Techno-Economic Analysis and Life Cycle Assessment of Pineapple Leaves Utilization in Costa Rica

Abstract

:1. Introduction

2. Materials and Methods

2.1. Feedstock and Location of the Biorefinery

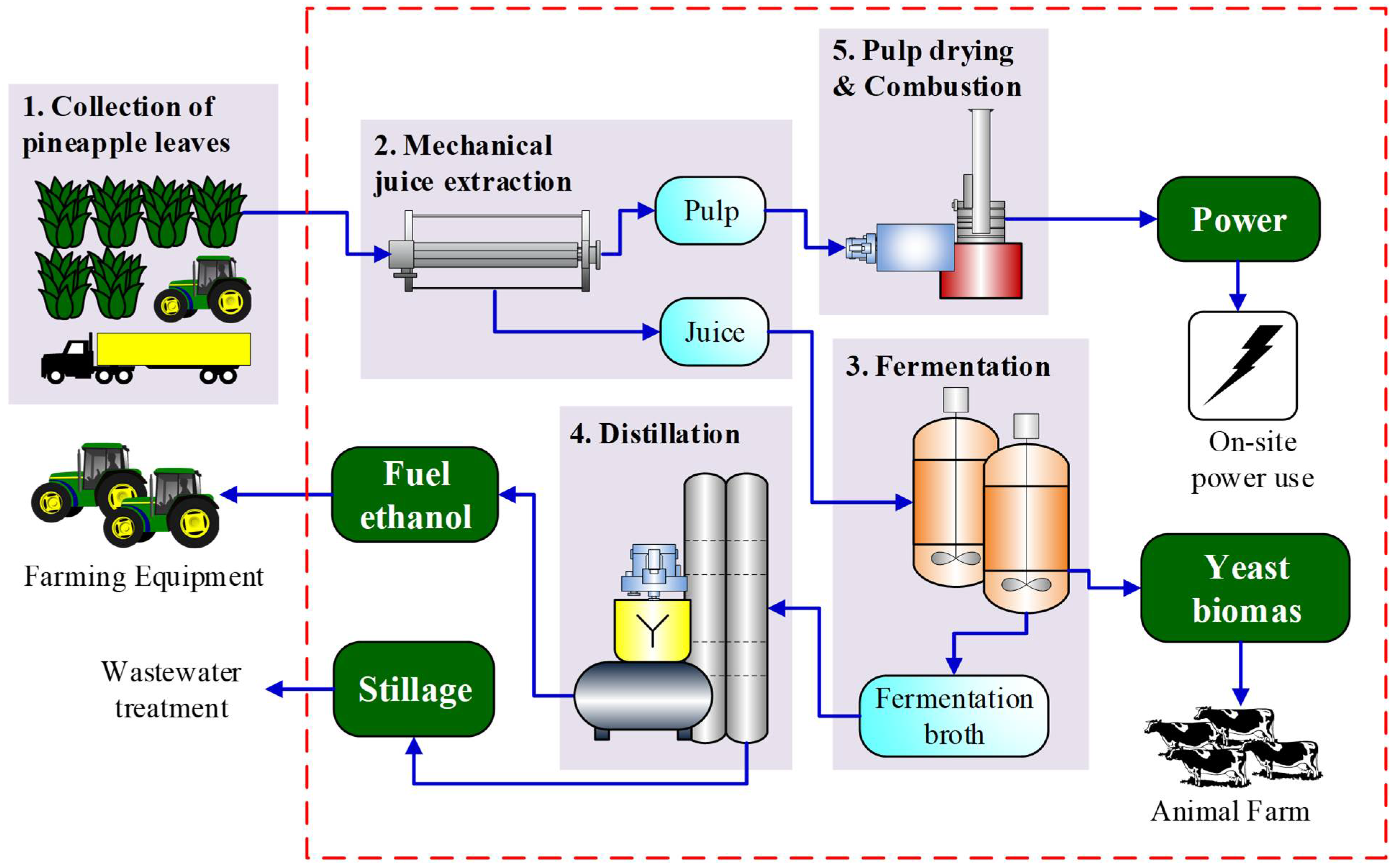

