Abstract

In the context of green energy and decarbonization, carbon dioxide storage in underground facilities, such as salt caverns, is one promising technical solution that has aroused attention. However, the thermodynamic behavior of CO2 and the geomechanical response of salt cavities have not been studied comprehensively. In this study, we proposed a thermomechanical model that integrated a salt cavity and wellbore and implemented a series of simulations for carbon dioxide storage in a salt cavern. The model was verified by gas capacity calculations using field testing data. The thermodynamic behaviors of CO2 were determined and compared to methane. The results showed that the critical point coordinates of carbon dioxide were within the storage operation conditions, a phase transition could occur, and the thermodynamic properties around the critical point varied dramatically. For a short CO2 withdrawal operation, the salt cavity remained stable, while the near-wellbore area (NWA) was prone to fracture due to tensile stress concentration. Thus, we concluded that the proposed thermomechanical coupling numerical simulation method provided a comprehensive and quantitative tool for the feasibility analysis of CO2 storage in underground salt caverns.

1. Introduction

Underground salt cavities have received increasing attention for the storage of not only oil and gas, but also compressed air, hydrogen, and even carbon dioxide [1,2,3,4]. Rock salt formation is recognized as being favorable for hosting geological storage among underground constructions [5,6,7,8] since it has the remarkable features of low permeability and creep characteristics [9,10,11]. Salt caverns are created via the dissolution of water-soluble salt minerals by pumping in fresh water and pumping out the saturated “brine”. The completed underground hollow cavity is approximately 1000–2000 m deep. Salt caverns are currently viewed as a very promising solution for green energy [12].

Since the Paris Conference of Parties (COP21) in 2015, more countries have been motivated and take actions with the ambition to decarbonize [13,14]. The most common option for CCUS is carbon dioxide via enhanced oil recovery (EOR) in oil and gas reservoir development [15]. It was reported that approximately 65% of the total oil production in the U.S. in 2020 was from unconventional reservoirs [16]. Additionally, CCUS includes the associated CO2 storage incidental to enhanced oil recovery (EOR), or dedicated CO2 storage in saline formations. Yi et al. 2020 studied the hydrodynamic and thermodynamic properties of CO2 during compressed carbon dioxide energy storage in aquifers (CCES-A) through numerical simulation [17].

The storge of carbon dioxide in salt caverns is an alternative strategy for carbon utilization and storage (CUS). Compared to CO2 storage in aquifers or depleted reservoirs, salt caverns have their own advantages due to their geological locations and offer a high deliverability of gas injection and withdrawal. After pressurization into liquid, the CO2 is transported by pipelines and then sequestered and stored underground, where the salt cavern exerts its function as a complimentary facility to CO2 transportation in pipelines. The density of compressed CO2 is greater than that of CH4 and that of air. Special attention must be paid to the thermodynamic state of carbon dioxide at the critical point, which is part of the temperature–pressure range of storage conditions in salt caverns [18].

To be able to employ salt caverns for underground carbon dioxide storage, the complete picture of the thermodynamic properties of CO2 and the response of the salt cavity are crucial points for research. The thermodynamic behavior associated with fluid injection and withdrawal throughout the salt cavern is a complex process and a multi-physics problem. We use the term “multiphysics” as a descriptor of the numerical simulations of physical phenomena, such as fluid flow, heat transfer, and geomechanics, towards gas storage and cycling loadings in salt caverns. Bérest focused on research related to salt caverns for decades, summarizing the heat transfer problem comprehensively and discussing the various aspects of the thermodynamic behavior of gas- and liquid-filled caverns (i.e., with brine bottom liquid) [19]. The thermal effect of salt caverns serving as underground gas storage facilities has been investigated in previous studies [20,21,22,23,24,25,26]. It is possible for microcracks or tensile fractures induced by thermal stress to form in the salt cavern’s wall during operation [27,28,29,30,31,32]. Li et al. 2021 [33] studied a field case with a block that fell off the surrounding wall of a salt cavity; the authors compared it with or without the thermal effect, confirming its influence on the integrity and stability of the salt cavity. There is a potential risk of gas depressurization and a return to low pressure [34,35,36,37]. Using CO2 as a cushion gas improves the gas storage capacity [38]. However, the thermodynamic behavior of carbon dioxide and the thermomechanical response of salt caverns subjected to the cyclic loadings have not been well studied thus far. Although we have experience in gas storage management, whether the CO2 behaves similarly to CH4 in geological storage, how the response of the salt cavern wall differs, how to determine the CO2 injection and withdrawal rate, and whether it is a risk to the stability of the cavity are questions that remain unanswered. The present study aimed to answer these questions. Without understanding the fundamentals of thermodynamic behavior, it is difficult to optimize the operation parameters for CO2 storage in salt caverns.

The main objective of this research was to establish a coupled thermomechanical model with an integrated wellbore/3D real cavern geometry for the investigation of the thermodynamic behavior of carbon dioxide and the thermomechanical response of the surrounding wall of the salt cavity. Section 2 describes the numerical model and thermodynamic coupling methodology. In Section 3, the temporospatial variations in thermodynamic behavior are compared between carbon dioxide and methane in the salt cavern environment under storage conditions. The effect of the CO2 injection and withdrawal rate, storage capacity, and cavern stability are discussed in Section 4. We believe the present study will contribute to the utilization of salt caverns for carbon dioxide storage and provide insightful fundamentals for large-scale applications.

2. Integrated Wellbore–Cavity Thermomechanical Coupling Model for Salt Caverns

2.1. Engineering Background

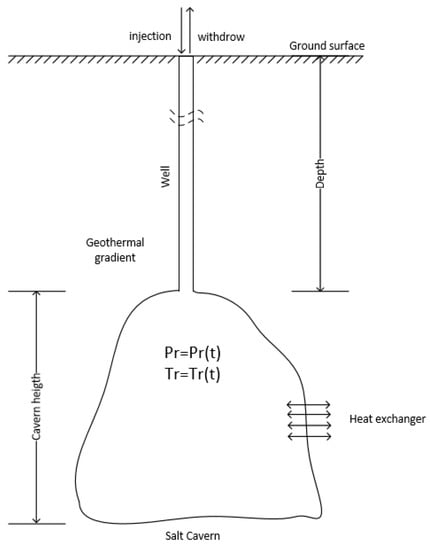

Underground salt cavern gas storage in China started in the 1990s; the first underground salt cavern gas storage was built in Jintan, Jiangsu Province. The Jintan salt mine in Jiangsu province has the best geological conditions for salt cavern construction in China [2,34]. It is far away from large fault zones and has a simple structure. The thickness of the salt layer is 150–230 m, there are few internal interlayers, the distribution is stable, the NaCl content is high, the average is over 80%, and the burial depth is 940–1240 m. The roof of the salt cavity layer is composed of calcium-bearing mirage mudstone and mudstone with a dense lithology, thickness of 107.22–150.45 m, stable distribution, and good sealing. The success of Jintan, as the district where underground gas storage was first built, depends on the technical specifications and geological conditions. Jintan gas storage is the complimentary underground facility to the remarkable West–East Gas Pipeline and has accumulated rich experience in storage construction, operation, and management. This study selected a cavity in Jintan as the simulation target (Figure 1).

