Variable Weight-Projection Gray Target Evaluation Model of Degree of Protection of Protective Layer Mining

Abstract

:1. Introduction

2. Quantitative Evaluation Index for Protection Degree of Protective Layer Mining

2.1. Coal and Gas Outburst Risk Evaluation Index

2.2. Evaluation Index of Coal Seam Pressure Relief and Permeability Enhancement Effect

2.2.1. Coal Seam Expansion Value

2.2.2. Coal Seam Permeability Coefficient

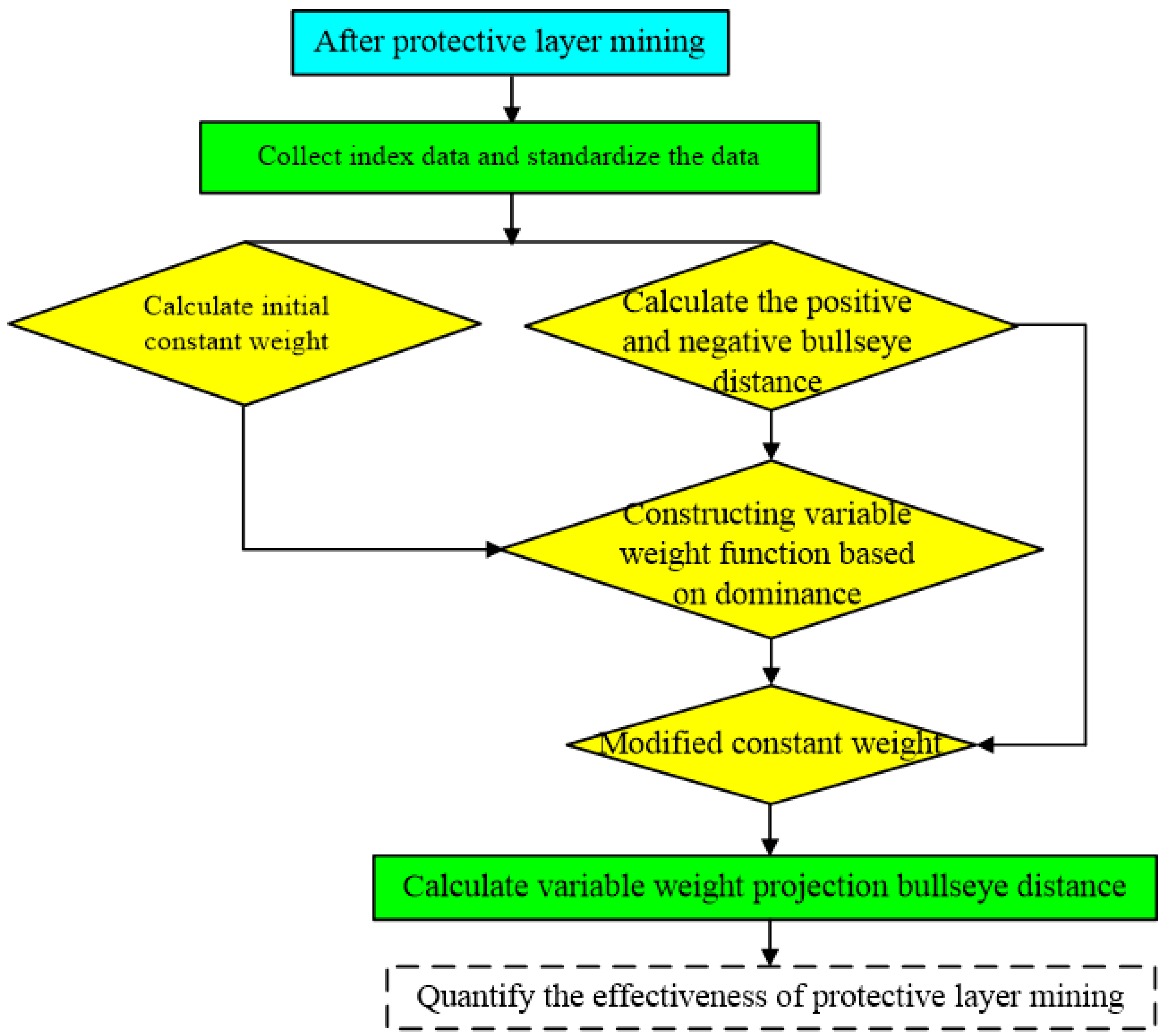

3. Dynamic Performance Evaluation Method of Protective Layer Mining Based on Variable Weight-Projection Gray Target

3.1. Data Normalization

3.2. Measurement of Index Relative Distance

3.3. Subjective Constant Weight Determined

3.4. Establish Variable Weight Function to Correct Fixed Subjective Weight

3.4.1. Positive and Negative Bullseye

3.4.2. Index Dominance Calculation

3.4.3. Variable Weight Function

3.5. Weighted Projection Grey Target Decision Method to Determine the Advantages and Disadvantages of the Scheme

4. Dynamic Evaluation of Degree of Protection by the Protective Layer

4.1. Evaluation Area Overview

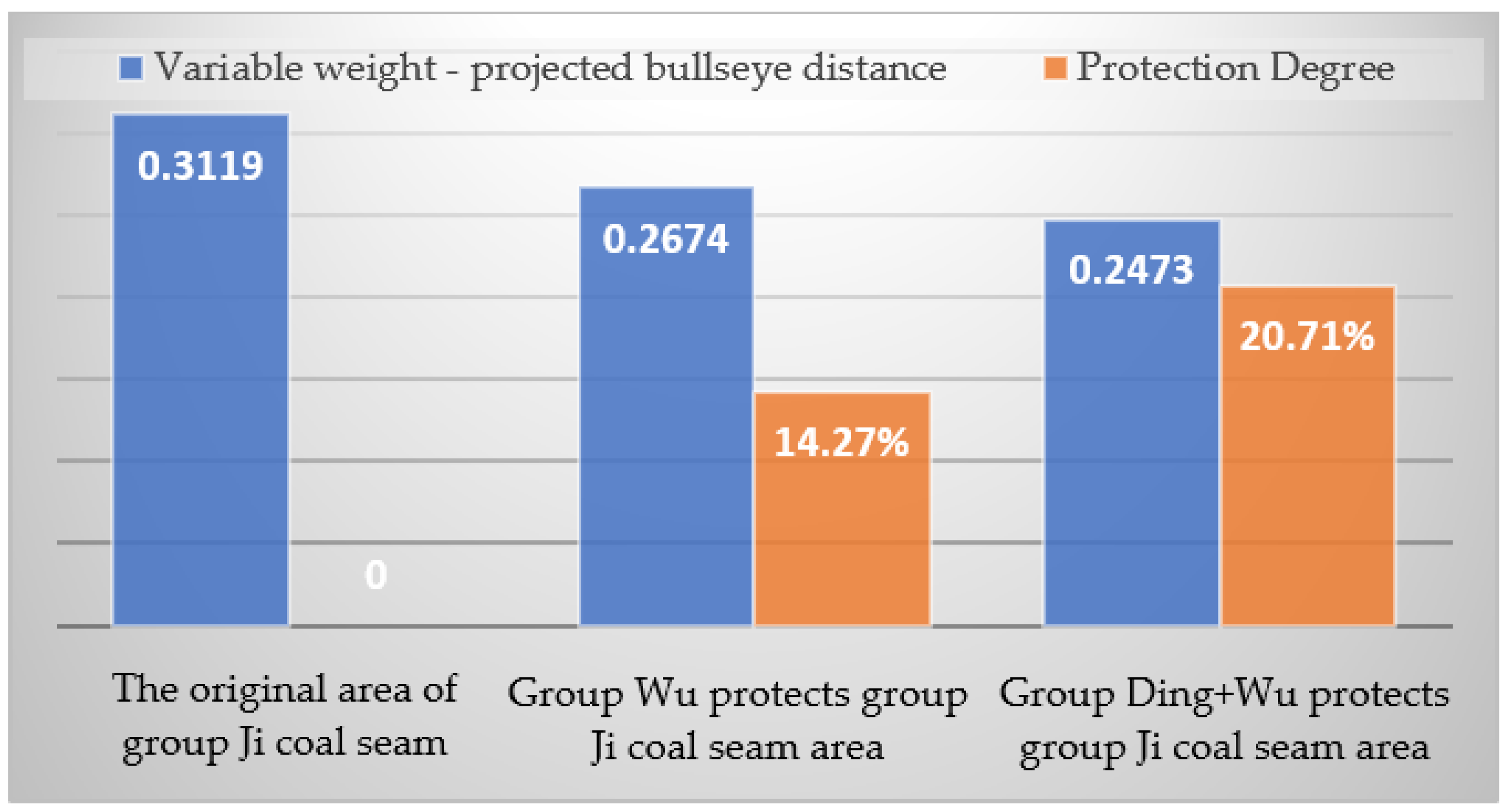

4.1.1. Spatial Distribution Relationship of Working Face

4.1.2. Parameter Test Scheme of Evaluation Area

4.1.3. Experimental Observation Data

- Gas content

- 2.

