Effects of Confining Pressure and Hydrostatic Pressure on the Fracturing of Rock under Cyclic Electrohydraulic Shock Waves

Abstract

:1. Introduction

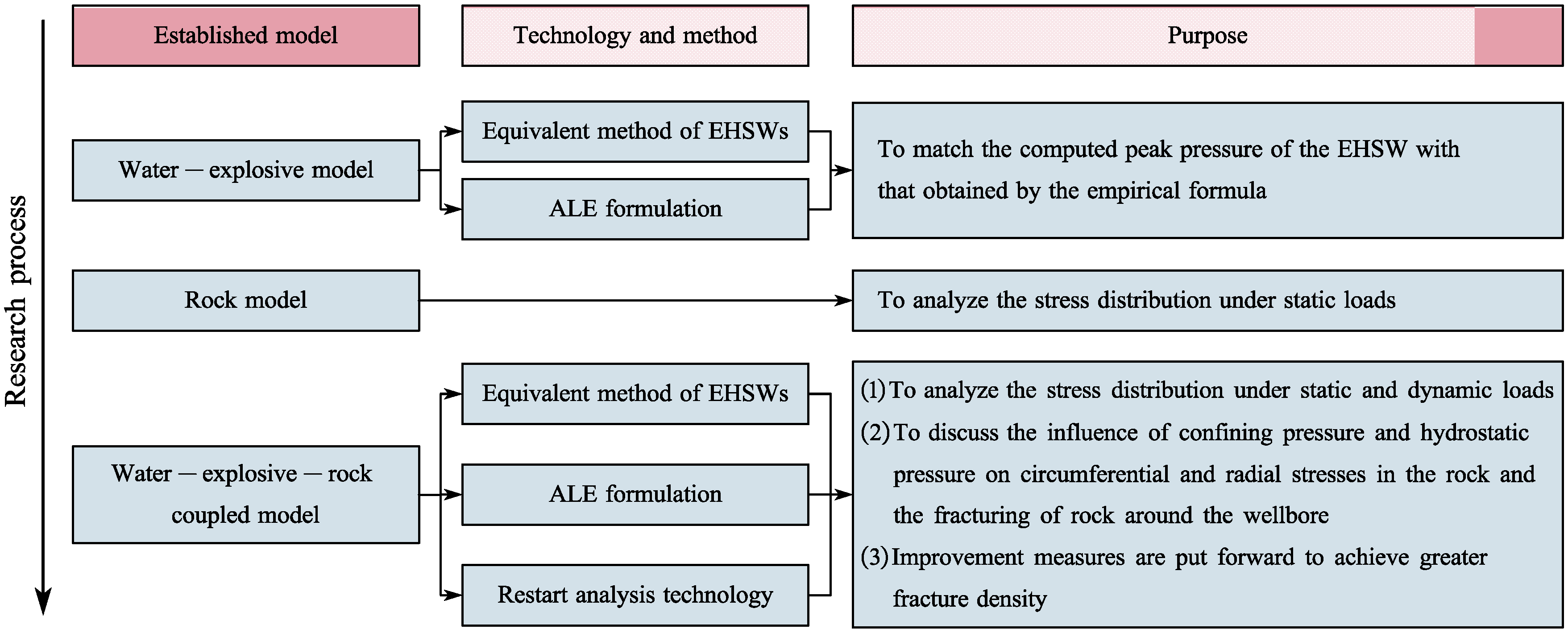

2. Descriptions of Simulation Methods and Material Parameters

2.1. Equivalent Method of EHSWs

2.2. Arbitrary Lagrangian–Eulerian Formulation

2.3. Simulation of Cumulative Damage

2.4. Material Models

2.4.1. Water

2.4.2. TNT

2.4.3. Rock

3. Numerical Investigation

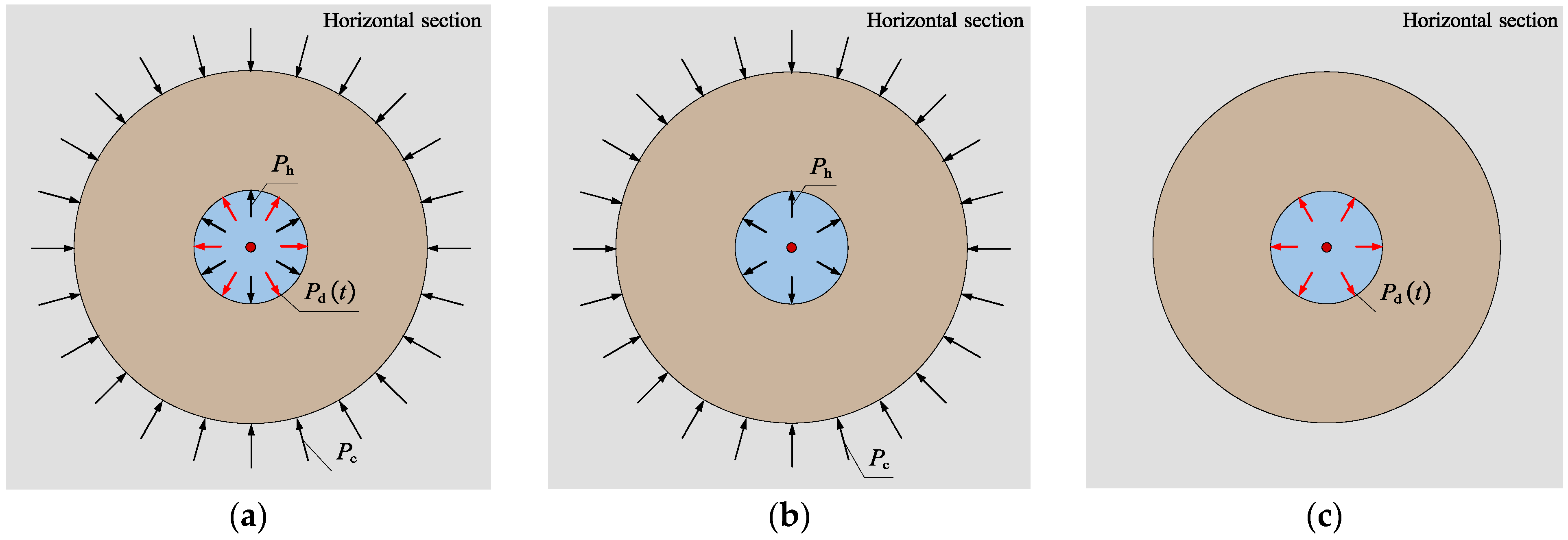

3.1. Model Simplification

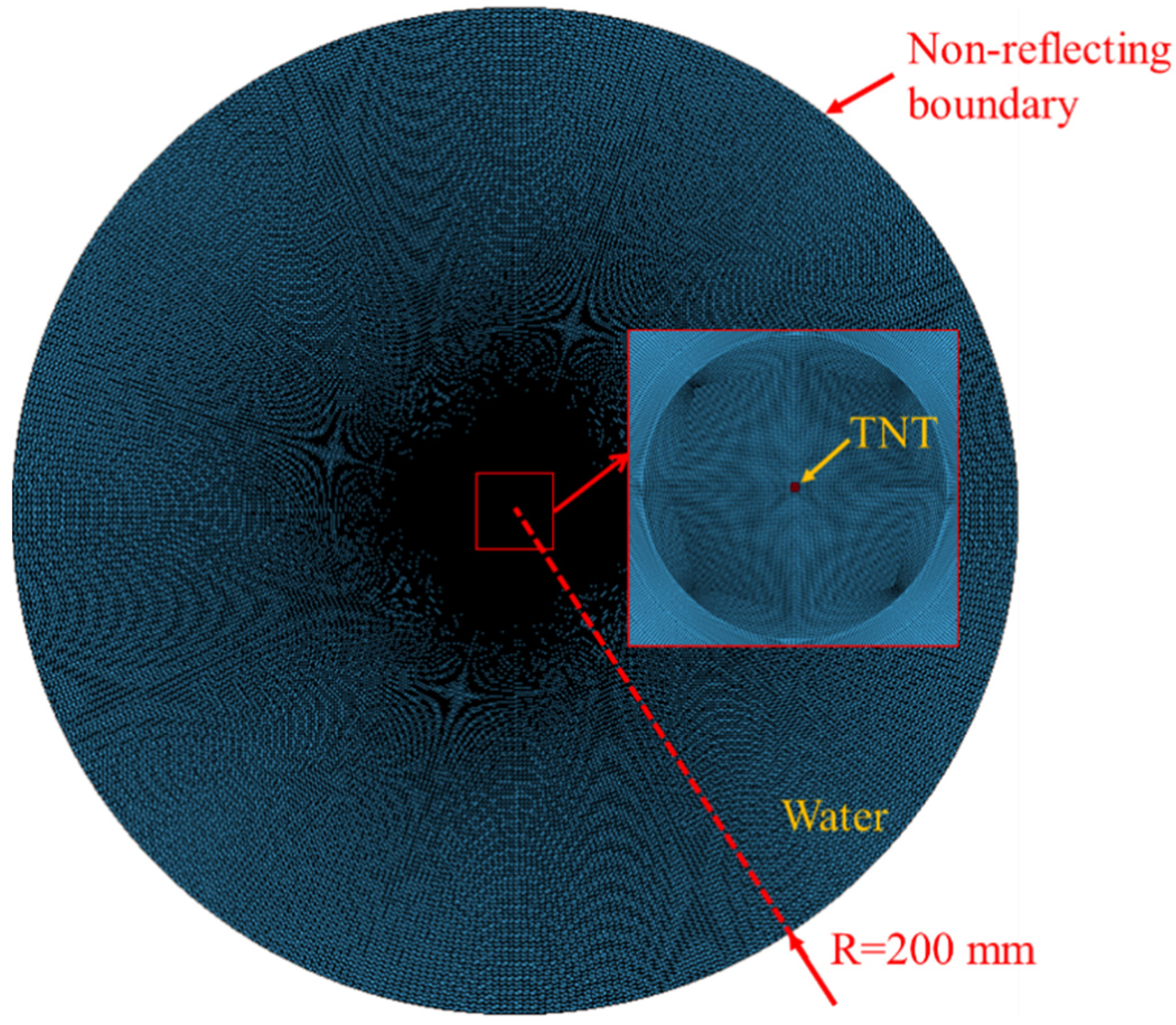

3.2. Parameter Calibration for the Peak Pressure of the EHSW

- (a)

