Is the Production of Agricultural Biogas Environmentally Friendly? Does the Structure of Consumption of First- and Second-Generation Raw Materials in Latvia and Poland Matter?

Abstract

:1. Introduction

2. Bioenergy in Energy Mix

3. Biogas as an Energy Source

3.1. Advantages and Disadvantages of Biogas Production

3.2. Production of Energy from Biogas in the European Union

4. Materials and Methods

- E = greenhouse gas emissions per MJ biomethane produced from co-digestion of the defined mixture of substrates;

- En = emissions in g CO2eq/MJ biomethane for the option as provided in Annex VI Part D of Directive (EU) 2018/2001;

- Sn = share of feedstock n in the energy content:

- Pn = energy yield (MJ) per kilogram of wet input of feedstock n in MJ biogas/kg (PMaize = 4.16 (MJ) biogas/kg, PManure = 0.50, PBiowaste = 3.41 (MJ) biogas/kg [65]);

- Wn = weighting factor of substrate n defined as:

- In = annual input to the digester of substrate n (ton of fresh matter);

- AMn = average annual moisture of substrate n (kg water/kg fresh matter);

- SMn = standard moisture for substrate n in kg water/kg fresh matter (SMMaize = 0.65; SMManure = 0.90; SMBiowaste = 0.76).

5. Results

5.1. Agricultural Biogas Plants and Biogas Production

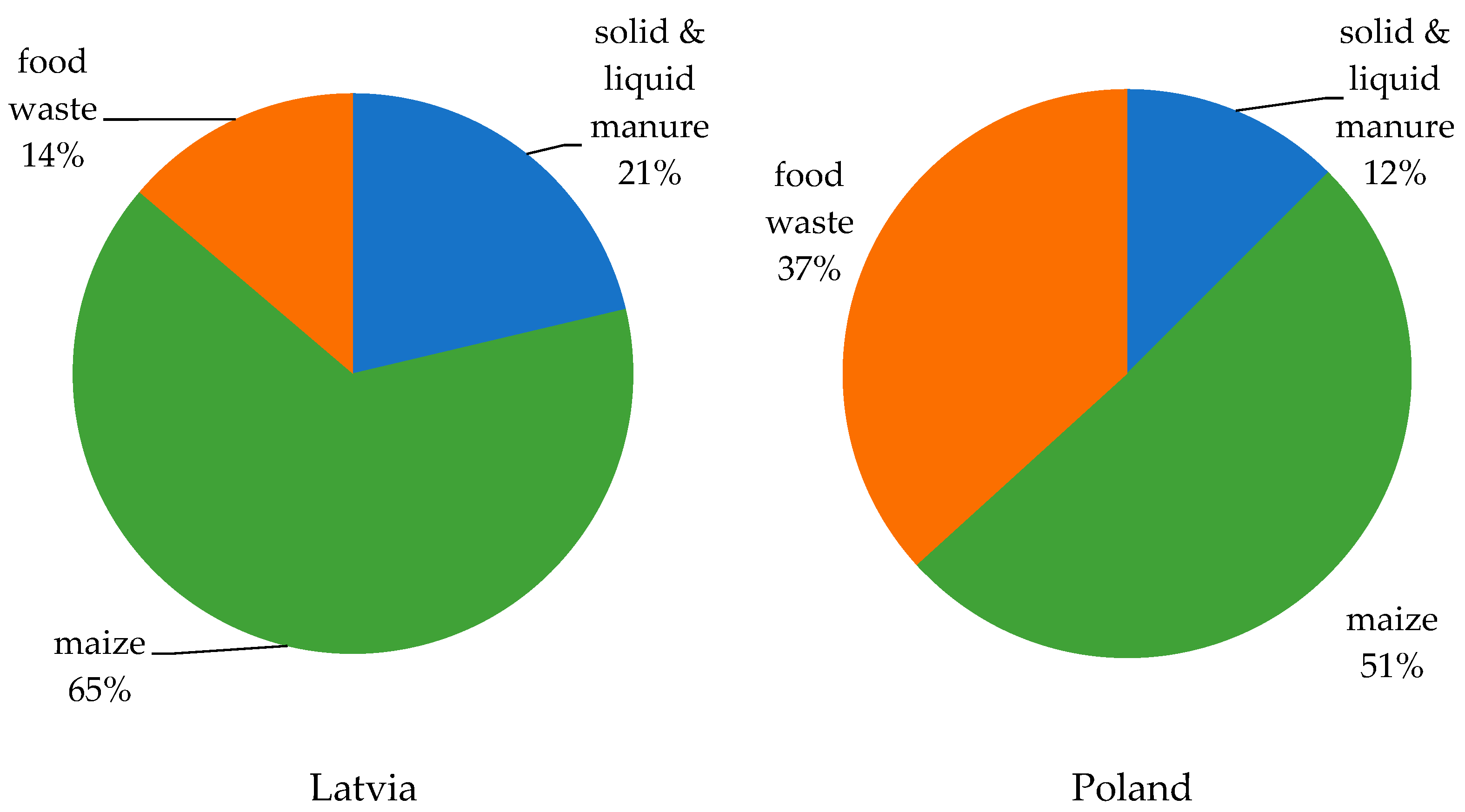

5.2. Feedstock Use in Biogas Plant

- For maize—AMMaize = 0.65;

- For manure—AMManure = 0.92;

- For food waste—AMBiowaste = 0.90.

