Application of Hydro Borehole Mining (HBM) Technology for Lignite Extraction—An Environmental Assessment (LCA) and a Comparative Study with the Opencast Method

Abstract

:1. Introduction

2. Materials and Methods

2.1. Choice of Methods for the Assessment

2.2. Application of LCAs in Coal Mining Industry

- The goal and scope definition phase (goal and scope definition);

- The inventory analysis phase (LCI);

- The impact assessment phase (LCIA);

- The interpretation phase (Interpretation) [31].

2.3. Hydro Borehole Mining (HBM)

3. Results

3.1. Results of the Non-Site-Specific LCA of an HBM Lignite Production Process from a Single Borehole

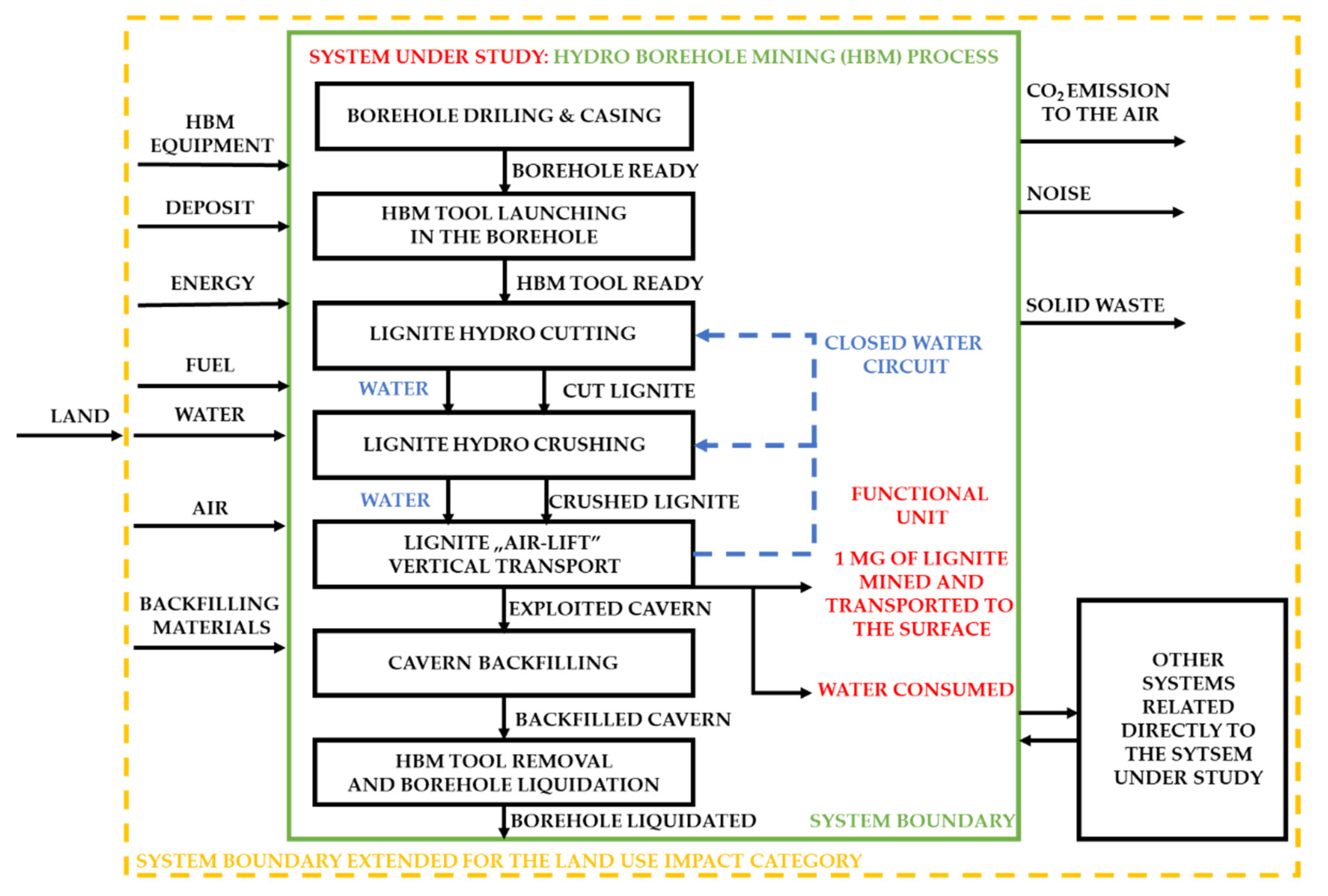

3.1.1. Results of the Goal and Scope Definition Phase

- Energy consumption;

- Fuel consumption;

- Water consumption;

- Carbon footprint;

- Land use;

- Solid waste generation;

- Abiotic resource depletion.