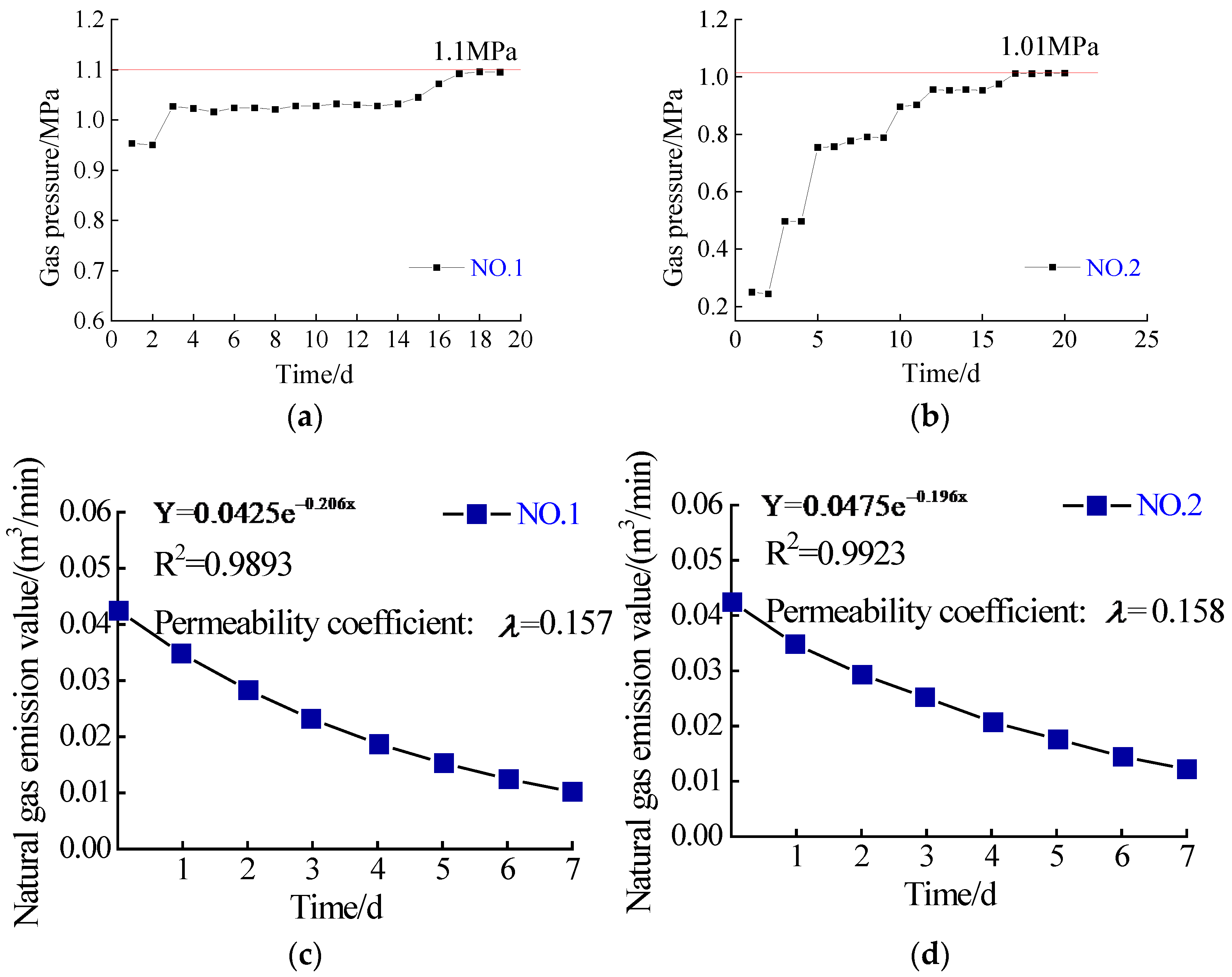

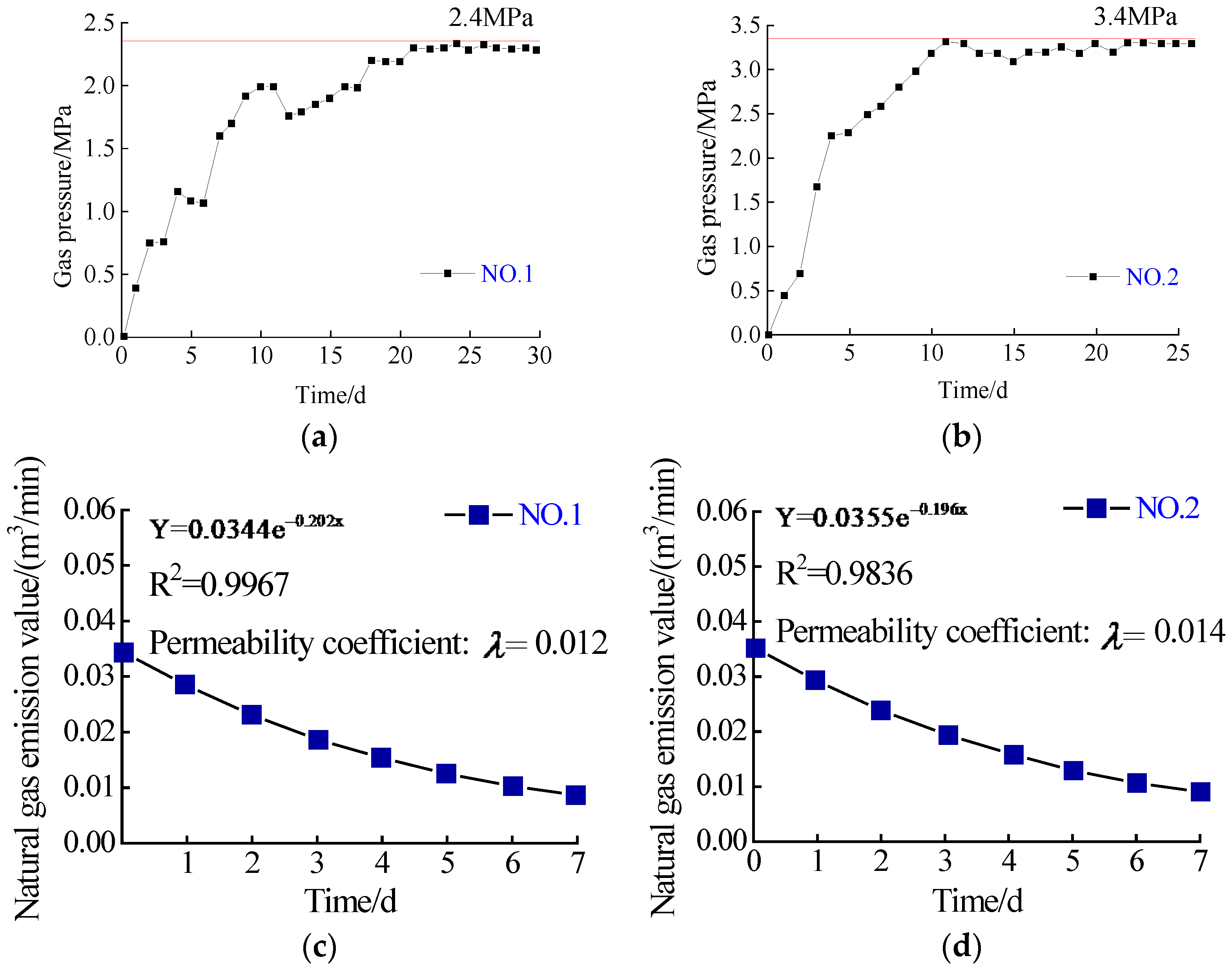

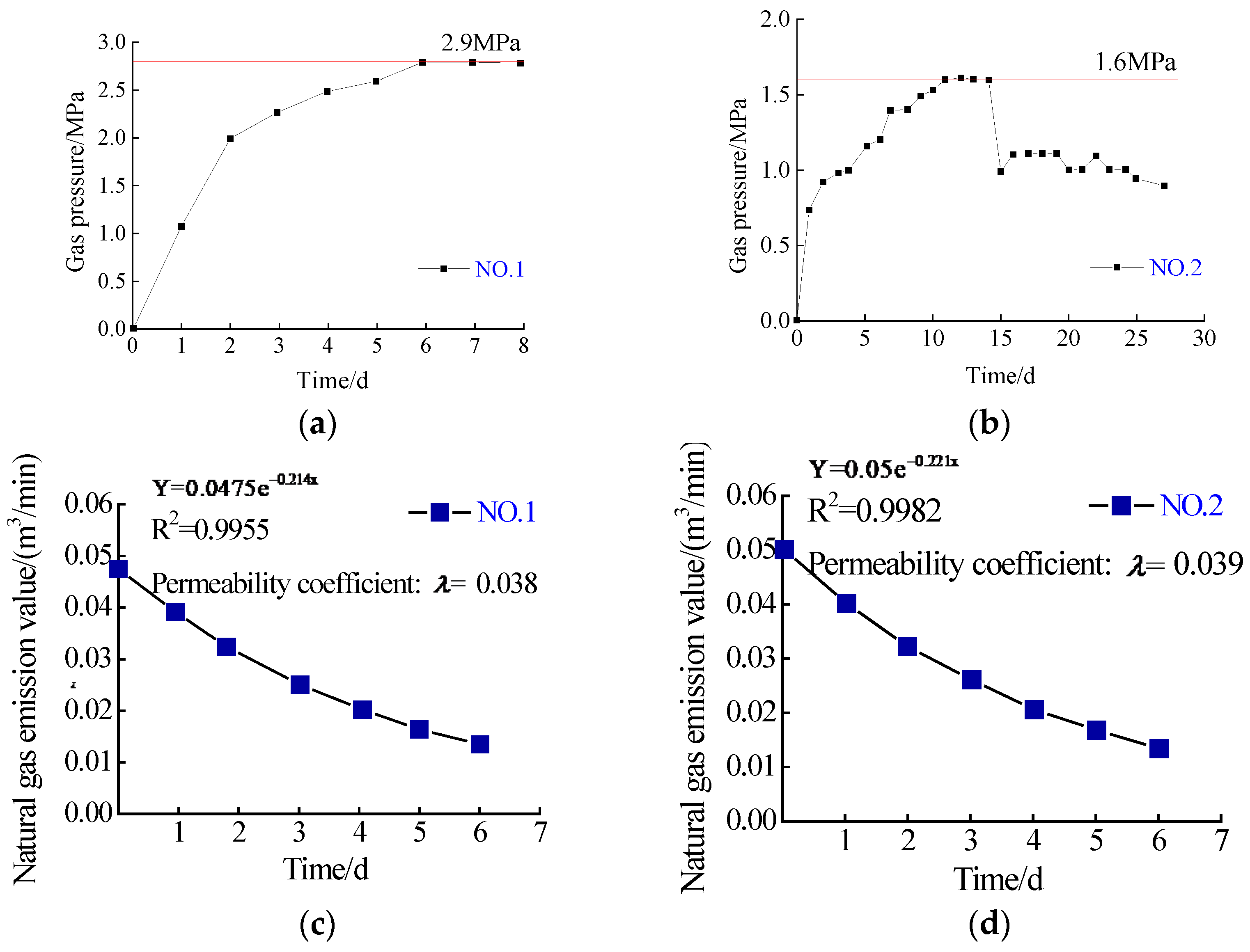

