Miscibility of Aviation Turbine Engine Fuels Containing Various Synthetic Components

Abstract

1. Introduction

- Simulating aircraft fuel supply systems during popularized synthetic components processes and their impact on the component composition of real fuel blends onboard aircraft;

- Deriving a preliminary study focusing on the impact of various synthetic component blends on processes within aviation turbine engine fuel systems—particularly the aviation turbine engine combustion system.

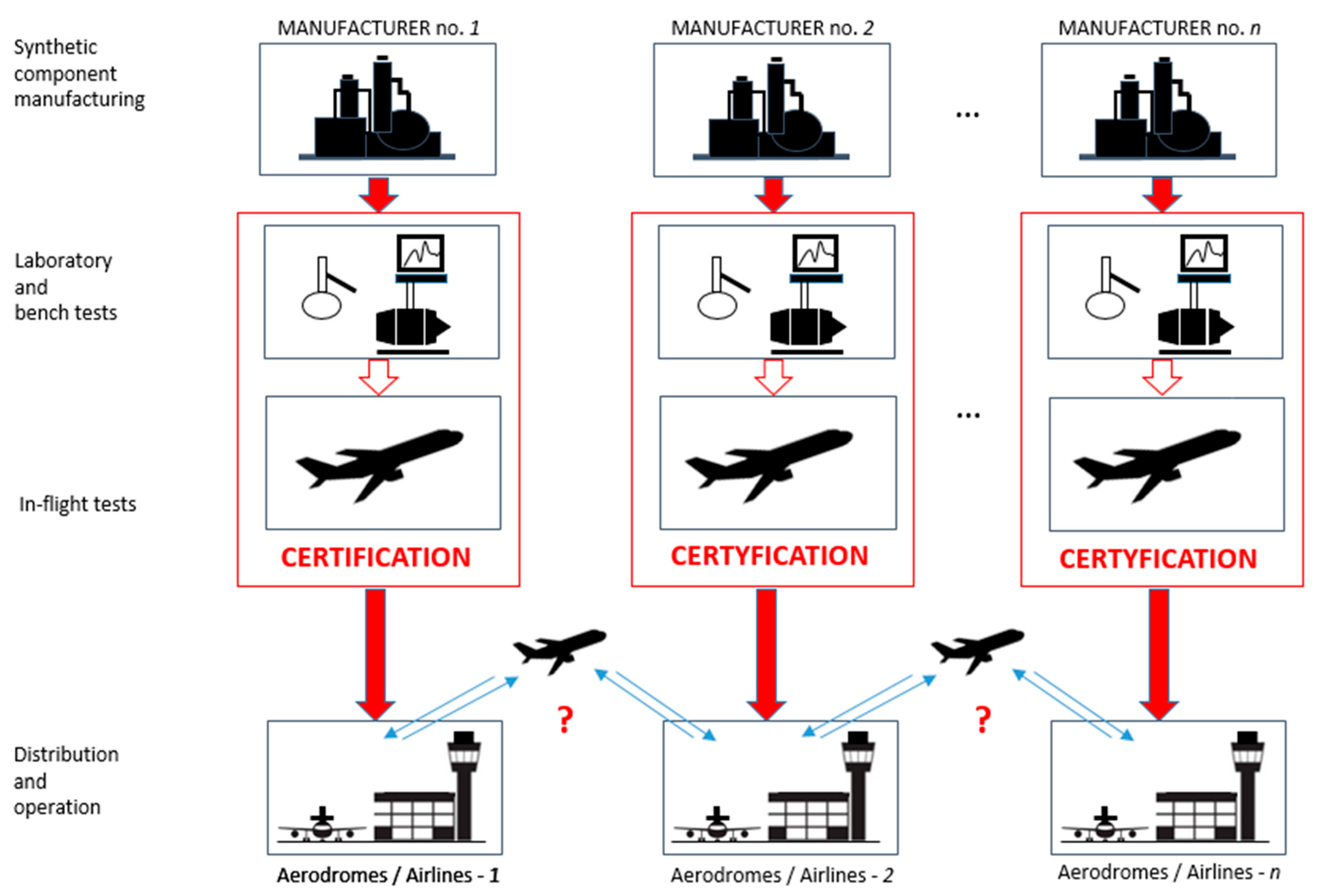

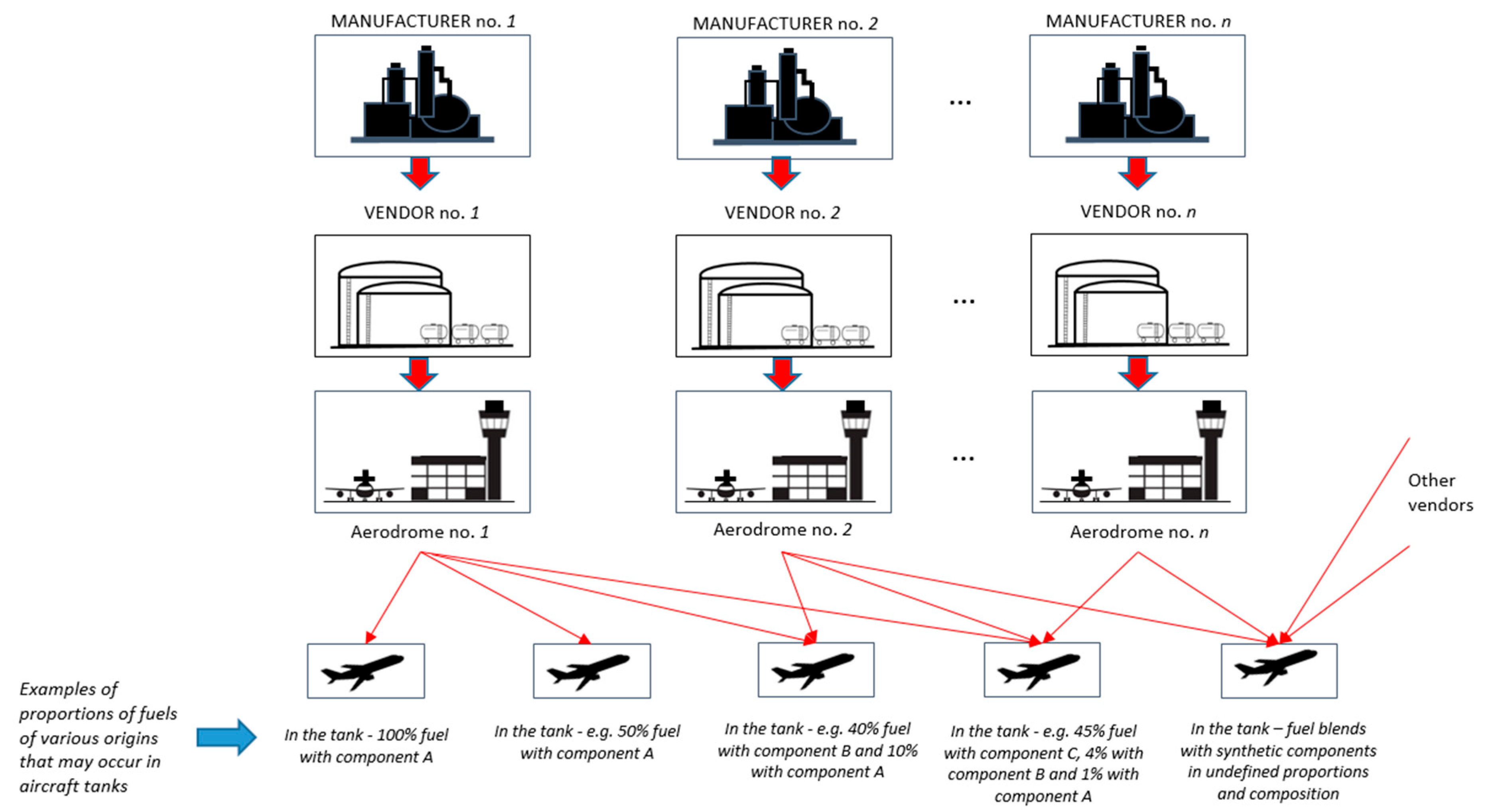

2. Logistic System Simulation

- Mixing of diverse synthetic fuels manufactured by different plants, in accordance with various technologies—each aerodrome will be supplied with different fuels;

- Mixing of diverse fuels manufactured by various plants, in accordance with the same or different technologies—a given aerodrome will be supplied with fuels from different manufacturing plants.

- Lack of miscibility tests for fuels containing synthetic components;

- No possibility to determine the chemical composition of fuels pumped through product pipelines and at further distribution stages;

- Possible noticeable impact of synthetic components at low concentrations on the properties of blends that determine turbine engine operation and the functioning of aviation fuel logistics systems.

3. Methodology Concept for Testing the Miscibility of Fuels Containing Various Synthetic Components

- Testing selected physical and chemical properties of fuels and their blends at different quantitative proportions;

- Testing the lubricity of fuels and their blends at different quantitative proportions;

- Testing the turbine engine combustion process of the fuels and their blends at different quantitative proportions.