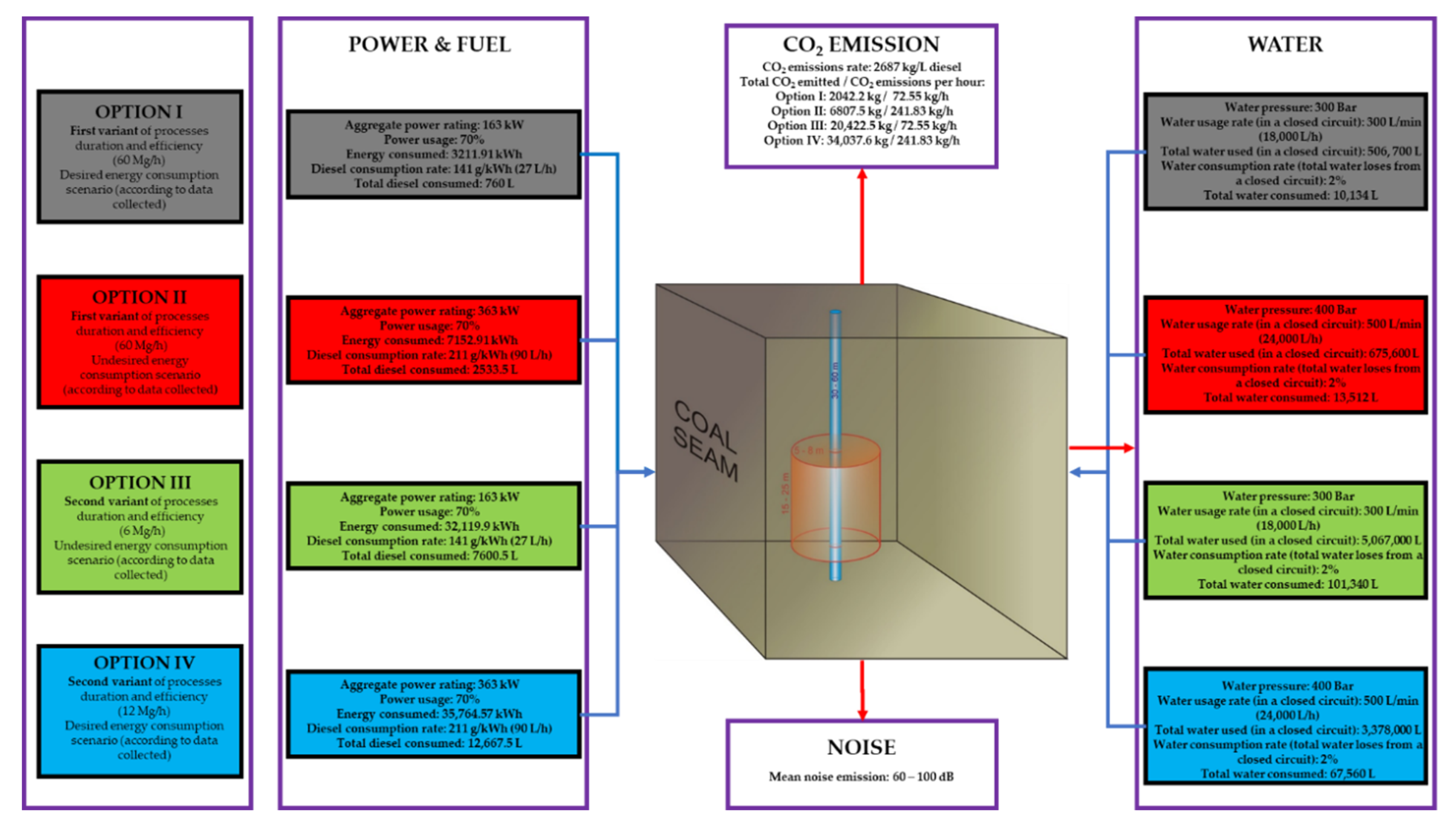

- Desired energy consumption scenario (minimum values from the data value ranges);

- Undesired energy consumption scenario (maximum values from the data value ranges).

