Abstract

In the era of Industry 4.0, manufacturing and production systems were revolutionized by increasing operational efficiency and developing and implementing new business models, services, and products. Concretely, the milestone set for Industry 4.0 was to improve the sustainability and efficiency of production systems. By extension, the emphasis was focused on both the digitization and the digitalization of systems, providing room for further improvement. However, the current technological evolution is more system/machine-oriented, rather than human-oriented. Thus, several countries have begun orchestrating initiatives towards the design and development of the human-centric aspect of technologies, systems, and services, which has been coined as Industry 5.0. The impact of Industry 5.0 will extend to societal transformation, which eventually leads to the generation of a new society, the Society 5.0. The developments will be focused on the social and human-centric aspect of the tools and technologies introduced under the framework of Industry 4.0. Therefore, sustainability and human well-being will be at the heart of what comes next, the Industry 5.0, as a subset of Society 5.0. Industry 5.0 will build on the foundations laid during Industry 4.0 by emphasizing human-centered, resilient, and sustainable design. Consequently, the authors in this research work, through a critical literature review, aim to provide adequate reasoning for considering Industry 5.0 as a framework for enabling the coexistence of industry and emerging societal trends and needs. The contribution of this research work extends to the provision of a framework to facilitate the transition from Industry 4.0 to Society 5.0.

1. Introduction

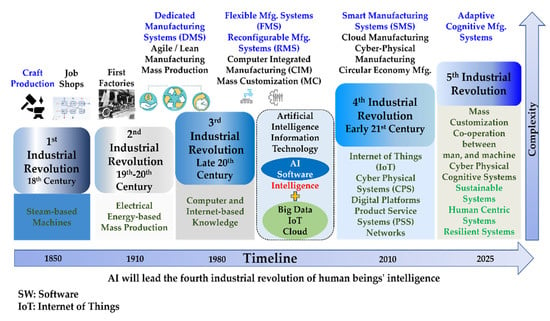

Humankind through the years has recognized the potential of using technology as a medium for advancement since the first Industrial Revolution (Industry 1.0). The First Industrial Revolution, which can be traced back to the end of eighteenth (18th) century (i.e., 1780s), began with the production of mechanical power using primitive resources, such as water, steam, and fossil fuels. In the 1870s, manufacturers who used assembly lines and mass production favored electrical energy during the second such revolution (Industry 2.0). During the Third Industrial Revolution (Industry 3.0), in the 1970s, the concept of integrating automation to production industries was introduced through the utilization of electronics and Information Technologies (IT). The Internet of Things (IoT) and cloud computing in conjunction with Artificial Intelligence (AI) are used in the fourth phase of the industrial revolution (Industry 4.0) in order to facilitate the realization of Smart Cyber–Physical Systems (CPS), which serve as a real-time interface between the virtual and physical worlds [1,2]. The technologically driven industrial revolution known as Industry 4.0 (I4.0) conceptualizes the recent decade’s rapid change in technology, industries, and societal patterns and processes. With the emergence and advancement of pillar technologies such as big data analytics, AI, and digital twins, production efficiency and improved product and service quality are promoted under the framework of I4.0 [3]. Despite the advances and the opportunities unveiled under the framework of I4.0, there are certain limitations, since in I4.0 engineers have mainly focused on the technological evolution of manufacturing and production systems and networks (digitization and digitalization) by prioritizing industrial flexibility and efficiency over industrial sustainability and worker welfare [4]. Consequently, the dawn of a new era for industrial transformation lies in the near future. This new era will enable engineers to fully utilize the current technological landscape to benefit humankind as well as to socialize factories (see Social Factories). Currently, several countries, among them the European Union, Japan, and the USA, have moved towards the establishment of the above-mentioned human-centric era, commonly known as Industry 5.0, a term extending to Society 5.0 as well. At this point, it has to be stressed that I4.0 is an ongoing technological evolution, and Society 5.0 (including Industry 5.0) is still under preparation, thus creating a misconception that Industry 5.0 will not be considered as an independent industrial revolution. Among the key contributions of the present research work, this is an open issue that is being discussed.

1.1. Industry 5.0

As such, even though Industry 4.0 has not been fully integrated worldwide, many business innovators and technological pioneers are already looking ahead to the Fifth Industrial Revolution or Industry 5.0 (I5.0) [5], which will involve autonomous manufacturing with human intelligence and AI as a backbone technology, in and on the loop (see Figure 1). Additionally, by 2027, it is predicted that the number of social media users (4.59 billion in 2022) will significantly increase to 5.85 billion, following the rapid growth of the Internet, and Internet-related technologies [6].

Figure 1.

Industrial Revolutions with key milestones and significance of AI towards human beings’ intelligence (derived from [7,8]).

1.2. Society 5.0

As a human-centric design solution where humans and cobots collaborate in a shared working environment, I5.0 [9] has constantly gained more attention during the last years, aiming to address the challenges exposed by Industry 4.0. Moreover, a similar concept named Society 5.0 (S5.0) [10] comes into view in these years to solve the problems in current society, which is a futuristic super-smart society in which everyone can enjoy high-quality and comfortable lives through the fusion of cyberspace and physical space by fully utilizing ICT (Information and Communication Technology). The plan is the Japanese government’s response to other socio-technological plans such as Made in China 2025 and I4.0 in China and Europe, respectively. Similarly, I5.0 is directly related to S5.0, and both will happen when AI is trained to think and lead organizational processes independently, which is predicted to happen in 2030 [10]. It is anticipated that human and technological relationships will continue to evolve in Society 5.0 through the CPS developed in I4.0 [11].

In order to ensure sustainable development in all societal aspects (e.g., education, health, democracy, and economy), it is important for people to have positive relationships with technology [12]. On the other hand, this issue raises the question of whether AI will have a negative impact on human society (e.g., job loss, ethical and practical concerns regarding the transfer of responsibility from people to machines, social control, and algorithmic errors, among others) [13].

1.3. Aim of Paper and Research Questions

Despite the fact that I5.0 and S5.0 are emerging trends which have been discussed at an abstract level so far, there is not adequate literature available online specifically addressing Industry 5.0 and Society 5.0 simultaneously. As such, the aim of this review paper and the contributions of this research work can be summarized to the following:

- Provision of the original definitions of I5.0 and S5.0.

- Summary and provision of the enablers and key technologies of I5.0 and S5.0 such as, edge computing (EC), digital twins (DT), Collaborative Robots, Internet of Everything (IoE), Big Data and Analytics, Blockchain, Product Service Systems (PSS), metaverse, and beyond.

- In-depth discussion of the most anticipated applications for Industry 5.0, including supply chain management, intelligent healthcare, cloud manufacturing, manufacturing production, and various other applications.

- Pointing out promising research directions for realizing and achieving I5.0 and S5.0.

Therefore, these co-existing ideas can be considered as two parallel concepts for the upcoming industrial and societal landscape. The following research question has been established in light of the social changes brought by the expected technological advancement of the Society 5.0. Thus, the research question arising is formed to “which fundamental technological innovations enable the transition from Society 4.0 and Industry 4.0 to Society 5.0 and Industry 5.0”? Furthermore, in this review paper the authors attempt to address the following research questions:

- Which are the main criteria to focus on I5.0 and S5.0 to ensure resiliency and social value creation?

- What are the key technological enablers of I5.0 and S5.0 to provide effective collaboration between human and technology?

- Can Industry 5.0 and Society 5.0 be considered as a framework for enabling the coexistence of industry and emerging societal trends and needs?

1.4. Paper Organization

The structure of the rest of the paper is as follows. In Section 2, the literature review methodology is presented and discussed, followed by the discussion of the most dominant definitions for Industry 5.0 and Society 5.0. Then, in Section 3, the role of Industry 5.0 in the concept of Society 5.0 is discussed. Then, in Section 4, Factories of the Future are investigated. In Section 5, a short discussion follows the literature review results presented in the previous sections. Furthermore, in Section 5, the research work is concluded, and future research directions are discussed based on the presentation of a conceptual framework.

2. State of the Art

2.1. Review Methodology

The comprehensive database Scopus was used to retrieve peer-reviewed articles and provide the necessary input for the bibliometric analysis. However, in order to include peer-reviewed publications from other important databases such as Web of Science and Science Direct, the same search query was also applied.

