1. Introduction

Electric cars are becoming more and more popular every day. Electric vehicles do not emit greenhouse gases and do not pollute the air. As a result of the technological advances, we have witnessed considerable progress in electric car design in recent years. Almost every major car manufacturer in the world is now starting to develop all-electric models, as the Allied Market Research (AMR) report [

1] illustrates.

The progress in electric cars depends on energy efficiency and the capacity of energy-storage equipment. Batteries are the leading element. Lithium-ion and lithium-iron phosphate dominate the current electric vehicles’ battery landscape. Arguments such as high efficiency, high energy density, low self-discharge, as well as low maintenance costs are listed as the main reasons for the use of the mentioned batteries [

2].

It has been experimentally found that the range of a passenger car is consistent with the data provided in the vehicle homologation certificate but under the condition of an appropriate ambient temperature of 18 °C. In the conditions of a negative outside temperature of −15 °C, the range decreases by almost four times [

3]. Additionally, supercapacitors have become one of the most promising energy-storage systems as they present multifold advantages of a high power density, fast charging–discharging, and long cyclic stability. However, the intrinsically low energy density inherent to traditional supercapacitors severely limits their widespread applications, triggering researchers to explore new types of supercapacitors with improved performance. Asymmetric supercapacitors assembled using two dissimilar electrode materials offer a distinct advantage of a wide operational voltage window, and thereby significantly enhance the energy density [

4].

Therefore, a complicated temperature monitoring system [

5] as well as charging and discharging cycles [

6] are assumed in such conditions.

Even in the case when batteries have a high energy density, they usually have a low power density, making them an element with a low efficiency for rapid energy transformations [

7]. Therefore, it is favorable to combine the batteries with the ultracapacitor (UC), which provides high power density combined with low energy density [

8]. In addition, the degradation of batteries is accelerated when they are subjected to cycles changing current profiles during the acceleration and braking of the car [

9].

Energy management systems in hybrid and electric cars are one of the most important areas of research. A commonly known and still tested strategy is based on the heuristic concept and includes algorithms based on learning rules and fuzzy logic [

10]. It has been experimentally found that the fuzzy logic control method, which is implemented and tested in the ADVISOR environment, can be utilized to design relevant energy management strategies for a vehicle using power sources consisting of battery, fuel cell, and ultracapacitor [

11].

Energy management strategies were dominated by fuzzy logic algorithms due to their simplicity of implementation. However, such strategies cannot guarantee optimal power distribution between the energy source and its receiver. In addition, fuzzy rules and logic require expert knowledge. To solve this problem, the theory of optimal control was proposed, including both dynamic programming, developed by Bellman [

12], and the Pontryagin minimum principle (PMP) [

13].

Simulation results show that we can achieve near optimal control, in which 86% of final values stay within 4% of the desired final value for the tested city driving schedules [

14].

The use of the PMP technique ensures continuity between offline and online energy management. However, in the latter, an adaptation rule is necessary since the future driving conditions are not known in advance in real time. There is a difference effect leading to the unavoidable discrepancy between the offline-calculated ideal behavior and the one obtained with a real controller on a real system [

15].

Over time, mainly because the computation time was too long, the real-time control had to be modified. Some researchers have proposed stochastic dynamic programming (SDP) [

16] to overcome this problem.

Considering the above, the aim of this publication is the evaluation of the applicability of multi-valued logic trees in decision support concerning electric energy management by an electric car driver.

2. Knowledge Discovery from a Classification Viewpoint

The issue of classification, discovery, and knowledge generation is an interactive and iterative process with the following stages:

- -

Analyzing and learning about the application domain, the identification of available knowledge, and user goals.

- -

Selecting the data related to the process objectives.

- -

Data pre-processing and data reduction.

- -

Selecting knowledge discovery task and algorithms.

- -

Extracting knowledge from the data (a basic data mining step).

- -

Interpretating and evaluating the discovered knowledge.

- -

Preparing the knowledge for use.

Currently, most research is focused on data mining algorithms, although other steps are equally important for the successful execution of the overall process.

The paper [

17] presents the application of the web data mining technique for enterprise management in e-commerce. It is an important issue for all scientific disciplines. By following certain web data mining procedures [

18], knowledge is discovered and the optimization of the operation management system is performed to provide decision support for e-commerce and web management.

The work in [

19] presents concepts and techniques for processing collected data and information that can be used in various applications. In particular, it explains data mining and tools used to discover knowledge from collected data. The authors focused on describing the feasibility, usefulness, effectiveness, and scalability of big data techniques.

By analyzing different interpretations of knowledge discovery it can be concluded that knowledge discovery tasks can be considered from two perspectives: prediction and description. Knowledge discovery is interdisciplinary and uses results from statistics, machine learning, data visualization, databases, and uncertain information processing (e.g., fuzzy set theory or rough set theory). Machine learning and statistics are currently most relevant as they provide algorithms for knowledge discovery. On the other hand, the specificity of knowledge discovery from databases poses new research problems for both machine learning and database handling.

The work in [

20] presents a wide range of applications of machine learning algorithms in database research. References [

21,

22] describe methods and techniques for privacy-preserving data mining (PPDM) using encryption and privacy. This is of particular importance from the perspective of creating innovative solutions and engineering patents.

In [

23], an automated expert system used for inventory management was presented. In turn, in [

24], the authors presented data mining methods for knowledge discovery in multi-objective optimization. The main part of the paper is devoted to methods that can generate explicit knowledge in a form usable by machines. A framework for knowledge-based optimization that includes both online and offline components of knowledge discovery is proposed. In particular, it is of great importance in discrete optimization, a domain in which expert systems are very common.

According to experimental research, technical objects available in the literature do not have one type of information classification and decision support methods.

In inductive and classification knowledge acquisition, the decision consists of fragments describing the essence of the action to be taken. With the development of information technology, the nature and possibilities of optimization methods and decision support systems are changing. There is a wide range of research into the development of methodologies supporting decision-making processes and management control, design methodologies, and systems of varying scales of complexity, including artificial intelligence. A special direction of development that strengthens the role of classification systems is the combination of various methods of processing, inference, and seeking knowledge developed separately under artificial intelligence into one coherent hybrid consulting system and SC (soft computing) [

23].

At the same time, the state-of-the-art in machine learning is constantly increasing. It covers the problems of constructing systems whose operation increases with the experience represented by the set of teaching examples. In this area, particular attention should be paid to the methods of trees and graphs.

In the case of decision trees, their fundament is logical decision trees, derived from Boolean algebra [

25], and graphs, which had their initial applications through the developed Karnaugh map method [

26]. Other decision-making systems are multi-valued logic trees.

3. Expert Systems in Driving Car Applications

There are multiple problems in diagnosing vehicles. Due to the lack of scientific knowledge in people performing vehicle diagnostics, these problems are solved based on their experience gained over the years of practice. In most cases, it turns out that this way of solving problems is inefficient and time-consuming. In this case, an expert in the field comes to help. Hiring an expert is often very expensive. For this reason, it is important to introduce expert systems in automotive diagnostics.

Advisory systems present solutions to the user, who is then able to evaluate their quality. The user can reject the solution offered by the system and request another solution. Systems that make decisions without human control are the final authority for themselves. They are used, for example, to control various objects where human participation is difficult or even impossible. For critique systems, on the other hand, a problem and its solution are presented. In this case, the system performs an analysis and comments on the resulting solution. Expert systems are programs that are significantly different from other programs as they:

- -

Deal with real, concrete, but highly complex issues, generally requiring a high degree of human knowledge.

- -

Must assure high quality and efficiency of operation emerging from speed and reliability.

- -

Must be able to understand, explain, and solve the task to convince the user of the correctness or rightness.

Initially, expert systems were used as design and control support tools in autonomous cars. In [

27], the application of expert systems was categorized into five categories as expert system, fuzzy expert system, neuro-fuzzy expert system, genetic plus neuro-fuzzy expert system, and transition systems. Due to their properties, fuzzy expert systems can be applied with a high probability of success in situations where there are difficulties arising from trying to create a mathematical model. In the further stage (after design), an appropriate algorithm is used for the control problem. The undoubted development of expert systems was the establishment of the group “Working Group D10 Applications of Expert Systems to Power System Protection of the Line Protection Subcommittee, Power System Relaying Committee” [

28]. Paper [

28] presents a description of the work performed by an established executive group that has given the green light to the application of expert systems in decision making for electrical automotive components. In [

29], an expert system for used car price forecasting using the adaptive neuro-fuzzy inference system (ANFIS) was presented. The proposed system consisted of three parts: a data acquisition system, a price prediction algorithm, and a performance analysis. The presented ANFIS model combines the capabilities of adaptive neural network and qualitative fuzzy logic approximation. The research presented in this paper was strongly influenced by the results obtained in [

30], where real driving patterns of electric and gasoline motorcycles were compared.

