The Characteristics of the After-Combustion in a Commercial CFBC Boiler Using the Solid Waste Fuel

Abstract

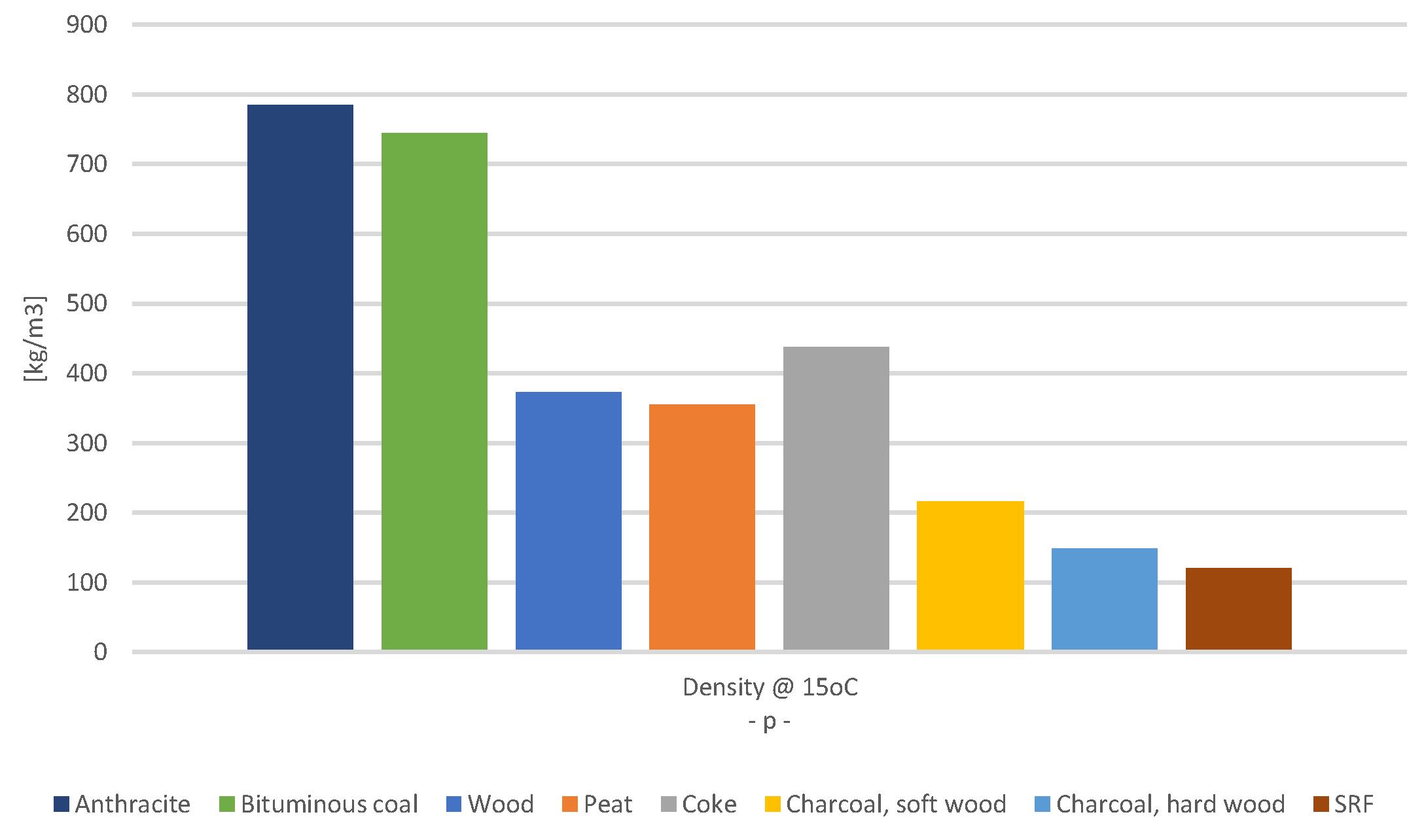

:1. Background

2. Experimental

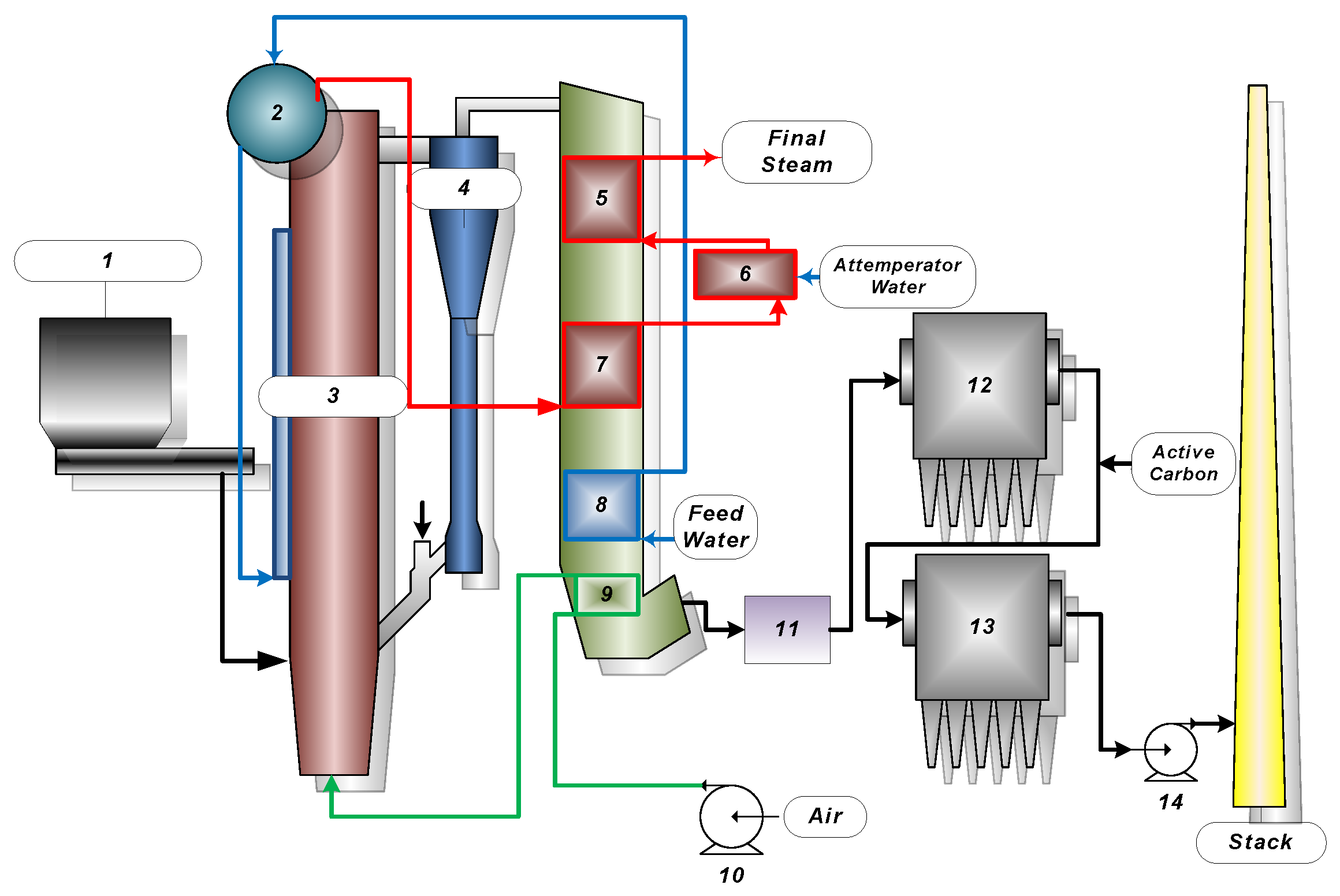

2.1. Dimension and Condition of Boiler

2.2. Boiler Design

3. Results and Discussion

3.1. The Effect of Air Heater on Flue Gas Temperature

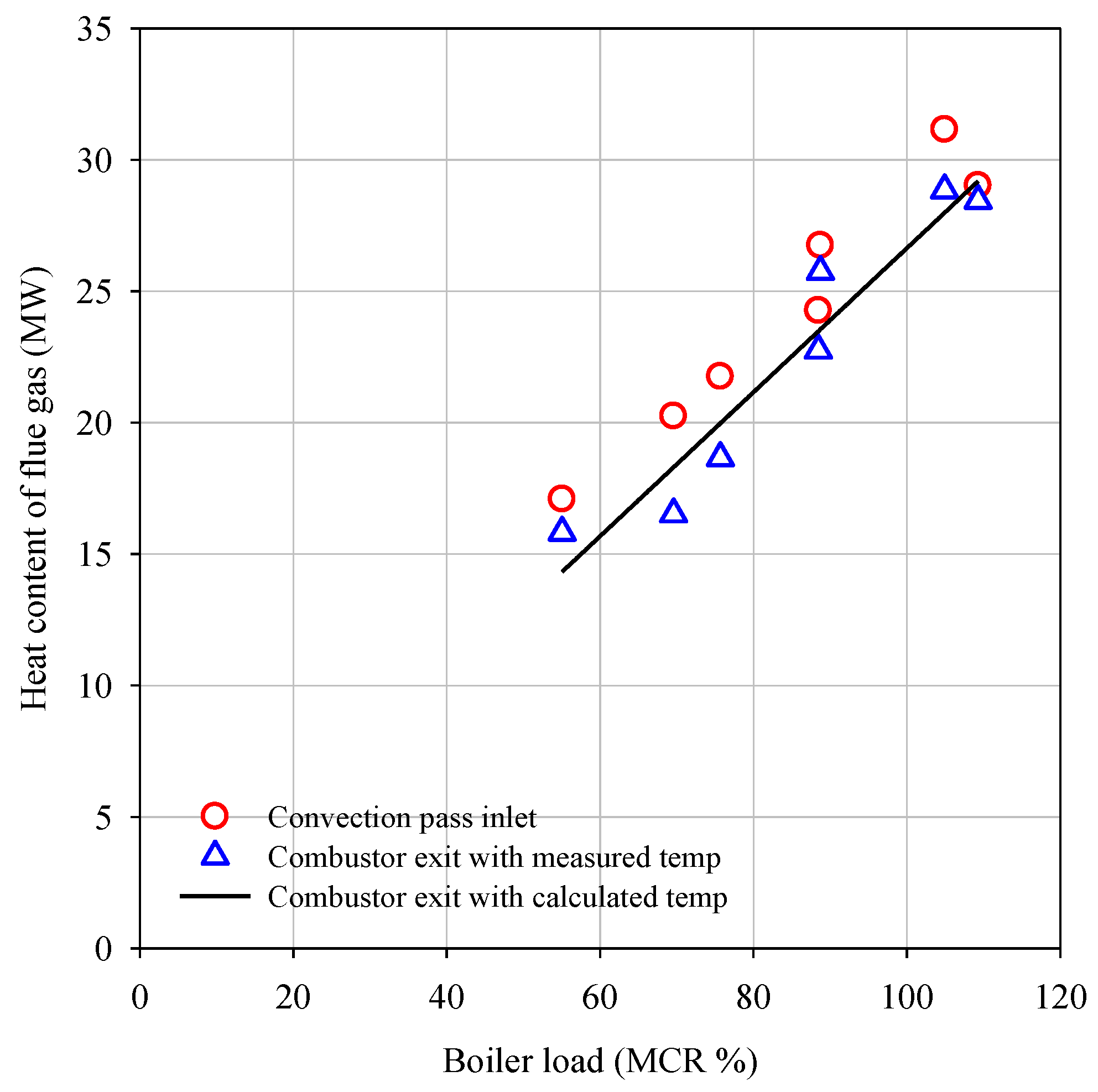