Figure 1.

A simplified model of underground salt cavern gas storage.

2.2. Model Description

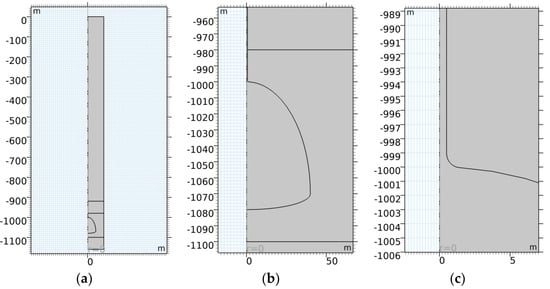

In this study, COMSOL software was adopted for numerical simulation. The geometric shape of the salt cavern for gas storage was simplified according to the actual shape of the dissolved salt cavity on site. The shape of the surrounding wall of the salt cavity on site was irregular; thus, it was simplified to a more regular shape, which was convenient for modeling. The cavity data measured by sonar was also modeled according to the shape measured by sonar, which was closer to the engineering practice. The buried depth of the salt cavern was generally between 500 m and 1500 m. If the wellbore and salt cavity were completely modeled, the area involved was very large and the calculation was extensively time consuming. Therefore, in order to improve the calculation efficiency, a two-dimensional axisymmetric modeling method was employed for the wellbore and cavity integrated thermodynamic coupling model. The specific geometric parameters of the model referred to a gas storage salt cave in Jintan, Jiangsu Province, China. The height of the model was 1100 m and the radius was 80 m, the maximum height of the cavity was 74 m and the maximum radius was 40.15 m, the volume of the cavity was approximately 198,720.1 m3, the buried depth of the cavity was 1012 to 1086 m, and the diameter of the wellbore was 0.25 m. The length of the wellbore was 1012 m, and the shape of the sonar-measured cavity is shown below.

According to the simplified shape of the sonar-measured cavity and engineering data, a geometric model of the wellbore cavity was obtained as shown in Figure 2. The cavity shape was composed of two quarter-ellipses. In order to avoid stress concentration, the joint between the wellbore and cavity was rounded.

Figure 2.

(a) Integration model of wellbore and cavity. (b) Shape of salt cavity. (c) Connection section between wellbore and salt cavity.

2.3. Basic Assumptions of the Model

The integrated wellbore–cavity thermomechanical coupling model was employed mainly to present the variation in the temperature and pressure of carbon dioxide in the salt cavern environment during the injection and withdrawal processes, as well as the influence of operation conditions and induced thermal stress on the stability of the rock surrounding the salt cavity. In order to convert the practical engineering problems into numerical models, the practical problems were simplified and several basic assumptions were made:

- (1)

- The cycling loading of CO2 in the salt cavity was dry, and the influence of brine at the bottom of the cavity and residual water at the cavity wall was not considered.

- (2)

- The composition of CO2 remained unchanged at any time during the processes of injection and withdrawal.

- (3)

- The solution mine was not newly built and put into withdrawal, and the influence of the cold zone caused by the cooling of the surrounding rock by low-temperature water circulation in the process of dissolving the cavity was ignored.

- (4)

- The creep behavior of salt rock was neglected because the period for the simulation was too short to account for the convergence of volume.

- (5)

- All rock materials in this model were isotropic.

2.4. Material Parameters

The integrated model included two materials—solid and fluid. The mechanical and thermophysical parameters of salt rock were selected from the experimental data provided by the Jintan underground gas storage facility. The basic parameters of salt rock are shown in Table 1 and Table 2.

Table 1.

Rock mechanical properties.

Table 2.

Rock thermal properties.

The physical properties of carbon dioxide change with variations in temperature and pressure. The thermophysical property parameters involved in the model mainly included density, constant pressure heat capacity, dynamic viscosity, thermal conductivity, and specific heat rate.

2.5. Physical Field and Governing Equation

The integrated wellbore–cavity thermomechanical coupling model was mainly used to simulate the three-dimensional temperature and pressure fields in the salt cavity while it was subjected to carbon dioxide injection and withdrawal processes, as well as to evaluate the stability of the cavity wall in response to different conditions. Therefore, the integrated model included three physical fields, namely turbulence, solid and fluid heat transfer, and solid mechanics, as well as two multi-physical fields, namely non-isothermal flow and thermal expansion. The non-isothermal flow multi-physical field is the coupling of the turbulence physical field and heat transfer physical field. The flow of fluid will affect the distribution of the temperature field, and the temperature will also affect the flow of fluid; thus, this multi-physical field is a bidirectional coupled physical field. The multi-physical field of thermal expansion is the coupling of the physical field of heat transfer and the physical field of solid mechanics. A change in the temperature field causes temperature expansion, induces thermal stress, and eventually influences the stress distribution at the cavity wall, while the temperature field is not affected by the mechanical field. Therefore, this multi-physical field is a unidirectional coupled physical field.

The flow and heat transfer of the fluid in the model can be described by the N–S equation:

where is density, is time, is the velocity vector, is pressure, is viscosity, is the identity matrix, is the heat capacity at a constant pressure, is the work performed by pressure, is the volume work, and is the viscous dissipation work. The work involved in Equation (1c) can be solved by the following formula:

Since the model is a two-dimensional axisymmetric model, the thermal conductivity differential equation of rock in a cylindrical coordinate system can be used to describe the thermal conductivity differential equation of the solids in the model:

where is the density of the rock, is the heat capacity of the rock, is the thermal conductivity of the rock, and is the temperature of the gas. At the cavity wall, the temperature of the rock was equal to the temperature of the gas adjacent to the cavity wall.

The rock surrounding the gas storage is subjected to two loads:—one is the gravity of the upper rock and the other is the gas pressure received at the cavity wall—and the thermal stress caused by the temperature change at the cavity wall must be considered. The differential equation of rock deformation is shown in Equation (1g):

where is the displacement vector, is the total displacement tensor, is the volume force received by the rock, is the initial displacement tensor, is the elastic tensor, is the elastic strain tensor, is the total strain tensor, is the thermal strain tensor, is the coefficient of thermal expansion, and is the ambient temperature.

2.6. Boundary Conditions

The integrated model is a two-position axisymmetric model. When setting the boundary conditions, only half of the vertical section of the model could be set, and the centerlines of the model were all axisymmetric boundary conditions. The turbulent physical field of the model included the wellbore and cavity regions. The initial state of fluid in the turbulent region was static, the initial value of velocity was 0, and the initial value of pressure was the initial value of the outlet pressure boundary condition. The well wall and the cavity wall constituted the wall of the turbulent region; the roughness of the wall was uniform and did not change with time. The upper part of the wellbore was the turbulent inlet and outlet boundary condition. When gas was produced, the upper part was the outlet boundary condition. When gas was injected, the inlet boundary condition was the inlet boundary condition.