The developed on-board system was installed in the test motorcycles to collect actual riding patterns in the urban cycle with mixed traffic and congestion. The driving cycles of both electric and gasoline motorcycles were developed and their driving performance, energy consumption, CO2 emissions, and energy costs were compared. The results show that with the same driving behaviors and road conditions, some driving parameters of the electric motorcycle, including average speed, average cruising speed, and proportion of time spent idling, were similar to those of the gasoline motorcycle. However, the top speed and the proportion of time spent accelerating and braking were lower for the electric motorcycle than those for the gasoline motorcycle. In contrast, average acceleration, average deceleration, and the percentage of time spent driving at cruising speed were higher for the electric motorcycle than for the gasoline motorcycle. Energy consumption, CO2 equivalent emissions, and energy costs for the electric motorcycle were eight, two, and six times lower, respectively, than those for the gasoline motorcycle when driving in a congested urban corridor. The authors focused on the “on-board” expert system to measure the actual driving patterns of electric and gasoline motorcycles while driving. The driving cycles of electric and gasoline motorcycles were developed by a recursive algorithm using the principle of least total variance in the target parameters. However, the target expert system has not been built to feature the repeatability of the study. This is very important to reflect the simulation results in the real mode.

The evaluation of energy consumption and exhaust emissions of passenger cars equipped with different powertrains in real operation was presented in [

31]. The authors used passenger cars with conventional engines of different emission classes, as well as the latest hybrid vehicles and an electric car for the study. This enabled a comparative assessment of energy consumption in different traffic conditions, with particular emphasis on the urban phase and the entire RDE (real driving emissions) test. The authors showed that the most promising solution seems to be a vehicle with only electric drive systems. If an expert system is used, then the assessment of energy consumption and efficiency could be carried out in real operating conditions, considering the possibility of repeatability of simulations. This is an important problem related to the operation of modern vehicles (with various power trains).

In [

32], a methodology was developed to construct a representative electric vehicle (EV) urban driving cycle as a basis for studying the differences in estimated energy consumption. A hybrid data collection method was used to combine the advantages of the chase car method and the on-board measurement method. For data processing, wavelet decomposition and reconstruction were applied to preprocess the original data. To reduce the number of kinematic parameters, the authors used principal components analysis (PCA). The fuzzy C-means algorithm (FCM) was used to cluster the driving segments. PCA is a statistical process in which a large number of strongly correlated variables are converted into a small number of uncorrelated variables through orthogonal transformation while preserving the characteristics of the original data as much as possible. The basic idea of the FCM algorithm is to search for the membership degree matrix and the clustering centers through an iterative process with the goal of realizing the minimum value of the objective function.

Another example of the application of an expert system based on fuzzy logic is presented by the authors of [

33]. Based on the described literature, the authors have built a fuzzy off-line expert system for fault diagnosis in the power distribution network. The system is based on the structure and operation of relay and circuit breakers. The description of the operation (correct operation, faulty operation, and no operation) of the relays and circuit breakers is described using fuzzy logic. The input data for the proposed fuzzy expert fault diagnosis system (FDS) were the alarm states and time signatures associated with the relays and circuit breakers. Moreover, it enables error identification and localization based on the Hamacher sum [

34]. The paper additionally discusses a method for modeling unknown information using a linear membership function for fuzzy sets. The system proposed by the authors makes it possible to precisely diagnose situations of incomplete information. At this point, we should also refer to [

35], which describes an expert system using fuzzy logic and parametric inference base for risk assessment of innovative projects.

In particular, the paper [

36] investigated an electric vehicle in urban mode. The authors proved that the driving technique has a great influence on the energy consumption characteristics of the electric vehicle, its range, and the performance characteristics of the batteries used. The method for measuring the energy consumption of the vehicle was tested on a chassis dynamometer, which, in the opinion of the authors, can effectively replace the real-mode tests. The use of an expert system would allow obtaining repeatability of simulations and tests—also from the point of view of optimal decision-making.

The paper [

37] presents knowledge management as an information flow in an expert system for the evaluation of operating modes and the technical condition of electrical equipment. The basis of the diagnostic method was the analysis of graphs, which are characterized by high sensitivity to slight deviations of signal parameter values (current consumption) from the reference value, as well as stability during the analysis period. The authors pointed out the possibility of using the method of intelligent real-time monitoring systems of electrical equipment. In particular, the MatCad programming environment was used. The paper [

37] presents knowledge management as information flow in an expert system for the evaluation of operating modes and the technical condition of electrical equipment. The basis of the diagnostic method was the analysis of graphs, which show high sensitivity to slight deviations of signal parameter values (current consumption) from the reference value, as well as stability during the analysis period. The authors pointed out the possibility of using the method of intelligent real-time monitoring systems of electrical equipment. In particular, the MatCad programming environment was used. Further works that present the possibilities of expert system applications include papers [

38] and [

39]. The work in [

38] presents the Vitruvius platform, where users without programming knowledge can design and quickly deploy rich web applications based on real-time data collected from connected vehicles and sensors. The work provides an excellent example of integrating information systems with electric cars. On the other hand, the work in [

39] presents an expert system based on fuzzy logic applied to speed control of an autonomous electric vehicle (EV). The individual decisions during driving at any time are defined by a set of fuzzy rules and the speed categories to be used. The experimental results obtained by the authors confirm the validity of the control methods used. In particular, the algorithm allows the operator to control the vehicle without extensive knowledge of the data.

Despite the existence of a very large number of studies on the application of expert systems to electric and autonomous cars, methods are still under development. In particular, there are few studies using expert systems based on decision trees.

3.1. Decision Trees in Machine Learning Classification for Expert Systems

Among many classification and decision support methods in design methodology, trees play a large role. There are many tree-based methods used in design methods based on decision variables and learning sets. Multi-valued decision trees have been used to rank the importance of design and/or performance parameters of machine systems and in systems of various complexities. Thanks to database systems, it is possible to collect and directly access an increasing amount of information. New classifiers and trees are created, which allow automatic processing and analysis of even very large datasets for numerous applications.

Trees allow the expert system to be applied to variables of any scale, both well-defined variables and fuzzy variables. It can also be applied to any type of relations, for example to time-invariant relations, space-invariant relations, deterministic, and probabilistic, with and without memory. Within the class of technical systems, we can distinguish many ways of creating models of objects, among them: functional models, research models (conceptual models, analytical models), and structural models, in which the similarity between the model and the original consists in structural similarity, i.e., showing common features of the internal structure of the model and the object.

The paper [

40] presents simulation cases for the UAH Autonomous Electric Car, related to typical driving scenarios in urban environments, focusing on the use of hierarchically interpreted binary Petri nets to implement the decision framework of the autonomous electric vehicle. In particular, the authors presented the possibility of implementing rules from decision trees. On the other hand, in [

41], the authors presented game tree-based decision-making methods for modeling driver decisions and interactions in traffic. In particular, they presented two algorithms based on Stackelberg policies and decision trees.

3.2. Learning from Examples

Decision rules are induced from datasets representing information about a set of objects called learning examples, described by a set of attributes. The problem considered in the field of machine learning is to find rules that determine whether an object belongs to a certain subset, called a (decision) class or concept. Most algorithms search for such rules by an inductive generalization of the description of learning examples [

42]. The rules generated for each decision class should be satisfied by examples belonging to that class (so-called positive examples). At the same time, the rules should not be satisfied by any or should be satisfied only by few examples from other classes (so-called negative examples).

The methods educated by machine learning make it possible to build intelligent programs that are capable of:

Acquiring knowledge about a given problem (environment) based on the interaction with it.

Processing (especially generalizing) the acquired knowledge to develop a general model of the problem.

Applying the acquired and processed knowledge to take certain decisions (actions) in new decision-making situations.

The task of a learning system is to acquire knowledge from a given subset of examples:

called a learning set, which is usually a random sample from the population of all objects,

U. The objects are described by a set of features (attributes, variables). A convenient way to represent the set of examples,

L, is a decision table. As a result of learning on a set of examples,

L, described by features, F, the machine learning system generates a hypothesis, hF (

L). This hypothesis is a classifier. Knowledge representation languages can be divided into:

- -

Symbolic (logical expressions, decision rules, decision trees, semantic networks).

- -

Sub-symbolic (represented mainly by neural networks).

A machine learning method for the diagnosis of internal combustion engine valve clearance is presented in [

43]. Among other things, the authors used a classifier in the form of a set of binary trees and applied divisions into first class features and calculated the weighted classification error. Finally, three binary trees specialized in the identification of individual valve clearance classes were proposed.

On the other hand, the paper [

44] presents the application of the dynamic fault tree (DFT) method, including Markov processes. With this method developed, more reliability indices and more damage information could be obtained.

Another approach to decision trees may involve the use of inductive decision trees involving the calculation of entropy gain [

45]. In [

46], a system was developed to identify the technical condition of the internal combustion engine of the Polaris Sportsman XP 850 quad model by fault identification based on the analysis of the block vibration signal in the frequency domain. A new method was proposed to identify selected faults against existing ones (developed by Ahirrao [

47] and Huang and Liu [

48], among others). The expert system, using indicational trees, analyzes the distribution of spectrum values around the analyzed harmonic, for which a compliance relation is created for a given excitation (motor load). In particular, very useful applications of tree methods can be found in [

49,

50]. In [

49], the authors used the dynamic failure tree method to perform Monte Carlo simulations. The developed and presented method enabled a correct depiction of the logical dependencies between the system and its components in terms of failures. An improved linear algebra representation (I-LAR) method was used to transfer the graphical non-failure tree (regardless of its size and complexity) to the modular reliability model used in the Monte Carlo simulation. The authors demonstrated the correctness of the proposed method with a numerical example involving two cases.