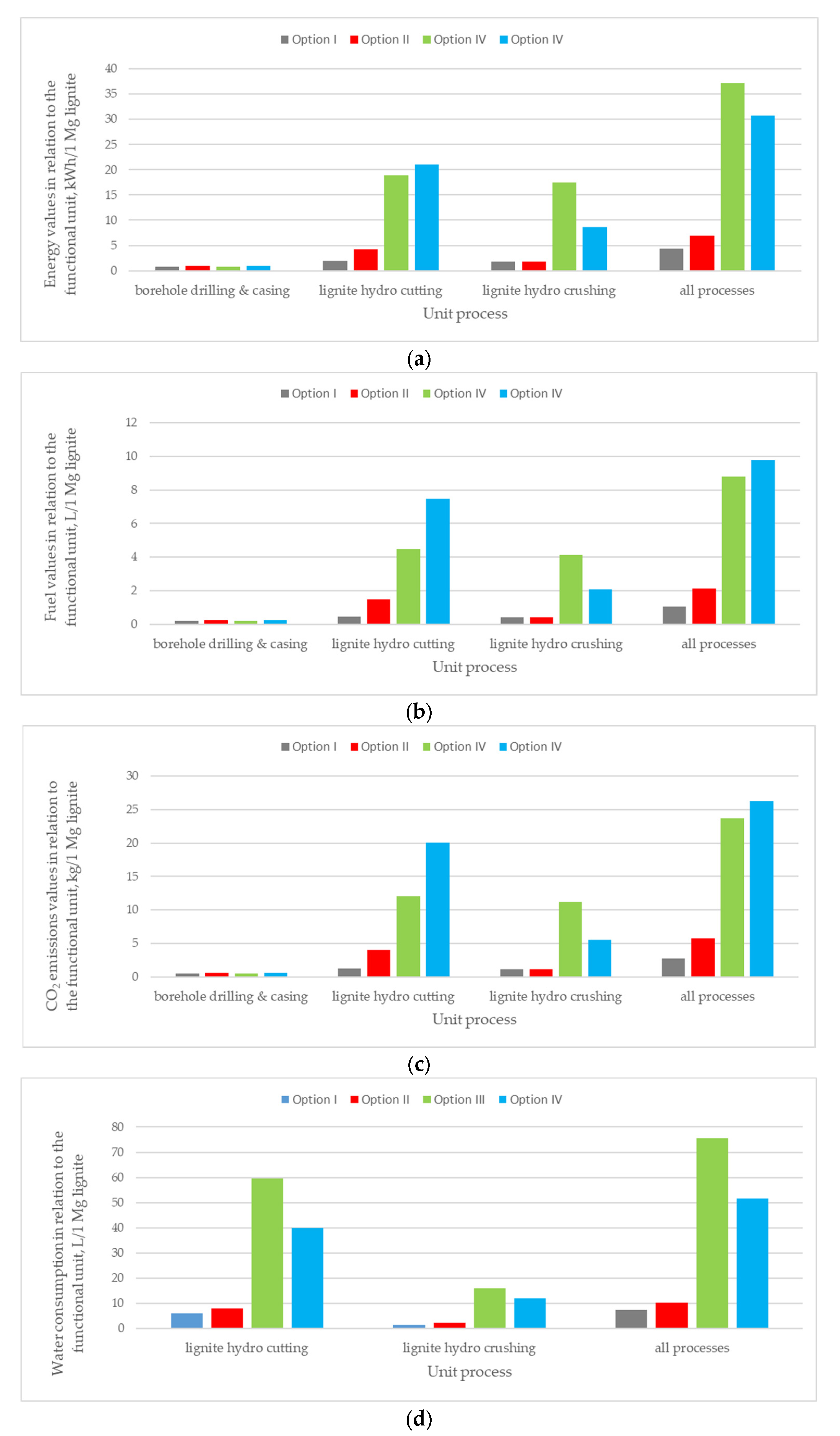

- Option I—a desired energy consumption scenario for the first variant of process duration and efficiency;

- Option II—an undesired energy consumption scenario for the first variant of process duration and efficiency;

- Option III—a desired energy consumption scenario for the second variant of process duration and efficiency;

- Option IV—an undesired energy consumption scenario for the second variant of process duration and efficiency.

