Small-Scale Combined Heat and Power Systems: The Prospects for a Distributed Micro-Generator in the ‘Net-Zero’ Transition within the UK

Abstract

:1. Introduction

1.1. Background

1.2. The Issues Considered

2. Micro-CHP System Requirements

2.1. The UK Housing Stock

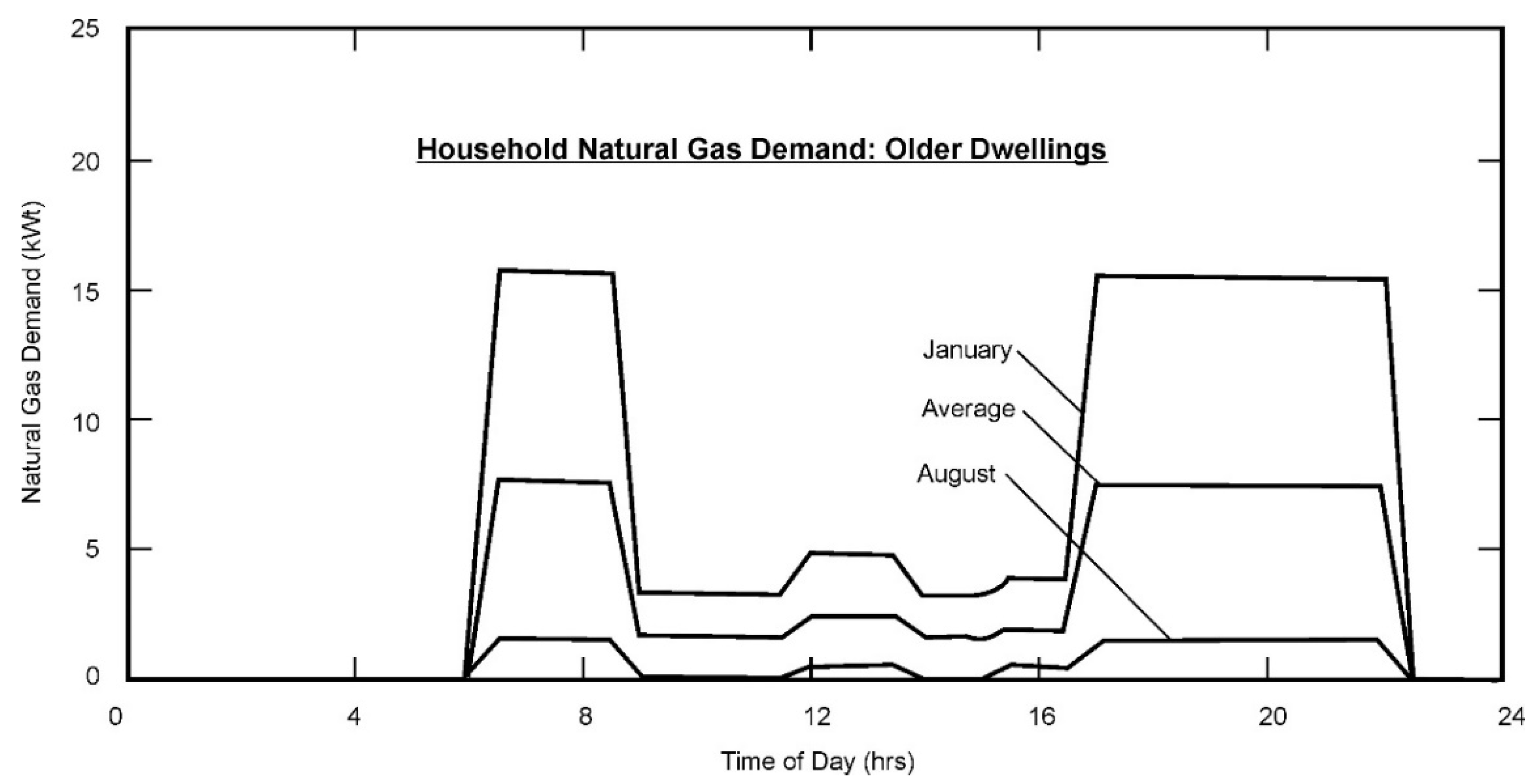

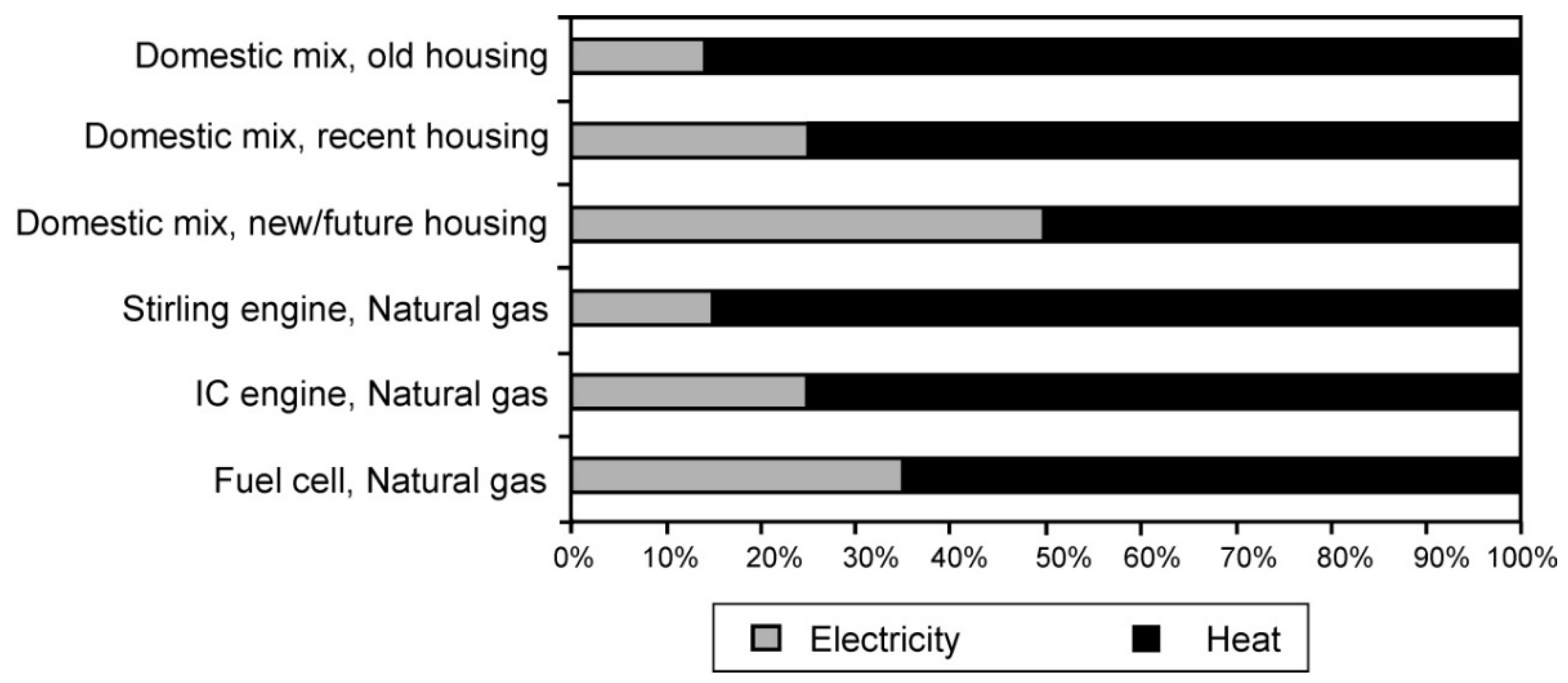

- Old. These mainly consist of ‘Victorian’ (i.e., late 19th Century) through to pre-World War II housing, particularly and many houses built before the 1970s. This housing is usually single-glazed and poorly insulated. Often draughty with poorly fitting doors and windows. Approximately 19 million houses in the UK fit into this category. According to Hitchin [43] these ‘old houses’ require about 15% of their total energy in the form of electricity, the remaining 85% as heat.

- Recent. Housing largely built from the mid-1970s, well-built and maintained houses from previous eras, mostly with double-glazed, well-fitted ‘unplasticised polyvinyl chloride’ (uPVC) doors and windows, cavity wall insulation and good roof insulation. Around 3.5 million UK houses fit this category. ‘Recently constructed houses’ require about 25% electricity, 75% heat [43].

- New and near-future. Housing built from mid-1990s, well designed and constructed, with energy conservation strongly in mind. Layout, materials and structure selected to maximise space heat retention, and featuring low-emissivity double (or even triple) glazing. High thermal insulation levels. This type of housing will form the basis of all new housing in the near future [20,44]. Much of the recent housing stock willalso be brought up to this standard. About 5 million new-build houses fit into this category. ‘New and near-future houses’ require about 50% each of heat and power [43].