The solid-containing wellbore heat transfer and fluid physical fields in the cavity and the surrounding rock in three parts were part of the initial value of the geothermal gradient of the surrounding rock; the value of the geothermal gradient tan region was determined using the measured value of 0.025 °C/m; when the ground temperature was 293 k, the temperature of the fluid field initial values could be set according to the actual working conditions if the gas storage salt cavity was left to stand for a long time. Due to sufficient heat exchange between the gas in the cavity and the surrounding rock, the initial temperature of the gas in the cavity could be set to the same geothermal gradient as that of the surrounding rock area. If the interval between gas injection and withdrawal was short, the initial value could be separately assigned to the fluid area. The upper, lower, and sides of the surrounding rock area were regarded as thermal insulation, and only the boundary adjacent to the fluid area had convective heat transfer. The upper boundary of the wellbore was used to set the inlet temperature and the outflow boundary condition, corresponding to the gas injection and gas withdrawal conditions, respectively.

The solid mechanical and physical field included the surrounding rock. The top of the surrounding rock was the ground; thus, the boundary load was 0, which was also a free boundary. The lateral displacement of the surrounding rock was only allowed in the axial direction, not in the normal phase; hence, the lateral support of the surrounding rock was a roller. The bottom of the surrounding rock did not allow displacement in the normal and axial directions; thus, the bottom was a fixed constraint. The boundary between the surrounding rock, cavity, and wellbore bears the pressure from gas and changes with time; therefore, it had to be coupled with the turbulent physical field to obtain the numerical value of gas pressure.

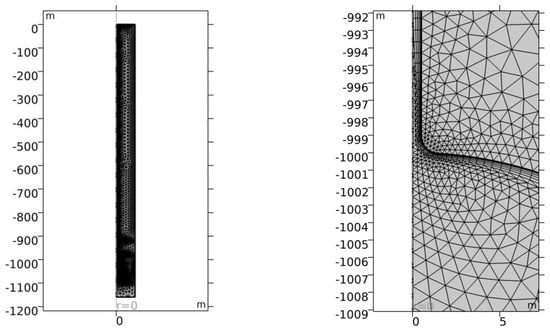

2.7. Grid Division

The integrated thermodynamic coupled model included multiple physical fields, including turbulence, solid and fluid heat transfer, solid mechanics, non-isothermal flow, and thermal expansion. The model was divided according to the characteristics of the physical fields. In the processes of gas injection and gas withdrawal, there is a large temperature gradient and stress gradient at the cavity wall and well wall; thus, the grid at the wall had to be encrypted. Therefore, five boundary layers were set at the wall; the model contained a total of 32,923 domain elements and 3185 boundary elements (Figure 3).

Figure 3.

Model mesh generation.

3. Thermodynamic Behavior

3.1. Comparison of the Thermodynamic Behavior of CO2 and CH4

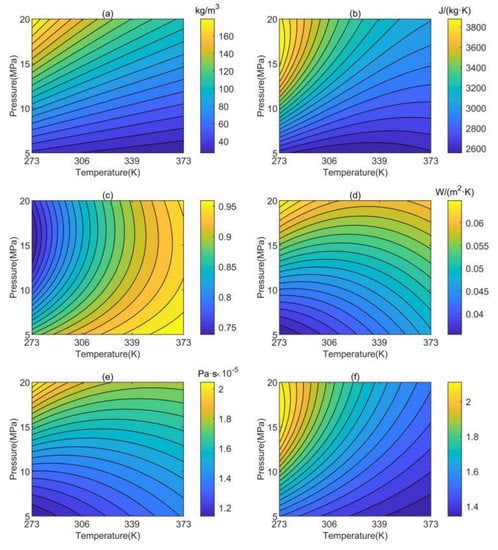

Experiments and simulations have been carried out to investigate the storage of natural gas in salt caverns. However, the use of salt caverns for underground carbon dioxide storage is not well studied. Generally, CO2 is expected to be stored in its gaseous phase in salt caverns. To further investigate the storage of CO2 in salt caverns, it is necessary to compare the thermodynamic behavior of carbon dioxide and methane during storage. Figure 4 illustrates the physical properties of methane when subjected to operation conditions, i.e., temperature ranging from 273 to 373 K and pressure ranging from 5 to 20 MPa. Figure 5 shows the contour plots of the thermophysical properties of methane, revealing its dependence on temperature and pressure. It can be seen that the density (Figure 5a) and specific heat capacity (Figure 5f) of methane increased with the elevation in pressure, but decreased with the elevation in temperature. Thermal conductivity (Figure 5d) and viscosity (Figure 5e) showed similar trends; both of them rose when the temperature and pressure increased. The heat capacity (Figure 5b) increased when pressure increased and decreased when temperature increased. The compressibility factor (Z; Figure 5c) showed a more complex variation with temperature and pressure.

Figure 4.

Physical property parameters of methane: (a) density, kg/m3; (b) isobaric heat capacity, J/(kg·K); (c) compressibility factor (Z); (d) thermal conductivity, W/(m·K); (e) viscosity, Pa·s; (f) specific heat capacity, J/(kg·K).

Figure 5.

Thermophysical properties of methane at temperatures ranging from 273 to 373 K and pressures ranging from 5 to 20 MPa: (a) density, kg/m3; (b) isobaric heat capacity, J/(kg·K); (c) compressibility factor (Z); (d) thermal conductivity, W/(m·K); (e) viscosity, Pa·s; (f) specific heat capacity, J/(kg·K).

