Kinematic and Dynamic Simulation Analysis of Modified Conventional Beam Pumping Unit

Abstract

:1. Introduction

2. Modulation Principle and Method

2.1. Modulation Principle

2.2. Modulation Method

2.3. Working Process and Balance Analysis

3. Simulation Modeling

3.1. Conditional Assumptions

- (1)

- The influence of the micro-stress deformation of each component was neglected and the unit was regarded as a purely rigid body;

- (2)

- The rotating bearing was simplified to be treated by the rotating pair in ADAMS and the friction between the bearing and the shaft and the dissipation of the friction energy were ignored;

- (3)

- The gear transmission was simplified to be treated by the gear pair in ADAMS and the energy dissipation during the gear transmission process was ignored;

- (4)

- The shapes of the fixed parts (such as the base, beam support, reducer base and reducer shell), were simplified as they had no impact on the dynamic performance of the pumping unit;

- (5)

- The influence of the motor load on speed change was ignored and the crank of the pumping unit was regarded as having a uniform angular speed rotation.

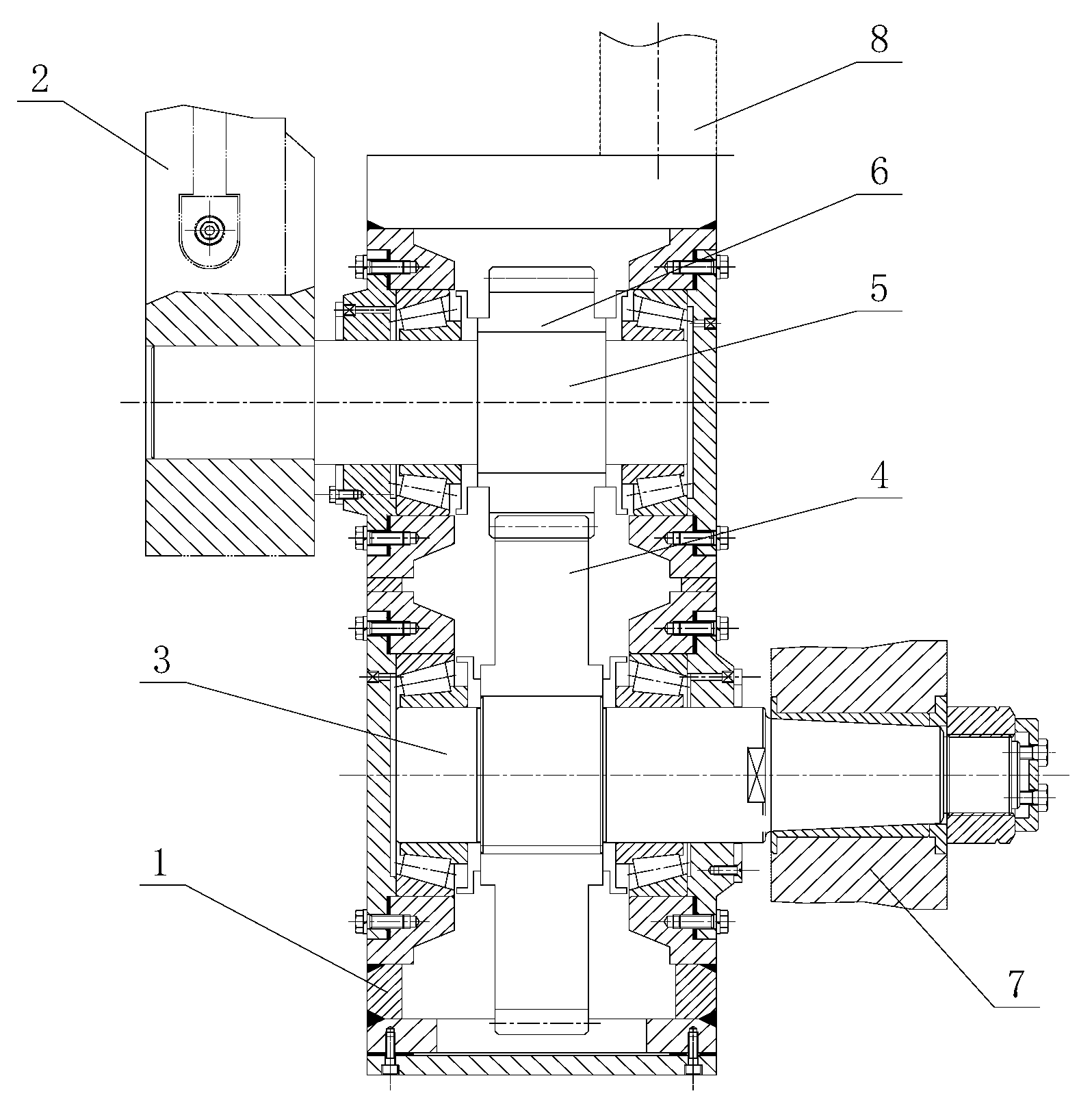

3.2. Virtual Prototype

3.3. Properties of the Modified Parts

3.4. Constraints

3.5. Boundary Conditions

4. Analysis of Simulation Results

4.1. Kinematic Simulation

4.2. Dynamic Simulation

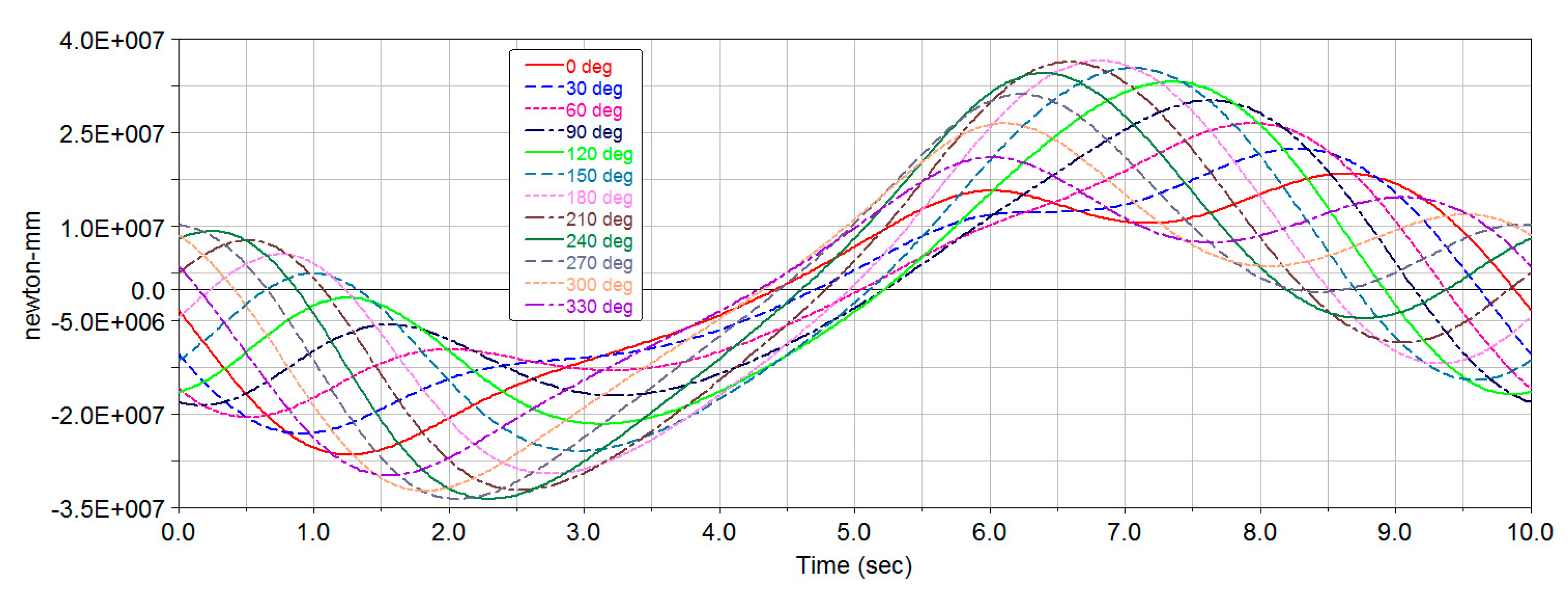

4.2.1. Analysis of the Torque Superposition Process

4.2.2. Influencing Factor Analysis of the Secondary Balance

- x, y, z are the mass center coordinates of the secondary balance crank after rotation (mm);

- x1, y1, z1 are the coordinates of the center of the secondary balance rotation (mm);

- θ is the rotation angle of the crank centroid (°);

- a is the radius of the crank centroid (mm).