5.3. Emission from Agricultural Biogas Generation

5.4. Level of Savings of GHG Emission

- EB = total emissions from biomass fuels;

- EF = total emissions from the fossil fuel comparator.

6. Discussion

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bruckner, T.; Bashmakov, I.A.; Mulugetta, Y.; Chum, H.; de la Vega Navarro, A.; Edmonds, J.; Faaij, A.; Fungtammasan, B.; Garg, A.; Hertwich, E.; et al. Energy systems. In Climate Change 2014: Mitigation of Climate Change: Contribution of Working Group III to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change; Edenhofer, O., Pichs-Madruga, R., Sokona, Y., Farahani, E., Kadner, S., Seyboth, K., Adler, A., Baum, I., Brunner, S., Eickemeier, P., et al., Eds.; Cambridge University Press: Cambridge, UK, 2014; pp. 511–597. [Google Scholar]

- IPCC. Climate Change 2014: Mitigation of Climate Change: Contribution of Working Group III to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change; Intergovernmental Panel on Climate Change: Cambridge, MA, USA, 2015. [Google Scholar] [CrossRef] [Green Version]

- Tonini, D.; Astrup, T. LCA of Biomass-Based Energy Systems: A Case Study for Denmark. Appl. Energy 2012, 99, 234–246. [Google Scholar] [CrossRef] [Green Version]

- NOAA. Carbon Dioxide Now More than 50% Higher than Pre-Industrial Levels. Available online: https://www.noaa.gov/news-release/carbon-dioxide-now-more-than-50-higher-than-pre-industrial-levels (accessed on 4 June 2022).

- Lee, R.A.; Lavoie, J.-M. From First- to Third-Generation Biofuels: Challenges of Producing a Commodity from a Biomass of Increasing Complexity. Anim. Front. 2013, 3, 6–11. [Google Scholar] [CrossRef]

- Dubrovskis, V.; Plume, I. Forecasting of GHG Emissions from Biomass Energy Usage in Latvia. In Proceedings of the Engineering for Rural Development, International Scientific Conference (Latvia), Jelgava, Latvia, 28 May 2009; LLU: Jelgava, Latvia, 2009; pp. 7–13. [Google Scholar]

- IEA. World Energy Outlook 2021; International Energy Agency: Paris, France, 2021. [Google Scholar]

- Searle, S.; Malins, C. A Reassessment of Global Bioenergy Potential in 2050. GCB Bioenergy 2015, 7, 328–336. [Google Scholar] [CrossRef]

- Venturini, G.; Pizarro-Alonso, A.; Münster, M. How to Maximise the Value of Residual Biomass Resources: The Case of Straw in Denmark. Appl. Energy 2019, 250, 369–388. [Google Scholar] [CrossRef]

- Muradin, M.; Foltynowicz, Z. Potential for Producing Biogas from Agricultural Waste in Rural Plants in Poland. Sustainability 2014, 6, 5065–5074. [Google Scholar] [CrossRef] [Green Version]

- IEA. Outlook for Biogas and Biomethane: Prospects for Organic Growth; International Energy Agency: Paris, France, 2020. [Google Scholar]

- IRENA; OECD/IEA; REN21. Renewable Energy Policies in a Time of Transition: Heating and Cooling; IRENA—OECD/IEA—REN21; International Renewable Energy Agency: Abu Dhabi, United Arab Emirates, 2021; ISBN 978-92-9260-289-5. [Google Scholar]

- Ślusarz, G.; Gołębiewska, B.; Cierpiał-Wolan, M.; Gołębiewski, J.; Twaróg, D.; Wójcik, S. Regional Diversification of Potential, Production and Efficiency of Use of Biogas and Biomass in Poland. Energies 2021, 14, 742. [Google Scholar] [CrossRef]

- IEA. Renewables Information: Overview; International Energy Agency: Paris, France, 2020. [Google Scholar]

- Smith, P.; Bustamante, M.; Ahammad, H.; Clark, H.; Dong, H.; Elsiddig, E.A.; Haberl, H.; Harper, R.; House, J.; Jafari, M.; et al. Agriculture, forestry and other land use (AFOLU). In Climate Change 2014: Mitigation of Climate Change; Contribution of Working Group III to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change; Edenhofer, O., Pichs-Madruga, R., Sokona, Y., Farahani, E., Kadner, S., Seyboth, K., Adler, A., Baum, I., Brunner, S., Eickemeier, P., et al., Eds.; Cambridge University Press: Cambridge, UK, 2014; pp. 811–922. [Google Scholar]

