Adhesive Strength of Modified Cement–Ash Mortars

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

4. Conclusions

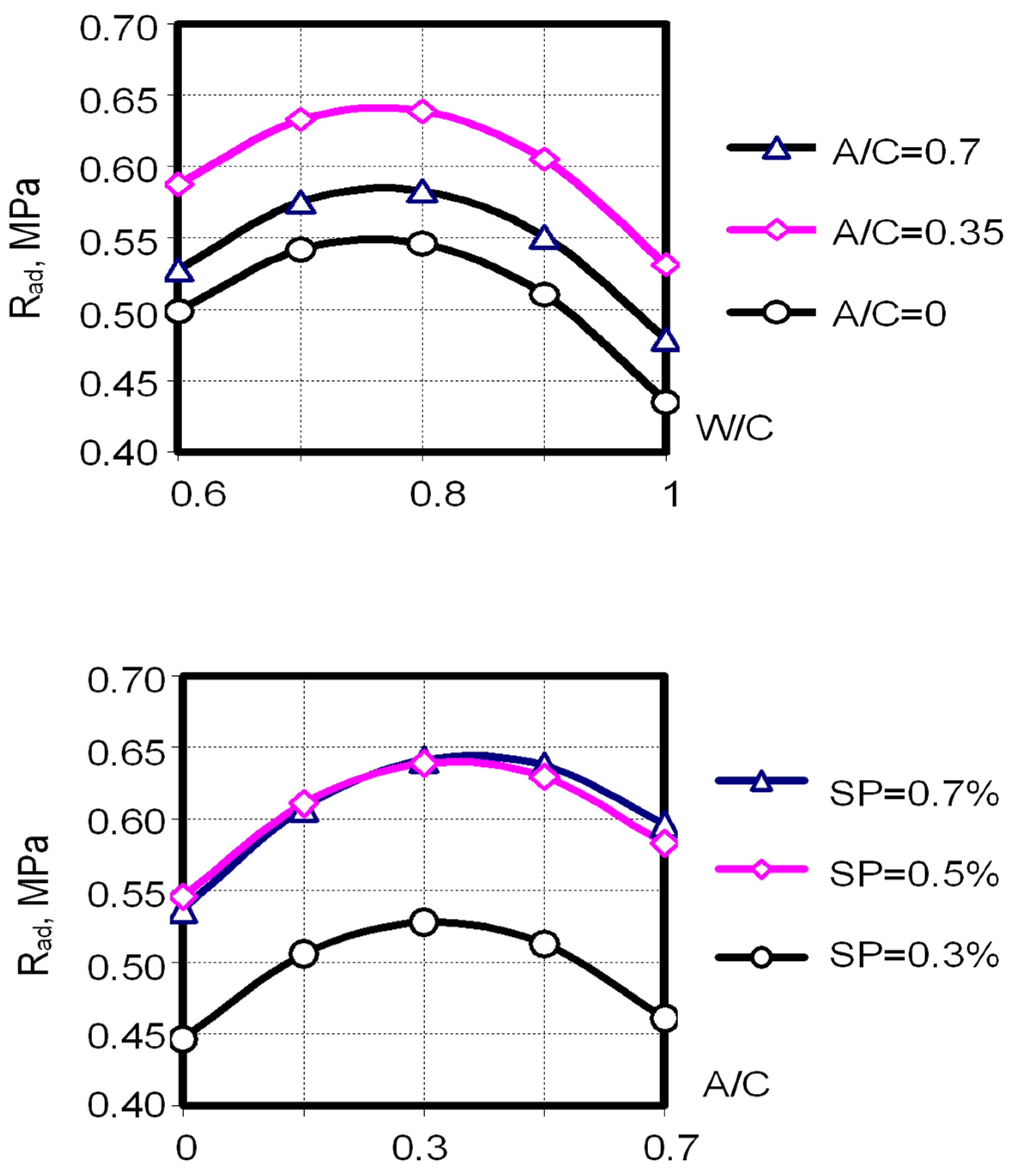

- The effect of the water and ash cement ratios on the adhesive strength of the ash–cement mixtures was studied. A significant decrease in adhesive strength occurred when the W/C ratio exceeded 0.75 and the ash–cement ratio was 0.4.

- The introduction of a superplasticizer additive of the naphthalene-formaldehyde type increased the adhesive strength of the mortar in the studied dose range. An increase in adhesive strength was also observed with the additional introduction of an air-entraining additive up to 0.025 by weight of cement.

- A significant increase in adhesive strength was also observed with the introduction of a complex modifier additive, including a superplasticizer and a water-retention additive Tylose in an amount of up to 0.15% of the mass of cement.