- Firstly, the required discharge parameters was determined. According to the typical discharge waveform provided in reference [15], the breakdown voltage is 30.1 kV and the capacitance is 3 μF, and then the discharge energy EB could be calculated to be 1.36 kJ according to the formula . By substituting EB into Formula (1), the peak pressure of shock waves under different distance from the charge center could be obtained.

- (b)

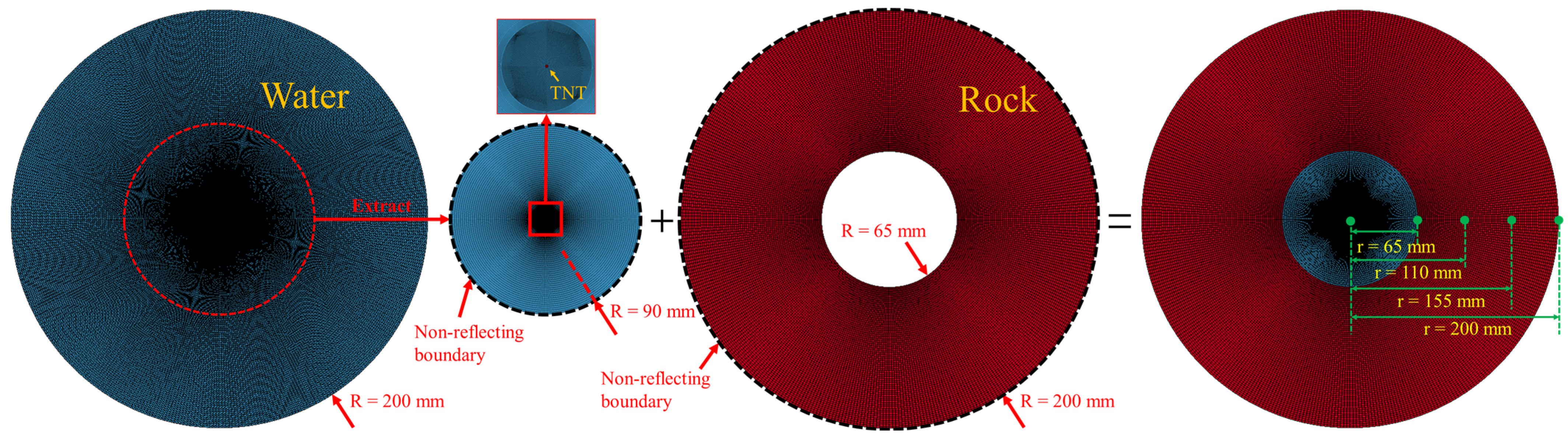

- Secondly, a 2D numerical model for a free-field underwater explosion was established. The 2D model was a cylinder with a single layer of solid mesh, as shown in Figure 4. The radius of the cylinder was 200 mm. All materials were modeled by the Euler grid. A non-reflecting boundary was applied at the truncating boundaries of the water.