The same search query was executed in Google Scholar and Web of Science. A literature search was conducted online in July 2022 with the following search query: TITLE-ABS-KEY (Industry 4.0 AND Society 5.0 OR Industry 5.0 AND Society 5.0) AND PUBYEAR > 2015 AND PUBYEAR > 2015. The specific literature for journals, conference proceedings, title words, and years was searched. The initial search returned a total of 114 scientific literacy articles. Among them, 57 journal articles, 45 conference papers, 7 book chapters, 3 review papers, 1 conference review, and 1 book. In addition to that and regarding the topic, the majority of the publications fall under the topics of Computer Science, Engineering, and Social Sciences. However, in order to refine the search query and include only high-quality research works, newspaper articles and reports were excluded from the dataset. In addition to that, the dataset was processed via the use of a custom Python script in order to check for duplicate entries and formalize data in a tabular form. Regarding the year range, in 2015, the first discussions and publications regarding Industry 5.0 and Society 5.0 were made online to the research community, especially from the Japanese Government. Therefore, searching past 2015 for Industry 5.0 and Society 5.0 would return no results. However, since Industry 5.0 will heavily rely on the developments made under the framework of Industry 4.0, which dates back to 2010 in several manuscripts from that year range (i.e., 2010–2022), it was included. Although 2022 has not finished yet, several research works (more than 15) were included in the manuscript in order to discuss the most current advances and developments in the field. Consequently, the inclusion of these research works facilitates tracking the most recent trends, shedding light on challenges and gaps in the literature, which ultimately are the goals of a state-of-the-art investigation.

Afterwards, the results dataset was converted to CSV (Comma-Separated Values) format for further processing. In an attempt to visualize the results and analyze their bibliometric form, the VOSviewer software was used. Concretely, VOSviewer provides the functionality of creating a keyword map based on shared networks, and thus it can create maps with multiple items as well as publication maps, country maps, journal maps based on networks (co-citation), and maps with multiple publications. Less relevant keywords can be removed, and the number of keywords used can be adapted by the users. Briefly, the functionalities of VOSviewer software extend to the support of data mining, mapping, and grouping of articles retrieved from scientific databases.

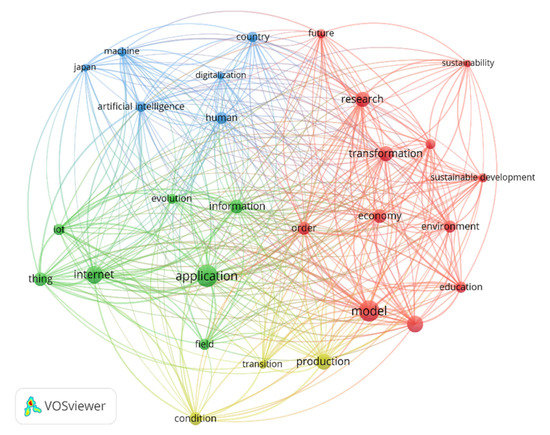

Topic mapping is crucial to bibliometric research [14]. Figure 2 shows all the subject areas pertaining to the overall keywords of scientific literacy. VOSviewer can display three different mapping visualizations for the bibliometric analysis, and Figure 3 shows the density visualization.

Figure 2.

The Network Visualization of Literacy Topic Area.

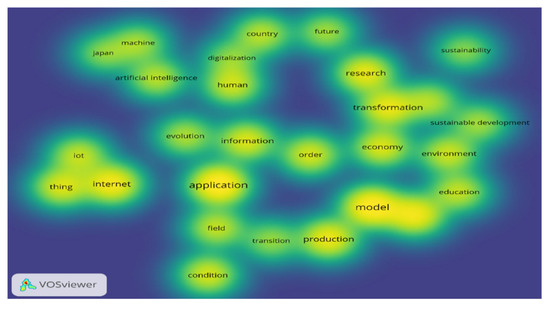

Figure 3.

The density visualization of the scientific literacy topic areas.

Figure 3 illustrates the breadth of research on the subject. Essentially, the visualization of Figure 3 serves as a heatmap for unveiling the trends in which researchers are working on more frequently. Consequently, by the findings of the literature, it can be concluded that there is a lot of discussion about IoT, Application, Human, AI, Transformation, Economy, Education, and Sustainable Development.

In order to further organize the key topics, a clustering operation was performed. The mapping of all topics produced four (4) clusters after being examined by the VOSviewer software as summarized in Table 1.

Table 1.

Clusters as constructed by VOSviewer Software.

The clusters facilitate the recognition of correlation between different topics, facilitating the interpretation of the acquired results. The strength of pairs of topic areas or keywords was indicated by the thickness of the connecting line. The size of the nodes also revealed the frequency of the keyword or topic, in addition to clusters and lines. Figure 2 illustrates that Economy, Education, Application, AI, and Condition were the most prevalent subjects or keywords. This indicates that between 2015 and 2022, these subjects received the most attention from researchers. Additionally, nodes or keywords without a network with other keywords could develop into fresh research areas.

2.2. Review Algorithm

The algorithm used is developed by the authors and is based on the utilization of APIs (Application Programming Interface) provided by scientific databases (including ScienceDirect, Scopus, and Web of Science). More specifically, the search algorithm utilizes three different APIs in order to search for publications and return results based on the search terms input by the user. The results are compiled and formatted in an XML (eXtensible Markup Language) file, including the Title, the Year, the Abstract, and the Keywords. Then, a recursive method for excluding results was implemented. More specifically, based on Information Theory metrics, the article Title was examined. Afterwards, the Keywords were examined, and finally, a third run was used for examining the Abstract of the manuscript. When the exclusion recursions were completed, a final XML list was automatically created by the developed algorithm and saved to the local storage media (e.g., hard drive), so that the users can find the manuscripts and download them. At this point, it is stressed that several other query criteria are also supported in order to facilitate the users’ refinement of their search queries. The algorithm can be realized as a stand-alone application developed for use on PCs. Future developments include the addition of automated download of the suitable manuscripts. The developed application is intended only for educational and research purposes. The main advantage of this search algorithm is the utilization of Machine Learning algorithms, which enable researchers to increase the breadth of their literature review, as well as to increase the level of detail during the search. Alongside the APIs, a web scraping module was also developed in order to retrieve useful insights from websites over the web. The added value of the web scraping algorithm is the ability to search and retrieve information from non-scientific sources (e.g., think tanks, leading companies, etc.).

2.3. Definitions of Industry 5.0

In order to provide the required context for the discussion of Society 5.0 and its aspects in the following section, the most pertinent definitions for Industry 5.0 are provided in this section.

The first definition is derived from the research work of (Breque et al., 20210. According to the authors, Industry 5.0 is a thoughtful concept that looks to the future of industry in the direction of a manufacturing system that is human-centric, sustainable, and resilient (Breque et al., 2021). With adaptable and flexible technologies, I5.0 is quick to act, resilient, and respects the limits of the planet while fostering talent, diversity, and empowerment [15].

Similarly, according to Michael Rada, the Industry 5.0 organization’s founder and leader, Industry 5.0 is the first industrial evolution to be driven by a human and is based on the 6R principles of industrial upcycling (Recognize, Reconsider, Realize, Reduce, Reuse, and Recycle), a methodical waste prevention technique and logistics efficiency designed to evaluate life standards, innovative creations, and produce high-quality custom products [16].

The third definition is provided by [8], stating that in the factory, the workforce and machines work together to increase process efficiency by utilizing human creativity and brainpower through the integration of workflows with intelligent systems.

According to Friedman and Hendry [17], I5.0 is expected to force business professionals, information technologists, and philosophers to concentrate on human factors when implementing new technologies in industrial systems.

Industry 5.0 is the era of the socially intelligent factory, in which cobots converse with people. Enterprise social networks are used by the Social Smart Factory to facilitate seamless communication between human and CPPS components [18].

Considering the definitions provided above, it becomes apparent that all of them converge on the aspects of human-centricity, system resiliency, and sustainability. A further interpretation of the definitions reveals some differences, as in the majority of the definitions of Industry 5.0 entail an entire era of technological and societal advances, whereas the rest of them focus more on the industrial transformation.

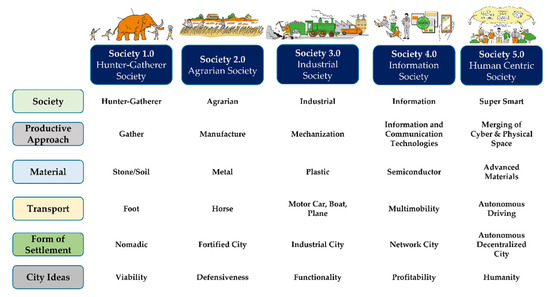

2.4. Definitions of Society 5.0

Following the concept of the previous section, in the current section, the most pertinent definitions for Society 5.0 will be discussed. Before diving into the definition of Society 5.0, in Figure 4, the societal revolutions were compiled based on the key aspects. Society, in parallel with Industry, has evolved. Taking into consideration the evolution of industry through its revolutions (as discussed in Section 1), the resemblance with society becomes evident. Consequently, the concept of Society 5.0 is a superset of what is known and conceived of so far as Industry 4.0.

Figure 4.

Societal evolutions categorized in key aspects.

The Japanese government in 2015 referred, for the first time, to their vision of a human-centered society, “Society 5.0”, as one in which a high degree of cyberspace and physical space integration can foster economic growth and address social problems, as a response to the challenges to the Japanese economy [19]. The biggest issues facing society today are an aging and shrinking working population, increased global competition necessitating infrastructure upgrades, natural disasters, terrorism, environmental issues, and lack of natural resources. This strategy is used in Granrath research on Japan’s Society 5.0 and moving beyond Industry 4.0 from 2017 [20].

