Flexible Sandwich-Structured Foldable Triboelectric Nanogenerator Based on Paper Substrate for Eco-Friendly Electronic Devices

Abstract

:1. Introduction

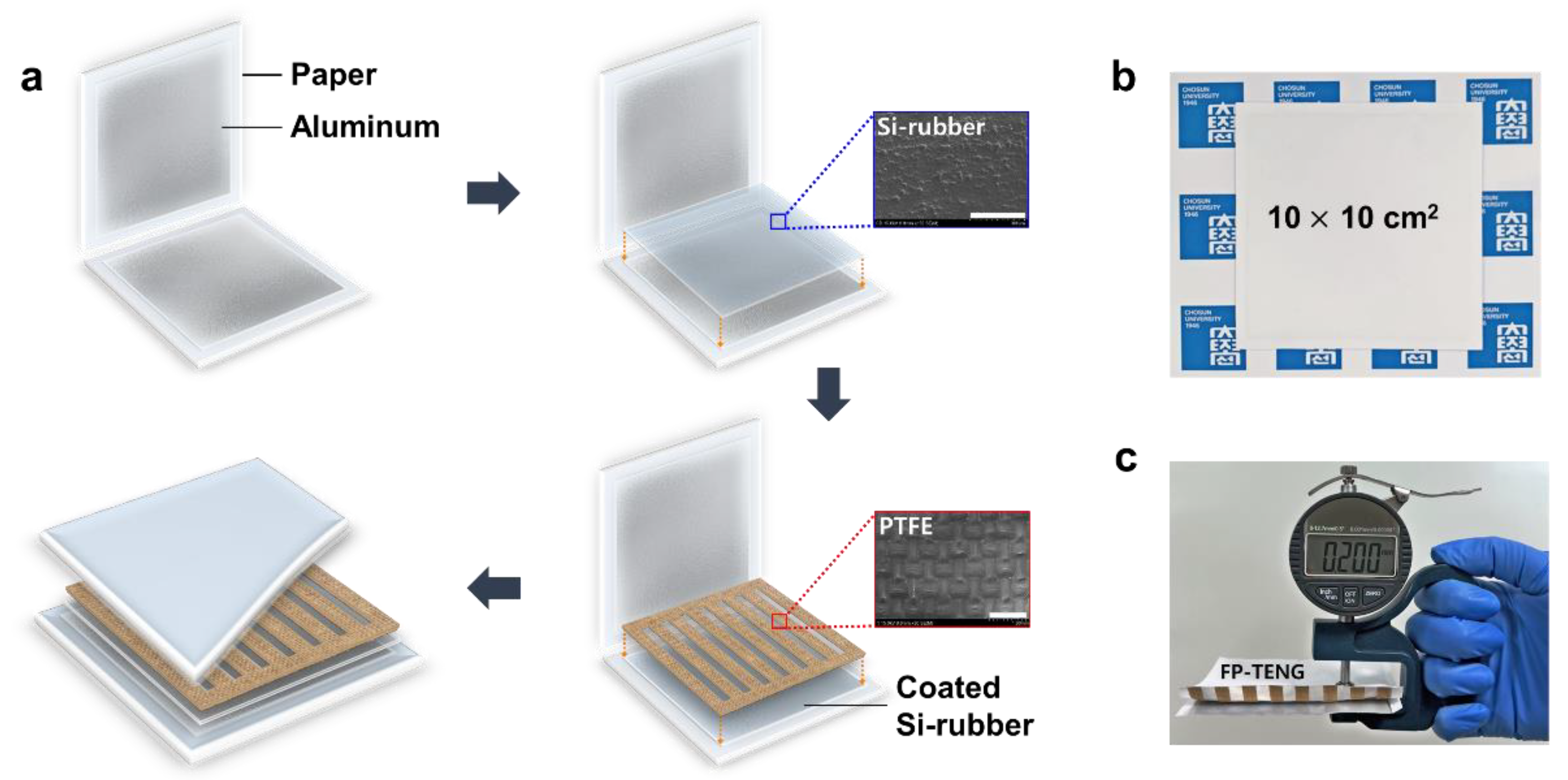

2. Experimental Details

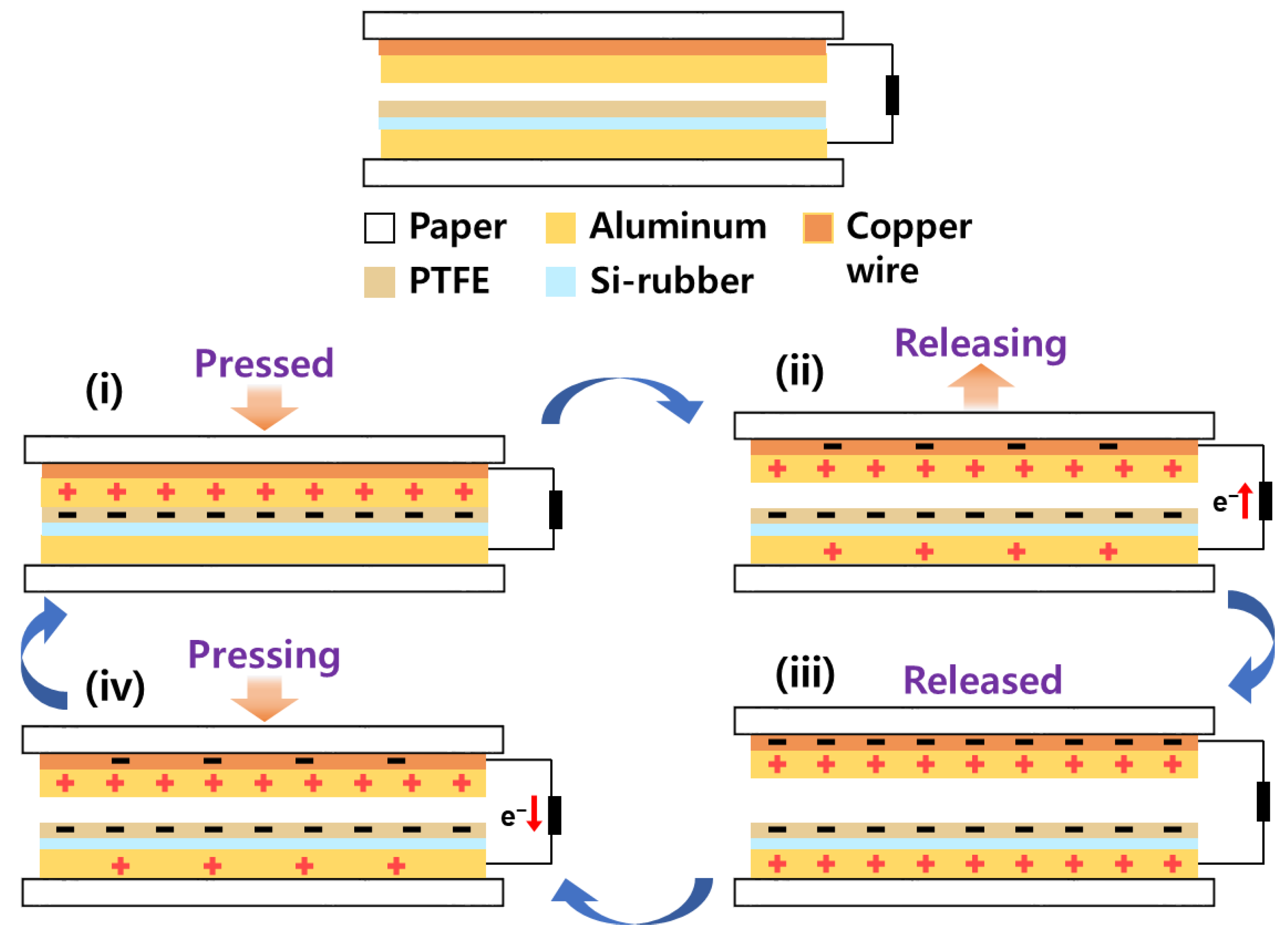

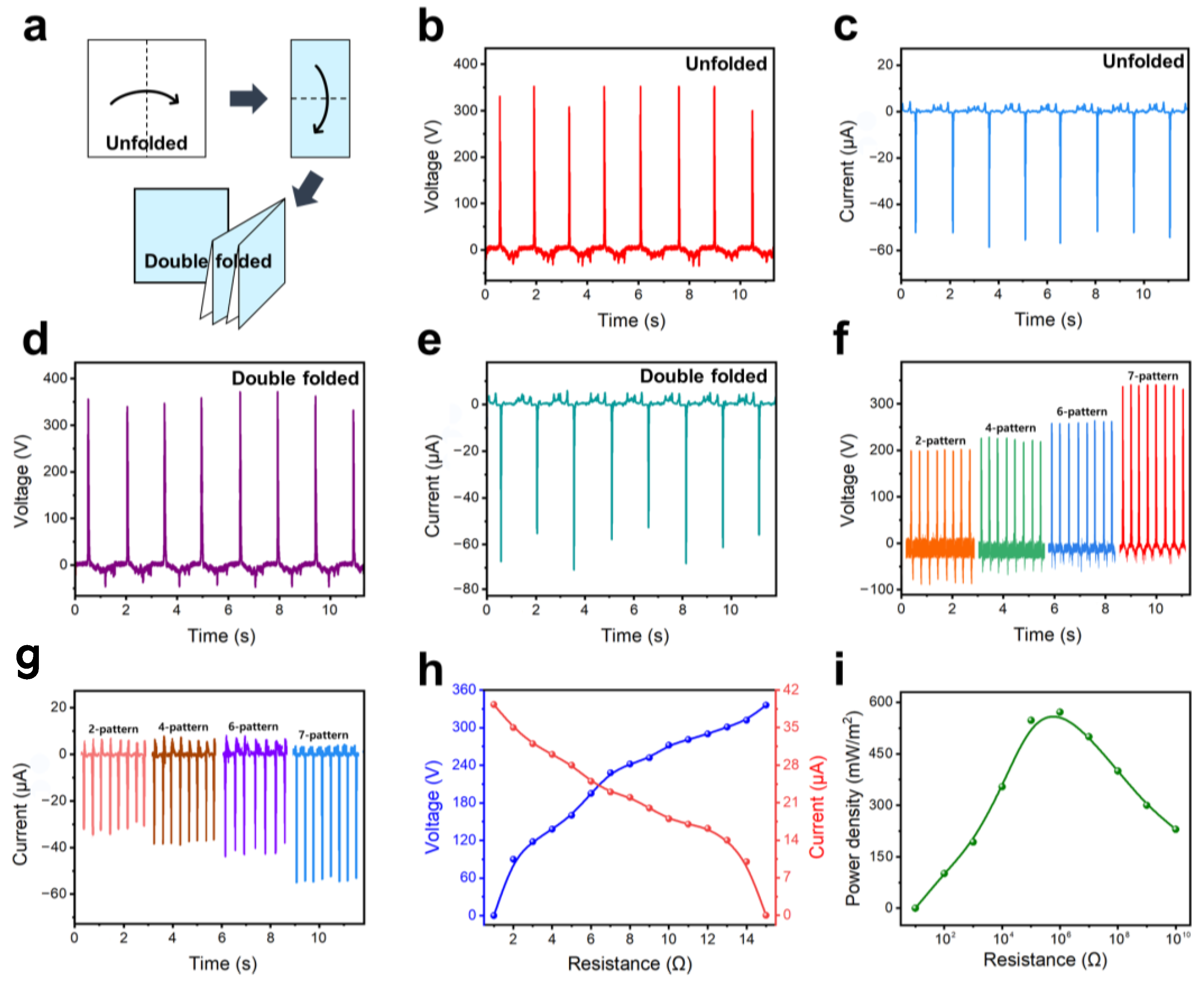

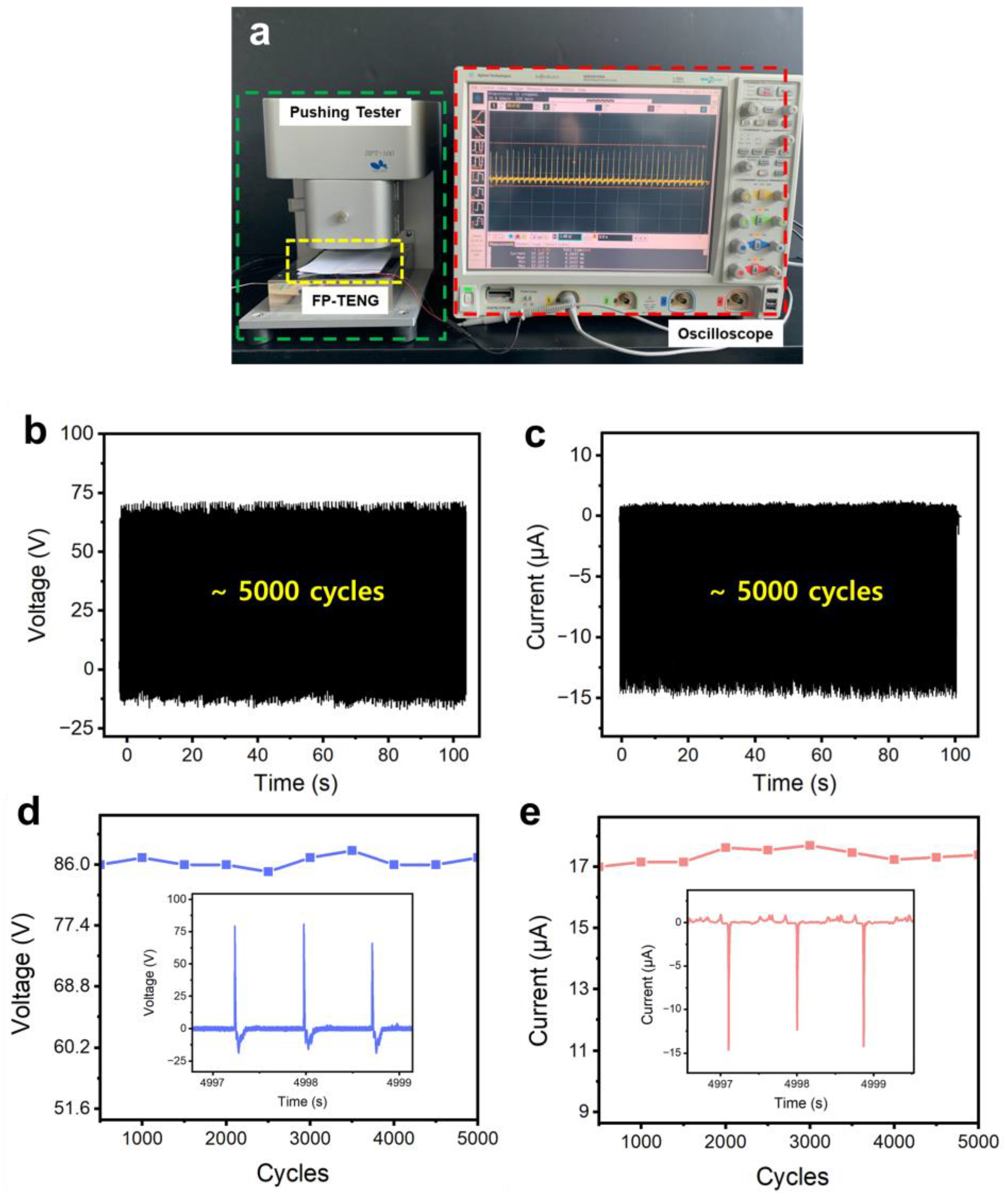