- (c)

- Finally, a large number of trial calculations were carried out by adjusting the radius of the spherical charge and the first-order artificial viscosity coefficient, in order to match the numerical results as well as possible to the results calculated by Formula (1).

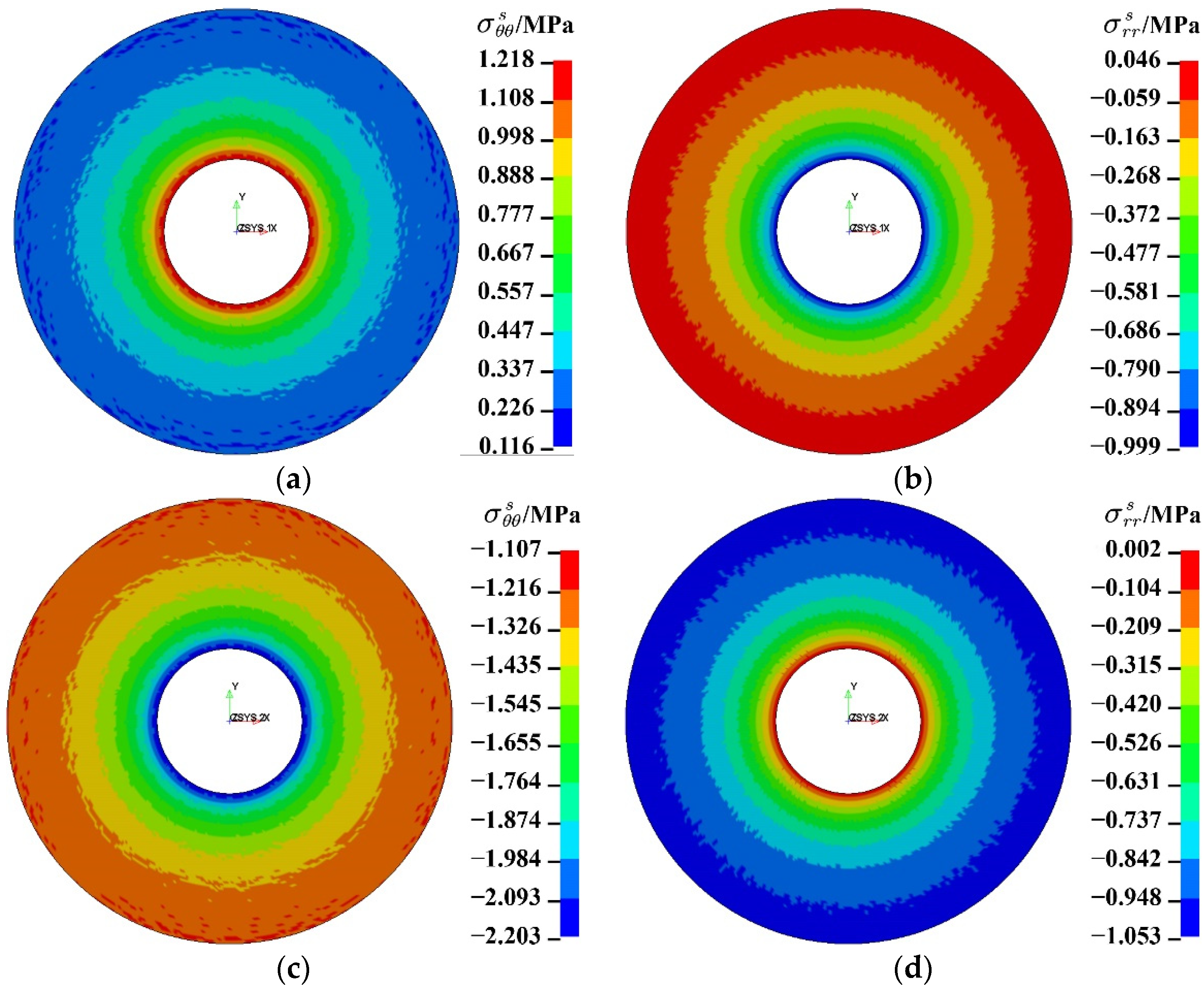

3.3. Stress Distributions under Static Loads

3.4. Stress Distributions under Static and Dynamic Loads

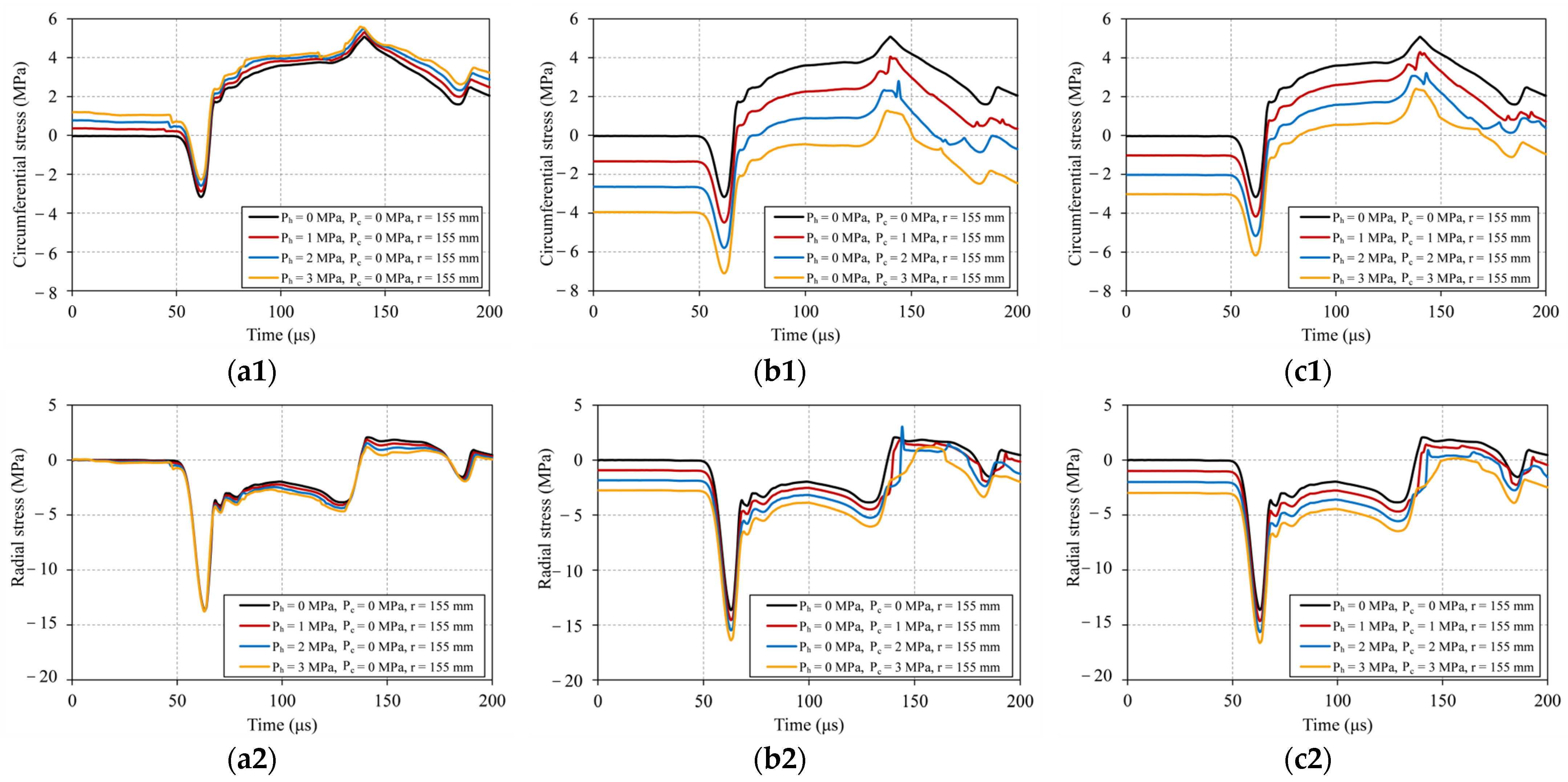

3.5. Effects of Confining Pressure and Hydrostatic Pressure on Circumferential and Radial Stresses

- (a)

- Case 1: Pc = 0 MPa; Ph = 0, 1, 2 or 3 MPa. This case is used to investigate the effect of Ph.

- (b)

- Case 2: Pc = 0, 1, 2 or 3 MPa; Ph = 0 MPa. This case is used to investigate the effect of Pc.

- (c)

- Case 3: Pc = Ph = 0, 1, 2 or 3 MPa. This case is used to investigate the degrees of influence of Ph and Pc.