According to Serpa (in MDPI encyclopedia) [21], Society 5.0 can be realized as a concept and a guide for social development, with a profound impact on current societal structures in multiple levels. The key to the societal development will be the improvement of humans’ quality of life and environmental sustainability through the adoption of the Smart Society paradigm.

Deguchi et al., in their book [22], define Society 5.0 as a highly intelligent society based on generation, processing, exchange of data, and more specifically knowledge, through the connection of the physical environment with the cyberspace.

In the same context, Rojas et al., in 2021 [23], following the definition of the Japanese government, define Society 5.0 as a “Superintelligent Society”, taking advantage of the technological advances gained during Industry 4.0 for the greater societal good and environmental sustainability.

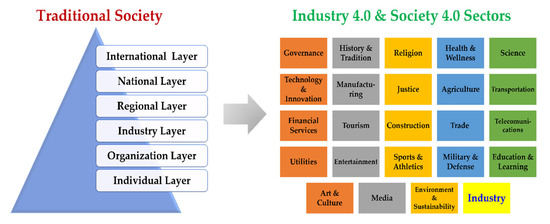

2.5. From Traditional Society to Industry 4.0 and Society 4.0

The development of the transistor and the microprocessor served as the foundation for the third industrial revolution (1960). These developments made it possible for the advancement of computer and communications technology to happen more quickly, and the automation of processes started. As a result, society started to transition from making goods and profit to becoming a post-industrial society based on knowledge production and the expansion of service industries. The post-industrial or information society, which focuses on the organization of knowledge and acts as social control, guiding innovation and change, underwent a shift in the 1980s with the advent of digitalization [24]. A global information society that aims to provide access to the Internet, better education, business support, and networking was exposed as a result of the development of the Internet. Since the existing information societies are based on a capitalist system, it is also important to highlight the institutional and cultural diversity of information systems (such as the distinctions between various countries and nations). Additionally, the modern information society is built on cutting-edge technological innovations for processing data and creating new knowledge. The information age has put a lot of emphasis on gathering and processing data at various stages. The traditional society is going through a rapid structural change as a result of the Fourth Industrial Revolution, as illustrated in Figure 5. An advanced AI system will be used to analyze and process vast amounts of data that are gathered by devices and sensors dispersed throughout the physical world. The activities of people and machines in physical space are then significantly impacted by the analysis. Cyberspace and the real world are becoming increasingly integrated. As a result, universities should focus on current career development, skills cultivation, and collaborative relationships [25]. Thus, it can be stressed that society is a specific type of social organization in which the collection, processing, and transmission of information become the main sources of power and productivity.

Figure 5.

From Traditional Society to Society 4.0.

2.6. Sustainable Concept of Society 5.0

Society 5.0 is a paradigm for sustainable development at all scales, although this model was developed for Japan, it and its components can be applied to any other nation. Therefore, it is essential to concentrate on the aspects of the concept that are connected to the growth of industry within the context of adapting it. The Industry 4.0 strategy has primarily been used by Europeans for a long time, but it only focuses on production. In contrast, Society 5.0 also deals with the social sphere. Therefore, we could use specifically those components of the Japanese concept that are intended to modernize other social processes unrelated to the industrial sector [26].

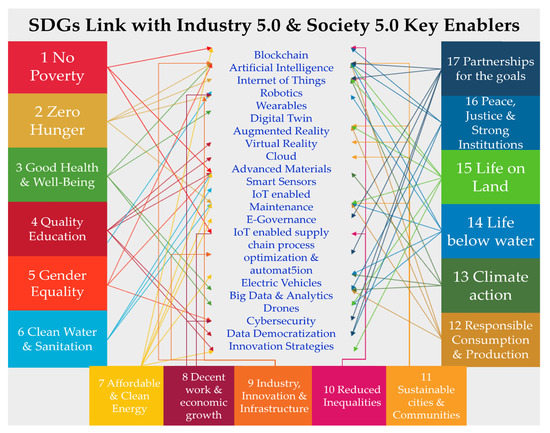

In order to solve social problems and coexist with nature, Society 5.0 aims to use the potential of the digital transformation in addition to promoting economic growth. The UN Sustainable Development Goals (SDGs) [27] can be achieved with its assistance. Therefore, a specific vision for the society, which is referred to as “Society 5.0 for SDGs”, is presented in Figure 6.

Figure 6.

Society 5.0 for Sustainable Development Goals.

The Keidanren will continue to develop this idea going forward and take the initiative to implement it, changing the Japanese economy and society in the process [28]. Society 5.0 will significantly alter social norms and business practices. People will be able to lead a variety of lifestyles thanks to close partnerships that cross borders and industries as well as the transformation of existing industries. The goal of S5.0 is to give everyone the freedom to pursue their own happiness and lifestyles while also playing a role in achieving sustainable development that is in tune with nature by resolving social issues. This is consistent with the SDGs which were adopted by the UN to address global issues and build sustainable societies. Many of the SDGs require S5.0, but it is insufficient on its own. While some objectives can be directly achieved by creating S5.0, others will profit from various solutions created on the foundation of S5.0. The concept of S5.0 for SDGs will be realized, as S5.0 encourages innovative problem solving from a variety of perspectives and supports these solutions with digital transformation. In order to achieve S5.0, this section lays out the direction for sector-specific reforms, including contributions to achieving SDGs.

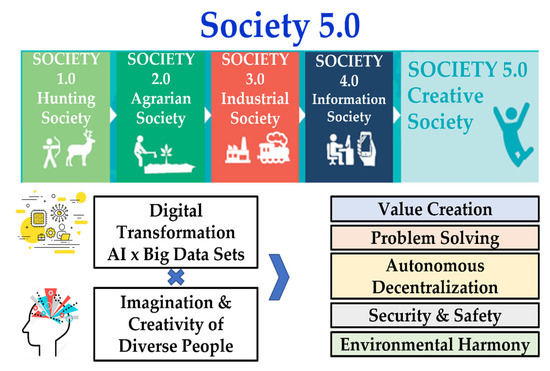

2.7. Digital Transformation

By fusing Digital Transformation (DX) with the imagination and creativity of a wide range of people to create values and find solutions to problems, the new Society 5.0 (Creative Society) will be a society that we will design itself. The idea of using DX to create a society for the future is crucial. The development of S5.0 is being triggered by the ongoing DX, which refers to the fundamental transformation of society as a result of advances in digital technology and data use, including profound changes to individual lives, government operations, the structure of the economy, and employment.

Different types of manufacturing innovation are sparked as large-scale data collection, transmission, storage, and analysis are made possible at low cost [29]. Data makes problems more visible and offers potential fixes. When such information and insights are instantly shared globally, management and social problems can be solved. The Internet of things (IoT), AI, 5G, robotics, and blockchains are examples of data-based technologies that are used in DX to bring about fundamental changes in society [30,31].

The change provoked by DX is not merely technological. It represents a significant shift in the lower level of society and culture, altering social norms. DX goes beyond straightforward labor-saving “kaizen”, automation, increased productivity, and digital technology-based optimization. In response to significant social changes, DX is reform that aims to establish new values, sometimes at the expense of preexisting ones. Therefore, it can be stressed that DX is a shift that alters the foundation of society and business, going beyond simple IT system modifications. Consequently, DX should be the top management priority for businesses, and they should work on it voluntarily and pro-actively [32]. The definition of DX in the Keidanren proposal is as follows:

“Fundamental and revolutionary changes in society, industry, and life as a result of advances in the use of digital technology and data; and radical changes implemented by industries, organizations, and individuals toward such transformation.”

2.8. The Nature of Society 5.0

Digital technologies and data should be used to create a society where people can pursue different lifestyles and types of happiness in their own ways, even though digital transformation ushers in a new stage of society. Although Society 5.0 was first described as a “super smart society” in the 5th Science and Technology Basic Plan, that is only one aspect of the new society [33,34]. Anyone can access advanced “abilities” thanks to digital transformation, as mentioned in Section 2.6. People can conduct activities and business that have the potential to significantly alter society if they have ambition and ideas.

Rich imaginations will be necessary for Society 5.0 in order to recognize the various needs and problems that exist throughout society and create scenarios to address them, as well as creativity in order to implement solutions that make use of digital technologies and data. Combining digital transformation with the imagination and creativity of various people will make it easier to solve problems and create value, which will pave the way for a better future.

Furthermore, in order to solve social issues and add value, Society 5.0 will be a Creative Society where digital transformation combines with the imagination and creativity of diverse people. Thus, in order to enable sustainable development, humans will use their imagination in Society 5.0 to find ways to symbiotically co-exist with nature and technology as well as with themselves, as presented in Figure 7.

Figure 7.

Evolution of society—Co-creating the future (adapted from [35]).

