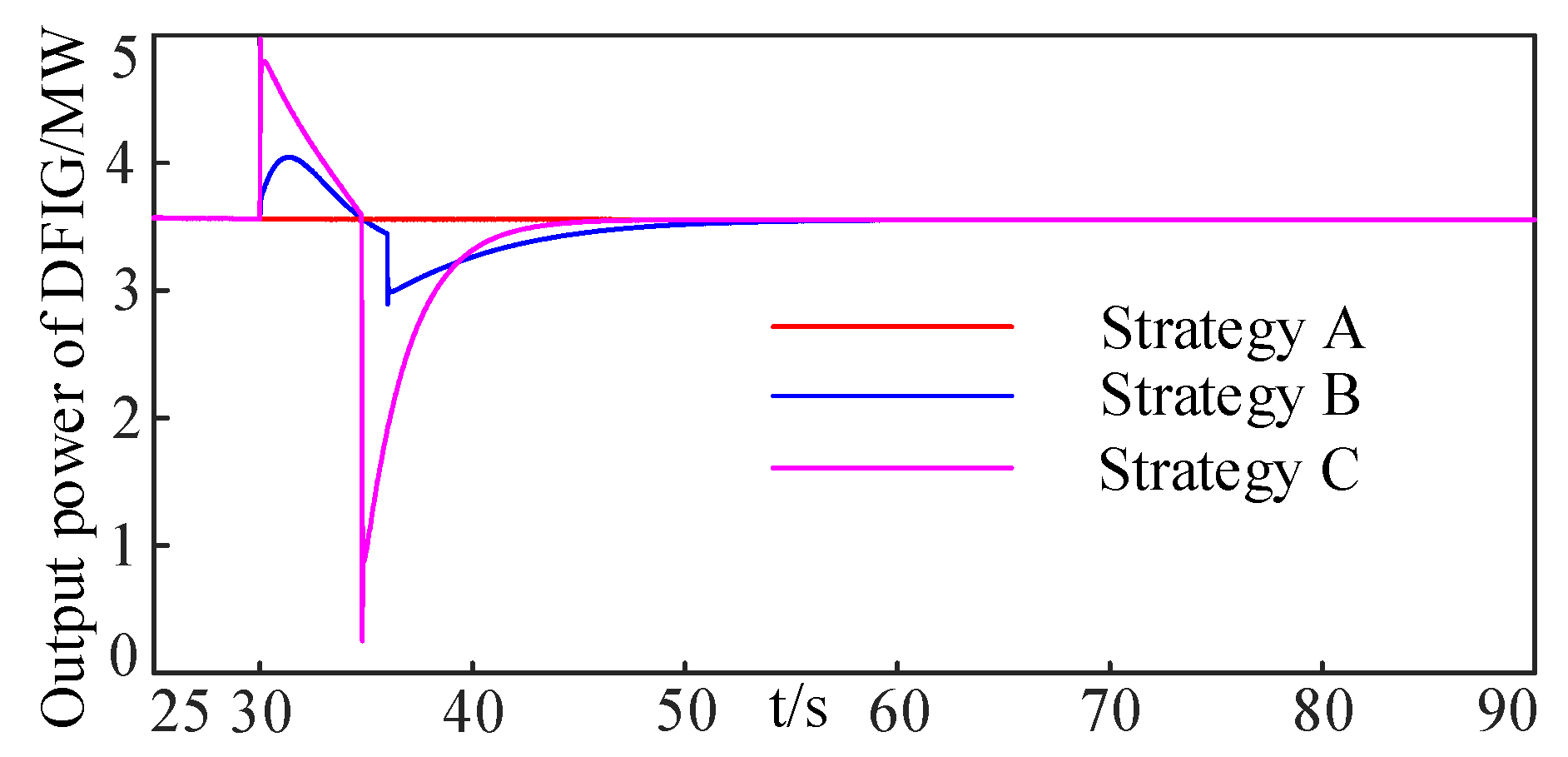

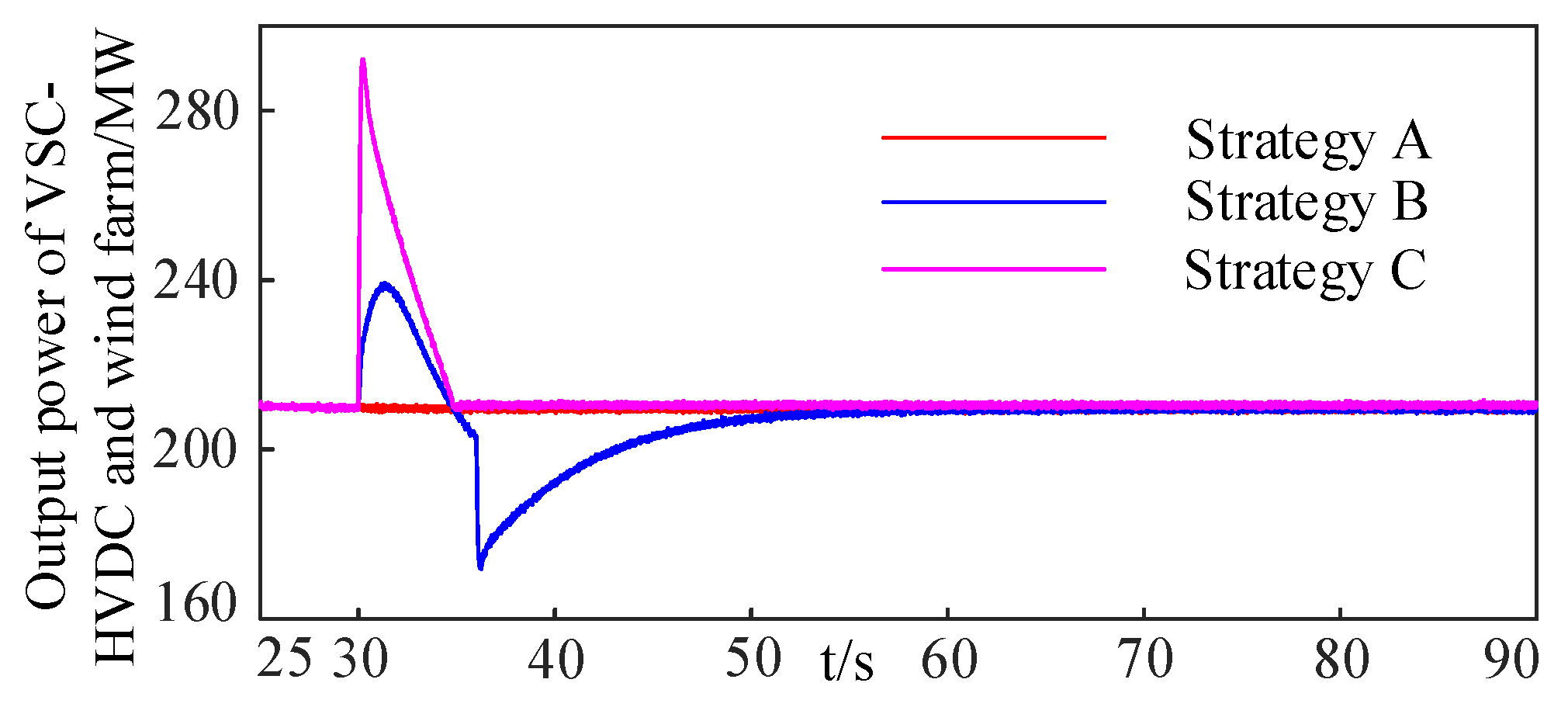

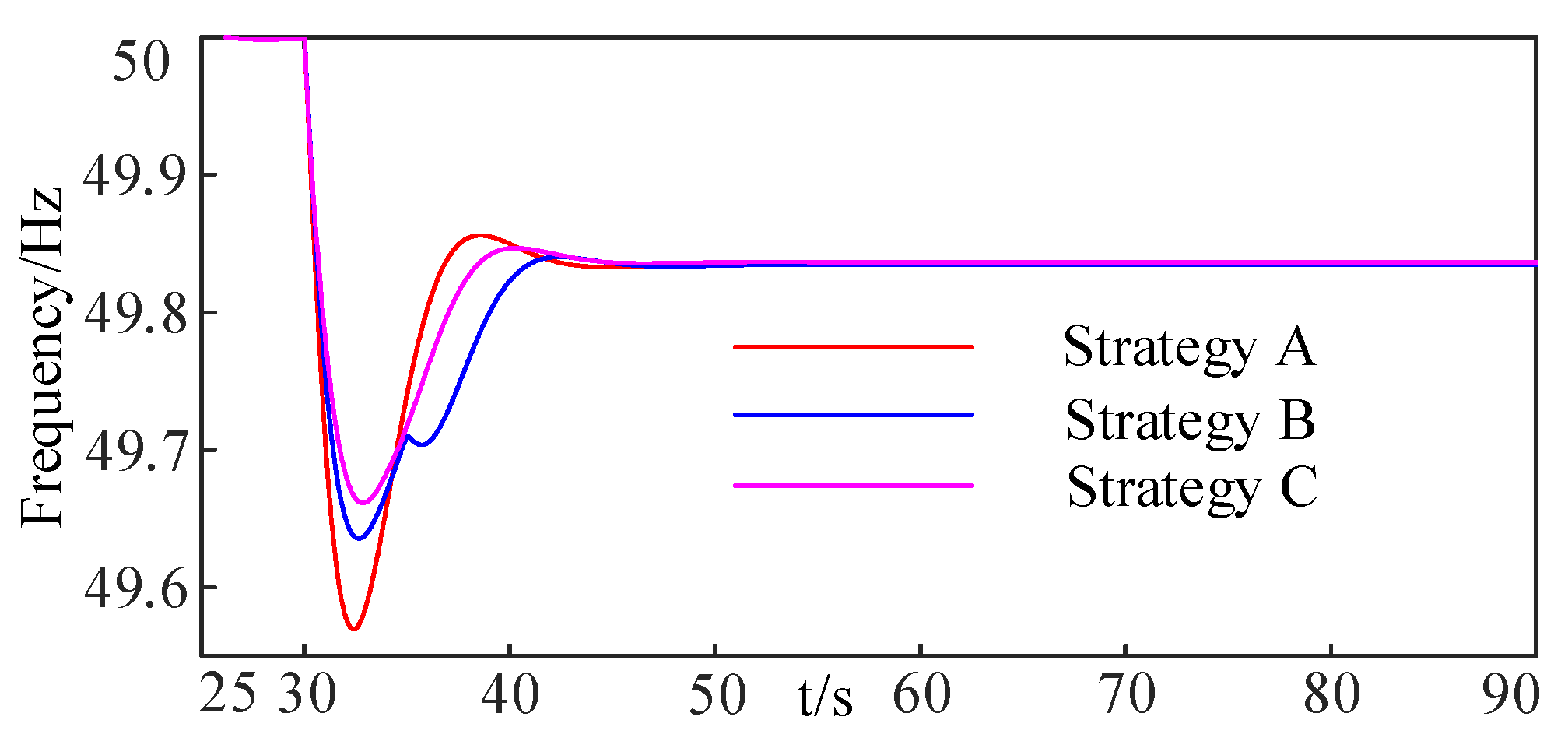

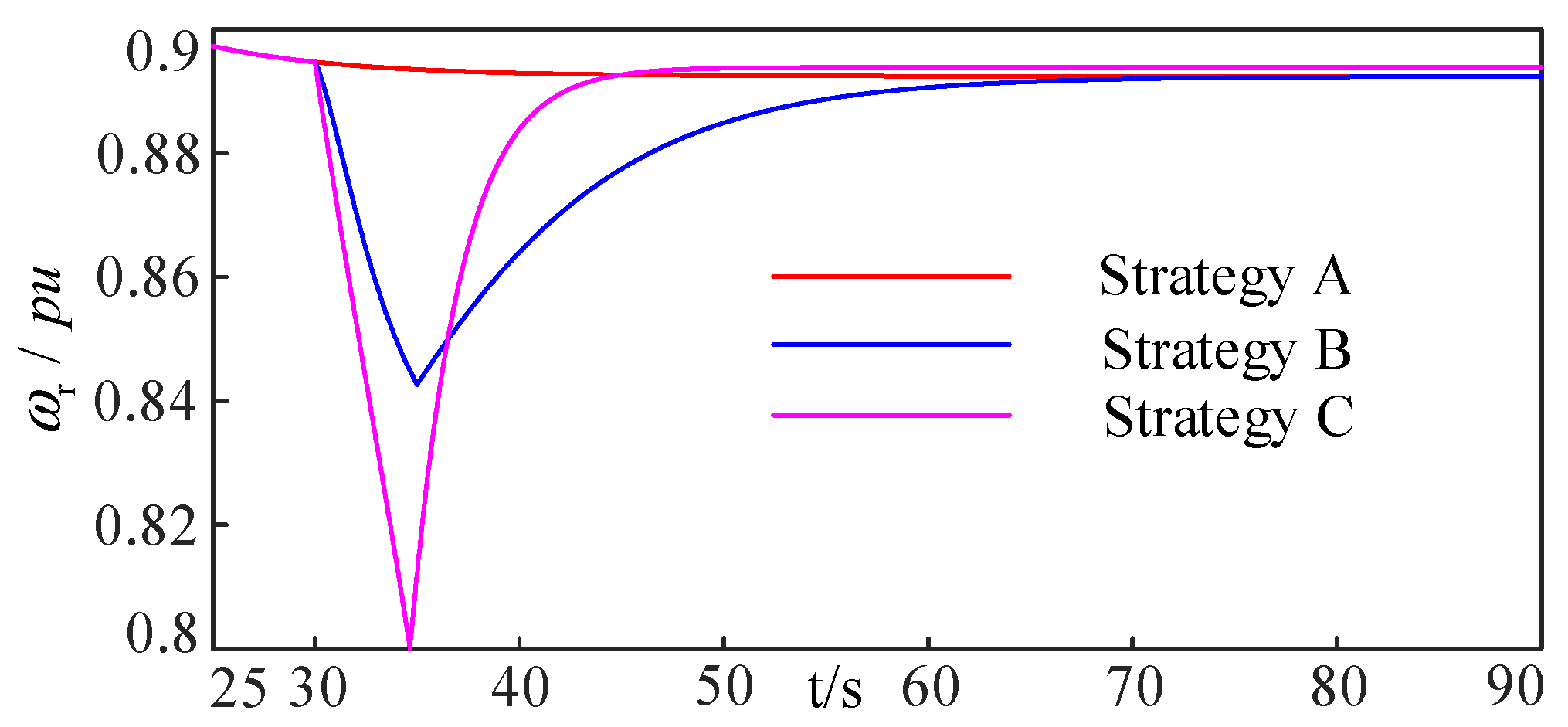

- An improved frequency regulation strategy for VSC-HVDC integrated offshore wind farm is proposed, which consists of the frequency decrease stage and the rotor speed recovery stage.

- (2)

- In the frequency decrease stage, the frequency nadir is improved by making full use of the mechanical power and rotor kinetic energy of WTs.

- (3)

- In the rotor speed recovery stage, the SFD problem can be avoided by releasing the power of the DC capacitors of VSC-HVDC.