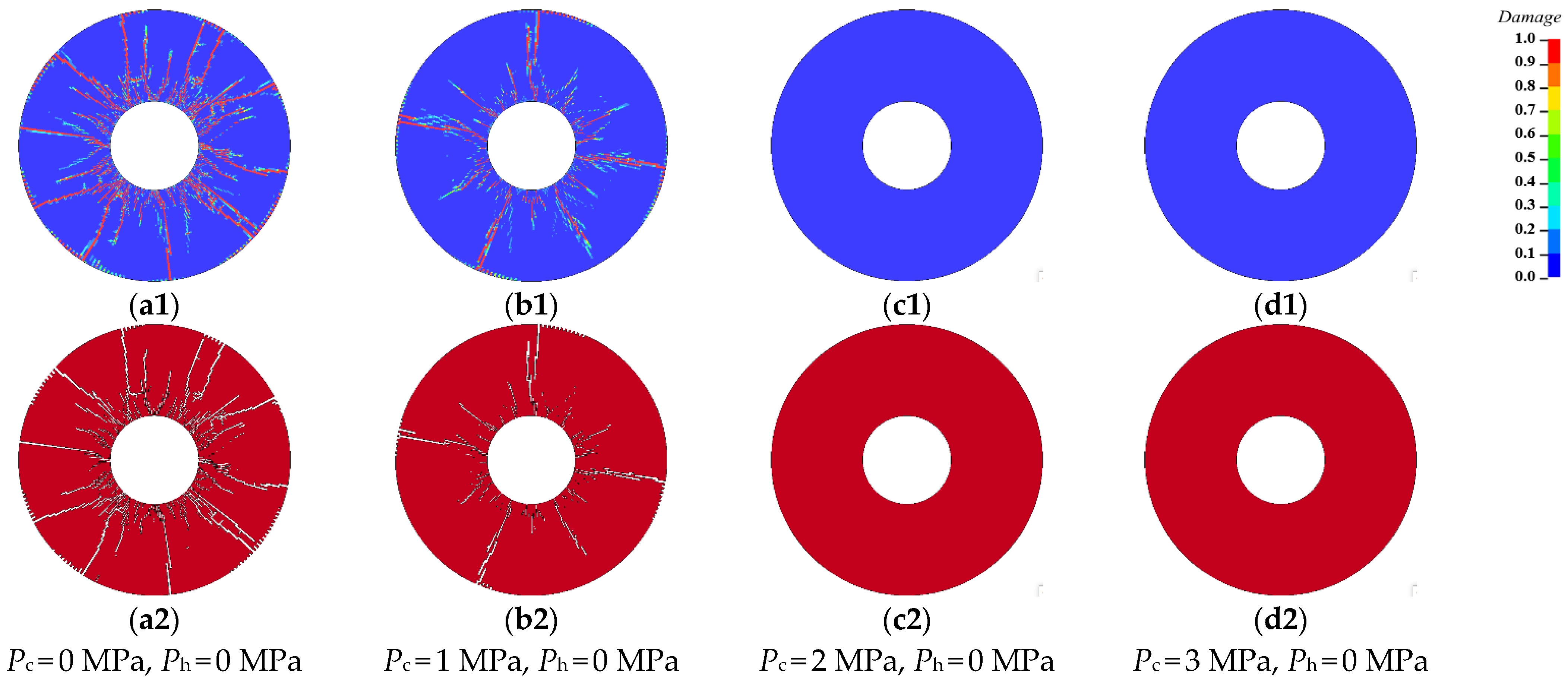

3.6. Effects of Confining Pressure and Hydrostatic Pressure on the Fracturing of the Rock

4. Improvement Measures

