Biodiesel Produced from Propanol and Longer Chain Alcohols—Synthesis and Properties

Abstract

:1. Introduction

2. Fatty Acid Propyl Esters

3. Fatty Acid Butyl Esters

4. Fatty Acid Pentyl Esters

5. Fatty Acid C6+ Alkyl Esters

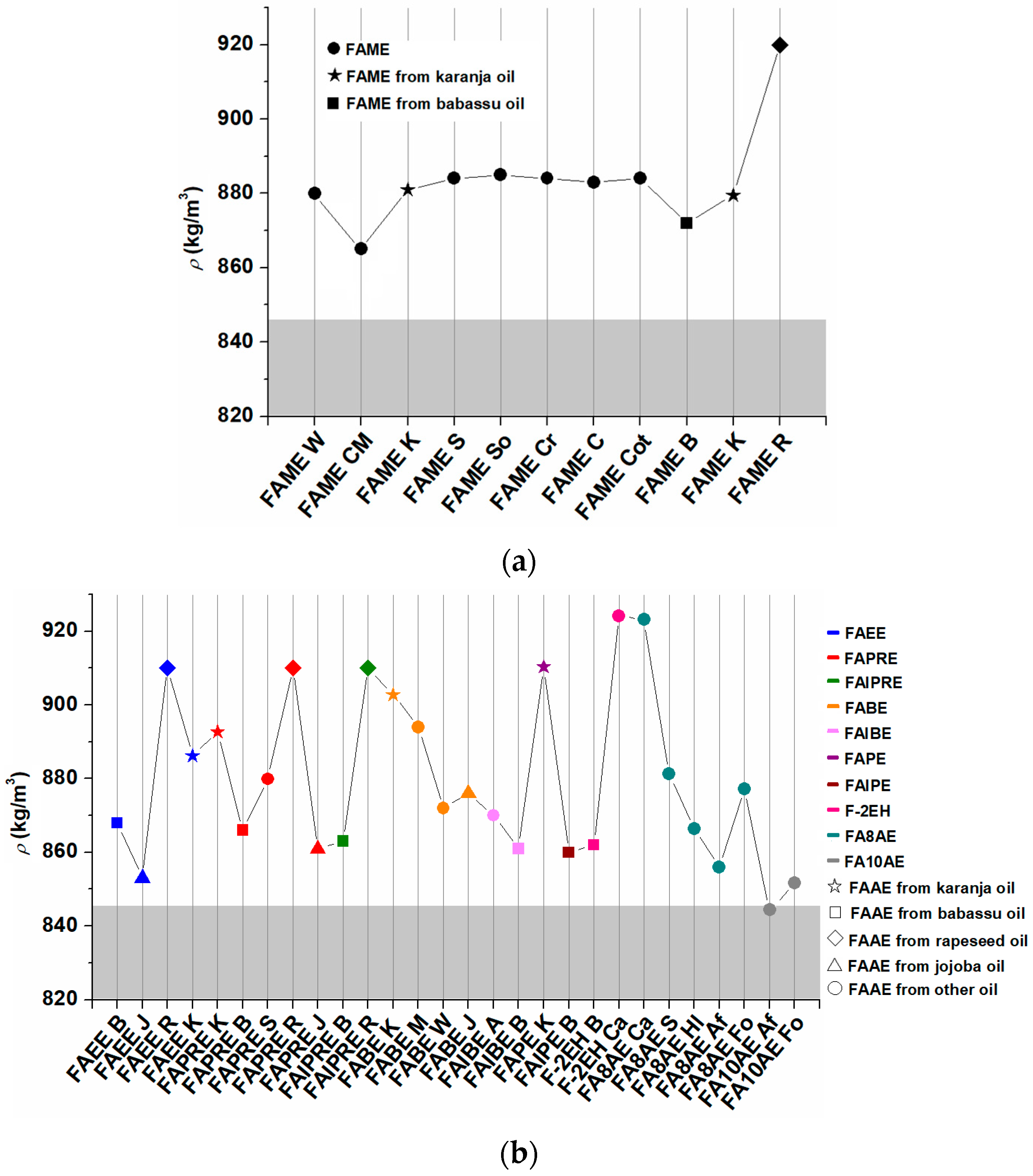

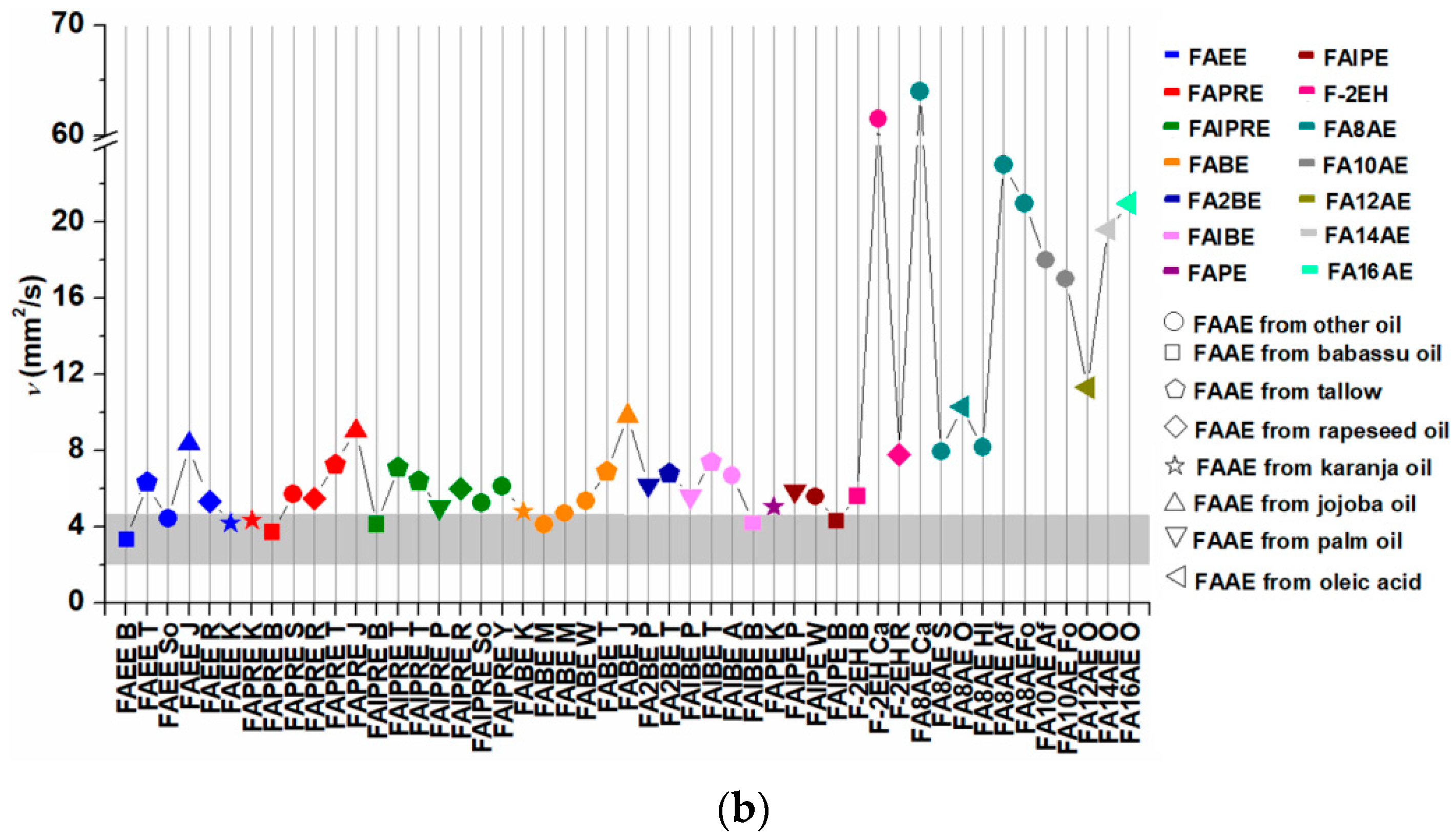

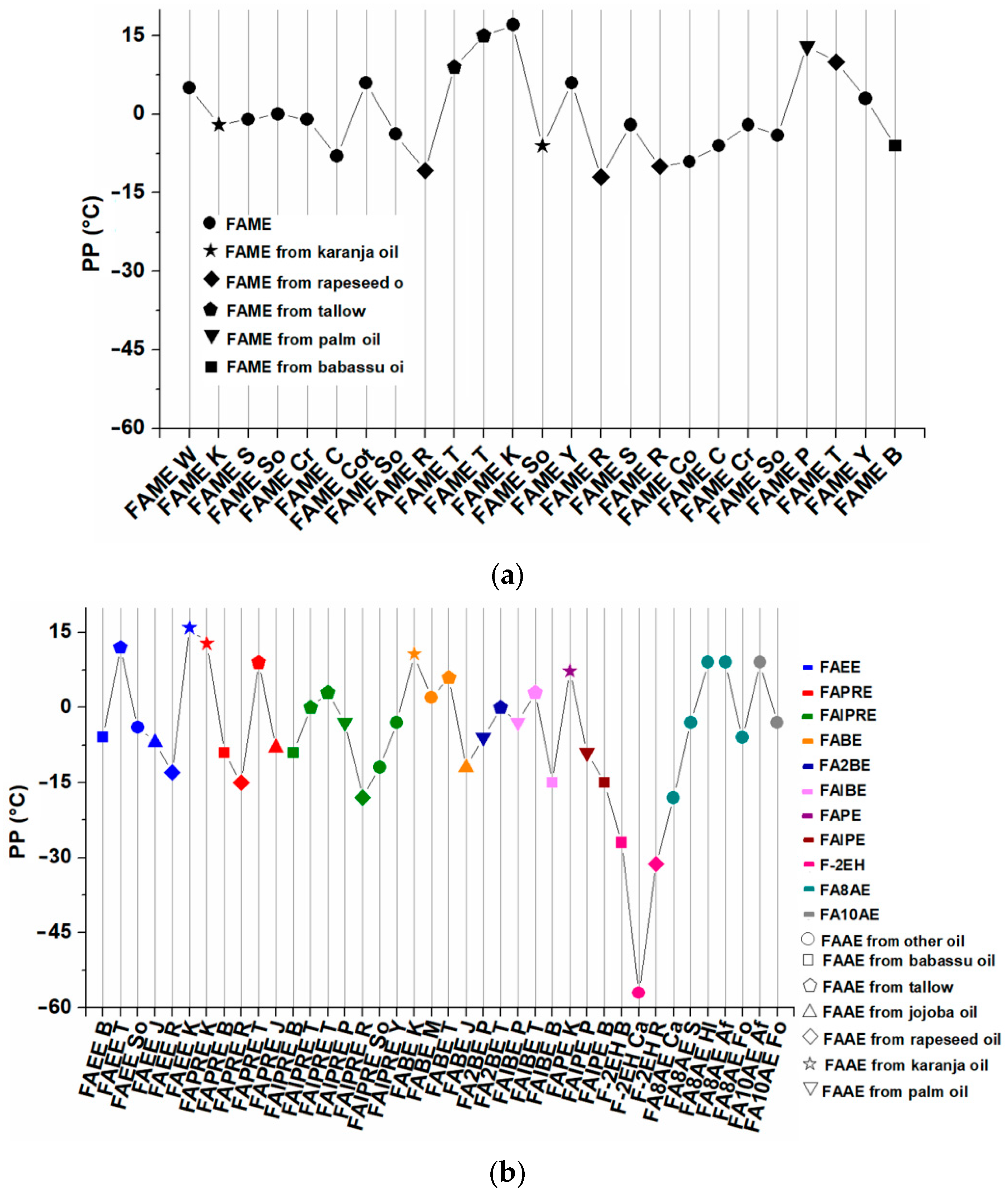

6. Comparative Property Analysis of Different FAAE

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Callegari, A.; Bolognesi, S.; Cecconet, D.; Capodaglio, A.G. Production technologies, current role, and future prospects of biofuels feedstocks: A state-of-the-art review. Crit. Rev. Environ. Sci. Technol. 2019, 50, 384–436. [Google Scholar] [CrossRef]

- Sanderson, M.A.; Reed, R.L.; McLaughlin, S.B.; Wullschleger, S.D.; Conger, B.V.; Parrish, D.J.; Wolf, D.D.; Taliaferro, C.; Hopkins, A.A.; Ocumpaugh, W.R.; et al. Switchgrass as a sustainable bioenergy crop. Bioresour. Technol. 1996, 56, 83–93. [Google Scholar] [CrossRef]

- U.S. Energy Information Administration. Form EIA-819 “Monthly Report of Biofuels, Fuels from Non-Biogenic Wastes, Fuel Oxygenates, Isooctane, and Isooctene”. Available online: https://www.eia.gov/biofuels/update/table1.pdf (accessed on 30 April 2022).