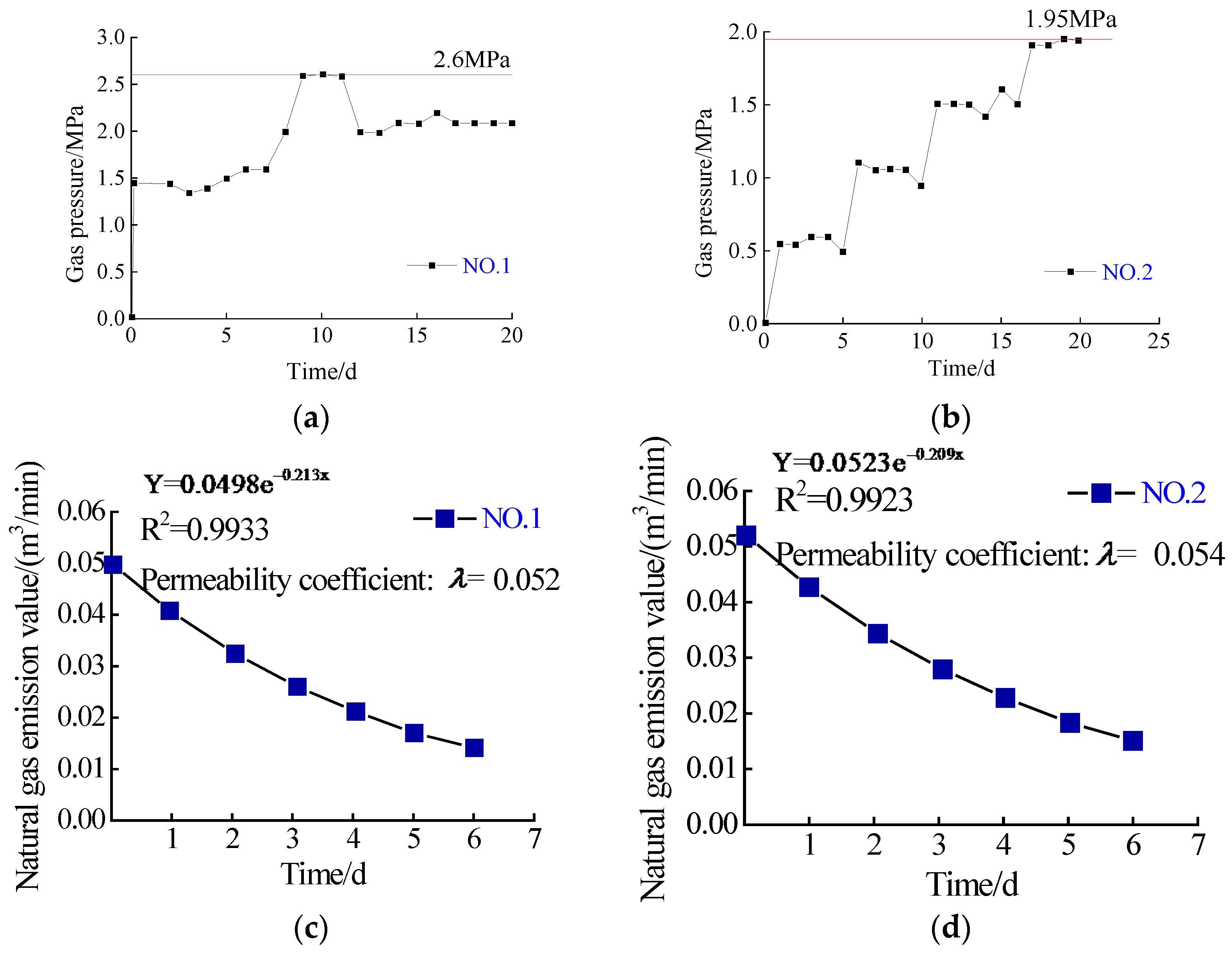

- Gas pressure and coal seam permeability coefficient

- 3.