3.1. Methods of Physical and Chemical Tests

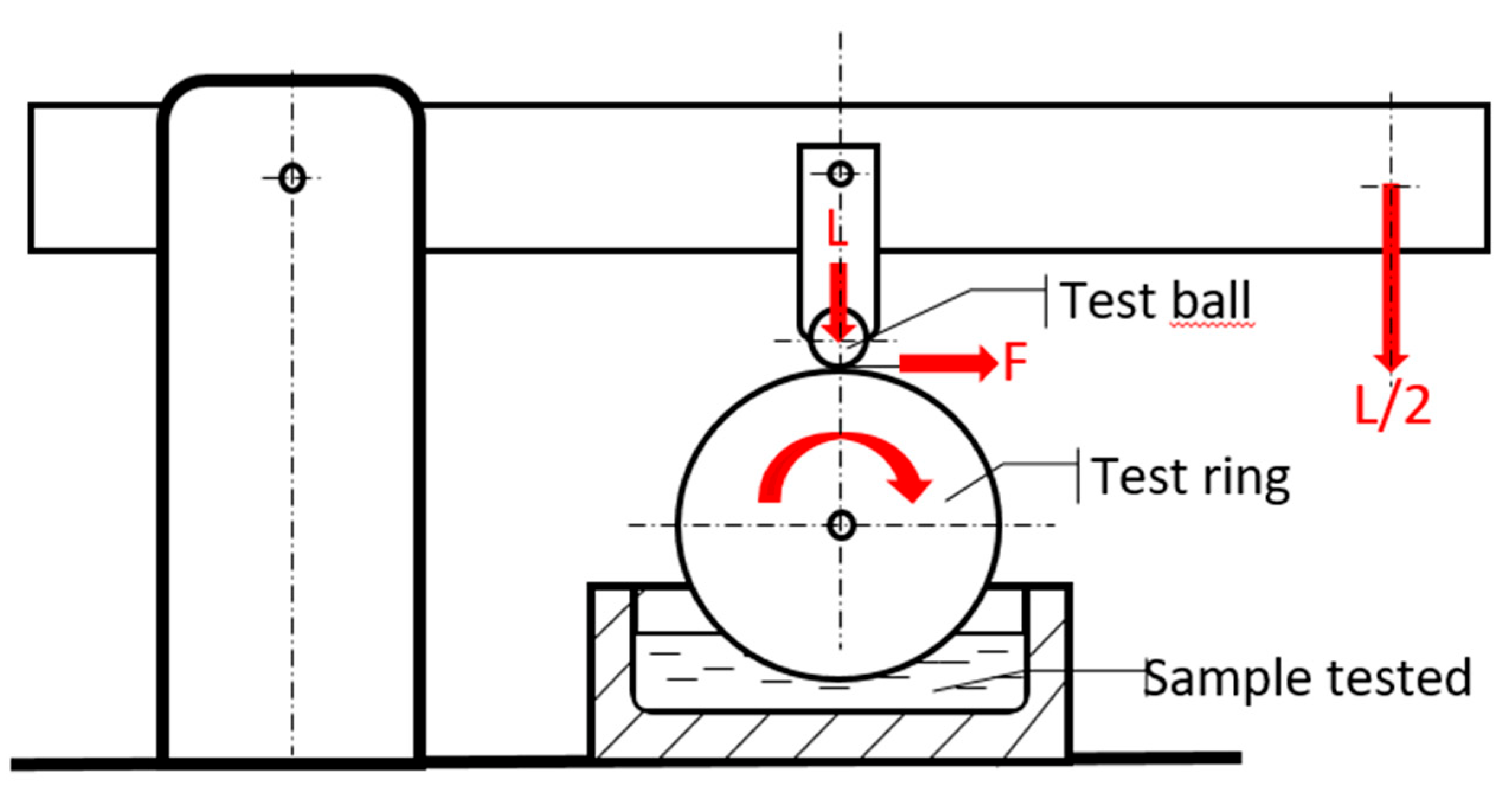

3.2. Methodology of Studying Lubricating Properties Using the Ball-on-Cylinder Lubricity Evaluator (BOCLE) Test Rig

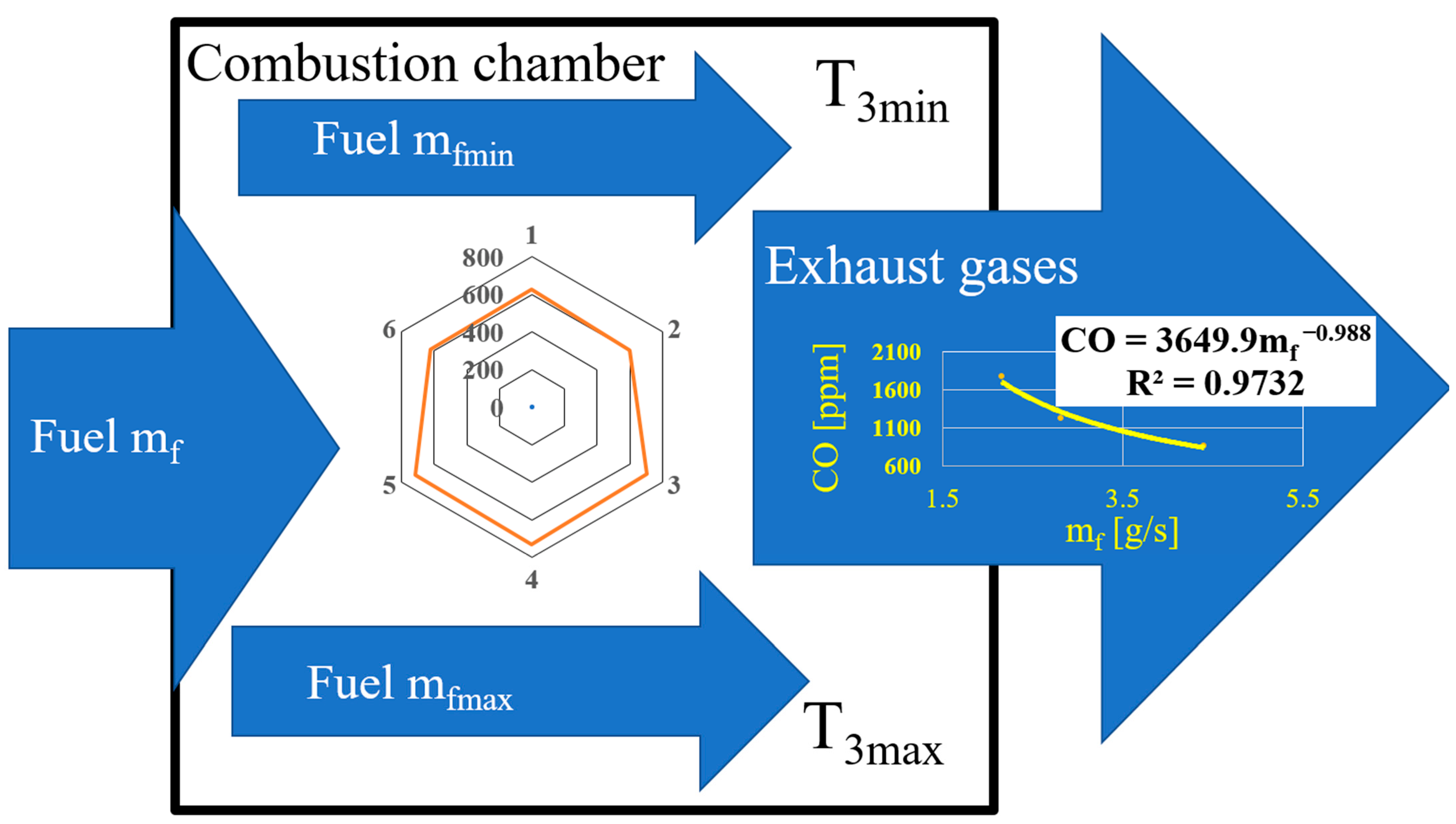

3.3. Methodology of Studying the Engine Fuel Combustion Process Using the MiniJetRig Engine Rig

- A miniature GTM 120 turbojet engine with a maximum thrust of 120 N, containing a single-stage axial compressor, powered by a single-stage axial turbine and an annular combustion chamber with a set of evaporators;

- An exhaust gas analyser that enables measuring CO content in exhaust gases;

- A control system with measurement data recording, based on a measuring card block, which records current, voltage and digital signals.

- Direct comparison of individual parameter values (obtained by conducting experimental tests) and formulating dependencies using a statistical apparatus;

- Using a theoretical mathematical model of a fuel combustion process as a basis for formulating functional dependencies, which are then experimentally verified.

- Magnitude of combustion-chamber temperature gradient;

- CO content in exhaust gases.

