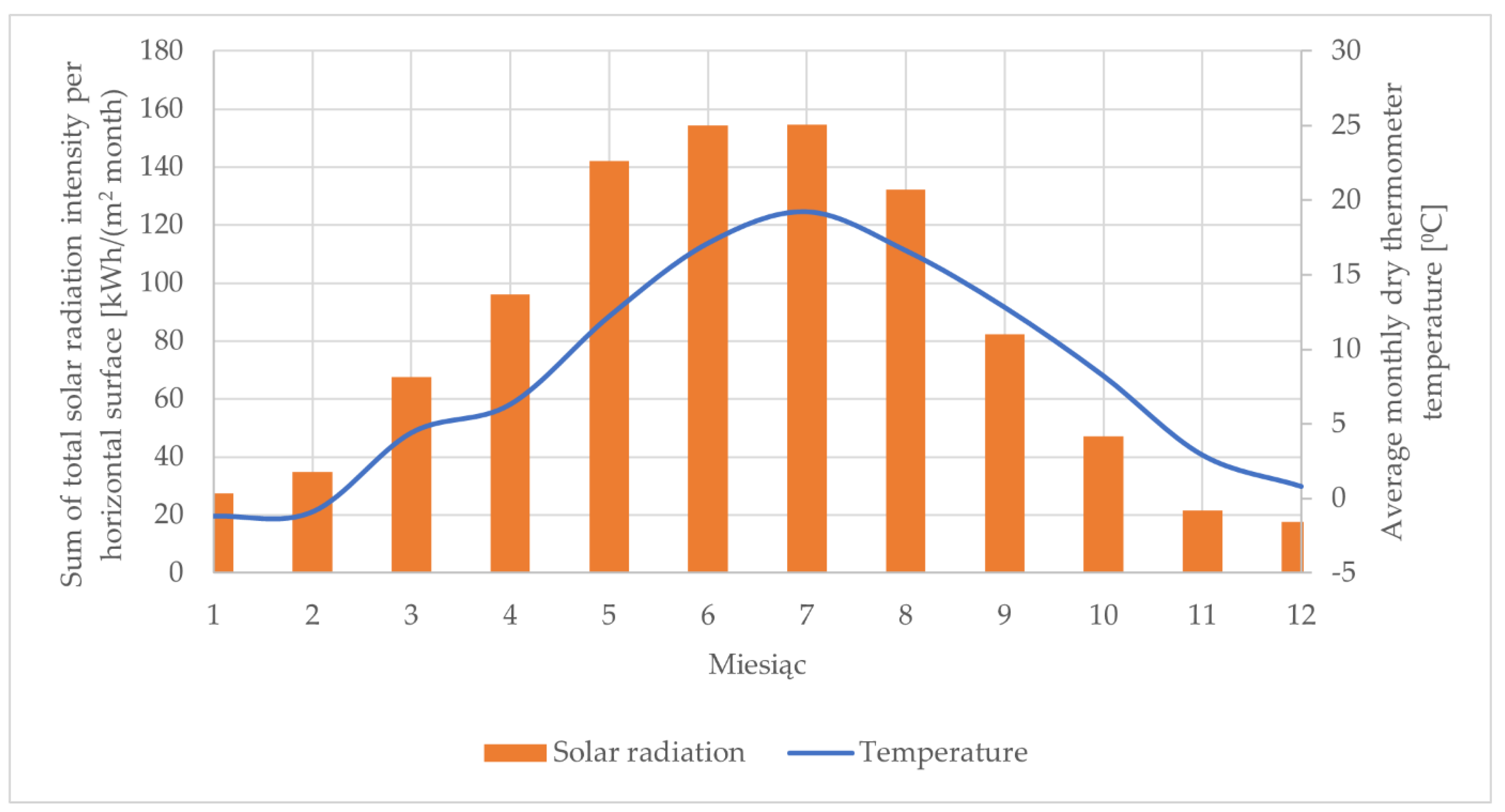

Possibilities of Integrating Adsorption Chiller with Solar Collectors for Polish Climate Zone