2. The Traditional Comprehensive Inertial Control of DFIG

2.1. Wind Turbine Model

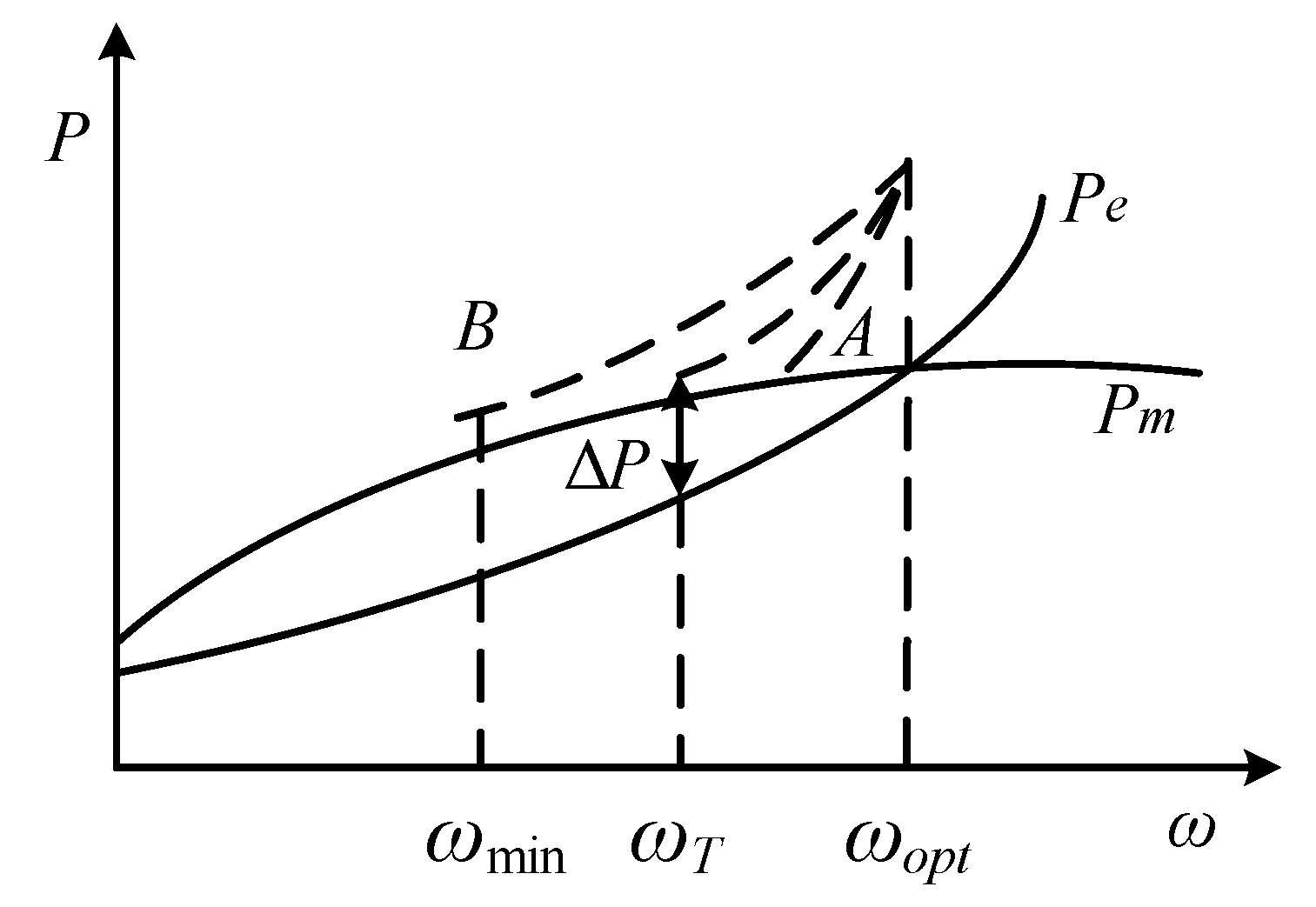

2.2. Traditional Comprehensive Inertial Control

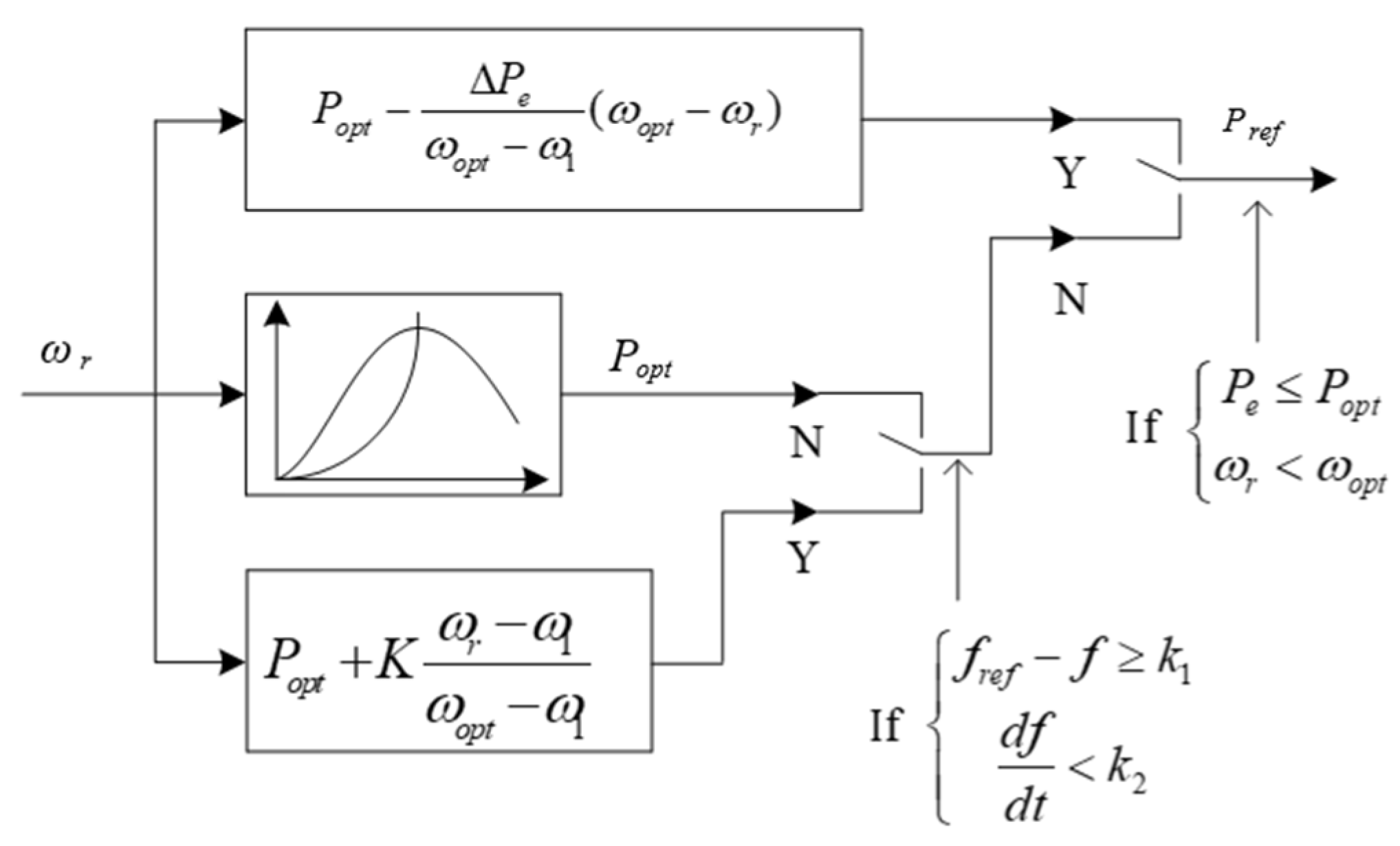