- For cement–ash mortar mixtures, an increase in adhesive strength was characteristic with an increase in the dispersion of ash and in the ratio of cement–ash binder to sand aggregate.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hossain, M.R.; Sultana, R.; Patwary, M.M.; Khunga, N.; Sharma, P.; Shaker, S.J. Self-healing concrete for sustainable buildings. A review. Environ. Chem. Lett. 2022, 20, 1265–1273. [Google Scholar] [CrossRef]

- Aliha, M.R.M.; Karimi, H.R.; Abedi, M. The role of mix design and short glass fiber content on mode-I cracking characteristics of polymer concrete. Constr. Build. Mater. 2022, 317, 126139. [Google Scholar] [CrossRef]

- Salustio, J.; Torres, S.M.; Melo, A.C.; Silva, Â.J.C.E.; Azevedo, A.C.; Tavares, J.C.; Leal, M.S.; Delgado, J.M.P.Q. Mortar Bond Strength: A Brief Literature Review, Tests for Analysis, New Research Needs and Initial Experiments. Materials 2022, 15, 2332. [Google Scholar] [CrossRef] [PubMed]

- Tarque, N.; Pancca-Calsin, E. Building constructions characteristics and mechanical properties of confined masonry walls in San Miguel (Puno-Peru). J. Build. Eng. 2022, 45, 103540. [Google Scholar] [CrossRef]

- Aucouturier, M.; Darque-Ceretti, E. Materials Surface Science Applied to the Investigation of Cultural Heritage Artefacts. Procedia Mater. Sci. 2015, 9, 31–47. [Google Scholar] [CrossRef]

- Karatasios, I.; Amenta, M.; Kilikoglou, V. Hydraulic mortars for joining archaeological stone fragments—A methodological approach. Procedia Struct. Integr. 2018, 10, 211–218. [Google Scholar] [CrossRef]

- Petit, J.Y.; Wirquin, E. Evaluation of various cellulose ethers performance in ceramic tile adhesive mortars. Int. J. Adhes. Adhes. 2013, 40, 202–209. [Google Scholar] [CrossRef]

- Žižlavský, T.; Bayer, P.; Vyšvařil, M. Bond Properties of NHL-Based Mortars with Viscosity-Modifying Water-Retentive Admixtures. Minerals 2021, 11, 685. [Google Scholar] [CrossRef]

- Benjeddou, O.; Alwetaishi, M.; Tounsi, M.; Alyousef, R.; Alabduljabbar, H. Effects of limestone filler fineness on the rheological behavior of cement—Limestone filler grouts. Ain Shams Eng. J. 2021, 12, 3569–3578. [Google Scholar] [CrossRef]

- Nepomuceno, M.C.S.; Bernardo, L.F.A.; Pereira-de-Oliveira, L.A.; Timóteo, R.O. Cement-based grouts for masonry consolidation with high content of limestone filler, metakaolin, glass powder and ceramic waste. Constr. Build. Mater. 2021, 306, 124947. [Google Scholar] [CrossRef]

- Giergiczny, Z. Fly ash and slag. Cem. Concr. Res. 2019, 124, 105826. [Google Scholar] [CrossRef]

- Barnat-Hunek, D.; Grzegorczyk-Frańczak, M.; Klimek, B.; Pavlíková, M.; Pavlík, Z. Properties of multi-layer renders with fly ash and boiler slag admixtures for salt-laden masonry. Constr. Build. Mater. 2021, 278, 122366. [Google Scholar] [CrossRef]

- Choo, H.; Won, J.; Burns, S.E. Thermal conductivity of dry fly ashes with various carbon and biomass contents. Waste Manag. 2021, 135, 122–129. [Google Scholar] [CrossRef] [PubMed]

- Bezborodov, V.A.; Belan, V.I.; Meshkov, P.I. Dry Mixes in Modern Construction, Novosibirsk, Russia, 1998; 94p.

- Karapuzov, E.K.; Lutz, G.; Gerold, H. Dry Building Mixes. K.: “Technique”. 2000; 226p. [Google Scholar]

- Adin, M.S.; Kılıçkap, E. Strength of double-reinforced adhesive joints. Mater. Test. 2021, 63, 176–181. [Google Scholar] [CrossRef]

- Gursel, A.; Mohamad, A.A.; Mohd Nazerib, M.F. Adhesion Mechanism and Failure Modes in Adhesively Bonded Joints. In Proceedings of the International Conference on Material Science and Technology in Kızılcahamam/ANKARA(IMSTEC), Cappadocia, Turkey, 18–20 October 2019; pp. 108–114. [Google Scholar]

