Research on Calculation Method for Discharge Capacity of Draining Well in Tailing Ponds Based on “Simplification-Fitting” Method

Abstract

:1. Introduction

Theoretical Calculation Formulas

- Hi—Discharging water head calculated at the working window fully submerged on the ith floor, m;

- H0—Discharging water head at the working window not submerged on the ith floor, m;

- H—Water head calculated, the difference between the water level in the pond and the elevation of the inlet section center of the draining pipe, m;

- Hz—Water head calculated, the difference between the water level in the pond and the elevation of downstream outlet section center of the draining pipe, or the height difference between the water level in the pond and the level of tail water when there is water downstream, m:

- —The area of one draining window, m2;

- —Flow shrinkage area at the wellhead, m2, ;

- —The total window area within the water depth range, m2;

- —Cross-section area of draining well shaft, m2;

- —Total window area of draining well, m2;

- —External surface area of draining well shaft, m2;

- —Water flow shrinkage area at draining pipe inlet, m2, Fs = εbFe;

- —Sectional area of draining pipe inlet, m2;

- —Sectional area of downstream outlet of draining pipe, m2;

- —Sectional area of calculating pipe segment of draining pipe, m2;

- —Local head loss coefficient of draining pipeline, including angle, bifurcation, section change, etc., which can be obtained by referring to relevant tables;

- —Coefficient, related to the shape of gate pier head;

- —Local head loss coefficient of draining window, ;

- —Local head loss coefficient of draining pipe inlet, rectangular entrance = 0.5, fillet angular or oblique angular entrance = 0.2~0.25, flare opening entrance = 0.1~0.2;

- —Local head loss coefficient of water diversion in a draining well;

- —Lateral contraction coefficient, ;

- —Sectional sudden contraction coefficient;

- —Inner diameter of draining well, m, but if the well shape is not circular, ;

- —Inner diameter of calculating pipe segment, m, but if the pipe is not circular, ;

- —The calculated length of the pipe segment of draining pipe (when there is no change in the cross section, the length is the full length of pipeline), m;

- —Coefficient, obtained with reference to relevant tables and based on ;

- —Hydraulic radius of calculating pipe segment of draining pipe, m;

- —Hydraulic radius of shaft section of drainage well, m;

- —Draining well diameter, m;

- —Width of one draining window, m;

- —Number of draining windows on the same cross-section;

- —Frictional head loss coefficient of draining well, ;

- —Frictional head loss coefficient of draining window, ;

- C—Chezy coefficient, with reference to relevant documents and according to and R; —Pipe wall roughness coefficient;

- (1)

- In the free discharge stage, as the water level increases, there will be three combined flow regimes—the weir flow, the orifice flow, and the weir flow + orifice flow. These correspond to the water levels within the elevation range of the first window, between two layers of windows, and within the elevation ranges of windows other than the first window. Therefore, the relationship between the water level and window position should be judged whenever necessary in the calculation. The discharge capacity under three flow regimes can be obtained by choosing and combining reasonable formulas, thus resulting in a complicated calculation process.

- (2)

- There are many parameters, iterations among parameters and applications in this method, and the water level is also closely involved. Furthermore, fluctuations in water level result in constant changes in calculation parameters.

- (3)

- The empirical formula method has to locate the intersection point among the free flow curve, the half-pressure flow curve, and the pressure flow curve, and choose the discharge capacity calculation formula according to the relative position relationship between the actual water level and the intersection point. This requirement will bring about logical difficulties in algorithm integration.