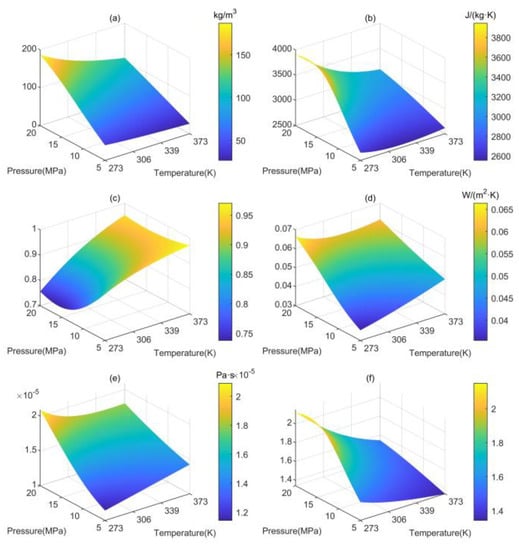

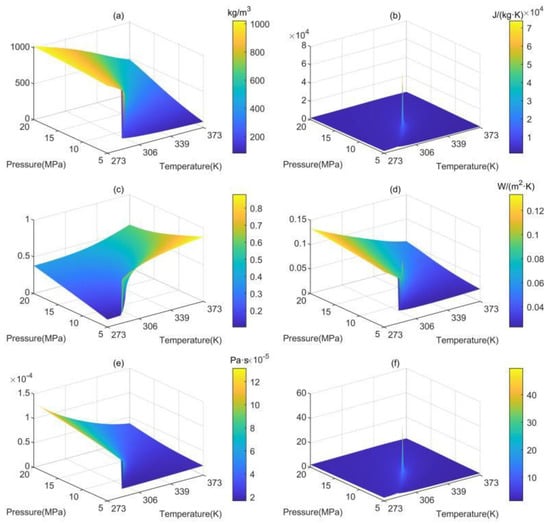

Figure 6 illustrates in a three-dimensional bar chart the physical properties of carbon dioxide when subjected to operation conditions, i.e., a temperature ranging from 273 to 373 K and pressure ranging from 5 to 20 MPa. Figure 7 shows the contour plots of the thermophysical properties of carbon dioxide. The critical temperature of CO2 was 304.13 K and the critical pressure was 7.4 MPa. There were sudden changes in the properties of CO2 near the critical temperature and pressure. Compared with methane, carbon dioxide showed a more complex variation with temperature and pressure, particularly around critical conditions.

Figure 6.

Physical property parameters of carbon dioxide: (a) density, kg/m3; (b) isobaric heat capacity, J/(kg·K); (c) compressibility factor (Z); (d) thermal conductivity, W/(m·K); (e) viscosity, Pa·s; (f) specific heat capacity, J/(kg·K).

Figure 7.

Thermophysical properties of methane at temperatures ranging from 273 to 373 K and pressures ranging from 5 to 20 MPa: (a) density, kg/m3; (b) isobaric heat capacity, J/(kg·K); (c) compressibility factor (Z); (d) thermal conductivity, W/(m·K); (e) viscosity, Pa·s; (f) specific heat capacity, J/(kg·K).

3.2. Thermodynamic Behavior of CO2 Subjected to Storage Conditions

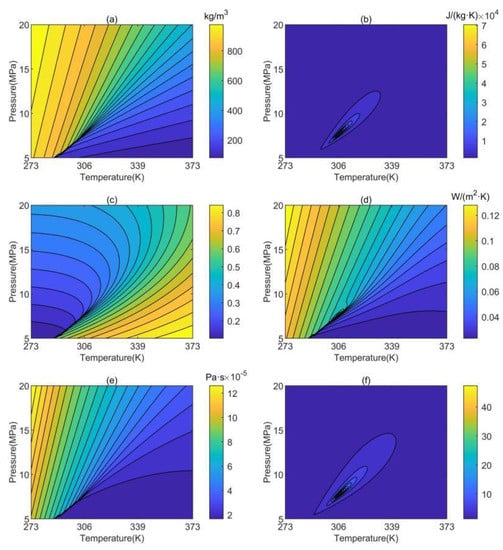

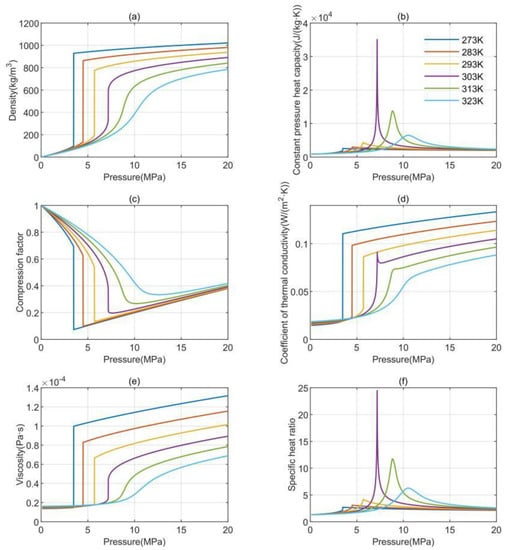

To more clearly demonstrate the dependence of CO2 on temperature and pressure, temperatures of 273 K, 283 K, 293 K, 303 K, 313 K, and 323 K were selected for the comparison of thermodynamic properties. Density (Figure 8a) increased with rising pressure. When the temperature was lower than the critical temperature, there was a dramatic change; when the temperature was higher than the critical temperature, the curve became smooth. The isobaric heat capacity (Figure 8b) fluctuated and reached its peak value at critical temperature; the corresponding pressure for the peak values at different temperatures increased. Specific heat capacity (Figure 8f) showed a similar variation to isobaric heat capacity. When the pressure was lower than the critical pressure, the compressibility factor (Z; Figure 8c) decreased with increasing pressure and then increased; after the critical temperature, the Z values were close to a constant of 0.4 and were mainly controlled by pressure. The thermal conductivity (Figure 8d) increased with rising pressure; when the pressure was higher than the critical pressure, the values of thermal conductivity differed between different temperatures. Viscosity (Figure 8e) showed a variation similar to thermal conductivity.

Figure 8.

Thermophysical properties of carbon dioxide curves at temperatures ranging from 273 to 373 K (six different temperatures) and pressures ranging from 5 to 20 MPa: (a) density, kg/m3; (b) isobaric heat capacity, J/(kg·K); (c) compressibility factor (Z); (d) thermal conductivity, W/(m·K); (e) viscosity, Pa·s; (f) specific heat capacity, J/(kg·K).

The thermodynamic behavior was closely related to the critical point of CO2. Close attention should be paid to a possible phase transition. As for the critical values among the thermophysical properties, the variation in the compressibility factor (Z) was the most significant, followed by density, thermal conductivity, viscosity, and heat capacity.

3.3. Joule–Thomson Effect Analysis

3.3.1. Analysis of the Joule–Thomson Effect

The Joule–Thomson effect refers to the phenomenon that occurs when a high-pressure gas passes through a suddenly compressed section; the pressure of the gas will be reduced, and the temperature will change due to local resistance. For underground salt cavern gas storage, during the processes of gas injection and withdrawal, the pressure in the storage cavern will change, and the gas temperature will also change due to the Joule–Thomson effect. According to molecular theory, the reason why the Joule–Thomson effect changes the temperature of the gas is the mutual transformation between heat and work. In the process of gas injection, the outside world performs work on the gas, the pressure in the gas storage tank increases, the work turns into heat, and the temperature of the gas in the storage tank rises. In the process of gas withdrawal, the gas performs work on the outside world, the pressure of the gas in storage decreases, the distance between molecules becomes larger, and the heat is converted to function to overcome the intermolecular forces; thus, the temperature of the gas in storage decreases.