2.2. Energy Demand in the Home

2.3. Micro-CHP Technological Status

3. Domestic Heating Strategy for the UK Net-Zero Transition to 2050

3.1. The COP26 Context

3.2. The 2021 UK ‘Heat and Buildings Strategy’

3.3. The Role of Building Energy Performance Standards and Associated Design Tools

4. Materials and Methods

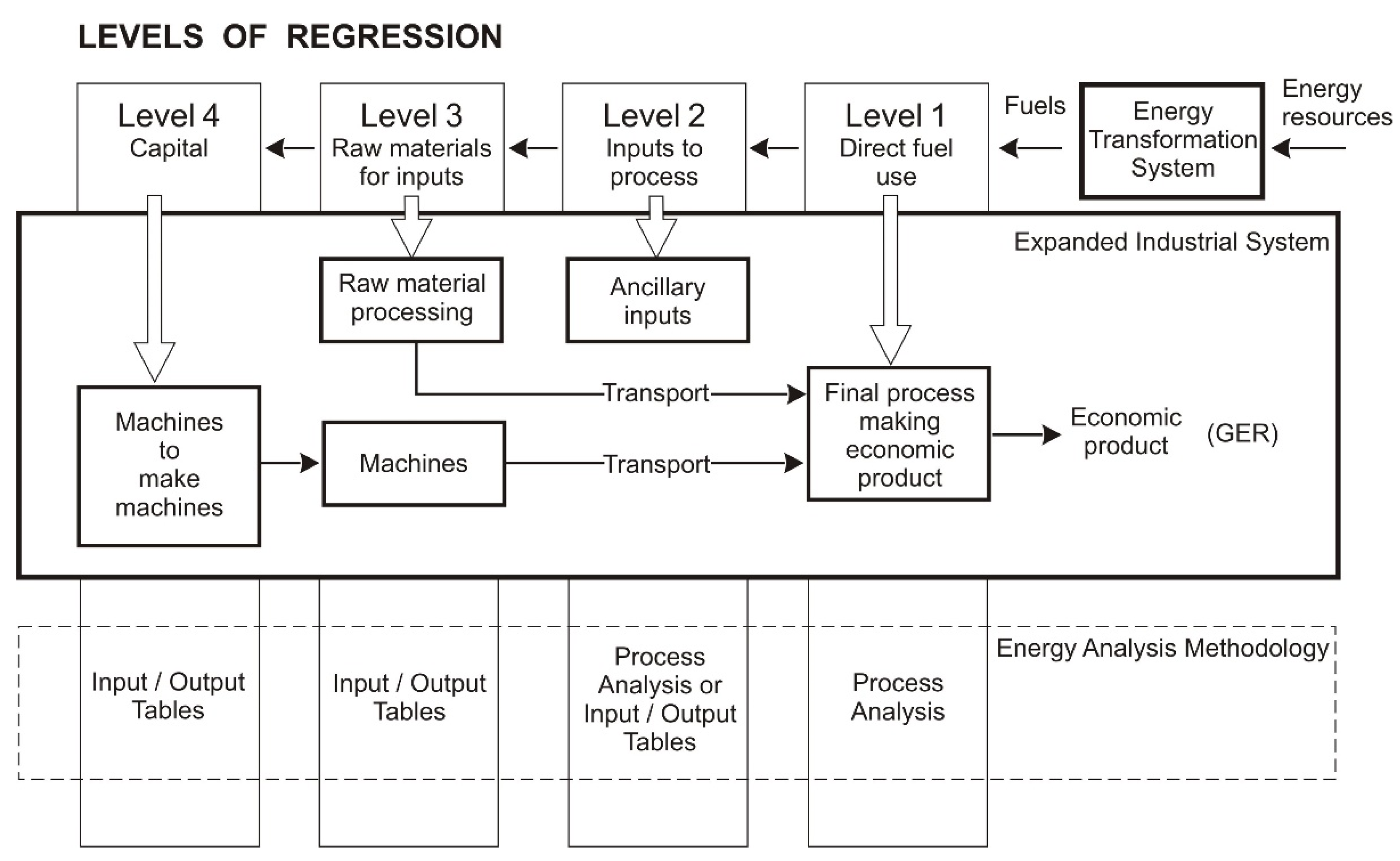

4.1. Energy Analysis

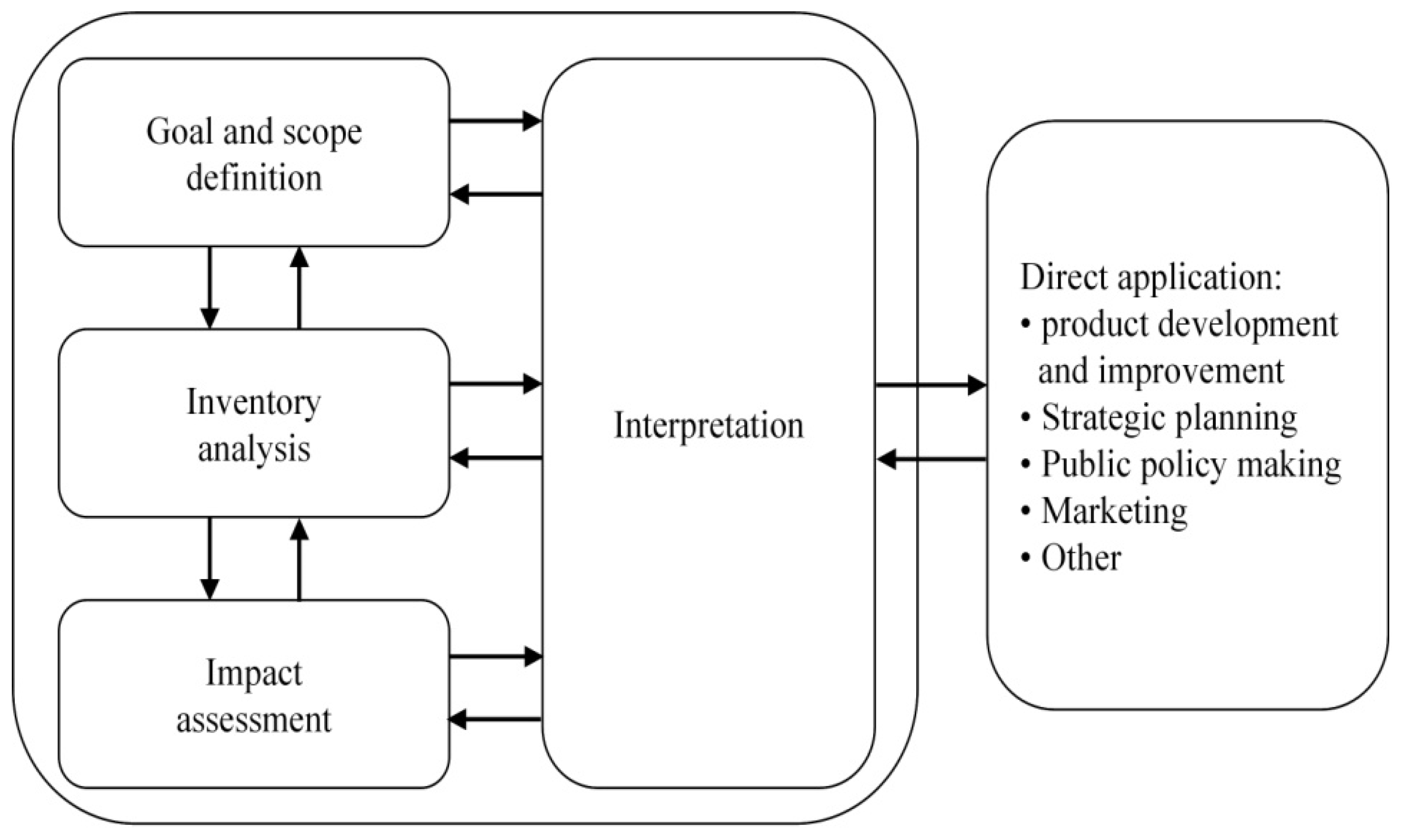

4.2. Environmental Life-Cycle Assessment

4.3. Financial Appraisal

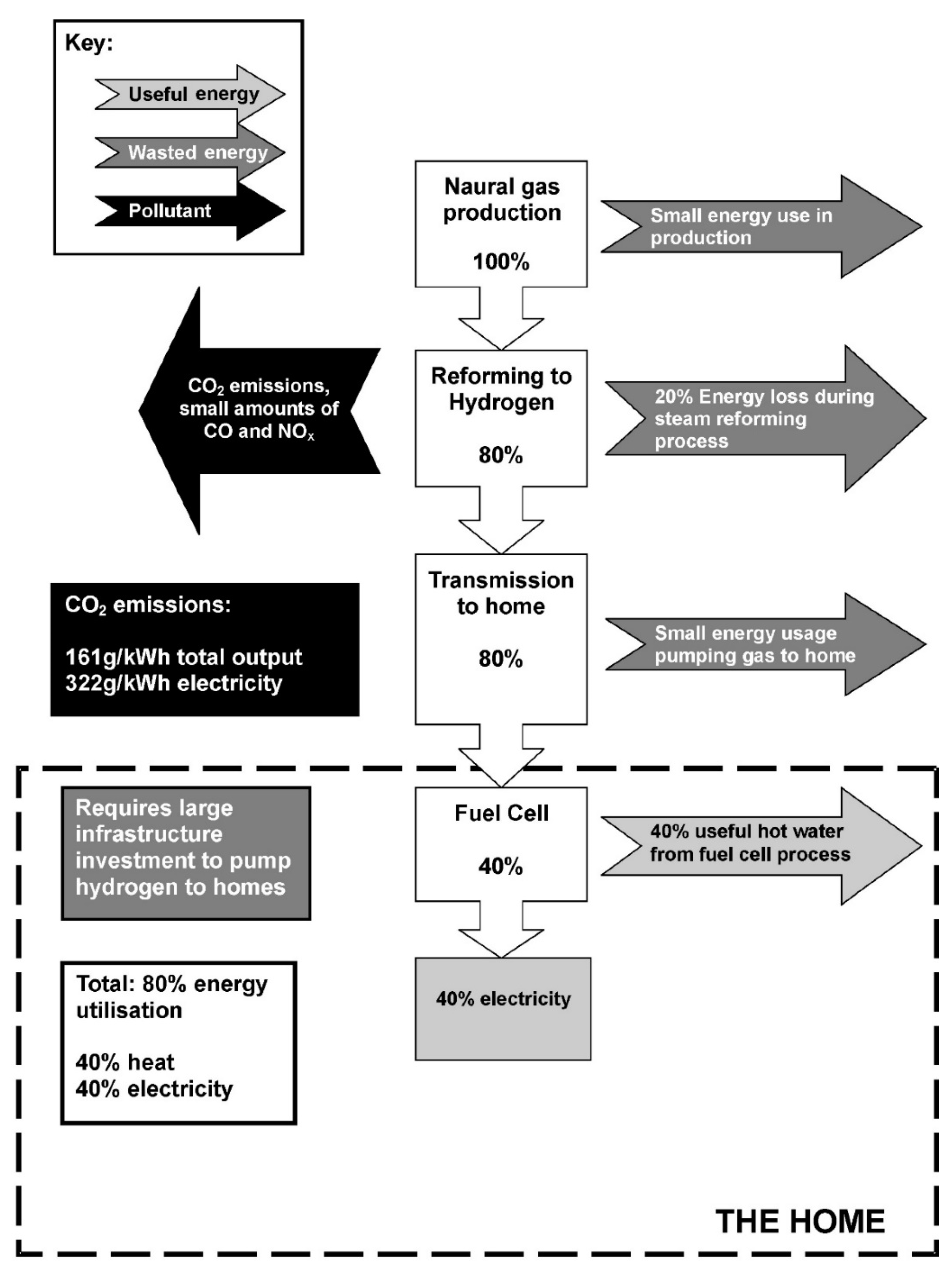

5. Full Fuel Cycle’ Analysis of Micro-CHP Systems

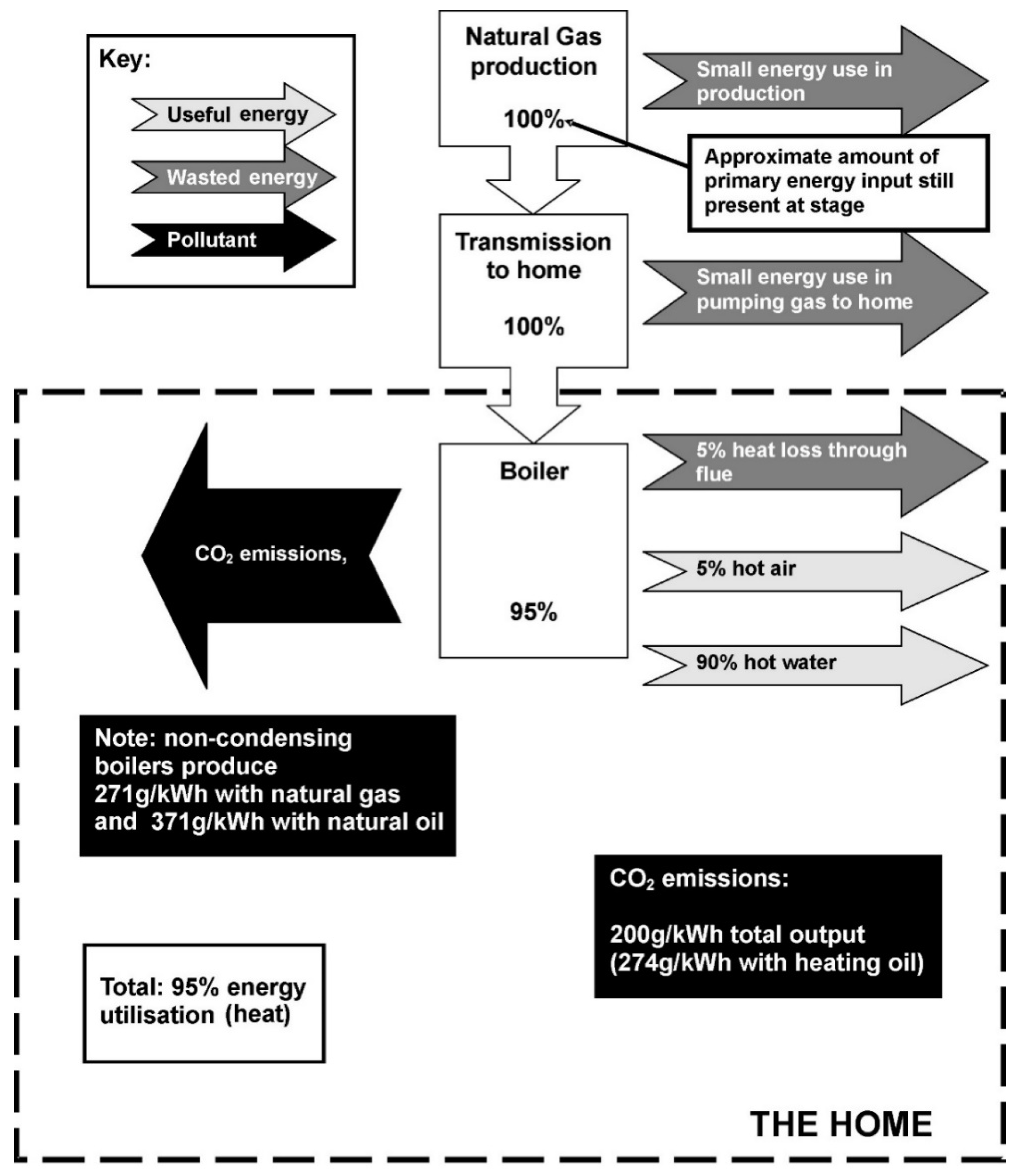

5.1. Practical Requirements of Domestic Energy Systems

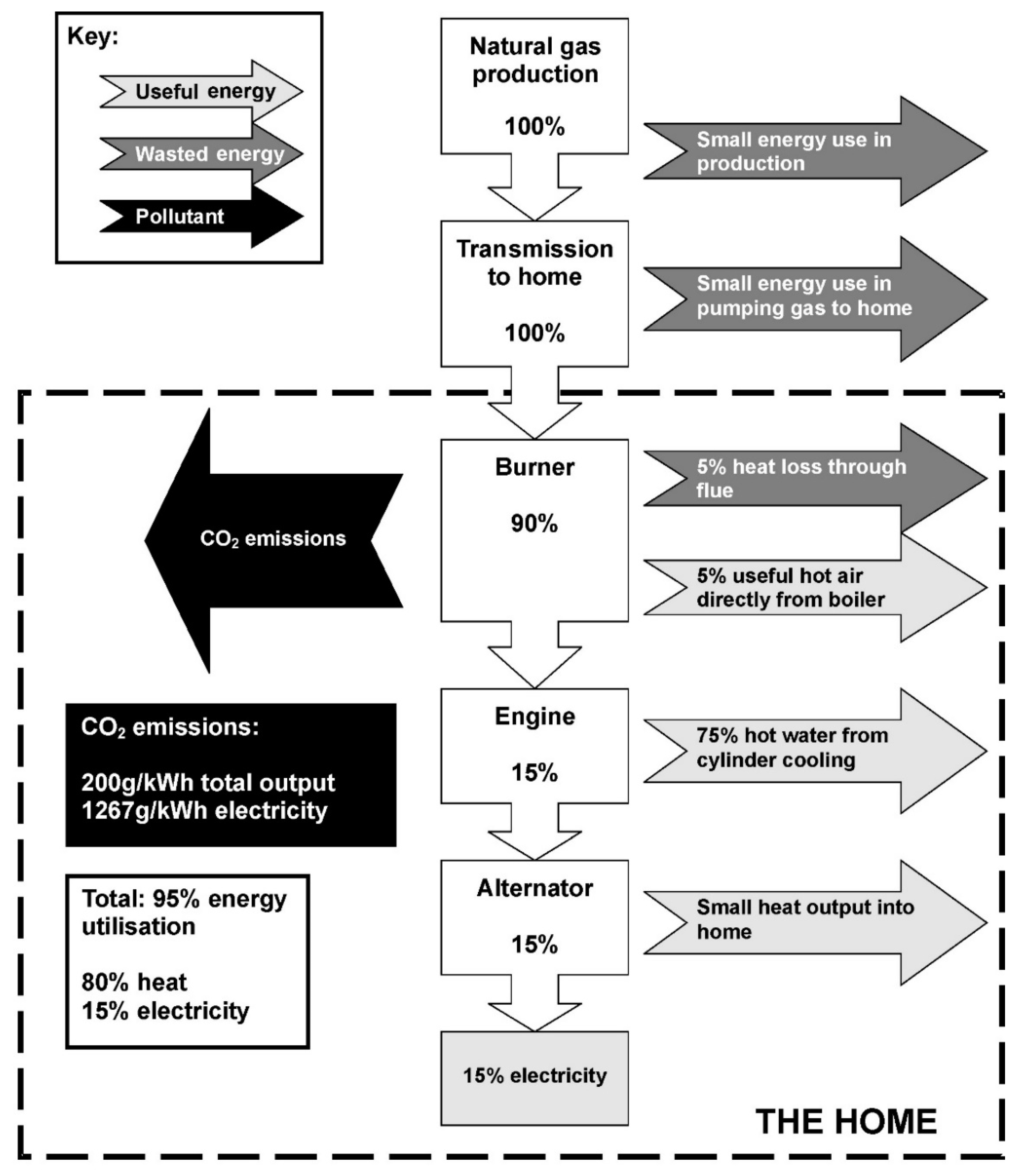

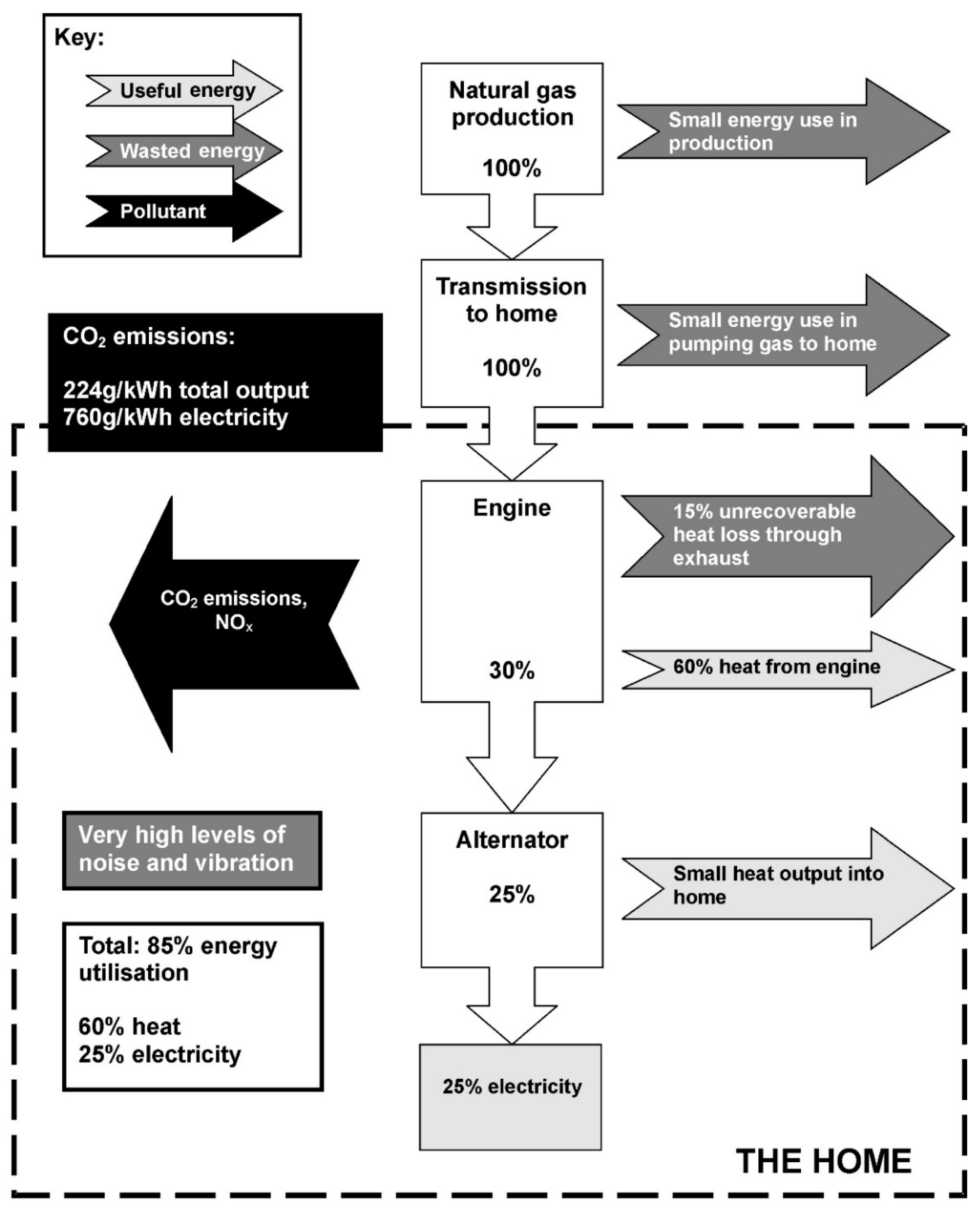

5.2. The Energy Performance of Micro-CHP Systems

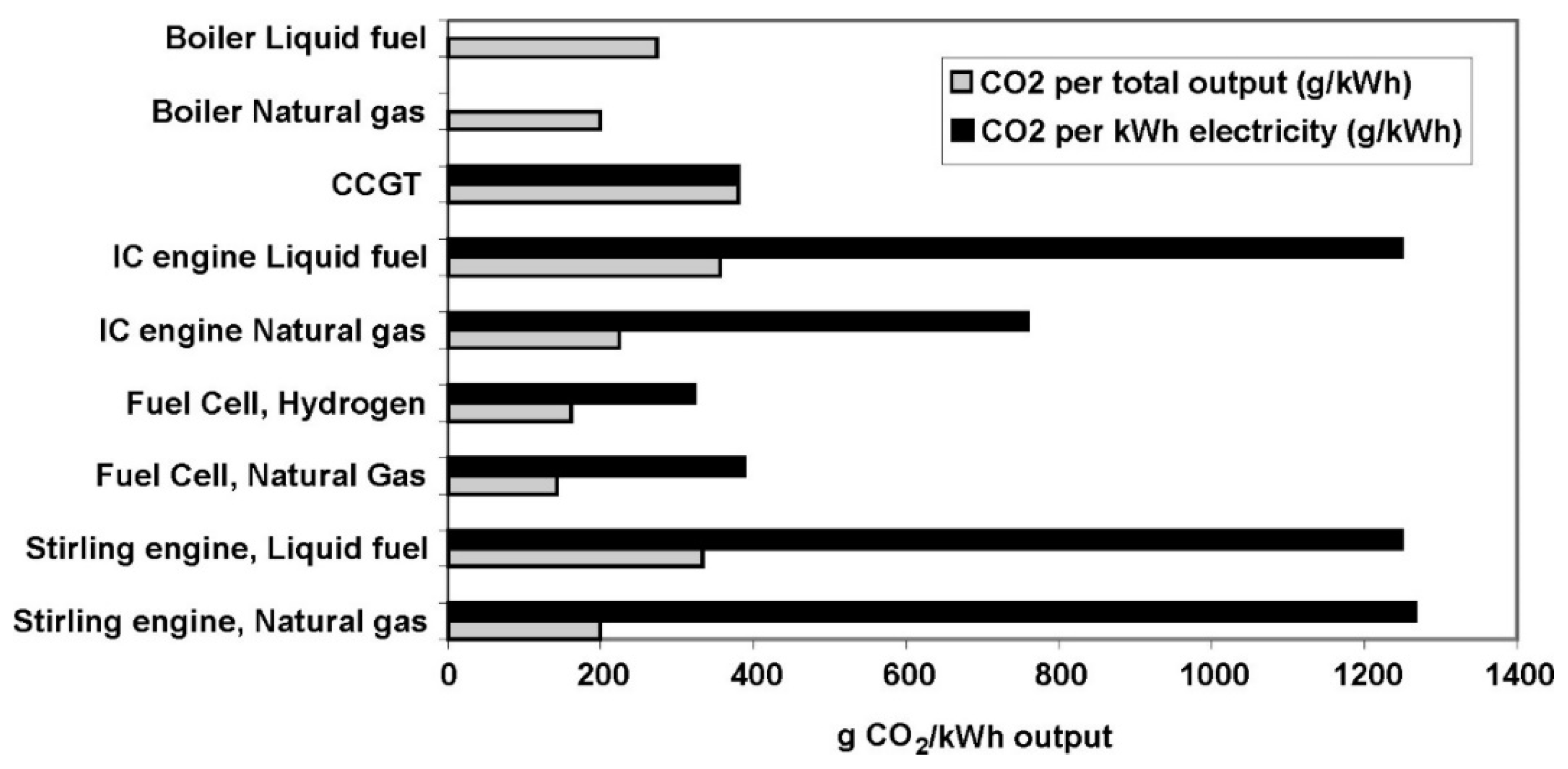

5.3. Carbon Dioxide Emissions Accounting of Micro-CHP Systems

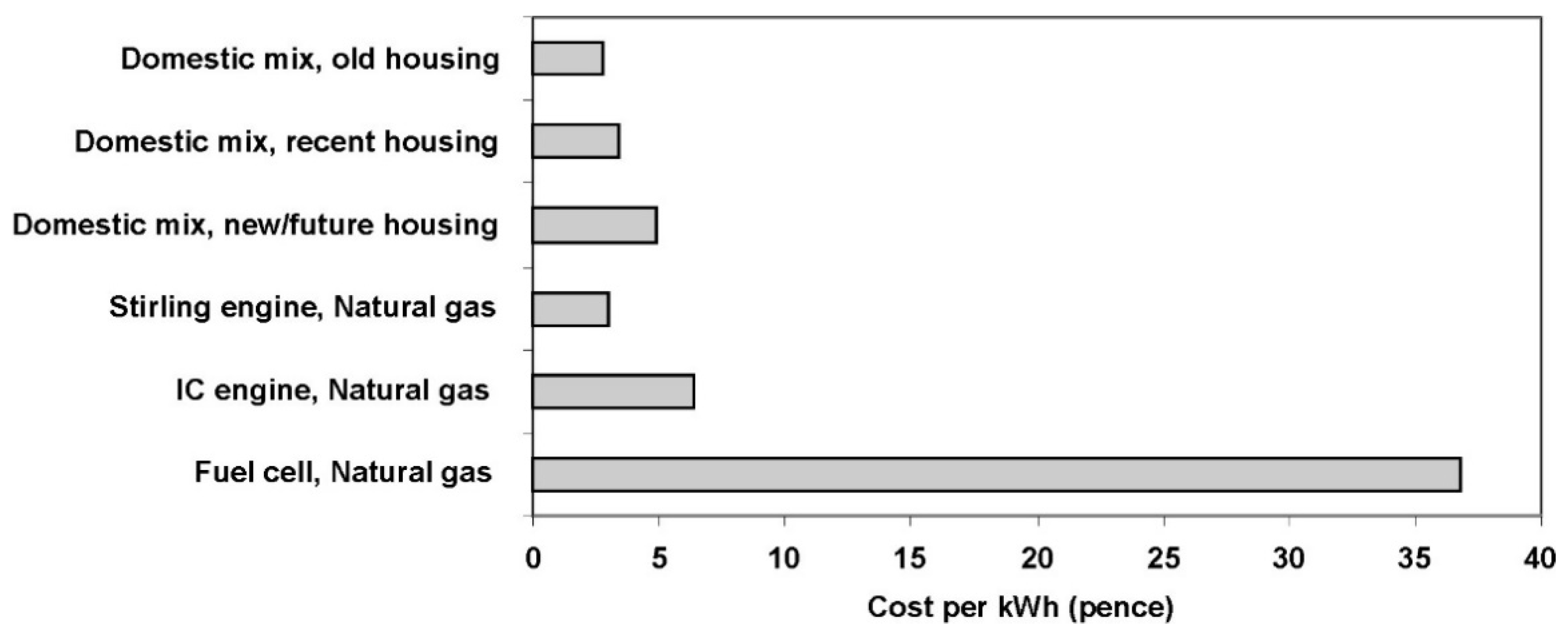

5.4. Financial Investment Appraisal of Micro-CHP Units

6. Competition between Heat Pumps and Micro-CHP Plants