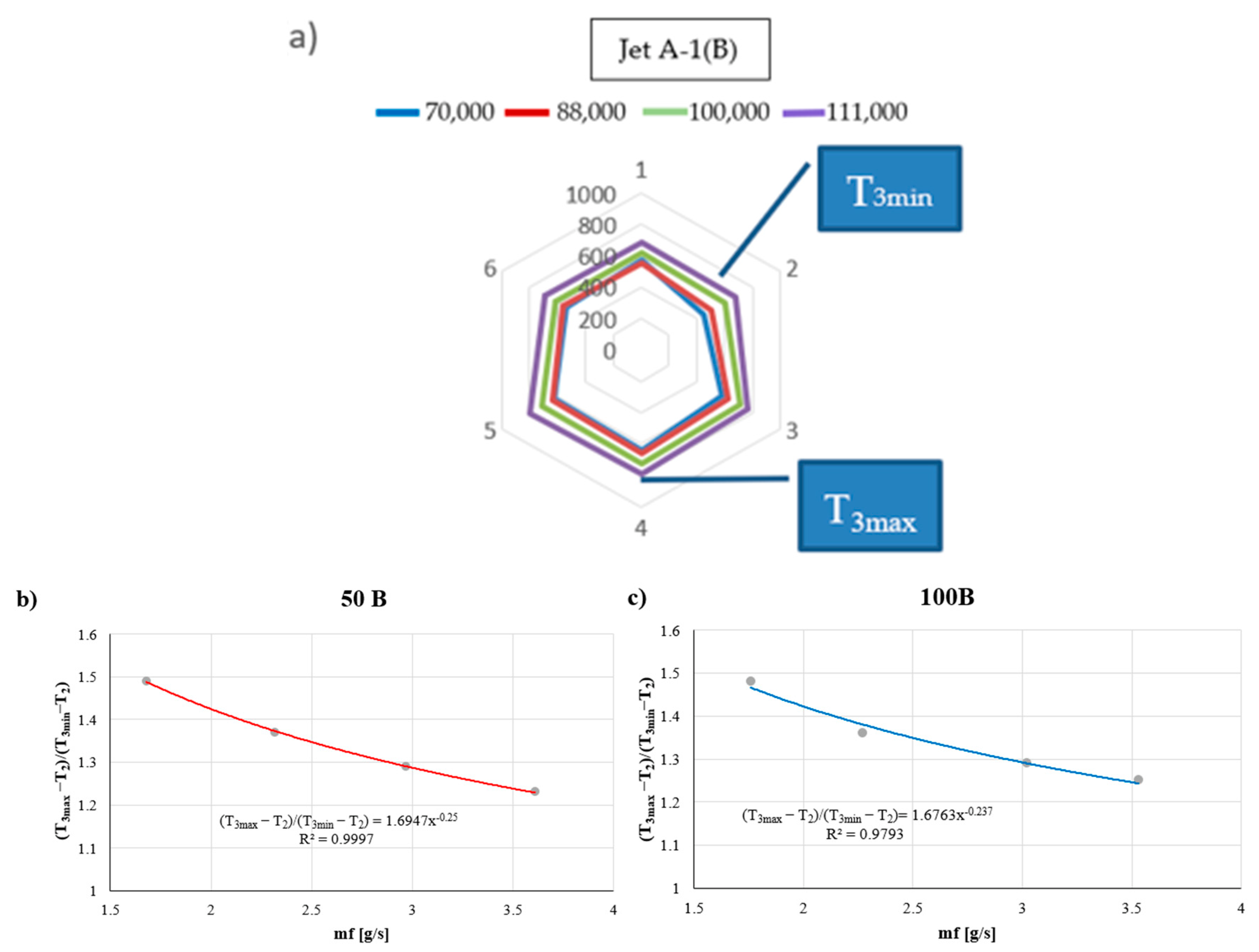

3.3.1. Description of the Studied Blend Combustion Process Using Functions: (T3max − T2)/(T3min − T2) = f1(mf)

- mfmax = amax mf;

- mfmin = aminmf;

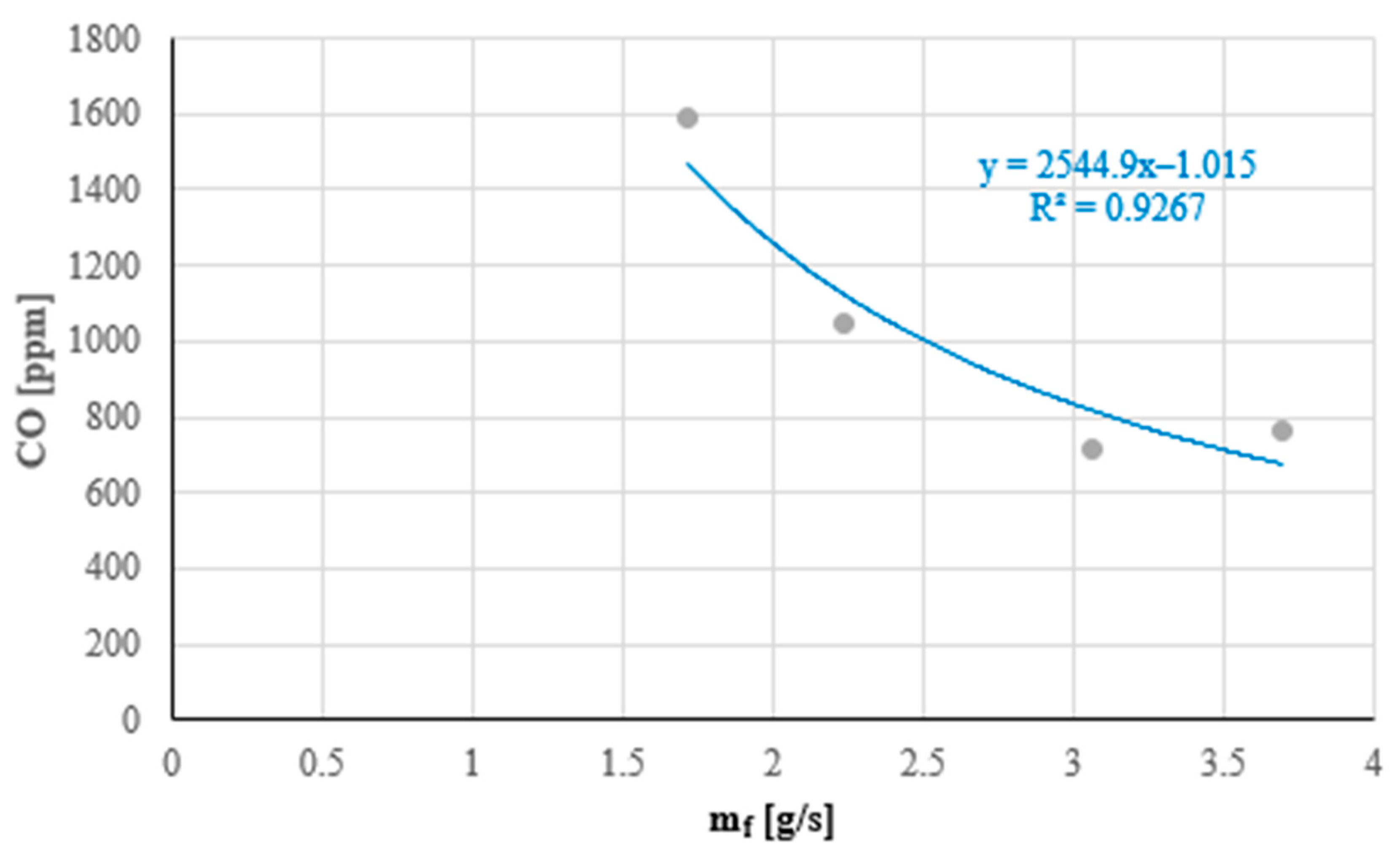

3.3.2. Description of the Studied Blend Combustion Process Using Functions: CO = f2(mf)

- Parallel reactions (18) and (19);

- Follow-up reactions (19) and (22).

- (a)

- (23) If parallel reactions (18) and (19):

- (b)

- (24) If follow-up reactions (19) and (22):

3.4. Adopted Definition of Miscibility and Fuel Miscibility Test Methodology

4. Materials—Studied Test Blends

- Jet A-1 (A)—Jet A-1 used to compose blends with synthetic component A;

- Jet A-1 (A1)—Jet A-1 fuel used to compose a blend with 50% (v/v) of synthetic component A;

- Jet A-1 (B)—Jet A-1 fuel used to compose blends with synthetic component B;

- Jet A-1 (A)—Jet A-1 used to compose blends with synthetic components B1, B2, B5 and B6.

- 5A—Jet A-1 (A) fuel containing 5% (m/m) of synthetic component A;

- 20A—Jet A-1 (A) fuel containing 20% (m/m) of synthetic component A;

- 30A—Jet A-1 (A) fuel containing 30% (m/m) of synthetic component A;

- 50A—Jet A-1 (A1) fuel containing 50% (m/m) of synthetic component A;

- 100A—synthetic component A;

- 50B—Jet A-1 (B) fuel containing 50% (m/m) of synthetic component B;

- 100B—synthetic component B;

- B1—Jet A-1 (B/A) fuel containing 50% (v/v) of synthetic component A;

- B2—Jet A-1 (B/A) fuel containing 25% (v/v) of synthetic component B;

- B5—Jet A-1 (B/A) fuel containing 20% (v/v) of synthetic component A;

- B6—Jet A-1 (B/A) fuel containing 10.5% (v/v) of synthetic component B.

- B1/B2—synthetic component blend with the following composition: 5% B1 + 95% B2; blend with Jet A-1 contains 2.5% of comp. A and 23.8% of comp. B (total share of synthetic components in the blend with Jet A-1 = 26.3%);

- B2/B1—synthetic component blend with the following composition: 5% B2 + 95% B1; blend with Jet A-1 contains 47.5% of comp. A and 1.25% of comp. B (total share of synthetic components in the blend with Jet A-1 = 48.75%);

- 5% B5 + 95% B6; (B5/B6), contains 1% of comp. A and 10.0% of comp. B (total share of synthetic components in the blend with Jet A-1 = 11.0%);

- 5% B6 + 95%B5; (B6/B5), contains 19.0% of comp. A and 0.5% of comp. B (total share of synthetic components in the blend with Jet A-1 = 19.5%).

