Reduction of the Electromagnetic Torque Oscillation during the Direct on Line (DOL) Starting of a 6 kV Motor by Means of a Controlled Vacuum Circuit-Breaker

Abstract

:1. Introduction

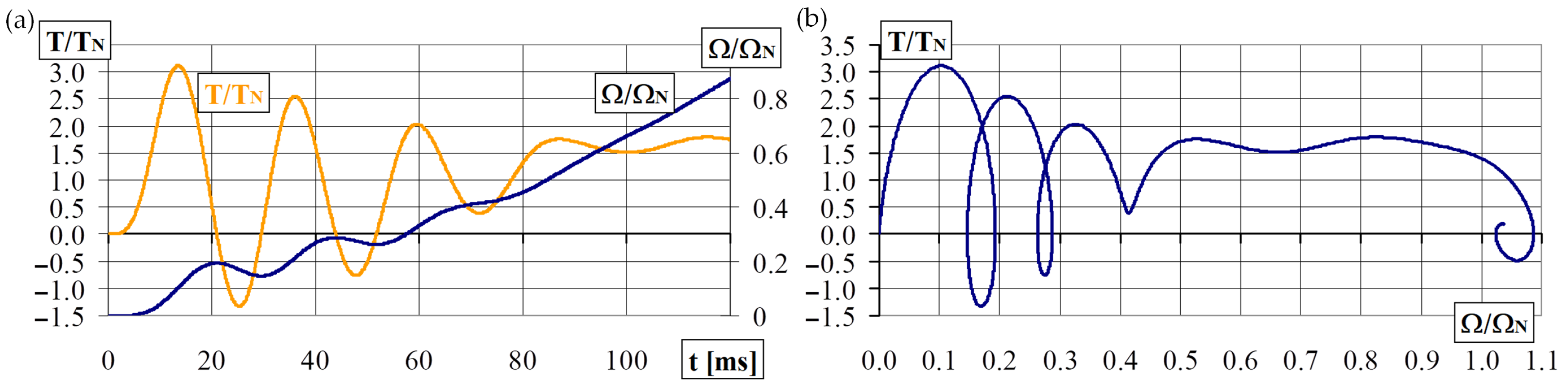