3. Improved Frequency Control Strategy

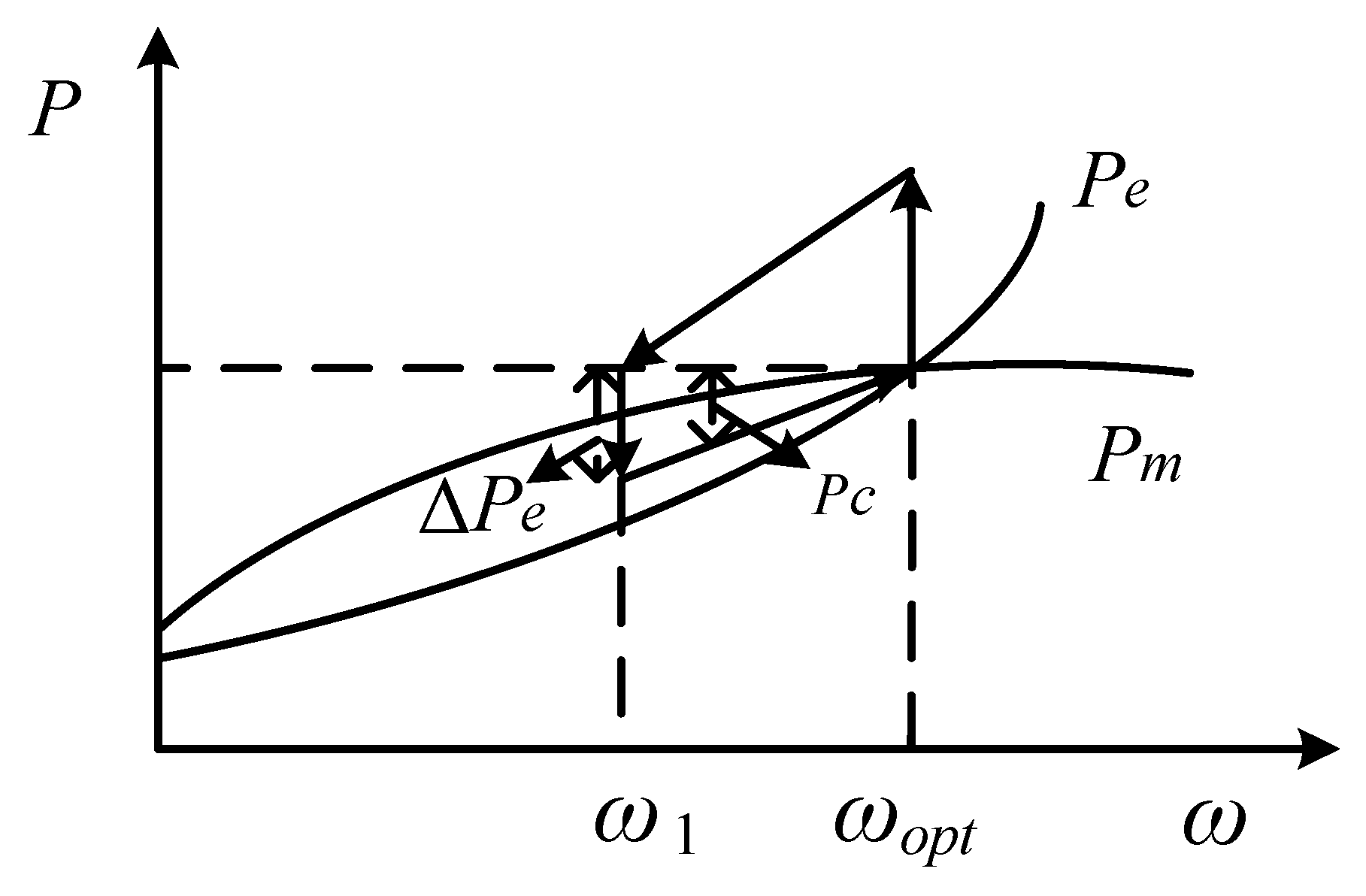

3.1. Improved Rotor Kinetic Energy Control Strategy

3.2. The Adjustment Parameter K