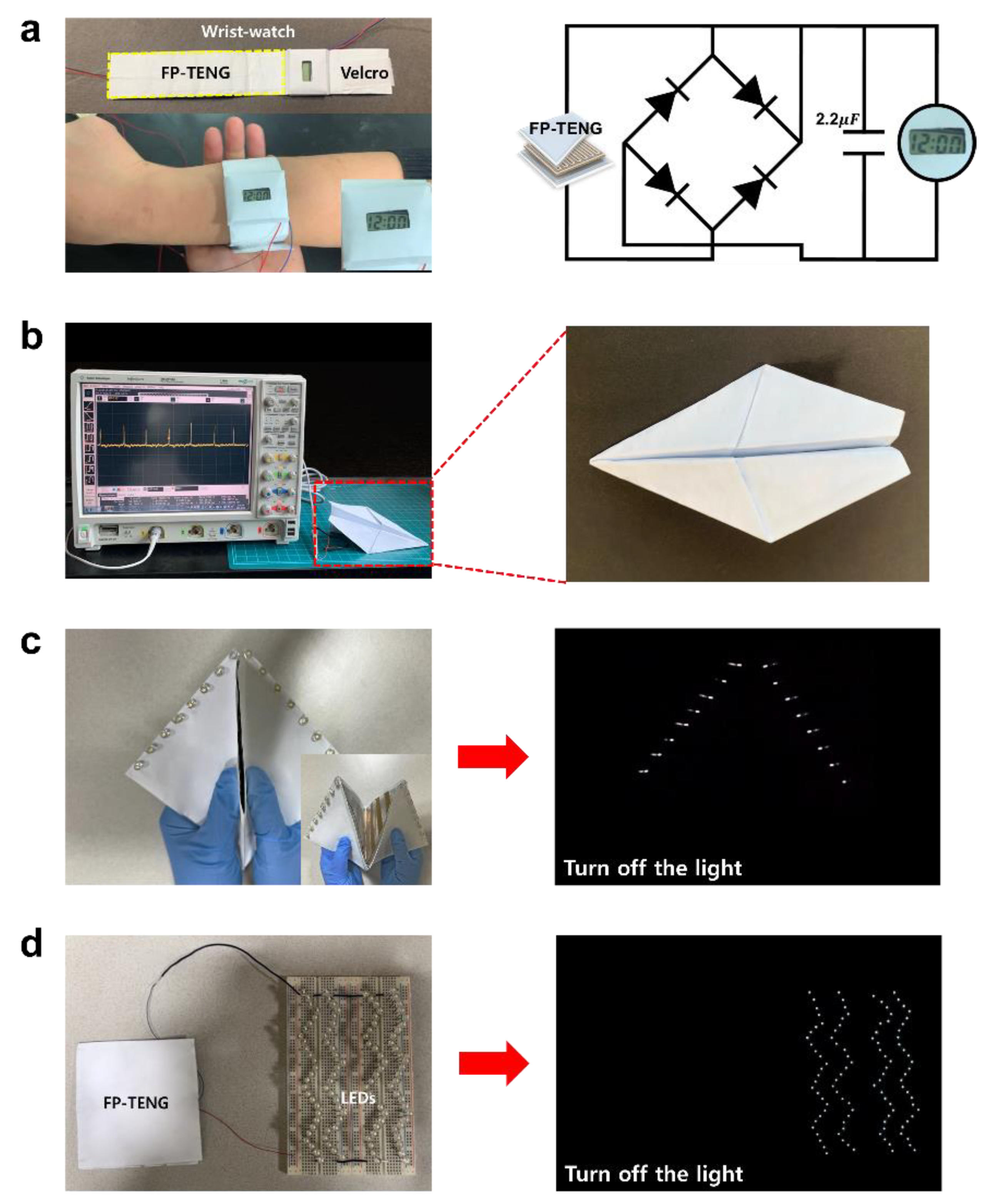

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, Z.L. Triboelectric nanogenerators as new energy technology and self-powered sensors—Principles, problems and perspectives. Faraday Discuss. 2014, 176, 447–458. [Google Scholar] [CrossRef]

- Zhu, G.; Peng, B.; Chen, J.; Jing, Q.; Wang, Z.L. Triboelectric nanogenerators as a new energy