Abstract

:1. Introduction

2. Materials and Methods

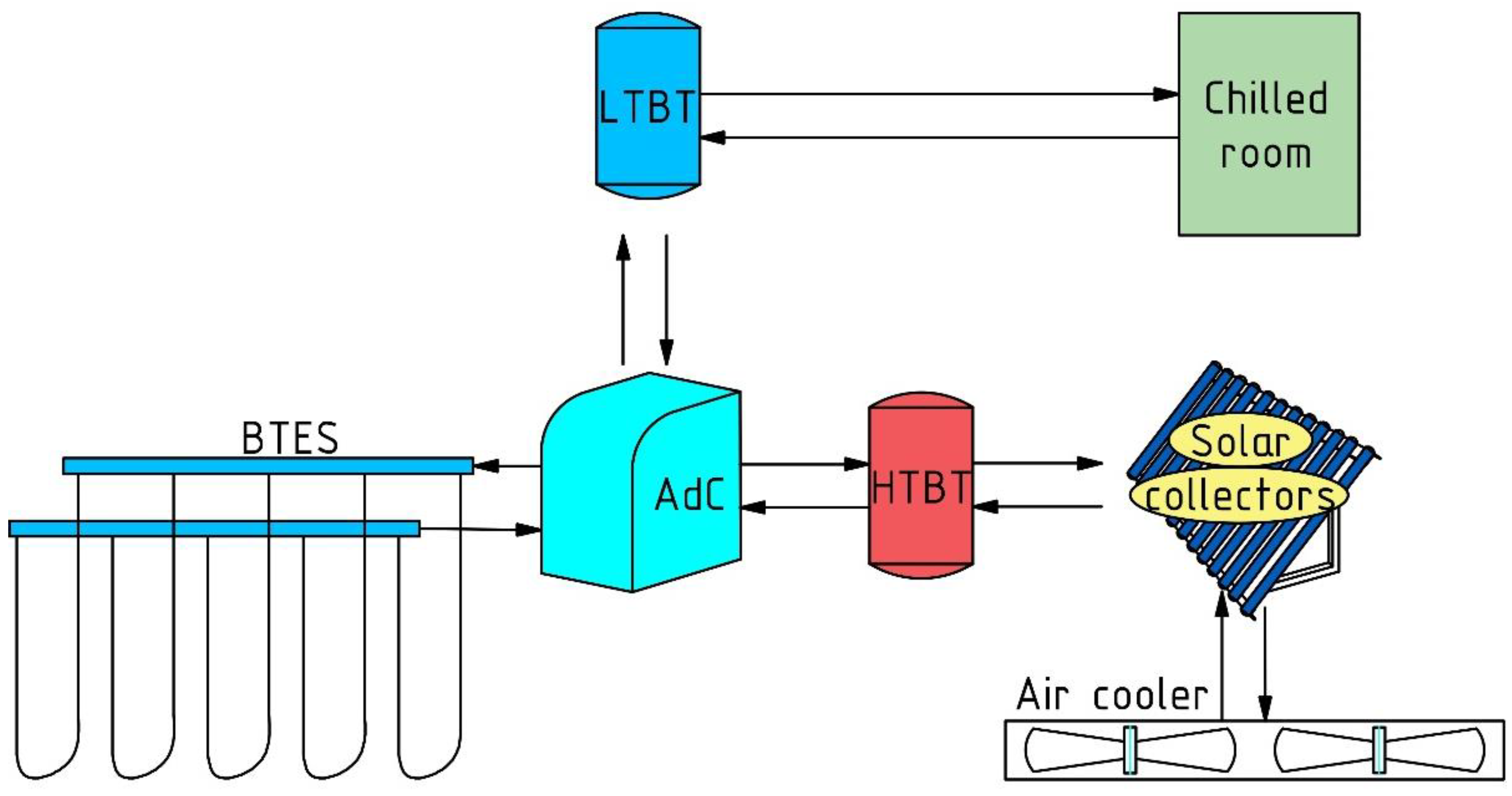

2.1. Description of the System

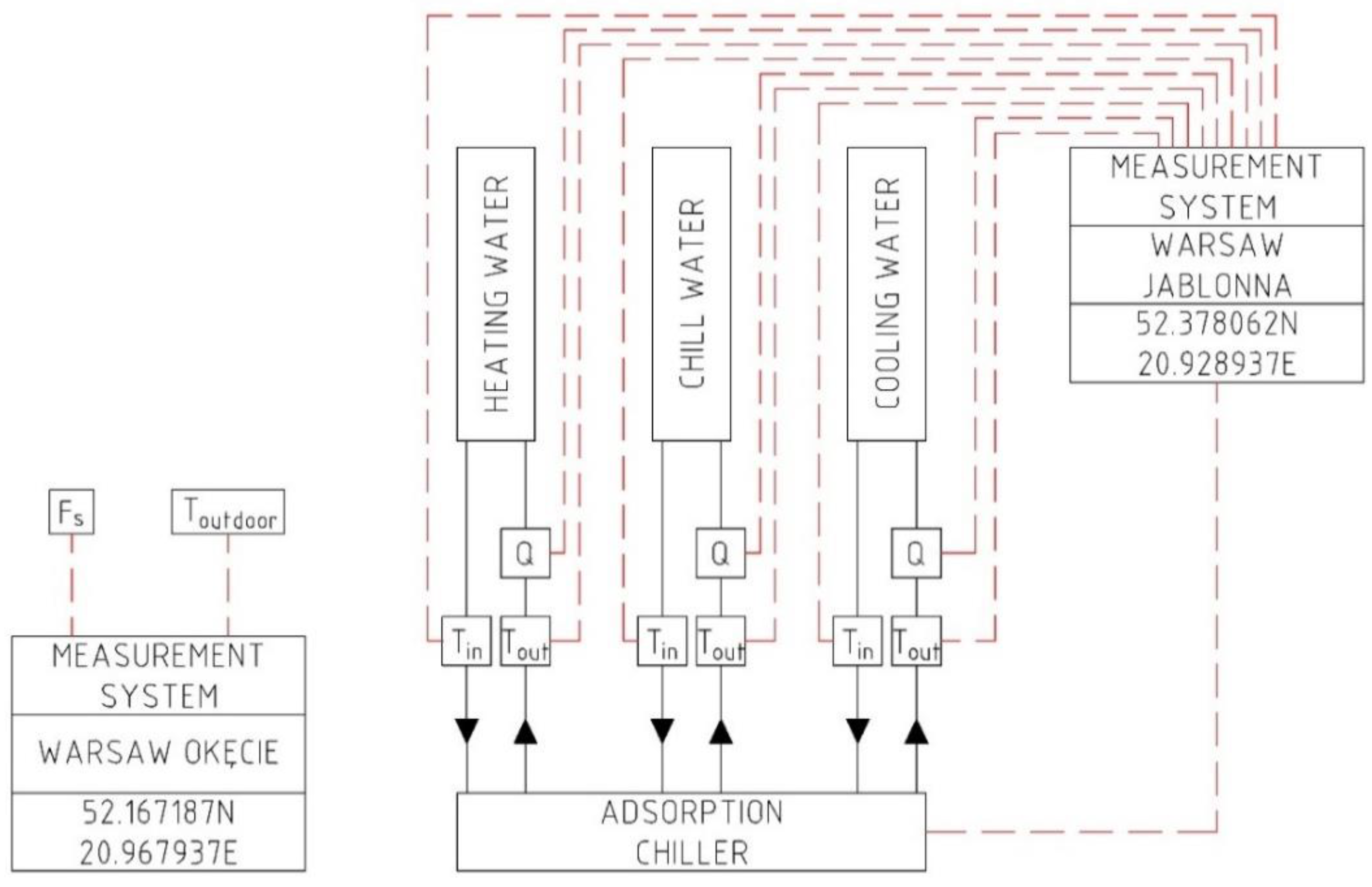

2.2. Methods

3. Results

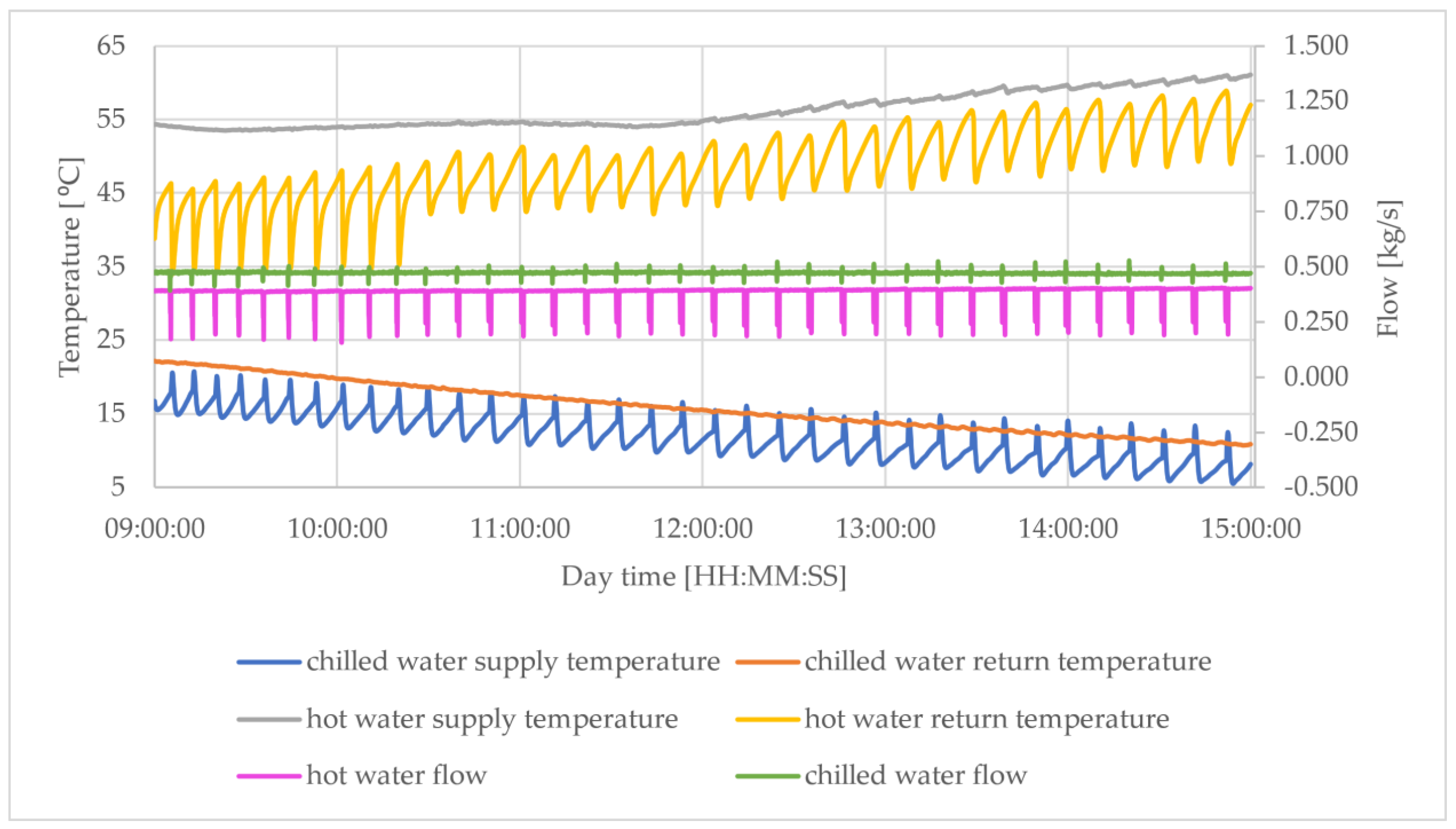

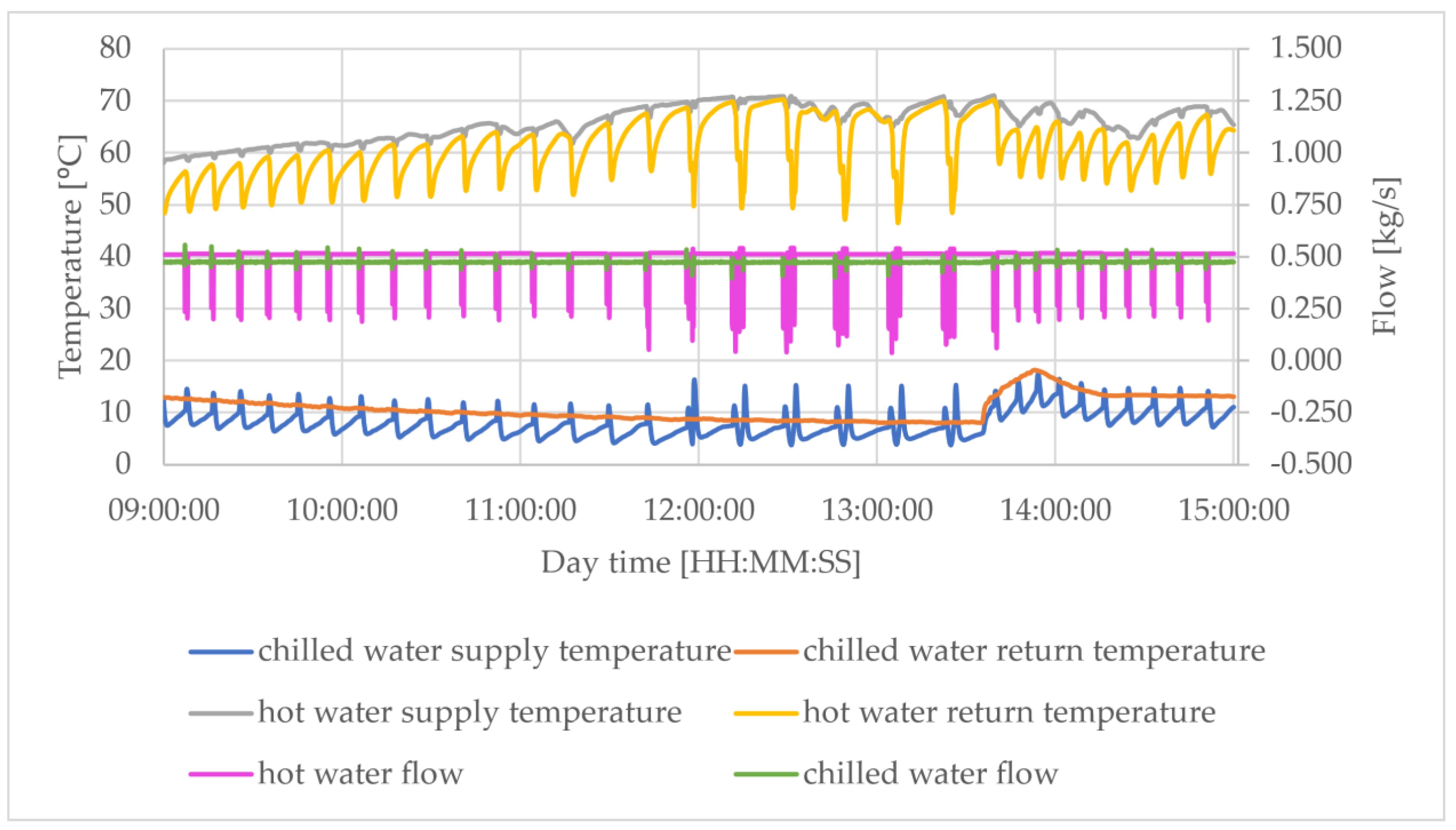

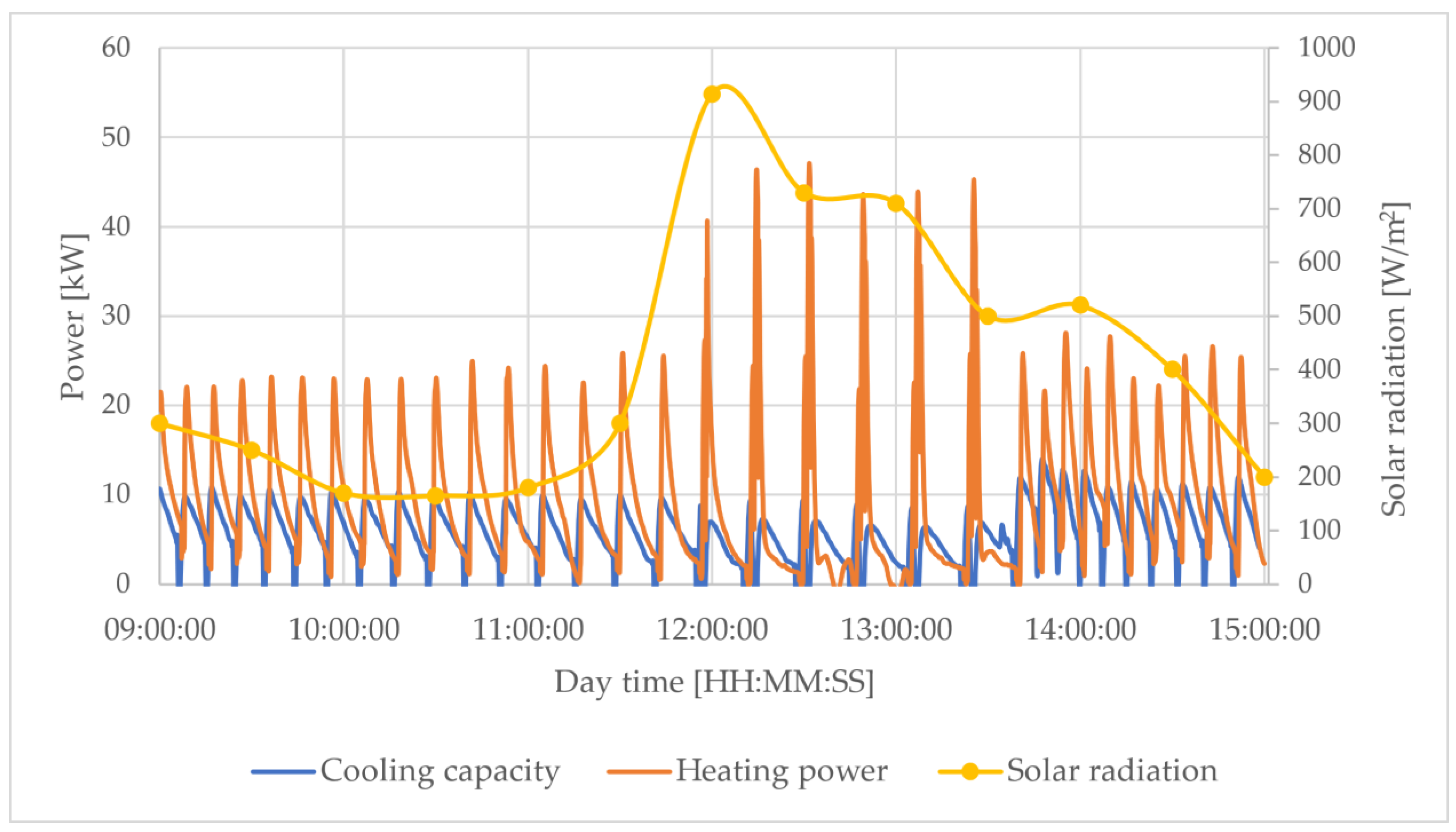

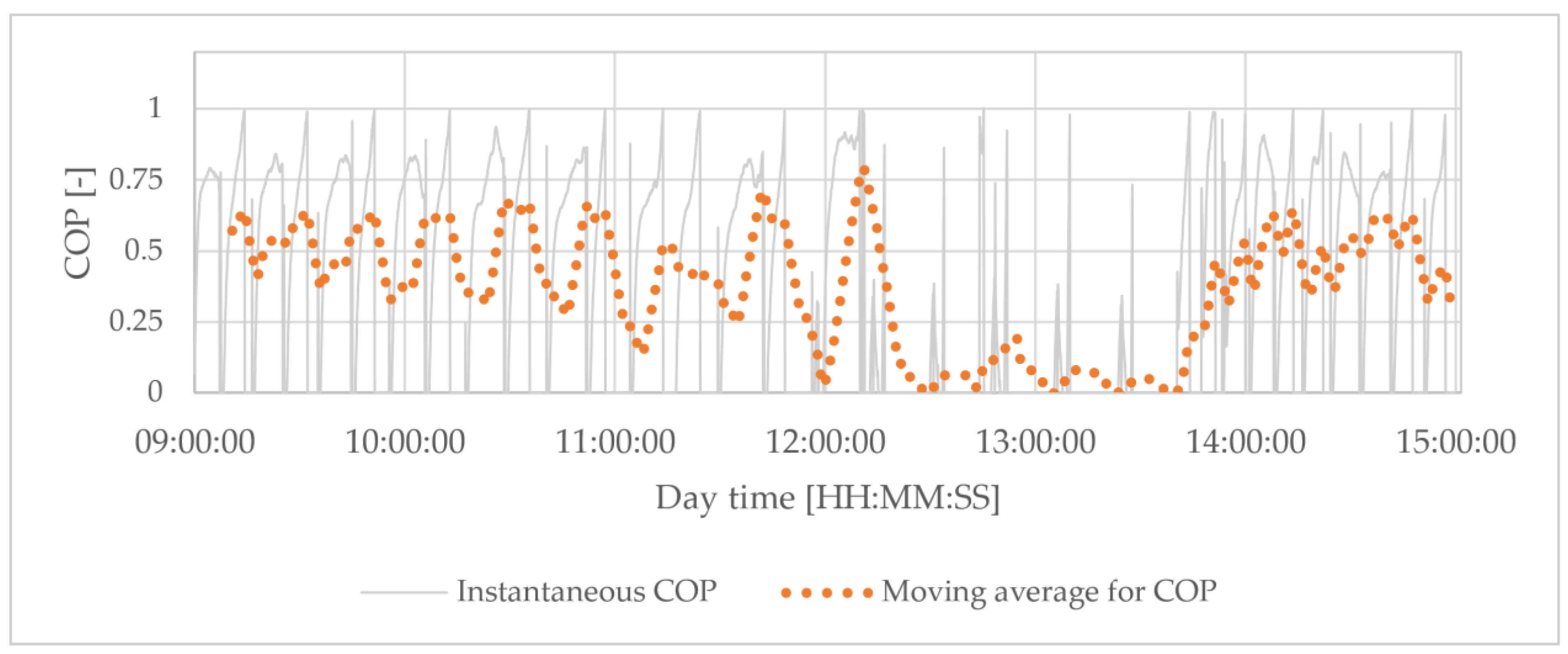

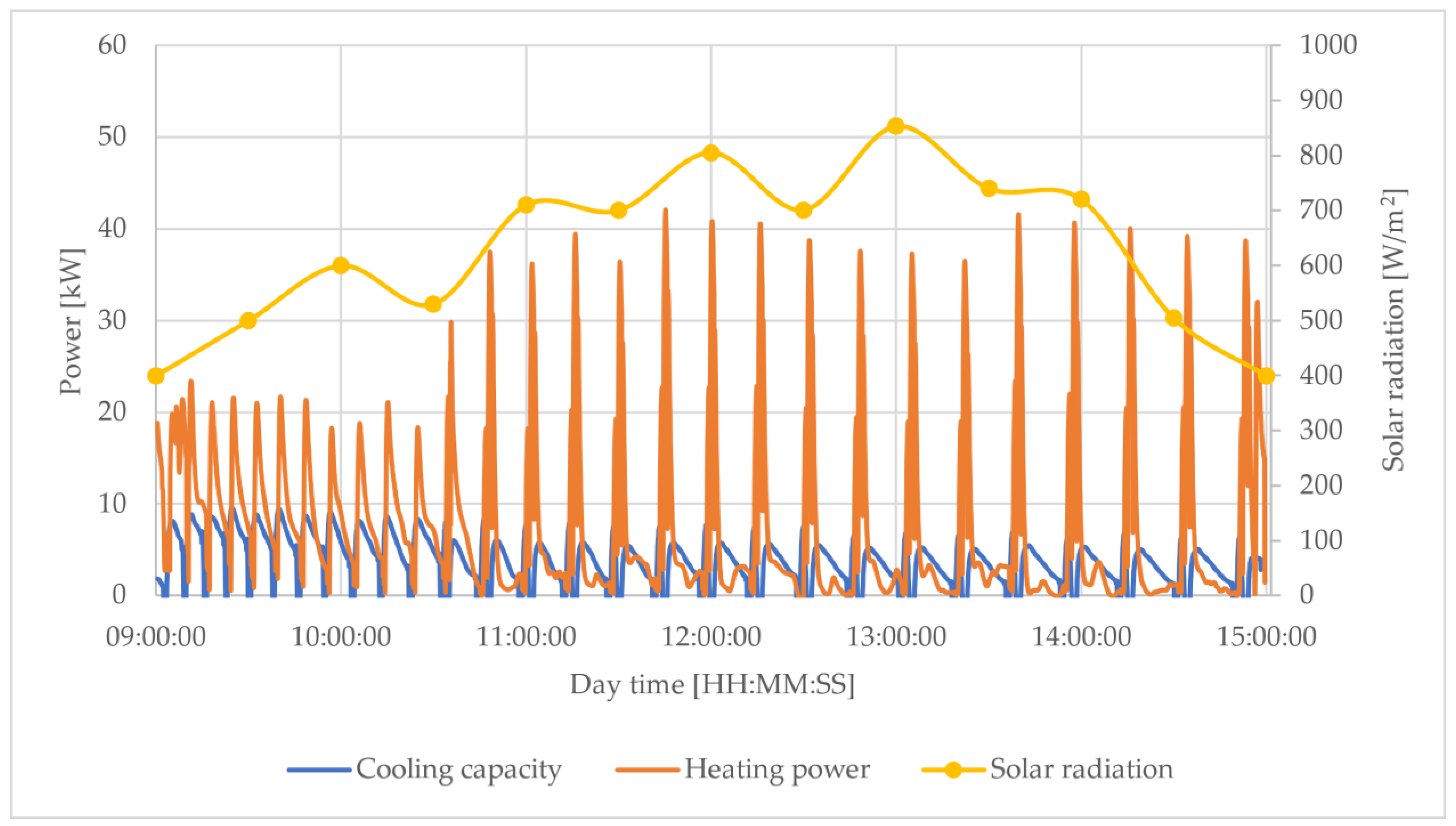

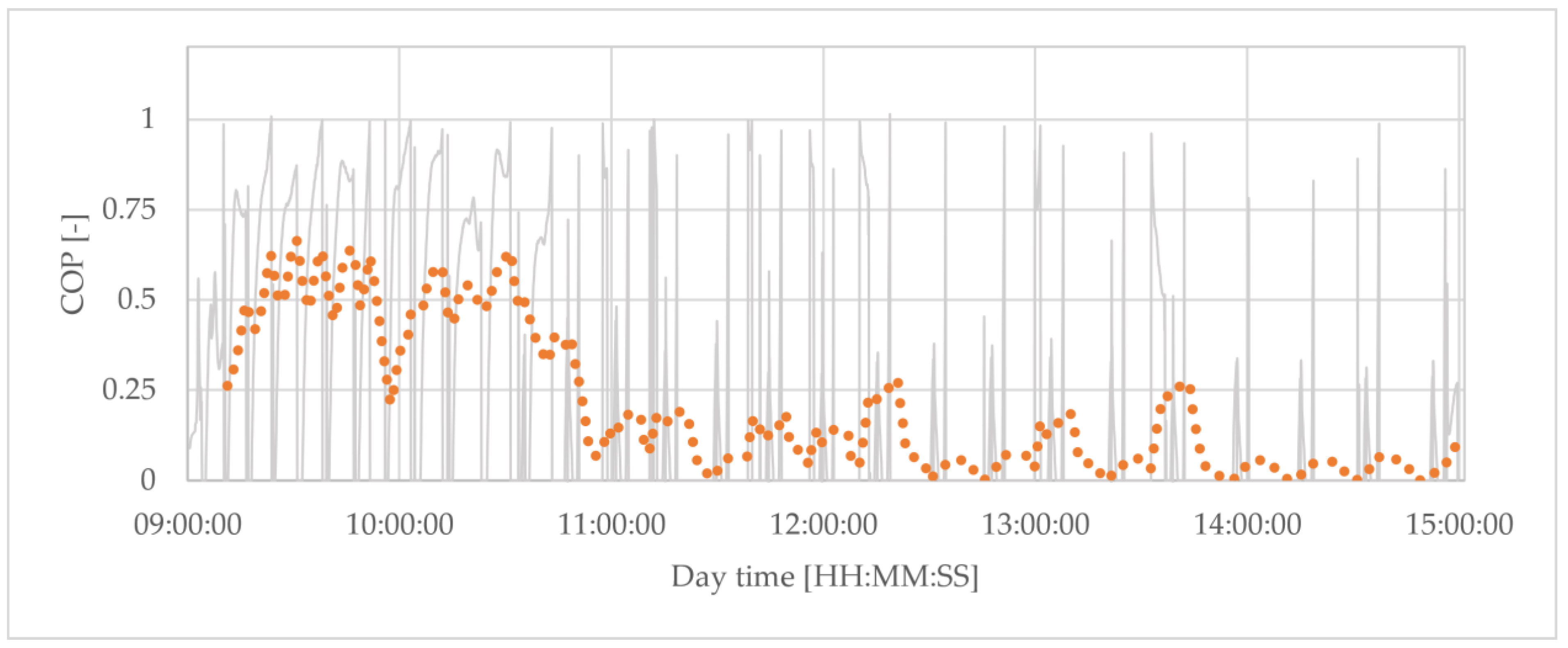

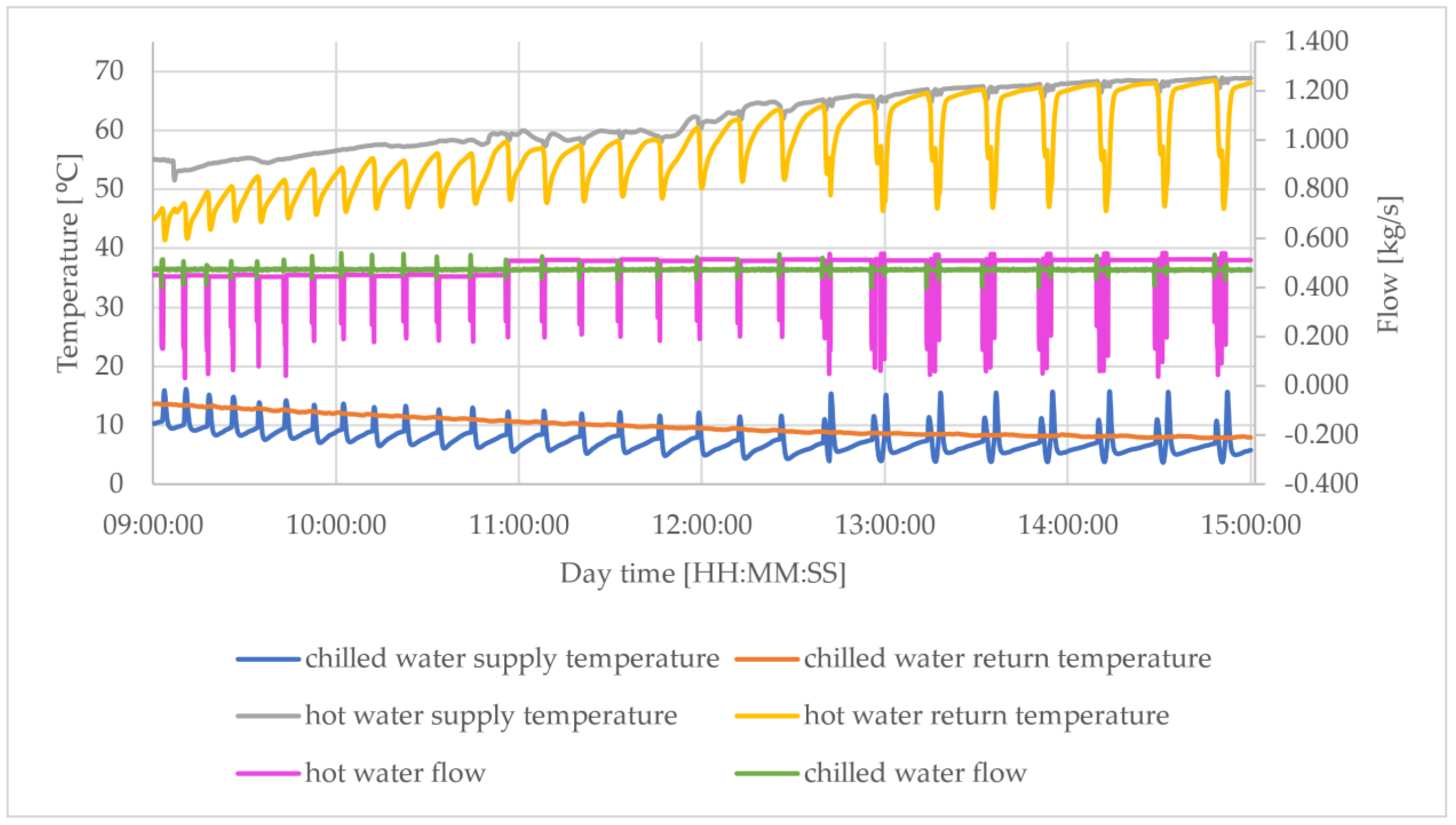

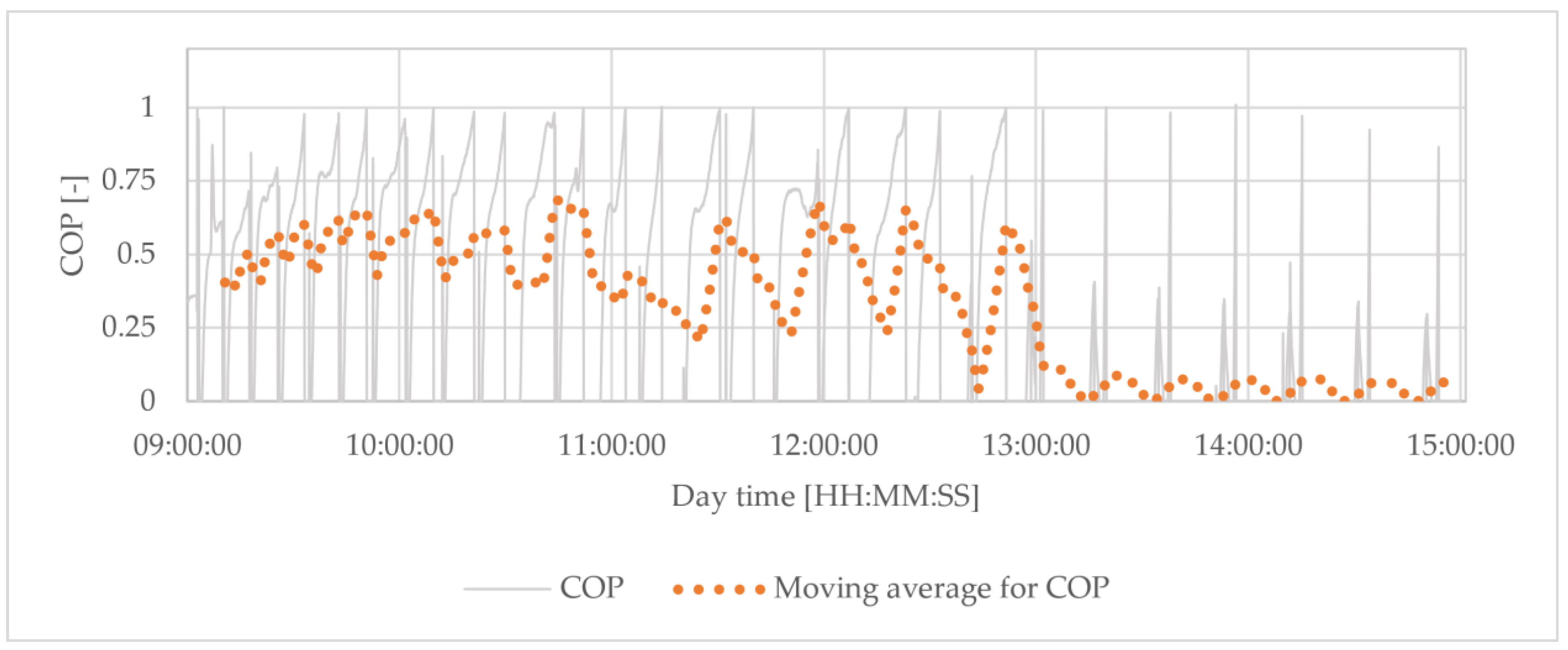

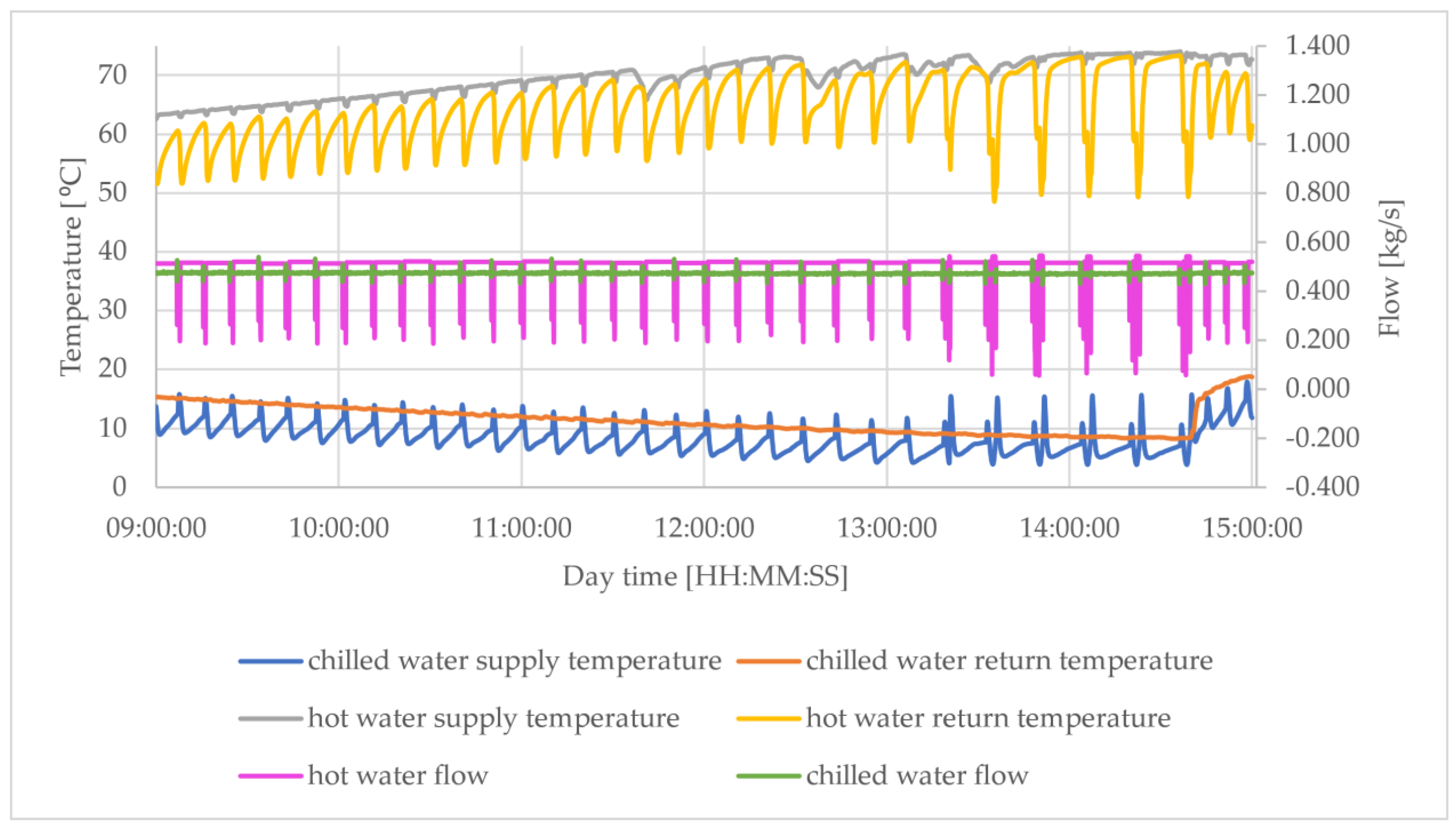

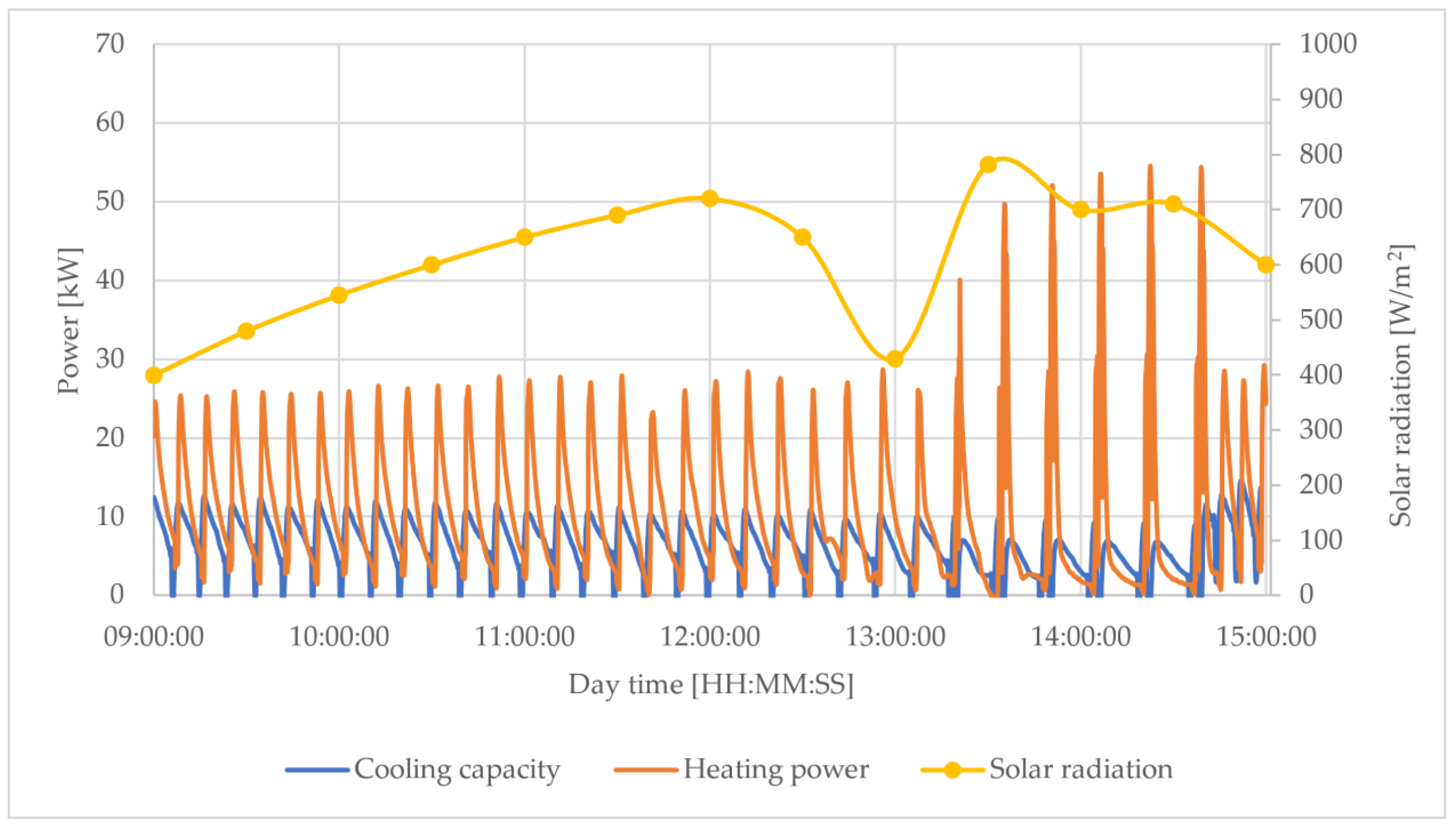

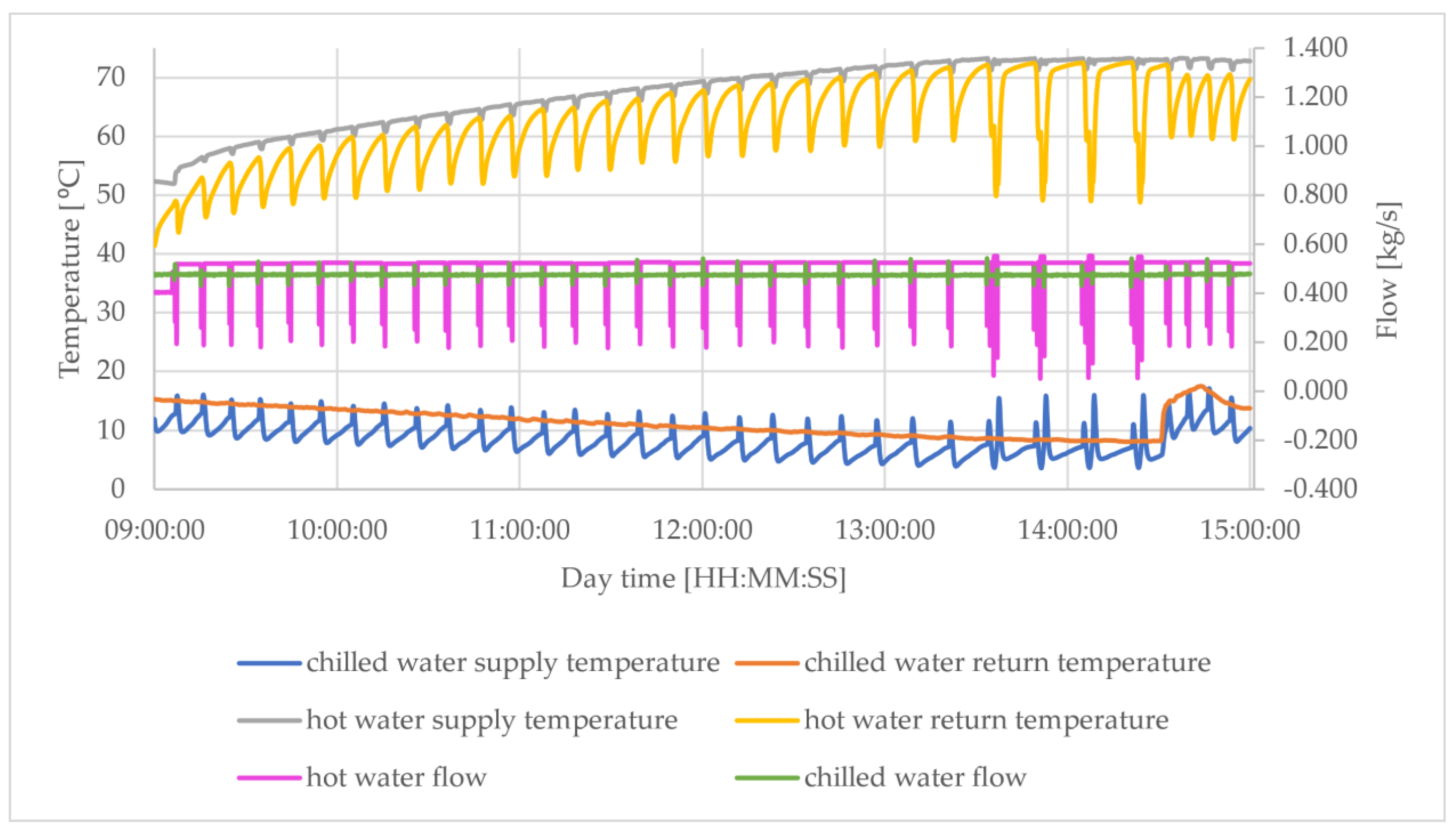

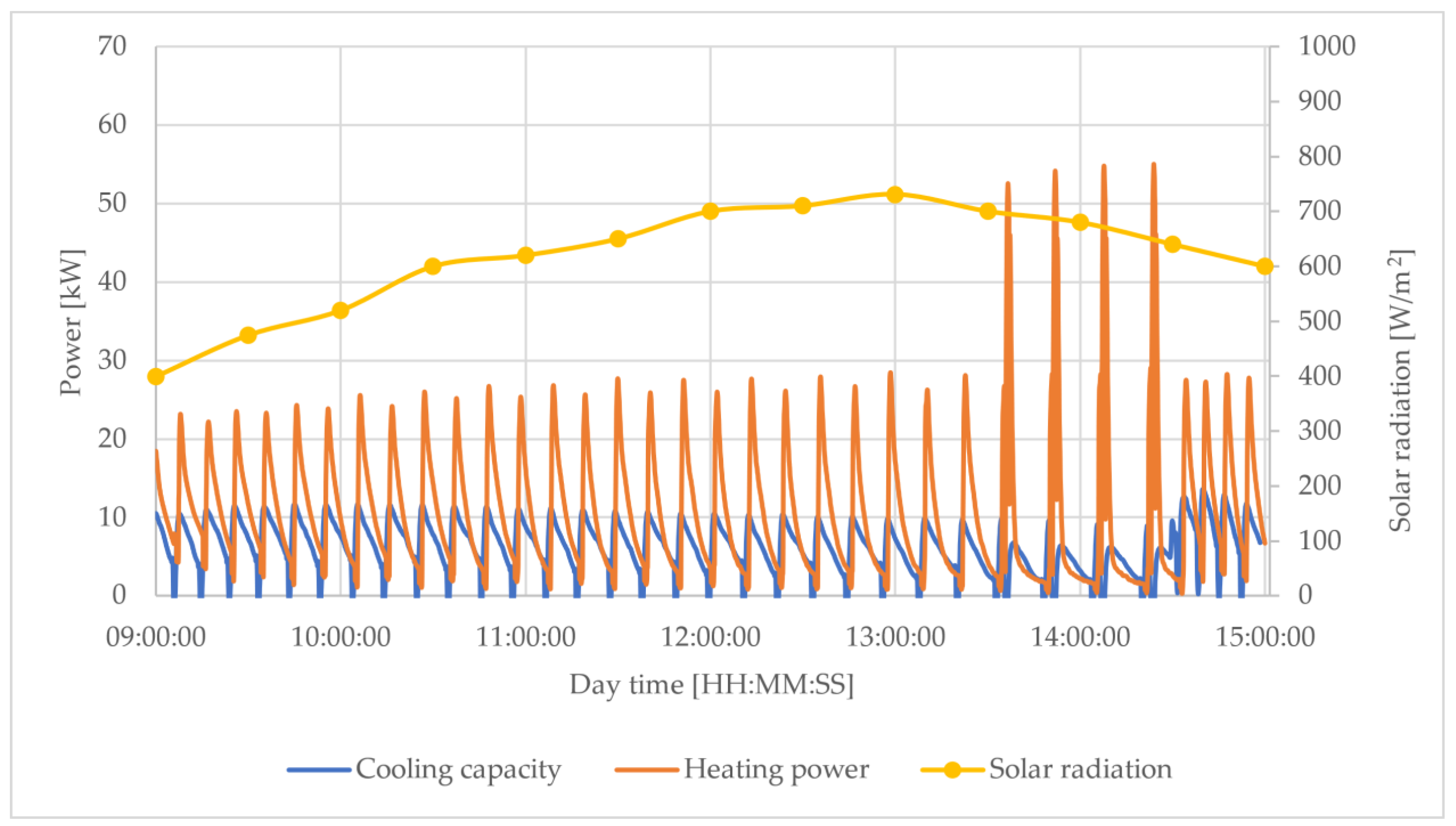

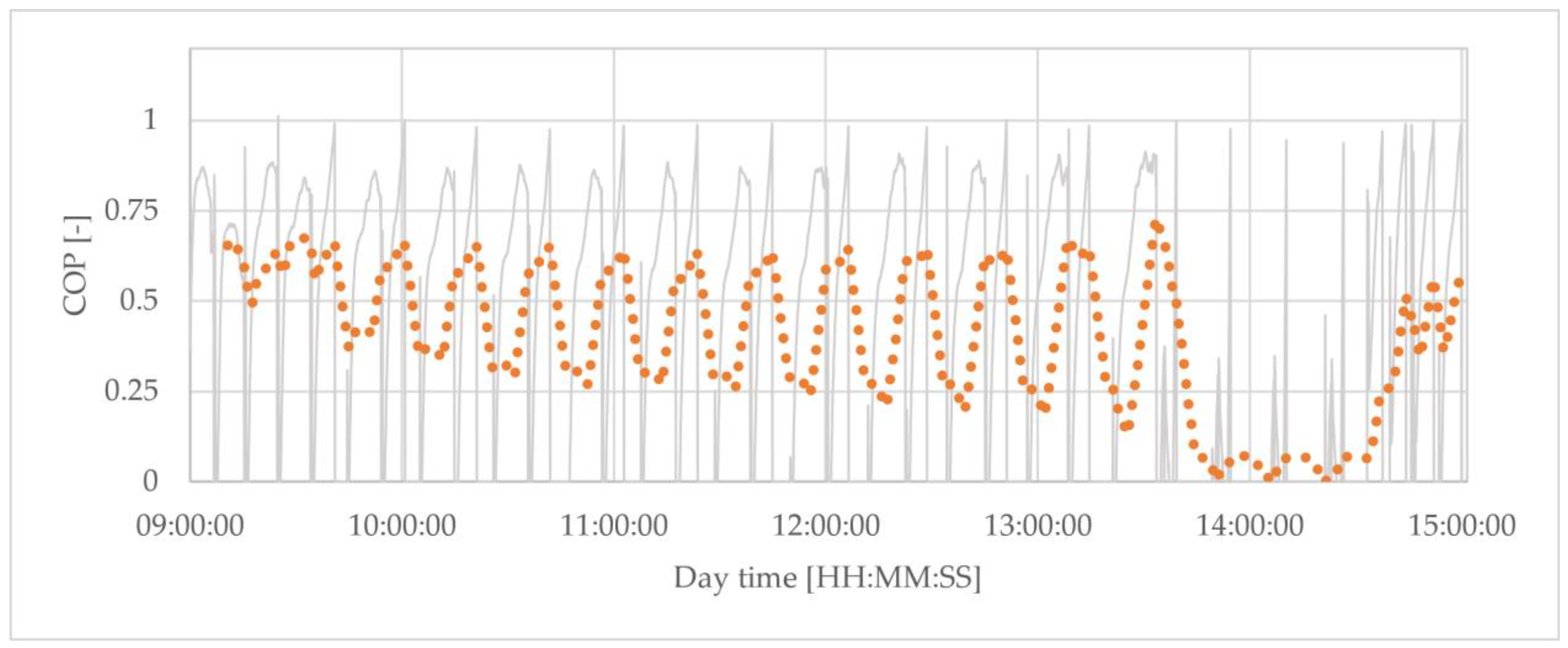

3.1. Measurements for Non-Standard Modes of Chiller Operation for July

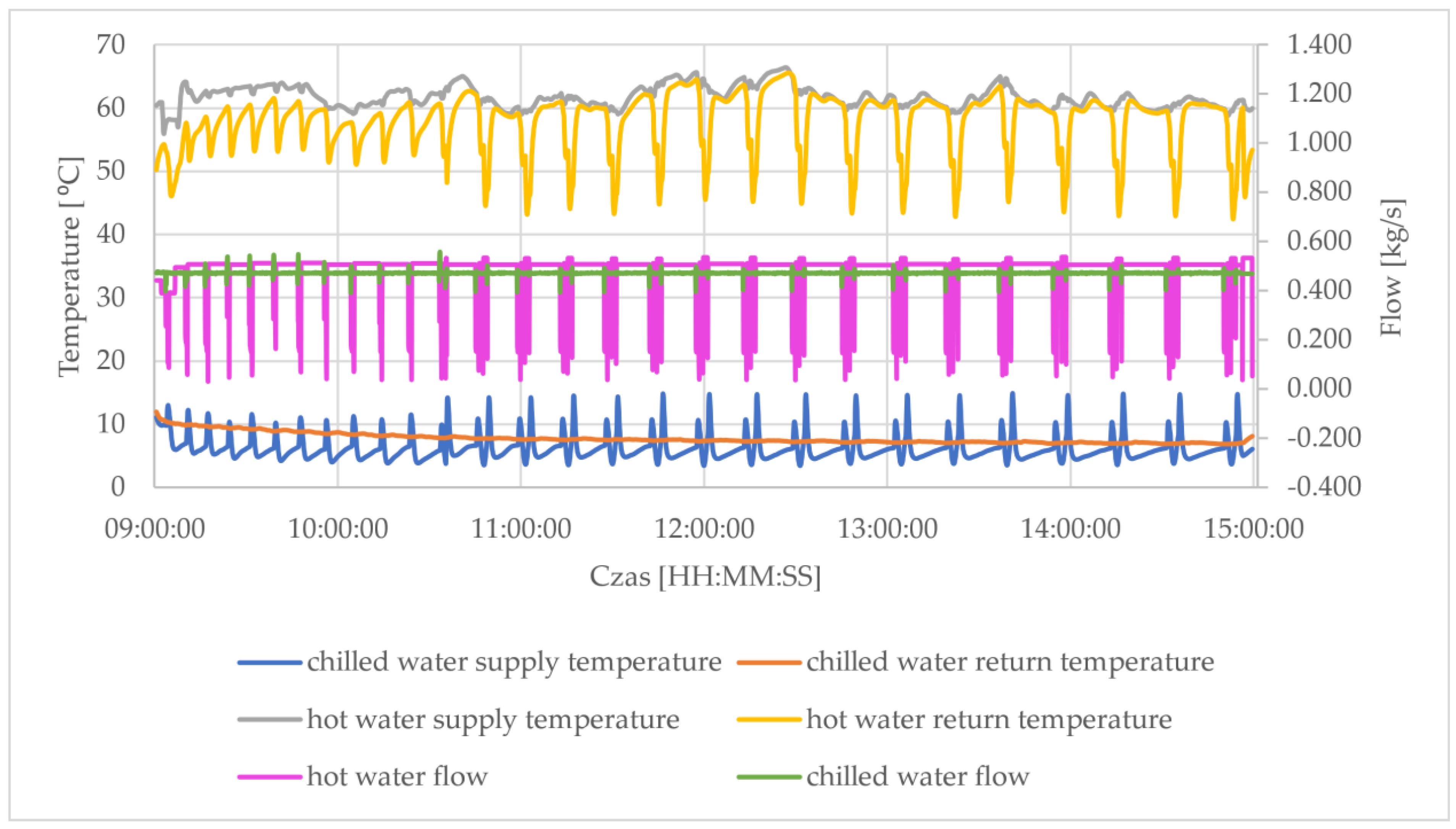

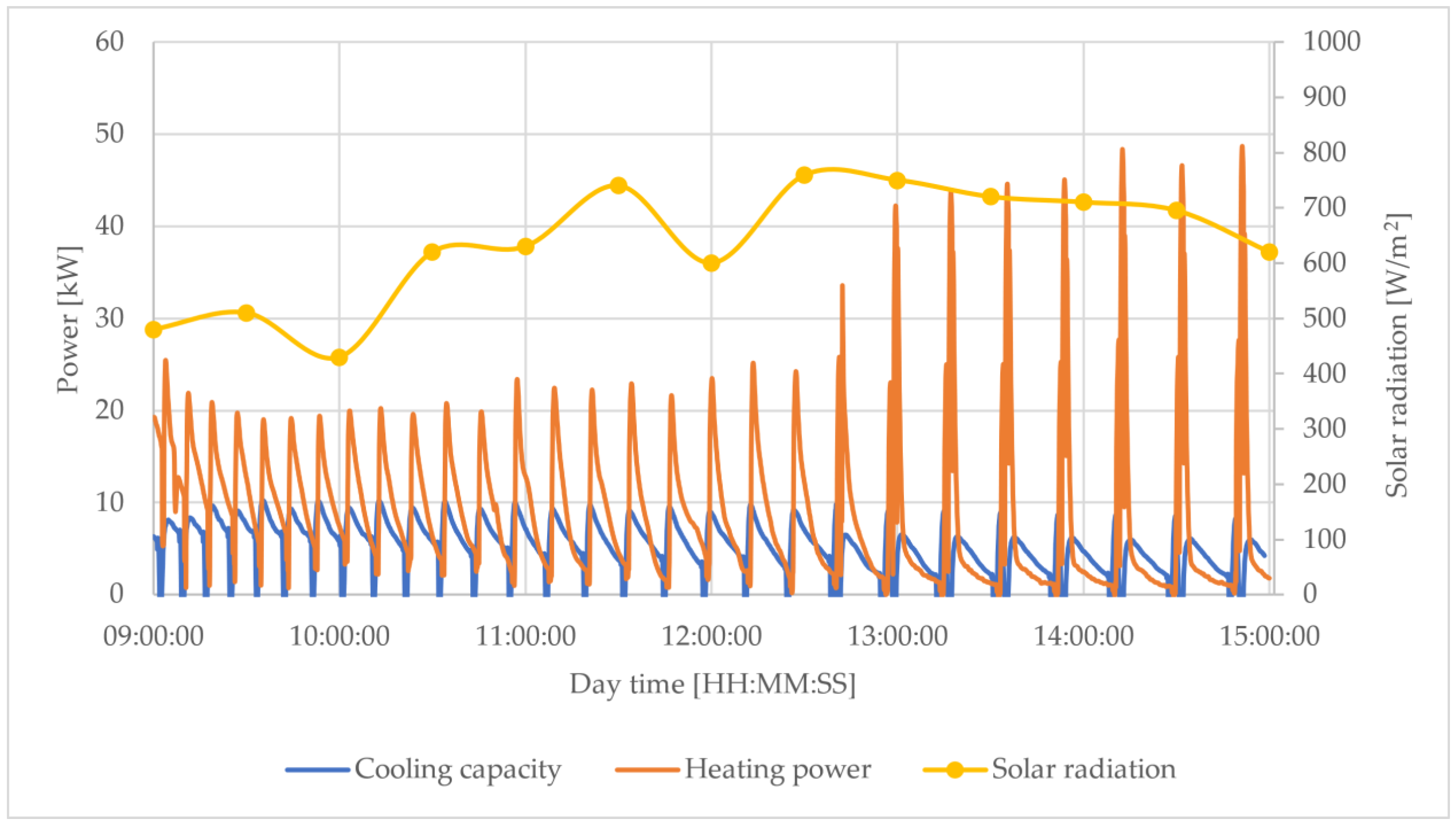