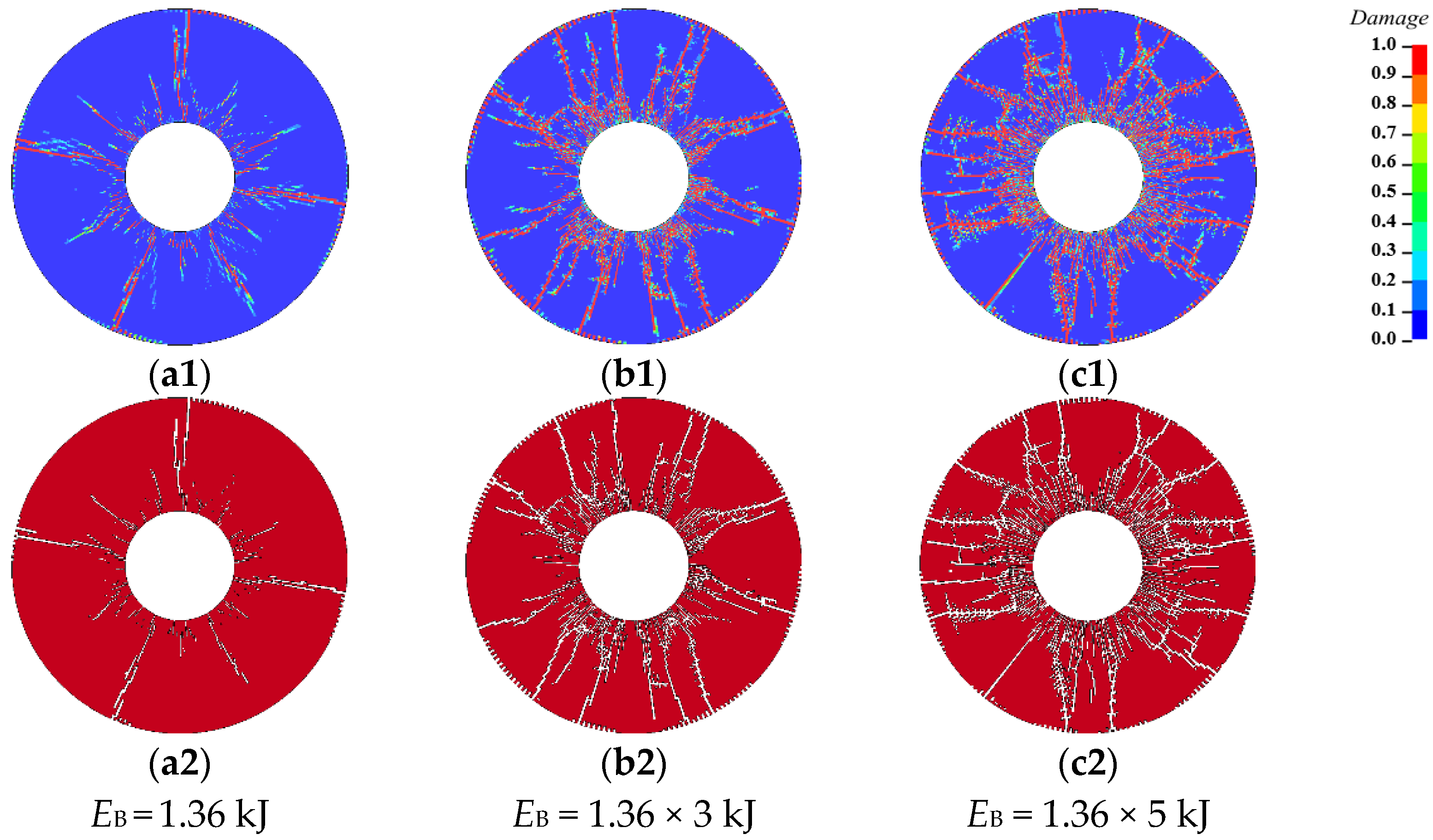

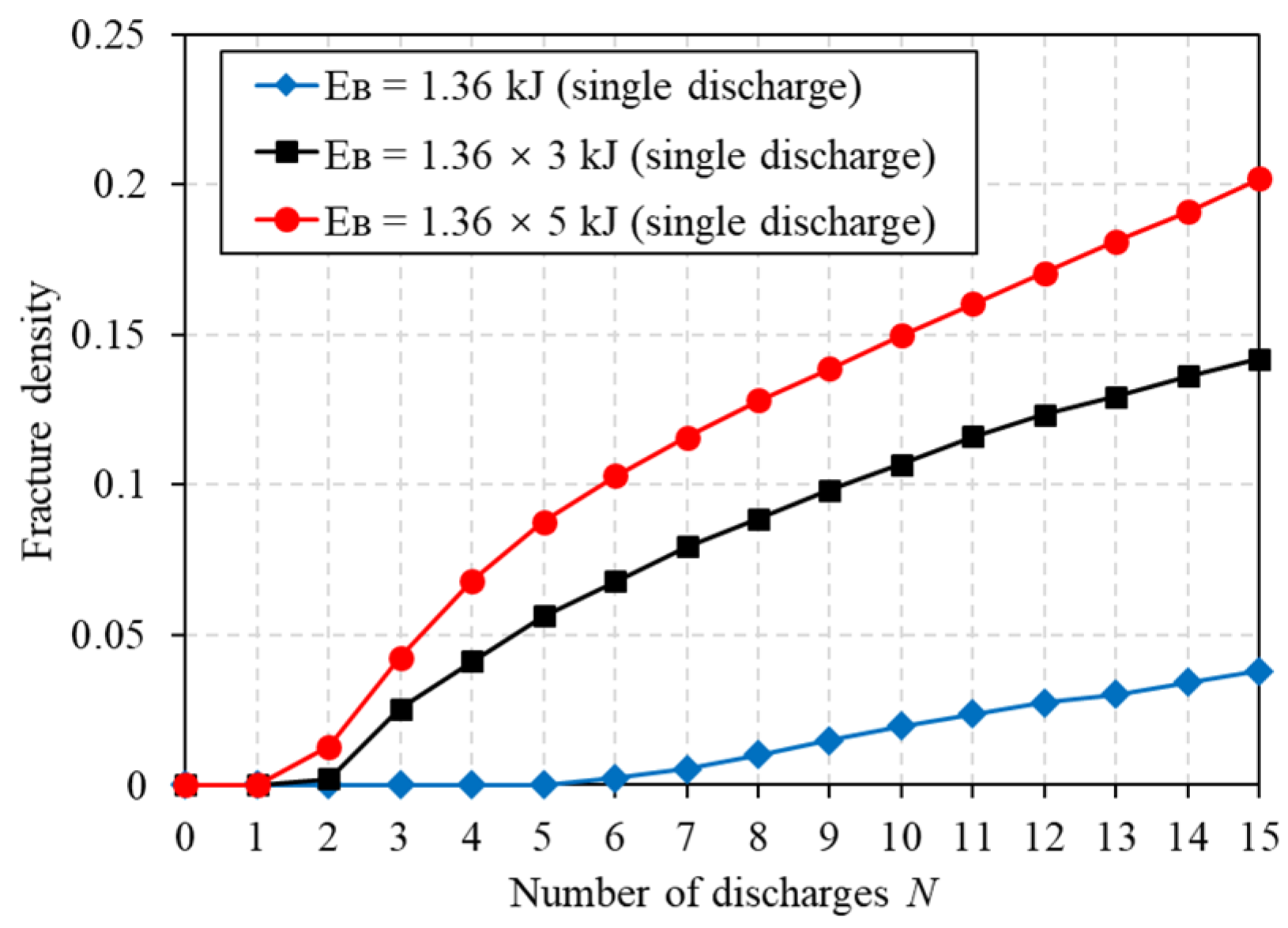

4.1. Effects of the Discharge Energy

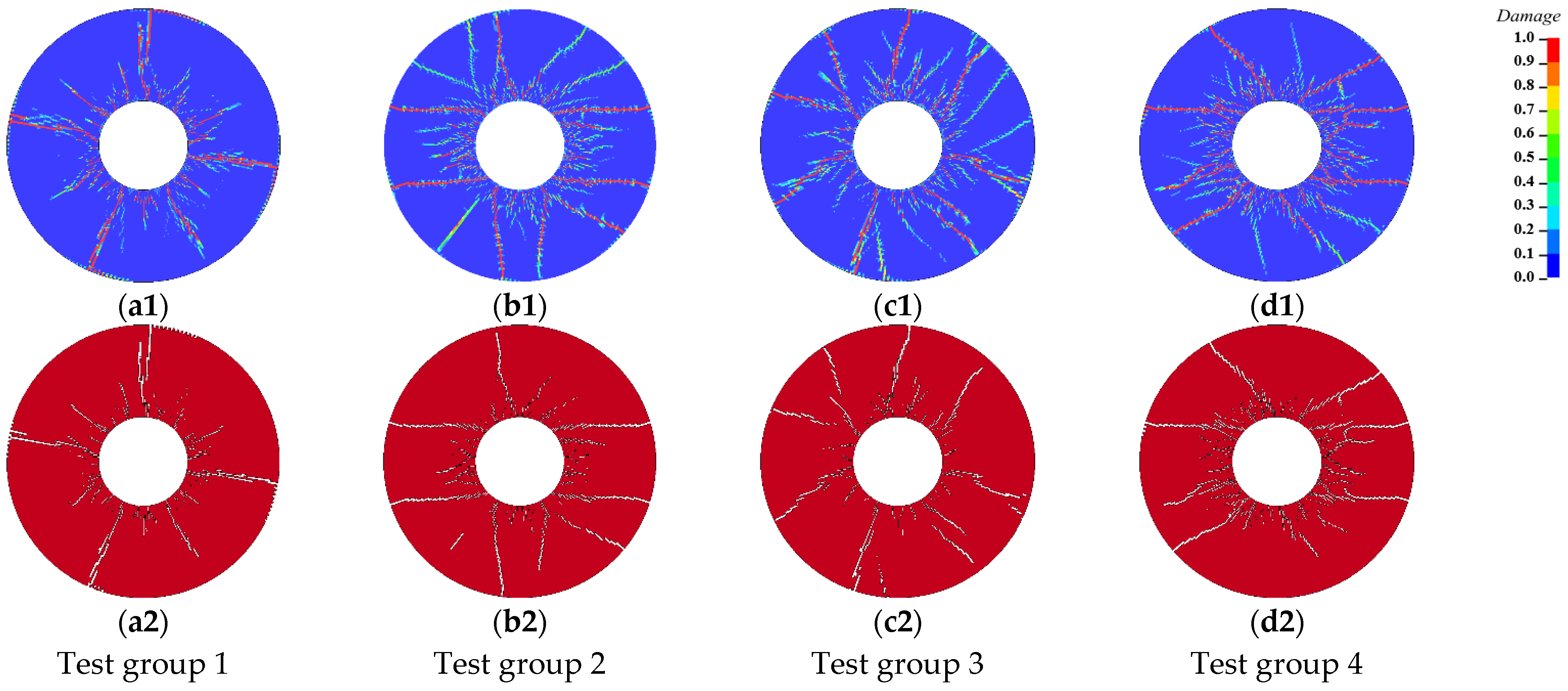