- Larsen, S.; Bentsen, N.S.; Dalgaard, T.; Jørgensen, U.; Olesen, J.E.; Felby, C. Possibilities for Near-Term Bioenergy Production and GHG-Mitigation through Sustainable Intensification of Agriculture and Forestry in Denmark. Environ. Res. Lett. 2017, 12, 114032. [Google Scholar] [CrossRef]

- Rehfeldt, M.; Worrell, E.; Eichhammer, W.; Fleiter, T. A Review of the Emission Reduction Potential of Fuel Switch towards Biomass and Electricity in European Basic Materials Industry until 2030. Renew. Sustain. Energy Rev. 2020, 120, 109672. [Google Scholar] [CrossRef]

- Bentivoglio, D.; Rasetti, M. Biofuel Sustainability: Review of Implications for Land Use and Food Price. Ital. Rev. Agric. Econ. 2015, 70, 7–31. [Google Scholar] [CrossRef]

- Kristoufek, L.; Janda, K.; Zilberman, D. Correlations between Biofuels and Related Commodities before and during the Food Crisis: A Taxonomy Perspective. Energy Econ. 2012, 34, 1380–1391. [Google Scholar] [CrossRef]

- Zilberman, D.; Hochman, G.; Rajagopal, D.; Sexton, S.; Timilsina, G. The Impact of Biofuels on Commodity Food Prices: Assessment of Findings. Am. J. Agric. Econ. 2013, 95, 275–281. [Google Scholar] [CrossRef]

- Wicki, L. Food and bioenergy—Evidence from Poland. In Proceedings of the Economic Science for Rural Development: Production and Cooperation in Agriculture, Jelgava, Latvia, 26–27 April 2017; pp. 299–305. [Google Scholar]

- Wicki, L. Development of Biofuels Production from Agricultural Raw Materials. In Proceedings of the International Scientific Conference: Rural Development, Kaunas, Lithuania, 23–24 November 2017; pp. 502–508. [Google Scholar] [CrossRef] [Green Version]

- Altman, I.; Bergtold, J.; Sanders, D.; Johnson, T. Willingness to Supply Biomass for Bioenergy Production: A Random Parameter Truncated Analysis. Energy Econ. 2015, 47, 1–10. [Google Scholar] [CrossRef]

- Bielski, S.; Marks-Bielska, R.; Zielińska-Chmielewska, A.; Romaneckas, K.; Šarauskis, E. Importance of Agriculture in Creating Energy Security—A Case Study of Poland. Energies 2021, 14, 2465. [Google Scholar] [CrossRef]

- Lyng, K.-A.; Brekke, A. Environmental Life Cycle Assessment of Biogas as a Fuel for Transport Compared with Alternative Fuels. Energies 2019, 12, 532. [Google Scholar] [CrossRef] [Green Version]

- Latvia Cabinet of Ministers. National Energy and Climate Plan of Latvia 2021–2030; Latvia Cabinet of Ministers: Riga, Latvia, 2018. [Google Scholar]

- IEA. Renewables 2020: Analysis and Forecast to 2025; International Energy Agency: Paris, France, 2020. [Google Scholar]

- Marks, S.; Dach, J.; Fernandez Morales, F.; Mazurkiewicz, J.; Pochwatka, P.; Gierz, Ł. New Trends in Substrates and Biogas Systems in Poland. J. Ecol. Eng. 2020, 21, 19–25. [Google Scholar] [CrossRef]

- Vasco-Correa, J.; Khanal, S.; Manandhar, A.; Shah, A. Anaerobic Digestion for Bioenergy Production: Global Status, Environmental and Techno-Economic Implications, and Government Policies. Bioresour. Technol. 2018, 247, 1015–1026. [Google Scholar] [CrossRef] [PubMed]

- Szabó, G.; Fazekas, I.; Szabó, S.; Szabó, G.; Buday, T.; Paládi, M.; Kisari, K.; Kerényi, A. The Carbon Footprint of a Biogas Power Plant. Environ. Eng. Manag. J. 2014, 13, 2867–2874. [Google Scholar] [CrossRef]

- Ehlers, M.-H. Farmers’ Reasons for Engaging in Bioenergy Utilisation and Their Institutional Context: A Case Study in Germany. In Proceedings of the IAMO Forum 2008, Halle, Germany, 25–27 June 2008; pp. 1–12. [Google Scholar]

- Souza, G.M.; Victoria, R.L.; Joly, C.A.; Verdade, L.M. Bioenergy & Sustainability: Bridging the Gaps; Scientific Committee on Problems of the Environment: São Paulo, Brazil, 2015; ISBN 978-2-9545557-0-6. [Google Scholar]