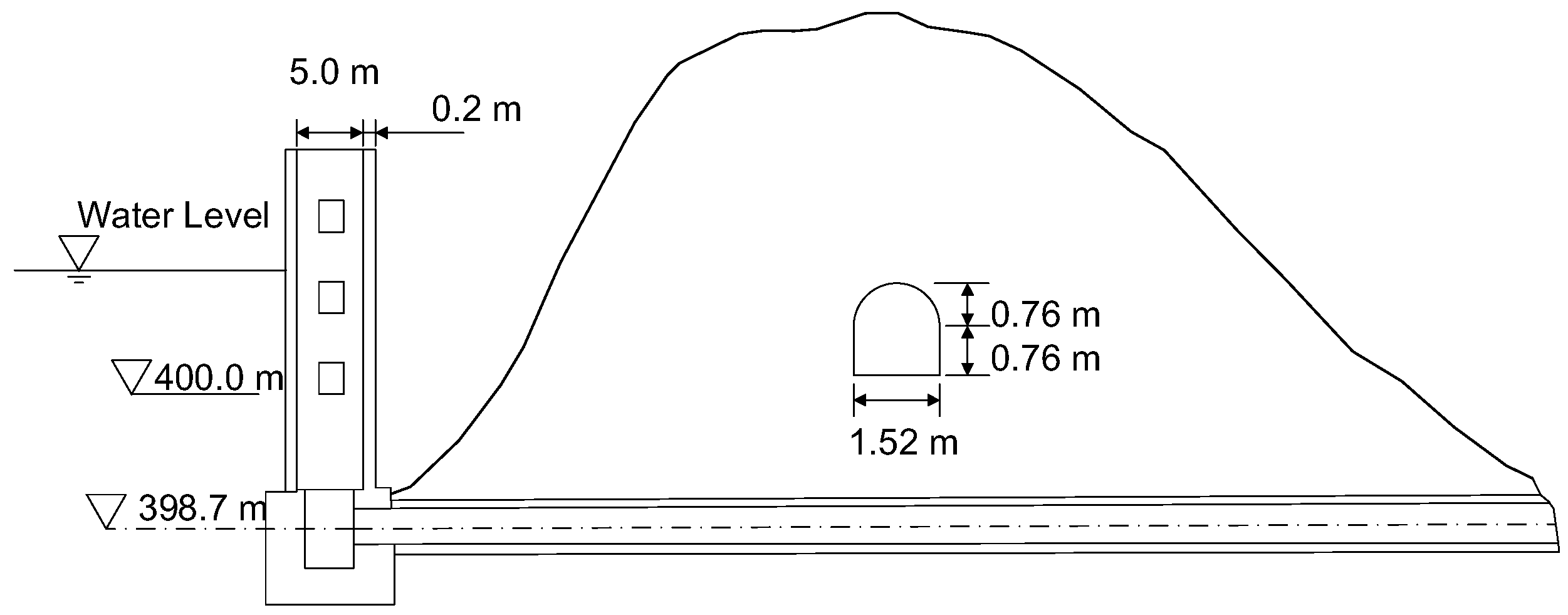

2. Physical Model

3. Method

- Step 1. The coordinates of discrete points for the simplified algorithm were obtained according to the dimension parameters of the window-type draining well input, including the window number on the same longitudinal section nz, the window height hc (or inner diameter Dc), the inlet elevation zj, etc.

- 2.

- Step 2. The free flow curve was calculated by the simplified algorithm according to the dimension parameters of a window-type draining well, such as the window number on the same cross-section nc, the window width bc (or window diameter Dc), and the draining well thickness δ. The simplified algorithm was shown as follows:

- 3.

- Step 3. According to the design characteristics of the flood-discharging system of tailing ponds, the parameters in empirical Formula (2) were simplified to determine the simplified calculation formula for half-pressure flow and the discharging curve under half-pressure flow according to the simplified algorithm. The simplification process of parameters is shown as follows:

- ➀

- Simplification Process for Submerged Window Area

- ➁

- Simplification process for parameters and . Parameters and can be determined when is determined.

- ➂

- Simplification process for parameter . The downstream outlet section of the draining pipe in a tailing pond is generally consistent with the designed shape of calculating a pipe segment of draining pipe, so the parameter is in the simplified algorithm.

- ➃

- Simplification process for parameter and . Since the draining pipe inlet is generally perpendicular to the draining well in a tailing pond, in the simplified algorithm for discharge capacity, the local head loss coefficient of the draining pipe inlet is =0.5 and the local loss coefficient of water diversion is =1.1.

- ➄

- Simplification process for parameter . Since the height of the draining well in tailing ponds is limited, and the well surface is smooth due to long-term exposure to water, the frictional head loss coefficient of the draining well in the simplified algorithm is 0.

- ➅

- Simplification process for parameter . There is no contraction section at the inlet section of draining pipe in tailing ponds, so the sectional contraction coefficient is 1.0.