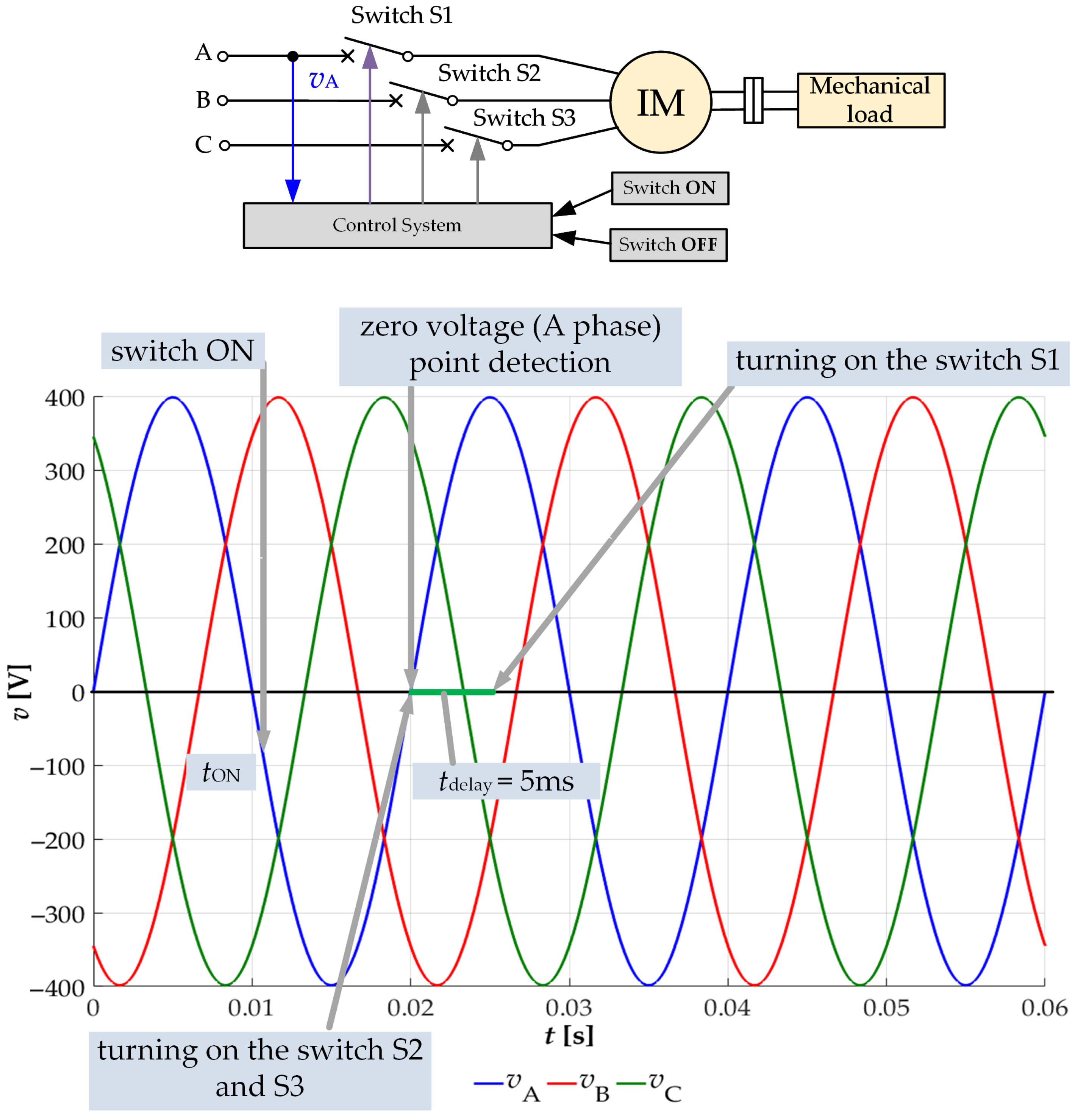

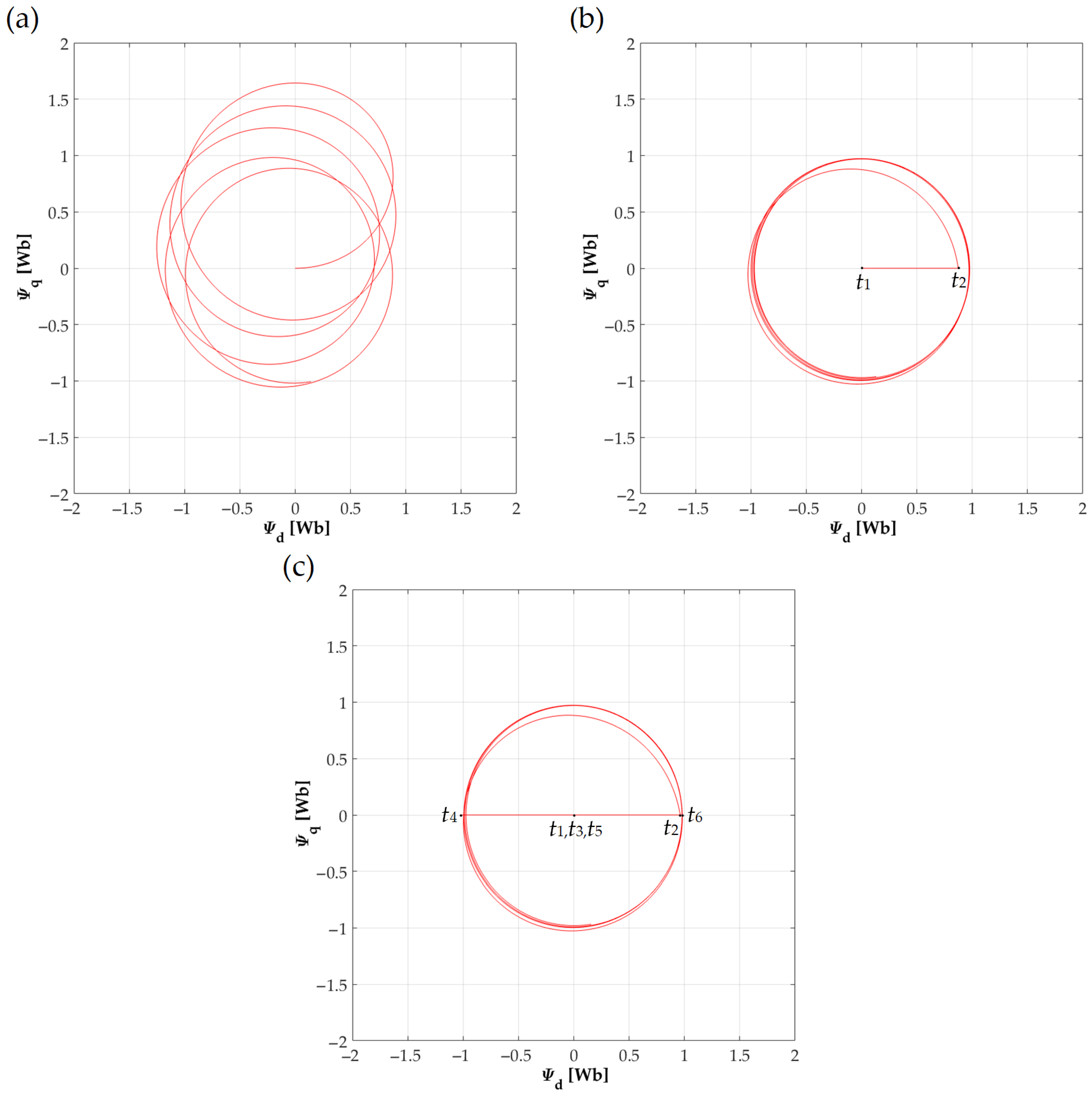

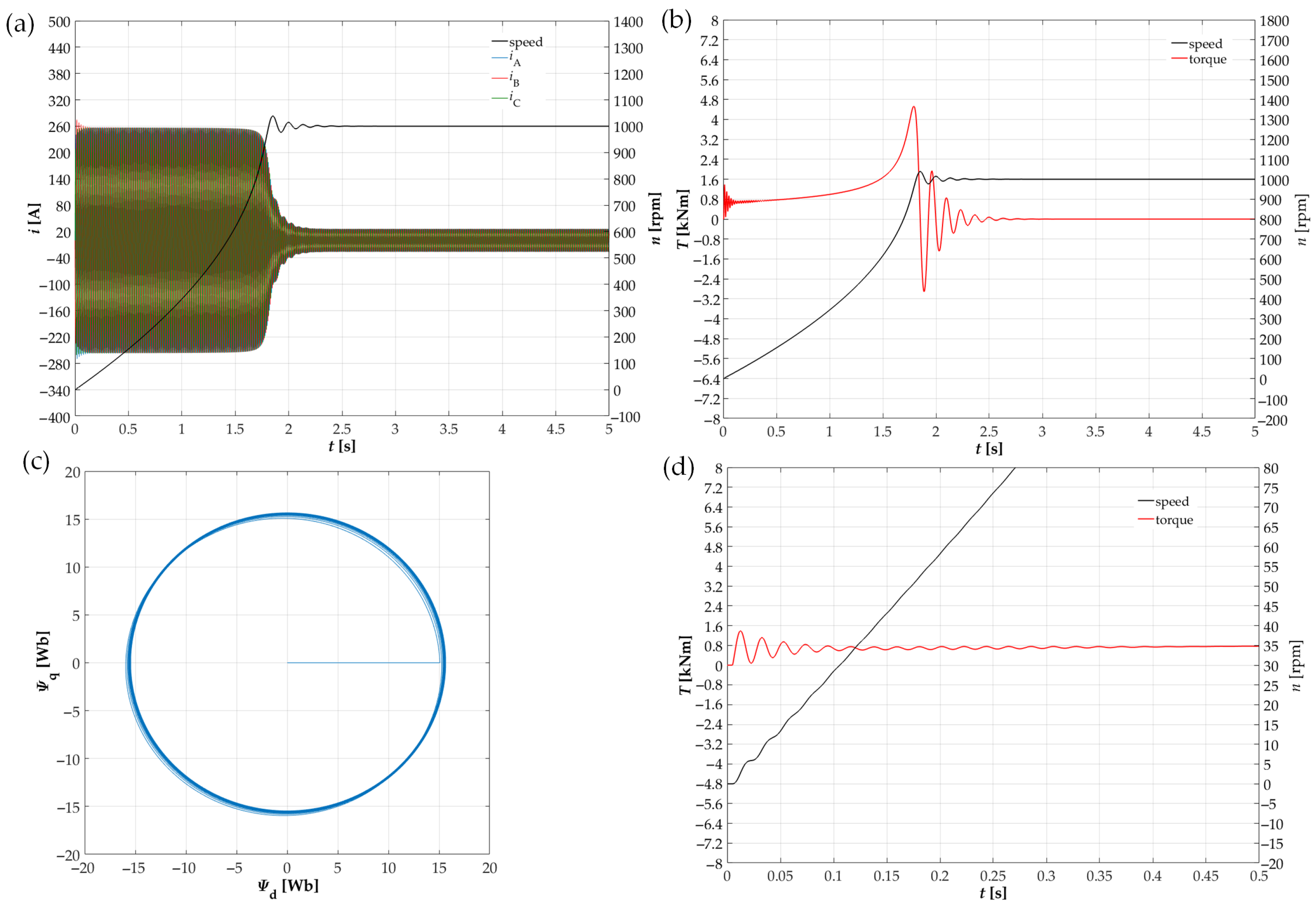

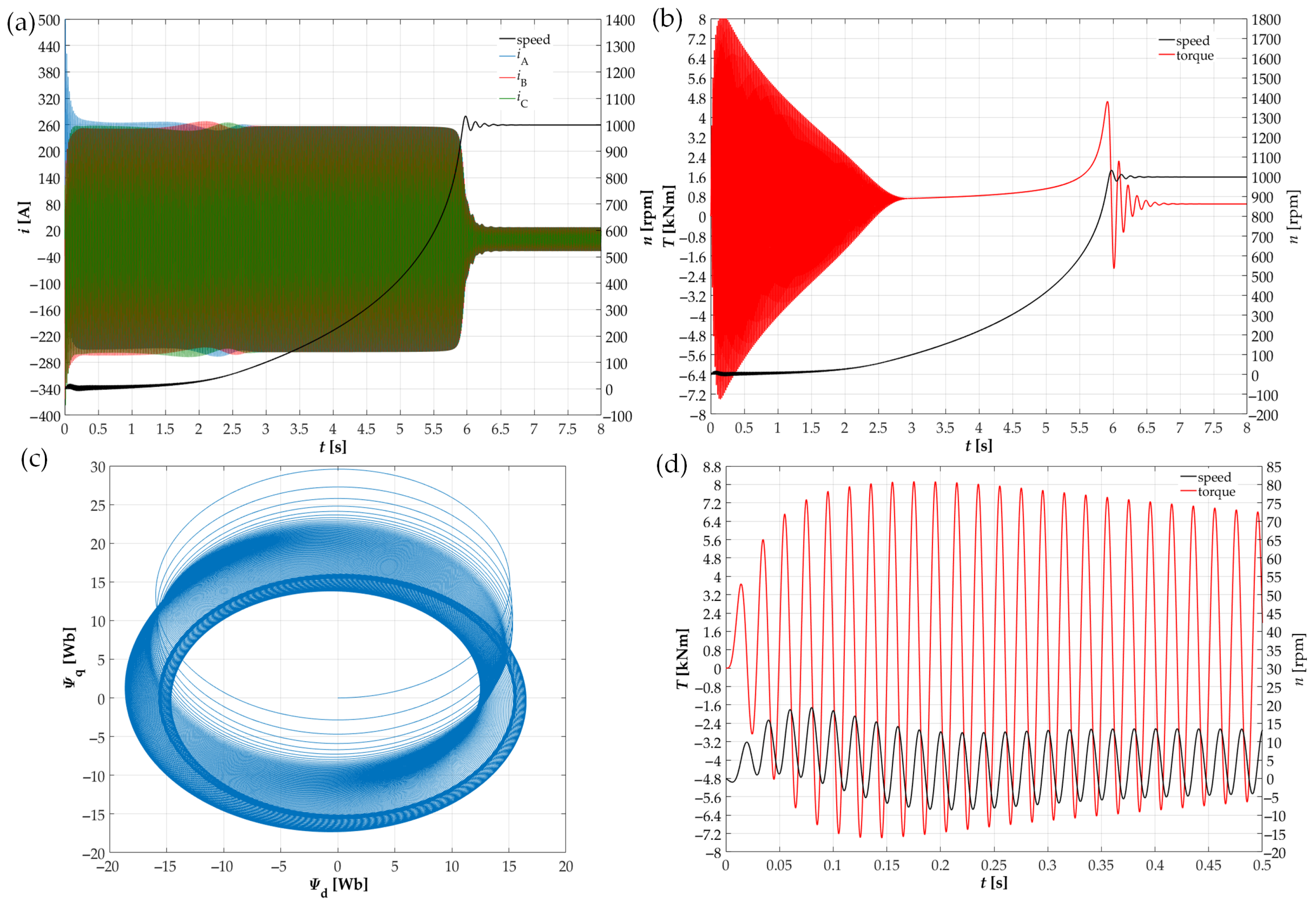