6.1. The International Micro-Generation Market Context

6.2. The Comparative Performance of Heat Pumps and Micro-CHP Systems

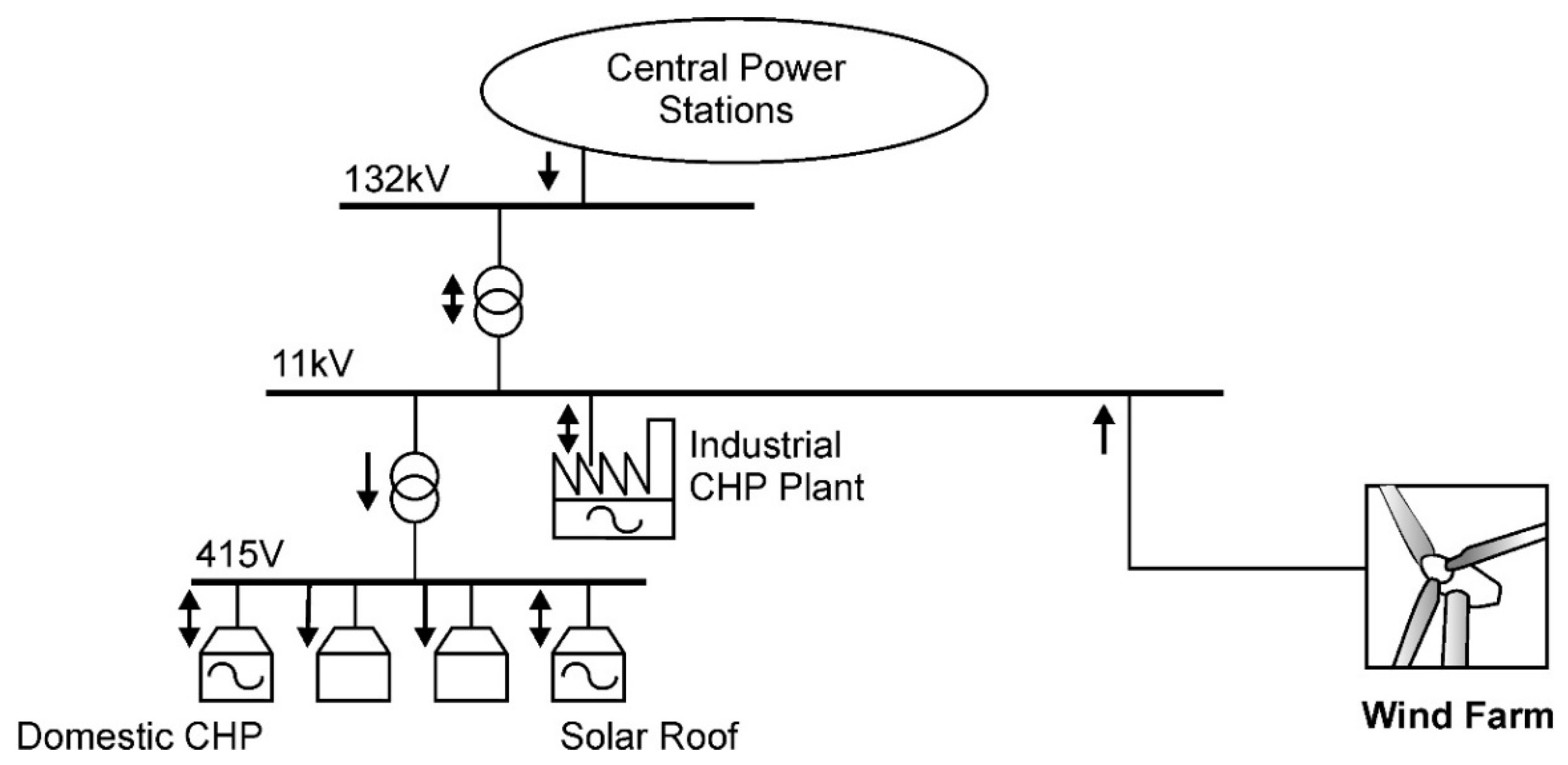

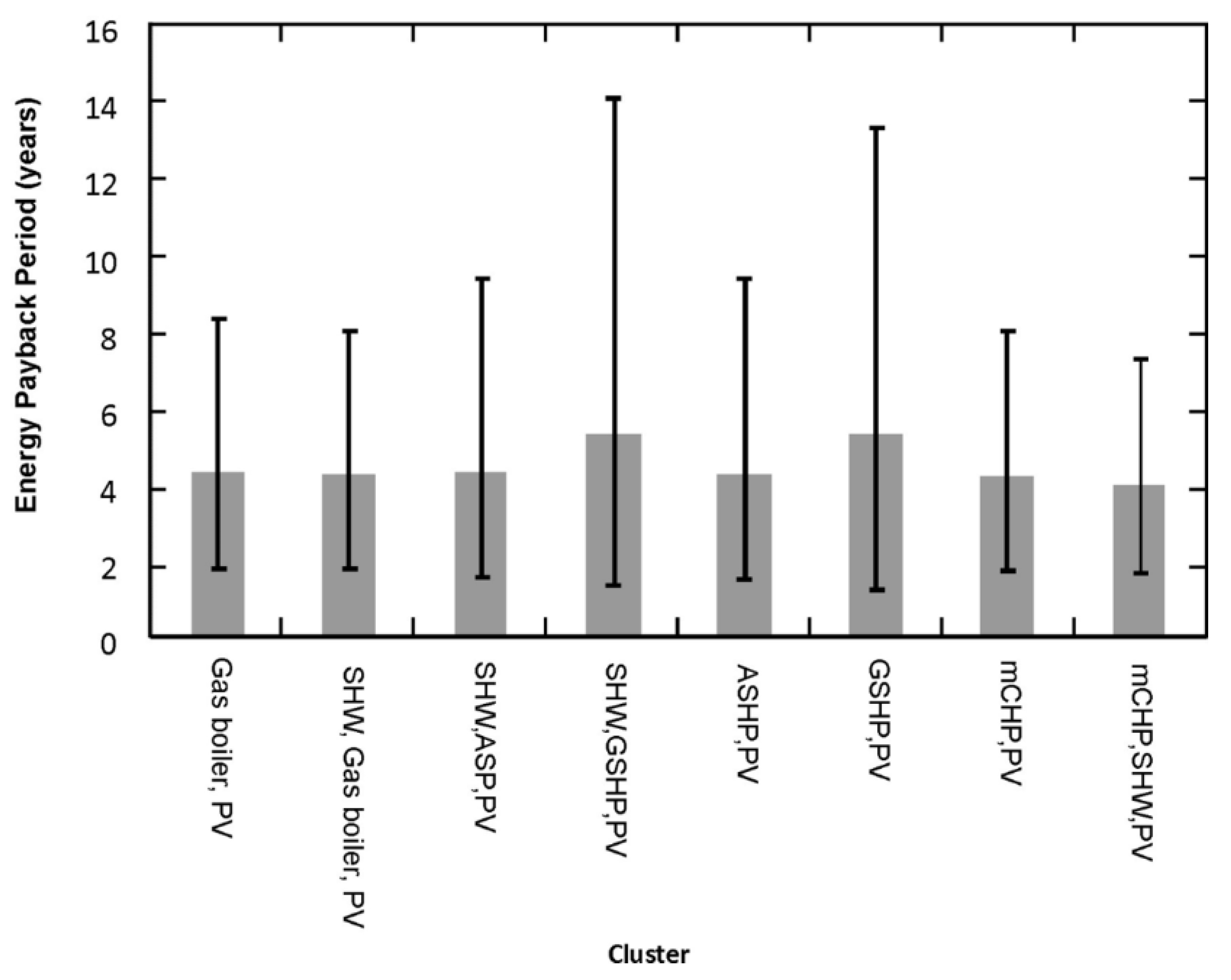

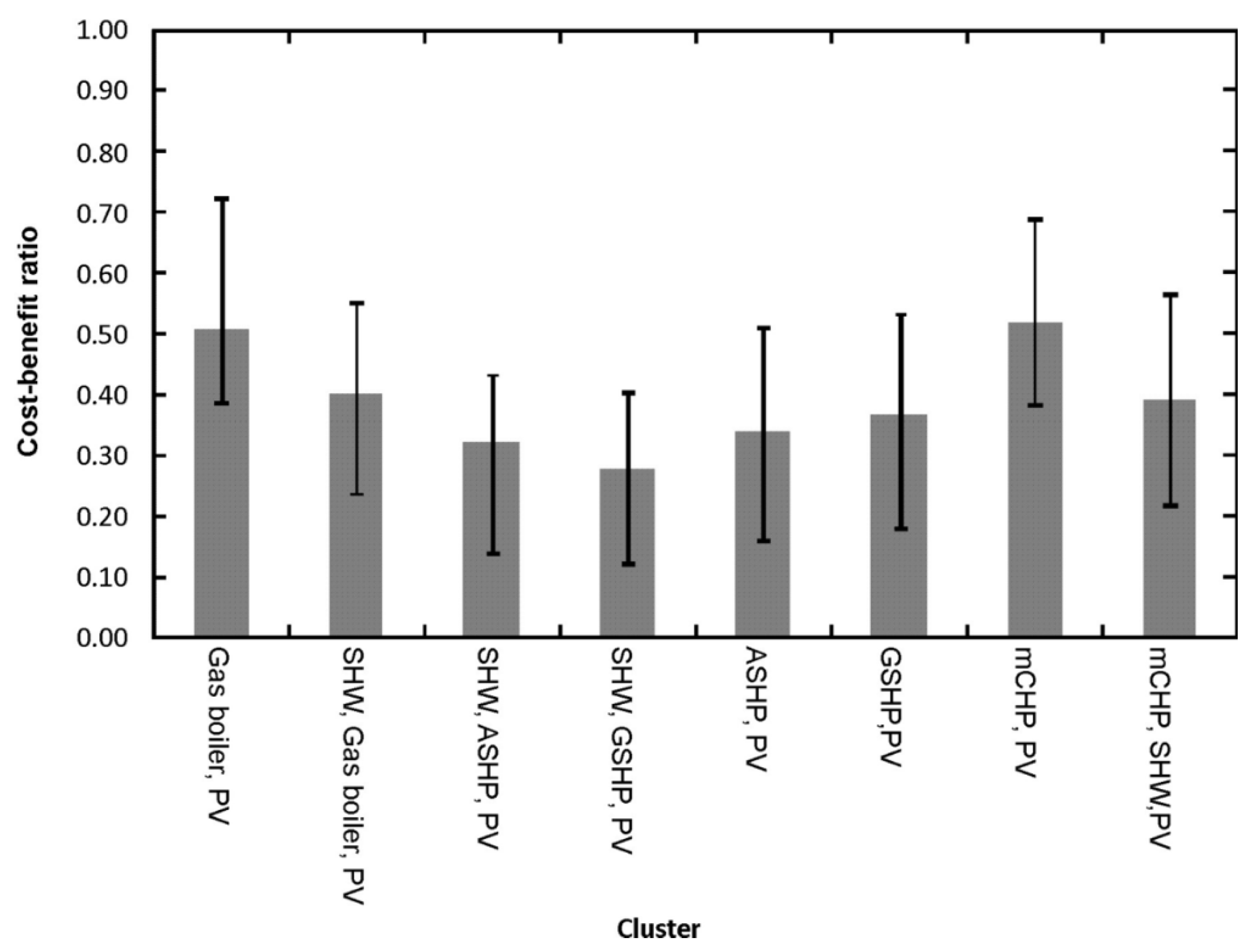

7. Clustering with Other Micro-Generators

8. Concluding Remarks

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hammond, G.P. Energy, environment and sustainable development: A UK perspective. Trans. IChemE Part B Process Saf. Environ. Prot. 2000, 78, 304–323. [Google Scholar] [CrossRef] [Green Version]

- Royal Commission on Environmental Pollution [RCEP]. Twenty-Second Report: Energy—The Changing Climate; Cm 4749; The Stationery Office: London, UK, 2000. [Google Scholar]

- Brown, A.I.; Hammond, G.P.; Jones, C.I.; Rogers, F.J. Greening the UK building stock: Historic trends and low carbon futures 1970–2050. Trans. Can. Soc. Mech. Eng. 2009, 33, 89–104. [Google Scholar] [CrossRef]

- Intergovernmental Panel on Climate Change [IPCC]. Climate Change 2021: The Physical Science Basis—Summary for Policymakers; Cambridge University Press: Cambridge, UK, 2021. [Google Scholar]