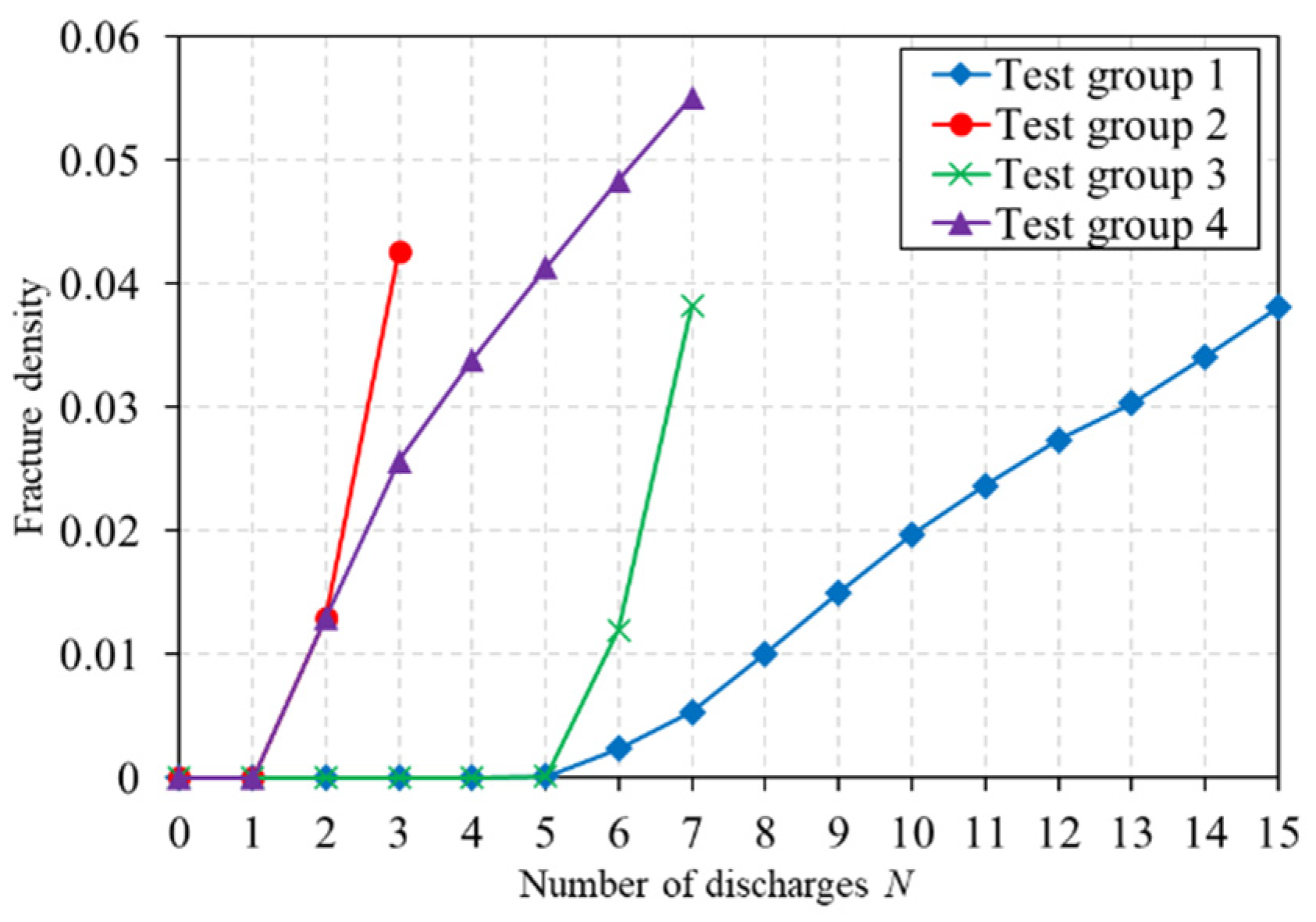

4.2. Effects of Repetitive Loading Modes

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| EHSWs | electrohydraulic shock waves |