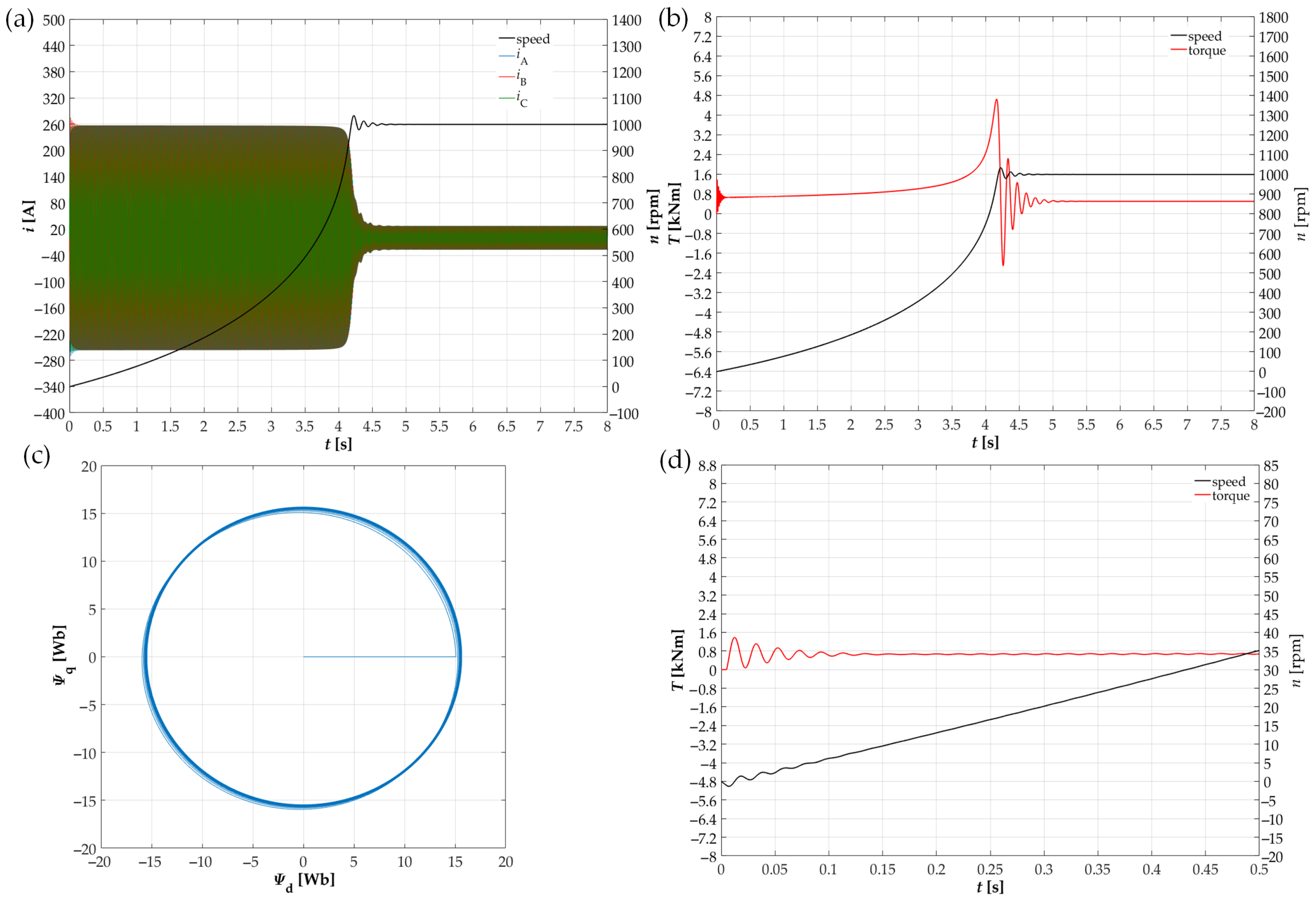

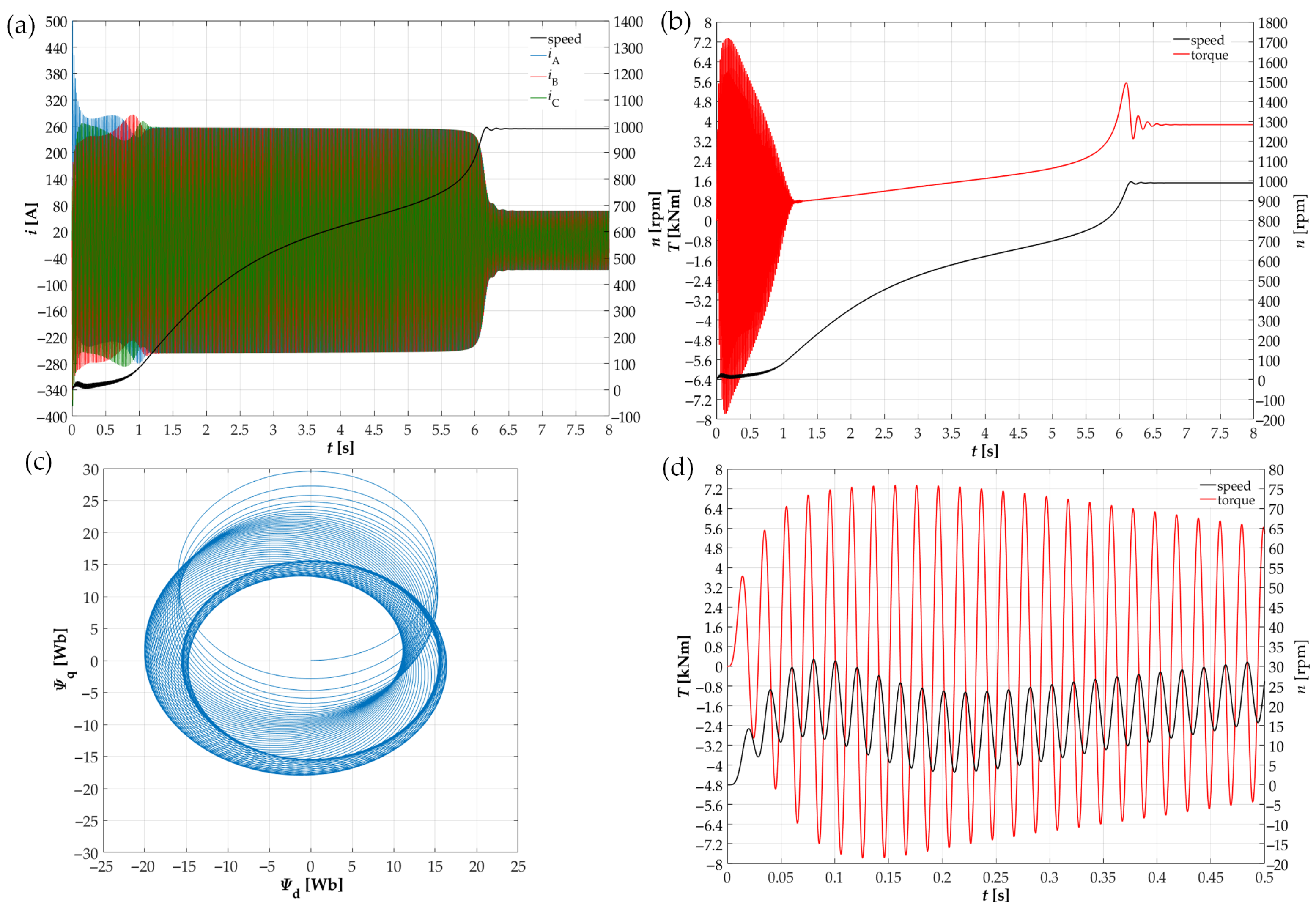

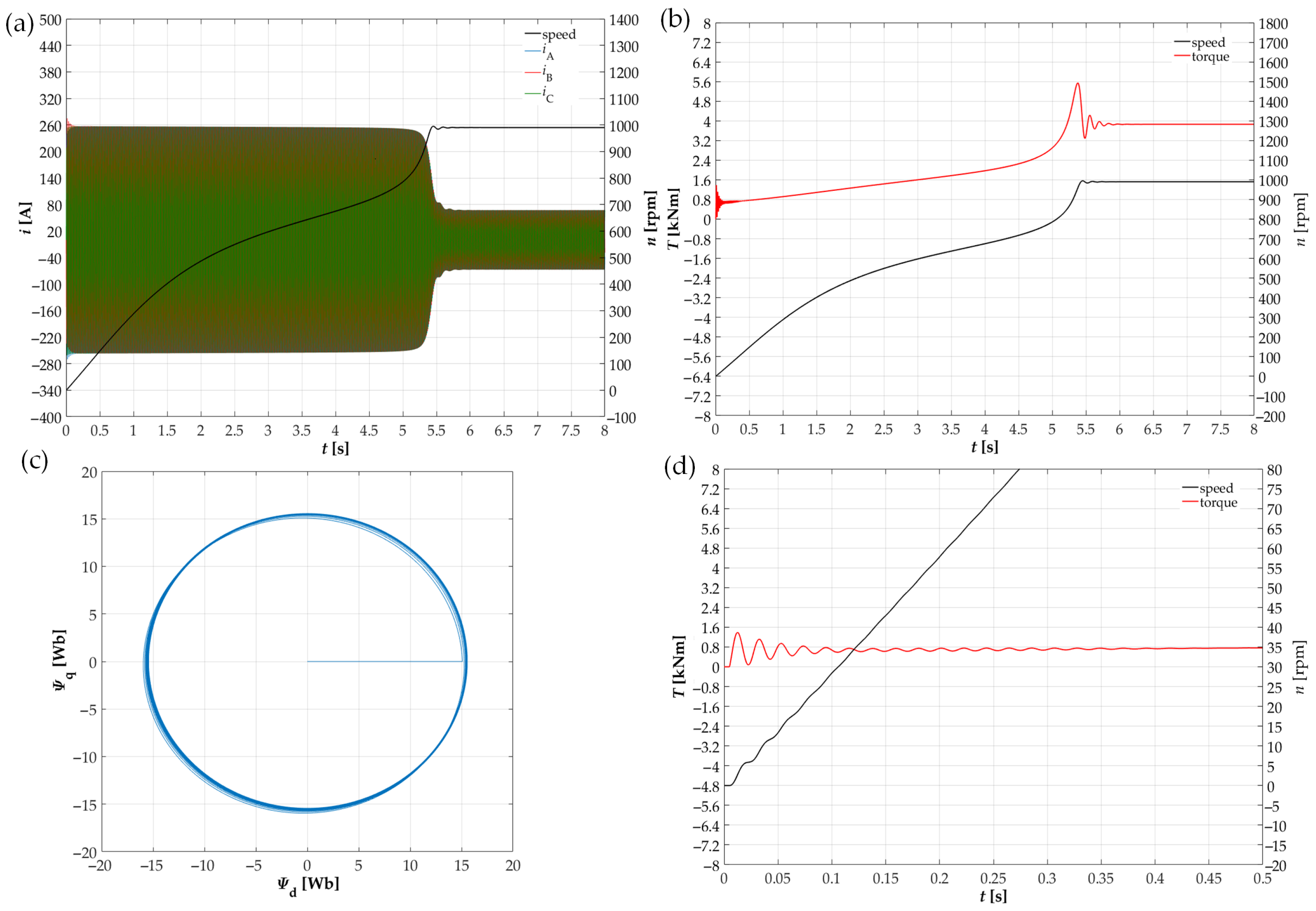

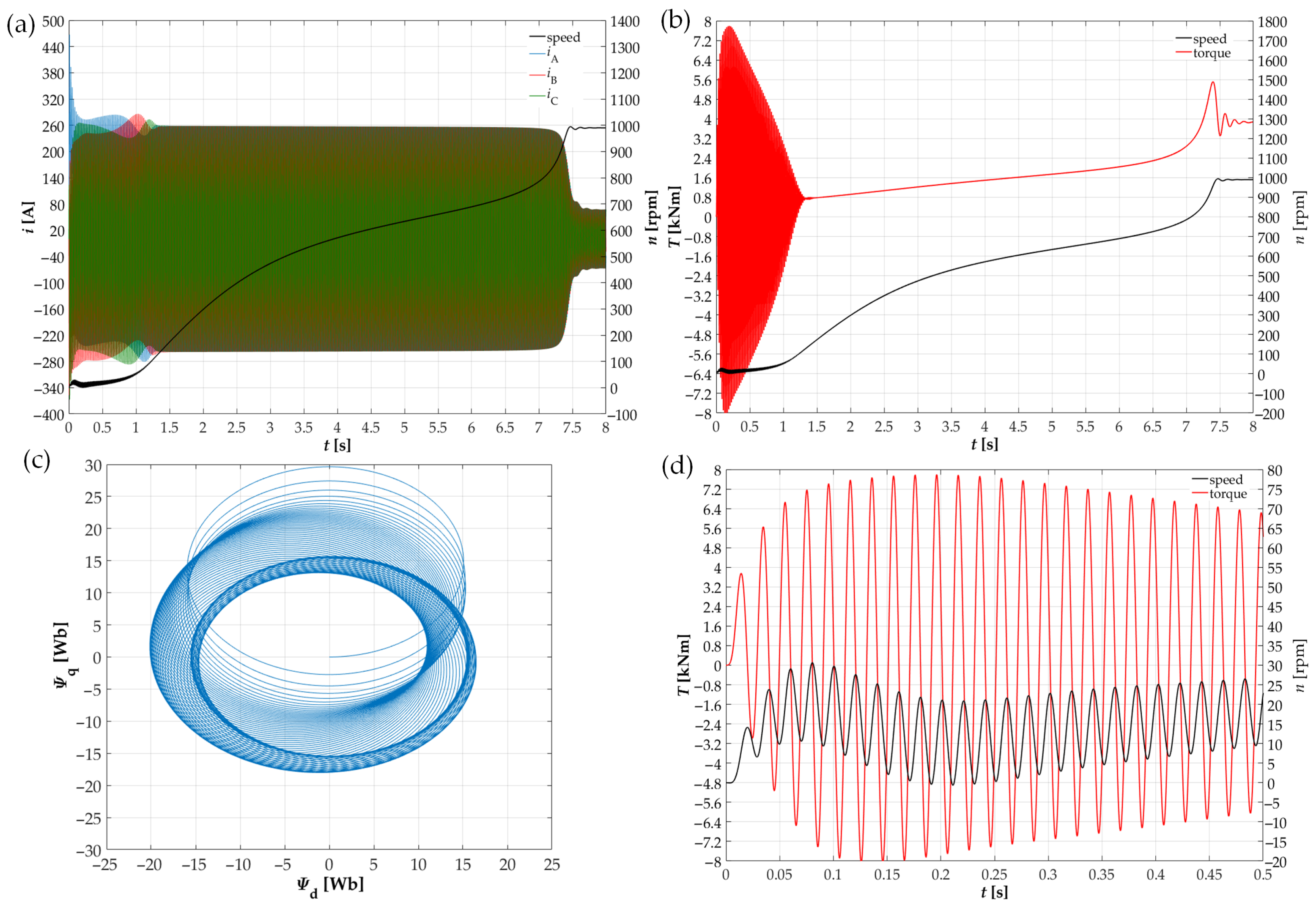

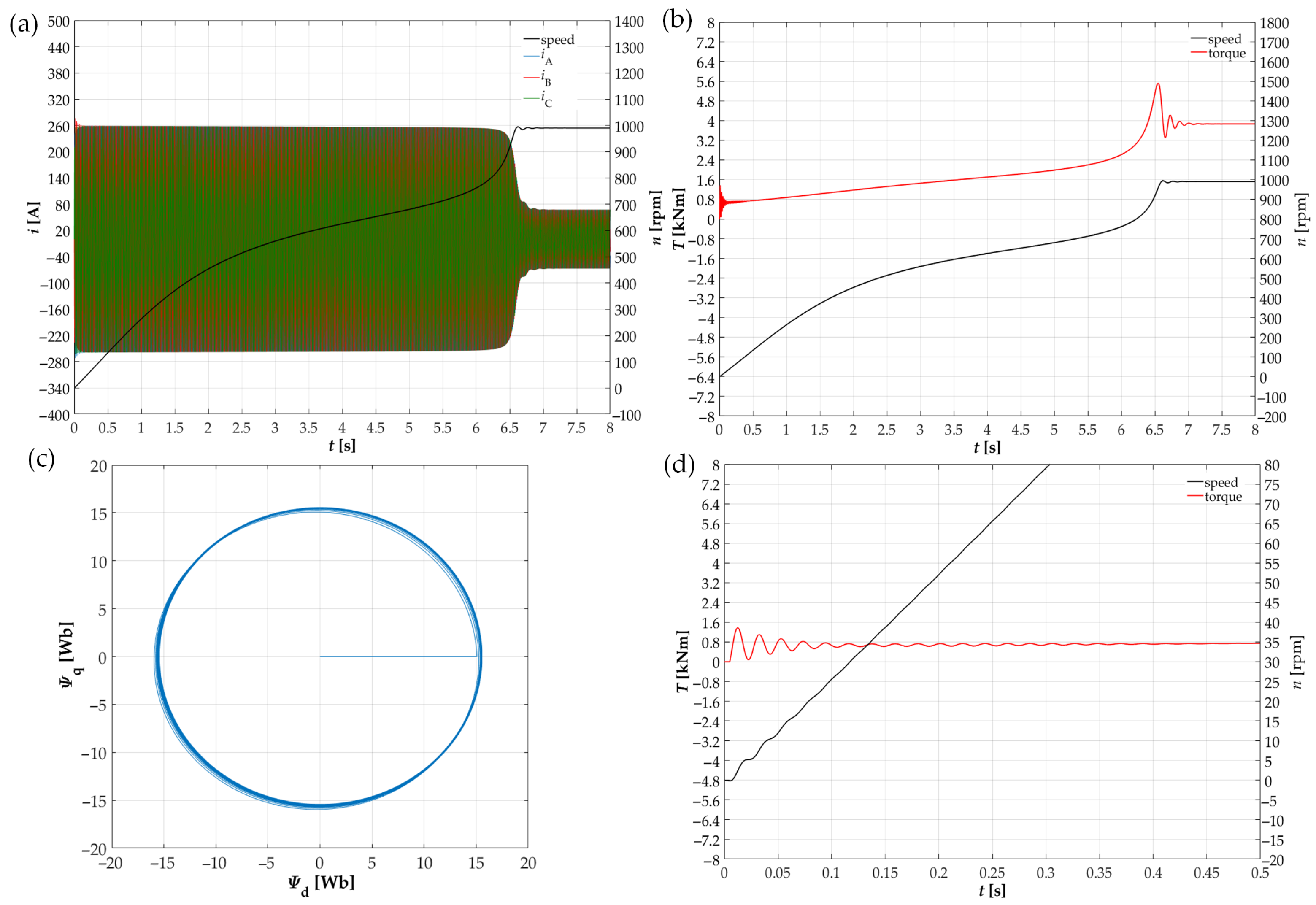