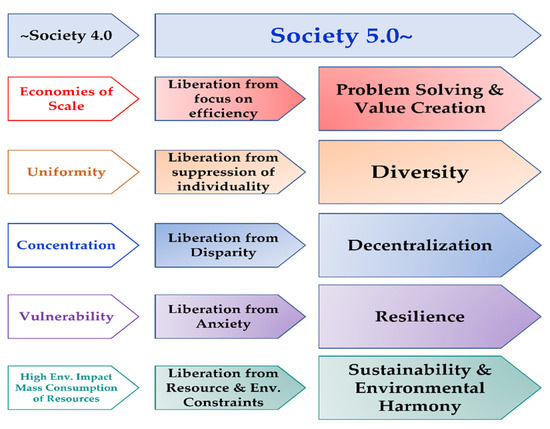

2.9. From Society 4.0 to Society 5.0

In contrast to Society 4.0, Society 5.0 is distinguished by value creation and problem solving, diversity, decentralization, resilience, sustainability, and environmental harmony, which are illustrated in Figure 8. Society 5.0 can be viewed as a human-centered Industry 4.0 environment. The Cabinet Office of Japan, from which the concept of Society 5.0 arose, defines it as “a human-centered society that balances economic advancement with the resolution of social problems through a system that highly integrates cyberspace and physical space”. Digital technologies and data should be used to foster a society in which people live diverse lives and pursue happiness in their own unique ways [35]. Additionally, people in Society 5.0 will be free of various constraints that previous incarnations, up until Society 4.0, were unable to overcome, and will be able to pursue diverse lifestyles and values. More specifically, people will be liberated from the focus on efficiency. Instead, the focus will be on meeting individual needs, solving problems, and creating value. People will be able to live, learn, and work free of suppressive influences on individuality, such as gender, race, nationality, as well as alienation due to their values and ways of thinking. In addition to to that, people will be released from the disparities caused by the concentration of wealth and information, and anyone will be able to find opportunities to participate at any time and from any location. Another aim of the transition from Society 4.0 to Society 5.0 is to eliminate the fear of terrorism, natural disasters, and cyberattacks, and to be able to live in peace thanks to strengthened safety nets for unemployment and poverty. Finally, as per the WEF Annual meeting in 2019, the goal is to create a society in which anyone can create value at any time and from any location, in safety and harmony with nature, and free of the various constraints that exist today [36].

Figure 8.

Changes from Society 4.0 to 5.0.

2.10. Sustainable Development Goals and Society 5.0

Life and business will change as a result of S5.0. This societal revolution will assist in achieving the SDGs by attempting to resolve social issues in harmony with the natural world. The list of the SDGs that referred with the corresponding number below is summarized in Table 2.

Table 2.

The 17 sustainable development goals (SDGs) to transform our world, derived from [37].

Specific reforms and roadmaps for each sector are summarized as follows:

- 1.

- Cities and Regions—SDGs: 3, 4, 5, 6, 8, 11, 12, and 13

Promoting autonomous systems such as automated driving and sharing economies will support a variety of lifestyles while drastically reducing their negative environmental effects. Additionally, while continuing to work to improve the competitiveness of big cities, sustainable, decentralized communities will be developed in suburbs and rural areas in order to create autonomous, prosperous regions where people live in harmony with nature by utilizing the unique qualities of their respective regions. It will be possible to receive high-quality healthcare and education services from anywhere in the world. Off-grid energy is one example of an autonomous, decentralized social infrastructure technology that will be used to create a stable, sustainable social infrastructure while easing financial burden. Autonomous vehicles will be made available to senior citizens who are unable to drive themselves in areas without public transportation systems, resolving issues with daily mobility such as shopping and hospital visits. Even in places with subpar infrastructure, high-standard, comfortable lives are possible.

- 2.

- Energy—SDGs: 7, 9, and 13

The energy landscape will change, and data will be used to create effective energy networks in order to achieve sustainable lives anywhere, including smart cities and decentralized communities. Microgrids that are decentralized demand-side controls, power storage, and decentralized renewable energy sources will all be integrated into the development of energy and will be coordinated with regional conditions. Off-grid energy systems that are independent of conventional energy networks will be an option. The majority of the global population, if not all, will have access to affordable, dependable energy, and other industries will use a decentralized infrastructure in a similar way. This will ensure diverse and sustainable lifestyles for the majority of the global population.

- 3.

- Disaster Prevention and Mitigation—SGGs: 3, 6, 11, and 13

Natural disasters are spreading and intensifying globally, necessitating quick and effective responses as well as increased resilience. By gathering information on damage and rescue supplies from evacuation centers, IoT devices, and social media and sharing it across regions and organizational boundaries in the public and private sectors, disaster information collaboration systems will be built to facilitate quick responses in the event of disasters. Digital technologies will also be used for infrastructure maintenance on a daily basis and to take effective precautions against infrastructure aging. In the event of disasters and accidents, water supply can continue with maintenance and prompt restoration of the water and sewer infrastructure. Decentralized energy systems will be encouraged to create resilient infrastructure.

- 4.

- Personalized Healthcare—SDG: 3

Technological trends such as the digitalization of individual physical characteristics and behaviors and advancements in the biotechnological investigation of life mechanisms will be used to achieve the provision of proper attention when needed to anyone who needs. While traditional medicine has offered uniform treatments for average patients or symptoms, new approaches will offer care that is customized to each patient’s health at the preventive stage to delay the onset and progression of illness and extend healthy life expectancy.

By promoting next-generation high-speed communication networks, AI-based medical, Agriculture and Food wellness support services, telemedicine, and the development of systems for people to actively use and manage their own life-stage data, access to high-quality healthcare services will be made possible from anywhere. Everyone will live healthy lives as a result. For instance, elderly people living in remote locations will be able to monitor their health through telemedicine, and in the event of a sudden illness, they will be transported for treatment to a hospital that is suitable for their needs as determined with the help of AI. By being implemented in isolated regions of developing nations, these technologies, operational know-how, and systems will improve healthcare on a global scale.

- 5.

- Agriculture and Food—SDGs: 2, 12, 14 and 15

Food production and agriculture will be transformed into appealing, independent industries where anyone can express their creativity. Modern tools such as AI-powered remote monitoring and control, robotic farming, and self-driving drones for on-site agricultural work will be fully utilized. Through the involvement of numerous players, including private corporations, young people, and agritech ventures, working hours will decrease significantly, work efficiency will improve dramatically, and productivity will rise exponentially. To protect the rich biodiversity on land and in the water, strategies for boosting biodiversity and reducing environmental impact will be encouraged. Data on various consumer needs will be gathered and quickly reflected in food production and processing. By combining data on production, logistics, and export, it will be possible to share stock and sales information in real time, and food loss will be reduced by coordinating delivery schedules, volume, and routes. Customers will have access to interactive communication tools, free production histories, and product details.

- 6.

- Logistics—SDGs: 11 and 12

By facilitating the flow of goods, logistics place economic growth and are a crucial component of the social infrastructure that underpins daily life and business operations. In Society 5.0, the rapid expansion of e-commerce and the globalization of supply chains will necessitate even more complex and varied logistics, and the adoption of cutting-edge technologies will transform logistics. For instance, IoT technologies such as Radio Frequency Identification (RFID) will be used to connect cargo and transportation methods to networks, enabling real-time logistical tracking and control.

- 7.

- Manufacturing and Services: SDGs: 5, 8, and 9

The distribution of abilities via AI will give manufacturing and service delivery new powerful tools. Up until now, data analysis and the production of useful products and services have required a significant financial commitment and specialized knowledge. These skills will be dispersed and made accessible as AI modules and services through digital transformation. Combining them will make it possible to quickly produce goods and services of higher quality. Services, and not hardware, will be the foundation of business models. Manufacturing and services will not be a continuation of those offered in the 20th century in the era of digitalization. As a result of a DX that generates a variety of forms of value, more people will be able to participate in manufacturing and service provision.

- 8.

- Finance—SDGs: 1, 5, 8, and 9

The transformation of financial services is another factor that enables individuals and small businesses to offer a variety of manufacturing and services. Financial services such as asset creation, financing, settlement, and insurance will all become more accessible thanks to DX. It will be possible for people to live anywhere without cash thanks to low-cost, practical, quick, secure, and varied methods of settlement. The development of new services will be made easier by applications that connect different services and smart contracts. With the help of digital devices and technologies, people will have more opportunities for financing, asset formation, insurance, settlement, and transfer, which will result in more stable lives, economic independence, higher living standards, and greater income equality in emerging countries.

As well as enabling lifestyles that were previously impossible, cryptocurrencies and token economies built on blockchain technologies and other innovations will create new ways to exchange value. A foundation for diverse manufacturing and service delivery will be created by the establishment of secure, intelligent, and traceable global contracts and settlement systems, allowing diverse people to expand their range of manufacturing and services on a global scale.

- 9.