- Dubrovskis, V. Biogas from Landfills in Latvia. In Proceedings of the 6th International Conference on Renewable Energy Gas Technology, Malmö, Sweden, 20–21 May 2019; pp. 1–2. [Google Scholar]

- Gostomczyk, W. Stan i Perspektywy Rozwoju Rynku Biogazu w UE i Polsce—Ujęcie Ekonomiczne. Zesz. Nauk. SGGW W Warszawie—Probl. Rol. Swiat. 2017, 17, 48–64. [Google Scholar] [CrossRef] [Green Version]

- Rozakis, S.; Bartoli, A.; Dach, J.; Jędrejek, A.; Kowalczyk-Juśko, A.; Mamica, Ł.; Pochwatka, P.; Pudelko, R.; Shu, K. Policy Impact on Regional Biogas Using a Modular Modeling Tool. Energies 2021, 14, 3738. [Google Scholar] [CrossRef]

- Bencheva, N.; Tepavicharova, M. Opportunities and Attitudes of Farmers to the Production of Biogas and Bio-Based Fertilisers in Bulgaria. Probl. Agric. Econ. 2017, 352, 92–102. [Google Scholar] [CrossRef]

- Chodkowska-Miszczuk, J.; Szymańska, D. Agricultural Biogas Plants—A Chance for Diversification of Agriculture in Poland. Renew. Sustain. Energy Rev. 2013, 20, 514–518. [Google Scholar] [CrossRef]

- Jørgensen, M.S.; Andersen, B.H. The Controversies Over Bioenergy in Denmark: ‘Bio’ Is Not the Same as ‘Sustainable’. Environ. Eng. Manag. J. 2012, 11, 2101–2119. [Google Scholar] [CrossRef]

- Ruģele, K.; Gruškeviča, K.; Rubulis, J.; Kalniņa, I. Risk Assessment of Nutrient Discharges from Biogas Production; Riga Technical University: Riga, Latvia, 2017. [Google Scholar]

- Banasik, P.; Białowiec, A.; Czekała, W.; Chomiuk, D.; Dach, J.; Filipiak, I.; Fugol, M.; Kacała, M.; Kowalczyk-Juśko, A.; Kolasiński, M.; et al. Biogaz w Polsce; Biomass Media Group Sp. z o.o.: Poznań, Poland, 2020. [Google Scholar]

- IEA. Technology Roadmap: Delivering Sustainable Bioenergy; International Energy Agency: Paris, France, 2017. [Google Scholar]

- Gasper, R.; Searchinger, T. The Production and Use of Renewable Natural Gas as a Climate Strategy in the United States; Working Paper; World Resources Institute: Washington, DC, USA, 2018; Available online: https://static1.squarespace.com/static/53a09c47e4b050b5ad5bf4f5/t/5b049d7d03ce646fda48e14f/1527029122737/production-use-renewable-natural-gas-climate-strategy-united-states.pdf (accessed on 12 February 2022).

- Li, H.; Tan, Y.; Ditaranto, M.; Yan, J.; Yu, Z. Capturing CO2 from Biogas Plants. Energy Procedia 2017, 114, 6030–6035. [Google Scholar] [CrossRef]

- Jensen, I.G.; Skovsgaard, L. The Impact of CO2-Costs on Biogas Usage. Energy 2017, 134, 289–300. [Google Scholar] [CrossRef] [Green Version]

- Kim, T.-J.; Lang, A.; Chikukwa, A.; Sheridan, E.; Dahl, P.I.; Leimbrink, M.; Skiborowski, M.; Roubroeks, J. Enzyme Carbonic Anhydrase Accelerated CO2 Absorption in Membrane Contactor. Energy Procedia 2017, 114, 17–24. [Google Scholar] [CrossRef]

- Fajardy, M.; Mac Dowell, N. Can BECCS Deliver Sustainable and Resource Efficient Negative Emissions? Energy Environ. Sci. 2017, 10, 1389–1426. [Google Scholar] [CrossRef] [Green Version]

- Consoli, C. Bioenergy and Carbon Capture and Storage: 2019 Perspective; Global CCS Institute: Melbourne, Australia, 2019. [Google Scholar]

- Scarlat, N.; Dallemand, J.-F.; Fahl, F. Biogas: Developments and Perspectives in Europe. Renew. Energy 2018, 129, 457–472. [Google Scholar] [CrossRef]

- Savickis, J.; Zemite, L.; Zeltins, N.; Bode, I.; Jansons, L. Natural Gas and Biomethane in the European Road Transport: The Latvian Perspective. Latv. J. Phys. Tech. Sci. 2020, 57, 57–72. [Google Scholar] [CrossRef]