- Statista. Available online: https://www.statista.com/statistics/274163/global-biofuel-production-in-oil-equivalent/ (accessed on 30 April 2022).

- Statista. Available online: https://www.statista.com/statistics/274180/biofuel-production-in-the-european-union-in-oil-equivalent/ (accessed on 30 April 2022).

- Statista. Available online: https://www.statista.com/statistics/1055597/indonesia-biodiesel-exports/ (accessed on 5 May 2022).

- Statista. Available online: https://www.statista.com/statistics/877042/brazil-biodiesel-production/ (accessed on 5 May 2022).

- Statista. Available online: https://www.statista.com/statistics/1113401/argentina-biodiesel-production/ (accessed on 5 May 2022).

- Organisation for Economic Co-operation and Development. Available online: https://stats.oecd.org (accessed on 19 February 2022).

- Bashir, M.A.; Wu, S.; Zhu, J.; Krosuri, A.; Khan, M.U.; Aka, R.J.N. Recent development of advanced processing technologies for biodiesel production: A critical review. Fuel Process. Technol. 2022, 227, 107120. [Google Scholar] [CrossRef]

- Mohadesi, M.; Aghel, B.; Maleki, M.; Ansari, A. Production of biodiesel from waste cooking oil using a homogeneous catalyst: Study of semi-industrial pilot of microreactor. Renew. Energy 2019, 136, 677–682. [Google Scholar] [CrossRef]

- Thangaraj, B.; Solomon, P.R.; Muniyandi, B.; Ranganathan, S.; Lin, L. Catalysis in biodiesel production—A Review. Clean Energy 2018, 3, 2–23. [Google Scholar] [CrossRef] [Green Version]

- Joshi, S.M.; Gogate, P.R.; Kumar, S.S. Intensification of esterification of karanja oil for production of biodiesel using ultrasound assisted approach with optimization using response surface methodology. Chem. Eng. Process. Process. Intensif. 2018, 124, 186–198. [Google Scholar] [CrossRef]

- Ramlee, N.N.B.; Mahdi, H.I.; Azelee, N.I.W. Chapter 7—Biodiesel Production Using Enzymatic Catalyst. In Biofuels and Bioenergy Opportunities and Challenges; Gurunathan, C., Janko, B., Eds.; Elsevier: Amsterdam, The Netherlands, 2022; pp. 133–169. [Google Scholar] [CrossRef]

- Gebremariam, S.N.; Marchetti, J.M. Economics of biodiesel production: Review. Energy Convers. Manag. 2018, 168, 74–84. [Google Scholar] [CrossRef]

- Mansir, N.; Teo, S.H.; Rashid, U.; Saiman, M.I.; Tan, Y.P.; Alsultan, G.A.; Taufiq-Yap, Y.H. Modified waste egg shell derived bifunctional catalyst for biodiesel production from high FFA waste cooking oil. A review. Renew. Sustain. Energy Rev. 2018, 82, 3645–3655. [Google Scholar] [CrossRef]

- Husin, H.; Abubakar, A.; Ramadhani, S.; Sijabat, C.F.B.; Hasfita, F. Coconut husk ash as heterogenous catalyst for biodiesel production from cerbera manghas seed oil. MATEC Web Conf. 2018, 197, 09008. [Google Scholar] [CrossRef] [Green Version]

- Buasri, A.; Worawanitchaphong, P.; Trongyong, S.; Loryuenyong, V. Utilization of Scallop Waste Shell for Biodiesel Production from Palm Oil—Optimization Using Taguchi Method. APCBEE Proc. 2014, 8, 216–221. [Google Scholar] [CrossRef] [Green Version]

- Madhu, D.; Chavan, S.B.; Singh, V.; Singh, B.; Sharma, Y.C. An economically viable synthesis of biodiesel from a crude Millettia pinnata oil of Jharkhand, India as feedstock and crab shell derived catalyst. Bioresour. Technol. 2016, 214, 210–217. [Google Scholar] [CrossRef] [PubMed]

- Maheshwari, P.; Haider, M.B.; Yusuf, M.; Klemeš, J.J.; Bokhari, A.; Beg, M.; Al-Othman, A.; Kumar, R.; Jaiswal, A.K. A review on latest trends in cleaner biodiesel production: Role of feedstock, production methods, and catalysts. J. Clean. Prod. 2022, 355, 131588. [Google Scholar] [CrossRef]

- El-Gharbawy, A.S.; Sadik, W.A.; Sadek, O.M.; Kasaby, M.A. A Review on Biodiesel Feedstock and Production Technologies. J. Chil. Chem. Soc. 2021, 66, 5098. [Google Scholar] [CrossRef]

- Canakci, M.; Sanli, H. Biodiesel production from various feedstocks and their effects on the fuel properties. J. Ind. Microbiol. Biot. 2008, 35, 431–441. [Google Scholar] [CrossRef] [PubMed]

- Schubert, T. Review: Production routes of advanced renewable C1 to C4 alcohols as biofuel components—A review. Biofuels Bioprod. Biorefining 2020, 14, 845–878. [Google Scholar] [CrossRef]

- Zaher, F.A.; Soliman, H.M. Biodiesel production by direct esterification of fatty acids with propyl and butyl alcohols. Egypt. J. Pet. 2015, 24, 439–443. [Google Scholar] [CrossRef] [Green Version]

- Gotovuša, M.; Medić, M.; Faraguna, F.; Šibalić, M.; Konjević, L.; Parlov Vuković, J.; Racar, M. Fatty acids propyl esters: Synthesis optimization and application properties of their blends with diesel and 1-propanol. Renew. Energy 2022, 185, 655–664. [Google Scholar] [CrossRef]

- Benjumea, P.N.; Agudelo, J.R.; Rios, L. Cold flow properties of palm oil biodiesel. Rev. Fac. Ing. Univ. Antioq. 2007, 42, 94–104. Available online: http://www.scielo.org.co/pdf/rfiua/n42/n42a07.pdf (accessed on 5 June 2022).