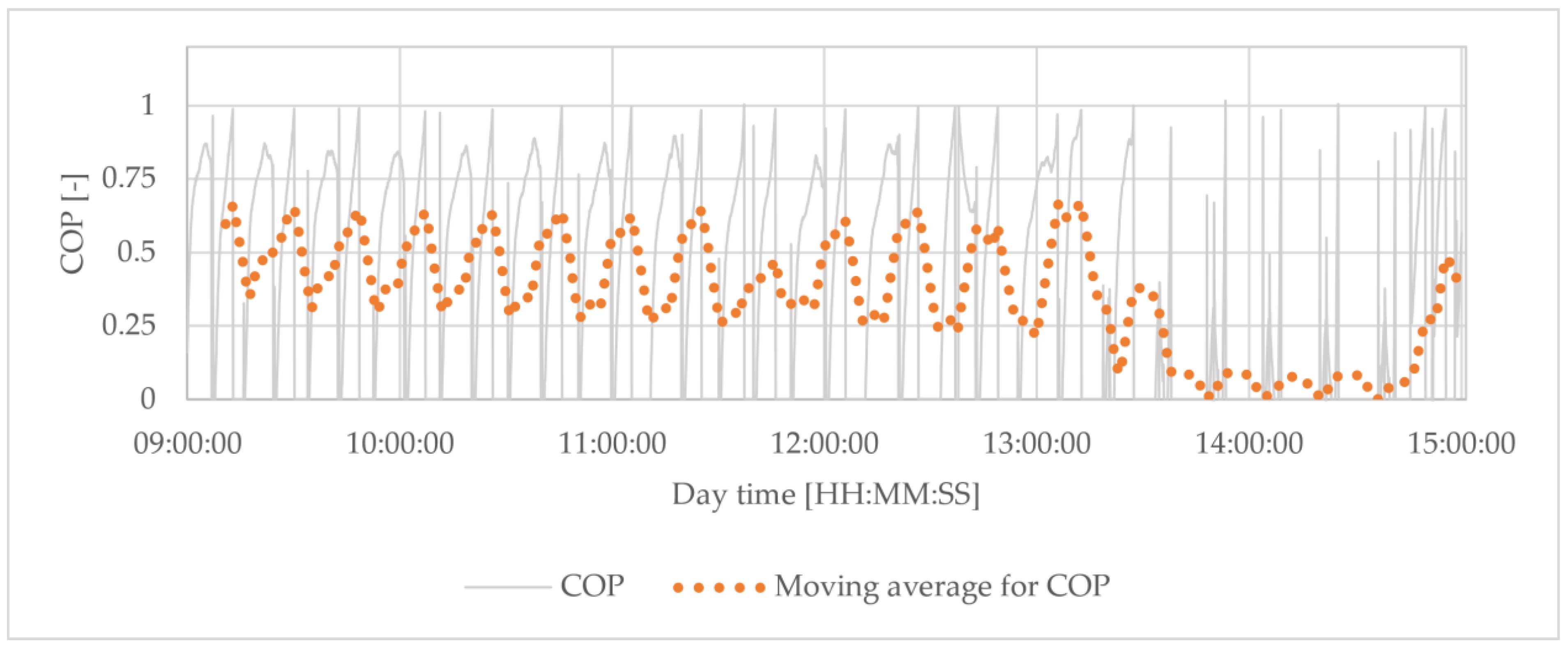

3.2. Measurements for Non-Standard Modes of Chiller Operation for August

4. Discussion

5. Conclusions

- (1)

- It is possible to use a solar thermal system to power an adsorption cooling system for solar radiation conditions characteristic of Central and Eastern European regions;

- (2)

- As the chilled water temperature decreases, the values of the cooling capacity of the unit and of the COP decrease;

- (3)

- Variations in solar irradiance during the day and changes in the cooling capacity can be effectively compensated for by heating and chilled water buffer tanks;

- (4)

- At the time of testing, the average COP was 0.400 ÷ 0.677, the average cooling capacity was 5.16 ÷ 8.71 kW, the average solar irradiance was 424.1 ÷ 718.9 W/m2, the average heating power demand was 13.32 ÷ 15.19 kW, and the average heating water supply temperature was 57.7 ÷ 67.2 °C.