- Public Services—SDGs: 1, 3, 4, 10, and 16

To support the various lives and industries mentioned above, public services will also undergo significant change. Governments at all levels will start by rebuilding their digitally based systems. They will deliver more innovative public services by digitizing many of their tasks and swiftly distributing data among various actors. For instance, accurate demographic and other data analysis can be used to predict demand for nurseries, schools, hospitals, and nursing homes, allowing public bodies to plan and offer the necessary services. Anyone can face a variety of challenges with security if appropriate safety nets are set up by governments.

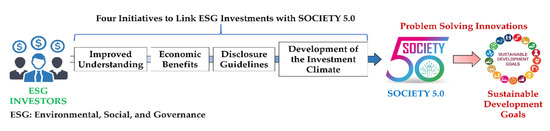

2.11. Environmental, Social, and Governance (ESG) Investments, Creating Society 5.0 and Achieving the SDGs

Japan’s growth strategy, known as S5.0, aims to fully harness DX in an attempt to facilitate people in overcoming a range of limitations on a personal level, develop solutions to major international problems such as the environment and human health, and promote the development of a sustainable, human-centered society. The accomplishment of the sustainable development goals (SDGs) supported by the United Nations will be significantly aided by this. A novel strategy, including four initiatives for increasing ESG investments and implementing the S5.0 vision (which are considered crucial for the timely and unambiguous achievement of the SDGs), is depicted in Figure 9. The four projects address the following topics: (1) the current state of S5.0 as well as steps for improving its understanding; (2) economic and social benefits; (3) policy guidelines for the disclosure of information on companies engaged in efforts to make S5.0 a reality; and (4) the development of a suitable and sustainable investment environment. To that end, Nakanishi, in [36], has presented an S5.0 implementation plan, considering the post-pandemic era and the objective of disseminating information on the four initiatives to expand ESG investments, both within Japan and abroad.

Figure 9.

Initiatives to Link ESG Investments with Society 5.0.

3. Industry in the Society 5.0 Era

So far, in the presented research work industries have been categorized according to their type and the products they produce. However, in the following section, they are categorized according to the value of the consumer experience and the problems they resolve. A flat co-creation structure will replace the pyramidal industrial structure, known as 5C Architecture [38], with large corporations at its summit. The Industrial transition from Society 4.0 to Society 5.0 and thereafter is presented in Table 3.

Table 3.

Industrial Focus of Societies.

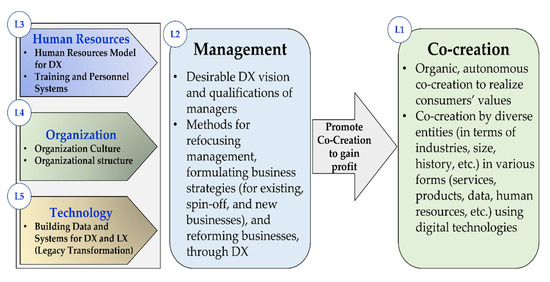

3.1. Overview of Digital Transformation Framework towards Industry 5.0

Co-creation is the primary component and differentiator of corporate DX. Based on co-creation, the management team responsible for the organization’s overall direction, the human resources model for DX promotion, the specific organizational structure and culture to be established, and the technological foundation, such as data and systems to be built for DX and legacy transformation, are all given direction in strategy and implementation (LX) (see Figure 10).

Figure 10.

Overview of Corporate DX.

3.1.1. Co-Creation in the Society 5.0 Era

Co-creation refers to a totally new level of partnership built on delivering values and addressing societal issues from the perspective of the consumer, going beyond straightforward business or corporate alliances. It is based on the implementation of new business models and ecosystems in which various entities are capable of producing revenue by combining several strategies to integrate their strengths and make up for each other’s weaknesses.

3.1.2. Co-Creation Methods

Companies work together towards the creation of new business opportunities by implementing one or more strategies, including those not on the list below. The key is to establish venues and mechanisms for participation from a variety of entities, for defining the goals and values of the consumers to be realized, ensuring multitiered communication, and for the development of suitable governance systems that support co-creation.

- Co-creation through services and products.

- Co-creation using data.

- Co-creation through human resources.

3.1.3. Management

The required skills of managers towards Society 5.0 are listed as follows:

- Understanding of and resolve to implement DX.

- Clear management vision and leadership in cocreation.

- Knowledge of new technologies and businesses.

- Refocusing.

- Timely decisions and actions.

3.1.4. Human Resources

Each phase of promoting DX requires a different set of personnel, with each requiring a specific set of skills and qualifications, including novel concepts, conceptualization, and creating and carrying out business plans.

3.1.5. Organization

The most important organizational culture is to generate new ideas and facilitate change through diversity.

3.1.6. Technology

It is crucial to quickly adopt digital technologies in order to maintain providing systems and services to customers, while becoming DX-ready. These require the capacity to reliably apply DX while concentrating on the most recent technological trends.

3.1.7. Data Co-Creation

In order to advance to co-creation, building a connectable yet autonomous and decentralized architecture as the common infrastructure is essential. Next, it is also important to define quality criteria for data to be transmitted and linked together in order to avoid factors impeding data sharing.

The Co-Creation DX Indices according to Keidanren [35] are presented in Table 4.

Table 4.

Co-Creation DX Indices.

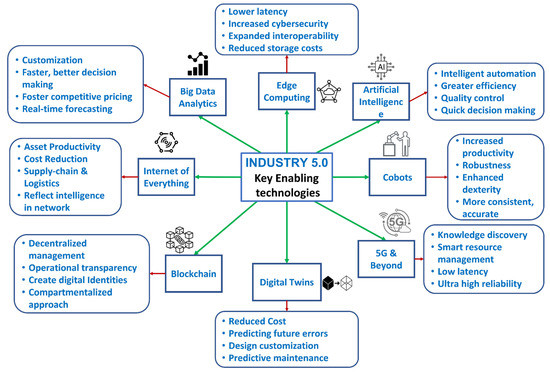

3.2. Enabling Technologies of Industry 5.0

Industry 5.0 refers to the concept of an innovative, resilient, socio-centered, and competitive industry that respects planetary boundaries and minimizes its negative environmental impact. It presents numerous new problems in the areas of technology, socioeconomics, rules, and governance. Considering this, on 2 and 9 July 2020, two virtual workshops were held in which participants from funding organizations and Research and Technology Organizations (RTOs) across Europe discussed the idea of Industry 5.0. The objective was to discuss the enabling technologies and potential difficulties, as well as to solicit feedback on the general idea. Participants agreed that social and environmental needs should be more effectively taken into account when developing new technologies. Participants also concurred that a systemic approach was necessary to address the complexity of the challenges rather than relying solely on individual technologies [39].

The Key Enabling Technologies (KET) supporting the transition from Industry 4.0 to the concept of Industry 5.0 include:

- Human-centric solutions and human–machine interaction technologies that connect and combine the strengths of humans and machines.

- Bio-inspired technologies and intelligent materials that enable recyclable materials with embedded sensors and improved features.

- Simulation and real-time digital twins to model entire systems.

- Cybersecure data analysis, transmission, and storage technologies that can manage system and data interoperability.

- Artificial intelligence, such as the ability to find causal relationships in complicated, dynamic systems and produce useful information.

- Energy-efficient and reliable autonomy technologies are necessary because the KET will use a lot of energy.

With the integration of cognitive skills and innovation, several enabling technological trends, including Edge Computing (EC), Digital Twin (DT), Internet of Everything (IoE), Big Data Analytics (BDA), Cobots, 5G, and blockchain, can assist industries increase production and deliver customized products more quickly. Industry 5.0 is an advanced production model with a focus on the interaction between machines and humans thanks to these enabling technologies. The key enabling technologies for Industry 5.0 are highlighted in Figure 11.

Figure 11.

Key Enabling Technologies in the transition from Industry 4.0 to Industry 5.0 (derived from [40]).

Edge Computing: Allows for data processing at the network edge. EC has been introduced as a result of the explosive growth of IoT and the availability of numerous cloud services. Additionally, EC can achieve the requirements related to latency costs, battery life restrictions, response time specifications, and data protection and privacy [41]. Additionally, it reduces communication costs and ensures that applications are effective even in remote locations. Additionally, EC has the capacity to process data without sending them to a public cloud, minimizing security concerns for important Industry 5.0 events [42].

Digital Twins: The data from physical objects are fed to their digital counterpart through IoT devices for simulation. It is now possible to analyze, monitor, and prevent issues before they arise in the real world thanks to the digital mapping of real-time objects and systems using DT. The quick development of AI, Machine Learning (ML), and BDA has made it possible for DT to lower maintenance costs and boost system performance [43,44]. In Industry 5.0, DT is employed for customization that can enhance the user’s experience with their product requirements.

Internet of Everything: IoE is a network of connections between individuals, organizations, systems, and physical objects. IoE can be extremely valuable in creating new possibilities for Industry 5.0 applications. Some of the key applications have the potential to bring about new functionalities, better user experience, and anticipated benefits for sectors and countries. The role of IoE in Industry 5.0 focuses on increasing customer satisfaction and loyalty and creating customized experiences using generated data [45,46].