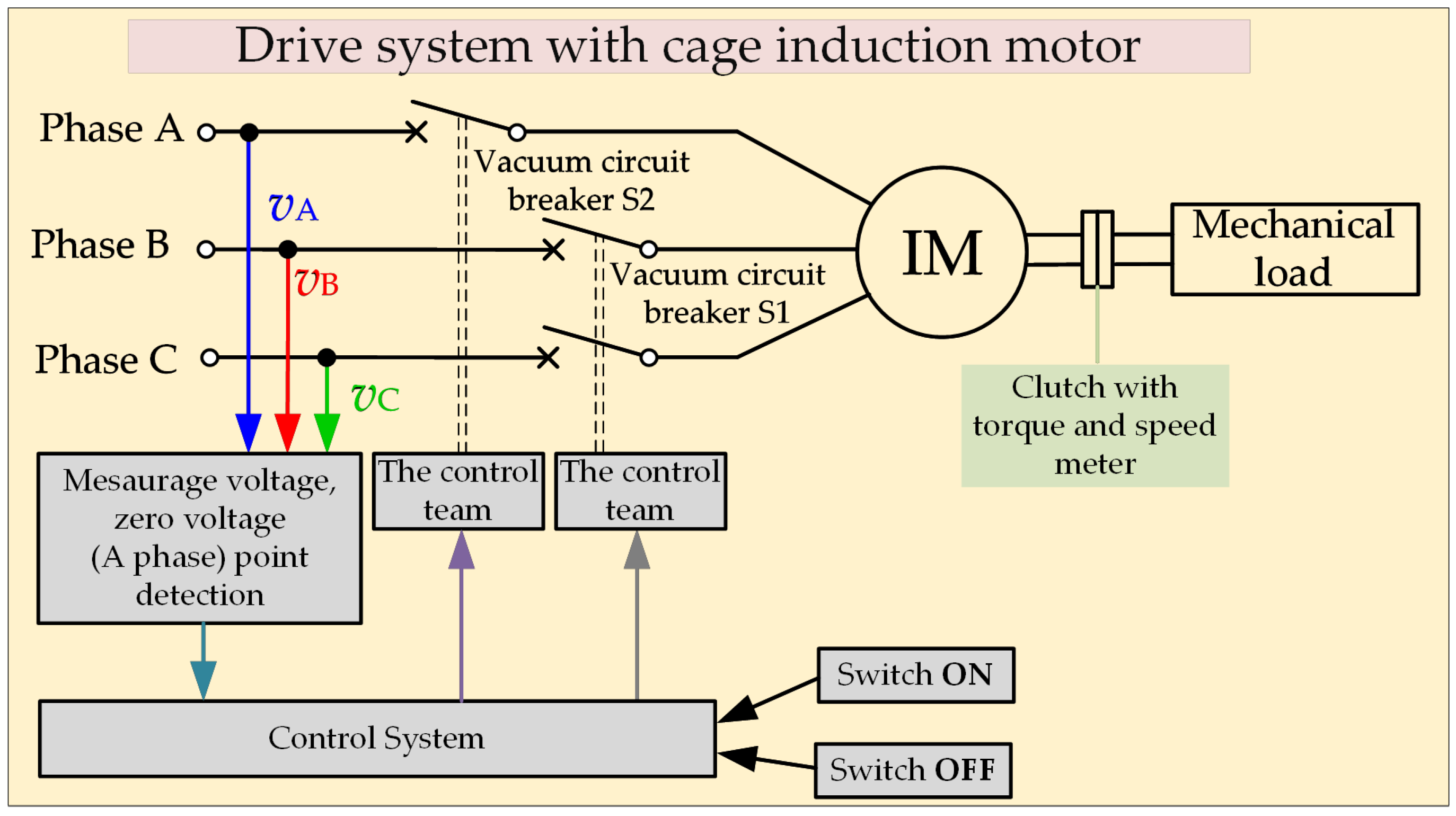

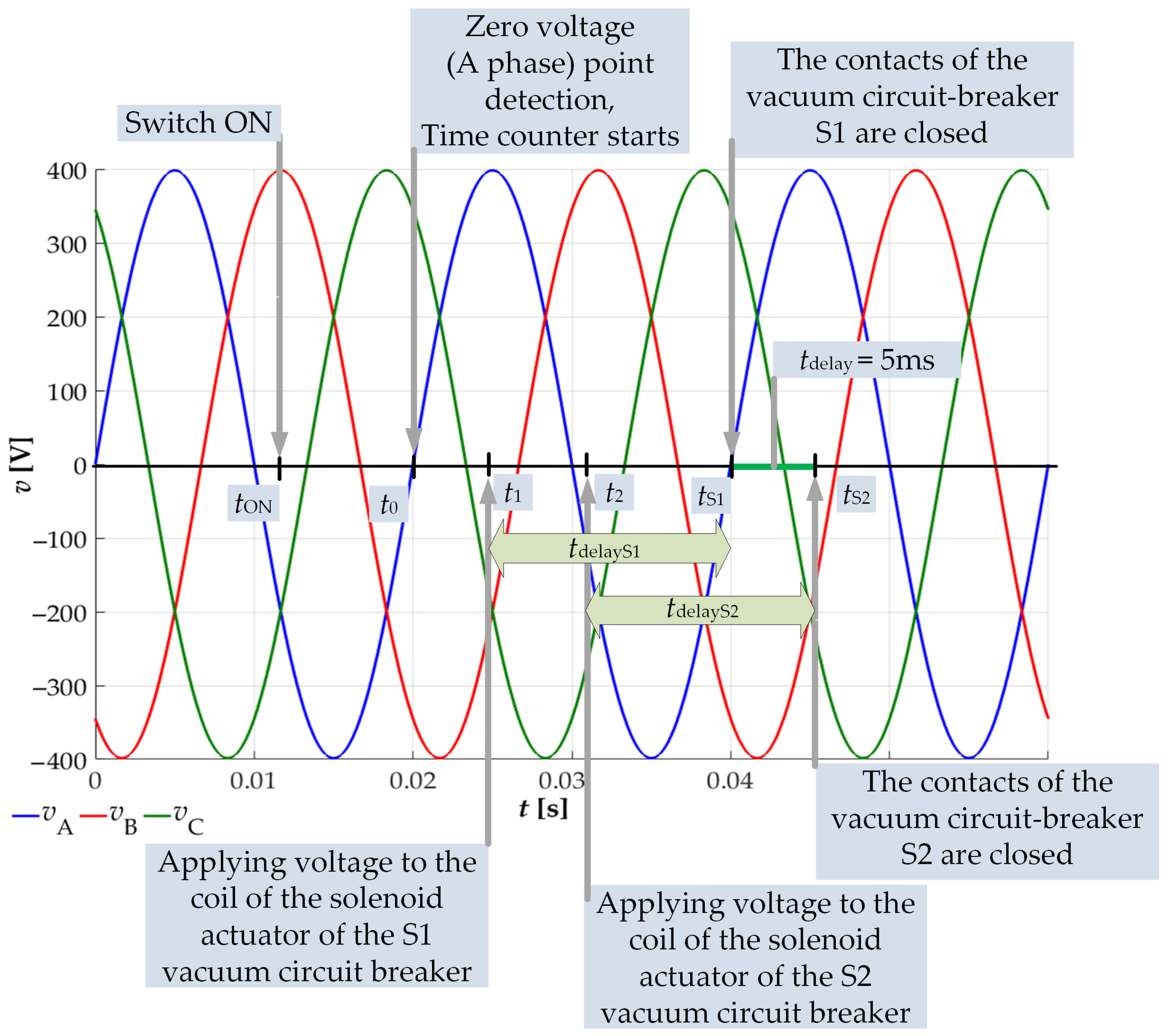

2. The Method of Minimizing the Oscillation of the Electromagnetic Torque of the Motor

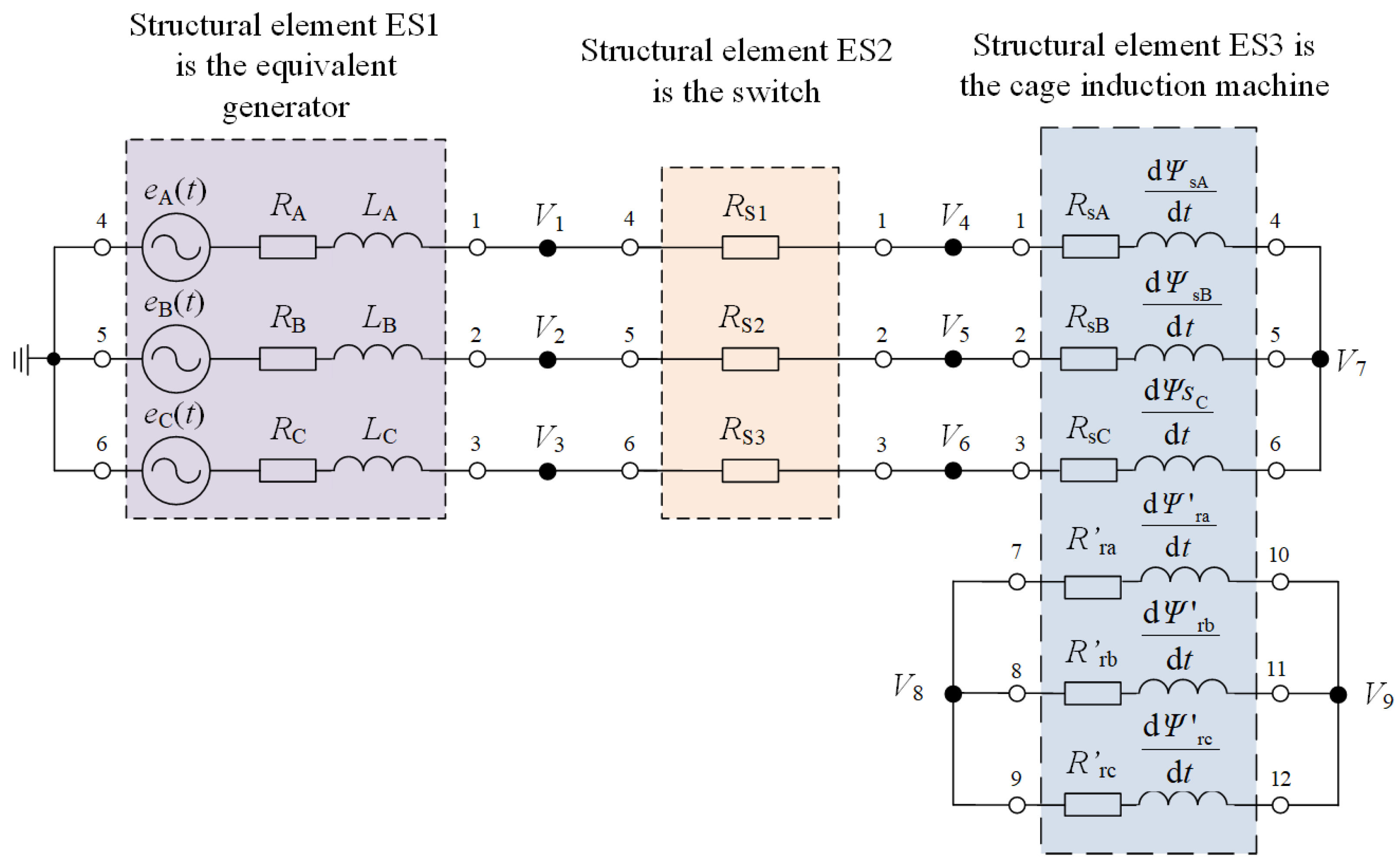

3. Mathematical Model of a Drive System with an Induction Motor

- constant torque with zero value; ,

- lifting torque—resistance torque with a constant value; ,

- fan torque—torque with a curve defined by the formula , where: —resistance torque of the working machine at rated speed ,

- fan torque with initial torque—torque with a curve defined by the formula = , where: —initial resistance torque of the working machine.