The paper [

50] presents the application of a hybrid method composed of:

- -

Kernel principal component analysis (KPCA),

- -

Lévy flight-based tree algorithm (LTSA) [

51],

- -

Extreme machine learning (ELM) for short-term load prediction.

The authors showed that the proposed methods can be successfully used for short-term electrical load forecasting. A hybrid approach using the fault tree analysis (FTA) and Mamdani fuzzy inference is presented in [

52]. The authors used the developed expert system to estimate the reliability of response as a function of several frequently operating pressures and temperatures. The discrete event simulation performed evaluated the reliability of the system under different operating conditions. The results presented in [

52] show how great the role of a properly built and tuned expert system is when pressure and temperature change during operating cycles, which significantly affect the reliability. In particular, work aimed at optimizing battery performance in electric cars has been performed. In [

53], the authors presented a joint sizing algorithm for a fuel cell (FC) stack and an auxiliary energy-storage system, considering a power-sharing strategy between the two energy sources. Furthermore, they introduced a new power-sharing method based on a fixed resistance of both the fuel cell stack and the lithium-ion battery modules. The authors demonstrate that the proposed sizing procedure can reduce the fuel consumption of the FCV and increase the expected lifetime of both the FC stack and the lithium-ion battery modules under a given power-sharing strategy. In contrast, the development of a bin-picking solution based on low-cost vision systems for manipulating automotive electrical connectors using machine learning techniques is presented in [

54]. In [

55], the authors investigated the breakdown of transient current imbalance caused by an asymmetric stray inductance. In particular, in [

56], the authors presented three different battery modeling approaches with a description of their parameter identification. The authors identified three easy-to-implement battery models suitable for the early stages of battery-powered system simulation and design. However, more accurate models should be used in the optimization phase of such systems. Different battery management strategies are presented in [

57], where the authors demonstrated that BEV drivers’ behavior related to the choice of battery charging en route is significantly affected by battery safety margins.

Other tree-based methods used in building expert systems can be multi-valued logic trees [

58].

3.3. Multi-Valued Logic Trees

The multi-valued logic tree method is effectively used in the discrete optimization of machine systems and decision making in knowledge management.

When each design and/or performance parameter taking numerical values within a specified interval is labeled with a predetermined binary or multi-valued Boolean variable, a discretization of such numerical intervals can be performed. The set of all numerical combinations forms a variant tree with the number of floors equal to the number of decision parameters. Representing a given Boolean function, written in canonical alternative normal form (KAPN), on a logic tree involves encoding the individual canonical products on the tree path from the root to the end vertex [

25,

26]. An individual path on the tree (from the root to the vertex) is a component of a singular logical function that describes the realization of one possible solution. The set of paths, on the other hand, is the set of all possible solutions.

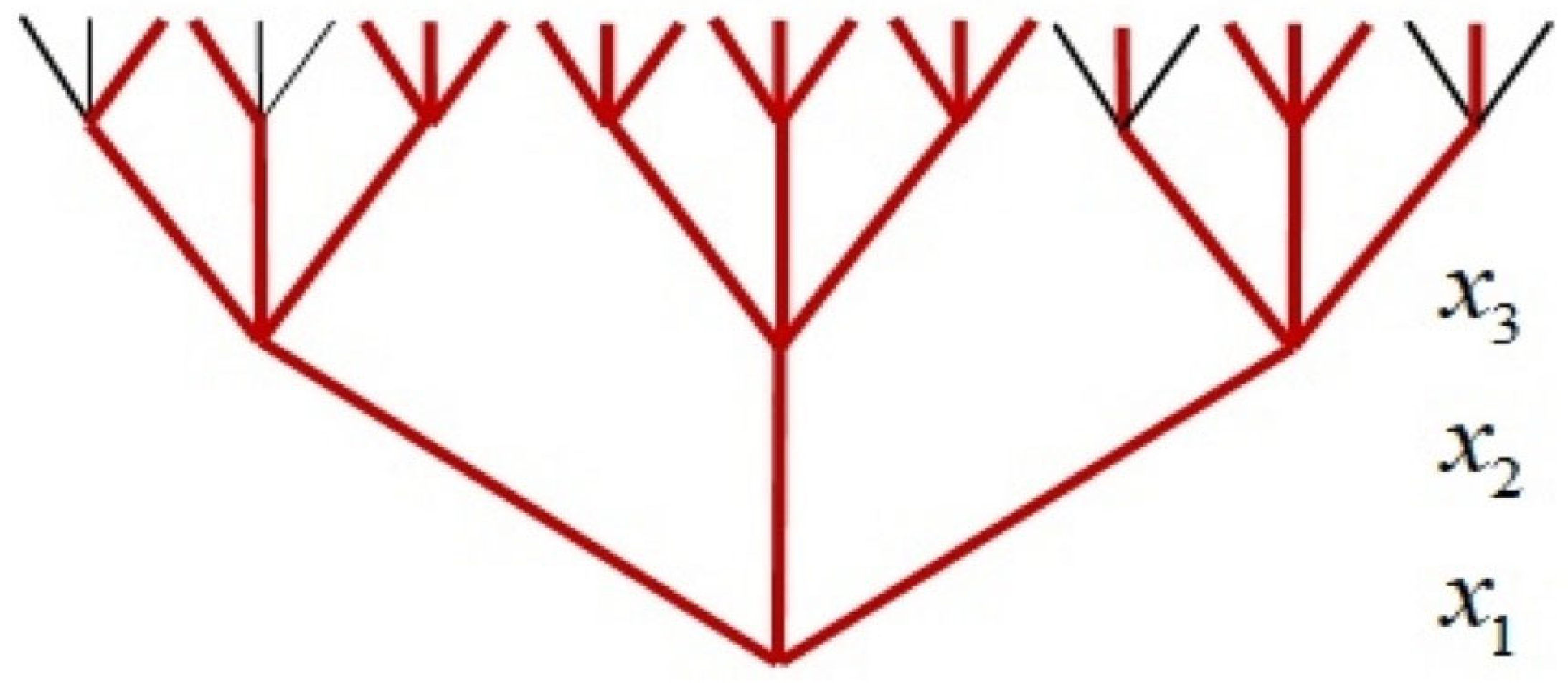

Figure 1 shows a logic tree that encodes a fixed Boolean function of three variables. Here are a few studies using expert systems based on decision trees.

In the Quine–McCluskey algorithm, by simplifying Boolean functions written in KAPN, one obtains a truncated alternative normal form (SAPN) and finally a minimum alternative normal form (MAPN) (

Figure 2).

The minimized form of the output function (with the minimum number of literals) is then obtained.

3.3.1. Quine–McCluskey Algorithm for Minimization of Partial Multi-Valued Logical Functions

In the case of multi-valued Boolean functions, as in Boolean functions, the concepts of incomplete gluing and elementary absorption play a fundamental role in the search for prime implicants, which are applied to the APN of a given Boolean function. The gluing operation is called a transformation:

An incomplete gluing operation is called a transformation:

An elementary absorption operation is called a transformation:

where:

, and

A is a partial elementary product whose variables of individual literals belong to the set

. If the above equation holds, then A absorbs

Aju(

xr).

There is a generalization of the bi-value quality indicator to a multi-valued one, (Ck − kimi) + (ki + Ki), where Ck is the number of branches of the k-th floor, ki is the simplification multiplicity on the k-th floor of the mi value variable, Ki is the number of branches of the (k − 1)-th floor from which non-simplifying branches on the k-th floor arose. In this way, one can obtain the minimum complex alternative normal form MZAPN of a given Boolean function without isolated branches on the decision tree, while having the minimum number of true (realizable) branches, which can be considered in particular as elementary design guidelines. All transformations involve the so-called Quine–McCluskey algorithm for minimizing individual partial multi-valued Boolean functions.