- Pardo, G.; del Prado, A.; Martínez-Mena, M.; Bustamante, M.A.; Martín, J.A.R.; Álvaro-Fuentes, J.; Moral, R. Orchard and Horticulture Systems in Spanish Mediterranean Coastal Areas: Is There a Real Possibility to Contribute to C Sequestration? Agric. Ecosyst. Environ. 2017, 238, 153–167. [Google Scholar] [CrossRef] [Green Version]

- Alvarez, R.A.; Zavala-Araiza, D.; Lyon, D.R.; Allen, D.T.; Barkley, Z.R.; Brandt, A.R.; Davis, K.J.; Herndon, S.C.; Jacob, D.J.; Karion, A.; et al. Assessment of Methane Emissions from the U.S. Oil and Gas Supply Chain. Science 2018, 361, 186–188. [Google Scholar] [CrossRef] [PubMed]

- Sulewski, P.; Majewski, E.; Was, A. Supporting Sustainable Agriculture: The Potential to Reduce GHG Emissions—The Case of Agricultural Biogas Production in Poland. Rocz. Ochr. Sr. 2018, 20, 662–680. [Google Scholar]

- Berdechowski, K. Assessment of the Key Factors Affecting GHG Emissions in the Life Cycle of Biomethane. Nafta-Gaz 2020, 76, 630–636. [Google Scholar] [CrossRef]

- Kampman, B.; Leguijt, C.; Scholten, T.; Tallat-Kelpsaite, J.; Brückmann, R.; Maroulis, G.; Lesschen, J.P.; Meesters, K.; Sikirica, N.; Elbersen, B. Optimal Use of Biogas from Waste Streams. An Assessment of the Potential of Biogas from Digestion in the EU beyond 2020; Directorate-General for Energy, European Commission: Brussel, Belgium, 2016. [Google Scholar]

- Agostini, A.; Battini, F.; Giuntoli, J.; Tabaglio, V.; Padella, M.; Baxter, D.; Marelli, L.; Amaducci, S. Environmentally Sustainable Biogas? The Key Role of Manure Co-Digestion with Energy Crops. Energies 2015, 8, 5234–5265. [Google Scholar] [CrossRef]

- Murphy, J.; Braun, R.; Weiland, P.; Wellinger, A. Biogas from Crop Digestion; IEA Bioenergy: Paris, France, 2011. [Google Scholar]

- Kalnina, I.; Rugele, K.; Rubulis, J. Digestate Management Practices in Latvia from Nitrogen Perspective. Energy Procedia 2018, 147, 368–373. [Google Scholar] [CrossRef]

- Latvian State Environmental Services. Nutrient Management at Biogas Plants in Latvia; Latvian State Environmental Services: Riga, Latvia, 2021.

- Pubule, J.; Blumberga, D. Impact Assessment of Biogas Projects in Latvia. Int. J. Sustain. Dev. Plan. 2014, 9, 251–262. [Google Scholar] [CrossRef] [Green Version]

- Melece, L.; Lakovskis, P. Land use changes and bioenergy in Latvia. In Proceedings of the Economic Science for Rural Development: Production and Cooperation in Agriculture, Jelgava, Latvia, 26–27 April 2017; pp. 180–188. [Google Scholar]

- Lask, J.; Martínez Guajardo, A.; Weik, J.; Cossel, M.; Lewandowski, I.; Wagner, M. Comparative Environmental and Economic Life Cycle Assessment of Biogas Production from Perennial Wild Plant Mixtures and Maize (Zea mays L.) in Southwest Germany. GCB Bioenergy 2020, 12, 571–585. [Google Scholar] [CrossRef]

- Menandro, L.M.S.; Cantarella, H.; Franco, H.C.J.; Kölln, O.T.; Pimenta, M.T.B.; Sanches, G.M.; Rabelo, S.C.; Carvalho, J.L.N. Comprehensive Assessment of Sugarcane Straw: Implications for Biomass and Bioenergy Production. Biofuels Bioprod. Biorefining 2017, 11, 488–504. [Google Scholar] [CrossRef]

- Novák, P.; Mašek, J.; Hůla, J.; Beneš, L.; Kumhálová, J. Soil tillage focusing on the reduction of water erosion of soil in the cultivation of selected field crops. In Proceedings of the 7th International Scientific Conference Rural Development 2015, Kaunas, Lithuania, 19 November 2015; Aleksandras Stulginskis University: Dotnuva, Lithuania, 2015. [Google Scholar]

- European Parliament. The European Parliament and of the Council Directive (EU) 2018/2001 of the European Parliament and of the Council of 11 December 2018 on the Promotion of the Use of Energy from Renewable Sources; Official Journal of the European Union; European Parliament: Strasbourg, France, 2018. [Google Scholar]

- Giuntoli, J.; Agostini, A.; Edwards, R.; Marelli, L. Solid and Gaseous Bioenergy Pathways: Input Values and GHG Emissions: Calculated According to the Methodology Set in COM(2010) 11 and SWD(2014) 259; Version 1a; European Commission: Luxembourgh, 2015. [Google Scholar]

- Ministry of Economics, Republic of Latvia. Vitenbergs: The Government Takes the Next Step in the Arrangement of the MPC System and Further Reinforces Supervision of Mandatory Procurement Power Plants. Available online: https://www.em.gov.lv/en/article/vitenbergs-government-takes-next-step-arrangement-mpc-system-and-further-reinforces-supervision-mandatory-procurement-power-plants (accessed on 20 April 2022).