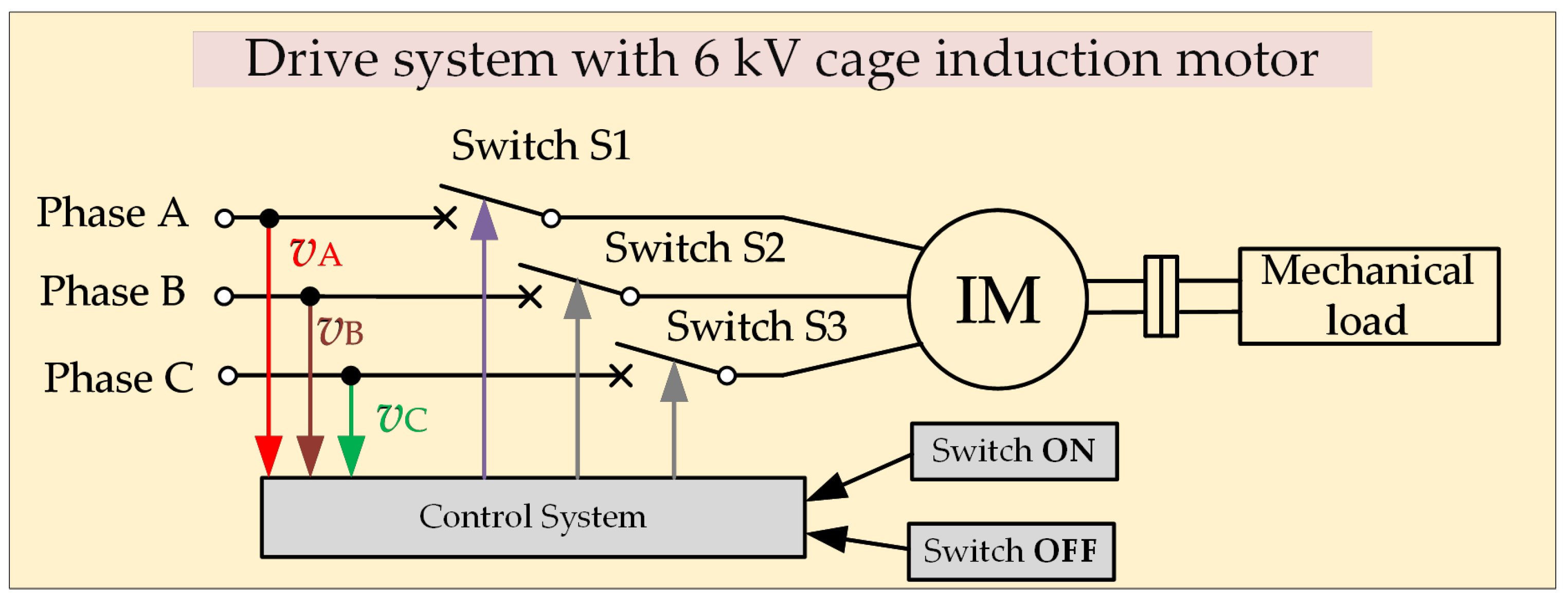

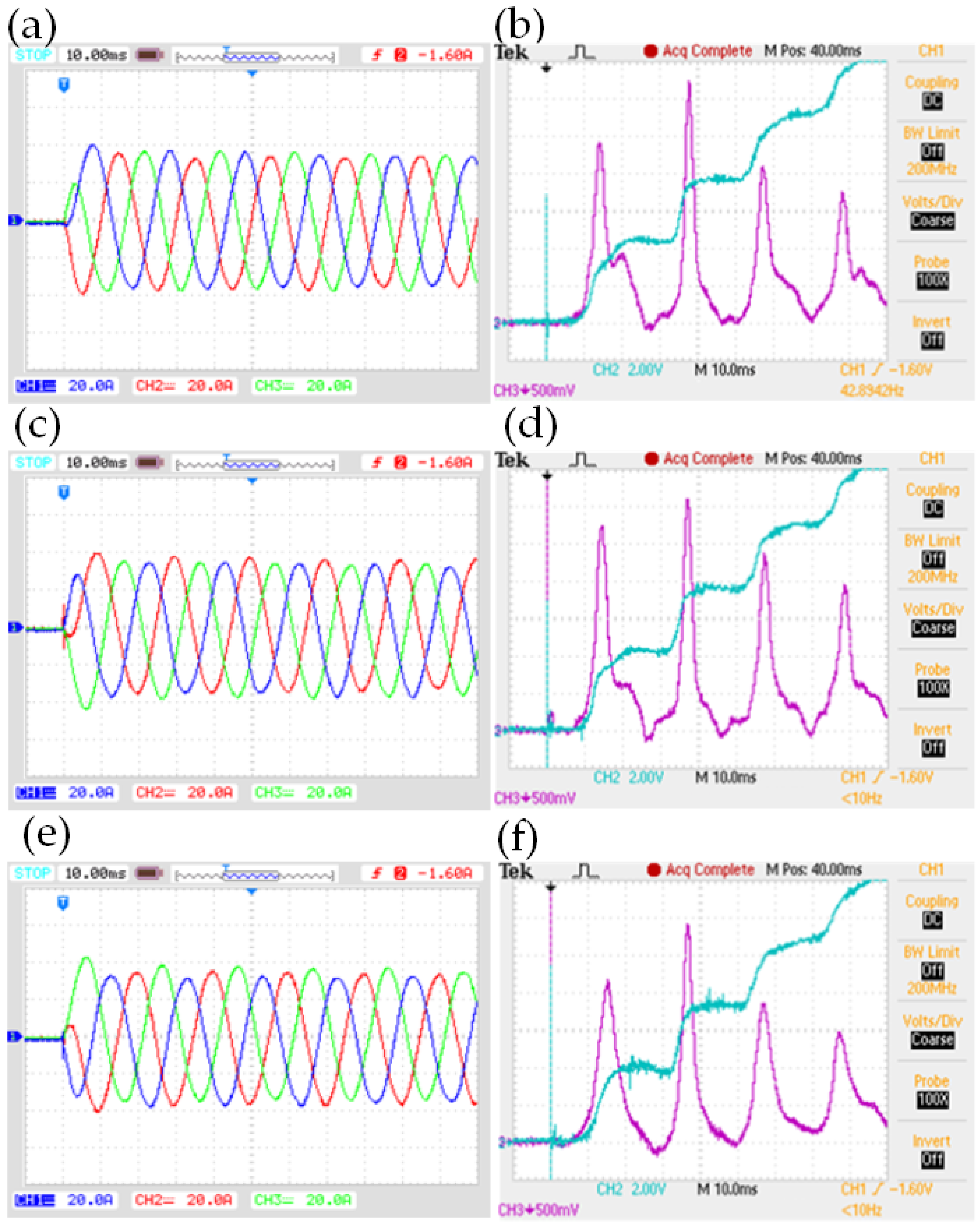

4. Experimental Research

- electrically—the same opening (closing) current impulse coming from the capacitors in the control unit is supplied to all the solenoid drive coils;