- Lee, I.; Johnson, L.A.; Hammond, E.G. Use of branched-chain esters to reduce the crystallization temperature of biodiesel. J. Am. Oil Chem. Soc. 1995, 72, 1155–1160. [Google Scholar] [CrossRef]

- Foglia, T.A.; Nelson, L.A.; Dunn, R.O.; Marmer, W.N. Low-Temperature Properties of Alkyl Esters of Tallow and Grease. J. Am. Oil Chem. Soc. 1997, 74, 951–955. [Google Scholar] [CrossRef]

- Wu, W.H.; Foglia, T.A.; Marmer, W.N.; Dunn, R.O.; Goering, C.E.; Briggs, T.E. Low-temperature property and engine performance evaluation of ethyl and isopropyl esters of tallow and grease. J. Am. Oil Chem. Soc. 1998, 75, 1173–1178. [Google Scholar] [CrossRef]

- Sun, J.; Yu, B.; Curran, P.; Liu, S.Q. Lipase-catalysed transesterification of coconut oil with fusel alcohols in a solvent-free system. Food Chem. 2012, 134, 89–94. [Google Scholar] [CrossRef]

- El-Boulifi, N.; Sánchez, M.; Martínez, M.; Aracil, J. Fatty acid alkyl esters and monounsaturated alcohols production from jojoba oil using short-chain alcohols for biorefinery concepts. Ind. Crop. Prod. 2015, 69, 244–250. [Google Scholar] [CrossRef]

- Sagiroglu, A. Conversion of Sunflower Oil to Biodiesel by Alcoholysis using Immobilized Lipase. Artif. Cell. Nanomed. B. 2008, 36, 138–149. [Google Scholar] [CrossRef] [PubMed]

- Iso, M.; Chen, B.; Eguchi, M.; Kudo, T.; Shrestha, S. Production of biodiesel fuel from triglycerides and alcohol using immobilized lipase. J. Mol. Catal. B Enzym. 2001, 16, 53–58. [Google Scholar] [CrossRef]

- Farobiea, O.; Leow, Z.Y.M.; Samanmulya, T.; Matsumura, Y. New insights in biodiesel production using supercritical 1-propanol. Energy Convers. Manag. 2016, 124, 212–218. [Google Scholar] [CrossRef]

- Natadiputri, G.H.; Suwanto, A.; Kim, H.K. One-step transesterification reaction using methanol-stable lipase for omega-3 fatty acid ethyl ester production. J. Korean Soc. Appl. Biol. 2015, 58, 195–202. [Google Scholar] [CrossRef]

- Sustere, Z.; Murnieks, R.; Kampars, V. Chemical interesterification of rapeseed oil with methyl, ethyl, propyl and isopropyl acetates and fuel properties of obtained mixtures. Fuel Process. Technol. 2016, 149, 320–325. [Google Scholar] [CrossRef]

- Wang, P.S.; Tat, M.E.; Gerpen, J.V. The Production of Fatty Acid Isopropyl Esters and Their Use as a Diesel Engine Fuel. J. Am. Oil Chem. Soc. 2005, 82, 845–849. [Google Scholar] [CrossRef]

- EN 590:2022; Automotive Fuels—Diesel—Requirements and Test Methods. European Committee for Standardization: Brussels, Belgium, 2022.

- Alptekin, E.; Canakci, M. Characterization of the key fuel properties of methyl ester–diesel fuel blends. Fuel 2009, 88, 75–80. [Google Scholar] [CrossRef]

- Li, F.; Liu, Z.; Ni, Z.; Wang, H. Effect of biodiesel components on its lubrication performance. J. Mater. Res. Technol. 2019, 8, 3681–3687. [Google Scholar] [CrossRef]

- Levine, F.; Kayea, R.V., III; Wexler, R.; Sadvary, D.J.; Melick, C.; La Scala, J. Heats of Combustion of Fatty Acids and Fatty Acid Esters. J. Am. Oil Chem. Soc. 2014, 91, 235–249. [Google Scholar] [CrossRef]

- Klopfenstein, W.E. Effect of Molecular Weights of Fatty Acid Esters on Cetane Numbers as Diesel Fuels. J. Am. Oil Chem. Soc. 1985, 62, 1029–1031. [Google Scholar] [CrossRef]

- Hellier, P.; Ladommatos, N.; Allan, R.; Rogerson, J. The Influence of Fatty Acid Ester Alcohol Moiety Molecular Structure on Diesel Combustion and Emissions. Energy Fuels 2012, 26, 1912–1927. [Google Scholar] [CrossRef]

- Knothe, G. Dependence of Biodiesel Fuel Properties on the Structure of Fatty Acid Alkyl Esters. Fuel Process. Technol. 2005, 86, 1059–1070. [Google Scholar] [CrossRef]

- Kumar, R.S.; Prasad, A.K.V. Environment friendly butyl ester biodiesel production from mahua oil: Optimization and characterization. Appl. Sci. 2019, 1, 872. [Google Scholar] [CrossRef] [Green Version]

- Liang, X.; Wu, F.; Xie, Q.; Wu, Z.; Cai, J.; Zheng, C.; Fu, J.; Nie, Y. Insights into biobased epoxidized fatty acid isobutyl esters from biodiesel: Preparation and application as plasticizer. Chin. J. Chem. Eng. 2022, 44, 41–50. [Google Scholar] [CrossRef]

- Freedman, B.; Butterfield, R.O.; Pryde, E.H. Transesterification Kinetics of Soybean Oil. J. Am. Oil Chem. Soc. 1985, 63, 1375–1380. [Google Scholar] [CrossRef]

- Ilmi, M.; Abduh, M.Y.; Hommes, A.; Winkelman, J.G.M.; Hidayat, C.; Heeres, H.J. Process Intensification of Enzymatic Fatty acid butyl ester Synthesis using a Continuous Centrifugal Contactor Separator. Ind. Eng. Chem. Res. 2018, 57, 470–482. [Google Scholar] [CrossRef] [Green Version]

- Nelson, L.A.; Foglia, T.A.; Marmer, W.N. Lipase-Catalyzed Production of Biodiesel. J. Am. Oil Chem. Soc. 1996, 73, 1191–1195. [Google Scholar] [CrossRef] [Green Version]