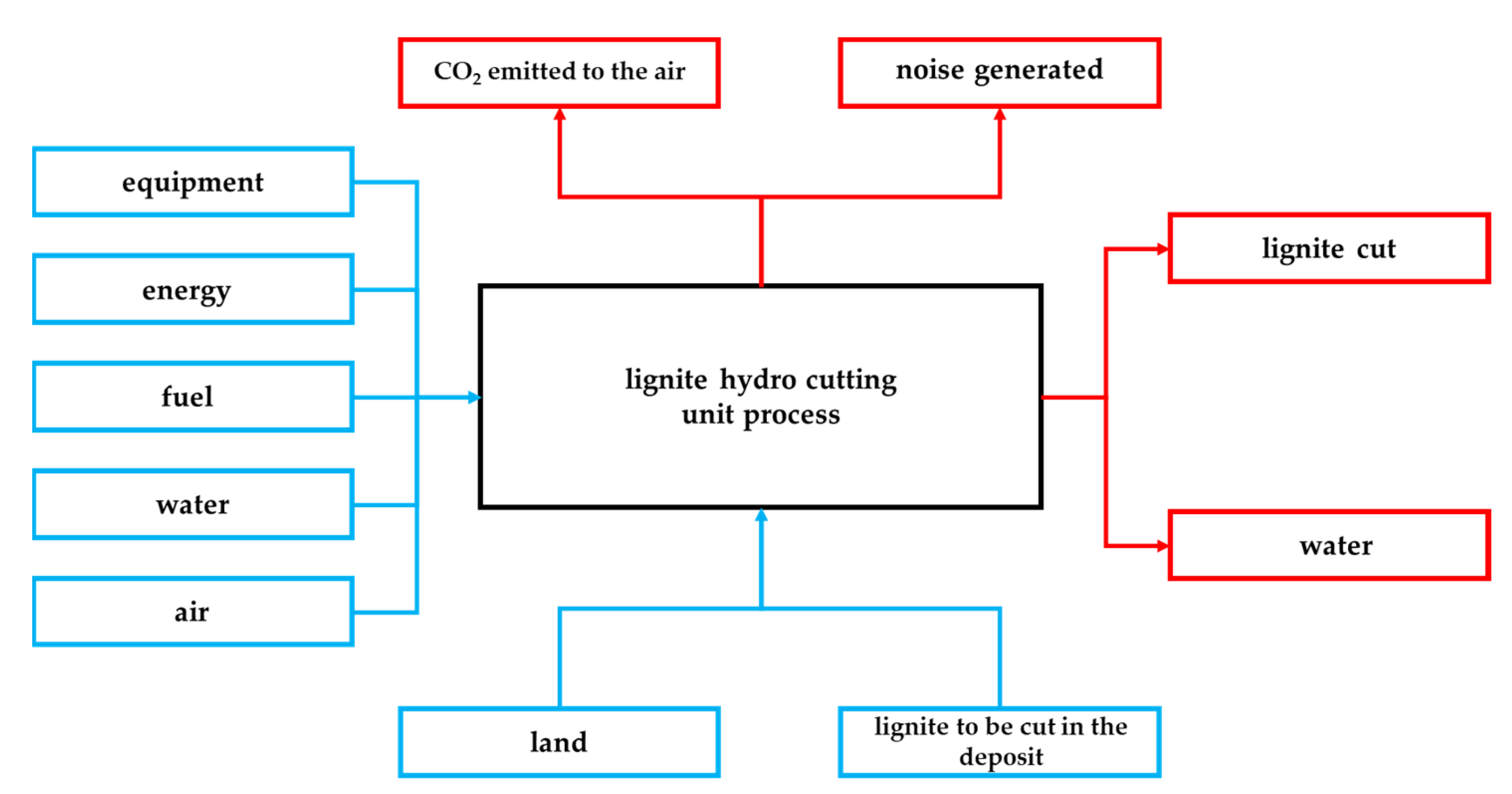

3.1.2. Results of the LCI (Life Cycle Inventory) Phase

- Unit process of borehole drilling and casing;

- Unit process of lignite hydro-cutting;

- Unit process of lignite hydro-crushing.

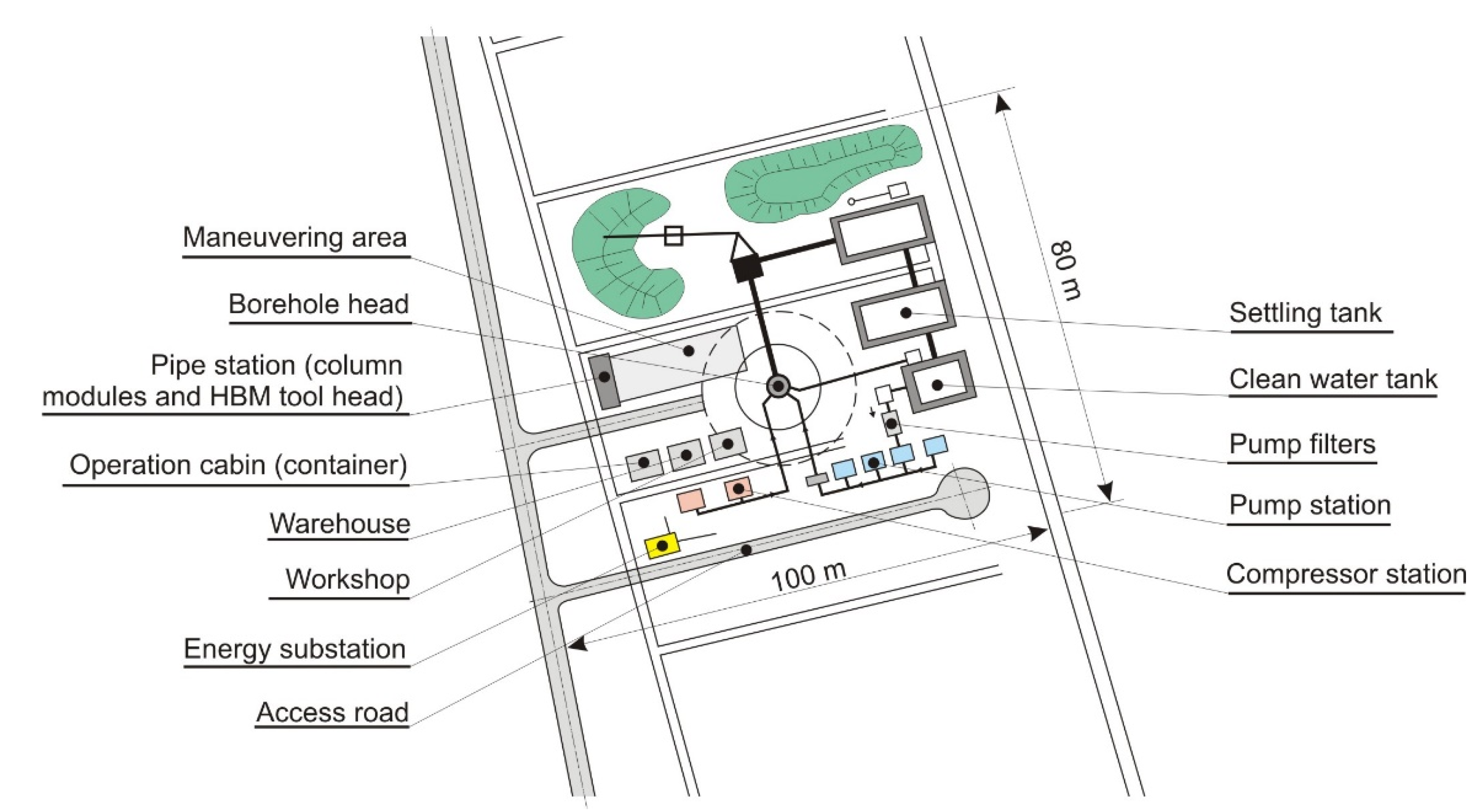

- A borehole head;

- Pipe station (column modules and HBM tool head);

- Clean water tanks;

- Clean water filters for hydraulic aggregates (pumps);

- Settling tank;

- Pump station;

- Compressor station;

- Operator’s cabin (container);

- Warehouse and workshop;

- Access roads and maneuvering area;

- Energy substation.