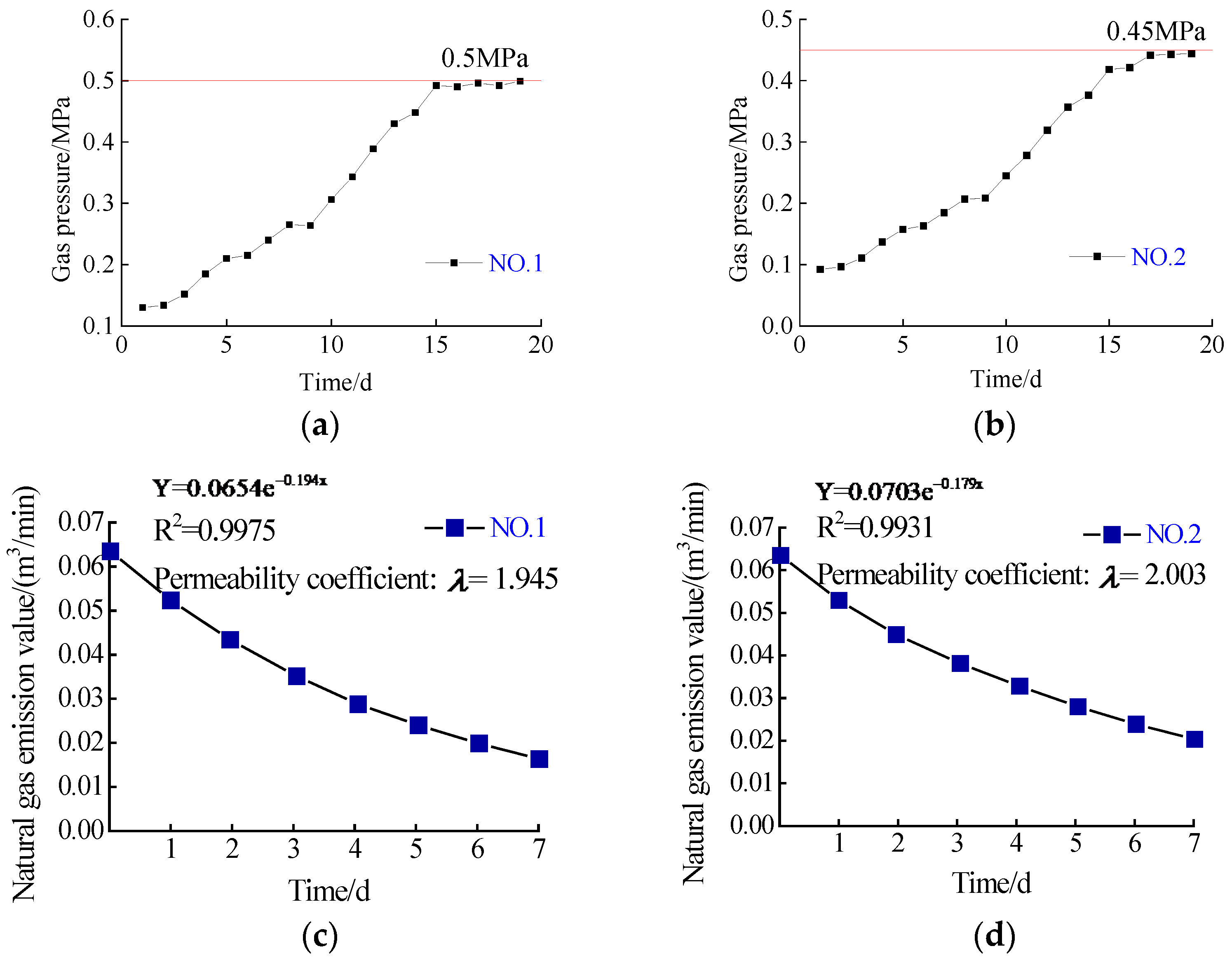

- Expansion deformation

4.2. Model Calculation

4.3. Results Analysis

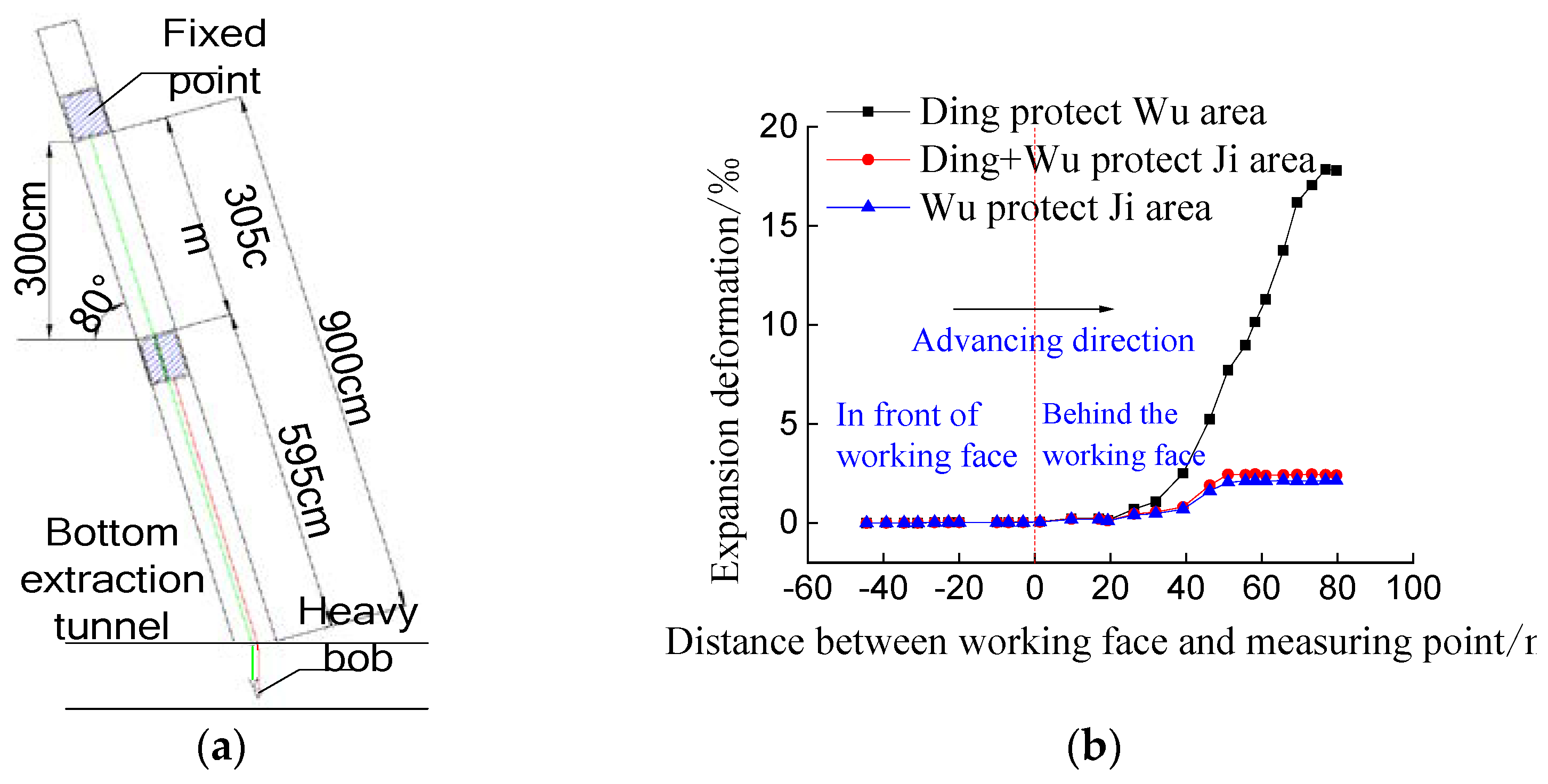

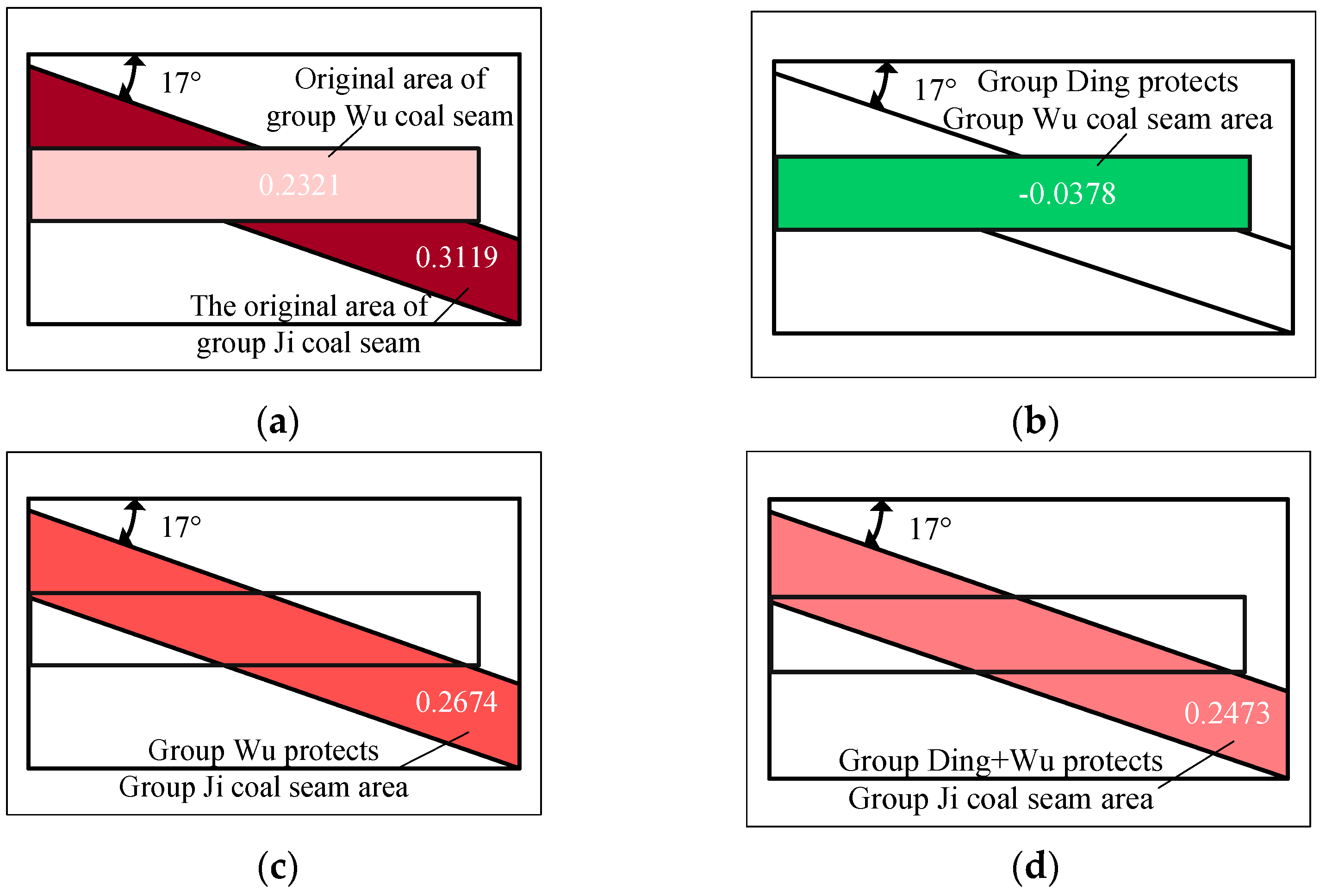

- The projected bullseye distance of the original area in the group Wu coal seam calculated by the model is 0.2321, which is dangerous (greater than zero). After mining the Ding group coal seam of the upper protective layer, the bullseye distance is reduced to −0.0378, which is effective for protection (less than zero). The degree of protection in the original area in the group Wu coal seam reaches 116.29%, which has a good protection effect. In terms of individual indexes, by comparing the gas parameters of the original area in group Wu and the area of Ding protected by group Wu, as shown in Table 4, it can be seen that the safety of coal seam mining is improved, the gas content is reduced by 40.6%, the gas pressure is reduced from 1.1 MPa to 0.5 MPa, the gas pressure is reduced by 54.5%, the permeability coefficient increased by 12.38-times, and the expansion value reaches 17.8‰. The gas content and gas pressure decrease significantly, and the values decrease to within the safe range of the outburst prevention index. At the same time, the permeability of the coal seam increases by 12.4-times. The effect of group Wu being protected by group Ding alone is more obvious.

- The projected bullseye distance of the original area in the group Ji coal seam is 0.3119, which is dangerous (greater than zero). After mining the upper protective layer in the group Wu coal seam, the bullseye distance is reduced to 0.2674, which is still dangerous (greater than zero). The degree of protection in the original area in the group Ji coal seam reached 14.27%, which reduced the degree of danger of the original area of the group Ji coal seam by 14.27%. Comparing the gas parameters of the original area in the group Ji coal seam and the area where the group Ji coal seam is protected by the