- Likozar, B.; Levec, J. Transesterification of canola, palm, peanut, soybean and sunflower oil with methanol, ethanol, isopropanol, butanol and tert-butanol to biodiesel: Modelling of chemical equilibrium, reaction kinetics and mass transfer based on fatty acid composition. Appl. Energy 2014, 123, 108–120. [Google Scholar] [CrossRef]

- Silva, L.N.; Cardoso, C.C.; Pasa, V.M.D. Production of Cold-Flow Quality Biodiesel from High-Acidity On-Edible Oils—Esterification and Transesterification of Macauba (Acrocomia aculeata) Oil Using Various Alcohols. BioEnergy Res. 2016, 9, 864–873. [Google Scholar] [CrossRef]

- Hellier, P.; Ladommatos, N. The influence of biodiesel composition on compression ignition combustion and emissions. Int. J. Electr. Power 2015, 229, 714–726. [Google Scholar] [CrossRef] [Green Version]

- Wagner, L.E.; Clark, S.J.; Schrock, M.D. Effects of Soybean Oil Esters on the Performance, Lubricating Oil, and Water of Diesel Engines. SAE Trans. 1984, 93, 57–72. Available online: https://www.jstor.org/stable/44467120 (accessed on 5 June 2022).

- Teo, W.S.; Ling, H.; Yu, A.Q.; Chang, M.W. Metabolic engineering of Saccharomyces cerevisiae for production of fatty acid short- and branched-chain alkyl esters biodiesel. Biotechnol. Biofuels 2015, 8, 177. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Da Silva, A.P.T.; Bredda, E.H.; de Castro, H.F.; Da Rós, P.C.M. Enzymatic catalysis: An environmentally friendly method to enhance the transesterification of microalgal oil with fusel oil for production of fatty acid esters with potential application as biolubricants. Fuel 2020, 273, 117786. [Google Scholar] [CrossRef]

- Calam, A.; Solmaz, H.; Uyumaz, A.; Polat, S.; Yilmaz, E.; İçingür, Y. Investigation of usability of the fusel oil in a single cylinder spark ignition engine. J. Energy Inst. 2015, 88, 258–265. [Google Scholar] [CrossRef]

- Dörmő, N.; Bélafi-Bakó, K.; Bartha, L.; Ehrenstein, U.; Gubicza, L. Manufacture of an environmental-safe biolubricant from fusel oil by enzymatic esterification in solvent-free system. Biochem. Eng. J. 2004, 21, 229–234. [Google Scholar] [CrossRef]

- Verma, P.; Sharma, M.P.; Dwivedi, G. Prospects of bio-based alcohols for Karanja biodiesel production: An optimisation study by Response Surface Methodology. Fuel 2016, 183, 185–194. [Google Scholar] [CrossRef]

- de Oliveira, V.F.; Parente, E.J.S., Jr.; Manrique-Rueda, E.D.; Cavalcante, C.L., Jr.; Luna, F.M.T. Fatty acid alkyl esters obtained from babassu oil using C1–C8 alcohols and process integration into a typical biodiesel plant. Chem. Eng. Res. Des. 2020, 160, 224–232. [Google Scholar] [CrossRef]

- Monroe, E.; Shinde, S.; Carlson, J.S.; Eckles, T.P.; Liu, F.; Varman, A.M.; George, A.; Davisa, R.W. Superior performance biodiesel from biomass-derived fusel alcohols and low grade oils: Fatty acid fusel esters (FAFE). Fuel 2020, 268, 117408. [Google Scholar] [CrossRef]

- Panchal, T.M.; Patel, A.; Chauhan, D.D.; Thomas, M.; Patel, J.V. A methodological review on bio-lubricants from vegetable oil based resources. Renew. Sustain. Energy Rev. 2017, 70, 65–70. [Google Scholar] [CrossRef]

- Lathi, P.S.; Mattiasson, B. Green approach for the preparation of biodegradable lubricant base stock from epoxidized vegetable oil. Appl. Catal. B Environ. 2007, 69, 207–212. [Google Scholar] [CrossRef]

- Oh, J.; Yang, S.; Kim, C.; Choi, I.; Kim, J.H.; Lee, H. Synthesis of biolubricants using sulfated zirconia catalysts. Appl. Catal. A Gen. 2013, 455, 164–171. [Google Scholar] [CrossRef]

- Wu, Y.; Li, W.; Zhang, M.; Wang, X. Improvement of oxidative stability of trimethylolpropane trioleate lubricant. Thermochim. Acta 2013, 569, 112–118. [Google Scholar] [CrossRef]

- Nemestóthy, N.; Gubicza, L.; Fehér, E.; Bélafi-Bakó, K. Biotechnological Utilisation of Fusel Oil, a Food Industry by-Product, a Kinetic Model on Enzymatic Esterification of i-Amyl Alcohol and Oleic Acid by Candida antarctica Lipase B. Food Technol. Biotech. 2008, 46, 44–50. [Google Scholar]

- Cerón, A.A.; Vilas Boas, R.N.; Biaggio, F.C.; de Castro, H.F. Synthesis of biolubricant by transesterification of palm kernel oil with simulated fusel oil: Batch and continuous processes. Biomass Bioenergy 2018, 119, 166–172. [Google Scholar] [CrossRef]

- Verma, P.; Dwivedi, G.; Behura, A.K.; Patel, D.K.; Verma, T.N.; Pugazhendhi, A. Experimental investigation of diesel engine fuelled with different alkyl esters of Karanja oil. Fuel 2020, 275, 117920. [Google Scholar] [CrossRef]

- Bokade, V.V.; Yadav, G.D. Synthesis of bio-diesel and bio-lubricant by transesterification of vegetable oil with lower and higher alcohols over heteropolyacids supported by Clay (K-10). Process. Saf. Environ. 2007, 85, 372–377. [Google Scholar] [CrossRef]

- Panchal, T.; Chauhan, D.; Thomas, M.; Patel, J. Bio based grease a value added product from renewable resources. Ind. Crop. Prod. 2015, 63, 48–52. [Google Scholar] [CrossRef]

- Malhotra, D.; Mukherjee, J.; Gupta, M.N. Lipase catalyzed transesterification of castor oil by straight chain higher alcohols. J. Biosci. Bioeng. 2015, 119, 280–283. [Google Scholar] [CrossRef] [PubMed]