technology: From fundamentals, devices, to applications. Nano Energy 2014, 14, 126–138. [Google Scholar] [CrossRef]

- Tang, Q.; Guo, H.; Yan, P.; Hu, C. Recent progresses on paper-based triboelectric nanogenerator for portable self-powered sensing systems. EcoMat 2020, 2, e12060. [Google Scholar] [CrossRef]

- Lin, C.; Yu, J.; Hua, Z.; Lan, J.; Huang, H.; Lu, D.; Cao, S.; Ma, X. Development progress, performance enhancement routes, and applications of paper-based triboelectric nanogenerators. Chem. Eng. J. 2021, 430, 132559. [Google Scholar] [CrossRef]

- Shankaregowda, S.A.; Ahmed, R.F.S.M.; Liu, Y.; Nanjegowda, C.B.; Cheng, X.; Shivanna, S.; Ramakrishna, S.; Yu, Z.; Zhang, X.; Sannathammegowda, K. Dry-coated graphite onto sandpaper for triboelectric nanogenerator as an active power source for portable electronics. Nanomaterials 2019, 9, 1585. [Google Scholar] [CrossRef]

- Chen, S.; Song, Y.; Xu, F. Flexible and Highly Sensitive Resistive Pressure Sensor Based on Carbonized Crepe Paper with Corrugated Structure. ACS Appl. Mater. Interfaces 2018, 10, 34646–34654. [Google Scholar] [CrossRef]