Wu group coal seam, as shown in Table 4, it can be seen that the gas content decreased from 9.71 m3/t to 8.91 m3/t, the gas content decreased by 8.2%, the gas pressure decreased from 3.4 MPa to 2.9 MPa, and the gas pressure decreased by 14.7%. The permeability of the coal seam increased by 3.2-times, and the expansion value reached 2.14‰, but it was still lower than the critical value of 3‰, as shown in Table 2. Only mining the protective layer in group Wu has a certain protective effect on group Ji.

- After mining the upper protective layer in the Ding + Wu coal seam, the bullseye distance was reduced to 0.2473 (greater than zero), and the degree of protection in the original coal seam area reached 20.71%, which reduced the danger level in the original coal seam area by 20.71%. Comparing the gas parameters of the original area in the group Ji coal seam and the area where the group Ji coal seam is protected by the Ding + Wu group coal seam, as shown in Table 4, it can be seen that the gas content decreased from 9.71 m3/t to 6.34 m3/t, the gas content decreased by 34.7%, the gas pressure decreased from 3.4 MPa to 2.6 MPa, and the gas pressure decreased by 23.5%. The permeability of the coal seam increased by 4.3-times, and the expansion value reached 2.13‰, which was also lower than 3‰, as shown in Table 2. From the results, it can be seen that the effect of the Ding + Wu protective layer on the group Ji coal seam is better than the effect of the separate mining in the group Wu coal seam to protect the group Ji coal seam.

4.4. Gas Control Data Analysis

- After group Wu protective layer mining, the gas drainage rate for the group Ji protected layer increased from 19% to 50.1% and increased by 163.68%. There were still outstanding dangers.

- After group Ding + Wu upper protective layer mining, the gas drainage rate for the group Ji protected layer increased from 25.4% to 68.8% and increased by 170.87%. There were still outstanding dangers.