3.2. Non-Homogeneity in Combustor

3.3. After-Combustion in Convection Pass

3.4. Improvement of Boiler Performance

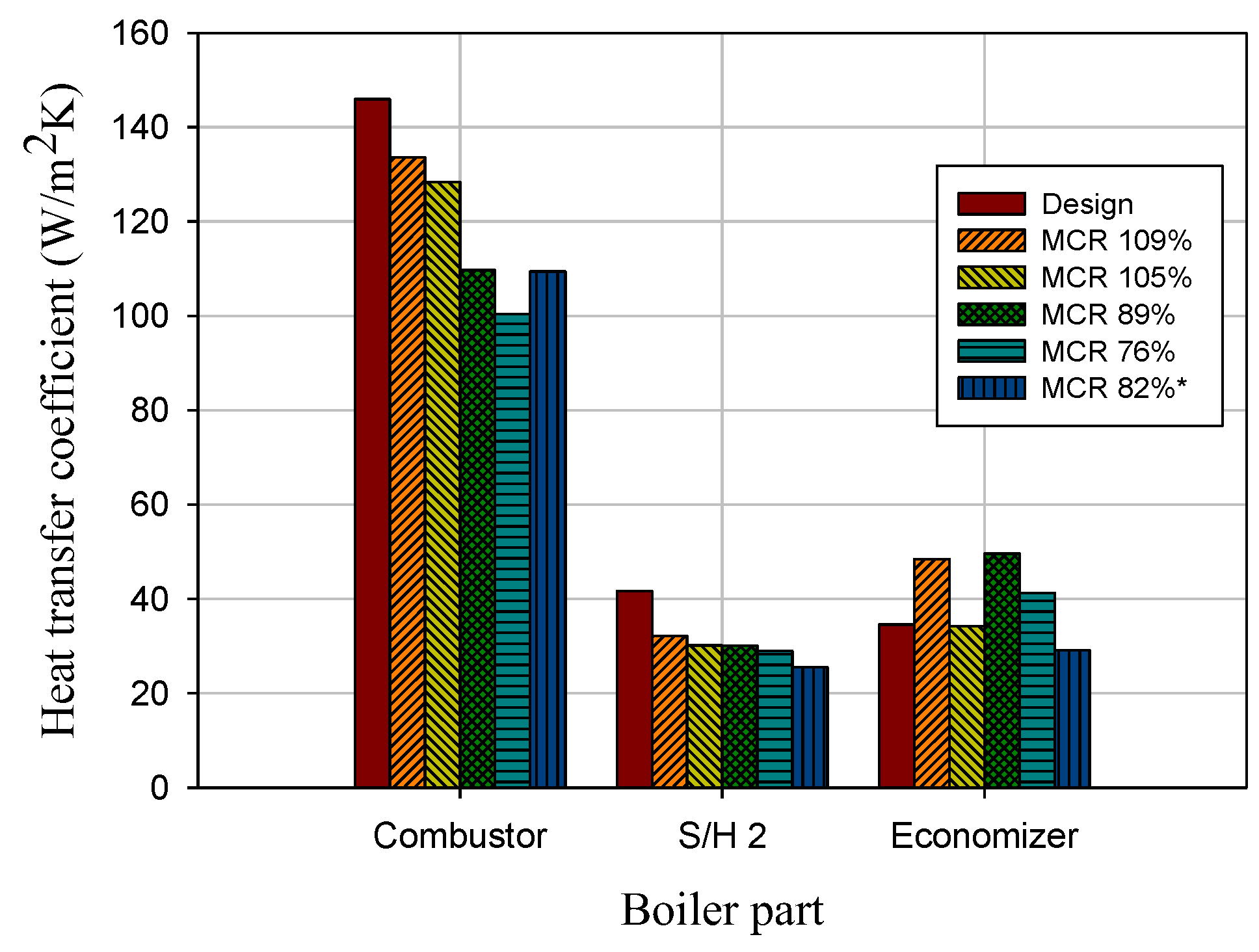

3.5. Heat Transfer Coefficient

4. Conclusions

- After-combustion occurred because of the light density of the fuel. The measured higher temperature at the combustor exit and the convection pass inlet could not represent its thermodynamic conditions due to non-homogeneous combustion characteristics. Thermodynamic calculation provided more consistent heat information on the variation of operation conditions. Inside of the convection pass, where combustion is completed and gas conditions are more homogeneous, the measured temperature and calculated temperature coincided well.

- The load distribution of the de-superheater decreases from 1.76% to 0.87% in 89% MCR before installation of the evaporator and 82* % MCR load distribution of each boiler part after installation. The change of the heat transfer area according to the installation of the evaporator directly affects the amount of spray water in the de-superheater. Through this, the improvement of the heating area for the prevention of after-combustion through the quantitative analysis of spray water seems reasonable.