- Guo, F.; Pei, J.; Zhang, J.; Xue, B.; Sun, G.; Li, R. Study on the adhesion property between asphalt binder and aggregate: A state-of-the-art review. Constr. Build. Mater. 2020, 256, 119474. [Google Scholar] [CrossRef]

- Myshkin, N.; Kovalev, A. Adhesion and surface forces in polymer tribology—A review. Friction 2018, 6, 143–155. [Google Scholar] [CrossRef]

- Chen, H.; Ling, M.; Hencz, L.; Yeu Ling, H.; Li, G.; Lin, Z.; Liu, G.; Zhang, S. Exploring Chemical, Mechanical, and Electrical Functionalities of Binders for Advanced Energy-Storage Devices. Chem. Rev. 2018, 118, 8936–8982. [Google Scholar] [CrossRef]

- Solomatov, V.I. Ways of Activation of Fillers of Composite Building Materials. Solomatov, V.I., Dvorkin, L.I., Chudnovsky, S.M., Eds.; Izv. Universities: Construction and Architecture, 1987; Volume N1, 60–63. [Google Scholar]

- Kulesza, M.; Debski, D.; Michalak, S. Effect of re-dispersible polymer powder on selected mechanical properties of thin-bed cementations mortars. Cem. Wapno. Beton 2020, 25, 168–177. [Google Scholar] [CrossRef]

- Dvorkin, L.I.; Solomatov, V.I.; Vyrovoy, V.N.; Chudnovsky, S.M. Cement Concrete with Mineral Fillers; Budivelnik: Kyiv, Ukraine, 1991; 136p. [Google Scholar]

- Jahani, Y.; Baena, M.; Barris, C.; Perera, R.; Torres, L. Influence of curing, post-curing and testing temperatures on mechanical properties of a structural adhesive. Constr. Build. Mater. 2022, 324, 126698. [Google Scholar] [CrossRef]

- Petit, J.Y.; Comelli, B.; Perrin, R.; Wirquin, E. Effect of formulation parameter on adhesive properties of ANSI 118-15 and 118-1. Int. Adhes. 2016, 66, 73–80. [Google Scholar] [CrossRef]

- Phoo-ngernkham, T.; Hanjitsuwan, S.; Li, L.Y.; Damrongwiriyanupap, N.; Chindaprasirt, P. Adhesion characterisation of Portland cement concrete and alkali-activated binders. Adv. Cem. Res. 2019, 31, 69–79. [Google Scholar] [CrossRef] [Green Version]

- Rebinder, P.A. Physical and Chemical Mechanics of Disperse Systems. M.: Nauka. 1966; 400p. [Google Scholar]

- Wang, C.P.; Chuang, Y.C.; Lin, J.Y. Evaluation on feasibility of fly ash cement mortar as adhesive of post-installed rebar. IOP Conf. Ser. Mater. Sci. Eng. 2019, 615, 012021. [Google Scholar] [CrossRef]

- Wieczorek, M. The effect of fly ash and granulated blast furnace slag on slip and tensile adhesion strength of tile adhesives mortars. MATEC Web Conf. 2020, 322, 01017. [Google Scholar] [CrossRef]

- Dvorkin, L.; Dvorkin, O.; Ribakov, Y. Mathematical Experiments Planning in Concrete Technology; Nova Science Publishers: New York, NY, USA, 2012; 172p. [Google Scholar]

- Stolz, C.M. Influence of the Interaction between the Rheological Parameters of Mortars and the Potential Area of Contact of Substrates in the Adhesion of Coating Mortars. Master’s Thesis, Federal University of Rio Grande do Sul, Porto Alegre, Brazil, 2011. [Google Scholar]

- Melo, A.C.; Silva, A.; Torres, S.; Delgado, J.; Azevado, A. Influences of the contact area in the adherence of mortar—Ceramic tiles interface. Constr. Build. Mater. 2020, 243, 118274. [Google Scholar] [CrossRef]

- Solomatov, V.I. Polymer-Cement Concretes and Plastbetons. M.: Stroyizdat. 1967; 184p. Available online: https://www.cia.gov/readingroom/document/cia-rdp86-00513r001652220011-1(accessed on 26 April 2022).