5. Test Results

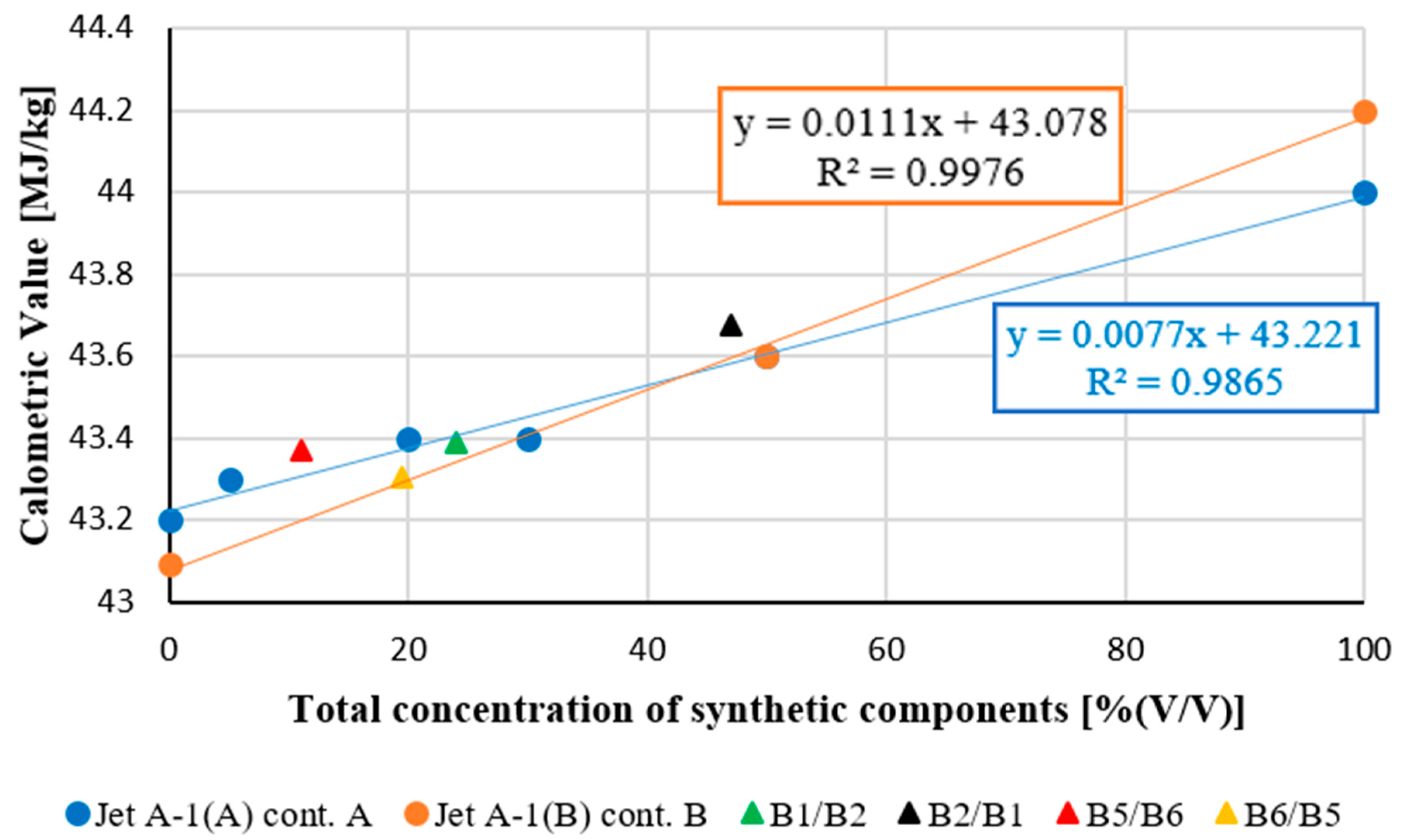

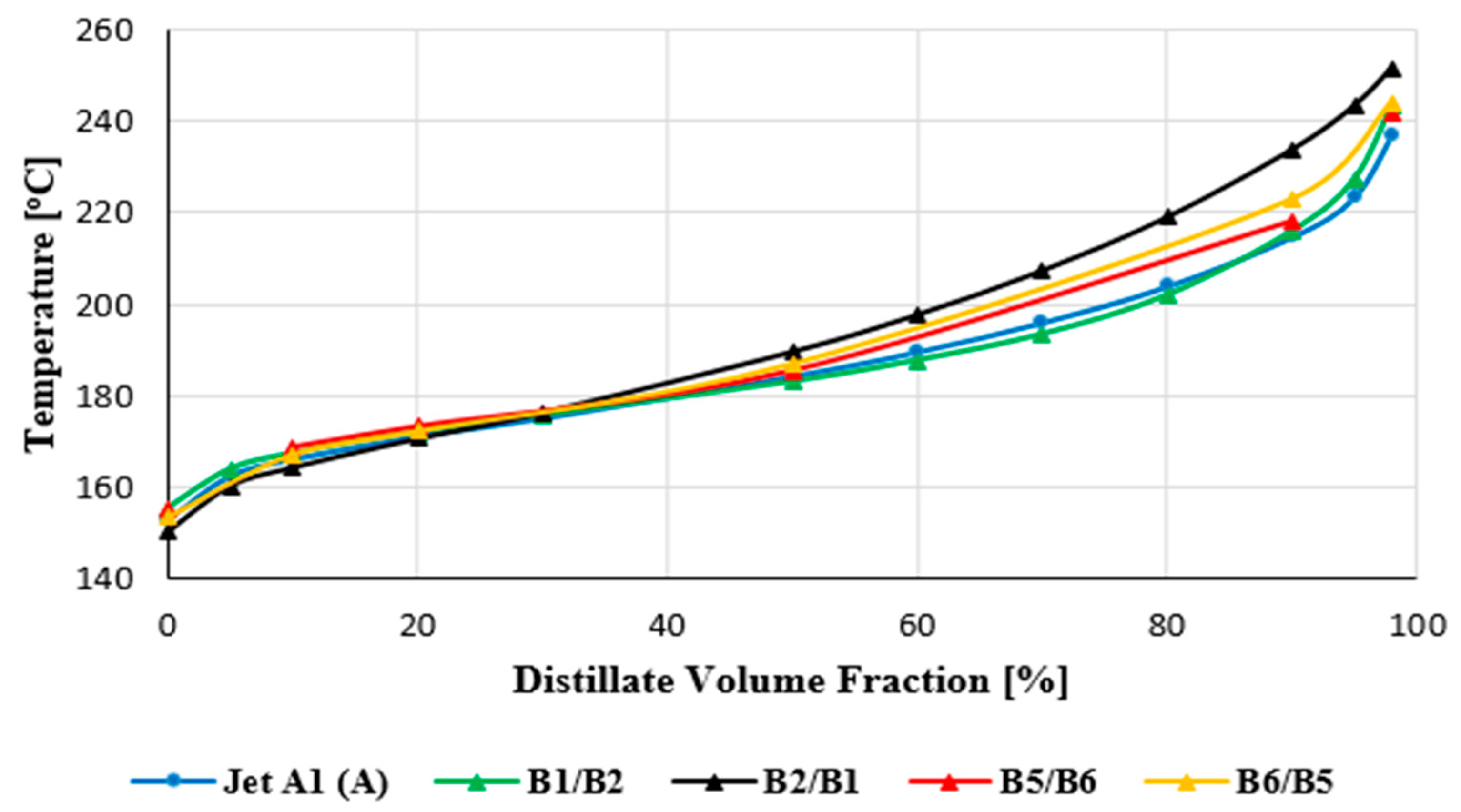

5.1. Physical and Chemical Properties

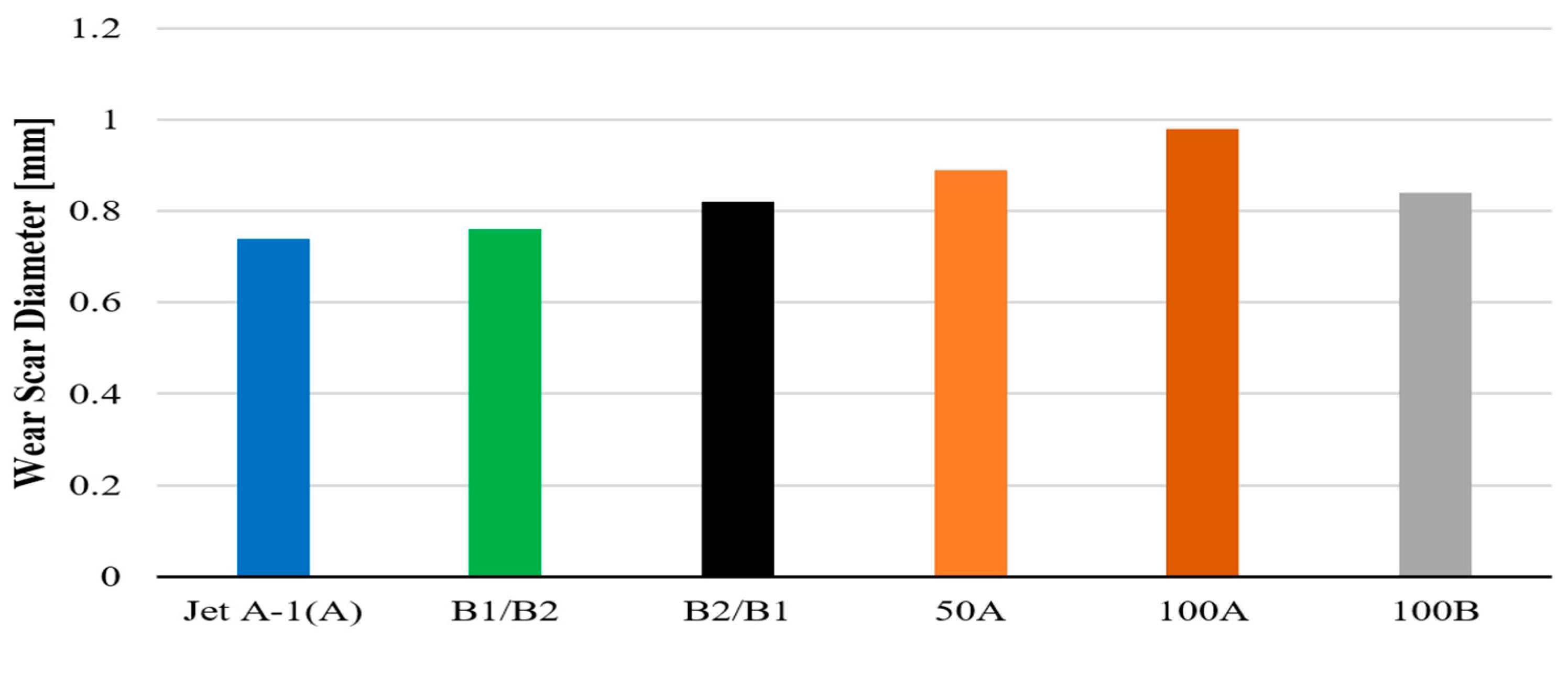

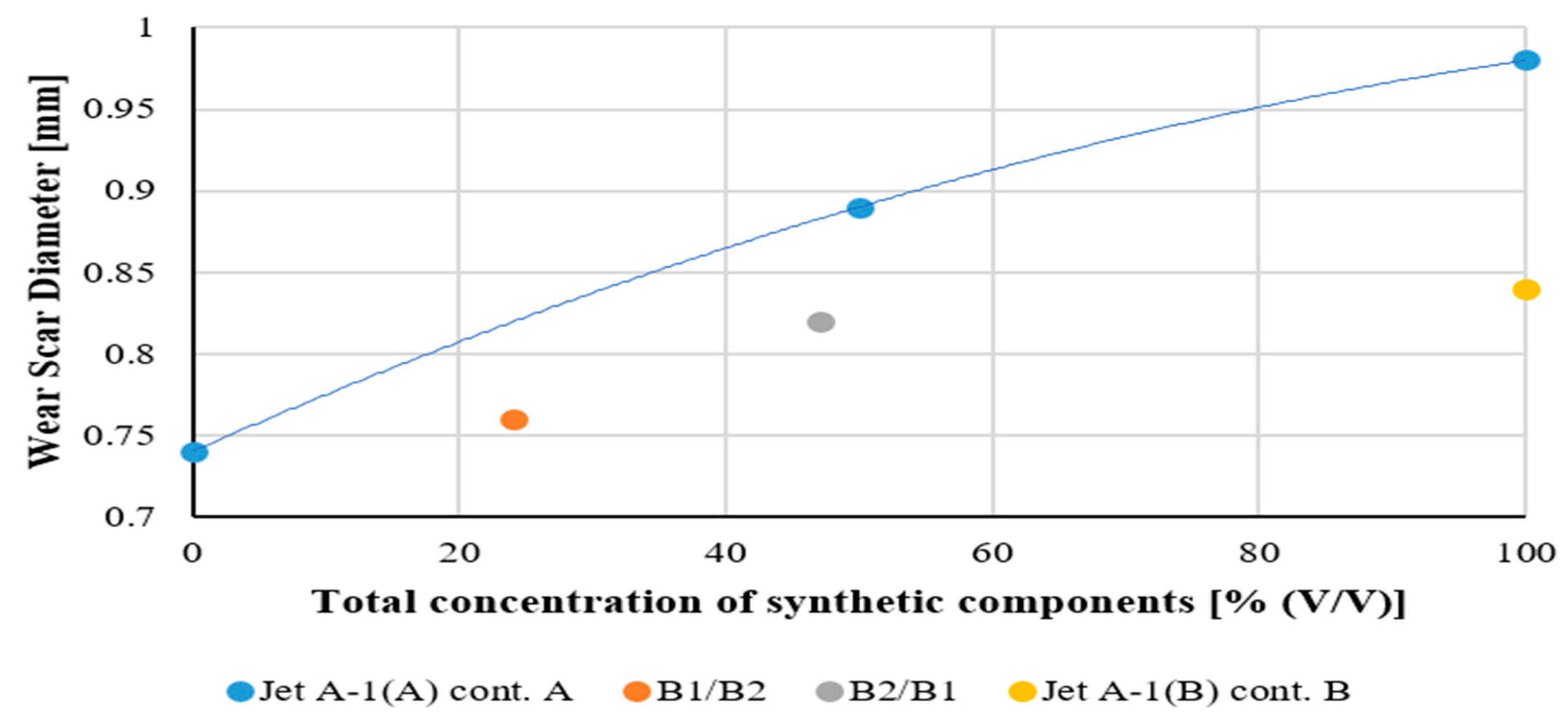

5.2. Lubricating Properties

5.3. MiniJetRig Engine Test Stand Results

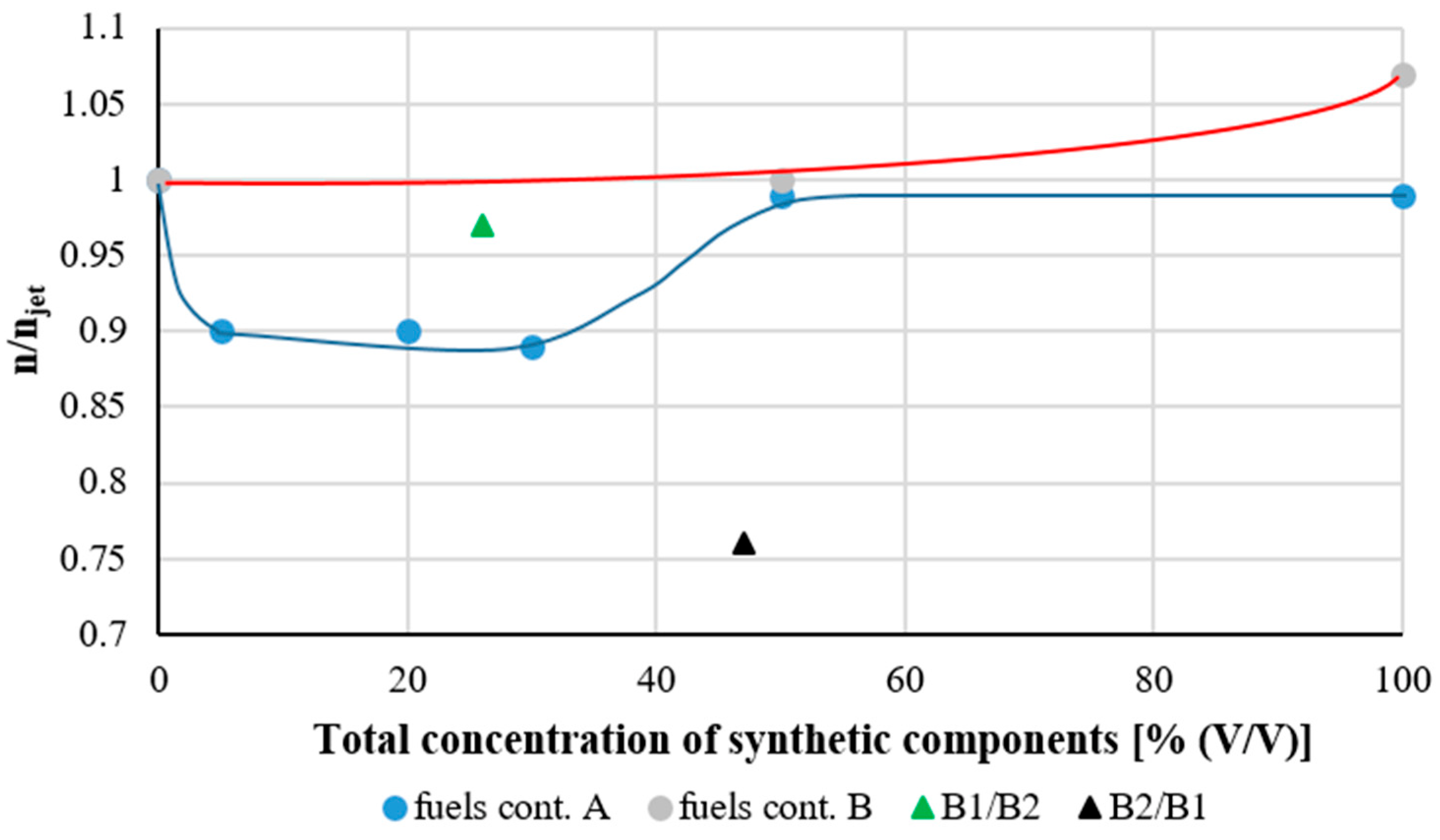

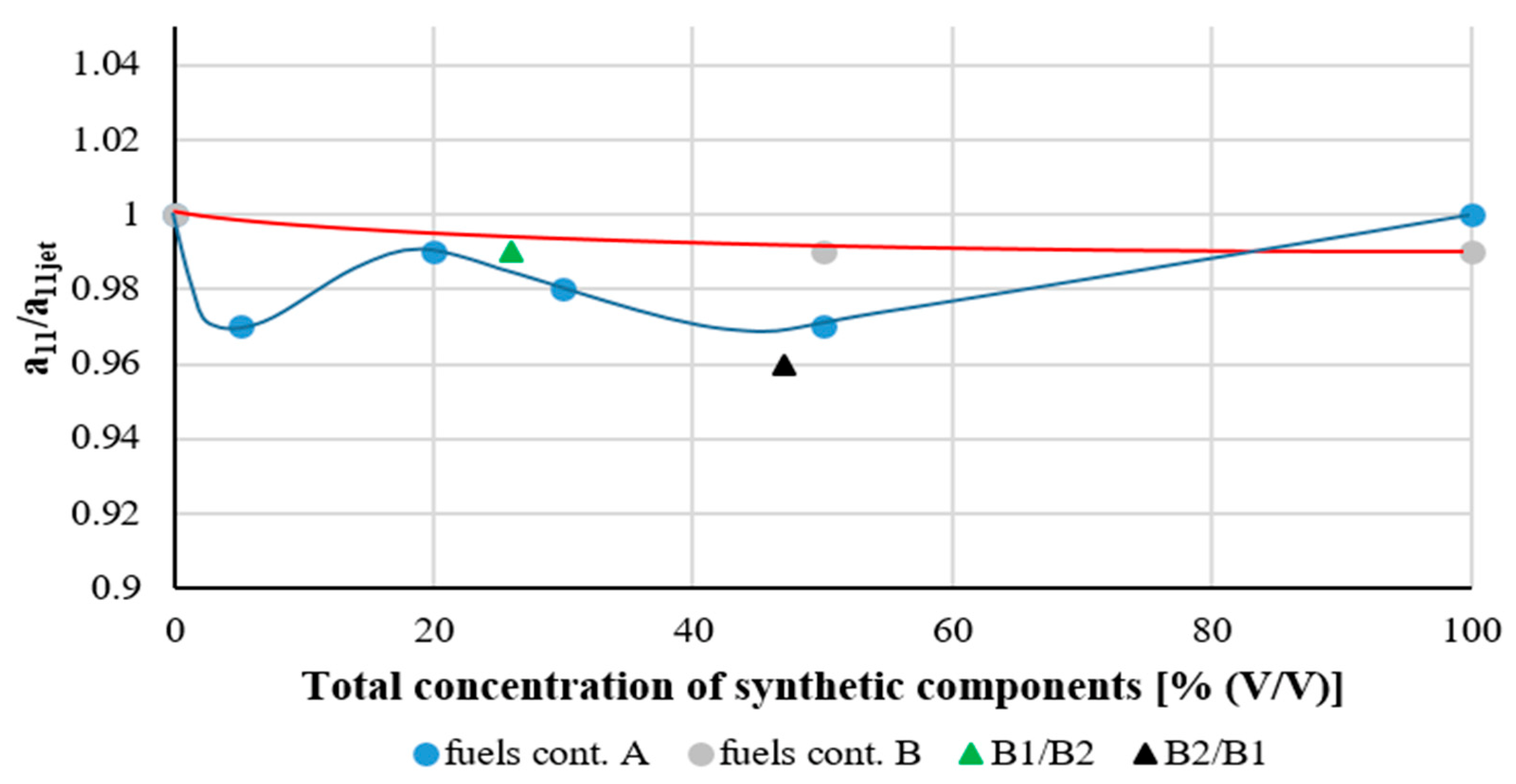

6. Discussion of the Results