4.2.3. Determination of a Reasonable Offset Angle

- (−119.6559262832, 3731.5087176225, −1407.2900367944)

- (−119.6559262832, 3900.7597523817, −1505.0071672729)

5. Conclusions

- (1)

- The small crank rotated with a non-uniform angular velocity, but its average angular velocity was approximately twice that of the large crank so as to ensure the repeatability and superposition of the motion cycle;

- (2)

- Secondary balance not only played the role of secondary balance in balancing negative torque, but also the role of the primary balance. Different secondary balance offset angles not only caused changes in the curve phase, but also led to changes in the curve amplitude. The best choice for the secondary balance offset angle was 315°. The secondary balance torque curve could realize the “peak cutting and valley filling” for the curve after the primary balance, which achieved full-cycle positive values for the reducer output shaft net torque and verified the feasibility of this modulation scheme;

- (3)

- When the radius of the secondary balance mass center increased, the amplitude of the torque curve increased obviously and the phase remained basically the same. Therefore, when the offset angle of the secondary balance weight was determined, the radius of the mass center could be changed by adjusting the position of the secondary balance weight to achieve balance adjustment.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Han, Y.; Li, K.; Ge, F.W.; Wang, Y.A.; Xu, W.S. Online fault diagnosis for sucker rod pumping well by optimized density peak clustering. ISA Trans. 2022, 120, 222–234. [Google Scholar] [CrossRef]

- Ahmedov, B.; Hajiyev, A.; Mustafayev, V. Estimation of the equality of the beamless sucker-rod oil pumping unit by the value of the consumption current. Nafta-Gaz 2021, 77, 571–578. [Google Scholar] [CrossRef]

- Ahmedov, B. Assessment of dynamic efforts taking into account of inertial and vibrating loads in deaxial pumping units. J. Pet. Explor. Prod. Technol. 2020, 10, 1401–1409. [Google Scholar] [CrossRef] [Green Version]

- Ye, Z.W.; Liu, Z.Y.; Cheng, C.; Tan, L.; Feng, K. Efficient evaluation model of beam pumping unit based on principal component regression analysis. Sci. Prog. 2020, 103, 003685041989576. [Google Scholar] [CrossRef] [PubMed]

- Feng, Z.M.; Tan, J.J.; Li, Q.; Fang, X. A review of beam pumping energy-saving technologies. J. Pet. Explor. Prod. Technol. 2018, 8, 299–311. [Google Scholar] [CrossRef] [Green Version]

- Feng, Z.M.; Guo, C.H.; Zhang, D.S.; Cui, W.; Tan, C.D.; Xu, X.F.; Zhang, Y. Variable speed drive optimization model and analysis of comprehensive performance of beam pumping unit. J. Petrol. Sci. Eng. 2020, 191, 107155. [Google Scholar] [CrossRef]

- Zhang, C.Y.; Wang, L.; Li, H. Experiments and Simulation on a Late-Model Wind-Motor Hybrid Pumping Unit. Energies 2020, 13, 994. [Google Scholar] [CrossRef] [Green Version]

- Gibbs, S.G. Computing Gearbox Torque and Motor Loading for Beam Pumping Units with Consideration of Inertia Effects. J. Petrol. Technol. 1975, 27, 1153–1159. [Google Scholar] [CrossRef]

- Takacs, G.; Kis, L. A new model to find optimum counterbalancing of sucker-rod pumping units including a rigorous procedure for gearbox torque calculations. J. Petrol. Sci. Eng. 2021, 205, 108792. [Google Scholar] [CrossRef]

- Badoiu, D.; Toma, G. Research Concerning the Predictive Evaluation of the Motor Moment at the Crankshaft of the Conventional Sucker Rod Pumping Units. Rev. Chim.-Bucharest 2019, 70, 378–381. [Google Scholar] [CrossRef]