- Rios, Í.C.; Cordeiro, J.P.; Parente, E.J.S.; Quintella, S.A.; Alemán, J.; Cavalcante, C.L.; Luna, F.M. Biodegradable base stock oils obtained from ricinoleic acid using C8 alcohols and process integration into a biodiesel industry. Biomass Convers. Biorefin. 2020, 11, 803–814. [Google Scholar] [CrossRef]

- Cai, Z.; Wu, S.; Sun, G.; Niu, Y.; Zheng, D.; Peng, S.; Yang, W.; Wang, Y.; Yang, D. High-purity fatty acid n-octyl esters from housefly (Musca domestica L.) larval lipids, a potential new biolubricant source. Energy Fuel 2017, 31, 10966–10974. [Google Scholar] [CrossRef]

- Bassi, J.J.; Todero, L.M.; Lage, F.A.P.; Khedy, G.I.; Ducas, J.D.; Custódio, A.P.; Pinto, M.A.; Mendes, A.A. Interfacial activation of lipases on hydrophobic support and application in the synthesis of a lubricant ester. Int. J. Biol. Macromol. 2016, 92, 900–909. [Google Scholar] [CrossRef]

- Kleinaitė, E.; Jaška, V.; Tvaska, B.; Matijošytė, I. A cleaner approach for biolubricant production using biodiesel as a starting material. J. Clean. Prod. 2014, 75, 40–44. [Google Scholar] [CrossRef]

- Lacaze-Dufaure, C.; Mouloungui, Z. Catalysed or uncatalysed esterification reaction of oleic acid with 2-ethyl hexanol. Appl. Catal. A Gen. 2000, 204, 223–227. [Google Scholar] [CrossRef]

- Chowdhury, A.; Mitra, D.; Biswas, D. Biolubricant synthesis from waste cooking oil via enzymatic hydrolysis followed by chemical esterification. J. Chem. Technol. Biotechnol. 2012, 88, 139–144. [Google Scholar] [CrossRef]

- Faraguna, F.; Racar, M.; Jukić, A. Test method for determination of different biodiesels (fatty acid alkyl esters) content in diesel fuel using FTIR-ATR. Renew. Energy 2019, 133, 1231–1235. [Google Scholar] [CrossRef]

- Faraguna, F.; Racar, M.; Glasova, Z.; Jukić, A. Correlation method for conversion determination of biodiesel obtained from different alcohols by 1H NMR spectroscopy. Energy Fuel 2017, 31, 3943–3948. [Google Scholar] [CrossRef]

- Sreeprasanth, P.S.; Srivastava, R.; Srinivas, D.; Ratnasamy, P. Hydrophobic, solid acid catalysts for production of biofuels and Lubricants. Appl. Catal. A Gen. 2006, 314, 148–159. [Google Scholar] [CrossRef]

- McNutt, J.; He, Q. Development of biolubricants from vegetable oils via chemical modification. J. Ind. Eng. Chem. 2016, 36, 1–12. [Google Scholar] [CrossRef]

- Saravanan, N.; Puhan, S.; Nagarajan, G.; Vedaraman, N. An experimental comparison of transesterification process with different alcohols using acid catalysts. Biomass Bioenergy 2010, 34, 999–1005. [Google Scholar] [CrossRef]

- Graboski, M.S.; McCormick, R.L. Combustion of fat and vegetable oil derived fuels in diesel engines. Prog. Energy Combust. Sci. 1998, 24, 125–164. [Google Scholar] [CrossRef]

- Hoekman, S.K.; Broch, A.; Robbins, C.; Ceniceros, E.; Natarajan, M. Review of biodiesel composition, properties, and speci-fications. Renew. Sustain. Energy Rev. 2012, 16, 143–169. [Google Scholar] [CrossRef]

- Gao, Y.; Chen, Y.; Gu, J.; Xin, Z.; Sun, S. Butyl-biodiesel production from waste cooking oil: Kinetics, fuel properties and emission performance. Fuel 2019, 236, 1489–1495. [Google Scholar] [CrossRef]

- Wang, M.; Nie, K.; Yun, F.; Cao, H.; Deng, L.; Wang, F.; Tan, T. Biodiesel with low temperature properties: Enzymatic syn-thesis of fusel alcohol fatty acid ester in a solvent free system. Renew. Energy 2015, 83, 1020–1025. [Google Scholar] [CrossRef]

- Matiliunaite, M.; Paulauskiene, T. From concept to practice: Manufacturing of bio-lubricants from renewable resources. Biomass Convers. Biorefinery 2018, 9, 353–361. [Google Scholar] [CrossRef]

| Alcohol/Alkyl Moiety Source | Triglicerides/FFA | Catalyst | Conversion a/ Yield b (%) | Ref. |

|---|---|---|---|---|

| 1-propanol | sunflower oil | potassium hydroxide | 99.8 a | [25] |

| 1-propanol | jojoba oil | potassium methoxide | 90 a | [31] |

| 1-propanol | sunflower oil | immobilized lipase—Candida rugosa (CRL) Porcine pancreatic (PPL) | 25 a (CRL) 75 a (PPL) | [32] |

| 1-propanol | triolein and safflower oil | immobilized Pseudomonas fluorescens lipase | 100 a | [33] |

| 1-propanol | canola oil | supercritical conditions | 93.8 b | [34] |

| 1-propanol | olive oil and menhaden oil | Staphylococcus haemolyticus lipase (l62) | - | [35] |

| 1-propanol | waste cooking sunflower oil | N,N′,N″-Tris(3-(dimethylamino)-propyl)guanidine | 66.8 a | [80] |

| 1-propanol | babassu oil | p-toluenesulfonic acid | 94.2 a | [59] |

| isopropanol | waste cooking sunflower oil | N,N′,N″-Tris(3-(dimethylamino)-propyl)guanidine | 83.5 a | [80] |

| propyl acetate | rapeseed oil | sodium methoxide solution in methanol | 87 b | [36] |

| isopropyl acetate | rapeseed oil | sodium methoxide solution in methanol | 88 b | [36] |

| isopropanol | soybean oil/yellow grease | sodium and potassium isopropoxide | - | [37] |