- (1)

- A long time is needed to ensure stable operation as compared with compressor chillers.

- (2)

- Chillers of this type have a small range of cooling capacity adjustment, i.e., 60–100%.

- (3)

- An additional heat discharge system is required to prevent the system from overheating if there is no cooling production. Such a situation was just observed in the case under review, where the cooling of the scientific and research centre is irregular due to the varying intensity of use of the facility. A similar situation is observed in public administration buildings, where cooling is also not required during the weekend period.

- (4)

- The highest heat production from solar thermal installations occurs in this type of building, mainly during the holiday season when there is usually a reduction in cooling demand due to reduced intensity building use.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Birol, F. The Future of Cooling: Opportunities for Energy-Efficient Air Conditioning; Report of the International Energy Agency, International Energy Agency: Paris, France, 2018; Available online: https://www.iea.org/reports/the-future-of-cooling (accessed on 12 July 2022).

- Dupont, J.L.; Domanski, P.; Lebrun, P.; Ziegler, F. The Role of Refrigeration in the Global Economy (2019), 38th Note on Refrigeration Technologies; Informatory note of the International Institute of Refrigeration; The International Institute of Refrigeration: Paris, France, 2019. [Google Scholar]

- Papakokkinos, G.; Castro, J.; Capdevila, R.; Damle, R. A Comprehensive Simulation Tool for Adsorption-Based Solar-Cooled Buildings—Control Strategy Based on Variable Cycle Duration. Energy Build. 2021, 231, 110591. [Google Scholar] [CrossRef]