3.3.2. Quine–McCluskey Algorithm for Minimization of Partial Multi-Valued Logical Functions

The multi-valued logical function,

f(

x1,

x2,

x3), where

x1,

x2,

x3 = 0, 1, 2, written in the form of KAPN: 100, 010, 002, 020, 101, 110, 021, 102, 210, 111, 201, 120, 022, 112, 211, 121, 212, 221, 122, with one MZAPN after applying the Quine–McCluskey algorithm of minimizing individual partial multi-valued logic functions, has 13 literals:

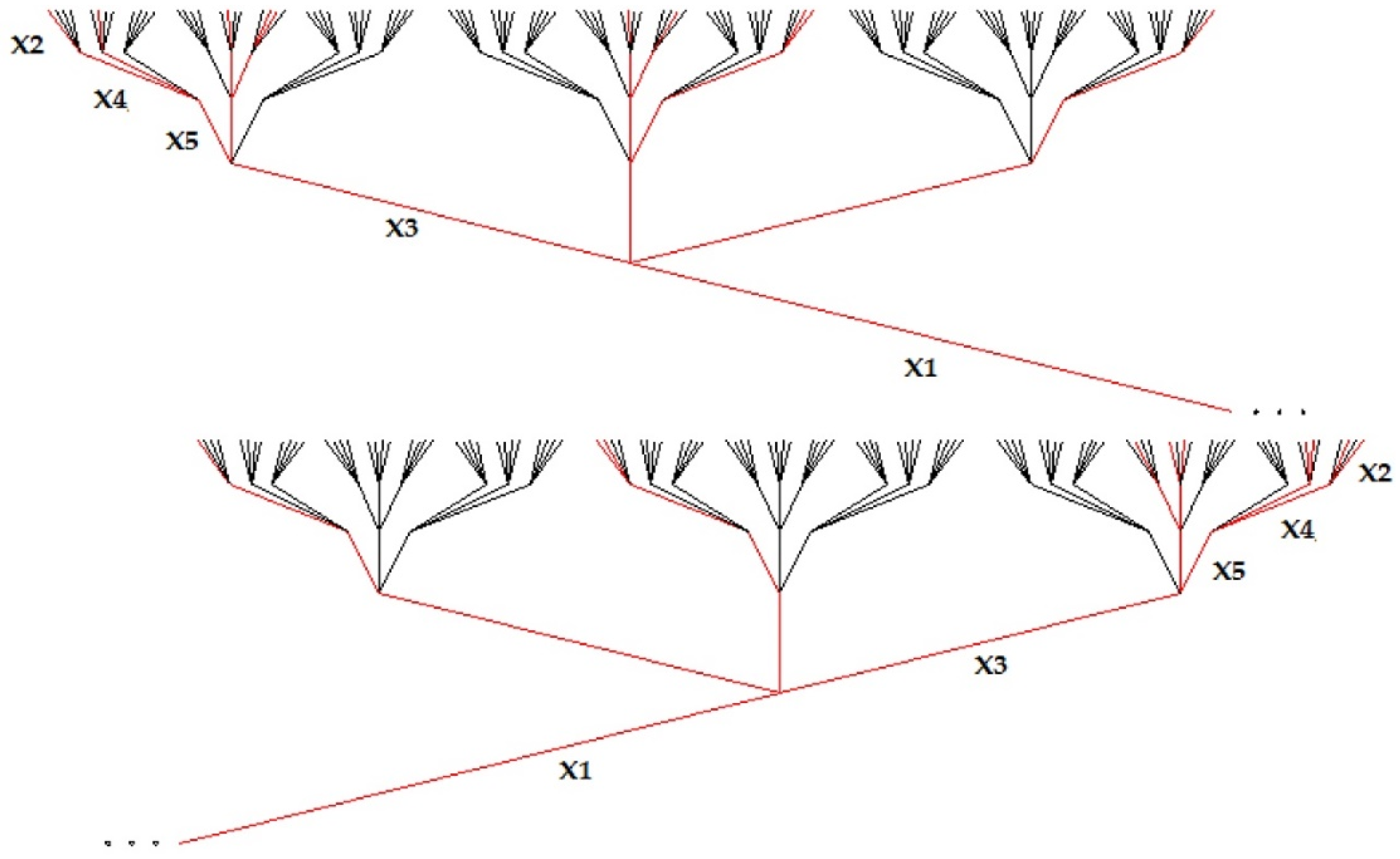

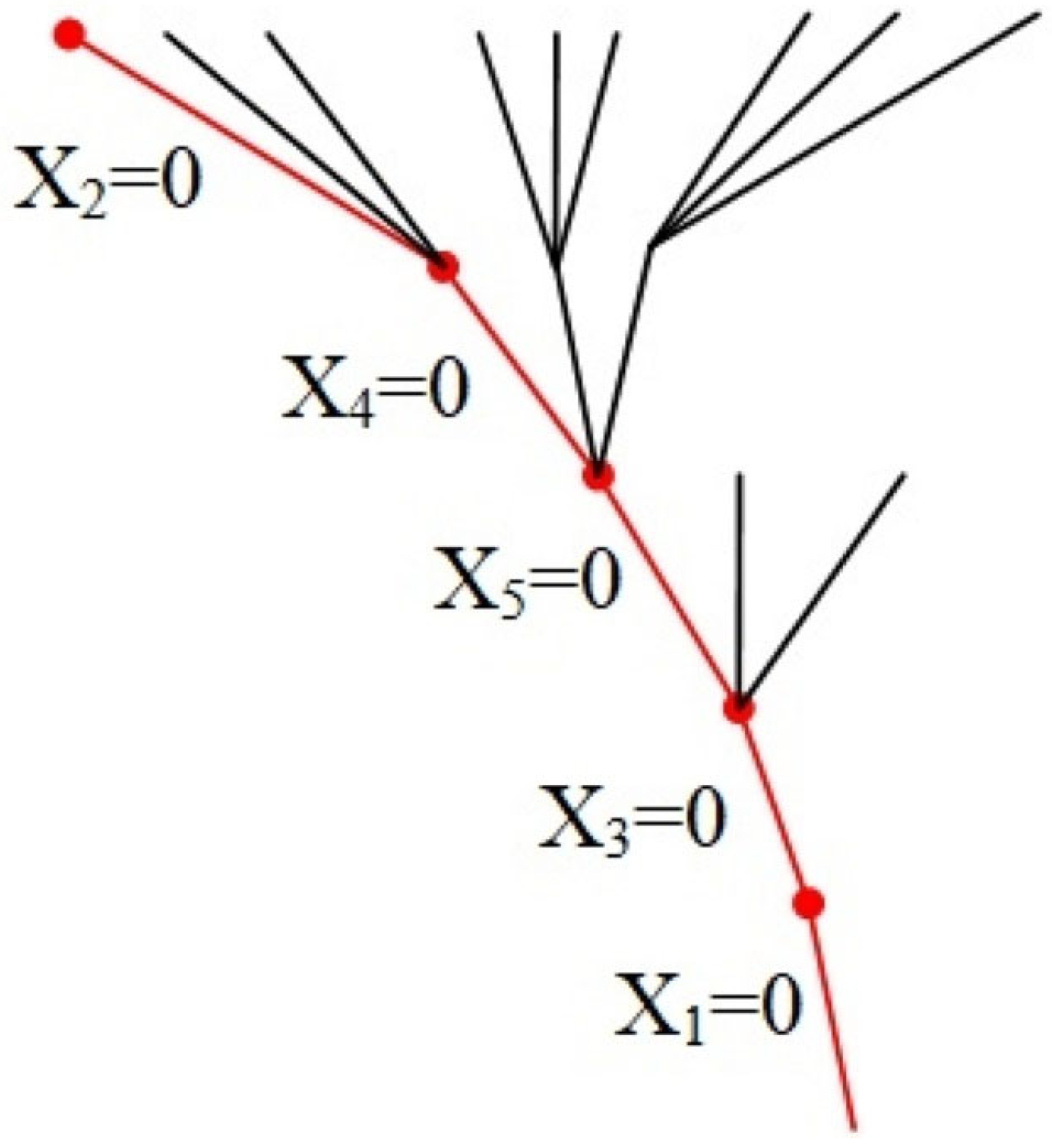

Figure 3 shows MZAPN (minimum reduced normal form) in the form of a logic tree.

The method of multi-valued logic trees can be combined with an expert system for the optimization of decision-making.

4. Application of Multi-Valued Decision Trees in Driving Analysis

The analysis concerns the determination of the most important operational parameters describing the selected driving cycle of a given type (

Table 1). Data for the analysis were obtained from simulation studies [

59]. It was found that the data included in the cited publication are interesting for further analysis because in this study, the integrated influences of the key factors, including ambient temperature and average driving speed, on energy intensity and energy efficiency are evaluated and discussed for the electric vehicle operation.

The data include two urban driving cycles and two highway driving cycles (

Table 1), differing in average speed (31.5, 40.97, 54.37, 77.7 km/h) and ambient temperature (−15° ÷ 40 °C). In the next stage, based on the logical rules generated by the optimal multi-valued logic trees, an expert system was built to support the decision-making for the driver. In the first step, for the Quine–McCluskey algorithm, code intervals were prepared for

Table 1. The following decision variables were assumed:

- -

Driving Cycle: X1

- -

Average speed (km/h): X2

- -

Efficiency (%): X3

- -

Ambient temperature (°C): X4

- -

Energy consumption (Wh/km): X5

The following coding was adopted for the individual decision variables:

- -

X1—bivalent: 0, 1

- -

X2—quadrivalent: 0, 1, 2, 3

- -

X3—trivalent: 0, 1, 2

- -

X4—trivalent: 0, 1, 2

- -

X5—trivalent: 0, 1, 2

Table 1 shows the code ranges of the decision variables for the related values. The number of decision trees needed for the analysis is calculated from the formula n!, where n is the number of parameters. In our case, n! or 120 trees were created: 2*4*3*3*3 = 216 possible combinations. The criterion of the function is profit maximization in a multi-criteria analysis from the point of view of all parameters, f(X

1, X

2, X

3, X

4, X

5). First, the algorithm determines the optimal combinations of encoding, that is, it determines the optimal decisions that should be made.

The optimal decisions are presented in

Table 2. The algorithm will be used to generate multi-valued decision trees (this is a learning file .

lrn).

All multi-valued logic trees are generated from 120 tables. Thus, 120 multi-valued logic trees were generated as a result of the algorithm.