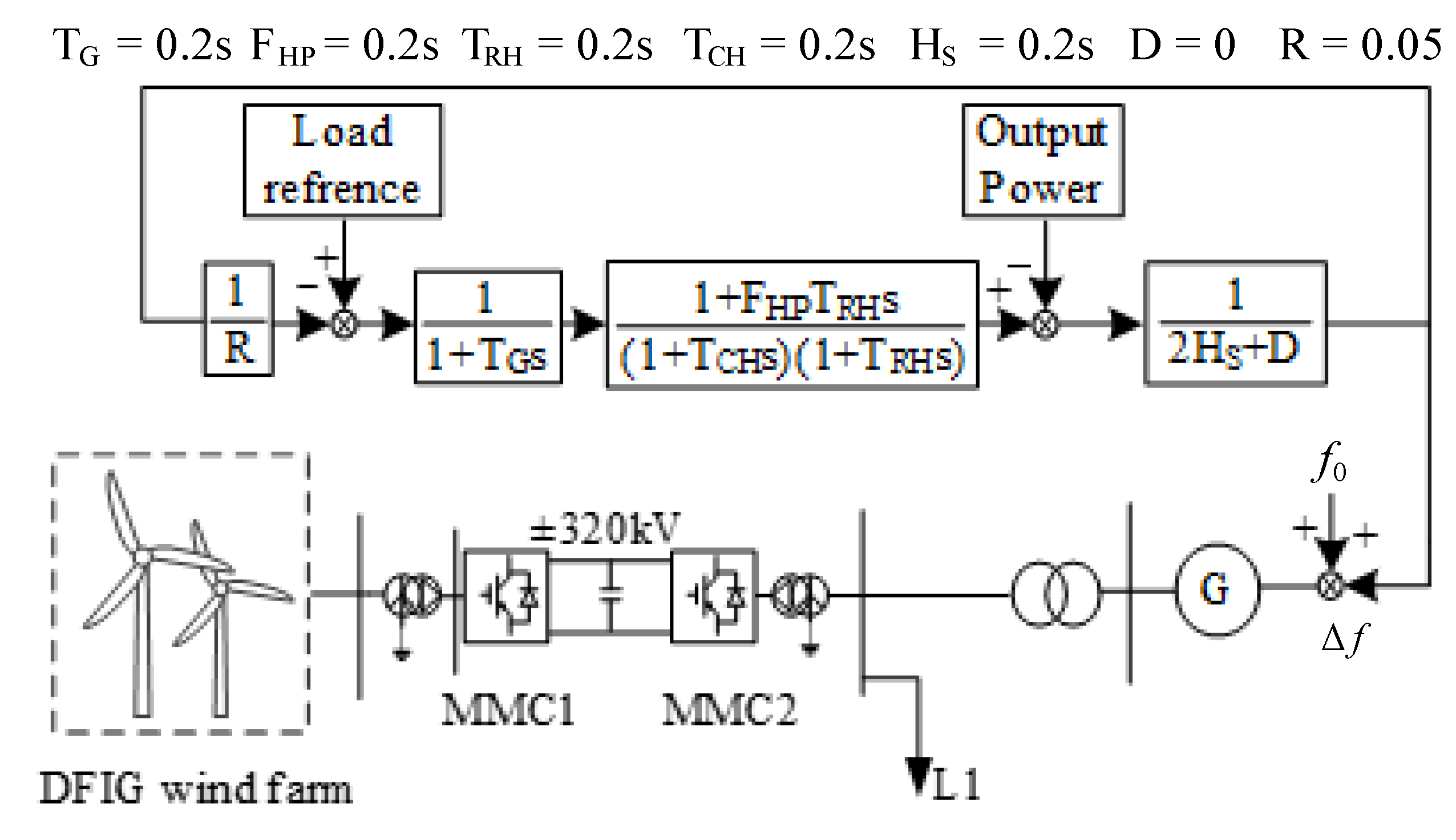

3.3. Auxiliary Frequency Regulation of VSC-HVDC

- (1)

- The increase of system load leads to the drop of system frequency and triggers the frequency regulation of DFIG.