2.2. The Biorefinery of Pineapple Leaf Utilization

2.3. Economic Assessment

2.4. Life Cycle Assessment

3. Results and Discussion

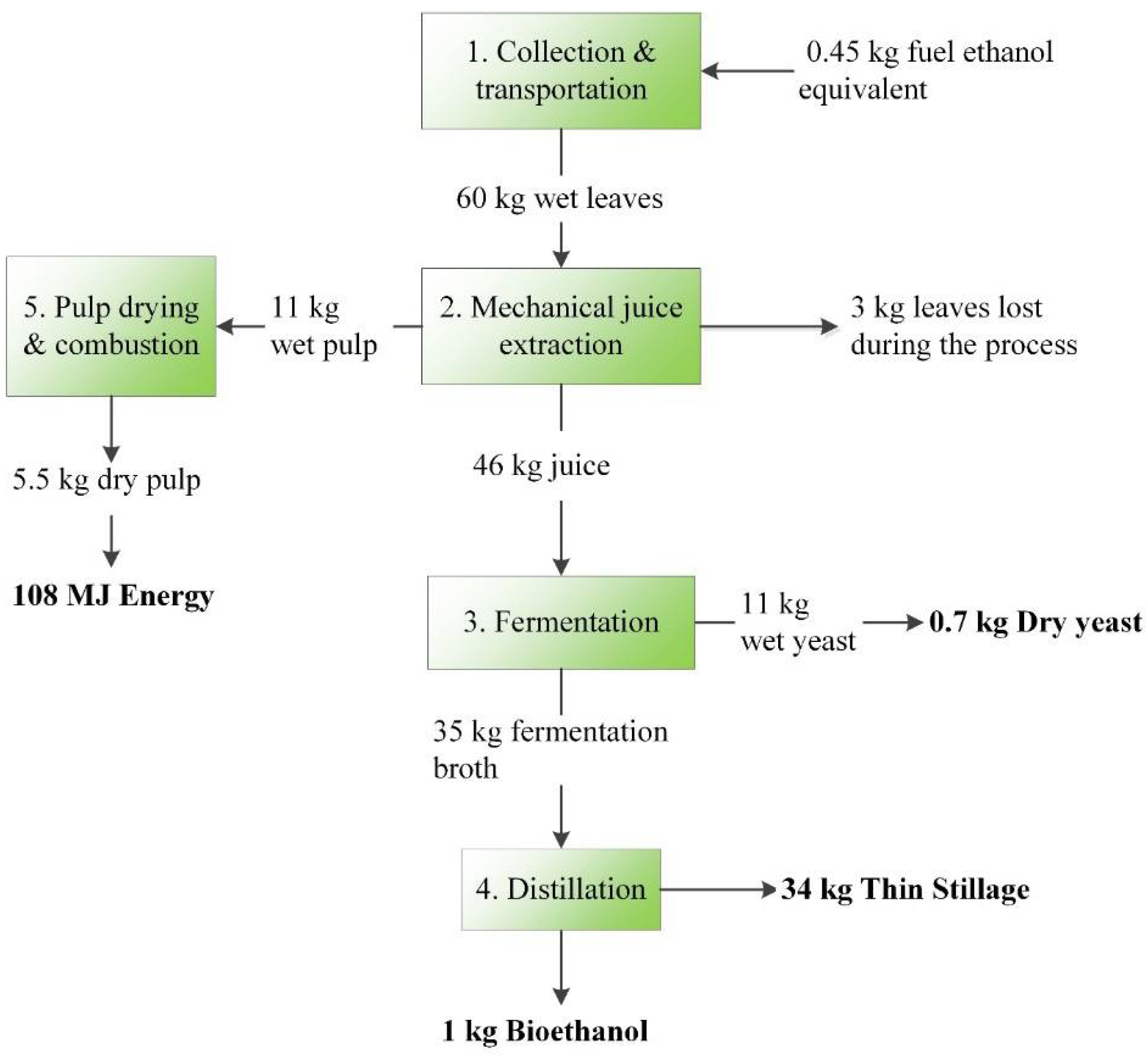

3.1. Mass and Energy Balance

3.2. Economic Analysis

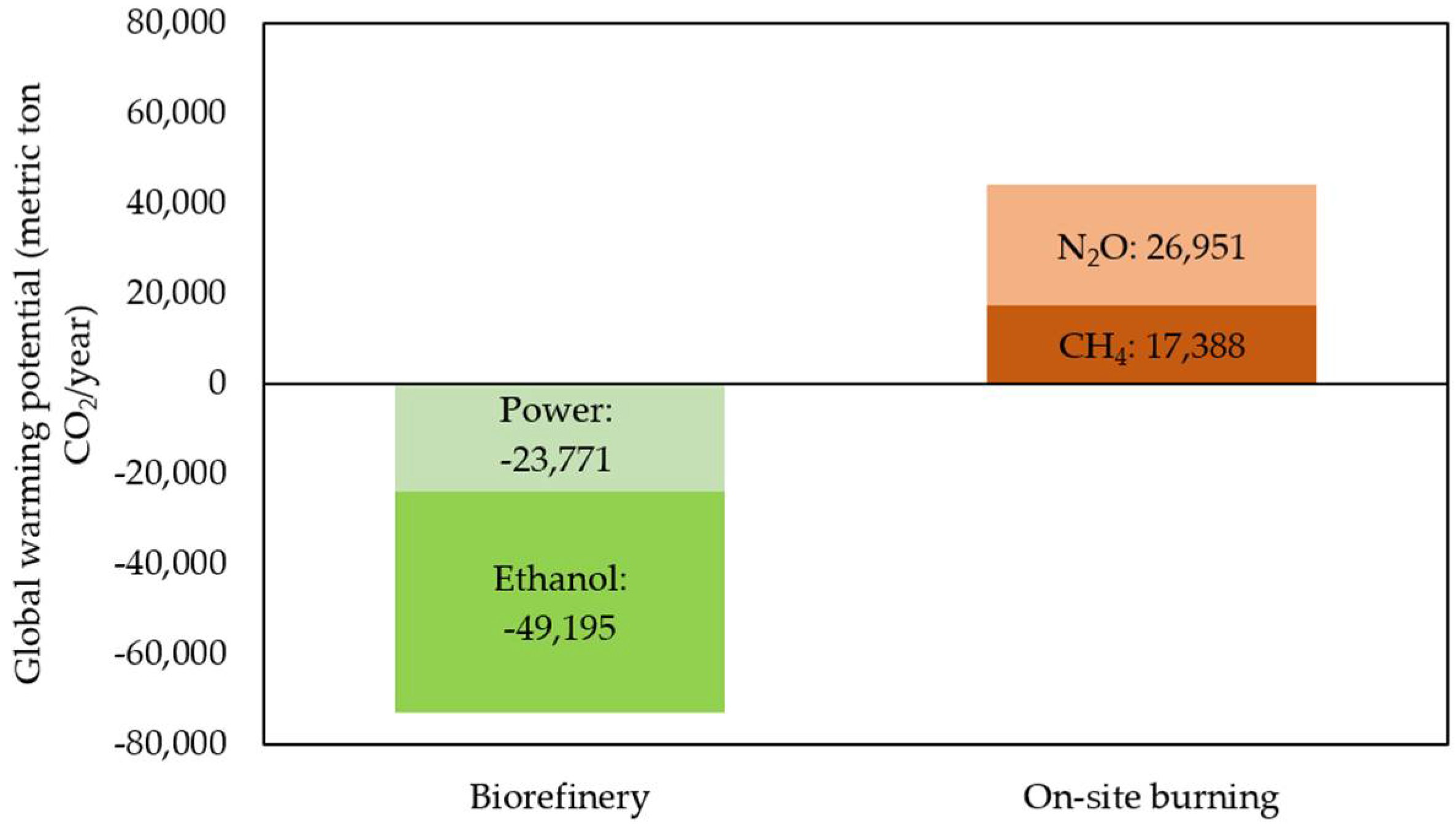

3.3. Life Cycle Assessment

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chaves, A. Exportaciones de Piña Cayeron en el 2020, Piña de Costa Rica. 2021, p. 4. Available online: https://www.pinadecostarica.com (accessed on 14 March 2022).