Figure 4 shows 4 exemplary multi-valued logic trees with the corresponding stacking of decision variables and the corresponding number of true branches. All permutations of code changes corresponding to multi-valued logic trees are presented in

Supplementary Materials S1.

Figure 5 shows the optimal multi-valued logic tree with a floor layout of X

1, X

3, X

5, X

4, X

2.

Table 3 shows the arrangement of decision variable parameters according to the calculation of multi-valued decision trees.

Complex multi-valued logic functions, by swapping the floors of the logic tree, rank the importance of logical variables from the most important (at the root) to the least important (at the top), as there is a generalization of the bivariate quality indicator to a multivariate one: (Ck − kimi) + (ki + Ki), where Ck is the number of branches of the k-th floor, ki is the multiplicity of simplification on the k-th floor of the mi-value variable, and Ki is the number of branches of the (k − 1)-th floor, from which non-simplifying branches of the k-th floor originated.

The multi-valued logic tree indicates what energy consumption (Wh/km) (X5) can be expected by an electric car driver, travelling at a chosen average speed (km/h) (X2), at the ambient temperature (°C) (X4).

For the purposes of this publication, the driver will travel at four different average speeds while driving urban and highway cycles (X1).

For example,

Figure 6 shows the situation from the optimal multi-valued decision tree in

Figure 5.

The tree (

Figure 6) shows that for a given driving condition:

- -

Urban driving cycle:

- -

Temperatures:

[°C]:

To achieve optimum efficiency:

[%] (under the conditions X1 = 0 and X4 = 0), the driver should drive at a speed within the interval: (km/h).

Then, the energy intensity of the car will be: .

In turn,

Figure 7 shows that for a given driving condition:

- -

The highway driving cycle:

X1 = 1 ∈ <Highway Driving>, and temperatures:

(°C):

To achieve optimum efficiency: (%) (under the conditions X1 = 1 and X4 = 1), the driver should drive at a speed within the interval: (km/h) (admittedly, the multi-valued tree also indicates the possibility of the driver moving at (km/h), but there is no such possibility for the driving cycle).

X1 = 1 ∈ <Highway Driving>.

Then, the energy intensity of the car will be: (Wh/km).

In this way, it is possible to obtain the minimum complex alternative normal form (MZAPN) of a given logical function which has no isolated branches on the decision tree. At the same time, it has the minimum number of real (realizable) branches. All transformations are described by the so-called Quine–McCluskey algorithm of minimization of individual partial multi-valued logical functions [

60]. In [

60], a modified logic function minimization algorithm for multi-valued decision trees with weighting factors is presented.

5. Implemented Simulation Model of an Electric Car with an Expert System

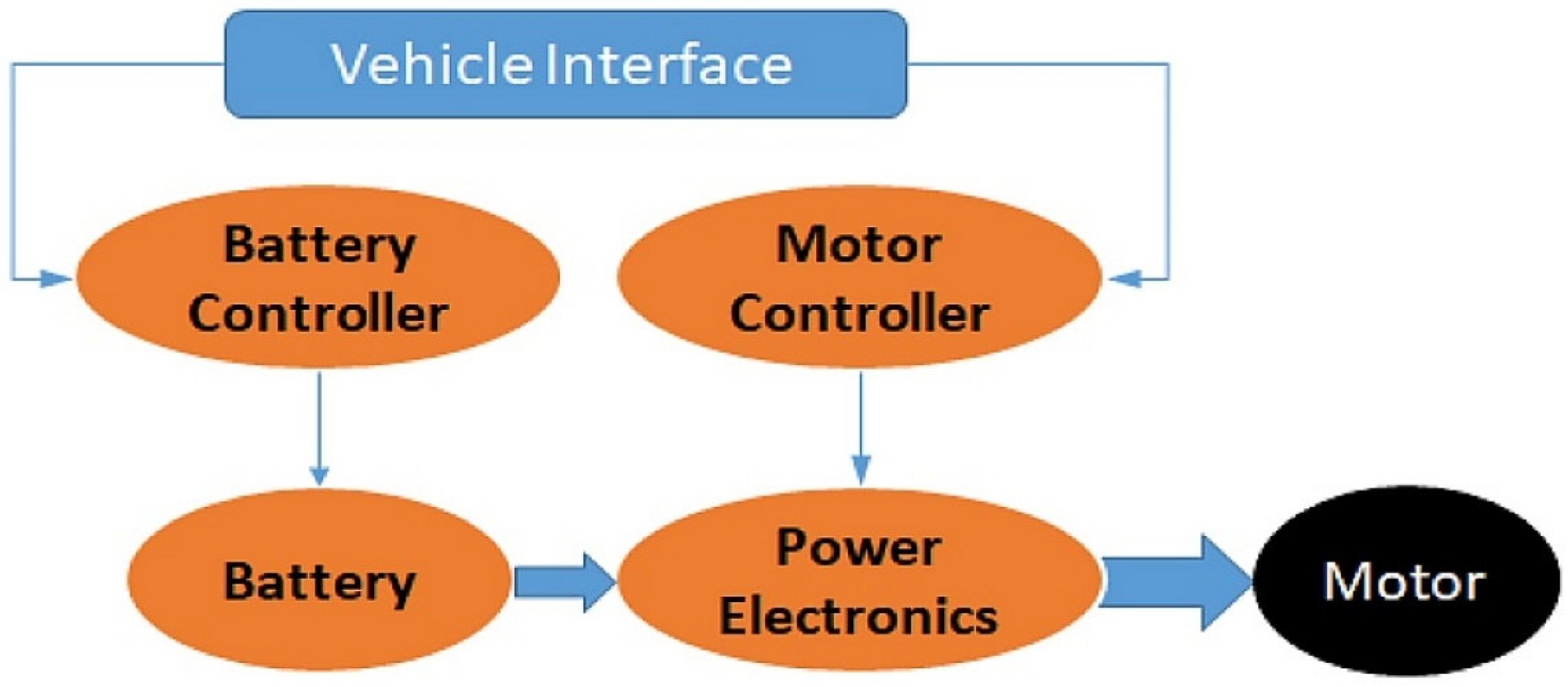

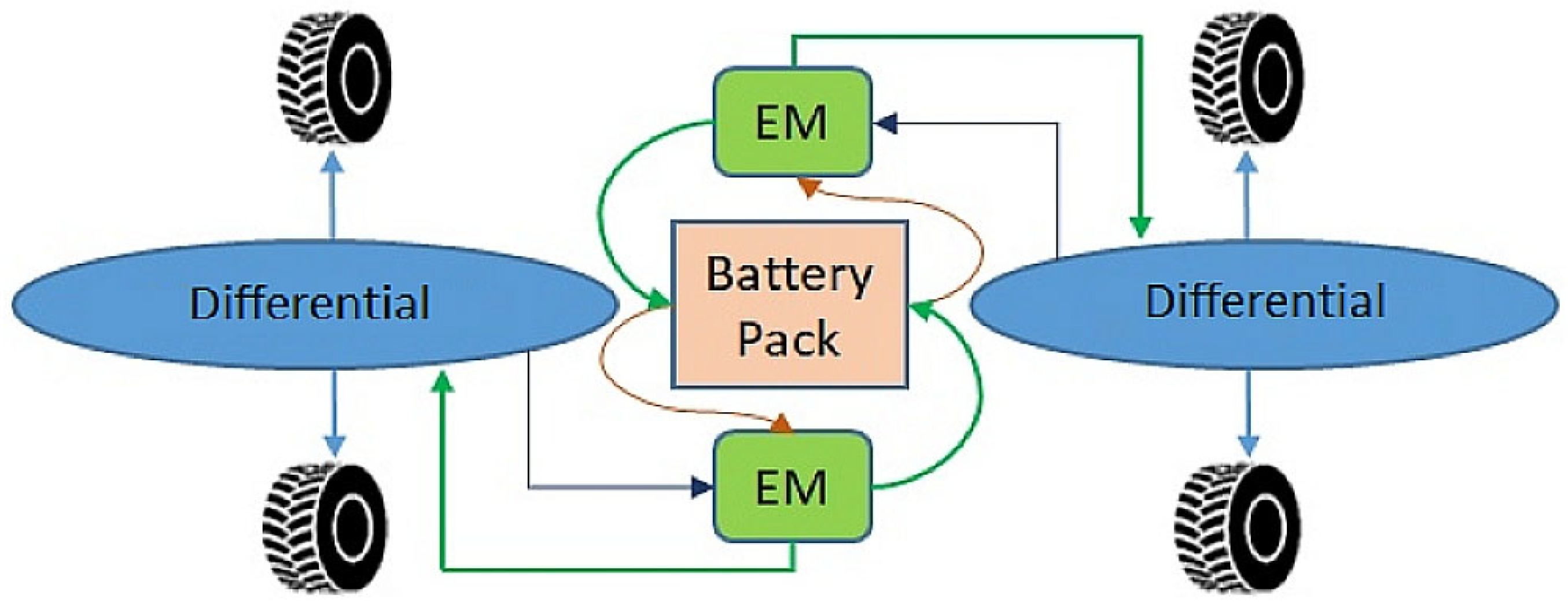

An electric vehicle was built with a motor, battery, controller, converters, and wheels. The motor was connected to the wheel differential.