Enthalpy is a thermodynamic state parameter, and ideal gases ignore the interaction force between molecules; thus, enthalpy is only a function of temperature. Previous studies that regarded the gas in injection and withdrawal processes as an ideal gas did not consider the Joule–Thomson effect. In this study, natural gas was considered as an actual gas, which is closer to reality. The enthalpy of the actual gas can be derived using Gibbs’ phase law. In physical chemistry, Gibbs’ phase law describes the relationship between the degree of freedom of a system and other variables in a particular phase state and can be represented as the following expression:

where F is the degree of freedom (when F is 0, this indicates that the state is in equilibrium); C is the number of elements of the system; P is the number of phase states in that state; n is the external factor; and the gas constant is 2.

The composition of natural gas does not change in a specific state. Thus, the state function of natural gas must have two degrees of freedom; that is, the state of natural gas can be completely determined on the premise of knowing two state parameters. The state function of natural gas includes temperature, pressure, enthalpy, entropy, specific volume, internal energy, etc. Therefore, the enthalpy of natural gas can be determined by two state parameters other than enthalpy. The enthalpy change in an actual gas can be expressed by the following formula:

where h is the specific enthalpy and is the heat capacity at a constant pressure. The first term on the right is the change in enthalpy for an ideal gas, and the second term is the change in enthalpy due to the non-ideality of the gas.

According to the definition of the Joule–Thomson coefficient , Equation (2b) can be transformed into:

The formula contains two variables, and , and the relationship between them can be described as follows:

By substituting the gas compressibility coefficient , we obtain:

Therefore, by calculating , can be obtained, which can be put into the equation for the state of a non-ideal gas , and the Joule–Thomson effect can be considered to achieve more accurate calculation results.

3.3.2. Analysis of Temperature Changes

In order to verify the influence of the Joule–Thomson effect on salt cavern gas storage, we designed two comparison schemes with different shapes and sizes to simulate the temperature change associated with the Joule–Thomson effect.

- (1)

- Different shapes

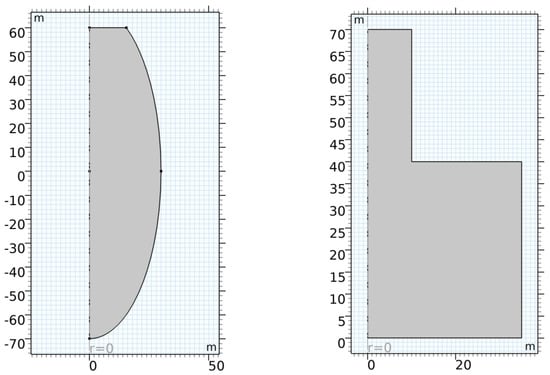

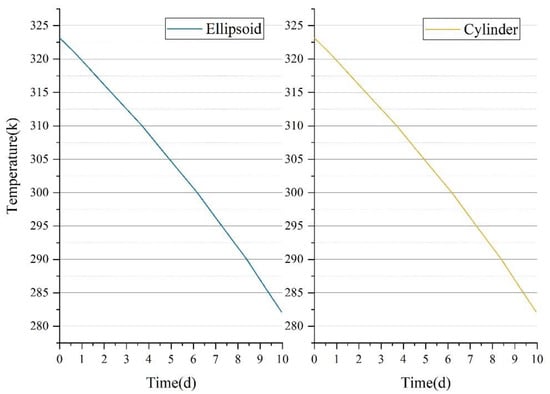

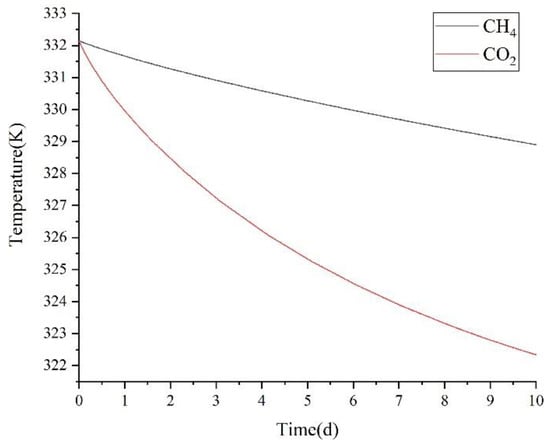

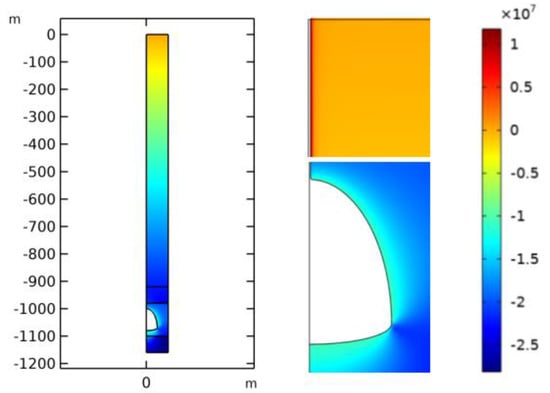

In order to explore the influence of container shape on the temperature change associated with the Joule–Thomson effect, two container shapes, ellipsoid and cylindrical, were designed for comparison. Both models were two-dimensional axisymmetric models, as shown in Figure 9. With the same boundary conditions, the outlet pressure was dropped from 10 MPa to 5 MPa at the same time, and the gas in the region was averaged. The simulated temperature results are shown in the Figure 10; it can be seen that the temperature trend and amplitude were the same.

Figure 9.

Models with different shapes.

Figure 10.

Diagram of temperature over time.

- (1)

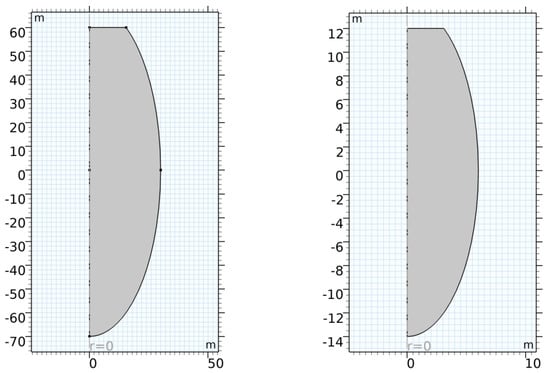

- Different sizes

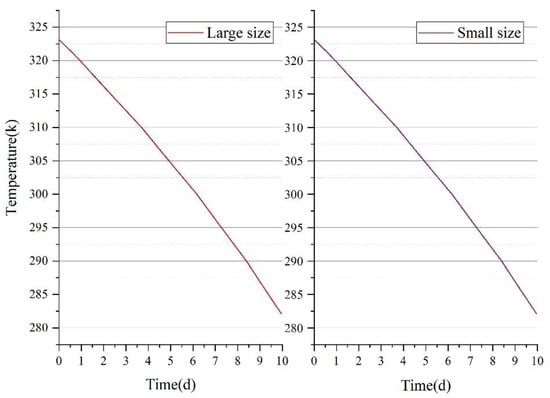

In order to explore the influence of volume on the temperature change associated with the Joule–Thomson effect, ellipsoidal models of two sizes were designed, as shown in Figure 11. Similarly, the two models with different sizes adopted the same boundary conditions, the outlet pressure was dropped from 10 MPa to 5 MPa at the same time, and the gas in the region was averaged. The simulated temperature results are shown in Figure 12; the same trend and amplitude of temperature change were observed.