3.1.3. Results of the LCIA (Life Cycle Impact Assessment) Phase

- The land use would be equal to 1.179 m2/1 Mg lignite (desired scenario);

- While the land use would be equal to 4.714 m2/1 Mg lignite (undesired scenario).

3.1.4. Key Insights of the Interpretation Phase

3.2. Results of an Additional Comparative Study of HBM and Opencast Lignite Mining

3.2.1. Land Use

- First, there is no need to remove the overburden, which is a very time-consuming activity; thus, the land is used for a much shorter period of time;

- Secondly, without the overburden removal, there is no need to create any external dumps, which are associated with using of another portion of land;

- Third, the mining area is left almost intact after the extraction ends unlike the opencast method.

3.2.2. Solid Waste

3.2.3. Energy Use

3.2.4. Fuel Use

3.2.5. Water Use and Water Consumption

3.2.6. Emissions to Air

3.2.7. Water Quality

4. Discussion

5. Conclusions

- The borehole drilling and casing, lignite hydro-cutting and lignite hydro-crushing unit processes were the most significant processes for HBM lignite production systems in terms of environmental performance;

- The HBM technology brings many opportunities to minimize the environmental impacts of lignite extraction in many areas, especially for the land use and solid waste generation impact categories, as it was compared in the second part of this article;

- The LCA procedure can be used in a less conventional way in order to assess processes; assess only the raw material acquisition stage of life cycles of products; even to assess processes within the raw material acquisition stage, as shown is this study;

- Any environmental assessment of mining processes and systems should be (where possible) site specific; in a non-site-specific environmental assessment, as in this case, many assumptions are required, and generalization of several issues may be inevitable.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bai, X.; Ding, H.; Lian, J.; Ma, D.; Yang, X.; Sun, N.; Xue, W.; Chang, Y. Coal production in China: Past, present, and future projections. Int. Geol. Rev. 2018, 60, 535–547. [Google Scholar] [CrossRef]

- Rutledge, D. Estimating long-term world coal production with logit and probit transforms. Int. J. Coal Geol. 2011, 85, 23–33. [Google Scholar] [CrossRef] [Green Version]

- Mohr, S.H.; Evans, G.M. Forecasting coal production until 2100. Fuel 2009, 88, 2059–2067. [Google Scholar] [CrossRef] [Green Version]

- Wen, J.; Chen, C. Optimizing the structure of the straight cone nozzle and the parameters of borehole hydraulic mining for Huadian oil shale based on experimental research. Energies 2017, 10, 2021. [Google Scholar] [CrossRef] [Green Version]

- Boone Beck, D.M. Applicability of Hydraulic Borehole Mining (‘Hbhm’) To Diamondiferous Deposits. Angew. Chem. Int. Ed. 2016, 6, 951–952. [Google Scholar] [CrossRef]

- Bondarchuk, I.B.; Shenderova, I.V. Classification of hydraulic borehole mining technological processes during pay zone development. IOP Conf. Ser. Earth Environ. Sci. 2015, 24, 012004. [Google Scholar] [CrossRef]

- Arens, V.Z.; Khrulev, A.S. Experience of Hydraulic Borehole Mining from Deep-Seated Gold Placeres. J. Min. Sci. 2003, 39, 27–34. [Google Scholar] [CrossRef]

- Rochev, V. Hydraulic borehole mining method possible application at Middle Larba alluvial gold field. E3S Web Conf. 2018, 56, 4–9. [Google Scholar] [CrossRef] [Green Version]

- Schmitke, B.W. Cigar Lake’s Jet Boring Mining Method. In Proceedings of the World Nuclear Association (WNA) Annual Symposium, London, UK, 9–12 September 2014. [Google Scholar]

- Jura, W. Attempt of adaptation of the method of hydro-openings in the coal deposits of strong methane threat and in “restricted” conditions (Próba adaptacji metody hydro-otworowej w złożach węgla kamiennego o silnym zagrożeniu metanowym oraz w warunkach “skrępowan. Bezp. Pr. I Ochr. Sr. W Gór. 2011, 4, 9–15. [Google Scholar]

- Jura, W.; Jura, B.; Skiba, J. Integrated extraction of coal and methane from the multi-coal seams using hydro borehole mining technology. In Proceedings of the 6th International Symposium on Green Mining, Wollongong, NSW, Australia, 24–26 November 2013; pp. 314–318. [Google Scholar]

- Lundin, M.; Morrison, G.M. A life cycle assessment based procedure for development of environmental sustainability indicators for urban water systems. Urban Water 2002, 4, 145–152. [Google Scholar] [CrossRef]

- Udo de Haes, H.A. Applications of life cycle assessment: Expectations, drawbacks and perspectives. J. Clean. Prod. 1993, 1, 131–137. [Google Scholar] [CrossRef]

- Suh, S.; Lenzen, M.; Treloar, G.J.; Hondo, H.; Horvath, A.; Huppes, G.; Jolliet, O.; Klann, U.; Krewitt, W.; Moriguchi, Y.; et al. Critical Review System Boundary Selection in Life-Cycle Inventories Using Hybrid Approaches. Environ. Sci. Technol. 2006, 38, 657–664. [Google Scholar] [CrossRef] [PubMed]