Figure 8 shows the block diagram of the electric vehicle.

Figure 9 shows a schematic of an electric vehicle drive system. In this configuration, a set of batteries is used to supply DC power to the circuit, which is then connected to the inverter circuit.

The end wheels are connected via a differential. The differential provides a balance between the rear drive and the front drive. Part of the differential in the adopted model is a gear mechanism that allows the drive shaft to rotate at different speeds. The fidelity of the transmission model is increased by specifying parameters of the differential transmission system, such as transmission inertia, gearing, and slipping. A battery pack is the source of power for the electric vehicle model. The lithium-ion battery attached to the electric vehicle (EV) model powers the motors.

Supplementary Materials S2 presents a proposed EV model in Matlab, including an expert system—with a detailed presentation of selected elements.

The developed simulation model has the ability to set driving conditions (speed, direction, elevation) based on a library of standard (normalized) cycles (e.g., ECE) or own data stored in text files. The model was developed, among others, using the work in [

61], appropriately modified to consider the variable grip of each wheel and the possibility of setting custom driving conditions such as, speed, direction, and elevation level.

When developing the simulation model of the electrical part of the drive, simplified energy models of the motor and the inverter were used. The basis for the development of the models were simulated maps of the dependence of motor and inverter efficiency on motor speed and load torque.

In each calculation step, the efficiency information of the motor or inverter was determined from the current motor speed and load torque.

The developed simulation model has the ability to set driving conditions (speed, direction, elevation) based on a library of standard (normalized) cycles (e.g., ECE) or own data stored in text files. The aim of the simulation studies was to analyze the energy consumption while driving a car according to the assumed data and to choose the optimal driving style using the expert system integrated with multi-valued decision trees.

The input data for the simulation was obtained from a car ride in mixed traffic (assumed: 1200 s, average speed: 45 km/h, distance: 20 km).

Figure 10 shows the change in speed (m/s) from the exemplary drive cycle.

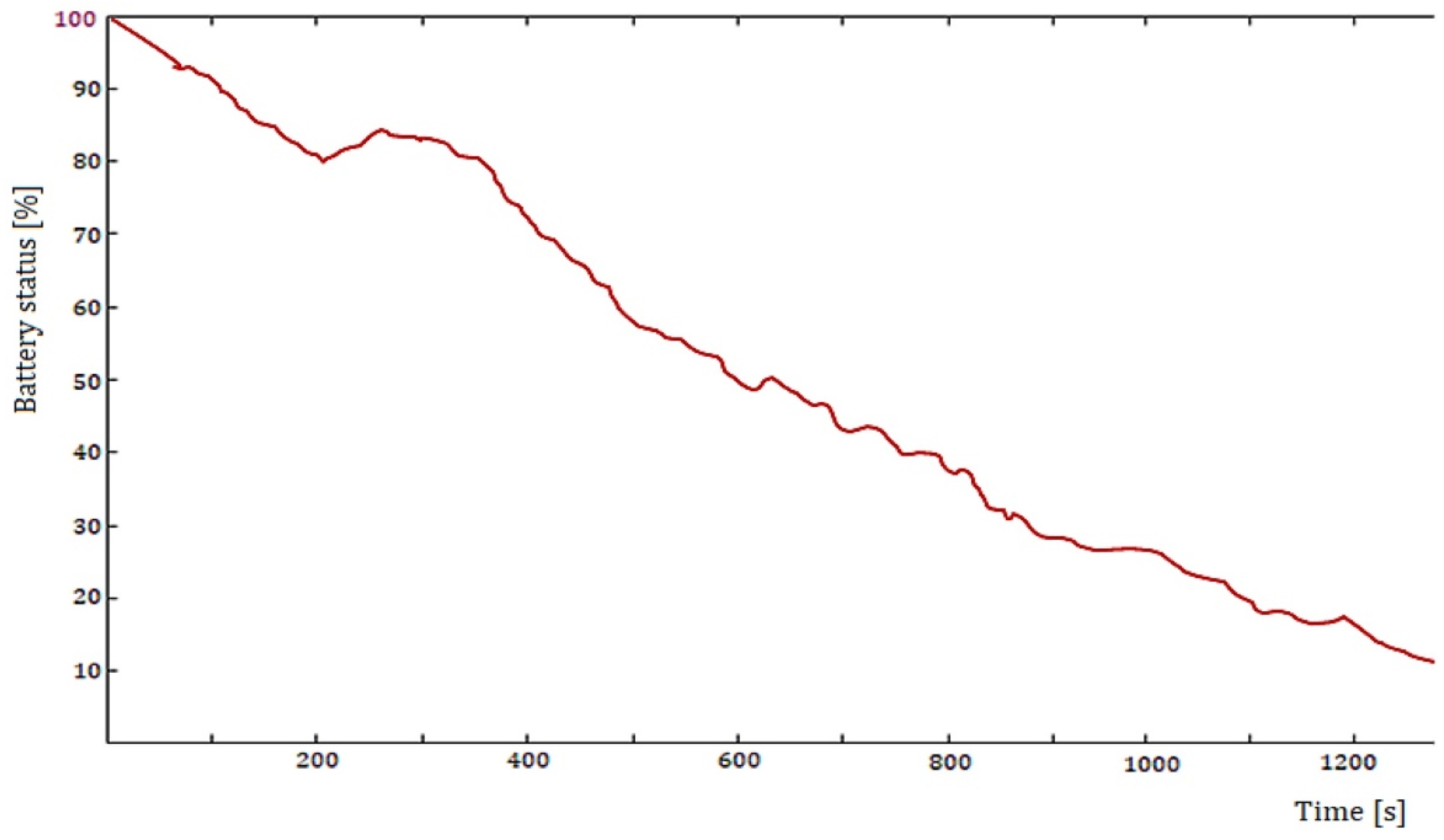

Battery Charge Analysis

The driving cycle has several acceleration and deceleration profiles that change randomly to reflect the actual driving scenario. This helps to track the nature of battery discharge during different acceleration profiles, as well as the possible effect of regenerative charging on the deceleration profiles.

Figure 11 shows an example of a battery charge simulation graph.

The accuracy of the calculations depends on the details of the technical data of the vehicle, engine, battery, and the adopted mathematical model. The precise characteristics of the road conditions in which the tested vehicle operates, and the frequency and accuracy of speed measurements, are also of great importance. Based on the calculated values (e.g., in a spreadsheet or in the Matlab/Simulink program), sample diagrams of the DoD the battery discharge rate were prepared [

62]. The signals of the studied quantities were recorded with a sampling time of 1 s. The recorded signals were preprocessed to remove coarse errors and reduce the contribution of high-frequency noise. A current variance analysis of the signals was used to search for coarse errors. To reduce the contribution of high-frequency noise, a Golay-Savitzky filter [

63] with a second-degree polynomial and a two-sided approximation of two points each was used.

In particular, graphs were drawn for each multi-valued logic tree describing the decision support system in the expert system.