- 4.

- Step 4. According to the design characteristics of the flood-discharging system of tailing ponds, the parameters in empirical Formula (3) were simplified to work out the simplified calculation formula for pressure flow and the discharging curve under pressure flow according to the simplified algorithm.

- 5.

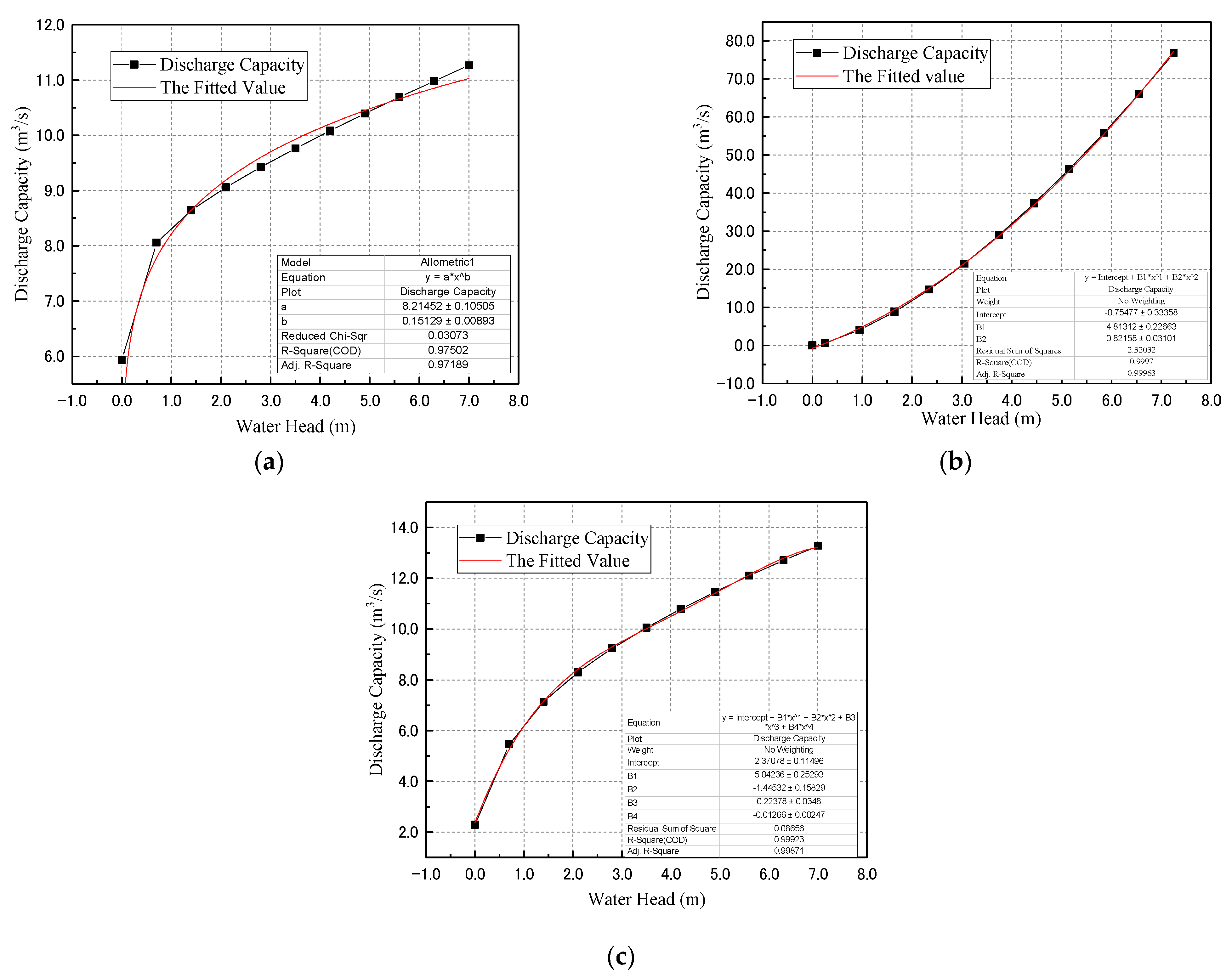

- Step 5. The curve of the final discharge capacity within the well height was calculated and fitted to a function. The method to determine the final discharge curve is as follows:

- 6.