- The installation of the additional heat transfer unit in the convection pass inlet (second evaporator) based on the spray water at the de-superheater amount and the heat balance calculation controlled the S/H 2 upstream temperature below 800 °C; thus, it was more effective to control after-combustion. The installation of the larger wingwall was relatively ineffective since it could only extract the remaining evaporator portion of spray water of around 0.9 MWth at 76% load.

- This suggests that it is appropriate to establish an after-combustion and a heat transfer area caused by the physical characteristics of the SRF fuel used. In addition, the quantitative change of the spray water supplied from the de-superheater can be used as a major calculation data to calculate the heat transfer area according to the load of the boiler. In the power generation equipment of all fuels in which the after-combustion generated, the problem resolution is possible in all facilities in which the de-superheater is installed and operating in the same method.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| heat transfer area | [m2] | |

| heat transfer area of evaporator | [m] | |

| heat capacity of air | [kJ/(kmolK)] | |

| heat capacity of gas | [kJ/(kmolK)] | |

| heat capacity of particle | [kJ/(kmolK)] | |

| heat capacity of flue gas and fly ash mixture | [kJ/(kmolK)] | |

| diameter of particle inside combustor | [m] | |

| emissivity of combustor | [-] | |

| emissivity of surface of water wall tube | [-] | |

| gravitational acceleration | [m/s2] | |

| enthalpy of feed water at economizer outlet | [kJ/kg] | |

| enthalpy of superheated steam | [kJ/kg] | |

| enthalpy of saturated steam at drum pressure | [kJ/kg] | |

| enthalpy of boiler feed water | [kJ/kg] | |

| combustor overall heat transfer coefficient | [W/(m2K)] | |

| convective heat transfer coefficient | [W/(m2K)] | |

| dispersed phase heat transfer coefficient | [W/(m2K)] | |

| radiative heat transfer coefficient | [W/(m2K)] | |

| thermal conductivity of gas | [W/(m2K)] | |

| mass flow rate of feed water with after-combustion | [kg/s] | |

| mass flow rate of spray water at de-superheater | [kg/s] | |

| mole flow rate of air | [kgmol/s] | |

| mass flow rate of flue gas and fly ash mixture | [kg/s] | |

| mass flow rate of feed water | [kg/s] | |

| Prandtl number | [-] | |

| heat input to the combustor by heated air through air heater | [kW] | |

| heat gain of air through air heater | [kW] | |

| heat load of boiler unit in convection pass | [W] | |

| heat loss by bottom ash discharge | [kW] | |

| heat input from flue gas to economizer | [kW] | |

| evaporator heat load | [W] | |

| heat input to the combustor by fuel combustion | [kW] | |

| heat input from flue gas and fly ash mixture to super heater | [kW] | |

| heat input from flue gas and fly ash mixture to super heater | [kW] | |

| temperature of combustor | [K] | |

| temperature of flue gas at combustor exit or super heater upstream | [K] | |

| flue gas temperature at economizer upstream | [K] | |

| inlet temperature at air heater | [K] | |

| outlet temperature at air heater | [K] | |

| reference temperature | [K] | |

| temperature of water wall tube | [K] | |

| measured convection pas inlet temperature | [K] | |

| overall heat transfer coefficient of evaporator | [W/(m2K)] | |

| overall heat transfer coefficient | [W/(m2K)] | |

| terminal velocity of particle | [m/s] | |

| density of particle | [kg/m3] | |

| density of particle | [kg/m3] | |

| Stefan-Boltzman constant, 5.67 × 10−8 | [W/(m2K4)] | |

| logarithmic mean temperature difference between the tube and the gas side inlet and outlet | [K] |

References

- Ferrer, E.; Aho, M.; Silvennoinen, J.; Nurminen, R.-V. Fluidized bed combustion of refuse-derived fuel in presence of protective coal ash. Fuel Process. Technol. 2005, 87, 33–44. [Google Scholar] [CrossRef]

- Narukawa, K.; Goto, H.; Chen, Y.; Yamazaki, R.; Moi, S.; Fujima, Y.; Hirama, T.; Hosoda, H. Japanese RDF-Fired Power Generation System and Fundamental Research on RDF Combustion; American Society of Mechanical Engineers: New York, NY, USA, 1997. [Google Scholar]

- Ryu, C.; Shin, D. Combined heat and power from municipal solid waste: Current status and issues in South Korea. Energies 2012, 6, 45–57. [Google Scholar] [CrossRef] [Green Version]

- Korea Ministry of Environment. Amendment of the Enforcement Decree of the Waste Control Act, ME Decree; Korea Ministry of Environment: Sejong City, Korea, 2007.