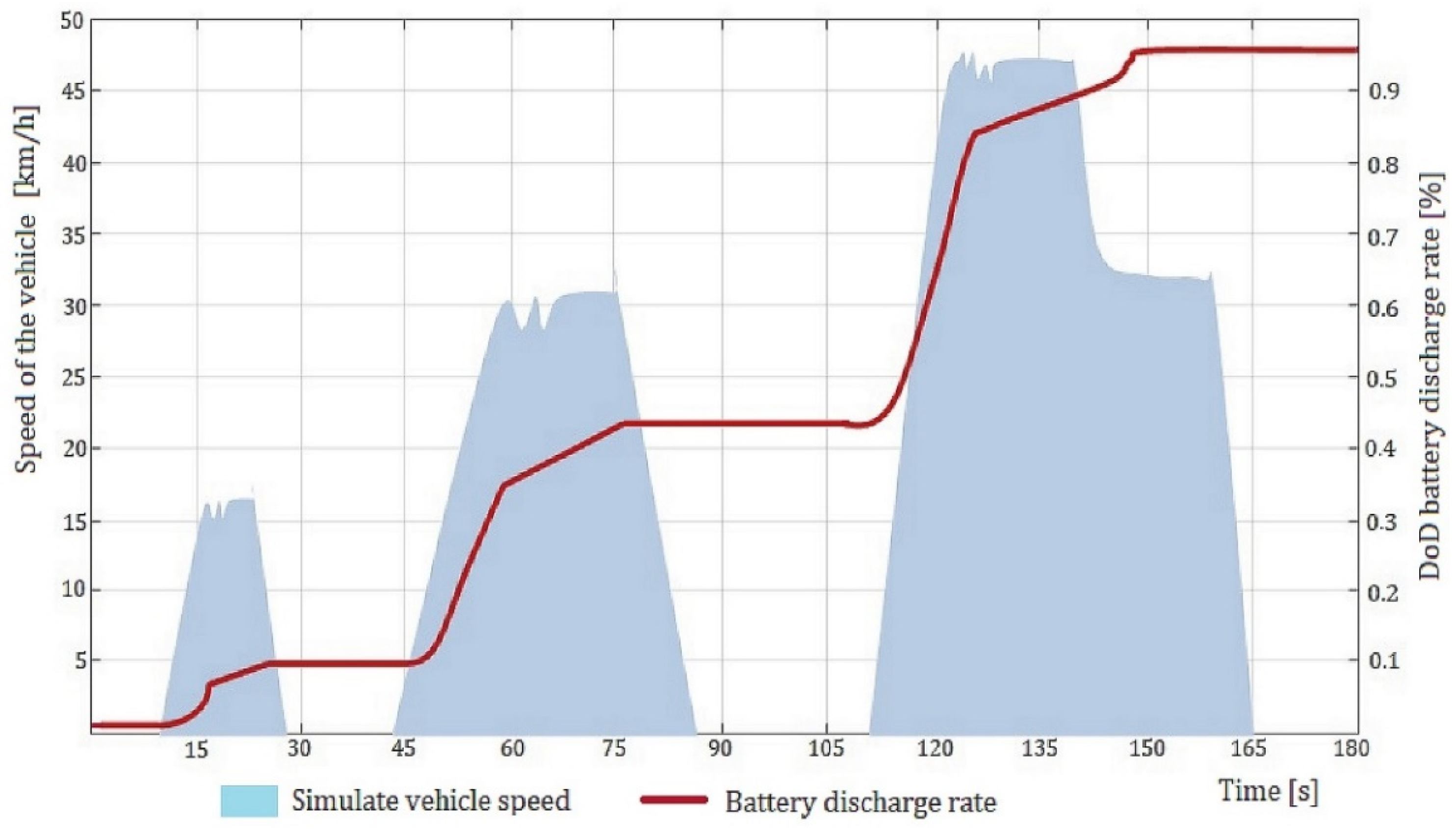

- (a)

X1, X2, X3, X4, X5

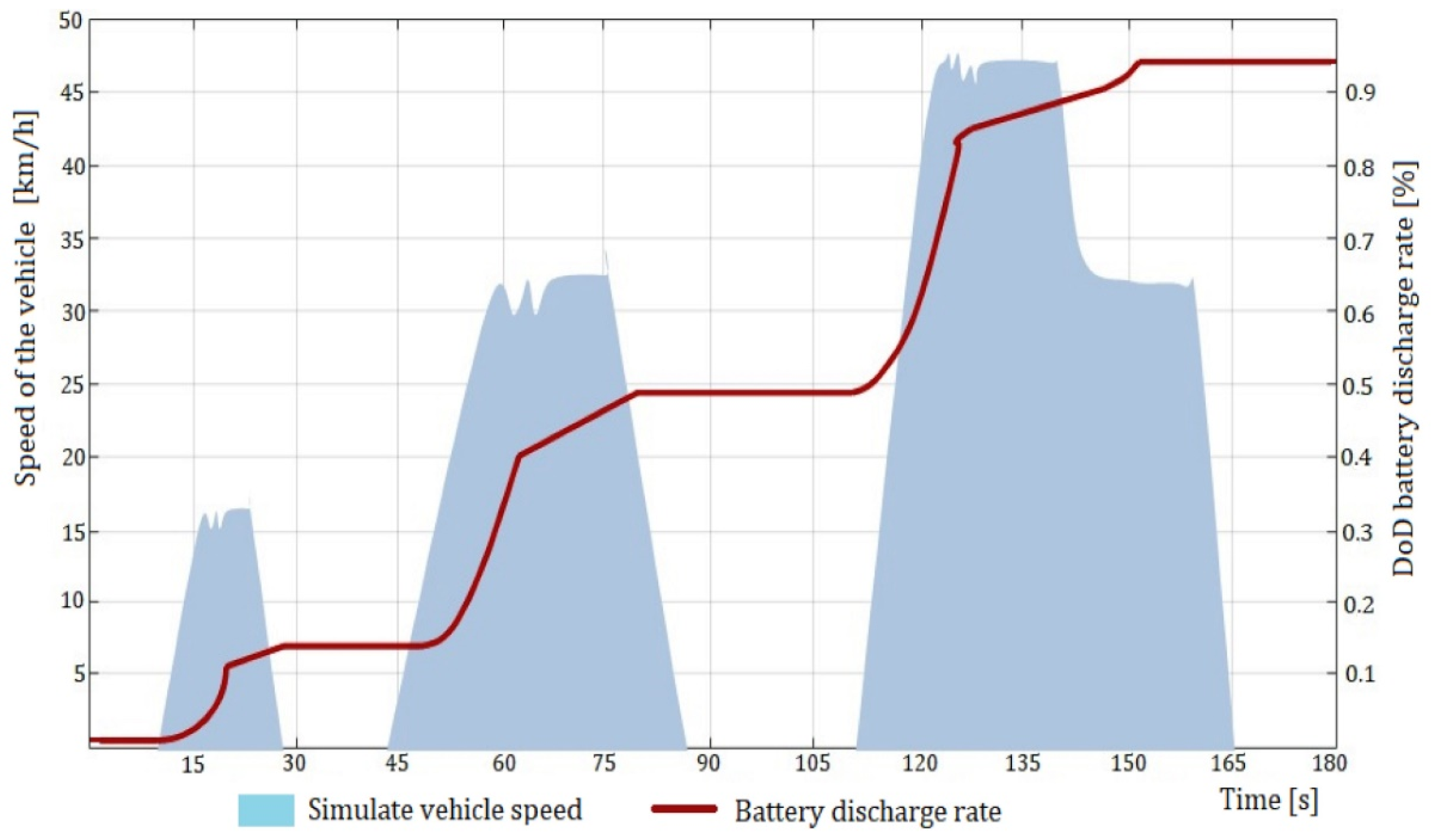

- (b)

X5, X4, X1, X2, X3

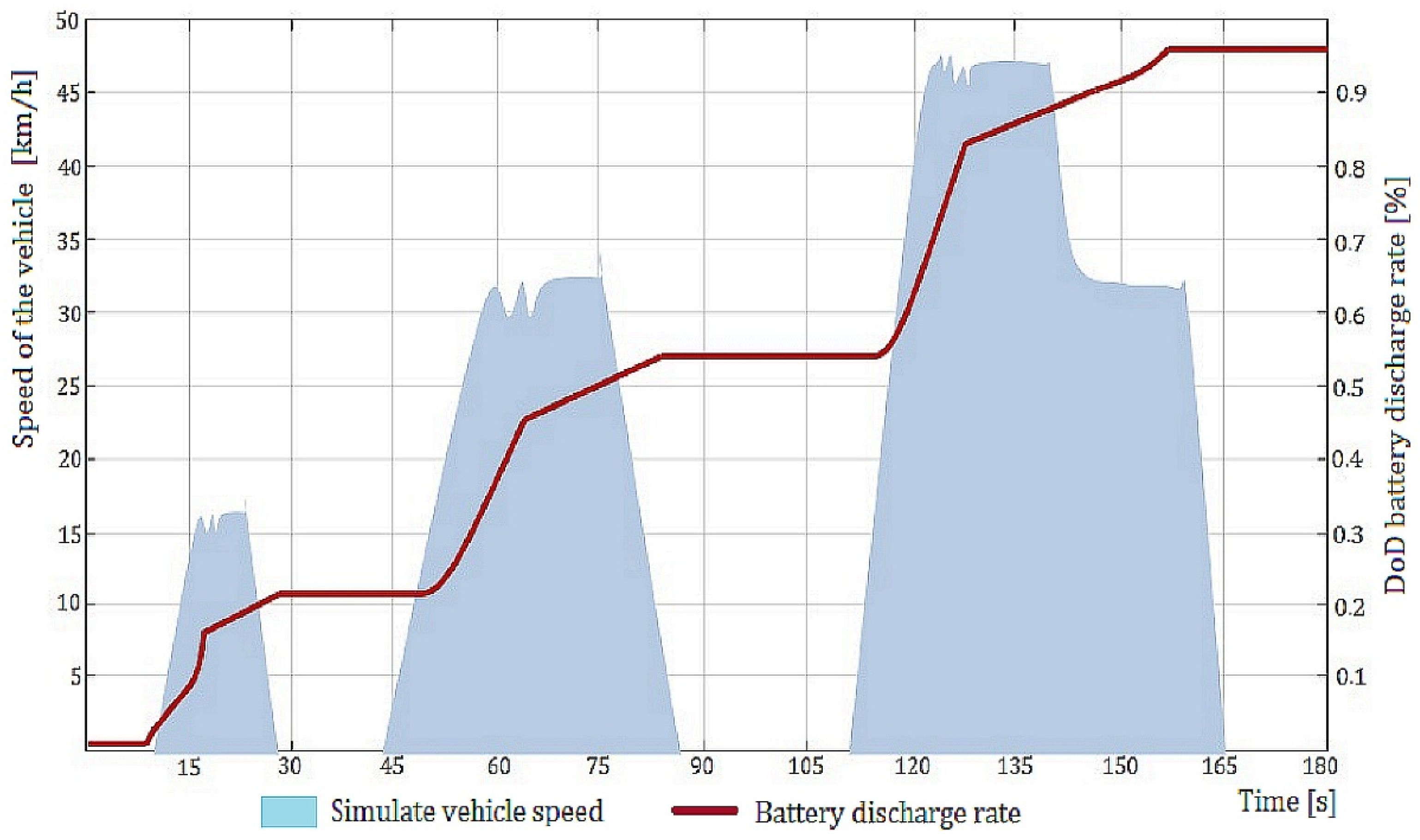

- (c)