- Solorzano, J.-A.; Gilles, J.; Bravo, O.; Vargas, C.; Gomez-Bonilla, Y.; Bingham, G.V.; Taylor, D.B. Biology and Trapping of Stable Flies (Diptera: Muscidae) Developing in Pineapple Residues (Ananas comosus) in Costa Rica. J. Insect Sci. 2015, 15, 145. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Okoli, I.C. Pineapple Wastes 3: Use of Leaves, Stem, and Crown as Animal Feed. 2020. Available online: https://researchtropica.com/pineapple-wastes-3-use-of-leaves-stem-and-crown-as-animal-feed/ (accessed on 10 December 2021).

- Zainuddin, M.F.; Shamsudin, R.; Mokhtar, M.N.; Ismail, D. Physicochemical Properties of Pineapple Plant Waste Fibers from the Leaves and Stems of Different Varieties. Bioresources 2014, 9, 5311–5324. [Google Scholar] [CrossRef] [Green Version]

- Roda, A.; Lambri, M. Food uses of pineapple waste and by-products: A review. Int. J. Food Sci. Technol. 2019, 54, 1009–1017. [Google Scholar] [CrossRef]

- Cheok, C.Y.; Adzahan, N.M.; Rahman, R.A.; Abedin, N.H.Z.; Hussain, N.; Sulaiman, R.; Chong, G.H. Current trends of tropical fruit waste utilization. Crit. Rev. Food Sci. Nutr. 2018, 58, 335–361. [Google Scholar] [CrossRef] [PubMed]

- Asim, M.; Abdan, K.; Jawaid, M.; Nasir, M.; Dashtizadeh, Z.; Ishak, M.R.; Hoque, M.E. A Review on Pineapple Leaves Fibre and Its Composites. Int. J. Polym. Sci. 2015, 2015, 950567. [Google Scholar] [CrossRef] [Green Version]

- Chen, A.; Guan, Y.J.; Bustamante, M.; Uribe, L.; Uribe-Lorio, L.; Roos, M.M.; Liu, Y. Production of renewable fuel and value-added bioproducts using pineapple leaves in Costa Rica. Biomass Bioenergy 2020, 141, 105675. [Google Scholar] [CrossRef]

- Pires, E.B.E.; de Freitas, A.J.; Souza, F.F.E.; Salgado, R.L.; Guimaraes, V.M.; Pereira, F.A.; Eller, M.R. Production of Fungal Phytases from Agroindustrial Byproducts for Pig Diets. Sci. Rep. 2019, 9, 9256. [Google Scholar] [CrossRef]

- Alves, E.D.P.; Morioka, L.R.I.; Suguimoto, H.H. Comparison of bioethanol and beta-galactosidase production by Kluyveromyces and Saccharomyces strains grown in cheese whey. Int. J. Dairy Technol. 2019, 72, 409–415. [Google Scholar] [CrossRef]

- Santharam, L.; Samuthirapandi, A.B.; Easwaran, S.N.; Mahadevan, S. Modeling of exo-inulinase biosynthesis by Kluyveromyces marxianus in fed-batch mode: Correlating production kinetics and metabolic heat fluxes. Appl. Microbiol. Biotechnol. 2017, 101, 1877–1887. [Google Scholar] [CrossRef]

- Fonseca, G.G.; Heinzle, E.; Wittmann, C.; Gombert, A.K. The yeast Kluyveromyces marxianus and its biotechnological potential. Appl. Microbiol. Biotechnol. 2008, 79, 339–354. [Google Scholar] [CrossRef]

- Maccaferri, S.; Klinder, A.; Brigidi, P.; Cavina, P.; Costabile, A. Potential Probiotic Kluyveromyces marxianus B0399 Modulates the Immune Response in Caco-2 Cells and Peripheral Blood Mononuclear Cells and Impacts the Human Gut Microbiota in an In Vitro Colonic Model System. Appl. Environ. Microbiol. 2012, 78, 956–964. [Google Scholar] [CrossRef] [Green Version]

- CANAPEP, Estadísticas CANAPEP, 2020. Available online: https://canapep.com/estadisticas/. (accessed on 29 June 2021).