- Tillman, A.M.; Ekvall, T.; Baumann, H.; Rydberg, T. Choice of system boundaries in life cycle assessment. J. Clean. Prod. 1994, 2, 21–29. [Google Scholar] [CrossRef] [Green Version]

- Hur, T.; Lee, J.; Ryu, J.; Kwon, E. Simplified LCA and matrix methods in identifying the environmental aspects of a product system. J. Environ. Manag. 2005, 75, 229–237. [Google Scholar] [CrossRef] [PubMed]

- Cluzel, F.; Yannou, B.; Millet, D.; Leroy, Y. Exploitation scenarios in industrial system LCA. Int. J. Life Cycle Assess. 2014, 19, 231–245. [Google Scholar] [CrossRef] [Green Version]

- Lesage, P.; Reid, C.; Margni, M.; Aubertin, M.; Deschênes, L. Use of LCA in the mining industry and research challenges. In Symposium 2008 Sur L’environnement Les Mines Concilier Rentabilité Prot L’environnement; RIME: Rouyn-Noranda, QC, Canada, 2008; pp. 1–14. Available online: https://www.researchgate.net/publication/235678782 (accessed on 14 April 2022).

- Roychoudhury, S.; Khanda, D.K. Application of life cycle assessment (LCA) in coal mining. In Proceedings of the 6th Asian Mining Congress, Kolkata, India: The Mining Geological and Metallurgical Institute of India (MGMI), Kolkata, India, 23–27 February 2016; pp. 357–366. [Google Scholar] [CrossRef]

- Durucan, S.; Korre, A.; Munoz-Melendez, G. Mining life cycle modelling: A cradle-to-gate approach to environmental management in the minerals industry. J. Clean. Prod. 2006, 14, 1057–1070. [Google Scholar] [CrossRef]

- Klopffer, W. Background and Future Prospects in Life Cycle Assesment; Springer: Frankfurt Am Main, Germany, 2014. [Google Scholar]

- Zhang, L.; Wang, J.; Feng, Y. Life cycle assessment of opencast coal mine production: A case study in Yimin mining area in China. Environ. Sci. Pollut. Res. 2018, 25, 8475–8486. [Google Scholar] [CrossRef]

- Adiansyah, J.S.; Haque, N.; Rosano, M.; Biswas, W. Application of a life cycle assessment to compare environmental performance in coal mine tailings management. J. Environ. Manag. 2017, 199, 181–191. [Google Scholar] [CrossRef]

- ISO 14040:2006; Environmental Management—Life Cycle Assessment—Principles and Framework. International Organization for Standardization: Geneva, Switzerland, 2006.

- ISO 14044:2006; Environmental Management—Life Cycle Assessment—Requirements and Guidelines. International Organization for Standardization: Geneva, Switzerland, 2006.

- ISO/TR 14047:2012; Environmental Management—Life Cycle Assessment—Illustrative Examples on How to Apply ISO 14044 Toimpact Assessment Situations. International Organization for Standardization: Geneva, Switzerland, 2012.

- ISO/TS 14048:2002; Environmental Management—Life Cycle Assessment—Data Documentation Format. International Organization for Standardization: Geneva, Switzerland, 2002.

- Krause, E.; Krzemień, K. Methane Risk Assessment in Underground Mines by Means of a Survey by the Panel of Experts (Sope). J. Sustain. Min. 2014, 13, 6–13. [Google Scholar] [CrossRef] [Green Version]

- Frejowski, A.; Kabiesz, J. Criteria for Assessing the Longevity of Hard Coal Mines. Arch. Min. Sci. 2020, 65, 433–452. [Google Scholar]

- Burchart-Korol, D.; Fugiel, A.; Czaplicka-Kolarz, K.; Turek, M. Model of environmental life cycle assessment for coal mining operations. Sci. Total Environ. 2016, 562, 61–72. [Google Scholar] [CrossRef] [PubMed]

- Hunkeler, D. Societal LCA methodology and case study. Int. J. Life Cycle Assess. 2006, 11, 371–382. [Google Scholar] [CrossRef]

- Jura, W. Hydro- borehole mining development. In Proceedings of the 19th World Mining Congress 2003, New Delhi, India, 1–5 November 2003. [Google Scholar]

- Dimitrijevic, B.; Mitrovic, V.; Pinka, J. Selection of technological parameters in borehole mining production by technical deep drilling and hydroexploitation. Acta Montan. Slovaca 2004, 9, 160–167. [Google Scholar]

- Dubiński, J.; Szczepiński, J.; Bajcar, A.; Jura, W.; Skiba, J.; Jura, B.; Szołtysek, W. HydroCoal Plus Project Concept; Węgiel Brunatny Poltegor-Instytut: Wrocław, Poland, 2018; Volume 4. [Google Scholar]

- Bajcar, A.; Piróg, K. Field test of lignite hydro-cutting—HydroCoal Plus project. Gór. Odkryw. 2019, 60, 22–24. [Google Scholar]

- Szczepiński, J.; Bajcar, A.; Rogosz, B. Research and development projects realised by “Poltegor-Institute” within Research Fund for Coal and Steel. Gór. Odkryw. 2020, 4–11. [Google Scholar]

- Jura, W. Hydraulic Borehole MIning (HBM) Technology. In Min. 21st Century—Quo Vadis? Ghose, A.K., Bose, L.K., Eds.; A.A. Balkema Publisher: Avereest, The Netherlands, 2003; pp. 905–916. [Google Scholar]