| PFC | Particle Flow Code |

| TNT | trinitrotoluene |

| ALE | Arbitrary Lagrangian–Eulerian |

| EOS | equation of state |

| JWL | Jones–Wilkins–Lee |

| RHT | Riedel–Hiermaier–Thoma |

References

- Woo, M.; Noh, H.; An, W.; Song, W.; Kang, B.; Kim, J. Numerical study on electrohydraulic forming process to reduce the bouncing effect in electromagnetic forming. Int. J. Adv. Manuf. Technol. 2017, 89, 1813–1825. [Google Scholar] [CrossRef]

- Jomni, F.; Aitken, F.; Denat, A. Experimental investigation of transient pressure waves produced in dielectric liquids. J. Acoust. Soc. Am. 2000, 107, 1203–1211. [Google Scholar] [CrossRef] [PubMed]

- Rassweiler, J.J.; Knoll, T.; Köhrmann, K.; Mcateer, J.A.; Lingeman, J.E.; Cleveland, R.O.; Bailey, M.R.; Chaussy, C. Shock wave technology and application: An update. Eur. Urol. 2011, 59, 784–796. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mao, R.; De Pater, H.; Leon, J.F.; Fram, J.; Storslett, S.; Ewy, R.; Stefani, J. Experiments on pulse power fracturing. In Proceedings of the SPE Western Regional Meeting, Bakersfield, CA, USA, 21–23 March 2012. [Google Scholar] [CrossRef]

- Montgomery, C.T.; Smith, M.B. Hydraulic fracturing: History of an enduring technology. J. Pet. Technol. 2010, 62, 26–40. [Google Scholar] [CrossRef]

- Chen, W.; Maurel, O.; Reess, T.; De Ferron, A.S.; La Borderie, C.; Pijaudier-Cabot, G.; Rey-Bethbeder, F.; Jacques, A. Experimental study on an alternative oil stimulation technique for tight gas reservoirs based on dynamic shock waves generated by pulsed arc electrohydraulic discharges. J. Petrol. Sci. Eng. 2012, 88–89, 67–74. [Google Scholar] [CrossRef]

- Liu, S.; Liu, Y.; Ren, Y.; Lin, F.; Liu, Y. Characteristic analysis of plasma channel and shock wave in electrohydraulic pulsed discharge. Phys. Plasmas 2019, 26, 93509. [Google Scholar] [CrossRef]

- Li, D.; Chen, L.; Lin, Y.; Ding, Y. Advances in the technology of explosion in fractures used in low permeability reservoirs. Strateg. Study CAE 2010, 12, 52–57. [Google Scholar] [CrossRef]

- Liu, B.; Wang, D.; Guo, Y. Effect of circuit parameters and environment on shock waves generated by underwater electrical wire explosion. IEEE Trans. Plasma Sci. 2017, 45, 2519–2526. [Google Scholar] [CrossRef]

- Cai, Z.; Zhang, H.; Liu, K.; Chen, Y.; Yu, Q. Experimental investigation and mechanism analysis on rock damage by high voltage spark discharge in water: Effect of electrical conductivity. Energies 2020, 13, 5432. [Google Scholar] [CrossRef]

- Ren, F.; Ge, L.; Arami-Niya, A.; Rufford, T.E.; Xing, H.; Rudolph, V. Gas storage potential and electrohydraulic discharge (ehd) stimulation of coal seam interburden from the surat basin. Int. J. Coal Geol. 2019, 208, 24–36. [Google Scholar] [CrossRef]

- Ren, F.; Ge, L.; Stelmashuk, V.; Rufford, T.E.; Xing, H.; Rudolph, V. Characterisation and evaluation of shockwave generation in water conditions for coal fracturing. J. Nat. Gas. Sci. Eng. 2019, 66, 255–264. [Google Scholar] [CrossRef]

- Li, H.; Yu, D.; Sun, W.; Liu, D.; Li, J.; Han, X.; Li, Z.; Sun, B.; Wu, Y. State-of-the-art of atmospheric discharge plasmas. High Volt. Eng. 2016, 42, 3697–3727. [Google Scholar] [CrossRef]

- Bian, D.; Zhao, J.; Niu, S.; Wu, J. Rock fracturing under pulsed discharge homenergic water shock waves with variable characteristics and combination forms. Shock. Vib. Deep. Min. Sci. 2018, 2018, 6236953. [Google Scholar] [CrossRef] [Green Version]

- Xiong, L.; Liu, Y.; Yuan, W.; Huang, S.; Liu, H.; Li, H.; Lin, F.; Pan, Y. Experimental and numerical study on the cracking characteristics of repetitive electrohydraulic discharge shock waves. J. Phys. D Appl. Phys. 2020, 53, 495502. [Google Scholar] [CrossRef]

- Bendezu, M.; Romanel, C.; Roehl, D. Finite element analysis of blast-induced fracture propagation in hard rocks. Comput. Struct. 2017, 182, 1–13. [Google Scholar] [CrossRef]

- Xie, L.X.; Lu, W.B.; Zhang, Q.B.; Jiang, Q.H.; Wang, G.H.; Zhao, J. Damage evolution mechanisms of rock in deep tunnels induced by cut blasting. Tunn. Undergr. Space Technol. 2016, 58, 257–270. [Google Scholar] [CrossRef]

- Park, H.; Lee, S.; Kim, T.; Kim, N. Numerical modeling of ground borehole expansion induced by application of pulse discharge technology. Comput. Geotech. 2011, 38, 532–545. [Google Scholar] [CrossRef]

- Wakeland, P.; Kincy, M.; Garde, J. Hydrodynamic loading of structural components due to electrical discharge in fluids. In Proceedings of the 14th IEEE International Pulsed Power Conference (IEEE Cat. No.03CH37472), Dallas, TX, USA, 15–18 June 2003; pp. 925–928. [Google Scholar] [CrossRef]

- Lu, X.; Zhang, H.; Pan, T.; Liu, K.; Liu, M. Study on the pressure characteristics of pulsed discharge in water. Explos. Shock Waves 2001, 21, 282–286. [Google Scholar] [CrossRef]