6.1. Impact of Synthetic Component Content on Selected Physical and Chemical Properties of the Fuels

6.2. Impact of Synthetic Component Content on Fuel Lubricity

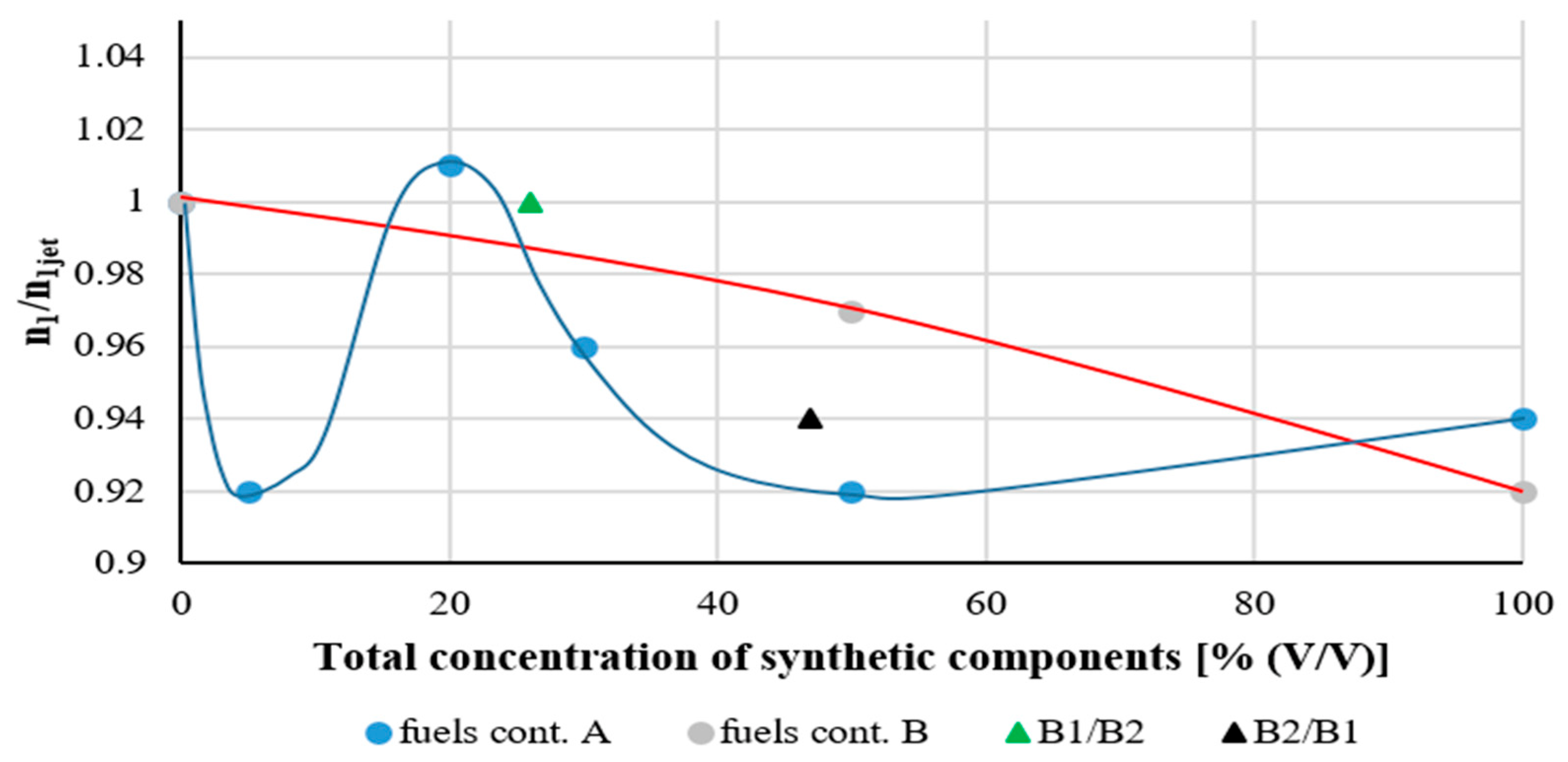

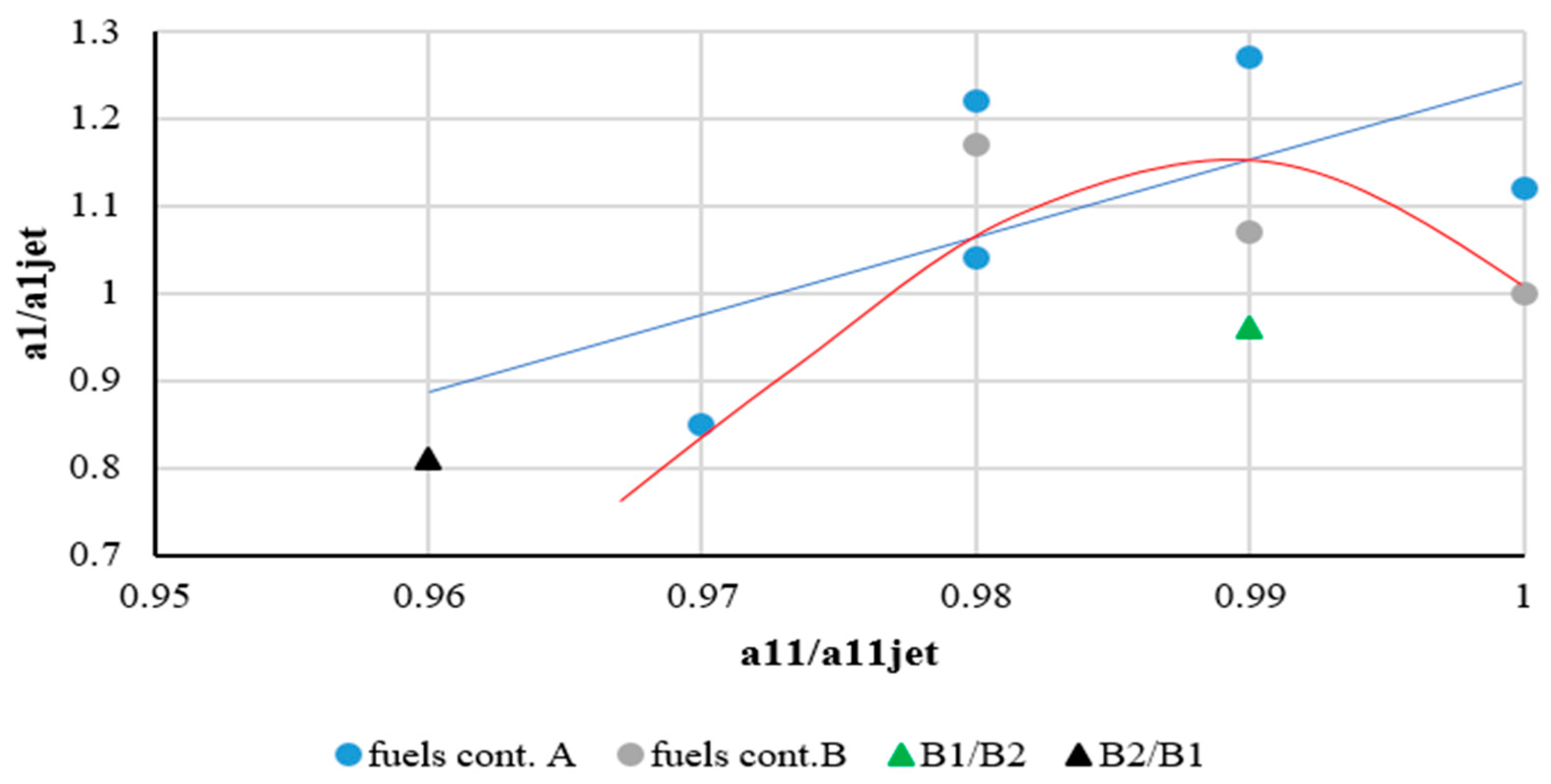

6.3. Impact of Synthetic Component Content on the GTM 120 Engine Fuel Combustion Process

- There is a clear relationship between the values of both criteria.

- It is different for synthetic component A and synthetic component B.

- The availability of a greater number of synthetic components, approved after satisfying criteria set out by ASTM, leads to them being mixed in the fuel tanks of aircraft.

- The blends formed in aircraft tanks will contain a relatively high concentration of one of the components and a relatively low concentration of the other component.