- Houghton, J. Global Warming: The Complete Briefing, 4th ed.; Cambridge University Press: Cambridge, UK, 2009; pp. 20–27. [Google Scholar]

- Archer, D.; Brovkin, V. The millennial atmospheric lifetime of anthropogenic CO2. Clim. Change 2008, 90, 283–297. [Google Scholar] [CrossRef] [Green Version]

- Ares, E.; Hirst, D. Paris Climate Change Conference; Briefing Paper CPB 7393; House of Commons Library: London, UK, 2015. [Google Scholar]

- Intergovernmental Panel on Climate Change [IPCC]. Global Warming of 1.5 °C—Summary for Policymakers; World Meteorological Organization: Geneva, Switzerland, 2018. [Google Scholar]

- Cohen, R.; Eames, P.C.; Hammond, G.P.; Newborough, M.; Norton, B. The 2021 Glasgow Climate Pact—Steps on the Transition Pathway Towards a Low Carbon World. Proc. Inst. Civil. Eng. Energy 2022, 175, 97–102. [Google Scholar] [CrossRef]

- Gao, Y.; Gao, X.; Zhang, X. The 2 °C global temperature target and the evolution of the long-term goal of addressing climate change—From the United Nations Framework Convention on Climate Change to the Paris Agreement. Engineering 2017, 3, 272–278. [Google Scholar] [CrossRef]

- Hammond, G.P.; Waldron, R. Risk assessment of UK electricity supply in a rapidly evolving energy sector. Proc. Inst. Mech. Eng. Part A J. Power Energy 2008, 222, 623–642. [Google Scholar] [CrossRef]

- Climate Change Act 2008. 2050 Target Amendment Order; Order No. 1056; The Stationary Office Limited: London, UK, 2019. [Google Scholar]

- HM Government [HMG]. Net Zero Strategy: Build Back Greener; Her Majesty’s Stationary Office [HMSO]: London, UK, 2021.

- Buchanan, R.A. The Power of the Machine; Penguin Books: Harmondsworth, UK, 1994. [Google Scholar]

- Hughes, T.P. Networks of Power: Electrification in Western Society 1880–1930; Johns Hopkins University Press: Baltimore, MD, USA, 1983. [Google Scholar]

- Allen, S.R.; Hammond, G.P.; McManus, M.C. Prospects for and barriers to domestic micro-generation: A United Kingdom perspective. Appl. Energy 2008, 85, 528–544. [Google Scholar] [CrossRef]

- Allen, S.R.; Hammond, G.P. Thermodynamic and carbon analyses of micro-generators for UK households. Energy 2010, 35, 2223–2234. [Google Scholar] [CrossRef]

- Hammond, G.P.; Titley, A. Micro-generators: The prospects for combined heat and power systems on a domestic scale. In Proceedings of the ECOS 2011—The 24th International Conference on Efficiency, Cost, Optimization, Simulation and Environmental Impact of Energy Systems, Novi Sad, Serbia, 4–7 July 2011; pp. 1770–1784. [Google Scholar]

- Department for Business, Energy & Industrial Strategy [BEIS]. Digest of United Kingdom Energy Statistics: Annual Data for the UK 2020; The Stationary Office Limited: London, UK, 2021. [Google Scholar]

- Shorrock, L.D.; Utley, J.I. Domestic Energy Factfile; Building Research Establishment (BRE): Watford, UK, 2008. [Google Scholar]

- Allen, S.R.; Cohen, B.; Hammond, G.P. Indicative appraisal of clustered micro-generators for a low-carbon transition in the UK building sector. Glob. Transit. 2020, 2, 83–97. [Google Scholar] [CrossRef]