Figure 11.

Models of different sizes.

Figure 12.

Diagram of temperature over time.

It can be seen from the figure that the gas temperature change caused by the Joule–Thomson effect during the processes of gas injection and withdrawal was only related to pressure and had nothing to do with the volume of gas storage and the time of gas injection and withdrawal. In view of the variations in temperature and gas pressure in gas storage after a period of gas injection and withdrawal, gas injection or withdrawal can be continued. The amount of gas injection and withdrawal and the standing time depend on the heat exchange between the gas and surrounding rock.

4. Simulation Results and Discussion

4.1. Temperature Response to Gas Withdrawal

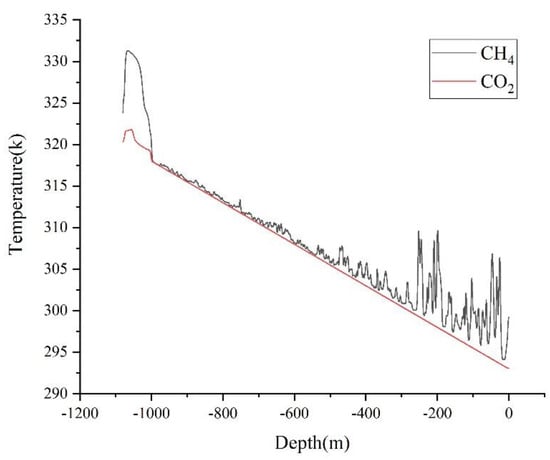

With the same numerical modeling and operation conditions, we conducted a 10-day gas withdrawal simulation case study of CH4 and CO2. In Figure 13, it can be seen that the temperature of CH4 fluctuated at the wellbore section and the bottom of the cavity. The variation trends of CH4 and CO2 were similar, although the temperature of CO2 was lower than CH4. The inlet pressure variation in response to the constant withdrawal of CH4 for 10 days is listed in Table 3. A comparison of the average temperatures of CH4 and CO2 is shown in Figure 14. Both temperatures decreased with decreasing pressure during the withdrawal process; the temperature of CO2 decreased more rapidly and was reduced to approximately 10 K, while that of CH4 was reduced to 3 K. The response of temperature to withdrawal was much more severe for CO2 due to the difference in thermal properties between CH4 and CO2. The response of the surrounding wall was not only associated with the thermal properties of the cycling loading fluid, but also the characteristics of creep of the rock salt.

Figure 13.

Temperature at cavity centerline at the end of withdrawal.

Table 3.

Inlet pressure over 10 days of constant gas withdrawal.

Figure 14.

Average temperature comparison at the centerline of the salt cavity at the end of withdrawal.

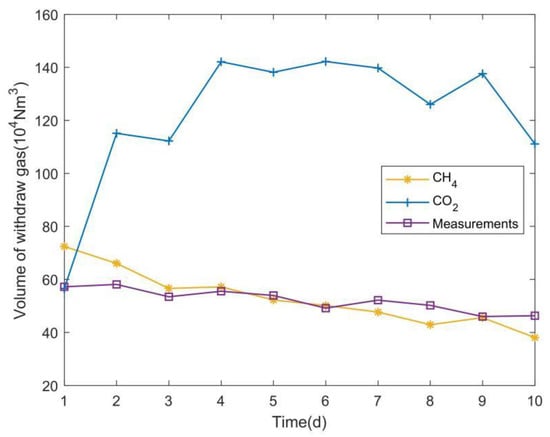

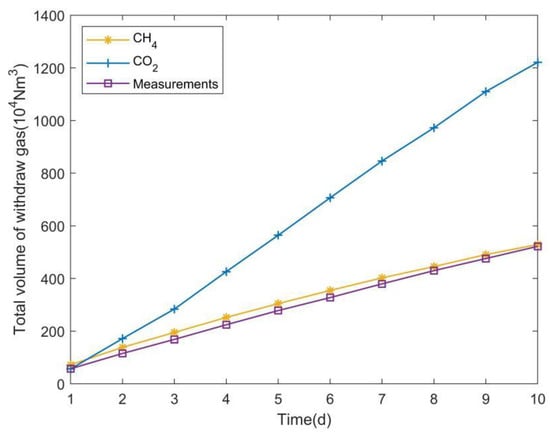

4.2. CO2 Storage Capacity

The proposed integrated wellbore–cavity thermomechanical coupling model was verified using the gas capacity data provided by the operators of the Jintan gas storage facility. In Figure 15, the simulation results of the numerical modelling for CH4 are compared with measurements from field testing. At the initial stage, the simulation result was higher than the measurement value; from day 3, the simulation value was consistent with measurements obtained during testing. Figure 16 illustrates the total volume of gas withdrawal. During the 10-day gas withdrawal period, the simulated calculation value was 5.288 million m and the measurement value was 5.2208 million m3; the error was 1.3%. The cause for error was identified as the swift operation between gas injection and withdrawal, causing a hysteresis effect on the temperature variation in the cavity. When the gas injection and withdrawal material was replaced by carbon dioxide, operating at the same rate of pressure drop, the volume of CO2 was much higher than that of CH4. The total volume of CO2 was 12.209 million m3, approximately 2.3 times the volume of CH4. In the context of the same operation conditions, a greater volume of CO2 can be stored in underground salt cavities.

Figure 15.

Daily gas withdrawal volume.

Figure 16.

Total gas withdrawal volume.

4.3. Stability Analysis

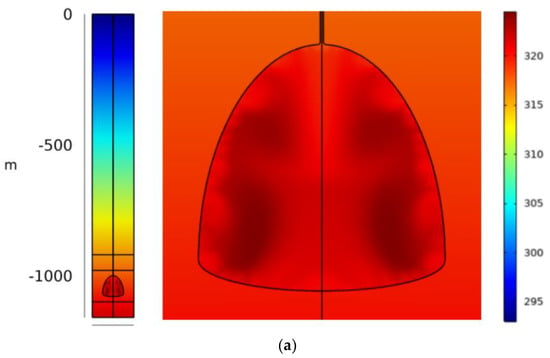

To investigate the response of the surrounding wall of the salt cavern to gas injection and withdrawal, a series of evaluation simulation cases were implemented based on the integrated wellbore–cavity thermomechanical model. Figure 17 illustrates the temporospatial variation in temperature in the context of the 10-day withdrawal operation. Figure 17a shows a 3D view of the temperature distribution around the ellipsoid shape of the salt cavity—the temperature was uniform on cavern wall. During the 10-day CO2 withdrawal, the temperature decreased rapidly, and the decreasing amplitude reached its largest at the centerline. The depth of the salt cavity was 1012 to 1086 m, and the maximum radius was 40.15 m. Figure 17c shows the temperature inside the cavity; there was a spatial fluctuation in the temperature around the cavity, but it was only several K in scale. When the CO2 withdrawal was finished, it was obvious that there was a drastic decrease of approximately 12 K.