- Key World Energy Statistics 2021; Report of the International Energy Agency; International Energy Agency: Paris, France, August 2021. Available online: https://www.iea.org/reports/key-world-energy-statistics-2021 (accessed on 12 July 2022).

- Cooling; Report of the International Energy Agency; International Energy Agency, Paris, France. 2021. Available online: https://www.iea.org/reports/cooling (accessed on 12 July 2022).

- Wang, L.; Bu, X.; Ma, W. Experimental study of an Adsorption Refrigeration Test Unit. Energy Procedia 2018, 152, 895–903. [Google Scholar] [CrossRef]

- Zajaczkowski, B. Optimizing performance of a three-bed adsorption chiller using new cycle time allocation and mass recovery. Appl. Therm. Eng. 2016, 100, 744–752. [Google Scholar] [CrossRef]

- Ng, K.C.; Thu, K.; Kim, Y.; Chakraborty, A.; Amy, G. Adsorption desalination: An emerging low-cost thermal desalination method. Desalination 2013, 308, 161–179. [Google Scholar] [CrossRef]

- Pan, Q.; Peng, J.; Wang, R. Experimental study of an adsorption chiller for extra low temperature waste heat utilization. Appl. Therm. Eng. 2019, 163, 114341. [Google Scholar] [CrossRef]

- Sztekler, K.; Kalawa, W.; Mika, L.; Krzywanski, J.; Grabowska, K.; Sosnowski, M.; Nowak, W.; Siwek, T.; Bieniek, A. Modeling of a Combined Cycle Gas Turbine Integrated with an Adsorption Chiller. Energies 2020, 13, 515. [Google Scholar] [CrossRef]

- Krzywanski, J.; Sztekler, K.; Bugaj, M.; Kalawa, W.; Grabowska, K.; Chaja, P.R.; Sosnowski, M.; Nowak, W.; Mika, Ł.; Bykuć, S. Adsorption chiller in a combined heating and cooling system: Simulation and optimization by neural networks. Bull. Pol. Acad. Sci. Tech. Sci. 2021, 69, e137054. [Google Scholar]

- Scopus Database. Available online: https://www.scopus.com/search/form.uri?display=basic#basic (accessed on 12 July 2022).