| isopropanol | babassu oil | p-toluenesulfonic acid | 92.7 a | [59] |

| 1-butanol | soybean oil | sodium butoxide | - | [47] |

| 1-butanol | soybean oil | sulfuric acid | - | [47] |

| 1-butanol | mahua oil | sulfuric acid | pre-treatment | [45] |

| 1-butanol | mahua oil | potassium hydroxide | 94.8 b | [45] |

| 1-butanol | mahua oil | sulfuric acid | 95 b | [81] |

| 1-butanol | sunflower oil | Rhizomucor miehei lipase | 92 b | [48] |

| 1-butanol | waste cooking sunflower oil | N,N′,N″-Tris(3-(dimethylamino)-propyl)guanidine | 95.8 | [80] |

| tert-butanol | canola oil | potassium hydroxide | 99.9 a | [50] |

| 2-butanol | tallow | Candida antarctica | 96.4 a | [49] |

| 2-butanol | waste cooking sunflower oil | N,N′,N″-Tris(3-(dimethylamino)-propyl)guanidine | 29.9 a | [80] |

| isobutanol | macauba oil | sodium methoxide | - | [52] |

| isobutanol | waste cooking sunflower oil | N,N′,N″-Tris(3-(dimethylamino)-propyl)guanidine | 93.3 a | [80] |

| isobutanol | babassu oil | p-toluenesulfonic acid | 94.5 a | [59] |

| 1-pentanol | karanja oil | sulfuric acid | pre-treatment | [58] |

| 1-pentanol | karanja oil | potassium hydroxide | 73.13 b | [58] |

| 1-pentanol | waste cooking sunflower oil | N,N′,N″-Tris(3-(dimethylamino)-propyl)guanidine | 90.4 a | [80] |

| isopentanol | babassu oil | p-toluenesulfonic acid | 99.1 a | [59] |

| isopentanol | waste cooking sunflower oil | N,N′,N″-Tris(3-(dimethylamino)-propyl)guanidine | 82.9 a | [80] |

| fusel oil | coconut oil | immobilized Lipozyme TL IM | - | [30] |

| fusel oil | corn oil | Aspergillus oryzae lipase | 97 a | [60] |

| fusel oil | palm kernel oil | immobilized Burkholderia cepacia lipase | 99 a | [66] |

| 1-hexanol | waste cooking sunflower oil | N,N′,N″-Tris(3-(dimethylamino)-propyl)guanidine | 93.5 a | [80] |

| 1-hexanol | castor oil | blend of RMIM with Novozym 435 | 95 a | [70] |

| hexanol | karanja oil methyl ester | sodium methoxide | 94.5 b | [69] |

| 2-ethyl-hexanol | ricinoleic acid | Amberlyst 15 | 95 a | [71] |

| 2-ethyl-hexanol | oleic acid | p-toluenesulfonic acid | 93 a | [75] |

| 2-ethyl-hexanol | rapeseed oil methyl esters | immobilized lipase Lipozyme TL IM | 100 a | [74] |

| 2-ethyl-hexanol | Babassu oil | p-toluenesulfonic acid | 99.1 a | [59] |

| 1-heptanol | waste cooking sunflower oil | N,N′,N″-Tris(3-(dimethylamino)-propyl)guanidine | 67.6 a | [80] |

| 1-octanol | ricinoleic acid | Amberlyst 15 | 98 a | [71] |

| 1-octanol | stearic acid | sulfated zirconia | 97.8 a | [63] |

| 1-octanol | oleic acid | sulfated zirconia | 90.4 a | [63] |

| 1-octanol | linoleic acid | sulfated zirconia | 86.3 a | [63] |

| 1-octanol | linolenic acid | sulfated zirconia | 82.7 a | [63] |

| 1-octanol | waste cooking oil | Amberlyst 15 | 100 a | [77] |

| 1-octanol | karanja oil methyl ester | sodium methoxide | 93.1 b | [69] |

| 1-octanol | sunflower oil | heteropolyacids supported by monmorillonite clay | 72 a | [68] |

| 1-octanol | castor oil | blend of RMIM with Novozym 435 | 90 a | [70] |

| 1-octanol | oleic acid | immobilized Thermomyces lanuginosus | 95 a | [73] |

| 1-octanol | housefly larva FFA | benzenesulfonic acid | 95.1 a | [72] |

| 1-octanol | waste cooking sunflower oil | N,N′,N″-Tris(3-(dimethylamino)-propyl)guanidine | 92.3 a | [80] |

| 2-octanol | oleic acid | sulfated zirconia | 85.2 a | [63] |

| 3-octanol | oleic acid | sulfated zirconia | 31.0 a | [63] |

| isooctanol | oleic acid | sulfated zirconia | 83.6 a | [63] |

| 1-decanol | waste cooking sunflower oil | N,N′,N″-Tris(3-(dimethylamino)-propyl)guanidine | 95.4 a | [80] |

| 1-dodecanol | waste cooking sunflower oil | N,N′,N″-Tris(3-(dimethylamino)-propyl)guanidine | 90.5 a | [80] |