- (2)

- The rotor speed decreases gradually. When the rotor speed reaches the set speed , the capacitor of VSC-HVDC is triggered to release power.

- (3)

- The rotor speed rises, and DFIG outputs electromagnetic power according to the command. When rotor speed reaches the optimal power operation point again, DFIG and VSC-HVDC exit the frequency regulation at the same time.

- (4)

- When the system frequency recovers to be stable, gradually increase the DC voltage of VSC-HVDC to the rated value to prepare for the next auxiliary frequency regulation.

4. Simulation Studies

4.1. Selection of the Adjustment Parameter K

4.2. Simulation Results

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kunjumuhammed, L.; Pal, B.; Gupta, R.; Dykes, K. Stability Analysis of a PMSG-Based Large Offshore Wind Farm Connected to a VSC-HVDC. In Proceedings of the 2018 IEEE Power & Energy Society General Meeting (PESGM), Portland, OR, USA, 5–10 August 2018. [Google Scholar]

- Guo, Y.; Gao, H.; Xing, H.; Wu, Q.; Lin, Z. Decentralized Coordinated Voltage Control for VSC-HVDC Connected Wind Farms Based on ADMM. IEEE Trans. Sustain. Energy 2019, 10, 800–810. [Google Scholar] [CrossRef]

- Li, Y.; Guo, J.; Zhang, X.; Wang, S.; Ma, S.; Zhao, B.; Wu, G.; Wang, T. Over-Voltage Suppression Methods for the MMC-VSC-HVDC Wind Farm Integration System. IEEE Trans. Circuits Syst. II 2020, 67, 355–359. [Google Scholar] [CrossRef]

- Lin, C.-H.; Wu, Y.-K. Overview of Frequency-Control Technologies for a VSC-HVDC-Integrated Wind Farm. IEEE Access 2021, 9, 112893–112921. [Google Scholar] [CrossRef]

- Lu, Z.; Ye, Y.; Qiao, Y. An Adaptive Frequency Regulation Method with Grid-Friendly Restoration for VSC-HVDC Integrated Wind Farms. IEEE Trans. Power Syst. 2019, 34, 3582–3593. [Google Scholar] [CrossRef]

- Li, Y.; Xu, Z.; Østergaard, J.; Hill, D.J. Coordinated Control Strategies for Offshore Wind Farm Integration via VSC-HVDC for System Frequency Support. IEEE Trans. Energy Convers. 2017, 32, 843–856. [Google Scholar] [CrossRef]

- Adeuyi, O.D.; Mane, M.C.; Liang, J.; Jenkins, N. Fast Frequency Response From Offshore Multiterminal VSC–HVDC Schemes. IEEE Trans. Power Deliv. 2017, 32, 2442–2452. [Google Scholar] [CrossRef]

- Liu, T.; Pan, W.; Quan, R.; Liu, M. A Variable Droop Frequency Control Strategy for Wind Farms that Considers Optimal Rotor Kinetic Energy. IEEE Access 2019, 7, 68636–68645. [Google Scholar] [CrossRef]

- Zhang, X.; Chen, Y.; Wang, Y.; Zha, X.; Yue, S.; Cheng, X.; Gao, L. Deloading Power Coordinated Distribution Method for Frequency Regulation by Wind Farms Considering Wind Speed Differences. IEEE Access 2017, 7, 122573–122582. [Google Scholar] [CrossRef]

- Xiong, L.; Yang, S.; Huang, S.; He, D.; Li, P.; Khan, M.; Wang, J. Optimal Allocation of Energy Storage System in DFIG Wind Farms for Frequency Support Considering Wake Effect. IEEE Trans. Power Syst. 2022, 37, 2097–2112. [Google Scholar] [CrossRef]

- Wang, Z.; Shi, L.; Wu, F.; Peng, Y.; Lou, B.; Lee, K.Y. Coordinated Droop and Virtual Inertia Control of Wind Farm for Frequency Regulation. In Proceedings of the 2020 IEEE Power & Energy Society General Meeting (PESGM), Montreal, QC, Canada, 2–6 August 2020. [Google Scholar]

- Sheng, K.; Zhu, X. Model Parameter Identification of Wind Farm’s Primary Frequency Control based on Actual Power Response Characteristic. In Proceedings of the 2021 IEEE 5th Conference on Energy Internet and Energy System Integration (EI2), Taiyuan, China, 22–24 October 2021. [Google Scholar]

- Hu, Y.-L.; Wu, Y.-K. Approximation to Frequency Control Capability of a DFIG-Based Wind Farm Using a Simple Linear Gain Droop Control. IEEE Trans. Ind. Appl. 2019, 55, 2300–2309. [Google Scholar] [CrossRef]