Figure 17.

Temporospatial distribution of temperature for 10-day withdrawal operation: (a) 3-D view of temperature distribution; (b) temperature at centerline and average temperature over 10 days; (c) average temperature at a depth of 1030 m.

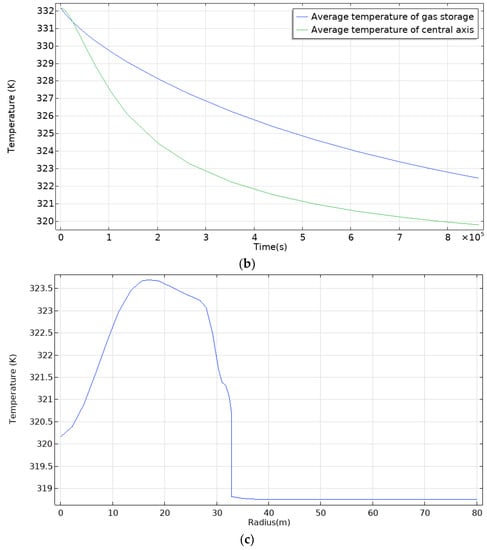

During gas depressurization, the thermal contraction of rock may occur, resulting in the onset of tensile stress concentration. The induction of tensile fracturing is very likely; hence, tensile stress evaluation is one concern in stability analysis. The tensile stress distribution based on the thermomechanical model is shown in Figure 18. During the 10-day CO2 withdrawal operation, the salt cavern remained stable; however, there was a concentration of tensile stress in the near-wellbore area (NWA), which is the connection between the wellbore and cavity, indicating that tensile failure may occur. The properties and performance of CO2 and CH4 in the salt cavern are summarized in Table 4.

Figure 18.

Tension stress distribution after 10-day CO2 withdrawal.

Table 4.

Comparison of CO2 and CH4 in salt cavern.

5. Conclusions

This study investigated the feasibility of CO2 storage in an underground salt cavern. An integrated wellbore–cavity thermomechanical numerical model was proposed to investigate the thermodynamic behavior of CO2 and the response of the surrounding wall of the salt cavity in underground storage conditions. The thermal effect induced by CO2 withdrawal was also considered.

The thermodynamic characteristics of carbon dioxide and methane were compared. Compared to CH4, the critical point coordinates of carbon dioxide were within the storage operation conditions, indicating that a phase transition could occur, and the thermodynamic properties varied dramatically around the critical point. The Joule–Thomson effect was discussed as well.

In the context of the same operation conditions, the underground salt cavity could store a greater volume of CO2. CO2 had a much more severe response to withdrawal, exhibiting a drastic variation in temperature. For a short CO2 withdrawal operation, although the salt cavity remained stable, the near-wellbore area (NWA) was prone to fracture due to tensile stress concentration. Additional investigations should be conducted to account for the creeping behavior of salt rock. In the future, we expect to continue to conduct related research focusing on the characteristics of CO2 working as a cushion gas in salt caverns.

Author Contributions

Conceptualization, Y.Z.; Investigation, Y.Z. and W.L.; Methodology, W.L.; Software, G.C.; Supervision, Y.Z.; Writing—original draft, W.L.; Writing—review and editing, Y.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Natural Science Foundation of China project (4210020040); Open Research Fund of State Key Laboratory of Water Resources and Hydropower Engineering Science, Wuhan University (2020SGG05).

Acknowledgments

The authors would like to acknowledge the support from Open Access Publishing.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Brouard, B.; Berest, P.; Djizanne, H.; Frangi, A. Mechanical stability of a salt cavern submitted to high-frequency cycles. In Mechanical Behavior of Salt VII.; Taylor & Francis Group: Paris, France, 2012; pp. 381–390. [Google Scholar]

- Fan, J.; Xie, H.; Chen, J.; Jiang, D.; Li, C.; Tiedeu, W.N.; Ambre, J. Preliminary feasibility analysis of a hybrid pumped-hydro energy storage system using abandoned coal mine goafs. Appl. Energy 2020, 258, 114007. [Google Scholar] [CrossRef]

- Wang, T.; Yang, C.; Yan, X.; Li, Y.; Liu, W.; Liang, C.; Li, J. Dynamic response of underground gas storage salt cavern under seismic loads. Tunn. Undergr. Space Technol. 2014, 43, 241–252. [Google Scholar] [CrossRef]

- Raju, M.; Khaitan, S.K. Modeling and simulation of compressed air storage in caverns: A case study of the Huntorf plant. Appl. Energy 2012, 89, 474–481. [Google Scholar] [CrossRef]

- Jackson, M.P.A.; Hudec, M.R. Salt Tectonics: Principles and Practice; Cambridge University Press: Cambridge, UK, 2017. [Google Scholar]

- Yang, C.; Wang, T.; Li, Y.; Yang, H.; Li, J.; Qu, D.; Xu, B.; Yang, Y.; Daemen, J. Feasibility analysis of using abandoned salt caverns for large-scale underground energy storage in China. Appl. Energy 2015, 137, 467–481. [Google Scholar] [CrossRef]

- Liu, X.; Shi, X.; Li, Y.; Li, P.; Zhao, K.; Ma, H.; Yang, C. Maximum gas production rate for salt cavern gas storages. Energy 2021, 234, 121211. [Google Scholar] [CrossRef]

- Li, S.-Y.; Urai, J.L. Rheology of rock salt for salt tectonics modeling. Pet. Sci. 2016, 13, 712–724. [Google Scholar] [CrossRef]

- Arson, C. Micro-macro mechanics of damage and healing in rocks. Open Géoméch. 2020, 2, 1–41. [Google Scholar] [CrossRef]

- Warren, J.K. Salt usually seals, but sometimes leaks: Implications for mine and cavern stabilities in the short and long term. Earth-Sci. Rev. 2017, 165, 302–341. [Google Scholar] [CrossRef]

- Shen, X.; Arson, C.; Ding, J.; Chester, F.M.; Chester, J.S. Mechanisms of Anisotropy in Salt Rock Upon Microcrack Propagation. Rock Mech. Rock Eng. 2020, 53, 3185–3205. [Google Scholar] [CrossRef]

- Wang, T.; Li, J.; Jing, G.; Zhang, Q.; Yang, C.; Daemen, J. Determination of the maximum allowable gas pressure for an underground gas storage salt cavern—A case study of Jintan, China. J. Rock Mech. Geotech. Eng. 2019, 11, 251–262. [Google Scholar] [CrossRef]

- BP Company. Statistical Review of World Energy; BP Company: London, UK, 2021. [Google Scholar]