- Andalib, M.; Hafez, H.; Elbeshbishy, E.; Nakhla, G.; Zhu, J. Treatment of thin stillage in a high-rate anaerobic fluidized bed bioreactor (AFBR). Bioresour. Technol. 2012, 121, 411–418. [Google Scholar] [CrossRef] [PubMed]

- Quintero, J.A.; Cardona, C.A. Process Simulation of Fuel Ethanol Production from Lignocellulosics using Aspen Plus. Ind. Eng. Chem. Res. 2011, 50, 6205–6212. [Google Scholar] [CrossRef]

- Humbird, D.; National Renewable Energy Laboratory (U.S.); Harris Group Inc. Process Design and Economics for Biochemical Conversion of Lignocellulosic Biomass to Ethanol Dilute-Acid Pretreatment and Enzymatic Hydrolysis of Corn Stover; Nrel/Tp 5100-47764; National Renewable Energy Laboratory: Golden, CO, USA, 2011; 136p. [Google Scholar]

- Amos, W. Report on Biomass Drying Technology; National Renewable Energy Laboratory: Golden, CO, USA, 1998. [Google Scholar]

- Tax Reform Bill of 1986: Text of H.R. 3838 Reported by the Senate Finance Committee on 29 May 1986: Released 2 June 1986. Illinois: Commerce Clearing House, 1986. Available online: https://www.congress.gov/bill/99th-congress/house-bill/3838 (accessed on 1 June 2022).

- Curran, M. Life Cycle Assessment: Principles and Practice; Scientific Applications International Corporation (SAIC): Reston, VA, USA, 2016. [Google Scholar]

- Bare, J. TRACI—The Tool for the Reduction and Assessment of Chemical and Other Environmental Impacts. J. Ind. Ecol. 2003, 6, 49–78. [Google Scholar] [CrossRef]

- Visschedijka, A.; Pacynab, J.; Pullesa, T.; Zandvelda, P.; Denier van der Gon, H. Coordinated European particulate matter emission inventory program (CEPMEIP). In Proceedings of the PM Emission Inventories Scientific Workshop, Lago Maggiore, Italy, 18 October 2004. [Google Scholar]

- Tieppo, R.C.; Andrea, M.C.S.; Gimenez, L.M.; Romanelli, T.L. Energy demand in sugarcane residue collection and transportation. Agric. Eng. Int. CIGR J. 2014, 2014, 52–58. [Google Scholar]

- Zanotti, M.; Ruan, Z.H.; Bustamente, M.; Liu, Y.; Liao, W. A sustainable lignocellulosic biodiesel production integrating solar- and bio-power generation. Green Chem. 2016, 18, 5059–5068. [Google Scholar] [CrossRef]

- Katzen, R.; Madson, P.; Moon, G., Jr. Ethanol Distillation: The Fundamentals. The Alcohol Textbook: A Reference for the Beverage, Fuel and Industrial Alcohol Industries; Jacques, K.A., Lyons, T.P., Kelsall, D.R., Eds.; Alltech Inc.: Nottingham, UK, 1999. [Google Scholar]

- Gu, Y.; Li, Y.; Li, X.; Luo, P.; Wang, H.; Wang, X.; Wu, J.; Li, F. Energy self-sufficient wastewater treatment plants: Feasibilities and challenges. Energy Procedia 2017, 105, 3741–3751. [Google Scholar] [CrossRef]

- Bustamante, M.; Liao, W. A self-sustaining high-strength wastewater treatment system using solar-bio-hybrid power generation. Bioresour. Technol. 2017, 234, 415–423. [Google Scholar] [CrossRef] [Green Version]

- RECOPE. Precios Vigentes, Refinadora Costarricense de Petróleo. 2022. Available online: https://www.recope.go.cr/productos/precios-nacionales/tabla-precios/ (accessed on 11 June 2022).