Big Data Analytics: BDA will have a significant impact on Industry 5.0. BDA can be used by the majority of businesses in Industry 5.0 to better understand consumer behavior, which can then be used to optimize product prices, concentrate on enhancing production efficiency, and assist in lowering overhead costs [47]. A significant challenge is comprehending user behavior, social relationships, and human behavior norms. Manufacturers can produce and manage large volumes of data thanks to real-time analytical shared data with smart systems and data centers. Another significant challenge facing Industry 5.0 is continuous process improvement, which frequently necessitates gathering comprehensive data on the entire manufacturing process [48].

Cobots (Collaborative Robots): Working with robots is becoming more and more crucial as a result of recent trends in automation and robotics. It is obvious that all devices with computational capabilities have become more intelligent, and a new technology known as cobots has been introduced because of the massively quick changes in AI and smart technology. Robots that are built to collaborate with people are known as collaborative robots, and this collaboration makes human capabilities more effective and simpler than ever for individuals and small businesses to automate [49]. Robots are significantly more tolerant than humans at high-volume product manufacturing and are also inferior to humans in their capacity for critical thought. When using robots, customization or personalization of products could be a significant challenge. Therefore, managing interpersonal relationships within production processes is essential. In Industry 5.0, cobots can accomplish their intended task, making it possible to deliver highly customized and personalized products quickly and accurately to customers [50].

5G and Beyond: Future Industry 5.0 services could significantly increase value thanks to 5G and 6G technologies in the future. It is difficult to build radio infrastructure with a very dense network of thousands or millions of sensors, hardware components, and robots. It will not be possible to meet the rapidly rising bandwidth needs due to the robust growth of smart infrastructure and potential applications with current networks (such as 4G and 5G networks). The Industry 5.0 revolution will be enabled by the use of 5G and beyond, which will enable the delivery of lower latency, support for high-quality services, extensive IoT infrastructure, and integrated AI capabilities [30,51].

Blockchain: Blockchain technology has the potential to significantly enhance Industry 5.0. In Industry 5.0, centralized management of a significant number of heterogeneous connected devices is a crucial challenge. By enabling distributed trust, blockchain can be used to design decentralized and distributed management and educational platforms [52,53]. Secure peer-to-peer communication made possible by blockchain technology offers an immutable ledger for keeping records. Additionally, operational accountability and transparency for significant events in Industry 5.0 applications are supported by the immutable ledger [54].

Other Enabling technologies—eXtended Reality (XR): The cutting-edge technology named XR has numerous application domains. By fusing the physical and virtual worlds, XR can enhance human–machine interactions. Virtual Reality (VR), Augmented Reality (AR), and Mixed Reality (MR) technologies are all combined under the umbrella term “XR” [55]. Different Industry 5.0 applications will be enabled by XR technologies in a significant way. Industry 5.0-related applications such as remote assistance [56], assembly line monitoring [57], remote healthcare [58], health education [59] and training [60], indoor and localized outdoor navigation [61] driver and pilot training, maintenance [62], and drone/UAV pilot education and training [63] already use XR technologies. In order to advance XR technologies toward Industry 5.0 applications, zero-touch networking, edge computing, highly capable devices, improved communication technologies, and high-precision computation capabilities will be crucial.

3.3. Mass Personalization Driven by IoT and AI

Recent developments in Deep Learning (DL) and Machine Learning (ML) have elevated the quality of industrial robotics and AI. The newest generation of systems powered by machine vision can inspect goods and identify potential flaws with greater accuracy than any human operator. Furthermore, sensors and AI-powered anomaly detection systems are heavily used in the oil and gas industry to identify abnormalities in equipment behavior and spot potential damage. Some leaders in this field have even gone so far as to have humans and robots coexist on production lines. Similarly, Siemens, another pioneer in Industry 4.0, has been able to automate about 75% of production processes. Currently, 1500 of the company field staff members operate software and keep track of production instead of handling the so-called “3D”: filthy, dangerous, and challenging tasks. Therefore, that is the kind of synergy Industry 5.0 aims for. While near-total automation was the ultimate goal of Industry 4.0, Industry 5.0 places more emphasis on the interaction between people and machines. The main objective of Industry 5.0 is to establish a new vector of technological and human collaboration in manufacturing facilities and beyond using robots, cobots, IoT devices, and other cognitive systems. Thus, it can be concluded that in Industry 5.0:

- Technology performs the mundane, repetitive, error-prone tasks.

- Humans set the strategy, provide oversight, and add creative input.

Businesses will benefit from this new division of labor by being able to access new value streams created by the human touch, as well as save money.

- Industry 4.0: High-efficiency, low-waste mass production.

- Industry 5.0: High-precision, low-cost mass personalization.

Business organizations can harmonize their manufacturing processes and become more agile to respond to market changes and customer customization requests by collaborating more closely with cognitive systems, robots, and humans [64].

The desire and the shift towards ultra-personalized goods and services are becoming more popular due to several factors, including:

- Commoditization of BDA and ML.

- Significant advancements in computer vision and 3D scanning/modeling.

- Decreased cost and increased availability of cobots.

- Increased adoption of 3D printing for prototyping.

- Higher degree of supply chain digitization.

Utilizing these innovations allows you to access the trillion-dollar value pool created by personalization and enhances the quality, efficacy, and speed of your manufacturing processes [65].

3.3.1. Technological Prerequisites for Ultra-Personalized Manufacturing in Industry 5.0

The first crucial step toward mass personalization is the change to a more agile supply chain and manufacturing process [66]. These procedures will also need to have a human element, such as input from the production team and customers, to remain personalized. Additionally, ultimately, the viability of Mass Personalization will strongly depend on its cost-effectiveness. Therefore, the authors in [64] have created a technological blueprint for Industry 5.0 initiatives, which are listed as follows:

- Data management platform and data governance processes.

- Multiscale dynamic modeling and simulation.

- Intelligent autonomous systems.

- Cognitive systems and new types of human machine interface.

- Additive manufacturing.

- The human touch.

3.3.2. Critical Skills towards Industry and Society 5.0

The AI-driven industrial revolution includes many different aspects, one of which is improving tools and production methods. Investing in talent to support those new initiatives is far more important for long-term success. The lack of technical skills is a significant barrier for 36% of manufacturers to maximizing their investments in smart factories [67]. Additionally, 57% of industrial leaders claim that they lack AI talent, which is necessary for all of the autonomous and intelligent solutions that will take over the 3D tasks. The top five critical skills for today and the future are listed in Table 5.

Table 5.

Top five critical skills for today and the future [25].

4. Discussion and Outlook

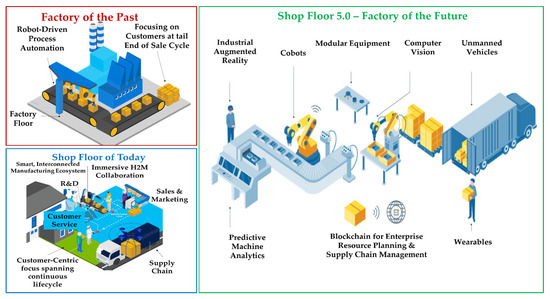

4.1. The Factory of the Future

The “Factory of the Future” is pushing the boundaries of Industry 4.0 by transforming every aspect of the connected ecosystem, including research and development, the plant, supply chain, product delivery, and customer service. The evolution from the factory of the past to the current smart factory and finally to the Shop Floor 5.0 is presented in Figure 12. The benefits of Shop Floor 5.0 are estimated as follows:

- Focus on delivering customer experience.

- Hyper customization.

- Responsive and distributed supply chain.

- Experience-activated (interactive) products.

- Return of manpower to factories.

Figure 12.

Towards Shop Floor 5.0 (derived from [68]).

Given the commitment of the European Union and others towards a more sustainable future, it is simple to understand why Industry 5.0 is viewed, correctly, as an evolution, incorporating key components of Industry 4.0 into a broader vision that benefits a wider range of stakeholders. The objective is to shift away from economic and resource-extraction-based value creation models and toward new varieties that enable a wider and more equitable distribution of economic prosperity. Instead of concentrating solely on shareholder value, the mission is more expansive and is driven by the principles of regenerative purpose and the transformation of industrial production. Key distinctions are outlined in the Table 6 below.

Table 6.

Comparison of Industry 4.0 versus Industry 5.0 [69].

Industry 5.0 will require updated goals for DX, new business models, value chains and supply chains, updated economic priorities to measure industry performance, innovative approaches to policymaking that better align the interests of business and industry, new ways to drive innovation and research capabilities, and new ways to better align the interests of businesses with the public. Thus, lessons learned from the pandemic highlight the urgent need to strengthen resilience across value chains while preserving employment and financial stability.