- Takacs, G. A critical analysis of power conditions in sucker-rod pumping systems. J. Petrol. Sci. Eng. 2022, 210, 110061. [Google Scholar] [CrossRef]

- Zhang, C.; Wang, L.; Li, H. Optimization method based on process control of a new-type hydraulic-motor hybrid beam pumping unit. Measurement 2020, 158, 107716. [Google Scholar] [CrossRef]

- Bello, O.; Dolberg, E.P.; Teodoriu, C.; Karami, H.; Devegowdva, D. Transformation of academic teaching and research: Development of a highly automated experimental sucker rod pumping unit. J. Petrol. Sci. Eng. 2020, 190, 107087. [Google Scholar] [CrossRef]

- Yu, Y.Q.; Chang, Z.Y.; Qi, Y.G.; Xue, X.; Zhao, J.N. Study of a new hydraulic pumping unit based on the offshore platform. Energy Sci. Eng. 2016, 4, 352–360. [Google Scholar] [CrossRef] [Green Version]

- Li, Z.H.; Song, J.C.; Huang, Y.J.; Li, Y.G.; Chen, J.W. Design and analysis for a new energy-saving hydraulic pumping unit. Part C J. Mech. Eng. Sci. 2018, 232, 2119–2131. [Google Scholar] [CrossRef]

- Yi, L.; Leinonen, T. Kinematic and dynamic simulation of a dual-beam pumping unit for increasing stroke and reducing force. J. Energy Resour. Technol. 2004, 126, 320–325. [Google Scholar] [CrossRef]

- Yang, H.K.; Wang, J.P.; Liu, H. Energy-saving mechanism research on beam-pumping unit driven by hydraulics. PLoS ONE 2021, 16, e0249044. [Google Scholar] [CrossRef] [PubMed]

- Kazak, A.S. New Type Oil-Field Deep-Well Pumping Units. Neft. Khozyaistvo 1989, 2, 62–63. [Google Scholar]

- Xu, J.C.; Meng, S.Y.; Li, W.; Wang, Y. Positive Torque Modulation Method and Key Technology of Conventional Beam Pumping Unit. Energies 2022, 15, 3141. [Google Scholar] [CrossRef]

- Feng, Z.M.; Ding, H.H.; Jiang, M.Z. New Secondary Balancing Method Saves Energy for Crank-Balanced Rod-Pumping Application. SPE Prod. Oper. 2015, 30, 141–145. [Google Scholar]

- Liu, Y.; Wu, H.; Liu, H. The Kinematic Analysis and Parametric Design of Beam Pumping Unit Based on ADAMS. In Proceedings of the 2011 Second International Conference on Digital Manufacturing & Automation, Zhangjiajie, China, 5–7 August 2011; pp. 1296–1300. [Google Scholar] [CrossRef]

| Pumping Unit Component | CYJ10-4.2-53HF |

|---|---|

| Forearm Length A | 4210 |

| Back Arm Length C | 2625 |

| Connecting Rod Length P | 3980 |

| Height of Support Center H | 6450 |

| Height of Reducer Center G | 2600 |

| H–G | 3850 |

| Horizontal Distance I | 3350 |

| Crank Rotation Radius r | 1205/1055/895 |

| Overall Dimensions | 10659 × 2188 × 8677 |

| Part Name | Quantity | Mass (kg) | Part Name | Quantity | Mass (kg) | ||

|---|---|---|---|---|---|---|---|

| Single | Total | Single | Total | ||||

| Beam | 1 | 1759.2 | 1759.2 | Tail Bearing Seat | 1 | 192.7 | 192.7 |

| Horsehead | 1 | 363.1 | 363.1 | Secondary Balance Crank | 2 | 160.3 | 320.6 |

| Primary Balance Crank | 2 | 1429 | 2858 | Secondary Balance Weight | 4 | 307 | 1228 |

| Large Counterweight | 2 | 1390 | 2780 | Speed Increasing Gearbox | 2 | 301.6 | 603.2 |