| 1-dodecanol | castor oil | blend of RMIM with Novozym 435 | 80 a | [70] |

| dodecanol | oleic acid | sulfated zirconia | 88.5 a | [63] |

| tetradecanol | oleic acid | sulfated zirconia | 87.3 a | [63] |

| hexadecanol | oleic acid | sulfated zirconia | 85.7 a | [63] |

| Fatty Acid Alkyl Ester | Application Property | Ref. | |||||

|---|---|---|---|---|---|---|---|

| Density (kg/m3) | Viscosity (mm2/s) | CFPP (°C) | PP (°C) | CP (°C) | CN | ||

| EN 590 | 820–845 | 2.0–4.5 | >51 | [38] | |||

| FAME W | 880 | 4.60 | 5 | 6 | [11] | ||

| FAME CM | 865–885 | 2.50–3.40 | [17] | ||||

| FAME K | 881 | 4.02 | −2 | −3 | 53 | [19] | |

| FAME S | 884 | 4.03 | −1 | [39] | |||

| FAME So | 885 | 3.97 | 0 | [39] | |||

| FAME Cr | 884 | 4.18 | −1 | [39] | |||

| FAME C | 883 | 4.34 | −8 | [39] | |||

| FAME Cot | 884 | 4.06 | 6 | [39] | |||

| FAME So | 4.08 | −4.4 | −3.8 | −0.5 | 50.9 | [82] | |

| FAME R | 4.83 | 3.6 | −10.8 | −4.0 | 52.9 | [82] | |

| FAME T | 4.80 | 11 | 9 | 13.9 | 58.8 | [82] | |

| FAME T | 7.90 | 15 | 17 | [28] | |||

| FAME K | 879.5 | 3.78 | 11.17 | 17.1 | 19.4 | 56 | [67] |

| FAME So | 4.593 | −6 | −2 | 50.4 | [37] | ||

| FAME Y | 5.916 | 6 | 8 | 62.6 | [37] | ||

| FAME R | 920 | 5.36 | −10 | −12 | −6 | [36] | |

| FAME S | 4.42 | −2 | −2 | 2 | 51.1 | [83] | |

| FAME R | 4.50 | −12 | −10 | −3 | 53.7 | [83] | |

| FAME Co | 2.75 | −5 | −9 | −3 | 59.3 | [83] | |

| FAME C | 4.38 | −9 | −6 | −2 | 53.7 | [83] | |

| FAME Cr | 4.19 | −8 | −2 | −3 | 55.7 | [83] | |

| FAME So | 4.26 | −4 | −4 | 0 | 51.3 | [83] | |

| FAME P | 4.61 | 9 | 13 | 14 | 61.9 | [83] | |

| FAME T | 4.69 | 13 | 10 | 13 | 58.9 | [83] | |

| FAME Y | 4.80 | 1 | 3 | 8 | 56.9 | [83] | |

| FAME B | 872 | 2.9 | −6 | −5 | [59] | ||

| FAEE B | 868 | 3.3 | −6 | −6 | [59] | ||

| FAEE T | 6.20 | 12 | 15 | [28] | |||

| FAEE So | 4.40 | −4 | 1 | [28] | |||

| FAEE J | 853 | 8.24 | −6 | −7 | −3 | [31] | |

| FAEE R | 910 | 5.25 | −10 | −13 | −6 | [36] | |

| FAEE K | 886.2 | 4.06 | 3.98 | 15.9 | 18.3 | 57.5 | [67] |

| FAPRE K | 892.7 | 4.45 | 12.8 | 15.1 | 59.7 | [58] | |

| FAPRE B | 866 | 3.7 | −9 | −8 | [59] | ||

| FAPRE S | 879.9 | 5.705 | −6 | [25] | |||

| FAPRE R | 910 | 5.47 | −13 | −15 | −9 | [36] | |

| FAPRE T | 7.30 | 9 | 12 | [28] | |||

| FAPRE J | 861 | 9.03 | −7 | −8 | −6 | [31] | |

| FAIPRE B | 863 | 4.1 | −9 | −4 | [59] | ||

| FAIPRE T | 7.10 | 0 | 8 | [28] | |||

| FAIPRE T | 6.40 | 5 | 3 | 9 | [29] | ||

| FAIPRE P | 5.02 | −3 | 6 | [26] | |||

| FAIPRE R | 910 | 5.96 | −15 | −18 | −14 | [36] | |

| FAIPRE So | 5.265 | −12 | −9 | 51.5 | [37] | ||

| FAIPRE Y | 6.10 | −3 | 0 | 65.6 | [37] | ||

| FABE K | 902.8 | 4.80 | 10.7 | 12.4 | 61.3 | [58] | |

| FABE M | 894 | 4.12 | 2 | 4 | 52 | [45] | |

| FABE M | 4.70 | [81] | |||||

| FABE W | 872 | 5.33 | 2 | 92.2 | [84] | ||

| FABE T | 6.90 | 6 | 9 | [28] | |||

| FABE J | 876 | 9.82 | −8 | −12 | −11 | [31] | |

| FA2BE P | 6.19 | −6 | 7 | [26] | |||

| FA2BE T | 6.80 | 0 | 9 | [28] | |||

| FAIBE P | 5.59 | −3 | 7 | [26] | |||

| FAIBE T | 7.40 | 3 | 8 | [28] | |||

| FAIBE A | 870 | 6.7 | −2 | [51] | |||

| FAIBE B | 861 | 4.2 | −15 | −13 | [59] | ||

| FAPE K | 910.3 | 5.04 | 7.3 | 9.6 | 63.6 | [58] | |

| FAIPE P | 5.86 | −9 | 8 | [26] | |||

| FAIPE W | 5.57 | −11 | [85] | ||||

| FAIPE B | 860 | 4.3 | −15 | −13 | [59] | ||

| F-2EH B | 862 | 5.6 | −27 | −26 | [59] | ||

| F-2EH Ca | 924.1 | 61.51 | −57 | [71] | |||

| F-2EH R | 7.8 | −31.3 | [80] | ||||

| FA8AE Ca | 923.2 | 64.05 | −18 | [71] | |||

| FA8AE S | 881.3 | 7.93 | −3 | [86] | |||

| FA8AE O | 10.3 | [63] | |||||

| FA8AE Hl | 866.4 | 8.16 | 9 | [72] | |||

| FA8AE Af | 856 | 23.0 | 9 | [86] | |||

| FA8AE Fo | 877.2 | 21.0 | −6 | [86] | |||

| FA10AE Af | 843.7 | 18.0 | 9 | [86] | |||

| FA10AE Fo | 851.7 | 17.0 | −3 | [86] | |||

| FA12AE O | 11.3 | [63] | |||||

| FA14AE O | 19.6 | [63] | |||||

| FA16AE O | 21.0 | [63] | |||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gotovuša, M.; Pucko, I.; Racar, M.; Faraguna, F. Biodiesel Produced from Propanol and Longer Chain Alcohols—Synthesis and Properties. Energies 2022, 15, 4996. https://doi.org/10.3390/en15144996

Gotovuša M, Pucko I, Racar M, Faraguna F. Biodiesel Produced from Propanol and Longer Chain Alcohols—Synthesis and Properties. Energies. 2022; 15(14):4996. https://doi.org/10.3390/en15144996

Chicago/Turabian StyleGotovuša, Mia, Ivan Pucko, Marko Racar, and Fabio Faraguna. 2022. "Biodiesel Produced from Propanol and Longer Chain Alcohols—Synthesis and Properties" Energies 15, no. 14: 4996. https://doi.org/10.3390/en15144996

APA StyleGotovuša, M., Pucko, I., Racar, M., & Faraguna, F. (2022). Biodiesel Produced from Propanol and Longer Chain Alcohols—Synthesis and Properties. Energies, 15(14), 4996. https://doi.org/10.3390/en15144996