X2, X3, X5, X4, X1

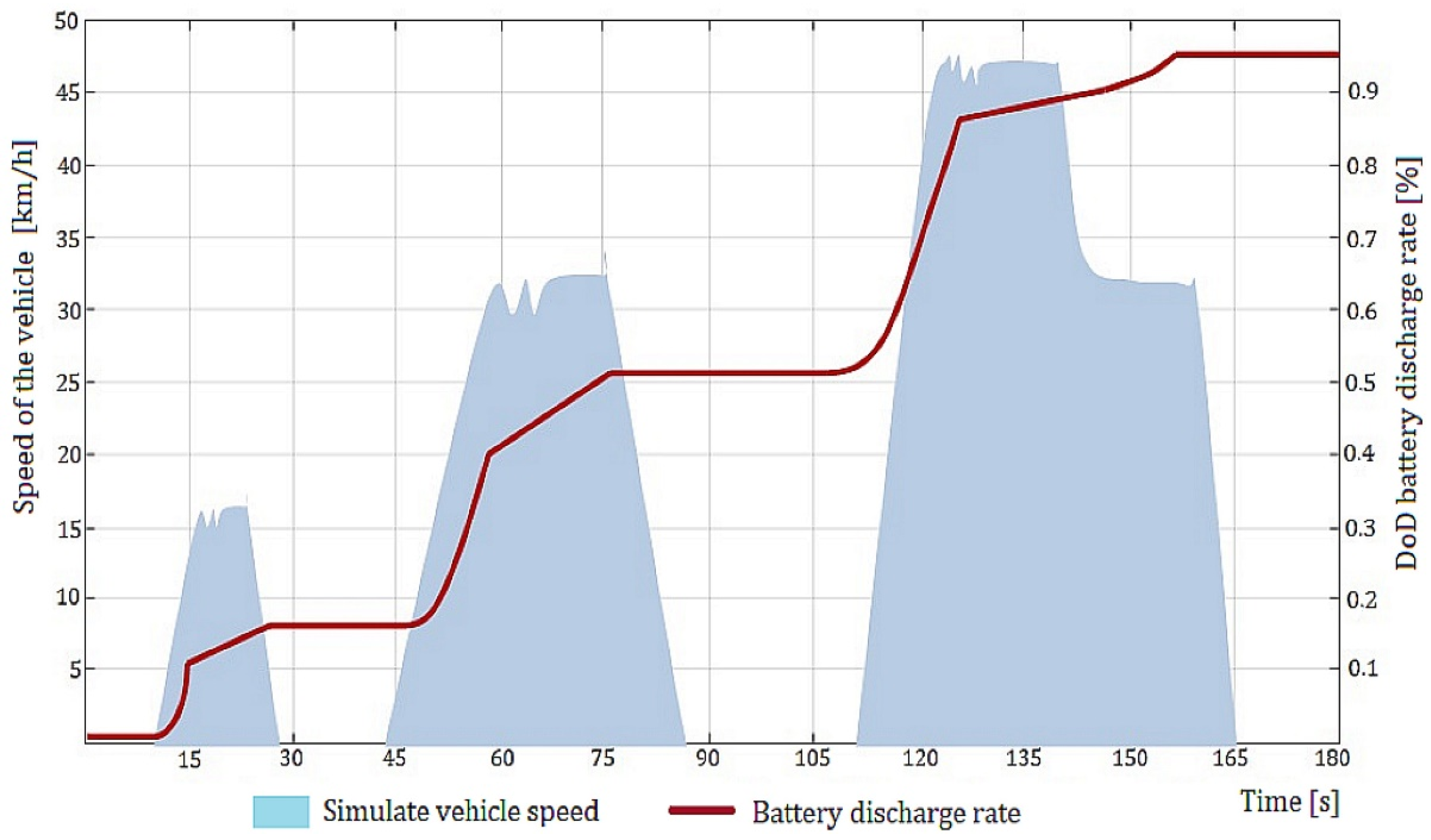

- (d)

X5, X2, X1, X4, X3

- (e)

X3, X5, X1, X2, X4

Figure 12.

Plot of the battery discharge rate and speed of an electric car for a multi-valued logic tree with the floor layout of decision variables of: X1, X2, X3, X4, X5.

Figure 12.

Plot of the battery discharge rate and speed of an electric car for a multi-valued logic tree with the floor layout of decision variables of: X1, X2, X3, X4, X5.

Figure 13.

Plot of the battery discharge rate and speed of an electric car for a multi-valued logic tree with the floor layout of decision variables of: X5, X4, X1, X2, X3.

Figure 13.

Plot of the battery discharge rate and speed of an electric car for a multi-valued logic tree with the floor layout of decision variables of: X5, X4, X1, X2, X3.

Figure 14.

Plot of the battery discharge rate and speed of an electric car for a multi-valued logic tree with the floor layout of decision variables of: X2, X3, X5, X4, X1.

Figure 14.

Plot of the battery discharge rate and speed of an electric car for a multi-valued logic tree with the floor layout of decision variables of: X2, X3, X5, X4, X1.

Figure 15.

Plot of the battery discharge rate and speed of an electric car for a multi-valued logic tree with the floor layout of decision variables of: X5, X2, X1, X4, X3.

Figure 15.

Plot of the battery discharge rate and speed of an electric car for a multi-valued logic tree with the floor layout of decision variables of: X5, X2, X1, X4, X3.

Figure 16.

Plot of the battery discharge rate and speed of an electric car for a multi-valued logic tree with the floor layout of decision variables of: X3, X5, X1, X2, X4.

Figure 16.

Plot of the battery discharge rate and speed of an electric car for a multi-valued logic tree with the floor layout of decision variables of: X3, X5, X1, X2, X4.

The developed simulation study in the expert system can be modified by entering new computational formulas into the spreadsheet (or Matlab) or removing redundant ones. In particular, different variants of the driver’s behavior can be analyzed by using a multi-valued logic tree algorithm. Depending on the needs, it is possible to plot the different quantities calculated in the expert system. It is advisable to perform simulations for a real vehicle with fully detailed technical characteristics of the drivetrain, the engine, and the power supply battery, and to compare them with the measurement results obtained in road or bench tests.

In future works, the authors will simulate the car driving in urban driving and highway driving cycles considering the possibility of braking energy recuperation.

6. Conclusions

The paper presents the concept of building an expert system for the decision support of an electric car driver in minimizing the energy consumption of an electric car’s movement. The controller block simulates the driver’s actions by controlling the accelerator pedal. Depending on the position or depth of depressing the pedal, a specific torque of the electric motor is generated, which influences the momentary travelling speed of the vehicle. The driving style and behavior of the driver (nervous/calm) and the average speed achieved are very important for the driving range. In addition, the influence of the ambient temperature on the efficiency of the vehicle and ultimately on energy consumption must be considered. All driving combinations in the driver–vehicle–environment system can be recorded by the decision support system. Decisions can be made in different dimensions (temporal, spatial) and situations (in specific sets of external and internal conditions). The application of the system should provide prompts to the driver (how to react by acting on the accelerator and brake pedal) as quickly as possible, and who should also obtain them in real time (which may be a prerequisite for some information). However, such analysis requires a wider implementation of the built system. The methodology for designing and implementing integrated decision support systems is described primarily in the area of software engineering, which is the practical application of energy management in electric cars.

6.1. Advantages of the Adopted Method

The structuring of the problem allows the introduction of appropriate formal notations, and in particular, it is even possible to combine complex quantitative and qualitative features with different degrees of detail according to the principles of the multidimensional morphological array. That is why, among others, when using a multidimensional morphological array, there is no need to extend the generation process to sub-arrays, because all information about the varieties of the main and detailed features and their numerous modifications can be immediately saved in this array and marked on the tree of variants.

Such conceptualization is similar to subjectively (according to a given driver) changing driving parameters, which corresponds to changes in a mathematical model. Of course, objective matters are not solved by all, even by advanced driver assistance systems and energy management assistance systems. In such a situation, decision-making in the management of energy intensity of car traffic is practically limited only to the initial multi- valued logic tree.

By using the method of multi-valued logical trees in the evaluation of energy intensity of electric car traffic, it is possible to obtain all the variants of the linkage (relations) that are most influential in the evaluation of energy intensity.

6.2. Disadvantages of the Adopted Method

The disadvantages of multi-valued logic trees include the need to perform data discretization. In this way, problems arise in the formal description of the characteristics of the variables of the system state using continuous and quasi-continuous functions in the description of the analysis of the movement of electric cars in the selected cycles of driving.

Future research should be focused on incorporating weighting factors into the driving test phase of an electric car. In addition, an application should be developed to automatically retrieve data and generate rules for relevant attributes. This type of application will perform analysis for a larger number of outcomes—for different drivers’ road characteristics. There should also be an effort to better reflect the physical models of the analyzed measurements into their mathematical models.

After the system has been adjusted and more simulation tests have been carried out, it will be possible to implement the developed model in any electric vehicle.