- Touya, G.; Reess, T.; Pécastaing, L.; Gibert, A.; Domens, P. Development of subsonic electrical discharges in water and measurements of the associated pressure waves. J. Phys. D Appl. Phys. 2006, 39, 5236–5244. [Google Scholar] [CrossRef]

- Cole, R.H.; Weller, R. Underwater explosions. Phys. Today 1948, 1, 35. [Google Scholar] [CrossRef]

- Hu, L.; Huang, R.; Li, S.; Qin, J.; Wang, J.; Rong, G. Shock wave simulation of underwater explosion. Chin. J. High Press. Phys. 2020, 34, 102–114. [Google Scholar] [CrossRef]

- Wang, J.; Yin, Y.; Esmaieli, K. Numerical simulations of rock blasting damage based on laboratory-scale experiments. J. Geophys. Eng. 2018, 15, 2399–2417. [Google Scholar] [CrossRef]

- De, A.; Niemiec, A.; Zimmie, T.F. Physical and numerical modeling to study effects of an underwater explosion on a buried tunnel. J. Geotech. Geoenviron. 2017, 143, 4017002. [Google Scholar] [CrossRef]

- Shin, Y.S.; Lee, M.; Lam, K.Y.; Yeo, K.S. Modeling mitigation effects of watershield on shock waves. Shock Vib. 1998, 5, 225–234. [Google Scholar] [CrossRef] [Green Version]

- Lee, E.L.; Hornig, H.C.; Kury, J.W. Adiabatic Expansion of High Explosive Detonation Products; University of California Radiation Lab: Livermore, CA, USA, 1968. [Google Scholar] [CrossRef] [Green Version]

- Borrvall, T.; Riedel, W. The RHT concrete model in ls-dyna. In Proceedings of the 8th European LS-DYNA User Conference, Strasbourg, France, 23–24 May 2011. [Google Scholar]

- Riedel, W.; Thoma, K.; Hiermaier, S.; Schmolinske, E. Penetration of reinforced concrete by beta-b-500 numerical analysis using a new macroscopic concrete model for hydrocodes. In Proceedings of the 9th International Symposium on Interaction of the Effects of Munitions with Structures, Berlin-Strausberg, Germany, 3–7 May 1999. [Google Scholar]

- Yang, J.; Liu, K.; Li, X.; Liu, Z. Stress initialization methods for dynamic numerical simulation of rock mass with high in-situ stress. J. Cent. South Univ. 2020, 27, 3149–3162. [Google Scholar] [CrossRef]

- Lu, M.; Luo, X. Foundations of Elasticity (i), 2nd ed; Tsinghua University Press: Beijing, China, 2001. [Google Scholar]

- Yi, C.P.; Johansson, D.; Greberg, J. Effects of in-situ stresses on the fracturing of rock by blasting. Comput. Geotech. 2018, 104, 321–330. [Google Scholar] [CrossRef]

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| Mass density RO (kg/m3) | 2.314 | Porosity exponent NP | 3.0 |

| Initial porosity ALPHA | 1.1884 | Reference compressive strain-rate EOC | 3 × 10−5 |

| Crush pressure PEL (MPa) | 23.3 | Reference tensile strain rate EOT | 3 × 10−6 |

| Compaction pressure PCO (GPa) | 0.6 | Break compressive strain rate EC | 3 × 1025 |

| Hugoniot polynomial coefficient A1 (GPa) | 35.27 | Break tensile strain rate ET | 3 × 1025 |

| Hugoniot polynomial coefficient A2 (GPa) | 39.58 | Compressive strain rate dependence exponent BETAC | 0.032 |

| Hugoniot polynomial coefficient A3 (GPa) | 9.04 | Tensile strain rate dependence exponent BETAT | 0.036 |

| Parameter for polynomial EOS B0 | 1.22 | Volumetric plastic strain fraction in tension PTF | 0.001 |

| Parameter for polynomial EOS B1 | 1.22 | Compressive yield surface parameter GC* | 0.53 |

| Parameter for polynomial EOS T1 (GPa) | 35.27 | Tensile yield surface parameter GT* | 0.7 |

| Parameter for polynomial EOS T2 | 0 | Erosion plastic strain EPSF | 2.0 |

| Elastic shear modulus SHEAR (GPa) | 16.7 | Shear modulus reduction factor XI | 0.5 |

| Compressive strength FC (MPa) | 35 | Damage parameter D1 | 0.04 |

| Relative tensile strength FT* | 0.1 | Damage parameter D2 | 1 |

| Relative shear strength FS* | 0.18 | Minimum damaged residual strain EPM | 0.01 |

| Failure surface Parameter A | 1.6 | Residual surface parameter AF | 1.6 |

| Failure surface Parameter N | 0.61 | Residual surface parameter AN | 0.61 |

| Lode angle dependence factor Q0 | 0.6805 | Gruneisen gamma GAMMA | 0 |

| Lode angle dependence factor B | 0.0105 |

| Test Group | First Level | Second Level | Total Energy EB |

|---|---|---|---|

| 1 | 15 times (1.36 × 1 kJ) | 0 | 1.36 × 15 kJ |

| 2 | 3 times (1.36 × 5 kJ) | 0 | 1.36 × 15 kJ |

| 3 | 5 times (1.36 × 1 kJ) | 2 times (1.36 × 5 kJ) | 1.36 × 15 kJ |

| 4 | 2 times (1.36 × 5 kJ) | 5 times (1.36 × 1 kJ) | 1.36 × 15 kJ |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, Q.; Zhang, H.; Yang, R.; Cai, Z.; Liu, K. Effects of Confining Pressure and Hydrostatic Pressure on the Fracturing of Rock under Cyclic Electrohydraulic Shock Waves. Energies 2022, 15, 6032. https://doi.org/10.3390/en15166032

Yu Q, Zhang H, Yang R, Cai Z, Liu K. Effects of Confining Pressure and Hydrostatic Pressure on the Fracturing of Rock under Cyclic Electrohydraulic Shock Waves. Energies. 2022; 15(16):6032. https://doi.org/10.3390/en15166032

Chicago/Turabian StyleYu, Qing, Hui Zhang, Ruizhi Yang, Zhixiang Cai, and Kerou Liu. 2022. "Effects of Confining Pressure and Hydrostatic Pressure on the Fracturing of Rock under Cyclic Electrohydraulic Shock Waves" Energies 15, no. 16: 6032. https://doi.org/10.3390/en15166032

APA StyleYu, Q., Zhang, H., Yang, R., Cai, Z., & Liu, K. (2022). Effects of Confining Pressure and Hydrostatic Pressure on the Fracturing of Rock under Cyclic Electrohydraulic Shock Waves. Energies, 15(16), 6032. https://doi.org/10.3390/en15166032