- ARESEP. Tarifas Vigentes de Electricidad, Autoridad Reguladora de los Servios Públicos. 2022. Available online: https://aresep.go.cr/electricidad/tarifas (accessed on 11 June 2022).

- MTSS. Lista de Salaries Mínimos del Sector Privado, Ministerio de Trabajo y Seguridad Social. 2022. Available online: https://www.mtss.go.cr/temas-laborales/salarios/lista-salarios.html (accessed on 11 June 2022).

- Romero-Perez, J.C.; Vergara, L.; González-Delgado, Á.D. Development of a Methodology for the Synthesis of Biorefineries Based on Incremental Economic and Exergetic Return on Investment. ACS Omega 2021, 6, 6112–6123. [Google Scholar] [CrossRef]

- Chen, R.; Rojas-Downing, M.M.; Zhong, Y.; Saffron, C.M.; Liao, W. Life Cycle and Economic Assessment of Anaerobic Co-digestion of Dairy Manure and Food Waste. Ind. Biotechnol. 2015, 11, 127–139. [Google Scholar] [CrossRef]

- IPCC. 2006 IPCC Guidelines for National Greenhouse Gas Inventories, Prepared by the National Greenhouse Gas Inventories Programme; Eggleston, H.S., Buendia, L., Miwa, K., Ngara, T., Tanabe, K., IPCC, Eds.; Institute for Global Environmental Strategies (IGES): Hayama, Japan, 2006. [Google Scholar]

- CCME. NOx/VOC Fact Sheets; Canadian Council of Ministers of the Environment (CCME), Ed.; Canadian Council of Ministers of the Environment (CCME): Ottawa, ON, Canada, 1998. [Google Scholar]

- Prosperi, P.; Bloise, M.; Tubiello, F.N.; Conchedda, G.; Rossi, S.; Boschetti, L.; Salvatore, M.; Bernoux, M. New estimates of greenhouse gas emissions from biomass burning and peat fires using MODIS Collection 6 burned areas. Clim. Chang. 2020, 161, 415–432. [Google Scholar] [CrossRef] [Green Version]

- Climate Change 2014: Mitigation of Climate Change: Working Group III contribution to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change; Cambridge University Press: New York, NY, USA, 2014.

- Darley, E.; Lerman, S. Air Pollutant Emissions from Burning Sugar Cane and Pineapple Residues from Hawaii; Environmental Protection Agency, Research Triangle Park: Research Triangle, NC, USA, 1975. [Google Scholar]

- Bare, J. TRACI 2.0: The tool for the reduction and assessment of chemical and other environmental impacts 2.0. Clean Technol. Environ. Policy 2011, 13, 687–696. [Google Scholar] [CrossRef]