- Korea Ministry of Environment. Amendment of the Enforcement Decree of the Clean Air Conservation Act, ME Act; Korea Ministry of Environment: Sejong City, Korea, 2007.

- Basu, P. Combustion of coal in circulating fluidized-bed boilers: A review. Chem. Eng. Sci. 1999, 54, 5547–5557. [Google Scholar] [CrossRef]

- Dong, H.; Jiang, X.; Lv, G.; Chi, Y.; Yan, J. Co-combustion of tannery sludge in a commercial circulating fluidized bed boiler. Waste Manag. 2015, 46, 227–233. [Google Scholar] [CrossRef]

- Okasha, F.; Zaater, G.; El-Emam, S.; Awad, M.; Zeidan, E. Co-combustion of biomass and gaseous fuel in a novel configuration of fluidized bed: Thermal characteristics. Energy Convers. Manag. 2014, 84, 488–496. [Google Scholar] [CrossRef]

- Shun, D.; Bae, D.-H.; Park, J.; Lee, S.-Y. Development of commercial CFBC boiler for refuse derived fuel. In Proceedings of the 27th Annual International Pittsburgh Coal Conference, Istanbul, Turkey, 11–14 October 2010; p. 2174. [Google Scholar]

- Shun, D.; Bae, D.-H.; Jo, S.-H.; Lee, S.-Y. Combustion Study of 1MWe Circulating Fluidized Boiler for RDF. Korean Chem. Eng. Res. 2012, 50, 837–842. [Google Scholar] [CrossRef]

- Shun, D.; Bae, D.-H.; Jo, S.-H.; Lee, S.-Y. Design of commercial scale of CFBC boiler for waste and biomass. In Proceedings of the International Conference on Advanced Technology & Sustainable Development, Ho Chi Minh City, Vietnam, 27–28 November 2016; p. 436. [Google Scholar]

- Ściubidlo, A.; Majchrzak-Kucęba, I.; Niedzielska, M. Comparison of fly ash from co-combustion of coal/solid recovered fuel (SRF) and coal/refuse derived fuel (RDF). J. Phys. Conf. Ser. 2019, 1398, 012015. [Google Scholar] [CrossRef]

- Wanchan, W.; Khongprom, P.; Limtrakul, S. Study of wall-to-bed heat transfer in circulating fluidized bed riser based on CFD simulation. Chem. Eng. Res. Des. 2020, 156, 442–455. [Google Scholar] [CrossRef]

- Abdelmotalib, H.M.; Youssef, M.A.; Hassan, A.A.; Youn, S.B.; Im, I.-T. Heat transfer process in gas–solid fluidized bed combustors: A review. Int. J. Heat Mass Transf. 2015, 89, 567–575. [Google Scholar] [CrossRef]

- Basu, P.; Nag, P.K. Heat transfer to walls of a circulating fluidized-bed furnace. Chem. Eng. Sci. 1996, 51, 1–26. [Google Scholar] [CrossRef]

- Kawahara, Y. Application of high temperature corrosion-resistant materials and coatings under severe corrosive environment in waste-to-energy boilers. J. Therm. Spray Technol. 2007, 16, 202–213. [Google Scholar] [CrossRef]

- Daouk, E.; Sani, R.; Minh, D.P.; Nzihou, A. Thermo-conversion of Solid Recovered Fuels under inert and oxidative atmospheres: Gas composition and chlorine distribution. Fuel 2018, 225, 54–61. [Google Scholar] [CrossRef] [Green Version]

- Varol, M.; Symonds, R.; Anthony, E.J.; Lu, D.; Jia, L.; Tan, Y. Emissions from co-firing lignite and biomass in an oxy-fired CFBC. Fuel Process. Technol. 2018, 173, 126–133. [Google Scholar] [CrossRef] [Green Version]