4.2. Skills for the Realization of Society 5.0

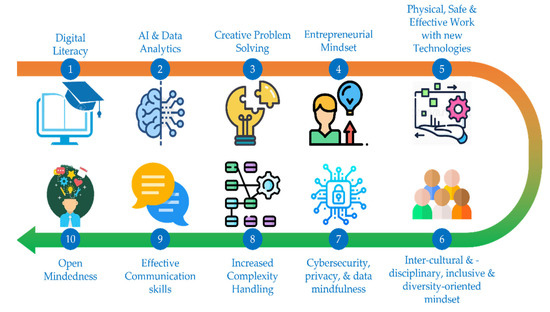

With a focus on three pillars such as Human Centricity, Resilience, and Sustainability, the vision for Industry 5.0 expands upon the technological and commercial tenets of Industry 4.0. It is the perfect time to look ahead to the next wave of innovation because many businesses are fully committed to implementing technology-enhanced processes and systems. The World Manufacturing Forum (WMF) [70] has identified ten (10) critical skills that will be required in the manufacturing sector in the future. It is crucial that this mix of skills includes cross-functional abilities related to creativity, flexibility, and open-minded thinking as well as digital and technological abilities as presented in Figure 13. To meet the demands of Industry 5.0, leaders, managers, and line employees will all need to adapt and upgrade their own skills and capabilities.

Figure 13.

Ten Critical Skills facilitating the realization of Society 5.0, derived from [70]).

A lot of research has been conducted on the ideas and foundations of digital transformation. Most executives are now proficient in technology and digital business. It is wise to concentrate on incorporating the principles of Human Centricity, Resilience, and Sustainability after building upon these fundamental concepts. Some key concepts to focus on for the years to come are listed below:

- Human-centricity re-orientation.

- Supporting resilience.

- The significance of sustainability.

Although preparing for Industry 5.0 is important, there are many forces arraying to compel companies to adopt the fundamental values of human-centricity, resilience, and sustainability. Instead of reacting to an unexpected disturbance to the system, it is much better to seize the chance to get ready in advance. Thus, Industry 5.0 promises to guide the next generation toward a balance of decisions that support smarter, cleaner, and more resilient industries and goes beyond the well-known “better, cheaper, and faster”.

4.3. Implications for Research, Practice, and Society

One of the key implications identified so far is the lack of a uniform pace globally for technological advancement [60]. More specifically, this is an implication which has been observed during Industry 4.0. However, it has not yet been adequately addressed. Therefore, it is imperative, that society, academia, and industry work in close collaboration towards bridging the technological gap, which is more evident between developed countries and developing countries [71]. It also has important implication for the transformation of universities. More specifically, universities are called upon to produce knowledge for cutting-edge technologies and social innovation as well. There are multiple ways of achieving a common global technological threshold. Through the SDGs established by the UN, key societal issues can be addressed and even eliminated. Another way is to focus more on research and development activities in developing countries, and the community should embrace and support such activities. Thirdly, another solution would be for developed countries to provide technologies and solutions in order to further facilitate less-developed countries to achieve a faster development pace.

4.4. Challenges and Opportunities

One of the main goals of the green and digital transitions included in Industry 5.0 and Society 5.0 is to ensure that people continue to live intentionally and creatively. Universities and businesses will thus play an increasingly important role in achieving this goal. Information Technology (IT) development must be accompanied by initiatives to develop industrial innovators and improve the information literacy of every citizen as we move toward a truly people-centric way of life. In order to advance the civil society that embodies Society 5.0, universities, in addition to advancing technology as before, must also be accountable for fostering literacy among information users through both general curricula towards personalized perception and education [60].

Summarizing, it can be stressed that Industry 5.0 is an integral part of Society 5.0. The upcoming fifth industrial revolution will accelerate social progress. Additionally, the next industrial revolution will be aided by society’s transformation. Similar issues and chances are noted in both Industry 5.0 and Society 5.0, as summarized in Table 7.

Table 7.

Summary of challenges and opportunities.

4.5. Proposed Framework for the Realization of Industry 5.0 and Society 5.0

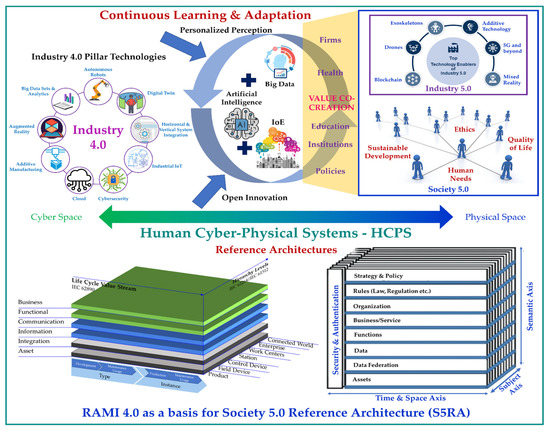

An important aspect of Industry 5.0, and by extension Society 5.0, is the compliance of technologies, actions, and changes with the SDGs as they have been established by the UN. It is important for academia, industry, and other organizations involved to unite and strengthen their collaboration in order to understand the concept of Society 5.0 fully and deeply. Towards this end, future research work will be focused on the design, development, and implementation of frameworks that integrate the technologies discussed in the previous paragraphs in an attempt to close the gap between society, industry, and academia, as presented in Figure 14. Concretely, in the conceptual framework in the above-mentioned figure, the connection between Industry 4.0 and Society 5.0 is highlighted. By extension, it is stressed that the technological advances achieved so far are not wasted, instead, they are repurposed/refocused towards the creation of what has been mentioned in the previous paragraphs as a super intelligent society. At the lower portion of the framework, two key reference architectures are also presented, in particular, (i) the RAMI 4.0 and (ii) the Society 5.0 Reference Architecture (S5RA), which was initially announced by the Cabinet Office in 2018 in the “Policy for the Development of a Data Exchange Platform” and, since then, it is under research and development. The two reference architecture models are focused on different aspects; more specifically, RAMI4.0 is focused on the technological and organization structure of companies, whereas S5RA is more general, including societal aspects. Consequently, the two reference architectures are not opposed to each other, rather, they act complimentary on each other. Thus, the connection between industry, society, and academia is underlined. Moreover, the S5RA has been further elaborated in the last years following several proof-of-concept tests of the Cross-ministerial Strategic Innovation Promotion Program (SIP). The S5RA, despite being a totally new reference architecture, is inspired by RAMI4.0, and a similarly layered structure has been adopted as displayed at the lower right portion of Figure 14, consisting of a cube shape similar to the EA3 cube framework. The three axes are as follows: (i) the x-axis is “time and space,” the y-axis is “Subject”, and the z-axis is “Semantic”. It is stressed that emphasis is given in the utilization of data/information. More specifically, two of the architecture’s layers are entirely dedicated to the handling of data and data federation as well. Simultaneously, all of the architecture’s layers are protected by security and authentication protocols.

Figure 14.

Industry 5.0 and Society 5.0 conceptual framework based on the integration of Industry 4.0 reference architecture model and technologies.

Beyond the technical information discussed about the reference architectures, two paradigms are also provisioned, in particular (i) Personalized Perception [60] and (ii) Open Innovation [71]. Regarding Personalized Perception, although the authors in [60] focus on Education for assessing individual needs and strengths of students utilizing key technologies of I4.0, the framework of the paradigm can be further expanded towards societal personalized perception. Similarly, the authors in [71] discuss the added value of Open Innovation towards the transition to Society 5.0 by reinforcing the collaboration between different stakeholders for the achievement of common goals, which falls under the scheme of value co-creation.

5. Conclusions and Outlook

In this research work, a comprehensive literature review was performed focusing on the upcoming Industry 5.0 and Society 5.0. This research paper attempted to develop a comprehensive literature review and to present a preliminary picture of the more useful components and technologies for the shift from Industry 4.0 to Industry 5.0 and Society 5.0 by advancing a conceptual model in a field that has not yet been thoroughly studied in the literature.

Through the investigation of scientific published works, and the documentation from governments and organizations working on such initiatives, it can be safely concluded that Industry 5.0 is much more than a trend, and Society 5.0 will therefore unfold unprecedent opportunities towards the creation of a highly intelligent global society. As part of the presented literature review, the technological background was presented and discussed in order to provide a clear view on the current technological readiness level as well the expected trends for the next years. The components of the scope of the paper were realized, and the raised research questions were addressed. Realizing the first component of our goal brought us to the research findings discussed in the relation between Industry 4.0 and Society 5.0. The insights demonstrated how the technologies supporting the construction of a physical to digital to physical loop, which is necessary to ensure the long-term growth of a society centered on people, serve as the link between the two concepts. Our research revealed three key issues that need to be addressed when bridging Society 5.0 and Industry 4.0, including: (1) human-oriented action, (2) sustainable development, and (3) the physical to digital to physical loop. Additionally, the clustering of word sets for the main keywords Industry 5.0 and Society 5.0 was also made at the stage of the literature and bibliometric analysis. This demonstrated that, in addition to society and economy, the leading sections during the studied period were those of education, IoT and Applications, Artificial Intelligence and Digitization, and the environment.