- Ministry of Economics, Republic of Latvia. In the 10 Months of This Year, State Aid Was Cancelled for 16 MPC Power Plants, Allowing the State to Save Around 24 Million EUR. Available online: https://www.em.gov.lv/en/article/10-months-year-state-aid-was-cancelled-16-mpc-power-plants-allowing-state-save-around-24-million-eur (accessed on 20 April 2020).

- NIK. Bariery Rozwoju Odnawialnych Źródeł Energii; Najwyższa Izba Kontroli: Warsaw, Poland, 2021.

- Gostomczyk, W. The Auction System as a New Way to Promote Renewable Energy. Zesz. Nauk. SGGW W Warszawie—Probl. Rol. Swiat. 2018, 18, 113–133. [Google Scholar] [CrossRef] [Green Version]

- KOWR. Dane Dotyczące Działalności Wytwórców Biogazu Rolniczego w Latach 2011–2021. Available online: https://bip.kowr.gov.pl/informacje-publiczne/odnawialne-zrodla-energii/biogaz-rolniczy/dane-dotyczace-dzialalnosci-wytworcow-biogazu-rolniczego-w-latach-2011-2021 (accessed on 20 April 2022).

- Jain, S.; Newman, D.; Nzihou, A.; Dekker, H.; le Feuvre, P.; Richter, H.; Gobe, F.; Morton, C.; Thompson, R. Global Potential of Biogas; The World Biogas Association: London, UK, 2019. [Google Scholar]

- Wicki, L. Changes in Land Use for Production of Energy Crops in Poland. Rocz. Nauk. Ekon. Rol. I Rozw. Obsz. Wiej. 2017, 104, 37–47. [Google Scholar] [CrossRef]

- Szempliński, W.; Parzonka, A.; Sałek, T. Yield and Energy Efficiency of Biomass Production of Some Species of Plants Grown for Biogas. Acta Sci. Pol. Agric. 2014, 13, 67–80. [Google Scholar]

- Gostomczyk, W. Agricultural Biogas Market in Poland and the Raw Material Used in 2011–2014. Zesz. Nauk. SGGW W Warszawie—Probl. Rol. Swiat. 2015, 15, 30–39. [Google Scholar]

- Błażejowska, M.; Gostomczyk, W. Warunki Tworzenia i Stan Rozwoju Spółdzielni i Klastrów Energetycznych w Polsce Na Tle Doświadczeń Niemieckich. Zesz. Nauk. SGGW W Warszawie—Probl. Rol. Swiat. 2018, 18, 20–32. [Google Scholar] [CrossRef] [Green Version]

- IRENA. Renewable Power Generation Costs in 2020; IRENA: Abu Dhabi, United Arab Emirates, 2021. [Google Scholar]

- Kowalczyk-Juśko, A. Biogazownie Szansą Dla Rolnictwa i Środowiska; Grzybek, A., Ed.; Fundacja na Rzecz Rozwoju Polskiego Rolnictwa: Warszawa, Poland, 2016. [Google Scholar]

- IRENA. Global Bioenergy. Supply and Demand Projections; A Working Paper for REmap 2030; International Renewable Energy Agency: Abu Dhabi, United Arab Emirates, 2014. [Google Scholar]

- Bahrs, E.; Angenendt, E. Status Quo and Perspectives of Biogas Production for Energy and Material Utilization. GCB Bioenergy 2019, 11, 9–20. [Google Scholar] [CrossRef]

- Instytut Energetyki Odnawialnej. Podsumowanie Aukcji OZE w 2021 Roku. Available online: https://www.ieo.pl/pl/aktualnosci/1547-podsumowanie-aukcji-oze-w-2021-roku (accessed on 27 July 2022).