- After group Ding upper protective layer mining, the index for the group Wu protected layer was below the outburst critical value; the wind flow gas concentration in the protected layer working face increased from 0.15% to 0.41% and increased by 173.33%; and the gas extraction rate increased from 25.4% to 78.3% and increased by 208.27%.

5. Discussion

5.1. Comparative Analysis with the Calculation Results of the Constant Weight-Projection Gray Target

5.2. Comparison with Related Literature

6. Conclusions

- In the dynamic evaluation model of the variable weight projection bullseye, the subjective constant weight is corrected by the variable weight function to adjust the evaluation result, and the evaluation model reflects the dynamic changes in the evaluation index. Based on the punishment–incentive mechanism, the local state variable weight function is constructed, and the weight dynamic correction model is established. A weak index will affect the overall evaluation results. The penalty mechanism is used to reduce the weight of these indexes, so that the overall evaluation value is reduced after the weight adjustment. For the advantage index, the reward mechanism is used to increase the index weight and the overall evaluation value is increased.

- The research object is the outburst elimination effect in the protected layer in the engineering of protective layer mining. Taking the critical value of the evaluation index for outburst elimination and increasing permeability as the bullseye, the bullseye distance was calculated for each scheme, and the variable weight function was used to balance the evaluation results, quantifying the degree of protection. If the bullseye distance is a negative value, this indicates that there is no outburst risk, and the larger the absolute value, the higher the degree of protection. If the bullseye distance is a positive value, this indicates that there is an outburst risk, and the larger the value, the lower the degree of protection.