- mechanically—the armature of each electromagnetic drive is mechanically connected to the synchronizing shaft running through the entire space of the drive chamber.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| DOL starting | direct on line starting |

Appendix A

| Nominal Data | Parameters of Equivalent Circuits | ||

|---|---|---|---|

| Rated power | 400 kW | Stator resistance | 0.362 |

| Voltage | 6000 V (Y) | Rotor resistance (1) | 0.3645 |

| Frequency | 50 Hz | Mutual inductance | 0.06 H |

| Speed rated | 990 rpm | Stator inductance | 0.0631 H |

| Stator current | 48.4 A | Rotor inductance (1) | 0.0631 H |

| Power factor | 0.84L | ||

| Inertia Moment | 21.8 kg·m2 | ||

| Efficiency | 94.4% | ||

Appendix B

| Nominal Data | |||

|---|---|---|---|

| Rated power | 2.2 kW | Rated voltagee | 400 V |

| Speed rated | 1420 rpm | Frequency | 50 Hz |

| Stator current | 4.2 A | Power factor | 0.81L |

References

- Ludwikowski, Z.; Cieślik, S. Limitation of mechanical vibration during start-up of induction squirrel-cage motors. In Proceedings of the Problems of Automated Electrodrives—Theory and Practice, Charkov, Ukraine, 15–20 September 2003; pp. 189–190. [Google Scholar]

- Ludwikowski, Z.; Cieślik, S. Mathematical modeling of an electric drive with a direct starting induction motor in computer optimization of electromagnetic torque oscillation. In Materiały VIII Konferencji Naukowo-Technicznej pod Patronatem Sekcji Teorii Elektrotechniki Komitetu Elektrotechniki PAN: Zastosowania Komputerów w Elektrotechnice; Institute of Industrial Electrical Engineering, Poznan University of Technology: Poznan, Polnad, 2003; pp. 517–520. (In Polish) [Google Scholar]

- Akbaba, M. A novel simple method for elimination of DOL starting transient torque pulsations of three-phase induction motors. Eng. Sci. Technol. Int. J. 2021, 24, 145–157. [Google Scholar] [CrossRef]

- Nithin, K.S.; Jos, B.M.; Rafeek, M. An Improved Method for Starting of Induction Motor with Reduced Transient Torque Pulsations. Int. J. Adv. Res. Electr. Electron. Instrum. Eng. 2013, 2, 1–9. [Google Scholar]

- Cieślik, S.; Ludwikowski, Z. Start-Up of Induction Motor with Limitation of Starting Electromagnetic Torque Oscillation—Laboratory Research; National Technical University of Kharkiv: Dnieprodierzynsk, Ukraine, 2007; pp. 58–59. [Google Scholar]

- Zenginobuz, G.; Cadirci, I.; Ermis, M.; Barlak, C. Performance Optimization of Induction Motors during Voltage-Controlled Soft Starting. IEEE Trans. Energy Convers. 2004, 19, 278–288. [Google Scholar] [CrossRef]

- Shabestari, P.M.; Mehrizi-Sani, A. Current Limiting and Torque Pulsation Reduction of the Induction Motors. In Proceedings of the 2019 IEEE Power & Energy Society General Meeting (PESGM), Atlanta, GA, USA, 4–8 August 2019. [Google Scholar]

- Cieslik, S.; Ludwikowski, Z. Oscillation Limitation of Electromagnetic Torque of Squirrel-Cage Motor on Starting. Computer Applications in Electrical Engineering; Institute of Industrial Electrical Engineering, Poznan University of Technology: Poznan, Polnad, 2004. [Google Scholar]

- Cieślik, S. Mathematical Modeling and Simulation of Electric Power Systems with Induction Generators; Wydawnictwo Uczelniane Uniwersytetu Technologiczno-Przyrodniczego w Bydgoszczy: Bydgoszcz, Poland, 2008. (In Polish) [Google Scholar]

- Ludwikowski, Z.; Cieslik, S.; Plakhtyna, O. Dynamic properties of the electric drive with an induction motor using start-up with limited oscillation of the electromagnetic torque. In Techniczna Elektrodinamika; Ukrainian National Academy of Sciences: Kijów, Ukraine, 2004; pp. 38–40. [Google Scholar]

- Ludwikowski, Z.; Cieslik, S.; Plakhtyna, O. The analysis a lag of induction motor’s one phase connecting influence on the electromagnetic torque oscillation under starting. In Tieoretyczna Elektrotechnika; Ukrainian National Academy of Sciences: Lwów, Ukraine, 2004; pp. 61–69. [Google Scholar]

- Kłosowski, Z.; Cieślik, S. The Use of a Real-Time Simulator for Analysis of Power Grid Operation States with a Wind Turbine. Energies 2021, 14, 2327. [Google Scholar] [CrossRef]

- Kłosowski, Z.; Cieślik, S. Real-Time Simulation of Power Conversion in Doubly Fed Induction Machine. Energies 2020, 13, 673. [Google Scholar] [CrossRef] [Green Version]

- Cieślik, S. Mathematical Modeling of the Dynamics of Linear Electrical Systems with Parallel Calculations. Energies 2020, 14, 2930. [Google Scholar] [CrossRef]

- Kutsyk, A.; Semeniuk, M.; Korkosz, M.; Podskarbi, G. Diagnosis of the Static Excitation Systems of Synchronous Generators with the Use of Hardware-in-the-Loop Technologies. Energies 2021, 14, 6937. [Google Scholar] [CrossRef]

- Kłosowski, Z.; Plakhtyna, O.; Grugel, P. Applying the method of average voltage on the integration step length for the analysis of electrical circuits. Zesz. Nauk.—Elektrotechnika 2014, 17, 17–31. [Google Scholar]

- Płachtyna, O.; Kłosowski, Z.; Żarnowski, R. Mathematical model of DC drive based on a step-averaged voltage numerical method. Przegląd Elektrotechniczny 2011, 87, 51–56. (In Polish) [Google Scholar]

- Plakhtyna, O.; Kutsyk, A.; Semeniuk, M. Real-Time Models of Electromechanical Power Systems, Based on the Method of Average Voltages in Integration Step and Their Computer Application. Energies 2020, 13, 2263. [Google Scholar] [CrossRef]

- Travida Electric. VACUUM CIRCUIT BREAKERS 15.5—27 KV—Technical Manuals. Available online: https://www.tavrida.com/upload/iblock/747/TES_CBdoc_UG_VCB_1(EN)_1.7.pdf (accessed on 6 June 2022).

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kłosowski, Z.; Fajfer, M.; Ludwikowski, Z. Reduction of the Electromagnetic Torque Oscillation during the Direct on Line (DOL) Starting of a 6 kV Motor by Means of a Controlled Vacuum Circuit-Breaker. Energies 2022, 15, 4246. https://doi.org/10.3390/en15124246

Kłosowski Z, Fajfer M, Ludwikowski Z. Reduction of the Electromagnetic Torque Oscillation during the Direct on Line (DOL) Starting of a 6 kV Motor by Means of a Controlled Vacuum Circuit-Breaker. Energies. 2022; 15(12):4246. https://doi.org/10.3390/en15124246

Chicago/Turabian StyleKłosowski, Zbigniew, Maciej Fajfer, and Zbigniew Ludwikowski. 2022. "Reduction of the Electromagnetic Torque Oscillation during the Direct on Line (DOL) Starting of a 6 kV Motor by Means of a Controlled Vacuum Circuit-Breaker" Energies 15, no. 12: 4246. https://doi.org/10.3390/en15124246

APA StyleKłosowski, Z., Fajfer, M., & Ludwikowski, Z. (2022). Reduction of the Electromagnetic Torque Oscillation during the Direct on Line (DOL) Starting of a 6 kV Motor by Means of a Controlled Vacuum Circuit-Breaker. Energies, 15(12), 4246. https://doi.org/10.3390/en15124246