- Mehrabankhomartash, M.; Saeedifard, M.; Yazdani, A. Adjustable Wind Farm Frequency Support Through Multi-Terminal HVDC Grids. IEEE Trans. Sustain. Energy 2021, 12, 1461–1472. [Google Scholar] [CrossRef]

- Qiao, Y.; Guo, X.; Lu, Z.; Sun, R. Parameter setting of auxiliary frequency regulation of wind turbines considering secondary frequency drop. Power Syst. Technol. 2020, 44, 807–815. [Google Scholar]

- Yang, D.; Kim, J.; Kang, Y.; Muljadi, E.; Zhang, N.; Hong, J.; Song, S.-H.; Zheng, T. Temporary Frequency Support of a DFIG for High Wind Power Penetration. IEEE Trans. Power Syst. 2018, 33, 3428–3437. [Google Scholar] [CrossRef]

- Xiong, Y.; Yao, W.; Wen, J.; Lin, S.; Ai, X.; Fang, J.; Wen, J.; Cheng, S. Two-Level Combined Control Scheme of VSC-MTDC Integrated Offshore Wind Farms for Onshore System Frequency Support. IEEE Trans. Power Syst. 2021, 36, 781–792. [Google Scholar] [CrossRef]

- Zhao, J.; Lyu, X.; Fu, Y.; Hu, X.; Li, F. Coordinated Microgrid Frequency Regulation Based on DFIG Variable Coefficient Using Virtual Inertia and Primary Frequency Control. IEEE Trans. Energy Convers. 2016, 31, 833–845. [Google Scholar] [CrossRef]

- Takahashi, R.; Tamura, J. Frequency control of isolated power system with wind farm by using Flywheel Energy Storage System. In Proceedings of the 2008 18th International Conference on Electrical Machines, Vilamoura, Portugal, 6–9 September 2008. [Google Scholar]

- Yan, X.; Wang, D.; Yang, L.; Jia, J.; Li, T. Coordinated control strategy of inertia support and primary frequency regulation of PMSG. Trans. China Electrotech. Soc. 2021, 36, 3282–3292. [Google Scholar]

- Shen, Z.; Zhu, J.; Ge, L.; Bu, S.; Zhao, J.; Chuang, C.-Y.; Li, X.; Wang, C. Variable-Inertia Emulation Control Scheme for VSC-HVDC Transmission Systems. IEEE Trans. Power Syst. 2022, 37, 629–639. [Google Scholar] [CrossRef]

- Yang, P.; Dong, X.; Li, Y.; Kuang, L.; Zhang, J.; He, B.; Wang, Y. Research on Primary Frequency Regulation Control Strategy of Wind-thermal Power Coordination. IEEE Access 2019, 7, 144766–144776. [Google Scholar] [CrossRef]

- Zhao, X.; Xue, Y.; Zhang, X.-P. Fast Frequency Support from Wind Turbine Systems by Arresting Frequency Nadir Close to Settling Frequency. IEEE Open Access J. Power Energy 2020, 7, 191–202. [Google Scholar] [CrossRef]

- Go, L.; Ren, Y.; Wang, Z.; Zhu, X.; Wang, X.; Li, X.; Yixin, L.; Zang, X.; Wang, C. Double-Layer Feedback Control Method for Synchronized Frequency Regulation of PMSG-Based Wind Farm. IEEE Trans. Sustain. Energy 2021, 12, 2423–2435. [Google Scholar] [CrossRef]

- Yan, X.; Cui, S.; Wang, D.; Wang, Y.; Li, T. Inertia and primary frequency regulation strategy of doubly-fed wind turbine based on super-capacitor energy storage control. Autom. Electr. Power Syst. 2020, 44, 111–120. [Google Scholar]

| Model Name | Parameter Name | Value |

|---|---|---|

| VSC-HVDC | Rated capacity/MW | 950 |

| Rated AC voltage/kV | 230 | |

| Rated DC voltage/kV | ±320 | |

| DC capacitor/mF | 10 | |

| Variation range of DC voltage | 0–10% | |

| DFIG | Rated capacity/MW | 5 |

| Rated voltage(kV)/Rated frequency (Hz) | 33/50 | |

| Blade radius/m | 68.5 | |

| Rated wind speed/m/s | 10 | |

| Actual active power/pu | 0.712 | |

| Inertia time constant/s | 4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zeng, R.; Wang, Y. Improved Frequency Control Strategy for Offshore Wind Farm Integration via VSC-HVDC. Energies 2022, 15, 6363. https://doi.org/10.3390/en15176363

Zeng R, Wang Y. Improved Frequency Control Strategy for Offshore Wind Farm Integration via VSC-HVDC. Energies. 2022; 15(17):6363. https://doi.org/10.3390/en15176363

Chicago/Turabian StyleZeng, Rui, and Yizhen Wang. 2022. "Improved Frequency Control Strategy for Offshore Wind Farm Integration via VSC-HVDC" Energies 15, no. 17: 6363. https://doi.org/10.3390/en15176363

APA StyleZeng, R., & Wang, Y. (2022). Improved Frequency Control Strategy for Offshore Wind Farm Integration via VSC-HVDC. Energies, 15(17), 6363. https://doi.org/10.3390/en15176363