- Xia, K.; Zhang, H.; Zhu, Z.; Xu, Z. Folding Triboelectric Nanogenerator on Paper Based on Conductive Ink and Teflon Tape. Sens. Actuators A Phys. 2018, 272, 28–32. [Google Scholar] [CrossRef]

- Xia, K.; Zhu, Z.; Zhang, H.; Du, C.; Wang, R.; Xu, Z. High Output Compound Triboelectric Nanogenerator Based on Paper for Self-Powered Height Sensing System. IEEE Trans. Nanotechnol. 2018, 17, 1217–1223. [Google Scholar] [CrossRef]

- Xia, K.; Zhu, Z.; Zhang, H.; Du, C.; Fu, J.; Xu, Z. Milk-based triboelectric nanogenrator on paper for harvesting energy from human body motion. Nano Energy 2018, 56, 400–410. [Google Scholar] [CrossRef]

- Xia, K.; Zhu, Z.; Zhang, H.; Du, C.; Xu, Z.; Wang, R. Painting a high-output triboelectric nanogenerator on paper for harvesting energy from human body motion. Nano Energy 2018, 50, 571–580. [Google Scholar]

- Chen, S.; Jiang, J.; Xu, F.; Gong, S. Crepe cellulose paper and nitrocellulose membrane-based triboelectric nanogenerators for energy harvesting and self-powered human-machine interaction. Nano Energy 2019, 61, 69–77. [Google Scholar] [CrossRef]

- Wang, Y.; Wu, Y.; Liu, Q.; Wang, X.; Cao, J.; Cheng, G.; Zhang, Z.; Ding, J.; Li, K. Origami triboelectric nanogenerator with double-helical structure for environmental energy harvesting. Energy 2020, 212, 118462. [Google Scholar]

- Bukhari, M.U.; Riaz, K.; Tauqeer, T.; Sajid, M. Simple and low cost triboelectric nanogenerator (TENG) for resource limited environment. In Proceedings of the 2019 International Conference on Robotics and Automation in Industry (ICRAI), Rawalpindi, Pakistan, 21–22 October 2019; pp. 1–4. [Google Scholar]

- Shankaregowda, S.A.; Ahmed, R.F.; Nanjegowda, C.B.; Wang, J.; Guan, S.; Puttaswamy, M.; Amini, A.; Zhang, Y.; Kong, D.; Sannathammegowda, K.; et al. Single-electrode triboelectric nanogenerator based on economical graphite coated paper for harvesting waste environmental energy. Nano Energy 2019, 66, 104141. [Google Scholar] [CrossRef]

- Zhang, L.; Li, H.; Xie, Y.; Guo, J.; Zhu, Z. Triboelectric nanogenerator based on Teflon/vitamin B1 powder for self-powered humidity sensing. Beilstein J. Nanotechnol. 2020, 11, 1394–1401. [Google Scholar] [CrossRef]

- Wu, C.; Wang, X.; Lin, L.; Guo, H.; Wang, Z.L. Paper-based triboelectric nanognerators made of stretchable interlocking kirigami patterns. ACS Nano 2016, 10, 4652–4659. [Google Scholar] [CrossRef]

- Dudem, B.; Dharmasena, R.I.; Riaz, G.R.; Vivekananthan, V.; Wijayantha, K.G.U.; Lugli, P.; Petti, L.; Silva, S.R. Wearable Triboelectric Nanogenerator from Waste Materials for Autonomous Information Transmission via Morse Code. ACS Appl. Mater. Interfaces 2022, 14, 5328–5337. [Google Scholar] [CrossRef]

- Guo, H.; Yeh, M.H.; Lai, Y.C.; Zi, Y.; Wu, C.; Wen, Z.; Hu, C.; Wang, Z.L. All-in-One Shape-Adaptive Self-Charging Power Package for Wearable Electronics. ACS Nano 2016, 10, 10580–10588. [Google Scholar] [CrossRef]

- Zhang, Z.; Xu, Y.; Wang, D.; Yang, H.; Guo, J.; Turng, L.S. Enhanced performance of an expanded polytetrafluoroethylene-based triboelectric nanogenerator for energy harvesting. Nano Energy 2019, 60, 903–911. [Google Scholar] [CrossRef]