- Mahmoudan, A.; Esmaeilion, F.; Hoseinzadeh, S.; Soltani, M.; Ahmadi, P.; Rosen, M. A geothermal and solar-based multigeneration system integrated with a TEG unit: Development, 3E analyses, and multi-objective optimization. Appl. Energy 2022, 308, 118399. [Google Scholar] [CrossRef]

- Luo, J.; Hou, Z.; Feng, G.; Liao, J.; Haris, M.; Xiong, Y. Effect of Reservoir Heterogeneity on CO2 Flooding in Tight Oil Reservoirs. Energies 2022, 15, 3015. [Google Scholar] [CrossRef]

- Jin, L.; Wojtanowicz, A.K.; Ge, J. Prediction of Pressure Increase during Waste Water Injection to Prevent Seismic Events. Energies 2022, 15, 2101. [Google Scholar] [CrossRef]

- Li, Y.; Yu, H.; Liu, Y.; Zhang, G.; Tang, D.; Jiang, Z. Numerical study on the hydrodynamic and thermodynamic properties of compressed carbon dioxide energy storage in aquifers. Renew. Energy 2020, 151, 1318–1338. [Google Scholar] [CrossRef]

- Soubeyran, A.; Rouabhi, A.; Coquelet, C. Thermodynamic analysis of carbon dioxide storage in salt caverns to improve the Power-to-Gas process. Appl. Energy 2019, 242, 1090–1107. [Google Scholar] [CrossRef]

- Bérest, P. Heat transfer in salt caverns. Int. J. Rock Mech. Min. Sci. 2019, 120, 82–95. [Google Scholar] [CrossRef]

- Böttcher, N.; Görke, U.-J.; Kolditz, O.; Nagel, T. Thermo-mechanical investigation of salt caverns for short-term hydrogen storage. Environ. Earth Sci. 2017, 76, 98. [Google Scholar] [CrossRef]

- Balland, C.; Billiotte, J.; Tessier, B.; Raingeard, A.; Hertz, E.; Hévin, G.; Tribout, D.; Thelier, N.; Hadj-Hassen, F.; Charnavel, Y.; et al. Acoustic monitoring of a thermo-mechanical test simulating withdrawal in a gas storage salt cavern. Int. J. Rock Mech. Min. Sci. 2018, 111, 21–32. [Google Scholar] [CrossRef]

- Bérest, P.; Louvet, F. Aspects of the thermodynamic behavior of salt caverns used for gas storage. Oil Gas Sci. Technol.—Rev. d’IFP Energ. Nouv. 2020, 75, 57. [Google Scholar] [CrossRef]

- Bérest, P.; Brouard, B.; Karimi-Jafari, M.; Van Sambeek, L. Transient behavior of salt caverns—Interpretation of mechanical integrity tests. Int. J. Rock Mech. Min. Sci. 2007, 44, 767–786. [Google Scholar] [CrossRef]

- Blanco-Martín, L.; Rouabhi, A.; Billiotte, J.; Hadj-Hassen, F.; Tessier, B.; Hévin, G.; Balland, C.; Hertz, E. Experimental and numerical investigation into rapid cooling of rock salt related to high frequency cycling of storage caverns. Int. J. Rock Mech. Min. Sci. 2018, 102, 120–130. [Google Scholar] [CrossRef]

- Berest, P. Thermomechanical Aspects of high frequency cycling in salt storage caverns. In Proceedings of the International Gas Union Research Conference, Seoul, Korea, 19–21 October 2011. [Google Scholar]

- Bérest, P.; Brouard, B.; Djizanne, H.; Hévin, G. Thermomechanical effects of a rapid depressurization in a gas cavern. Acta Geotech. 2014, 9, 181–186. [Google Scholar] [CrossRef]

- Sicsic, P.; Bérest, P. Thermal cracking following a blowout in a gas-storage cavern. Int. J. Rock Mech. Min. Sci. 2014, 71, 320–329. [Google Scholar] [CrossRef]

- Ngo, D.; Pellet, F. Numerical modeling of thermally-induced fractures in a large rock salt mass. J. Rock Mech. Geotech. Eng. 2018, 10, 844–855. [Google Scholar] [CrossRef]

- Zapf, D.; Leuger, B.; Donadei, S.; Horváth, P.L.; Zander-Schiebenhoefer, D.; Fleig, S.; Henneberg, M.; Onneken, J.; Gast, S.; Roehling, S.; et al. Development of a Supporting Tool for the Evaluation of Storage Capacity of Caverns for Renewable Energies—Rock Mechanical Design for Hydrogen Storage Caverns. In Proceedings of the 54th US Rock Mechanics/Geomechanics Symposium, American Rock Mechanics Association, Golden, CO, USA, 28 June–1 July 2020. [Google Scholar]

- Pudewills, A.; Droste, J. Numerical modeling of the thermomechanical behavior of a large-scale underground experiment. Comput. Struct. 2003, 81, 911–918. [Google Scholar] [CrossRef]

- Serbin, K.; Ślizowski, J.; Urbańczyk, K.; Nagy, S. The influence of thermodynamic effects on gas storage cavern convergence. Int. J. Rock Mech. Min. Sci. 2015, 79, 166–171. [Google Scholar] [CrossRef]

- Hoseinzadeh, S.; Heyns, S. Thermo-structural fatigue and lifetime analysis of a heat exchanger as a feedwater heater in power plant. Eng. Fail. Anal. 2020, 113, 104548. [Google Scholar] [CrossRef]

- Li, W.; Nan, X.; Chen, J.; Yang, C. Investigation of thermal-mechanical effects on salt cavern during cycling loading. Energy 2021, 232, 120969. [Google Scholar] [CrossRef]

- Li, W.; Miao, X.; Yang, C. Failure analysis for gas storage salt cavern by thermo-mechanical modelling considering rock salt creep. J. Energy Storage 2020, 32, 102004. [Google Scholar] [CrossRef]

- Habibi, R.; Moomivand, H.; Ahmadi, M.; Asgari, A. Stability analysis of complex behavior of salt cavern subjected to cyclic loading by laboratory measurement and numerical modeling using LOCAS (case study: Nasrabad gas storage salt cavern). Environ. Earth Sci. 2021, 80, 317. [Google Scholar] [CrossRef]

- Li, W.; Zhu, C.; Han, J.; Yang, C. Thermodynamic response of gas injection-and-withdrawal process in salt cavern for underground gas storage. Appl. Therm. Eng. 2019, 163, 114380. [Google Scholar] [CrossRef]

- AbuAisha, M.; Rouabhi, A. On the validity of the uniform thermodynamic state approach for underground caverns during fast and slow cycling. Int. J. Heat Mass Transf. 2019, 142, 118424. [Google Scholar] [CrossRef]

- Li, W.G.; Chen, W.G.; Ding, S.; Zhang, Y. A method for assessing the dynamic gas capacity and thermodynamic state analysis for salt cavern under operation. J. Energy Storage 2022, 50, 104316. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).