- Bielowicz, B.; Morga, R. Micro-raman spectroscopy of selected macerals of the huminite group: An example from the szczerców lignite deposit (central Poland). Energies 2021, 14, 281. [Google Scholar] [CrossRef]

- Wieczorek, D.; Stoiński, A.; Krzyszkowski, D.; Wachecka-Kotkowska, L.; Krzymińska, J. The results of new studies of Quaternary sediments in the Kleszczów Graben, Szczerców Outcrop, Bełchatów Lignite Opencast Mine. Landf. Anal. 2015, 29, 63–71. [Google Scholar] [CrossRef]

- Wagner, M.; Styrnol, B. Selected geological features of coal complex and technological quality of coal from the “Szczerców” lignite deposit. Gór. I Geol. 2007, 2, 93–108. [Google Scholar]

- Ossés de Eicker, M.; Hischier, R.; Kulay, L.A.; Lehmann, M.; Zah, R.; Hurni, H. The applicability of non-local LCI data for LCA. Environ. Impact Assess. Rev. 2010, 30, 192–199. [Google Scholar] [CrossRef]

- Pinsonnault, A.; Lesage, P.; Levasseur, A.; Samson, R. Temporal differentiation of background systems in LCA: Relevance of adding temporal information in LCI databases. Int. J. Life Cycle Assess. 2014, 19, 1843–1853. [Google Scholar] [CrossRef]

- Jura, W. Development of a Conceptual Design for the Method of Hydro-Borehole Mining of Hard Coal and Lignite (Hydraulic Borehole Mining) for Testing under the Conditions of the Experimental Mining; Central Mining Institute: Katowice, Poland, 2019. [Google Scholar]

- Kudełko, J.; Nowak, J.; Wanielista, K. Industrial criteria for minerals exctrated in open pits, which value is not related with content of useable elements. Gór. Odkryw. 2013, 54, 41–45. [Google Scholar]

- Janiak, H. Mine drainage treatment in Polish lignite mining. Mine Water Environ. 1992, 11, 35–44. [Google Scholar] [CrossRef]

- Kaden, S.; Luckner, L.; Peukert, D.; Tiemer, K. Decision support model systems for regional water policies in open-pit lignite mining areas. Int. J. Mine Water 1985, 4, 1–16. [Google Scholar] [CrossRef]

- Urbański, P.; Latoń, D. Technical progress in the construction of pumping stations at KWB Bełchatów (in Polish). Gór. I Geoinżynieria 2011, 35, 259–272. [Google Scholar]

- Widera, M.; Kasztelewicz, Z.; Ptak, M. Lignite mining and electricity generation in Poland: The current state and future prospects. Energy Policy 2016, 92, 151–157. [Google Scholar] [CrossRef]

- Murdza, J.; Sowińska, G.; Tomala, M. Chemical properties of surface waters in areas of waste water discharge from the Belchatow brown coal surface mine. Gór. Odkryw. 1991, 33, 60–72. [Google Scholar]

- Jachimenko, B. The influence of lignite mining on water quality. In Water Quality Monitoring and Assessment; IntechOpen: Rijeka, Croatia, 2012; Chapter 16; pp. 373–390. [Google Scholar]

| Years of Experience | Number of Experts from a Scientific Entity | Number of Experts from Industry |

|---|---|---|

| 14–25 | 8 | 4 |

| 25–40 | 4 | 2 |

| Over 40 | 3 | 1 |

| Indicator of Experts’ Competence | Number of Experts from a Scientific Entity | Number of Experts from Industry |

| 0.5–0.6 | 2 | 1 |

| 0.7–0.8 | 8 | 4 |

| 0.9–1.0 | 5 | 2 |

| Parameter | Value | Unit |

|---|---|---|

| HBM production borehole depth | 45 | m |

| HBM production borehole diameter | 550 | mm |

| HBM production cavern target radius | 4 | m |

| Lignite seam depth interval | 20–45 | m |

| Unit weight of lignite | 1.35 | Mg/m3 |

| Data | Value | Unit |

|---|---|---|

| Material from drilling amount | 10.7 | m3 |

| Amount of solid waste from drilling | 4.8 | m3 |

| Amount of lignite from drilling | 5.9 | m3 |

| HBM production cavern target diameter | 8.0 | m |

| HBM production cavern target height | 25.0 | m |

| Lignite volume to be mined | 1251.1 | m3 |

| Lignite mass to be mined | 1689.0 | Mg |

| Total lignite volume (including the lignite from drilling) | 1257.0 | m3 |

| Total lignite mass (including the lignite from drilling) | 1697.0 | Mg |

| Unit Process | Parameter | Unit | OPTION I | OPTION II | OPTION III | OPTION IV |

|---|---|---|---|---|---|---|

| Values for Variant I—Desired Scenario | Values for Variant I—Undesired Scenario | Values for Variant II—Desired Scenario | Values for Variant II—Undesired Scenario | |||

| Borehole drilling and casing | Energy consumed | kWh | 1260 | 1680 | 1260 | 1680 |

| Diesel consumed | L | 300 | 400 | 300 | 400 | |

| CO2 emitted | kg | 806 | 1075 | 806 | 1075 | |

| Lignite hydro cutting | Energy consumed | kWh | 3212 | 7153 | 32,119 | 35,765 |