- Allen, S.R.; Hammond, G.P.; Harajli, H.A.; Jones, C.I.; McManus, M.C.; Winnett, A.B. Integrated appraisal of micro-generators: Methods and applications. Proc. Inst. Civil. Eng. Energy 2008, 161, 73–86. [Google Scholar] [CrossRef]

- Staffell, I.; Baker, P.; Barton, J.P.; Bergman, N.; Blanchard, R.; Brandon, N.P.; Brett, D.J.; Hawkes, A.; Infield, D.; Jardine, C.N.; et al. UK microgeneration. Part II: Technology overviews. Proc. Inst. Civil. Eng. Energy 2010, 163, 143–165. [Google Scholar] [CrossRef] [Green Version]

- Cooper, S.; Hammond, G.P.; McManus, M.C. Thermodynamic efficiency of low-carbon domestic heating systems: Heat pumps and micro-generation. Proc. Inst. Mech. Eng. Part A J. Power Energy 2013, 227, 18–29. [Google Scholar] [CrossRef] [Green Version]

- Cooper, S.J.G.; Hammond, G.P.; McManus, M.C.; Ramallo-Gonzlez, A.; Rogers, J.G. Effect of operating conditions on performance of domestic heating systems with heat pumps and fuel cell micro-cogeneration. Energy Build. 2014, 70, 52–60. [Google Scholar] [CrossRef] [Green Version]

- Cooper, S.J.G.; Hammond, G.P.; McManus, M.C.; Rogers, J.G. Impact on energy requirements and emissions of heat pumps and micro-cogenerators participating in demand side management. Appl. Therm. Eng. 2014, 71, 872–881. [Google Scholar] [CrossRef] [Green Version]

- Stamford, L.; Greening, B.; Azapagic, A. Life cycle environmental and economic sustainability of Stirling engine micro-CHP systems. Energy Technol. 2018, 6, 1119–1138. [Google Scholar] [CrossRef] [Green Version]

- Cheekatamarla, P.; Abu-Heiba, A. A comprehensive review and qualitative analysis of micro-combined heat and power modeling approaches. Energies 2020, 13, 3581. [Google Scholar] [CrossRef]

- De Souza, R.; Casisi, M.; Micheli, D.; Reini, M. A review of small–medium combined heat and power (CHP) technologies and their role within the 100% renewable energy systems scenario. Energies 2021, 14, 5338. [Google Scholar] [CrossRef]

- Cooper, S.J.G.; Dowsett, J.; Hammond, G.P.; McManus, M.C.; Rogers, J.G. Potential of demand side management to reduce carbon dioxide emissions associated with the operation of heat pumps. J. Sustain. Dev. Energy Water Environ. Syst. 2013, 1, 94–108. [Google Scholar] [CrossRef] [Green Version]

- Cooper, S.J.G.; Hammond, G.P.; McManus, M.C.; Pudjianto, D. Detailed simulation of electrical demands due to nationwide adoption of heat pumps, taking account of renewable generation and mitigation. IET Renew. Power Gener. 2016, 10, 380–387. [Google Scholar] [CrossRef] [Green Version]

- Allen, S.R.; Hammond, H.A.; Harajli, H.A.; McManus, M.C.; Winnett, A.B. Integrated appraisal of a solar hot water system. Energy 2010, 35, 1351–1362. [Google Scholar] [CrossRef]

- Hammond, G.P.; Harajli, H.A.; Jones, C.I.; Winnett, A.B. Whole systems appraisal of a UK building integrated photovoltaic (BIPV) system: Energy, environmental, and economic evaluations. Energy Policy 2012, 40, 219–230. [Google Scholar] [CrossRef]

- Allen, S.R.; Hammond, G.P.; McManus, M.C. Energy analysis and environmental life cycle assessment of a micro-wind turbine. Proc. Inst. Mech. Eng. Part A J. Power Energy 2008, 222, 669–684. [Google Scholar] [CrossRef]

- Ellsworth-Krebs, K.; Reid, L. Conceptualising energy prosumption: Exploring energy production, consumption and microgeneration in Scotland, UK. Environ. Plan. A Econ. Space 2016, 48, 1988–2005. [Google Scholar] [CrossRef] [Green Version]

- Bergman, N.; Hawkes, A.; Brett, D.J.; Baker, P.; Barton, J.; Blanchard, R.; Brandon, N.P.; Infield, D.; Jardine, C.; Kelly, N.; et al. UK microgeneration. Part I: Policy and behavioural aspects. Proc. Inst. Civil. Eng. Energy 2009, 162, 23–36. [Google Scholar] [CrossRef] [Green Version]

- Hammond, G.P.; Stapleton, A.J. Exergy analysis of the United Kingdom energy system. Proc. Inst. Mech. Eng. Part A J. Power Energy 2001, 215, 141–162. [Google Scholar] [CrossRef]

- Hammond, G.P.; Winnett, A.B. Interdisciplinary perspectives on environmental appraisal and valuation techniques. Proc. Inst. Civil. Eng. Waste Resour. Manag. 2006, 159, 117–130. [Google Scholar] [CrossRef]

- Hammond, G.P.; Jones, C.I. Sustainability criteria for energy resources and technologies. In Handbook of Sustainable Energy; Galarraga, I., González-Eguino, M., Markandya, A., Eds.; Edward Elgar: Cheltenham, UK, 2011; Chapter 2; pp. 21–46. [Google Scholar]

- Hammond, G.P.; Jones, C.I.; O’Grady, A. Environmental life cycle assessment (LCA) of energy systems. In Handbook of Clean Energy Systems, Vol. 6.—Sustainability of Energy Systems; Yan, J., Ed.; John Wiley and Sons: Chichester, UK, 2015; Chapter 22; pp. 3343–3368. [Google Scholar]

- Foxon, T.J.; Hammond, G.P.; Pearson, P.J.G. Socio-technical transitions in UK electricity: Part 1—History, actors and pathways. Proc. Inst. Civil. Eng. Energy 2020, 173, 109–122. [Google Scholar] [CrossRef]

- Foxon, T.J.; Hammond, G.P.; Pearson, P.J.G. Socio-technical transitions in UK electricity: Part 2—Technologies and sustainability. Proc. Inst. Civil. Eng. Energy 2020, 173, 123–136. [Google Scholar] [CrossRef]

- Hitchin, R. Housepower. Build. Serv. J. 2001, 29–30. Available online: https://en.wikipedia.org/wiki/Horsepower (accessed on 17 August 2022).

- Boardman, B. Home Truths: A Low-Carbon Strategy to Reduce UK Housing Emissions by 80% by 2050; Environmental Change Institute, University of Oxford: Oxford, UK, 2007. [Google Scholar]

- Clarke, J.A. Energy Simulation in Building Design, 2nd ed.; Butterworth-Heinemann: London, UK, 2001. [Google Scholar]

- Thomson, M.; Infield, D. Modelling the impact of micro-combined heat and power generators on electricity distribution networks. Proc. Inst. Mech. Eng. Part A J. Power Energy 2008, 222, 697–706. [Google Scholar] [CrossRef]

- Bonnet, S.; Alaphilippe, M.; Stouffs, P. Energy, exergy and cost analysis of a micro-cogeneration system based on an Ericsson engine. Int. J. Therm. Sci. 2005, 44, 1161–1168. [Google Scholar] [CrossRef]

- Carbon Trust. Micro-CHP Accelerator: Final Report; Carbon Trust: London, UK, 2011. [Google Scholar]

- Hammond, G.P.; Newborough, M. Briefing: Glasgow Climate Pact—A step on the way towards a lower carbon dioxide world. Proc. Inst. Civil. Eng. Civ. Eng. 2022, 175, 8. [Google Scholar]

- HM Government [HMG]. Heat and Buildings Strategy; CP 388; Her Majesty’s Stationary Office [HMSO]: London, UK, 2021. [Google Scholar]

- House of Commons Business, Energy and Industrial Strategy [BEIS] Committee. Decarbonising Heat in Homes; HC 1038; House of Commons: London, UK, 2022.

- Climate Change Act 2008. In Climate; Her Majesty’s Stationery Office: London, UK, 2008; Chapter 27.