- Santos, D.P.; Azevedo, A.R.G.; Alexandre, J.; Monteiro, S.N.; Xavier, G.C.; Mendes, B.C.; Pedroti, L.G. Evaluation of the Properties of the Adhesive Mortar in the Fresh State with Addition of Glass Waste. In Characterization of Minerals, Metals, and Materials 2017; The Minerals, Metals & Materials Series; Springer: Cham, Switzerland, 2017. [Google Scholar] [CrossRef]

- Barnat-Hunek, D.; Siddique, R.; Łagód, G. Properties of hydrophobised lightweight mortars with expanded cork. Constr. Build. Mater. 2017, 155, 15–25. [Google Scholar] [CrossRef]

| Name of Indicator | Value for Class, MPa | ||

|---|---|---|---|

| C0 | C1 | C2 | |

| Strength of the adhesive bond after exposure to an air-dry environment for 28 days | ≥0.5 | ≥0.5 | ≥1.0 |

| Strength of the adhesive bond after exposure to the aquatic environment | - | ≥0.5 | ≥1.0 |

| Adhesive bond strength after exposure to high temperatures | - | ≥0.5 | ≥1.0 |

| Adhesive strength after cyclic freezing and thawing | - | ≥0.5 | ≥1.0 |

| Name Material | Oxide Content, % | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| L.O.I. | SiO2 | Al2O3 | Fe2O3 | CaO | MgO | SO3 | K2O | Na2O | CaOfree | |

| Clinker | - | 21.80 | 5.32 | 4.11 | 66.80 | 0.95 | 0.63 | 0.54 | 0.42 | - |

| Fly ash | 5.1 | 84.5 | 2.1 | 2.0 | 2.3 | 1.2 | 2.5 | |||

| Indicators | Portland Cement | Unground Ash | Ground Ash |

|---|---|---|---|

| Specific surface, m2/kg | 350 | 290 | 455 |

| Fraction content, µm, % | |||

| up to 20 | - | 17.8 | 29.7 |

| 20–40 | - | 35.9 | 40.25 |

| 40–80 | - | 32.6 | 27.3 |

| >80 | 8 | 13.7 | 2.75 |

| Normal consistence, % | 25.2 | 26.0 | 28.5 |

| Absorption activity CaO, mg/g | - | 36.3 | 52.1 |

| Compressive strength, MPa in 28 days | 53.4 | - | - |

| Technological Factors | Levels of Variation | |||

|---|---|---|---|---|

| Natural view | coded view | −1 | 0 | +1 |

| Water–cement ratio (W/C) | X1 | 0.6 | 0.8 | 1.0 |

| Ash–cement ratio (A/C) | X2 | 0 | 0.35 | 0.7 |

| The content of the superplasticizer, % of the mass of cement | X3 | 0 | 0.35 | 0.7 |

| The content of the air-entraining additive (Airad), % of the mass of cement | X4(I) | 0 | 0.025 | 0.05 |

| The content of the water-retaining additive Tylose (EC), % of the mass of cement | X4(II) | 0 | 0.15 | 0.3 |

| Test No. | Factors | Polyfunctional Modifier PFM1 (SP + Airad) | Polyfunctional Modifier PFM2 (SP + EC) | |||||