| Diesel consumed | L | 760 | 2533 | 7600 | 12,667 | |

| CO2 emitted | kg | 2042 | 6807 | 20,422 | 34,038 | |

| Water consumed | L | 10,134 | 13,512 | 101,340 | 67,560 | |

| Lignite hydro crushing | Energy consumed | kWh | 2956 | 2956 | 29,557 | 14,779 |

| Diesel consumed | L | 704 | 704 | 7037 | 3519 | |

| CO2 emitted | kg | 1891 | 1891 | 18,910 | 9455 | |

| Water consumed | L | 2702 | 4053 | 27,024 | 20,268 | |

| Total | Energy consumed | kWh | 7428 | 11,789 | 62,936 | 52,224 |

| Diesel consumed | L | 1764 | 3637 | 14,937 | 16,586 | |

| CO2 emitted | kg | 4739 | 9773 | 40,138 | 44,568 | |

| Water consumed | L | 12,836 | 17,565 | 128,364 | 87,828 |

| Option | Unit Process | Energy Consumption | Fuel Consumption | CO2 Emissions | Water Consumption | ||||

|---|---|---|---|---|---|---|---|---|---|

| Value, kWh | Value, kWh/1 Mg Lignite | Value, L | Value, L/1 Mg Lignite | Value, kg | Value, kg/1 Mg Lignite | Value, L | Value, L/1 Mg Lignite | ||

| OPTION I | borehole drilling & casing | 1260 | 0.74 | 300 | 0.18 | 806 | 0.47 | ||

| lignite hydro cutting | 3212 | 1.89 | 760 | 0.45 | 2042 | 1.20 | 10,134 | 5.97 | |

| lignite hydro crushing | 2956 | 1.74 | 704 | 0.41 | 1891 | 1.11 | 2702 | 1.59 | |

| TOTAL FOR OPTION I | 7428 | 4.38 | 1764 | 1.04 | 4739 | 2.79 | 12,836 | 7.56 | |

| OPTION II | borehole drilling & casing | 1680 | 0.99 | 400 | 0.24 | 1075 | 0.63 | ||

| lignite hydro cutting | 7153 | 4.22 | 2533 | 1.49 | 6807 | 4.01 | 13,512 | 7.96 | |

| lignite hydro crushing | 2956 | 1.74 | 704 | 0.41 | 1891 | 1.11 | 4053 | 2.39 | |

| TOTAL FOR OPTION II | 11,789 | 6.95 | 3637 | 2.14 | 9773 | 5.76 | 17,565 | 10.35 | |

| OPTION III | borehole drilling & casing | 1260 | 0.74 | 300 | 0.18 | 806 | 0.47 | ||

| lignite hydro cutting | 32,119 | 18.93 | 7600 | 4.48 | 20,422 | 12.03 | 101,340 | 59.72 | |

| lignite hydro crushing | 29,557 | 17.42 | 7037 | 4.15 | 18,910 | 11.14 | 27,024 | 15.92 | |

| TOTAL FOR OPTION III | 62,937 | 37.09 | 14,938 | 8.80 | 40,138 | 23.65 | 128,364 | 75.64 | |

| OPTION IV | borehole drilling & casing | 1680 | 0.99 | 400 | 0.24 | 1075 | 0.63 | ||

| lignite hydro cutting | 35,765 | 21.08 | 12,667 | 7.46 | 34,038 | 20.06 | 67,560 | 39.81 | |

| lignite hydro crushing | 14,779 | 8.71 | 3519 | 2.07 | 9455 | 5.57 | 20,268 | 11.94 | |

| TOTAL FOR OPTION IV | 52,223 | 30.77 | 16,586 | 9.77 | 44,567 | 26.26 | 87,828 | 51.75 | |

| Impact Category | Value | Unit |

|---|---|---|

| Solid waste generation | 0.0028 | m3/L Mg lignite |

| Abiotic resource depletion | 1 | Mg/L Mg lignite |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Maksymowicz, M.; Frejowski, A.; Bajcar, A.; Jura, B. Application of Hydro Borehole Mining (HBM) Technology for Lignite Extraction—An Environmental Assessment (LCA) and a Comparative Study with the Opencast Method. Energies 2022, 15, 4845. https://doi.org/10.3390/en15134845

Maksymowicz M, Frejowski A, Bajcar A, Jura B. Application of Hydro Borehole Mining (HBM) Technology for Lignite Extraction—An Environmental Assessment (LCA) and a Comparative Study with the Opencast Method. Energies. 2022; 15(13):4845. https://doi.org/10.3390/en15134845

Chicago/Turabian StyleMaksymowicz, Marcin, Aleksander Frejowski, Adam Bajcar, and Bartłomiej Jura. 2022. "Application of Hydro Borehole Mining (HBM) Technology for Lignite Extraction—An Environmental Assessment (LCA) and a Comparative Study with the Opencast Method" Energies 15, no. 13: 4845. https://doi.org/10.3390/en15134845

APA StyleMaksymowicz, M., Frejowski, A., Bajcar, A., & Jura, B. (2022). Application of Hydro Borehole Mining (HBM) Technology for Lignite Extraction—An Environmental Assessment (LCA) and a Comparative Study with the Opencast Method. Energies, 15(13), 4845. https://doi.org/10.3390/en15134845