- Through the quantitative results, the protective layer mining of this mine was found to have a certain protective effect. Group Ding protects the group Wu coal seam area, with the degree of protection in the original coal seam reaching 116.29%, a good protective effect. After the mining of the protective layer, all indexes are within the safe value. Inside, the coal seam collapses. The group Wu coal seams protecting the group Ji coal seams area, and the group Ding + Wu coal seams protecting the group Ji coal seams, did not eliminate outbursts. In the area where the group Ji coal seam is protected by the Wu group coal seam, compared with the original area, the degree of risk in the group Ji coal seam was reduced by 14.27%. In the area where the group Ji coal seam is protected by the Ding + Wu group coal seam, the degree of risk in the group Ji coal seam was reduced by 20.71%. The degree of protection in group Ding + Wu to protect the group Ji coal seam scheme was slightly greater than that in group Wu to protect the group Ji coal seam scheme, and it can be increased by a small increase in permeability measures or by an improvement in gas drainage drilling design.

- This study obtains the variable weight-projection gray target model for evaluating the effectiveness of protective layer mining, and quantifies the degree of protection, provides a theoretical basis for judging whether the working face should be strengthened with enhanced permeability, and guides the formulation of a secondary outburst elimination scheme for an incompletely eliminated outburst coal seam.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Cheng, Y.G. Theory and Engineering Application of Coal Mine Gas Prevention and Control, 1st ed.; China University of Mining and Technology Press: Beijing, China, 2010; pp. 21–36. [Google Scholar]

- Zhang, H.T.; Wen, Z.H.; Yao, B.H.; Chen, X.Q. Numerical simulation on stress evolution and deformation of overlying coal seam in lower protective layer mining. Alexandria Eng. J. 2020, 59, 3623–3633. [Google Scholar] [CrossRef]

- He, A.P.; Fu, H.; Huo, B.J.; Fan, C.J. Permeability Enhancement of Coal Seam by Lower Protective Layer Mining for Gas Outburst Prevention. Shock Vib. 2020, 2020, 8878873. [Google Scholar] [CrossRef]

- Zou, Q.L.; Liu, H.; Zhang, Y.J.; Li, Q.M.; Fu, J.W.; Hu, Q.T. Rationality evaluation of production deployment of outburst-prone coal mines: A case study of nantong coal mine in Chongqing. Saf. Sci. 2020, 122, 104515. [Google Scholar] [CrossRef]

- China University of Mining and Technology, National Engineering Research Center for Coal Mine Gas Control. Technical Criterion of Protective Coal Seam Exploitation, 1st ed.; China State Administration of Work Safety: Beijing, China, 2008; pp. 2–3.

- Liang, B.; Qin, B.; Sun, W.J.; Wang, S.Y.; Shi, Y.S. The application of intelligent weighting grey target decision model in the assessment of coal-gas outburst. J. China. Coal. Soc. 2013, 38, 1611–1615. [Google Scholar]

- Chen, C.X.; Su, J.; Li, W.B. Investigation on regional outburst prevention effect with mining of upper protective seam extraction. Saf. Coal. Min. 2017, 43, 110–112. [Google Scholar]

- Kang, J.D. Study on the Influence of Coal Pillar on the Pressure Relief and Outburst Elimination of the Upper Protective Layer Mining. Min. Saf. Environ. Prot. 2018, 45, 17–21. [Google Scholar]

- Yuan, L.; Xue, S. Defining outburst-free zones in protective mining with seam gas content-method and application. J. China Coal Soc. 2014, 39, 1786–1791. [Google Scholar]

- Liu, Y.W.; Li, G.F. Reliability research of protective layer mining and pressure-relief gas drainage. J. Min. Saf. Eng. 2013, 30, 426–431. [Google Scholar]

- Du, Z.S.; Qin, B.T.; Fan, Y.C. A reliability evaluation model of exploitation efficiency of the protective layer and its application. J. Min. Saf. 2017, 34, 186–191. [Google Scholar]

- Sun, G.D.; Guan, X. Research on hybrid multi-attribute decision-making. In Proceedings of the 2016 International Conference on Cyber-Enabled Distributed Computing and Knowledge Discovery (CyberC), Chengdu, China, 13–15 October 2016; Computer Society: Washington, DC, USA; pp. 272–277. [Google Scholar]

- Ma, J.S. Generalised grey target decision method for mixed attributes with index weights containing uncertain numbers. J. Intell. Fuzzy Syst. 2018, 34, 625–632. [Google Scholar] [CrossRef]

- Ma, J.S. A generalized grey target decision method with mixes data type of index and weight. Stat. Decis. 2018, 7, 58–61. [Google Scholar]

- Ma, J.S. Generalised grey target decision method with Index and weight both containing mixed attribute values based on improved gini-simpson index. J. Stat. Inf. 2019, 34, 28–34. [Google Scholar]

- Zhang, Z.; Li, L.L.; Wei, Z.H.; Yu, H.F. Dynamic effectiveness evaluation of command control system based on variable weight-projection gray target. Syst. Eng. Electron. 2019, 4, 801–809. [Google Scholar]

- Zou, R.H.; Wang, Y.C.; Deng, Y.J. Condition assessment method for transmission line with multiple outputs based on variable weight principle and fuzzy comprehensive evaluation. High Volt. Eng. 2017, 43, 1289–1295. [Google Scholar]

- Li, S.Q.; Wu, Q.; Li, Z.; Zeng, Y.F.; Yuan, Q.D.; Yu, Y.L. Vulnerability evaluation and application of floor water inrush in mining area with multiple coal seams and single aquifer based on variable weight. J. China Univ. Min. Technol. 2021, 50, 587–597. [Google Scholar]

- Xu, L.M.; Li, M.J.; Dai, Q.Z. Dynamic evaluation method based on grey target. J. Syst. Sci. Math. Sci. 2017, 37, 112–124. [Google Scholar]

- Bing, L.; Qin, B.; Sun, F.Y.; Wang, Y.; Sun, Y.N.; Phuclo, K. Application of evaluation index system of coal and gas co-extraction and evaluation model. J. China Coal Soc. 2015, 40, 728–735. [Google Scholar]

- Chen, G.B.; Teng, P.C.; Li, T.; Wang, C.Y.; Chen, S.J.; Zhang, G.H. Evaluation model of rock burst in coal mine and its application. J. Taiyuan Univ. Technol. 2021, 52, 966–973. [Google Scholar]

- China State Administration of Coal Mine Safety. Detailed Rules for Prevention and Control of Coal and Gas Outburst, 1st ed.; Coal Industry Press: Beijing, China, 2019; pp. 22–23.