- Madanayake, B.N.; Gan, S.; Eastwick, C.; Ng, H.K. Biomass as an energy source in coal co-firing and its feasibility enhancement via pre-treatment techniques. Fuel Process. Technol. 2017, 159, 287–305. [Google Scholar] [CrossRef]

- Hernandez-Atonal, F.D.; Ryu, C.; Sharifi, V.N.; Swithenbank, J. Combustion of refuse-derived fuel in a fluidized bed. Chem. Eng. Sci. 2007, 62, 627–635. [Google Scholar] [CrossRef]

- Omer, A.; Weng, M. Effect of primary air maldistribution due to nozzle wear on CFBC performance. Fuel Process. Technol. 2018, 173, 191–196. [Google Scholar] [CrossRef]

- Lee, S.H.; Themelis, N.J.; Castaidi, M.J. High-temperature corrosion in waste-to-energy boilers. J. Therm. Spray Technol. 2007, 16, 104–110. [Google Scholar] [CrossRef] [Green Version]

- Sorell, G. The role of chlorine in high temperature corrosion in waste-to-energy plants. Mater. High Temp. 1997, 14, 207–220. [Google Scholar] [CrossRef]

- Park, J.H.; Lee, D.-H.; Han, K.-H.; Shin, J.-S.; Bae, D.-H.; Shim, T.-E.; Lee, J.H.; Shun, D. Effect of chemical additives on hard deposit formation and ash composition in a commercial circulating fluidized bed boiler firing Korean solid recycled fuel. Fuel 2019, 236, 792–802. [Google Scholar] [CrossRef]

- Basu, P. Circulating Fluidized Bed Boilers: Design, Operation and Maintenance; Elsevier: Amsterdam, The Netherlands, 2015. [Google Scholar]

- Basu, P. Combustion and Gasification in Fluidized Beds; CRC Press: Boca Raton, FL, USA, 2006. [Google Scholar]

- Wen, C.-Y.; Miller, E. Heat transfer in solids-gas transport lines. Ind. Eng. Chem. 1961, 53, 51–53. [Google Scholar] [CrossRef]

- Singh, S. Pre-determination of the Fouling and Cleanliness Factor of the Heat Exchanger. Int. J. Eng. Res. Appl. 2012, 2, 1177–1179. [Google Scholar]

- Zbogar, A.; Frandsen, F.J.; Jensen, P.A.; Glarborg, P. Heat transfer in ash deposits: A modelling tool-box. Prog. Energy Combust. Sci. 2005, 31, 371–421. [Google Scholar] [CrossRef]

- Walter, A.; Hofmann, R. How can the heat transfer correlations for finned-tubes influence the numerical simulation of the dynamic behavior of a heat recovery steam generator. Appl. Therm. Eng. 2011, 31, 405–417. [Google Scholar] [CrossRef] [Green Version]

| Specifications | Unit | Value |

|---|---|---|

| Net electricity output | MWe | 5.5–14.5 |

| Maximum steam rate | ton/h | 60 |

| Final steam temperature | °C | 450 |

| Final steam pressure | Ata | 45 |

| Feed water temperature | °C | 143 |

| Boiler load variation | % MCR | 55–109 |

| Fuel flow range | ton/h | 5.4–10.6 |

| Parameter | Design Fuel | Test Fuel Low | Test Fuel High |

|---|---|---|---|

| Carbon, wt% | 43.5 | 41.4 | 44.6 |

| Hydrogen, wt% | 5.8 | 5.8 | 6.3 |

| Nitrogen, wt% | 0.7 | 1.0 | 1.0 |

| Sulfur, wt% | 0.2 | 0.2 | 0.2 |

| Oxygen, wt% | 24.2 | 21.3 | 24.2 |

| Chloride, wt% | 1.4 | 1.0 | 1.1 |

| Water, wt% | 7.0 | 12.4 | 8.9 |

| Ash, wt% | 17.2 | 16.9 | 13.7 |

| Bulk density, kg/m3 | 700 | 400 | 400 |

| High Heating Value, analysis, kJ/kg | 18,744 | 18,990 | 20,781 |

| % Load | 109 | 105 | 88 | 76 | 55 | 82 * | 76 * |

|---|---|---|---|---|---|---|---|

| Steam rate (kg/h) | 65,600 | 62,900 | 53,000 | 45,400 | 33,000 | 48,000 | 45,600 |