- There is a real possibility that many different components appear simultaneously within a blend, which may significantly complicate the scenarios described in this article.

- T2 temperature upstream of the combustion chamber (°C);

- T3 combustion chamber temperature (six measurements) (°C);

- CO content in exhaust gases (ppm).

7. Conclusions

- The development of fuels containing synthetic components will cause them to mix in aircraft tanks. Therefore, there is a need to develop research on the methodology of evaluating the miscibility of fuels containing different synthetic components.

- The methodology of testing the miscibility of fuels containing various synthetic components proposed in this article includes the following: standard laboratory tests (mainly normal distillation and calorific value measurement), BOCLE lubricity test and engine tests providing experimental data for relationships (33) and (34).

- The proposed methodology was initially verified in laboratory, lubricity and engine tests using blends of mineral Jet A-1 fuel and synthetic components A and B, both tested following the ASTM procedure and approved (entered in the ASTM D1655 standard [11]). As a result of the research, the following was observed.

- ○

- In the case of high concentrations of synthetic components added individually, the values of the a11/a11jet, n1/n1jet, a/ajet and n/njet parameters undergo a change proportional to the concentration of the synthetic component in the fuel.

- ○

- However, in the case of lower concentrations (up to 30% (v/v)), the changes in the a11/a11jet, n1/n1jet, a/ajet and n/njet parameters are different than for high concentrations.

- ○

- The impact of each of the tested components on the course of the aforementioned relationships differs.

- ○

- The values of the a11/a11jet, n1/n1jet, a/ajet and n/njet parameters obtained for the B1/B2 and B2/B1 blends deviate from the trend line for changes acquired for blends containing individual synthetic components A and B. This indicates that the presence of even a very small quantity of one of the components impacts the course of the combustion process in an aviation turbine engine.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Directive (EU). 2018/2001 of the European parliament and of the council of 11 December 2018 on the promotion of the use of energy from renewable sources. Off. J. Eur. Union 2018, 5, 82–209. [Google Scholar]

- Gawron, G.; Białecki, T. Impact of a jet A-1/HEFA blend on the performance and emission characteristics of a miniature turbojet engine. Int. J. Environ. Sci. Technol. 2018, 15, 1501–1508. [Google Scholar] [CrossRef]

- Yang, J.; Xin, Z.; Corscadden, K.; Niu, H. An overview on performance characteristics of bio-jet fuels. Fuel 2019, 237, 916–936. [Google Scholar] [CrossRef]

- Kumal, R.R.; Liu, J.; Gharpure, A.; Wal, R.L.V.; Kinsey, J.S.; Giannelli, B.; Stevens, J.; Leggett, C.; Howard, R.; Forde, M.; et al. Impact of biofuel blends on black carbon emissions from a gas turbine engine. Energy Fuels 2020, 34, 4958–4966. [Google Scholar] [CrossRef] [PubMed]

- ASTM D4054; Standard Practice for Evaluation of New Aviation Turbine Fuels and Fuel. ASTM International: West Conshohocken, PA, USA, 2022.

- Dzięgielewski, W.; Gawron, B.; Kulczycki, A. Low temperature properties of fuel mixtures of kerosene and fame type used to supply turbine engines in marine and other non-aeronautical applications. Pol. Marit. Res. 2015, 22, 101–105. [Google Scholar] [CrossRef][Green Version]

- AFIT Technical Documentation—Internal documentation, not to be published in full.

- Schripp, T.; Grein, T.; Zinsmeister, J.; Oßwald, P.; Koehler, M.; Mueller-Langer, F.; Posselt, D.; Hauschild, S.; Marquardt, C.; Scheuermann, S.; et al. Technical application of a ternary alternative jet fuel blend—Chemical characterization and impact on jet engine particle emission. Fuel 2021, 288, 119606. [Google Scholar] [CrossRef]

- Müller-Langer, F.; Dögnitz, N.; Marquardt, C.; Zschocke, A.; Schripp, T.; Oehmichen, K.; Majer, S.; Bullerdiek, N.; Halling, A.; Posselt, D.; et al. Multiblend JET A-1 in practice: Results of an R&D project on synthetic paraffinic kerosenes. Chem. Eng. Technol. 2020, 43, 1514–1521. [Google Scholar] [CrossRef]

- ASTM D7566; Standard Specification for Aviation Turbine Fuel Containing Synthesized Hydrocarbons. 2022. Available online: https://www.astm.org/d7566-22.html (accessed on 21 August 2022).

- ASTM D1655; Standard Specification for Aviation Turbine Fuels. 2022. Available online: https://www.astm.org/d1655-22.html (accessed on 21 August 2022).

- ASTM D3338; Standard Test Method for Estimation of Net Heat of Combustion of Aviation Fuels. 2020. Available online: https://www.astm.org/d3338-20.html (accessed on 21 August 2022).

- ASTM D4052; Standard Test Method for Density and Relative Density of Liquids by Digital Density Meter. 2022. Available online: https://www.astm.org/d4052-22.html (accessed on 21 August 2022).

- ASTM D445; Standard Test Method for Kinematic Viscosity of Transparent and Opaque Liquids (the Calculation of Dynamic Viscosity). 2021. Available online: https://www.astm.org/d445-21.html (accessed on 21 August 2022).

- ASTM D86; Standard Test Method for Distillation of Petroleum Products at Atmospheric Pressure. 2020. Available online: https://www.astm.org/d86-20.html (accessed on 21 August 2022).

- ASTM D5001; Standard Test Method for Measurement of Lubricity of Aviation Turbine Fuels by the Ball-on-Cylinder Lubricity Evaluator (BOCLE). 2019. Available online: https://www.astm.org/d5001-19.html (accessed on 21 August 2022).

- Gawron, B.; Białecki, T. The laboratory test rig with miniature jet engine to research aviation fuels combustion process. J. KONBiN 2017, 4, 79–89. [Google Scholar] [CrossRef]

- Tanaka, S.; Ayala, F.; Keck, J.C.; Heywood, J.B. Two-stage ignition in HCCI combustion and HCCI control by fuels and additives. Combust. Flame 2003, 132, 219–239. [Google Scholar] [CrossRef]

- ARP 1533C; Procedure for the Analysis and Evaluation of Gaseous Emission from Aircraft Engines. SAE International: Warrendale, PA, USA, 2016.

- Pawlak, W.I.; Balicki, W. Influence of an inequality of gas thermal field at the jet engine turbine inlet on to the speed of transient processes—The results of experiments with real engine. J. Kones Intern. Combust. Engines 2003, 10, 3–4. [Google Scholar]

- Białecki, T.; Dzięgielewski, W.; Kowalski, M.; Kulczycki, A. Reactivity model as a tool to compare the combustion process in aviation turbine engines powered by synthetic fuels. Energies 2021, 14, 6302. [Google Scholar] [CrossRef]

- Govindan, R.; Jakhar, O.; Mathur, Y. Computational analysis of Thumba biodiesel-diesel blends combustion in CI engine using Ansys-fluent. IJCMS 2014, 3, 29–39. [Google Scholar]

- Kulczycki, A. Theoretical approach to modelling the combustion process in turbine engines fuelled by alternative aviation fuels containing various components/bio components. Combust. Engines 2017, 71, 245–249. [Google Scholar] [CrossRef]

- Białecki, T.; Dzięgielewski, W.; Gawron, B.; Kaźmierczak, U.; Kulczycki, A. The role of molecularly ordered structures in energy transport enhancement during combustion process—A new conception of a reaction mechanism of fuel components oxidation. J. KONES Powertrain Transp. 2018, 25, 17–24. [Google Scholar]

- Przysowa, R.; Gawron, B.; Białecki, T.; Łęgowik, A.; Merkisz, J.; Jasiński, R. Performance and emissions of a micro-turbine and turbofan powered by alternative fuels. Aerospace 2021, 8, 25. [Google Scholar] [CrossRef]

- Józef, B.; Artur, K.; Jerzy, P. The impact of unevenness and instability of flue gas temperature on the technical condition of gas turbine blades. J. KONES Power Train Transp. 2018, 25, 45–51. [Google Scholar]

| Parameter | Requirement |

|---|---|

| Fluid Volume | 50 ± 1.0 mL |

| Fluid Temperature | 25 ± 1 °C |

| Conditioner Air | 10 ± 0.2% relative humidity at 25 ± 1 °C |

| Fluid pre-treatment | 0.50 L/min flowing through and 3.3 L/min over the fluid form 15 min |

| Fluid test conditions | 3.8 L/min flowing over the fluid |

| Applied Load | 1000 g (500 g weight) (±1 g) |

| Cylinder Rotational Speed | 240 ± 1 rpm |

| Test Duration | 30 ± 0.1 min |

| Test Ring of SAE 8720 steel, possessing a Rockwell hardness “C” scale (HRC) number of 58 to 62 and a surface finish of 0.56 to 0.71 µm root mean square | |

| Test Ball chrome alloy steel, made from AISI standard steel No. E-52100, with a diameter of 12.7 mm, Grade 5 to 10; the HRC shall be 64 to 66; the ball is described in ISO 3290-1 | |

| (a) | |||||||

| Fuel Properties | Jet A1 (A) | 5% A | 20% A | 30% A | 50% A | 100%A | Repeatability of the Method in Laboratory |

| Density at 15 °C, kg/m3 | 793.1 | 790.5 | 787.0 | 782.7 | 770.7 | - | 0.11 |

| Viscosity at −20 °C, mm2/s | 3.069 | 3.288 | 3.403 | 3.470 | 3.481 | - | 0.008 |

| Calorific value, MJ/kg | 43.312 | 43.335 | 43.484 | 43.570 | 43.740 | 44.200 | 0.021 |