| Parameter | Leaf | Juice | Pulp |

|---|---|---|---|

| Total solids (%) | 13.8 | 6.2 | 51.6 |

| Cellulose (%TS) | 22.6 | -- | 36.8 |

| Hemicellulose (%TS) | 26.1 | -- | 28.1 |

| Lignin (%TS) | 7.3 | -- | 5.1 |

| Crude protein (%TS) | 6.9 | 14 | 5.7 |

| Crude fat (%TS) | 3.0 | 3.5 | 4.0 |

| Potassium (%TS) | 2.6 | 3.76 | 0.56 |

| Nitrogen (%TS) | 1.1 | 2.24 | 0.912 |

| Phosphorus (%TS) | 0.11 | 0.18 | 0.08 |

| Sulfur (%TS) | 0.13 | 0.21 | 0.06 |

| Ash (%TS) | 6.1 | 10.02 | 1.65 |

| Energy Demand | Energy (MJ/kg Ethanol Produced) |

|---|---|

| 1. Leaves collection and transportation c | −12.0 |

| 2. Mechanical juice extraction d | −23.6 |

| 3. Fermentation e | −18.5 |

| 4. Distillation f | −18.5 |

| 5. Pulp drying and combustion g | −14.7 |

| 6. Yeast drying g | −26.5 |

| 7. Wastewater treatment of stillage h | −0.51 |

| Energy Production | Energy (MJ/kg Ethanol Produced) |

| 3. Fermentation i | 8.9 |

| 4. Distillation j | 10.9 |

| 3. Distilled ethanol k | 26.7 |

| 5. Pulp combustion l | 106.7 |

| Overall Energy Balance | |

| Net energy m | 38.9 |

| Parameter | Value |

|---|---|

| Pineapple plantation (hectare) | 44,500 |

| Leaf residue production (wet metric ton/year) a | 5,562,500 |

| Total ethanol production (metric ton/year) | 92,708 |

| Dry yeast biomass (metric ton/year) | 64,859 |

| Potential energy generation (GJ/year) b | 9,892,019 |

| Electricity generation (GJ/year) c | 2,924,872 |

| Net energy generation (GJ/year) d | 1,066,523 |

| Capital Expenditure (CapEx) | Unit Cost (USD) | Unit | Cost (USD) | Reference |

|---|---|---|---|---|

| Juice extraction a | 50,000 | 2 | 1,000,000 | - |

| Ethanol fermentation b | 7,800,743 | 1 | 7,800,743 | [16] |

| Ethanol distillation b | 4,348,701 | 1 | 4,348,701 | [16] |

| Pulp drying c | 816,200 | 1 | 816,200 | [18] |

| Yeast drying c | 1,293,380 | 1 | 1,293,380 | [18] |

| Boiler and generator d | 50,809,782 | 1 | 50,809,782 | [17] |

| Utilities e | 1,885,782 | 1 | 1,885,782 | [17] |

| Wastewater treatment plant f | 13,501,106 | 1 | 13,501,106 | [17] |

| Added direct and indirect cost (45% of total CapEx) g | 66,645,568 | 1 | 66,645,568 | [17] |

| Total CapEx | 148101262 | |||

| Operational Expenditure (OpEx) | Unit Cost | Unit | Cost (USD) | Reference |

| Diesel fuel for leaves collection and transportation h | 0.94 USD/kg for collection 21.53 USD/kg for transportation | 11,601,343 kg/year for collection 1,584,402 kg/year for transportation | 44,965,768 USD/year | [28] |

| Electricity for the juice extraction | 0.15 USD/kWh | 328,333,324 kWh/year | 49,250,197 USD/year | [29] |

| Electricity for the fermentation | 0.15 USD/kWh | 35,593,107 kWh/year | 5,338,966 USD/year | [29] |

| Electricity for the distillation | 0.15 USD/kWh | 5,050,167 kWh/year | 757,525 USD/year | [29] |

| Electricity for the pulp drying | 0.15 USD/kWh | 3,990,419 kWh/year | 598,563 USD/year | [29] |

| Electricity for the yeast drying | 0.15 USD/kWh | 7,216,700 kWh/year | 1,082,505 USD/year | [29] |

| Electricity for the wastewater treatment | 0.15 USD/kWh | 7,036,140 kg/year | 1,055,421 USD/year | [29] |

| Maintenance i | - | - | 1,629,114 USD/year | - |

| Labor Cost | Unit Cost (USD) | Unit | Cost (USD) | Reference |

| Plant manager | 50,000/employee /year | 1 employee | 50,000 /year | [30] |

| Plant engineer | 40,000/employee /year | 2 employees | 80,000 /year | [30] |

| Maintenance supervisor | 30,000/employee /year | 1 employee | 30,000 /year | [30] |

| Maintenance technician | 25,000/employee /year | 8 employees | 200,000 /year | [30] |

| Lab manager | 30,000/employee /year | 1 employee | 30,000 /year | [30] |

| Lab technician | 20,000/employee /year | 3 employees | 60,000 /year | [30] |

| Shift supervisor | 20,000/employee /year | 4 employees | 80,000 /year | [30] |

| Shift operator | 15,000/employee /year | 16 employees | 240,000 /year | [30] |

| Yard employee | 10,000/employee /year | 2 employees | 20,000 /year | [30] |

| Clerk and secretary | 15,000/employee /year | 2 employees | 30,000 /year | [30] |

| Labor burden j | 738,000 /year | |||

| Total labor cost | 1,558,000 /year | |||

| Total OpEX | 106,236,059 /year | |||

| Revenue | Unit Cost | Unit | Cost (USD) | Reference |

| Ethanol | 1.11 USD/kg | 50,000,000 kg/year | 55,500,000 /year | Current price |