| Measured combustor exit temperature (°C) | 905 | 913 | 894 | 831 | 760 | 785 | 800 |

| Calculated combustor exit temperature (°C) | 882 | 889 | 864 | 861 | 668 | 816 | 801 |

| Convection pass inlet temperature (°C) | 921 | 978 | 947 | 953 | 815 | 894 | 881 |

| 2nd evaporator down temperature (°C) | - | - | - | - | - | 805 | 757 |

| Heat transfer coefficient of wall, measured (W/m2-K) | 134 | 128 | 110 | 100 | 89 | 109 | 99 |

| Radiative heat transfer coefficient, calculated (W/m2-K) | 129 | 131 | 125 | 111 | 95 | 101 | 104 |

| Convective heat transfer coefficient, calculated (W/m2-K) | 37 | 37 | 37 | 35 | 34 | 34 | 34 |

| Average density in freeboard (kg/m3) | 33.4 | 24.2 | 8.6 | 10.4 | 4.6 | 7.8 | 6.4 |

| SO2 emission (ppm) | 1.6 | 2.0 | 1.3 | 2.8 | 3.4 | 0.1 | 0.1 |

| NOx emission (ppm) | 35.4 | 34.4 | 42.2 | 0.8 | 1.6 | 43.5 | 35.7 |

| O2 (%) | 4.6 | 5.5 | 4.7 | 5.3 | 9.1 | 7.4 | 7.7 |

| HCl (ppm) | 6.6 | 7.7 | 6.7 | 9.6 | 18.9 | 3.5 | 5.0 |

| Heat Content [MW]\% Load | 109 | 105 | 88 | 76 | 55 | 82 * | 76 * |

|---|---|---|---|---|---|---|---|

| Total boiler output | 49.8 | 47.8 | 40.4 | 34.7 | 24.9 | 37.3 | 34.7 |

| Evaporator | 28.3 | 27.6 | 23.0 | 19.0 | 14.7 | 21.5 | 20.2 |

| Flue gas at combustor exit | 28.4 | 28.8 | 22.7 | 18.7 | 16.5 | 22.6 | 21.5 |

| Flue gas at 2nd evaporator down | - | - | - | - | - | 26.2 | 23.9 |

| Flue gas at convection pass inlet | 29.0 | 31.2 | 24.3 | 21.8 | 17.1 | 23.3 | 20.2 |

| Spray water heat rate | 2.7 | 2.6 | 2.5 | 3.2 | 1.0 | 1.6 | 1.4 |

| Spray water evaporation portion | 1.6 | 1.6 | 1.5 | 1.9 | 0.6 | 0.9 | 0.9 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shin, J.-S.; Shun, D.; Cho, C.-H.; Choi, Y.; Bae, D.-H. The Characteristics of the After-Combustion in a Commercial CFBC Boiler Using the Solid Waste Fuel. Energies 2022, 15, 5507. https://doi.org/10.3390/en15155507

Shin J-S, Shun D, Cho C-H, Choi Y, Bae D-H. The Characteristics of the After-Combustion in a Commercial CFBC Boiler Using the Solid Waste Fuel. Energies. 2022; 15(15):5507. https://doi.org/10.3390/en15155507

Chicago/Turabian StyleShin, Jong-Seon, Dowon Shun, Churl-Hee Cho, Yujin Choi, and Dal-Hee Bae. 2022. "The Characteristics of the After-Combustion in a Commercial CFBC Boiler Using the Solid Waste Fuel" Energies 15, no. 15: 5507. https://doi.org/10.3390/en15155507

APA StyleShin, J.-S., Shun, D., Cho, C.-H., Choi, Y., & Bae, D.-H. (2022). The Characteristics of the After-Combustion in a Commercial CFBC Boiler Using the Solid Waste Fuel. Energies, 15(15), 5507. https://doi.org/10.3390/en15155507