- Tao, K.; Yi, H.; Yang, Y.; Tang, L.; Yang, Z.; Wu, J.; Chang, H.; Yuan, W. Miura-origami-inspired electret/triboelectric power generator for wearable energy harvesting with water-proof capability. Microsyst. Nanoeng. 2020, 6, 56. [Google Scholar] [CrossRef]

- Tao, K.; Yi, H.; Yang, Y.; Chang, H.; Wu, J.; Tang, L.; Yang, Z.; Wang, N.; Hu, L.; Fu, Y.; et al. Origami-inspired electret-based triboelectric generator for biomechanical and ocean wave energy harvesting. Nano Energy 2019, 67, 104197. [Google Scholar] [CrossRef]

- Zhang, H.; Yang, C.; Yu, Y.; Zhou, Y.; Quan, L.; Dong, S.; Luo, J. Origami-tessellation-based triboelectric nanogenerator for energy harvesting with application in road pavement. Nano Energy 2020, 78, 105177. [Google Scholar] [CrossRef]

- Chen, C.; Howard, D.; Zhang, S.L.; Do, Y.; Sun, S.; Cheng, T.; Wang, Z.L.; Abowd, G.D.; Oh, H. SPIN(self-powered paper interfaces): Bridging triboelectric nanogenerator with folding paper creases. In Proceedings of the Fourteenth International Conference on Tangible, Embedded, and Embodied Interaction, Sydney, Australia, 9–12 February 2020; pp. 431–442. [Google Scholar]

- Guo, H.; Yeh, M.H.; Zi, Y.; Wen, Z.; Chen, J.; Liu, G.; Hu, C.; Wang, Z.L. Ultralight cut-paper-based self-charging power unit for self-powered portable electronic and medical systems. ACS Nano 2017, 11, 4475–4482. [Google Scholar] [CrossRef]

- Xiao-Sheng, Z.; Meng, S.; Jürgen, B.; Beomjoon, K. Penciling a triboelectric nanogenerator on paper for autonomous power MEMS applications. Nano Energy 2017, 33, 393–401. [Google Scholar]

- Han, J.; Xu, N.; Liang, Y.; Ding, M.; Zhai, J.; Sun, Q.; Wang, Z.L. Paper-based triboelectric nanogenerators and their applications: A review. Beilstein J. Nanotechnol. 2021, 12, 151–171. [Google Scholar] [CrossRef]

| Ref. | Electrode | Triboelectric | Typical Performance | |

|---|---|---|---|---|

| ISC (μA) | VOC (V) | |||

| [8] | Conductive ink | PTFE tape | 72 | 218 |

| [9] | Conductive ink | Cardboard, PTFE | 43.6 | 292.5 |

| [11] | Copper | Crepe cellulose, NCM | 45 | 103.2 |

| [13] | Copper wire | Graphite, PET | 75.6 | 69.8 |

| [15] | Copper foil | B1 powder, Teflon | 46.3 | 340 |

| [21] | Copper | FEP | 0.00264 | 7.32 |

| [25] | Copper | Graphite, Teflon | 3.75 | 85 |

| This work | Copper, aluminum | Aluminum, PTFE/Si rubber | 75.8 | 456 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, D.E.; Park, J.; Kim, Y.T. Flexible Sandwich-Structured Foldable Triboelectric Nanogenerator Based on Paper Substrate for Eco-Friendly Electronic Devices. Energies 2022, 15, 6236. https://doi.org/10.3390/en15176236

Kim DE, Park J, Kim YT. Flexible Sandwich-Structured Foldable Triboelectric Nanogenerator Based on Paper Substrate for Eco-Friendly Electronic Devices. Energies. 2022; 15(17):6236. https://doi.org/10.3390/en15176236

Chicago/Turabian StyleKim, Da Eun, Jiwon Park, and Youn Tae Kim. 2022. "Flexible Sandwich-Structured Foldable Triboelectric Nanogenerator Based on Paper Substrate for Eco-Friendly Electronic Devices" Energies 15, no. 17: 6236. https://doi.org/10.3390/en15176236

APA StyleKim, D. E., Park, J., & Kim, Y. T. (2022). Flexible Sandwich-Structured Foldable Triboelectric Nanogenerator Based on Paper Substrate for Eco-Friendly Electronic Devices. Energies, 15(17), 6236. https://doi.org/10.3390/en15176236