|---|---|---|---|---|---|---|---|---|

| X1 | X2 | X3 | X4 | Rad,7, MPa | Rad,28, MPa | Rad,7, MPa | Rad,28, MPa | |

| 1 | +1 | +1 | +1 | +1 | 0.22 | 0.41 | 0.28 | 0.54 |

| 2 | +1 | +1 | +1 | −1 | 0.18 | 0.35 | 0.21 | 0.42 |

| 3 | +1 | +1 | −1 | +1 | 0.15 | 035 | 0.21 | 0.38 |

| 4 | +1 | +1 | −1 | −1 | 0.11 | 0.29 | 0.14 | 0.27 |

| 5 | +1 | −1 | +1 | +1 | 0.23 | 0.38 | 0.27 | 0.46 |

| 6 | +1 | −1 | +1 | −1 | 0.19 | 0.32 | 0.19 | 0.33 |

| 7 | +1 | −1 | −1 | +1 | 0.16 | 0.37 | 0.19 | 0.36 |

| 8 | +1 | −1 | −1 | −1 | 0.12 | 0.31 | 0.12 | 0.25 |

| 9 | −1 | +1 | +1 | +1 | 0.28 | 0.45 | 0.33 | 0.58 |

| 10 | −1 | +1 | +1 | −1 | 0.25 | 0.41 | 0.26 | 0.48 |

| 11 | −1 | +1 | −1 | +1 | 0.21 | 0.39 | 0.26 | 0.42 |

| 12 | −1 | +1 | −1 | −1 | 0.18 | 0.35 | 0.20 | 0.33 |

| 13 | −1 | −1 | +1 | +1 | 0.27 | 0.44 | 0.32 | 0.52 |

| 14 | −1 | −1 | +1 | −1 | 0.24 | 0.39 | 0.25 | 0.42 |

| 15 | −1 | −1 | −1 | +1 | 0.20 | 0.42 | 0.24 | 0.42 |

| 16 | −1 | −1 | −1 | −1 | 0.17 | 0.38 | 0.18 | 0.34 |

| 17 | +1 | 0 | 0 | 0 | 0.28 | 053 | 0.31 | 0.58 |

| 18 | −1 | 0 | 0 | 0 | 0.34 | 0.59 | 0.36 | 0.64 |

| 19 | 0 | +1 | 0 | 0 | 0.31 | 0.57 | 0.36 | 0.66 |

| 20 | 0 | -I | 0 | 0 | 0.31 | 0.57 | 0.34 | 0.62 |

| 21 | 0 | 0 | +1 | 0 | 0.37 | 0.60 | 0.41 | 0.70 |

| 22 | 0 | 0 | −1 | 0 | 0.30 | 0.57 | 0.33 | 0.58 |

| 23 | 0 | 0 | 0 | +1 | 0.33 | 0.61 | 0.38 | 0.69 |

| 24 | 0 | 0 | 0 | −1 | 0.29 | 0.56 | 0.32 | 0.59 |

| Additive | Mathematical Models of Adhesive Strength | |

|---|---|---|

| Polyfunctional modifier PFM1 (SP + Airad) | Rad,7 = 0.356 − 0.028Х1 + 0.035Х3 + 0.017Х4 − 0.0459Х − 0.0459Х − 0.0209Х − 0.0459Х − 0.004Х1Х2 | (3) |

| Rаd,28 = 0.639 − 0.028Х1 + 0.018Х2 + 0.057Х3 + 0.026Х4 − 0.0792Х − 0.074Х − 0.0542Х − 0.0542Х + 0.004Х1Х2 + 0.004Х1Х4 + 0.011Х2Х3 | (4) | |

| Polyfunctional modifier PFM2 (SP + EC) | Rаd,7 = 0.392 − 0.027Х1 + 0.007Х2 + 0.036Х3 + 0.034Х4 − 0.0574Х − 0.0424Х − 0.0224Х − 0.0424Х + 0.002Х1Х4 + 0.002Х3Х4 | (5) |

| Rаd,28 = 0.706 − 0.030Х1 + 0.021Х2 + 0.060Х3 + 0.052Х4 − 0.097Х − 0.067Х − 0.067Х − 0.067Х + 0.006X1X2 + 0.006X1X4 + 0.016X2X3 + 0.003X3X4 | (6) |

| (Cement + Ash)/Sand (C + A)/S | Specific Surface Ss, m2/kg | Adhesion Strength, MPa, Aged | |

|---|---|---|---|

| 7 Days | 28 Days | ||

| Modifier PFM1 (W/C = 0.8; A/C = 0.6; SP = 0.5%; Airad = 0.03%) | |||

| 1:3 | 290 | 0.34 | 0.60 |

| 340 | 0.38 | 0.66 | |

| 390 | 0.43 | 0.71 | |

| 1:4.5 | 290 | 0.28 | 0.53 |

| 340 | 0.32 | 0.57 | |

| 390 | 0.35 | 0.62 | |

| Modifier PFM2 (W/C = 0.8; A/C = 0.6; SP = 0.5%; EC = 0.3%) | |||

| 1:3 | 290 | 0.38 | 0.64 |

| 340 | 0.42 | 0.69 | |

| 390 | 0.45 | 0.73 | |

| 1:4.5 | 290 | 0.29 | 0.55 |

| 340 | 0.31 | 0.59 | |

| 390 | 0.33 | 0.62 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dvorkin, L.; Duży, P.; Brudny, K.; Choińska, M.; Korniejenko, K. Adhesive Strength of Modified Cement–Ash Mortars. Energies 2022, 15, 4229. https://doi.org/10.3390/en15124229

Dvorkin L, Duży P, Brudny K, Choińska M, Korniejenko K. Adhesive Strength of Modified Cement–Ash Mortars. Energies. 2022; 15(12):4229. https://doi.org/10.3390/en15124229

Chicago/Turabian StyleDvorkin, Leonid, Patrycja Duży, Karolina Brudny, Marta Choińska, and Kinga Korniejenko. 2022. "Adhesive Strength of Modified Cement–Ash Mortars" Energies 15, no. 12: 4229. https://doi.org/10.3390/en15124229

APA StyleDvorkin, L., Duży, P., Brudny, K., Choińska, M., & Korniejenko, K. (2022). Adhesive Strength of Modified Cement–Ash Mortars. Energies, 15(12), 4229. https://doi.org/10.3390/en15124229