| Aromatics, % (v/v) | 15.1 | 14.3 | 12.1 | 10.6 | 7.6 | - | 1.0 |

| Distillation: | - | - | |||||

| 10% Recovery, °C | 166.1 | 170.6 | 169.9 | 169.0 | 2.3 | ||

| 50% Recovery, °C | 183.4 | 186.8 | 188.3 | 189.3 | 1.8 | ||

| 90% Recovery, °C | 208.1 | 214.1 | 220.2 | 224.7 | 2.6 | ||

| end point, °C | 231.2 | 239.4 | 246.7 | 249.5 | 3.9 | ||

| (b) | |||||||

| Fuel Properties | Jet A-1 B | 50% B | 100% B | Repeatability of the Method in Laboratory | |||

| Density at 15 °C, kg/m3 | 793.0 | 776.1 | 758.6 | 0.11 | |||

| Viscosity at −20 °C, mm2/s | 3.062 | 3.654 | 4.740 | 0.008 | |||

| Calorific value, MJ/kg | 43.231 | 43.599 | 44.027 | 0.021 | |||

| Aromatics, % (v/v) | 17.3 | 8.8 | 0.0 | 1.0 | |||

| Distillation: | |||||||

| 10% Recovery, °C | 166.1 | 175.5 | 170.5 | 2.3 | |||

| 50% Recovery, °C | 183.4 | 181.2 | 182.1 | 1.8 | |||

| 90% Recovery, °C | 208.1 | 210.3 | 209.0 | 2.6 | |||

| end point, °C | 231.2 | 262.7 | 246.2 | 3.9 | |||

| (c) | |||||||

| Fuel Properties | Jet A-1 (B/A) | B1/B2 | B2/B1 | B5/B6 | B6/B5 | Repeatability of the Method in Laboratory | |

| Density at 15 °C, kg/m3 | 800.5 | 789.5 | 777.0 | - | - | 0.11 | |

| Viscosity at −20 °C, mm2/s | 3.176 | 3.428 | 3.564 | - | - | 0.008 | |

| Calorific value, MJ/kg | 43.094 | 43.388 | 43.676 | 43.371 | 43.307 | 0.021 | |

| Distillation: | |||||||

| 10% Recovery, °C | 166.1 | 167.3 | 164.3 | 168.8 | 167.2 | 2.3 | |

| 50% Recovery, °C | 184.3 | 183.0 | 189.6 | 185.5 | 187.0 | 1.8 | |

| 90% Recovery, °C | 214.7 | 215.8 | 233.8 | 218.2 | 223.0 | 2.6 | |

| end point, °C | 236.9 | 243.4 | 251.7 | 241.7 | 244.1 | 3.9 | |

| Fuel | rpm | CO | mf | a/ajet | n/njet |

|---|---|---|---|---|---|

| Jet A-1 (B) | 70,000 | 1588 | 1.72 | 1 | 1 |

| 88,000 | 1047 | 2.24 | |||

| 104,000 | 714 | 3.06 | |||

| 111,000 | 765 | 3.7 | |||

| 50B | 70,000 | 1660 | 1.68 | 1.07 | 1.03 |

| 88,000 | 1076 | 2.32 | |||

| 104,000 | 770 | 2.97 | |||

| 111,000 | 782 | 3.61 | |||

| 100B | 70,000 | 1715 | 1.76 | 1.17 | 1.05 |

| 88,000 | 1170 | 2.27 | |||

| 104,000 | 842 | 3.02 | |||

| 111,000 | 841 | 3.53 | |||

| Jet A-1 (A) | 70,000 | 1150 | 2.11 | 1 | 1 |

| 88,000 | 714 | 2.80 | |||

| 104,000 | 382 | 4.36 | |||

| 111,000 | 405 | 5.15 | |||

| 5A | 70,000 | 1203 | 2.11 | 1.04 | 0.97 |

| 88,000 | 794 | 2.77 | |||

| 104,000 | 416 | 4.36 | |||

| 111,000 | 445 | 5.41 | |||

| 20A | 70,000 | 1525 | 2.1 | 1.27 | 0.95 |

| 88,000 | 992 | 2.75 | |||

| 104,000 | 549 | 4.45 | |||

| 111,000 | 535 | 5.24 | |||

| 30A | 70,000 | 1488 | 2.08 | 1.22 | 0.93 |

| 88,000 | 1007 | 2.73 | |||

| 104,000 | 532 | 4.42 | |||

| 111,000 | 528 | 5.33 | |||

| 50A | 70,000 | 1329 | 2.14 | 0.85 | 0.99 |

| 88,000 | 853 | 2.68 | |||

| 111,000 | 544 | 3.37 | |||

| 100A | 70,000 | 1350 | 2.01 | 1.12 | 0.99 |

| 88,000 | 810 | 2.76 | |||

| 111,000 | 550 | 4.14 | |||

| B2/B1 | 70,000 | 1577 | 2.23 | 0.81 | 0.76 |

| 88,000 | 1413 | 2.86 | |||

| 111,000 | 970 | 4.33 | |||

| B1/B2 | 70,000 | 1680 | 2.25 | 0.96 | 0.97 |

| 88,000 | 1191 | 2.87 | |||

| 111,000 | 856 | 4.46 |

| Fuel | rpm | T3max | T3min | T2 | mf | a11/a11jet | n1/n1jet |

|---|---|---|---|---|---|---|---|

| Jet A-1 (B) | 70,000 | 638 | 455 | 77 | 1.72 | 1 | 1 |

| 88,000 | 662 | 505 | 106 | 2.24 | |||

| 104,000 | 730 | 601 | 143 | 3.06 | |||

| 111,000 | 793 | 675 | 163 | 3.7 | |||

| 50B | 70,000 | 636 | 451 | 74 | 1.68 | 0.99 | 0.98 |

| 88,000 | 661 | 511 | 106 | 2.32 | |||

| 104,000 | 729 | 594 | 140 | 2.97 | |||

| 111,000 | 783 | 667 | 161 | 3.61 | |||

| 100B | 70,000 | 637 | 456 | 76 | 1.76 | 0.98 | 0.93 |

| 88,000 | 661 | 514 | 107 | 2.27 | |||

| 104,000 | 725 | 594 | 140 | 3.02 | |||

| 111,000 | 798 | 669 | 161 | 3.53 | |||

| Jet A-1 (A) | 70,000 | 618 | 441 | 70 | 2.11 | 1 | 1 |

| 88,000 | 636 | 496 | 100 | 2.80 | |||

| 111,000 | 762 | 658 | 154 | 4.36 | |||

| 117,000 | 833 | 740 | 169 | 5.15 | |||

| 5A | 70,000 | 609 | 438 | 69 | 2.11 | 0.98 | 0.97 |

| 88,000 | 623 | 489 | 99 | 2.77 | |||

| 111,000 | 752 | 654 | 154 | 4.36 | |||

| 117,000 | 844 | 749 | 172 | 5.41 | |||

| 20A | 70,000 | 616 | 438 | 70 | 2.1 | 0.99 | 1.03 |

| 88,000 | 623 | 492 | 99 | 2.75 | |||

| 111,000 | 751 | 661 | 155 | 4.45 | |||

| 117,000 | 825 | 743 | 170 | 5.24 | |||

| 30A | 70,000 | 618 | 441 | 69 | 2.08 | 0.98 | 0.95 |

| 88,000 | 636 | 497 | 98 | 2.73 | |||

| 111,000 | 750 | 658 | 154 | 4.42 | |||

| 117,000 | 832 | 743 | 170 | 5.33 | |||

| 50A | 70,000 | 620 | 441 | 72 | 2.14 | 0.97 | 0.92 |

| 88,000 | 644 | 498 | 100 | 2.68 | |||

| 111,000 | 784 | 663 | 156 | 3.37 | |||

| 100A | 70,000 | 617 | 438 | 70 | 2.01 | 1.00 | 0.94 |

| 88,000 | 652 | 498 | 100 | 2.76 | |||

| 111,000 | 793 | 670 | 157 | 4.14 | |||

| Jet A-1 (A1) | 70,000 | 613 | 437 | 77 | 2.16 | 1 | 1 |

| 88,000 | 643 | 498 | 103 | 2.75 | |||

| 111,000 | 785 | 670 | 157 | 3.39 | |||

| B2/B1 | 70,000 | 650 | 461 | 73 | 2.23 | 0.96 | 0.94 |

| 88,000 | 666 | 529 | 103 | 2.86 | |||

| 111,000 | 770 | 686 | 156 | 4.33 | |||

| B1/B2 | 70,000 | 652 | 460 | 73 | 2.25 | 0.99 | 1 |

| 88,000 | 668 | 527 | 104 | 2.87 | |||

| 111,000 | 776 | 695 | 156 | 4.46 | |||

| Jet A-1 (B/A) | 70,000 | 653 | 457 | 73 | 2.16 | 1 | 1 |

| 88,000 | 668 | 523 | 103 | 2.82 | |||

| 111,000 | 777 | 691 | 157 | 4.40 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kaźmierczak, U.; Dzięgielewski, W.; Kulczycki, A. Miscibility of Aviation Turbine Engine Fuels Containing Various Synthetic Components. Energies 2022, 15, 6187. https://doi.org/10.3390/en15176187

Kaźmierczak U, Dzięgielewski W, Kulczycki A. Miscibility of Aviation Turbine Engine Fuels Containing Various Synthetic Components. Energies. 2022; 15(17):6187. https://doi.org/10.3390/en15176187

Chicago/Turabian StyleKaźmierczak, Urszula, Wojciech Dzięgielewski, and Andrzej Kulczycki. 2022. "Miscibility of Aviation Turbine Engine Fuels Containing Various Synthetic Components" Energies 15, no. 17: 6187. https://doi.org/10.3390/en15176187

APA StyleKaźmierczak, U., Dzięgielewski, W., & Kulczycki, A. (2022). Miscibility of Aviation Turbine Engine Fuels Containing Various Synthetic Components. Energies, 15(17), 6187. https://doi.org/10.3390/en15176187