| Small Counterweight | 2 | 1116 | 2232 | Large Gear | 2 | 57.6 | 115.2 |

| Composite Balance Weight | 1 | 458 | 458 | Small Gear | 2 | 19.8 | 39.6 |

| Crossbeam | 1 | 237.4 | 237.4 | Large Gear Shaft of Speed Increasing Gearbox | 2 | 39.8 | 79.6 |

| Connecting Rod | 2 | 52 | 104 | Small Gear Shaft of Speed Increasing Gearbox | 2 | 33 | 66 |

| Constraint Type | Constrained Parts |

|---|---|

| Fixed Pair | Base and ground |

| Support and base | |

| Reducer and base | |

| The output shaft of the reducer and the large crank | |

| The large crank and the input shaft of the speed increasing gearbox | |

| The small crank and the output shaft of the speed increasing gearbox | |

| The connecting rod frame and the speed increasing gearbox | |

| Rotating Pair | Beam and support |

| The reducer and the output shaft of the reducer | |

| The input shaft of the speed increasing gearbox and the speed increasing gearbox | |

| The output shaft of the speed increasing gearbox and the speed increasing gearbox | |

| Gear Pair | The large gear and the pinion of the speed increasing gearbox |

| Driving Constraint | The output shaft of the reducer |

| Offset Angle | x | y | z |

|---|---|---|---|

| 0° | −119.6559262832 | 4012.3454134886 | −1771.9753325099 |

| 30° | −119.6559262832 | 3960.7594783429 | −1957.7503325099 |

| 60° | −119.6559262832 | 3822.5415871441 | −2098.9432237087 |

| 90° | −119.6559262832 | 3633.7915871441 | −2149.5253325099 |

| 120° | −119.6559262832 | 3445.0165871441 | −2098.9432237087 |

| 150° | −119.6559262832 | 3306.8236959452 | −1957.7503325099 |

| 180° | −119.6559262832 | 3256.2415871441 | −1771.9753325099 |

| 210° | −119.6559262832 | 3306.8236959452 | −1583.2003325099 |

| 240° | −119.6559262832 | 3445.0165871441 | −1445.0074413110 |

| 270° | −119.6559262832 | 3633.7915871441 | −1394.4253325099 |

| 300° | −119.6559262832 | 3822.5415871441 | −1445.0074413110 |

| 330° | −119.6559262832 | 3960.7594783429 | −1583.2003325099 |

| Centroid Radii (mm) | x | y | z |

|---|---|---|---|

| 377.55 | −119.6559262832 | 3822.5415871441 | −1445.0074413110 |

| 500 | −119.6559262832 | 4012.3454134886 | −1771.9753325099 |

| 750 | −119.6559262832 | 4008.7915871441 | −1122.4562796715 |

| Secondary Balance Offset Angle | Minimum Value | Maximum Value | Average Value | Root Mean Square Value |

|---|---|---|---|---|

| 285° | −6.877 | 47,199 | 17,980 | 22,636 |

| 300° | 1753.6 | 45,094 | 17,978 | 21,955 |

| 315° | 2396.5 | 42,869 | 17,974 | 21,499 |

| 330° | −275.74 | 40,667 | 17,970 | 21,168 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, J.; Li, W.; Meng, S. Kinematic and Dynamic Simulation Analysis of Modified Conventional Beam Pumping Unit. Energies 2022, 15, 5496. https://doi.org/10.3390/en15155496

Xu J, Li W, Meng S. Kinematic and Dynamic Simulation Analysis of Modified Conventional Beam Pumping Unit. Energies. 2022; 15(15):5496. https://doi.org/10.3390/en15155496

Chicago/Turabian StyleXu, Jinchao, Wei Li, and Siyuan Meng. 2022. "Kinematic and Dynamic Simulation Analysis of Modified Conventional Beam Pumping Unit" Energies 15, no. 15: 5496. https://doi.org/10.3390/en15155496

APA StyleXu, J., Li, W., & Meng, S. (2022). Kinematic and Dynamic Simulation Analysis of Modified Conventional Beam Pumping Unit. Energies, 15(15), 5496. https://doi.org/10.3390/en15155496