- Doronin, A.; Polishchuk, O.; Rybchak, V. Potential of Renewable Sources in Ukraine. Tur. I Rozw. Reg. 2021, 15, 25–31. [Google Scholar] [CrossRef]

- Trypolska, G.; Kyryziuk, S.; Krupin, V.; Wąs, A.; Podolets, R. Economic Feasibility of Agricultural Biogas Production by Farms in Ukraine. Energies 2021, 15, 87. [Google Scholar] [CrossRef]

- Bórawski, P.; Guth, M.; Bełdycka-Bórawska, A.; Jankowski, K.J.; Parzonko, A.; Dunn, J.W. Investments in Polish Agriculture: How Production Factors Shape Conditions for Environmental Protection? Sustainability 2020, 12, 8160. [Google Scholar] [CrossRef]

- Świechowski, K.; Hnat, M.; Stępień, P.; Stegenta-Dąbrowska, S.; Kugler, S.; Koziel, J.A.; Białowiec, A. Waste to Energy: Solid Fuel Production from Biogas Plant Digestate and Sewage Sludge by Torrefaction-Process Kinetics, Fuel Properties, and Energy Balance. Energies 2020, 13, 3161. [Google Scholar] [CrossRef]

- Koryś, K.A.; Latawiec, A.E.; Grotkiewicz, K.; Kuboń, M. The Review of Biomass Potential for Agricultural Biogas Production in Poland. Sustainability 2019, 11, 6515. [Google Scholar] [CrossRef] [Green Version]

- Zaborowska, M.; Bernat, K.; Jankowski, D. Wykorzystanie Odpadów z Przemysłu Rolno-Spożywczego Do Współfermentacji z Osadami Ściekowymi. In Współczesne Problemy Ochrony Środowiska i Energetyki 2019; Pikoń, K., Bogacka, M., Eds.; Silesian University of Technology (PolSL): Gliwice, Poland, 2020; Volume 2019, pp. 15–22. [Google Scholar]

| Year | Information about Agricultural Biogas Production | |||||

|---|---|---|---|---|---|---|

| Number of Plants | Biogas Production in Million m3 | Energy Produced in Biogas in TJ | ||||

| Latvia | Poland | Latvia | Poland | Latvia | Poland | |

| 2011 | 15 | 8 | 26.2 | 36.6 | 497 | 634 |

| 2012 | 36 | 16 | 91.1 | 73.2 | 1731 | 1463 |

| 2013 | 49 | 28 | 119.5 | 112.4 | 2270 | 2084 |

| 2014 | 53 | 42 | 141.5 | 174.3 | 2688 | 2825 |

| 2015 | 54 | 58 | 170.5 | 206.2 | 3239 | 3413 |

| 2016 | 55 | 78 | 175.2 | 250.2 | 3328 | 3504 |

| 2017 | 50 | 94 | 182.3 | 291.7 | 3463 | 4921 |

| 2018 | 50 | 96 | 170.7 | 303.6 | 3243 | 5585 |

| 2019 | 49 | 96 | 156.3 | 306.4 | 2970 | 5693 |

| Year | Feedstock Use in kt of Wet Matter (In) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Latvia | Poland | ||||||||

| Manure | Corn Silage | Food Waste | Total | Manure | Corn Silage | Food Waste | Fatty Waste | Total | |

| 2011 | 158.5 | 96.8 | 61.1 | 316.5 | 277.6 | 129.0 | 62.5 | 0.3 | 469.4 |

| 2012 | 555.7 | 336.2 | 212.6 | 1104.4 | 372.7 | 282.8 | 258.9 | 2.7 | 917.1 |

| 2013 | 675.2 | 446.3 | 278.8 | 1400.3 | 486.4 | 402.8 | 673.5 | 10.9 | 1573.5 |

| 2014 | 841.9 | 524.3 | 330.2 | 1696.4 | 622.9 | 638.5 | 854.8 | 7.0 | 2123.2 |

| 2015 | 912.2 | 633.4 | 426.3 | 1971.8 | 658.9 | 654.9 | 1168.2 | 2.8 | 2484.8 |

| 2016 | 911.0 | 649.1 | 452.6 | 2012.8 | 886.8 | 748.1 | 1583.5 | 5.8 | 3224.1 |

| 2017 | 920.6 | 669.0 | 501.3 | 2091.0 | 911.0 | 885.2 | 1992.8 | 7.9 | 3796.9 |

| 2018 | 904.7 | 617.9 | 483.7 | 2006.3 | 865.5 | 847.1 | 2275.1 | 12.6 | 4000.3 |

| 2019 | 843.2 | 559.1 | 460.1 | 1862.5 | 838.1 | 731.8 | 2366.3 | 21.2 | 3957.5 |

| Share 1 | 45.2% | 31.5% | 23.4% | 100.0% | 23.8% | 22.1% | 53.7% | 0.3% | 100.0% |

| CAGR 2 | 14.7% | 16.4% | 20.0% | 16.4% | 14.3% | 19.9% | 39.7% | 35.0% | 25.2% |

| Year | Emission from Particular Feedstocks in g CO2 per 1 MJ Energy from Agricultural Biogas (En × Sn) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Latvia | Poland | ||||||||

| Manure | Corn Silage | Food Waste | Total | Manure | Corn Silage | Food Waste | Fatty Waste | Total | |