- Climate Change Committee [CCC]. Independent Assessment: The UK’s Heat and Buildings Strategy; CCC: London, UK, 2022. [Google Scholar]

- Chapman, P.F. The Milton Keynes Energy Cost Index. Energy Build. 1990, 14, 83–101. [Google Scholar] [CrossRef]

- Building Research Establishment [BRE]. The Government's Standard Assessment Procedure for Energy Rating of Dwellings; BRE: London, UK, 2005. [Google Scholar]

- Forde, J.; Hopfe, C.J.; McLeod, R.S.; Evins, R. Temporal optimization for affordable and resilient Passivhaus dwellings in the social housing sector. Appl. Energy 2020, 261, 114383. [Google Scholar] [CrossRef]

- Hammond, G.P.; Jones, C.I. Embodied energy and carbon in construction materials. Proc. Inst. Civil. Eng. Energy 2008, 161, 87–98. [Google Scholar] [CrossRef] [Green Version]

- Hammond, G.; Jones, C. Embodied Carbon: The Inventory of Carbon and Energy (ICE); Lowrie, F., Tse, P., Eds.; A BSRIA Guide—BG 10/2011; BSRIA Ltd.: Bracknell, UK, 2011. [Google Scholar]

- Roberts, F. The aims, methods and uses of energy accounting. Appl. Energy 1978, 4, 199–217. [Google Scholar] [CrossRef]

- Slesser, M. Energy in the Economy; Macmillan Press: London, UK, 1978. [Google Scholar]

- Boustead, I.; Hancock, G.F. Handbook of Industrial Energy Analysis; Ellis Horwood Ltd.: Chichester, UK, 1979. [Google Scholar]

- Chapman, P.F.; Roberts, F. Metal Resources and Energy; Butterworths: London, UK, 1983. [Google Scholar]

- Heijungs, R.; Guinee, J.B.; Huppes, G.; Lankreijer, R.M.; Udo de Haes, H.A.; Sleeswijk, A. Environmental Life Cycle Assessment of Products—Guide and Background; Report CML 92; Leiden University: Leiden, Belgium, 1992. [Google Scholar]

- Bauman, H.; Tillman, A.-M. The Hitch Hiker’s Guide to LCA: An Orientation in Life Cycle Assessment Methodology and Application; Studentlitteratur: Lund, Sweden, 2004. [Google Scholar]

- Udo de Haes, H.A.; Heijungs, R. Life-cycle assessment for energy analysis and management. Appl. Energy 2007, 84, 817–827. [Google Scholar] [CrossRef]

- Vogtländer, J.G. LCA: A Practical Guide for Students, Designers and Business Managers; VSSD: Delft, The Netherlands, 2010. [Google Scholar]

- Curran, M.A. Life Cycle Assessment Handbook: A Guide for Environmentally Sustainable Products; Wiley-Scrivener: Beverly, CA, USA, 2012. [Google Scholar]

- Klöpffer, W.; Grahl, B. (Eds.) Life Cycle Assessment (LCA): A Guide to Best Practice; Wiley-VCH Verlag GmbH: Weinheim, Germany, 2014. [Google Scholar]

- Hauschild, M.; Rosenbaum, R.K.; Olsen, S. (Eds.) Life Cycle Assessment: Theory and Practice; Springer International Publishing AG: Cham, Switzerland, 2018. [Google Scholar]

- Schebek, L.; Herrmann, C.; Cerdas, F. (Eds.) Progress in Life Cycle Assessment; Springer Nature Switzerland AG: Basel, Switzerland, 2019. [Google Scholar]

- ENO ISO 14040; Environmental Management—Life Cycle Assessment—Principles and Framework, 2nd ed. ISO: Geneva, Switzerland, 2006.

- ENO ISO 14044; Environmental Management—Life Cycle Assessment—Requirements and Guidelines. ISO: Geneva, Switzerland, 2006.

- Short, W.; Packey, D.J.; Holt, T. A Manual for the Economic Evaluation of Energy Efficiency and Renewable Energy Technologies; Report NREL/TP-462-5173; National Renewable Energy Laboratory: Golden, CO, USA, 1995. [Google Scholar]

- Brent, R.J. Applied Cost-Benefit Analysis, 2nd ed.; Edward Elgar Publishing: Cheltenham, UK, 2006. [Google Scholar]

- Snell, M. Cost–Benefit Analysis, 2nd ed.; ICE Publishing: London, UK, 2011. [Google Scholar]

- Götze, U.; Northcott, D.; Schuster, P. Investment Appraisal: Methods and Models; Springer: Berlin, Germany, 2015. [Google Scholar]

- Boardman, A.E.; Greenberg, D.H.; Vining, A.R.; Weimer, D.L. Cost-Benefit Analysis: Concepts and Practice, 5th ed.; Cambridge University Press: Cambridge, UK, 2018. [Google Scholar]

- Watson, J.; Sauter, R.; Bahaj, B.; James, P.; Myers, L.; Wing, R. Domestic micro-generation: Economic, regulatory and policy issues for the UK. Energy Policy 2008, 36, 3095–3106. [Google Scholar] [CrossRef]

- Department for Business, Energy & Industrial Strategy [BEIS]. 2021 Government Greenhouse Gas Conversion Factors for Company Reporting Methodology Paper for Conversion Factors; Final Report; BEIS: London, UK, 2021.

- Research and Markets [RM]. Global Micro Combined Heat and Power (micro-CHP) Market 2021–2025; RM: Dublin, Ireland, 2022. [Google Scholar]

- Global Market Insights [GMI]. Micro Combined Heat and Power Market Statistics By Fuel—Industry Analysis Report, Regional Outlook, Competitive Market Share & Forecast, 2020–2026; GMI: Selbyville, DE, USA, 2020. [Google Scholar]

- Patterson, W. Transforming Electricity: The Coming Generation of Change; Earthscan: London, UK, 1999. [Google Scholar]

- Entchev, E.; Gusdorf, J.; Swinton, M.; Bell, M.; Szadkowski, F.; Kalbfleisch, W.; Marchand, R. Micro-generation technology assessment for housing technology. Energy Build. 2004, 36, 925–931. [Google Scholar] [CrossRef]

- Johnson, V.C.A.; Hall, S. Community energy and equity: The distributional implications of a transition to a decentralised electricity transition. People Place Policy 2014, 8, 149–167. [Google Scholar]

- Nikas, A.; Stavrakas, V.; Arsenopoulos, A.; Doukas, H.; Antosiewicz, M.; Witajewski-Baltvilks, J.; Flamos, A. Barriers to and consequences of a solar-based energy transition in Greece. Environ. Innov. Soc. Transit. 2020, 35, 383–399. [Google Scholar] [CrossRef]

- Brisbois, M.C. Decentralised energy, decentralised accountability? Lessons on how to govern decentralised electricity transitions from multi-level natural resource governance. Glob. Transit. 2020, 2, 16–25. [Google Scholar] [CrossRef]

- Rosato, A.; Ciervo, A.; Ciampi, G.; Scorpio, M.; Sibilio, S. Integration of micro-cogeneration units and electric storages into a micro-scale residential solar district heating system operating with a seasonal thermal storage. Energies 2020, 13, 5456. [Google Scholar] [CrossRef]

- Rosato, A.; Ciervo, A.; Ciampi, G.; Scorpio, M.; Guarino, F.; Sibilio, S. Energy, environmental and economic dynamic assessment of a solar hybrid heating network operating with a seasonal thermal energy storage serving an Italian small-scale residential district: Influence of solar and back-up technologies. Therm. Sci. Eng. Prog. 2020, 19, 100591. [Google Scholar] [CrossRef]

- Brandoni, C.; Renzi, M.; Caresana, F.; Polonara, F. Simulation of hybrid renewable microgeneration systems for variable electricity prices. Appl. Therm. Eng. 2014, 71, 667–676. [Google Scholar] [CrossRef]

- Entchev, E.; Yang, L.; Ghorab, M.; Lee, E.J. Performance analysis of a hybrid renewable microgeneration system in load sharing applications. Appl. Therm. Eng. 2014, 71, 697–704. [Google Scholar] [CrossRef]

- Yang, L.; Entchev, E.; Ghorab, M.; Lee, E.J.; Kang, E.C. Energy and cost analyses of a hybrid renewable microgeneration system serving multiple residential and small office buildings. Appl. Therm. Eng. 2014, 65, 477–486. [Google Scholar] [CrossRef]

- Balcombe, P.; Rigby, D.; Azapagic, A. Environmental impacts of microgeneration: Integrating solar PV, Stirling engine CHP and battery storage. Appl. Energy 2015, 139, 245–259. [Google Scholar] [CrossRef]

- Energy Saving Trust [EST]. Pathway Beyond Zero Carbon Homes; EST: London, UK, 2006. [Google Scholar]

- Ecoinvent. Ecoinvent Database [v3.8]; Ecoinvent: Zurich, Switzerland, 2021. [Google Scholar]

| Strengths | Weaknesses |

|---|---|

| Holistic environmental appraisal | Static/Snapshot assessments |

| Established international standards | Variation in assessment due to value choice/methodological approaches |

| Procedural transparency | Only predefined environmental impacts assessed |

| Allows level playing field for comparison | A target for sustainable activity not specified only embodied impacts quantified |

| Pinpoints environmental/inefficient hotspots | Data quality |

| Springboard for communication | Inaccessible results |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hammond, G.P.; Titley, A.A. Small-Scale Combined Heat and Power Systems: The Prospects for a Distributed Micro-Generator in the ‘Net-Zero’ Transition within the UK. Energies 2022, 15, 6049. https://doi.org/10.3390/en15166049

Hammond GP, Titley AA. Small-Scale Combined Heat and Power Systems: The Prospects for a Distributed Micro-Generator in the ‘Net-Zero’ Transition within the UK. Energies. 2022; 15(16):6049. https://doi.org/10.3390/en15166049

Chicago/Turabian StyleHammond, Geoffrey P., and Adam A. Titley. 2022. "Small-Scale Combined Heat and Power Systems: The Prospects for a Distributed Micro-Generator in the ‘Net-Zero’ Transition within the UK" Energies 15, no. 16: 6049. https://doi.org/10.3390/en15166049

APA StyleHammond, G. P., & Titley, A. A. (2022). Small-Scale Combined Heat and Power Systems: The Prospects for a Distributed Micro-Generator in the ‘Net-Zero’ Transition within the UK. Energies, 15(16), 6049. https://doi.org/10.3390/en15166049