- Henan Provincial People’s Government. Available online: http://yjglt.henan.gov.cn/2014/10-25/987526.html (accessed on 25 October 2014).

| Classification | Coal Seam Permeability Coefficient (m2·MPa−2·d−1) |

|---|---|

| easy draw | >10 |

| normal draw | 0.1~10 |

| hard draw | <0.1 |

| Category | Gas Pressure (MPa) | Gas Content (m3·t−1) | Coal Seam Permeability Coefficient (m2·MPa−1·d−1) | Expansion Value (‰) |

|---|---|---|---|---|

| Positive bullseye | critical value | critical value | 5 | 3 |

| Negative bullseye | 0.74 | 8 | 0.1 | 0 |

| Investigation Contents | Borehole Number | Coal Sample Quality (g) | Loss Amount W1 (m3/t) | Natural Desorption Amount W2 (m3/t) | Crushing Desorption Amount W3 (m3/t) | Non-Desorbable Amount Wc (m3/t) | Gas Content W (m3/t) |

|---|---|---|---|---|---|---|---|

| Original area of group Wu | NO. 1 | 693.4 | 1.06 | 1.59 | 1.53 | 2.23 | 6.41 |

| NO. 2 | 588.0 | 2.74 | 2.08 | 2.85 | 2.23 | 9.90 | |

| Original area of group Ji | NO. 1 | 575.5 | 1.51 | 3.09 | 3.25 | 1.28 | 9.13 |

| NO. 2 | 586.2 | 1.67 | 3.35 | 3.41 | 1.28 | 9.71 | |

| Group Wu protect group Ji area | NO. 1 | 494.2 | 0.78 | 2.19 | 2.13 | 1.28 | 6.38 |

| NO. 2 | 498.9 | 1.27 | 3.00 | 3.36 | 1.28 | 8.91 | |

| Group Ding+Wu protect group Ji area | NO. 1 | 614.0 | 0.57 | 2.22 | 2.15 | 1.28 | 6.22 |

| NO. 2 | 519.7 | 0.72 | 2.60 | 1.74 | 1.28 | 6.34 | |

| Group Ding protect group Wu area | NO. 1 | 531.7 | 0.62 | 2.31 | 1.67 | 1.28 | 5.88 |

| NO. 2 | 522.3 | 0.66 | 2.28 | 1.30 | 1.28 | 5.52 |

| Evaluation Scheme | Gas Content W/m3·t−1 | Gas Pressure P/MPa | Permeability Coefficient λ/m2·MPa−1·d−1 | Expansion Value/‰ |

|---|---|---|---|---|

| Group Wu coal seam original area | 9.90 | 1.1 | 0.157~0.158 | 0.000 |

| Group Ji coal seam original area | 9.71 | 3.4 | 0.012~0.014 | 0.000 |

| The area where the group Ji coal seam is protected by the Wu group coal seam | 8.91 | 2.9 | 0.038~0.039 | 2.140 |

| The area where the group Ji coal seam is protected by the Ding + Wu group coal seam | 6.34 | 2.6 | 0.052~0.054 | 2.130 |

| The area where the group Wu coal seam is protected by the Ding group coal seam | 5.88 | 0.5 | 1.945~2.003 | 17.80 |

| Index | Expert 1 | Expert 2 | Expert 3 | Average Score | Ideal Ordering | Index Action | Relative Importance | Subjective Constant Weight |

|---|---|---|---|---|---|---|---|---|

| x1 | 3 | 4 | 4 | 1.333 | x2 | 4 | \ | 0.333 |

| x2 | 1 | 1 | 2 | 3.667 | x4 | 2 | 1 | 0.250 |

| x3 | 4 | 3 | 3 | 1.667 | x3 | 4 | 0.5 | 0.217 |

| x4 | 2 | 2 | 1 | 3.333 | x1 | 2 | 2 | 0.200 |

| Index | x1 | x2 | x3 | x4 | |

|---|---|---|---|---|---|

| Scheme | |||||

| 1 | 0.1949 | 0.3229 | 0.2081 | 0.2742 | |

| 2 | 0.1920 | 0.3195 | 0.2099 | 0.2767 | |

| 3 | 0.1946 | 0.3236 | 0.2095 | 0.2724 | |

| 4 | 0.1966 | 0.3218 | 0.2094 | 0.2722 | |

| 5 | 0.1933 | 0.3606 | 0.2069 | 0.2391 | |

| Evaluation Scheme | The Original Area of the Ji Group Coal Seam | The Area Where the Group Ji Coal Seam Is Protected by the Wu Group Coal Seam | The Area Where the Group Ji Coal Seam Is Protected by the Ding + Wu Group Coal Seam |

|---|---|---|---|

| Variable weight—projected bullseye distance | 0.3119 | 0.2674 | 0.2473 |

| Evaluation scheme | The original area of Wu group coal seam | The area where the group Wu coal seam is protected by the Ding group coal seam | \ |

| Variable weight—projected bullseye distance | 0.2321 | −0.0378 | \ |

| Calculation Results | Group Wu Coal Seam Original Area | The Area Where the Group Wu Coal Seam is Protected by the Group Ding Coal Seam |

|---|---|---|

| Constant weight bullseye distance | 0.2182 | −0.0015 |

| Variable weight bullseye distance | 0.2321 | −0.0378 |

| Calculation Results | Group Ji Coal Seam Original Area | The Area Where the Group Ji Coal Seam Is Protected by the Wu Group Coal Seam | The Area Where the Group Ji Coal Seam Is Protected by the Ding + Wu Group Coal Seam |

|---|---|---|---|

| Constant weight bullseye distance | 0.2948 | 0.2630 | 0.2559 |

| Variable weight bullseye distance | 0.3119 | 0.2673 | 0.2473 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qin, B.; Shi, Z.; Hao, J.; Liang, B.; Sun, W.; He, F. Variable Weight-Projection Gray Target Evaluation Model of Degree of Protection of Protective Layer Mining. Energies 2022, 15, 4654. https://doi.org/10.3390/en15134654

Qin B, Shi Z, Hao J, Liang B, Sun W, He F. Variable Weight-Projection Gray Target Evaluation Model of Degree of Protection of Protective Layer Mining. Energies. 2022; 15(13):4654. https://doi.org/10.3390/en15134654

Chicago/Turabian StyleQin, Bing, Zhanshan Shi, Jianfeng Hao, Bing Liang, Weiji Sun, and Feng He. 2022. "Variable Weight-Projection Gray Target Evaluation Model of Degree of Protection of Protective Layer Mining" Energies 15, no. 13: 4654. https://doi.org/10.3390/en15134654

APA StyleQin, B., Shi, Z., Hao, J., Liang, B., Sun, W., & He, F. (2022). Variable Weight-Projection Gray Target Evaluation Model of Degree of Protection of Protective Layer Mining. Energies, 15(13), 4654. https://doi.org/10.3390/en15134654