| 2011 | −10.1 | 17.5 | 1.4 | 8.8 | −13.2 | 17.4 | 1.1 | 0.0 | 5.3 |

| 2012 | −10.2 | 17.5 | 1.4 | 8.7 | −7.6 | 16.4 | 1.9 | 0.2 | 10.8 |

| 2013 | −9.4 | 17.7 | 1.4 | 9.7 | −5.8 | 13.6 | 2.9 | 0.4 | 11.1 |

| 2014 | −9.9 | 17.5 | 1.4 | 9.0 | −5.2 | 15.2 | 2.6 | 0.2 | 12.7 |

| 2015 | −8.9 | 17.5 | 1.5 | 10.1 | −5.0 | 14.0 | 3.2 | 0.1 | 12.3 |

| 2016 | −8.6 | 17.5 | 1.6 | 10.4 | −5.4 | 12.9 | 3.5 | 0.1 | 11.1 |

| 2017 | −8.4 | 17.3 | 1.7 | 10.6 | −4.6 | 12.7 | 3.7 | 0.1 | 11.9 |

| 2018 | −8.8 | 17.0 | 1.7 | 10.0 | −4.2 | 11.7 | 4.0 | 0.2 | 11.7 |

| 2019 | −8.9 | 16.8 | 1.8 | 9.7 | −4.2 | 10.5 | 4.3 | 0.3 | 10.9 |

| Year | Biogas Energy Production in Agricultural Biogas Plant in TJ, Broken down by Type of Substrate | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Latvia | Poland | ||||||||

| Manure | Corn Silage | Food Waste | Total | Manure | Corn Silage | Food Waste | Fatty Waste | Total | |

| 2011 | 57.0 | 362.0 | 78.1 | 497.0 | 95.2 | 459.9 | 76.2 | 2.8 | 634.0 |

| 2012 | 200.1 | 1259.0 | 271.9 | 1731.0 | 126.5 | 998.2 | 312.1 | 26.1 | 1463.0 |

| 2013 | 243.0 | 1670.6 | 356.4 | 2270.0 | 137.4 | 1183.4 | 675.9 | 87.3 | 2084.0 |

| 2014 | 303.1 | 1962.7 | 422.2 | 2688.0 | 167.6 | 1786.7 | 817.1 | 53.6 | 2825.0 |

| 2015 | 327.8 | 2367.1 | 544.1 | 3239.0 | 192.2 | 1986.9 | 1210.4 | 23.4 | 3413.0 |

| 2016 | 327.1 | 2423.7 | 577.2 | 3328.0 | 215.0 | 1885.9 | 1363.5 | 39.7 | 3504.0 |

| 2017 | 330.1 | 2494.8 | 638.5 | 3463.4 | 257.3 | 2600.5 | 1999.6 | 63.5 | 4921.0 |

| 2018 | 324.2 | 2302.9 | 615.6 | 3242.8 | 266.8 | 2715.9 | 2491.4 | 110.5 | 5584.7 |

| 2019 | 302.0 | 2082.6 | 585.4 | 2970.0 | 273.3 | 2482.0 | 2741.1 | 196.7 | 5693.2 |

| Share 1 | 9.9% | 71.9% | 18.2% | 100.0% | 5.2% | 50.5% | 42.4% | 1.9% | 100.0% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wicki, L.; Naglis-Liepa, K.; Filipiak, T.; Parzonko, A.; Wicka, A. Is the Production of Agricultural Biogas Environmentally Friendly? Does the Structure of Consumption of First- and Second-Generation Raw Materials in Latvia and Poland Matter? Energies 2022, 15, 5623. https://doi.org/10.3390/en15155623

Wicki L, Naglis-Liepa K, Filipiak T, Parzonko A, Wicka A. Is the Production of Agricultural Biogas Environmentally Friendly? Does the Structure of Consumption of First- and Second-Generation Raw Materials in Latvia and Poland Matter? Energies. 2022; 15(15):5623. https://doi.org/10.3390/en15155623

Chicago/Turabian StyleWicki, Ludwik, Kaspars Naglis-Liepa, Tadeusz Filipiak, Andrzej Parzonko, and Aleksandra Wicka. 2022. "Is the Production of Agricultural Biogas Environmentally Friendly? Does the Structure of Consumption of First- and Second-Generation Raw Materials in Latvia and Poland Matter?" Energies 15, no. 15: 5623. https://doi.org/10.3390/en15155623

APA StyleWicki, L., Naglis-Liepa, K., Filipiak, T., Parzonko, A., & Wicka, A. (2022). Is the Production of Agricultural Biogas Environmentally Friendly? Does the Structure of Consumption of First- and Second-Generation Raw Materials in Latvia and Poland Matter? Energies, 15(15), 5623. https://doi.org/10.3390/en15155623