| Dry yeast | 0.5 USD/kg | 35,000,000 kg/year | 17,500,000 /year | Current price |

| Electricity for national grid k | 0.15 USD/kWh | 438,183,086 kWh/year | 65,727,463 /year | Current price |

| Total revenue | 138,727,463 /year | |||

| Net revenuel | 32,491,404 /year | |||

| Payback time (years) m | 4.72 |

| Item | Base Value | Sensitivity Range | Change on Dynamic Payback Period |

|---|---|---|---|

| CapEx of the boiler/generator | USD 5,080,9782 | USD 38,107,337–63,512,228 | 16.5%–16.5% |

| CapEx of the wastewater treatment | USD 13,501,106 | USD 10,125,829–16,876,382 | 4.4%–4.4% |

| OpEx of the collection and transportation | 44,965,768 USD/year | USD 33,724,326–56,207,210 | 26.1%–52.3% |

| OpEx of the juice extraction | 49,250,197 USD/year | USD 36,937,648–61,562,746 | 28%–60.4% |

| Process | Item | Value | Unit | Reference |

|---|---|---|---|---|

| Raw material inventory | Pineapple leaves (wet amount) | 3,000,000 | Metric ton/year | - |

| Total solids (TS) of pineapple leaves | 13.8 | % | - | |

| On-site burning (Control) | Amount of pineapple leaves burned | 80 | % of TS | [35] |

| CH4 emission factor | 1.6 | kg CH4/metric ton dry pineapple leaves burned | [36] | |

| N2O emission factor | 0.21 | kg N2O/metric ton dry pineapple leaves burned | [36] | |

| Particulate matter (PM) factor | 11.5 | kg/metric ton dry pineapple leaves burned | [37] | |

| SO2 emission factor | 0.21 | kg SO2/metric ton dry pineapple leaves burned | [37] | |

| NOx emission factor | 2.6 | kg NOx/metric ton dry pineapple leaves burned | [37] | |

| Biorefinery | Energy consumption of the process | 575,000,000 | MJ/year | |

| CO2 emission factor from energy consumption of the process | 0.117 | kg CO2/MJ energy consumed | [38] | |

| Net ethanol production | 27,500 | Metric ton ethanol/year | - | |

| Energy content of ethanol a | 26.7 | MJ/kg | - | |

| Reduction factor of CO2 emission from replacing gasoline fuel | 0.067 | kg CO2/MJ fuel consumed | [38] |

| Parameter | Biorefinery | On-Site Burning |

|---|---|---|

| Particulate matter potential (metric ton/year) | 0 | 5951 |

| Global warming potential (metric ton CO2-e/year) | −71,620 | 44,339 |

| Air acidification (metric ton SO2-e/year) | 0 | 923 |

| Smog potential (metric ton O3-e/year) | 0 | 28,167 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liao, C.Y.; Guan, Y.J.; Bustamante-Román, M. Techno-Economic Analysis and Life Cycle Assessment of Pineapple Leaves Utilization in Costa Rica. Energies 2022, 15, 5784. https://doi.org/10.3390/en15165784

Liao CY, Guan YJ, Bustamante-Román M. Techno-Economic Analysis and Life Cycle Assessment of Pineapple Leaves Utilization in Costa Rica. Energies. 2022; 15(16):5784. https://doi.org/10.3390/en15165784

Chicago/Turabian StyleLiao, Clara Yuqi, Ysabel Jingyi Guan, and Mauricio Bustamante-Román. 2022. "Techno-Economic Analysis and Life Cycle Assessment of Pineapple Leaves Utilization in Costa Rica" Energies 15, no. 16: 5784. https://doi.org/10.3390/en15165784

APA StyleLiao, C. Y., Guan, Y. J., & Bustamante-Román, M. (2022). Techno-Economic Analysis and Life Cycle Assessment of Pineapple Leaves Utilization in Costa Rica. Energies, 15(16), 5784. https://doi.org/10.3390/en15165784