Author Contributions

Conceptualization and methodology D.M., J.A. and N.P.; Investigation N.P.; Writing—original draft preparation J.A.; Supervision D.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Mourtzis, D. Challenges and future perspectives for the life cycle of manufacturing networks in the mass customisation era. Logist. Res. 2016, 9, 2. [Google Scholar] [CrossRef]

- ElMaraghy, H.; Monostori, L.; Schuh, G.; ElMaraghy, W. Evolution and future of manufacturing systems. CIRP Ann. 2021, 70, 635–658. [Google Scholar] [CrossRef]

- Rüßmann, M.; Lorenz, M.; Gerbert, P.; Waldner, M.; Justus, J.; Engel, P.; Harnisch, M. Industry 4.0: The Future of Productivity and Growth in Manufacturing Industries. Boston Consult. Group 2015, 9, 54–89. [Google Scholar]

- Xu, X.; Lu, Y.; Vogel-Heuser, B.; Wang, L. Industry 4.0 and Industry 5.0—Inception, conception and perception. J. Manuf. Syst. 2021, 61, 530–535. [Google Scholar] [CrossRef]

- European Commission; Directorate-General for Research and Innovation; Breque, M.; de Nul, L.; Petridis, A. Industry 5.0: Towards a Sustainable, Human-Centric and Resilient European Industry; Publications Office: Luxembourg, 2021. [Google Scholar] [CrossRef]

- Number of Social Media Users Worldwide from 2018 to 2027. Available online: https://www.statista.com/statistics/278414/number-of-worldwide-social-network-users/ (accessed on 15 June 2022).

- Mourtzis, D. (Ed.) Design and Operation of Production Networks for Mass Personalization in the Era of Cloud Technology, 1st ed.; Elsevier: Amsterdam, The Netherlands, 2022. [Google Scholar] [CrossRef]

- Nahavandi, S. Industry 5.0—A Human-Centric Solution. Sustainability 2019, 11, 4371. [Google Scholar] [CrossRef]

- Mourtzis, D. Towards the 5th Industrial Revolution: A literature review and a framework for Process Optimization Based on Big Data Analytics and Semantics. J. Mach. Eng. 2021, 21, 5–39. [Google Scholar] [CrossRef]

- Harayama, Y.; Fukuyama, M. Society 5.0: Aiming for a New Human-Centered Society Japan’s Science and Technology Policies for Addressing Global Social Challenges. 2017. Available online: https://www.hitachi.com/rev/archive/2017/r2017_06/trends/index.html (accessed on 15 June 2022).

- Shiroishi, Y.; Uchiyama, K.; Suzuki, N. Society 5.0: For Human Security and Well-Being. Computer 2018, 51, 91–95. [Google Scholar] [CrossRef]

- Ferreira, C.M.; Serpa, S. Society 5.0 and Social Development: Contributions to a Discussion. Manag. Organ. Stud. 2018, 5, 26. [Google Scholar] [CrossRef]

- Makridakis, S. The forthcoming Artificial Intelligence (AI) revolution: Its impact on society and firms. Futures 2017, 90, 46–60. [Google Scholar] [CrossRef]

- van Eck, N.J.; Waltman, L. Software survey: VOSviewer, a computer program for bibliometric mapping. Scientometrics 2010, 84, 523–538. [Google Scholar] [CrossRef]

- Mourtzis, D.; Angelopoulos, J.; Panopoulos, N. Chapter 2—Digital Manufacturing: The evolution of traditional manufacturing toward an automated and interoperable Smart Manufacturing Ecosystem. In The Digital Supply Chain; MacCarthy, B.L., Ivanov, D., Eds.; Elsevier: Amsterdam, The Netherlands, 2022; pp. 27–45. [Google Scholar] [CrossRef]

- Rada, M. INDUSTRY 5.0 Definition. Available online: https://michael-rada.medium.com/industry-5-0-definition-6a2f9922dc48 (accessed on 21 January 2018).

- Friedman, B.; Hendry, D.G. Value Sensitive Design: Shaping Technology with Moral Imagination; Mit Press: Cambridge, MA, USA, 2019. [Google Scholar]

- Koch, P.J.; van Amstel, M.K.; Dębska, P.; Thormann, M.A.; Tetzlaff, A.J.; Bøgh, S.; Chrysostomou, D. A Skill-based Robot Co-worker for Industrial Maintenance Tasks. Procedia Manuf. 2017, 11, 83–90. [Google Scholar] [CrossRef]

- Cabinet Office Society 5.0. Available online: https://www8.cao.go.jp/cstp/english/society5_0/index.html (accessed on 7 June 2022).

- Granrath, L. Japan’s Society 5.0: Going Beyond Industry 4.0. Available online: https://www.japanindustrynews.com/2017/08/japans-society-5-0-going-beyond-industry-4-0/ (accessed on 29 August 2017).

- Serpa, S. Society 5.0. Available online: https://encyclopedia.pub/entry/123 (accessed on 30 October 2020).

- Deguchi, A.; Hirai, C.; Matsuoka, H.; Nakano, T.; Oshima, K.; Tai, M.; Tani, S. What Is Society 5.0? In Society 5.0: A People-Centric Super-Smart Society; Springer: Singapore, 2020; pp. 1–23. [Google Scholar] [CrossRef]

- Rojas, C.N.; Peñafiel, G.A.A.; Buitrago, D.F.L.; Romero, C.A.T. Society 5.0: A Japanese Concept for a Superintelligent Society. Sustainability 2021, 13, 6567. [Google Scholar] [CrossRef]

- Mourtzis, D.; Angelopoulos, J.; Panopoulos, N. From Industry4.0 to Society4.0: Identifying Challenges and Opportunities. 2019. Available online: http://www.scopus.com/inward/record.url?eid=2-s2.0-85079490454&partnerID=MN8TOARS (accessed on 5 June 2022).

- Mourtzis, D. Development of Skills and Competences in Manufacturing Towards Education 4.0: A Teaching Factory Approach. In Proceedings of the 3rd International Conference on the Industry 4.0 Model for Advanced Manufacturing, Belgrade, Serbia, 5–7 June 2018; pp. 194–210. [Google Scholar]

- Onday, O. Japan’s Society 5.0: Going Beyond Industry 4.0. Bus. Econ. J. 2019, 10, 1000389. [Google Scholar] [CrossRef]

- United Nations Do you Know All 17 SDGs? Available online: https://sdgs.un.org/goals (accessed on 10 June 2022).

- B20 Tokyo 2019 Society 5.0 for SDGs. Mar. 2019. Available online: http://www.b20tokyo.org/ (accessed on 13 June 2022).

- Mamasioulas, A.; Mourtzis, D.; Chryssolouris, G. A manufacturing innovation overview: Concepts, models and metrics. Int. J. Comput. Integr. Manuf. 2020, 33, 769–791. [Google Scholar] [CrossRef]

- Mourtzis, D.; Angelopoulos, J.; Panopoulos, N. Smart Manufacturing and Tactile Internet Based on 5G in Industry 4.0: Challenges, Applications and New Trends. Electronics 2021, 10, 3175. [Google Scholar] [CrossRef]

- Mourtzis, D. Simulation in the design and operation of manufacturing systems: State of the art and new trends. Int. J. Prod. Res. 2020, 58, 1927–1949. [Google Scholar] [CrossRef]

- Keidanren. Digital Transformation—Opening up the Future through Co-creation of Values. Available online: https://www.keidanren.or.jp/en/policy/2020/038.html (accessed on 19 May 2020).

- Nagasato, Y.; Yoshimura, T.; Shinozaki, R. Realizing Society 5.0 Expectations from Japanese Business. J. Inf. Manag. 2018, 38, 3–8. [Google Scholar]

- Keidanren. Toward Realization of the New Economy and Society—Reform of the Economy and Society by the Deepening of ‘Society 5.0’. Available online: https://www.keidanren.or.jp/en/policy/2016/029.html (accessed on 19 April 2016).

- Keidanren. Society 5.0—Co-Creating the Future. Available online: https://www.keidanren.or.jp/en/policy/2018/095.html (accessed on 13 November 2018).

- Nakanishi, H. Modern Society has Reached Its Limits. Society 5.0 Will Liberate Us. Available online: https://www.weforum.org/agenda/2019/01/modern-society-has-reached-its-limits-society-5-0-will-liberate-us/ (accessed on 19 January 2019).

- United Nations Department of Economic and Social Affairs Disability #Envision2030: 17 Goals to Transform the World for Persons with Disabilities. Available online: https://www.un.org/development/desa/disabilities/envision2030.html (accessed on 30 May 2022).

- Jiang, J.-R. An improved cyber-physical systems architecture for Industry 4.0 smart factories. Adv. Mech. Eng. 2018, 10, 1687814018784192. [Google Scholar] [CrossRef] [Green Version]

- European Commission; Directorate-General for Research and Innovation; Müller, J. Enabling Technologies for Industry 5.0: Results of a Workshop with Europe’s Technology Leaders; Publications Office: Luxembourg, 2020. [Google Scholar] [CrossRef]