- Fan, Y.; Luo, L.; Souyri, B. Review of solar sorption refrigeration technologies: Development and applications. Renew. Sustain. Energy Rev. 2007, 11, 1758–1775. [Google Scholar] [CrossRef]

- Younes, M.M.; El-Sharkawy, I.I.; Kabeel, A.E.; Saha, B.B. A review on adsorbent-adsorbate pairs for cooling applications. Appl. Therm. Eng. 2017, 114, 394–414. [Google Scholar] [CrossRef]

- Choudhury, B.; Saha, B.B.; Chatterjee, P.K.; Sarkar, J.P. An overview of developments in adsorption refrigeration systems towards a sustainable way of cooling. Appl. Energy 2013, 104, 554–567. [Google Scholar] [CrossRef]

- Wang, D.C.; Li, Y.H.; Li, D.; Xia, Y.Z.; Zhang, J.P. A review on adsorption refrigeration technology and adsorption deterioration in physical adsorption systems. Renew. Sustain. Energy Rev. 2010, 14, 344–353. [Google Scholar] [CrossRef]

- Alelyani, S.M.; Bertrand, W.K.; Zhang, Z.; Phelan, P.E. Experimental study of an evacuated tube solar adsorption cooling module and its optimal adsorbent bed design. Sol. Energy 2020, 211, 183–191. [Google Scholar] [CrossRef]

- Liu, Y.M.; Yuan, Z.X.; Wen, X.; Du, C.X. Evaluation on performance of solar adsorption cooling of silica gel and SAPO-34 zeolite. Appl. Therm. Eng. 2021, 182, 116019. [Google Scholar] [CrossRef]

- Bouzeffour, F.; Khelidj, B.; Abbes, M.T. Experimental investigation of a solar adsorption refrigeration system working with silicagel/water pair: A case study for Bou-Ismail solar data. Sol. Energy 2016, 131, 165–175. [Google Scholar] [CrossRef]

- Lattieff, F.A.; Atiya, M.A.; Al-Hemiri, A.A. Test of solar adsorption air-conditioning powered by evacuated tube collectors under the climatic conditions of Iraq. Renew. Energy 2019, 142, 20–29. [Google Scholar] [CrossRef]

- Qadir, N.U.; Said, S.A.M.; Mansour, R.B.; Imran, H.; Khan, M. Performance comparison of a two-bed solar-driven adsorption chiller with optimal fixed and adaptive cycle times using a silica gel/water working pair. Renew. Energy 2020, 149, 1000–1017. [Google Scholar] [CrossRef]

- Pan, Q.W.; Wang, R.Z. Study on operation strategy of a silica gel-water adsorption chiller in solar cooling application. Sol. Energy 2018, 172, 24–31. [Google Scholar] [CrossRef]

- Rouf, R.A.; Amanul, K.C.A.; Saha, B.B.; Kabir, K.M.A. Utilizing Accessible Heat Enhancing Cooling Effect with Three Bed Solar Adsorption Chiller. Heat. Transf. Eng. 2019, 40, 1049–1059. [Google Scholar] [CrossRef]

- Alahmer, A.; Wang, X.; Al-Rbaihat, R.; Alam, K.C.A.; Saha, B.B. Performance evaluation of a solar adsorption chiller under different climatic conditions. Appl. Energy 2016, 175, 293–304. [Google Scholar] [CrossRef]

- Jaiswal, A.K.; Mitra, S.; Dutta, P.; Srinivasan, K.; Murthy, S.S. Influence of cycle time and collector area on solar driven adsorption chillers. Sol. Energy 2016, 136, 450–459. [Google Scholar] [CrossRef]

- Halon, T.; Lukmin, P.; Szyc, M.; Bialko, B.; Zajaczkowski, B. Case study of the adsorption chiller driven by combined municipal heat and solar energy. In Proceedings of the 25th IIR International Congress of Refrigeration, Montréal, QC, Canada, 24–30 August 2019. [Google Scholar] [CrossRef]

- Alahmer, A.; Wang, X.; Alam, K.C.A. Dynamic and Economic Investigation of a Solar Thermal-Driven Two-Bed Adsorption Chiller under Perth Climatic Conditions. Energies 2020, 13, 1005. [Google Scholar] [CrossRef]

- El-Sharkawy, I.I.; AbdelMeguid, H.; Saha, B.B. Potential application of solar powered adsorption cooling systems in the Middle East. Appl. Energy 2014, 126, 235–245. [Google Scholar] [CrossRef]

- Reda, A.M.; Ali, A.H.H.; Taha, I.S.; Morsy, M.G. Performance of a small-scale solar-powered adsorption cooling system. Int. J. Green Energy 2017, 14, 75–85. [Google Scholar] [CrossRef]

- Rouf, R.A.; Jahan, N.; Alam, K.C.A.; Sultan, A.A.; Saha, B.B.; Saha, S.C. Improved cooling capacity of a solar heat driven adsorption chiller. Case Stud. Therm. Eng. 2020, 17, 100568. [Google Scholar] [CrossRef]

- Chen, Q.F.; Du, S.W.; Yuan, Z.X.; Sun, T.B.; Li, Y.X. Experimental study on performance change with time of solar adsorption refrigeration system. Appl. Therm. Eng. 2018, 138, 386–393. [Google Scholar] [CrossRef]

- Elsheniti, M.B.; Rezk, A.; Shaaban, M.; Roshdy, M.; Nagib, Y.M.; Elsamni, O.A.; Saha, B.B. Performance of a solar adsorption cooling and desalination system using aluminum fumarate and silica gel. Appl. Therm. Eng. 2021, 194, 117116. [Google Scholar] [CrossRef]

- Robbins, T.; Garimella, S. An autonomous solar driven adsorption cooling system. Sol. Energy 2020, 211, 1318–1324. [Google Scholar] [CrossRef]

- Sha, A.A.; Baiju, V. Thermodynamic analysis and performance evaluation of activated carbon-ethanol two-bed solar adsorption cooling system. Int. J. Refrig. 2021, 123, 81–90. [Google Scholar] [CrossRef]

- Fernandes, M.S.; Brites, G.J.V.N.; Costa, J.J.; Gaspar, A.R.; Costa, V.A.F. Review and future trends of solar adsorption refrigeration systems. Renew. Sustain. Energy Rev. 2014, 39, 102–123. [Google Scholar] [CrossRef]

- SorTech AG Company Materials. Operating Manual of SorTech eCoo 2.0. 13.12.2016.

- Kingspan Environmental Sp. z o.o. Company Materials. Available online: https://www.kingspan.com (accessed on 12 July 2022).

- Hassan, A.A.; Elwardany, A.E.; Ookawara, S.; El-Sharkawy, I.I. Performance investigation of integrated PVT/adsorption cooling system under the climate conditions of Middle East. Energy Rep. 2020, 6, 168–173. [Google Scholar] [CrossRef]

- Angrisani, G.; Entchev, E.; Roselli, C.; Sasso, M.; Tariello, F.; Yaïci, W. Dynamic simulation of a solar heating and cooling system for an office building located in Southern Italy. Appl. Therm. Eng. 2016, 103, 377–390. [Google Scholar] [CrossRef]

| Parameter | Unit | Value |

|---|---|---|

| Cooling capacity | kW | max. 16.0 |

| COP | - | max. 0.65 |

| Heating water temperature range | °C | 50–95 |

| Nominal heating water flow rate | L/h | 2500 |

| Cooling water temperature range | °C | max. 40 |

| Nominal cooling water flow rate | L/h | 5100 |

| Chilled water temperature range | °C | min. 8 |

| Nominal chilled water flow rate | L/h | 2900 |

| Parameter | Unit | DF400-30 | HP400-20 | HP400-30 |

|---|---|---|---|---|

| Type | - | Direct flow | Heat pipe | Heat pipe |

| Max operating pressure | bar | 8 | 10 | 10 |

| Volume | l | 5.6 | 1.2 | 1.7 |

| Gross area | m2 | 3.23 | 2.13 | 3.20 |

| Heat transfer fluid | - | water/glycol | water/glycol | water/glycol |

| Stagnation temperature | °C | 313 | 166 | 166 |

| Parameter | Unit | Accuracy | Type |

|---|---|---|---|

| Temperature of cooling and heating water | °C | ±0.2 | Pt1000 |

| Temperature of chilled water | °C | ±0.2 | Pt100 |

| Flow rate | kg/s | 0.5% | electromagnetic |

| Date | Average Solar Radiation [W/m2] | Average Cooling Capacity [kW] | Average Heating Power [kW] | Average COP [-] | Average Hot Water Temperature [°C] | Average Chilled Water Flow [kg/s] | Average Chilled Water Temperature [°C] |

|---|---|---|---|---|---|---|---|

| 8th July | 424.1 | 7.18 | 13.36 | 0.605 | 61.7 | 0.474 | 11.7 |

| 22nd July | 718.9 | 8.71 | 13.32 | 0.677 | 57.7 | 0.471 | 12.5 |

| 31st July | 647.0 | 5.16 | 14.27 | 0.400 | 60.2 | 0.471 | 8.6 |

| 6th August | 642.8 | 6.79 | 13.54 | 0.584 | 62.0 | 0.473 | 8.1 |

| 11th August | 621.4 | 7.83 | 15.19 | 0.584 | 67.6 | 0.475 | 12.7 |

| 21st August | 627.2 | 7.53 | 14.00 | 0.582 | 62.5 | 0.478 | 11.1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bujok, T.; Sowa, M.; Boruta, P.; Mika, Ł.; Sztekler, K.; Chaja, P.R. Possibilities of Integrating Adsorption Chiller with Solar Collectors for Polish Climate Zone. Energies 2022, 15, 6233. https://doi.org/10.3390/en15176233

Bujok T, Sowa M, Boruta P, Mika Ł, Sztekler K, Chaja PR. Possibilities of Integrating Adsorption Chiller with Solar Collectors for Polish Climate Zone. Energies. 2022; 15(17):6233. https://doi.org/10.3390/en15176233

Chicago/Turabian StyleBujok, Tomasz, Marcin Sowa, Piotr Boruta, Łukasz Mika, Karol Sztekler, and Patryk Robert Chaja. 2022. "Possibilities of Integrating Adsorption Chiller with Solar Collectors for Polish Climate Zone" Energies 15, no. 17: 6233. https://doi.org/10.3390/en15176233

APA StyleBujok, T., Sowa, M., Boruta, P., Mika, Ł., Sztekler, K., & Chaja, P. R. (2022). Possibilities of Integrating Adsorption Chiller with Solar Collectors for Polish Climate Zone. Energies, 15(17), 6233. https://doi.org/10.3390/en15176233