- Step 6. Judgment of discharge curve convergence beyond well height.

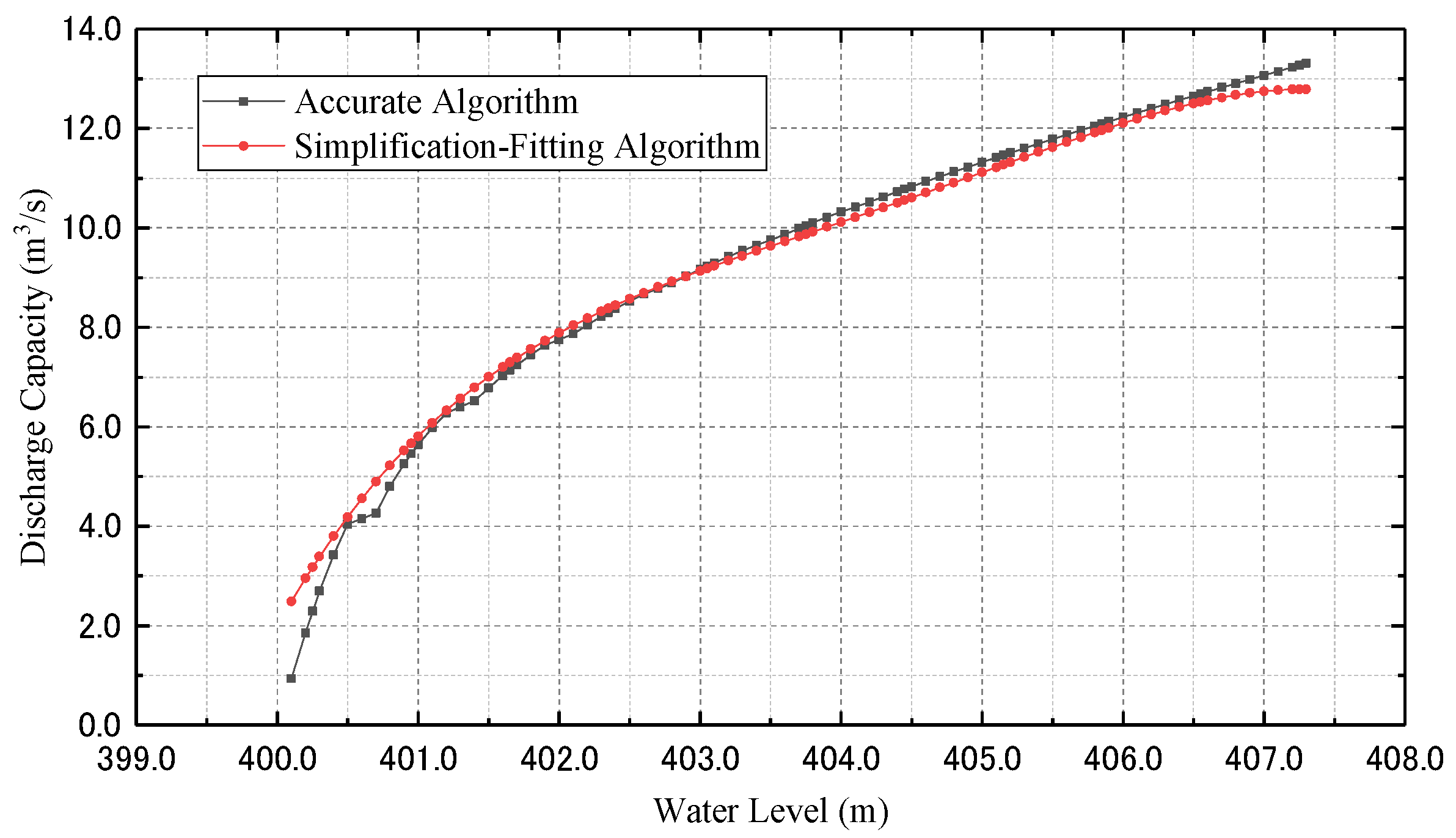

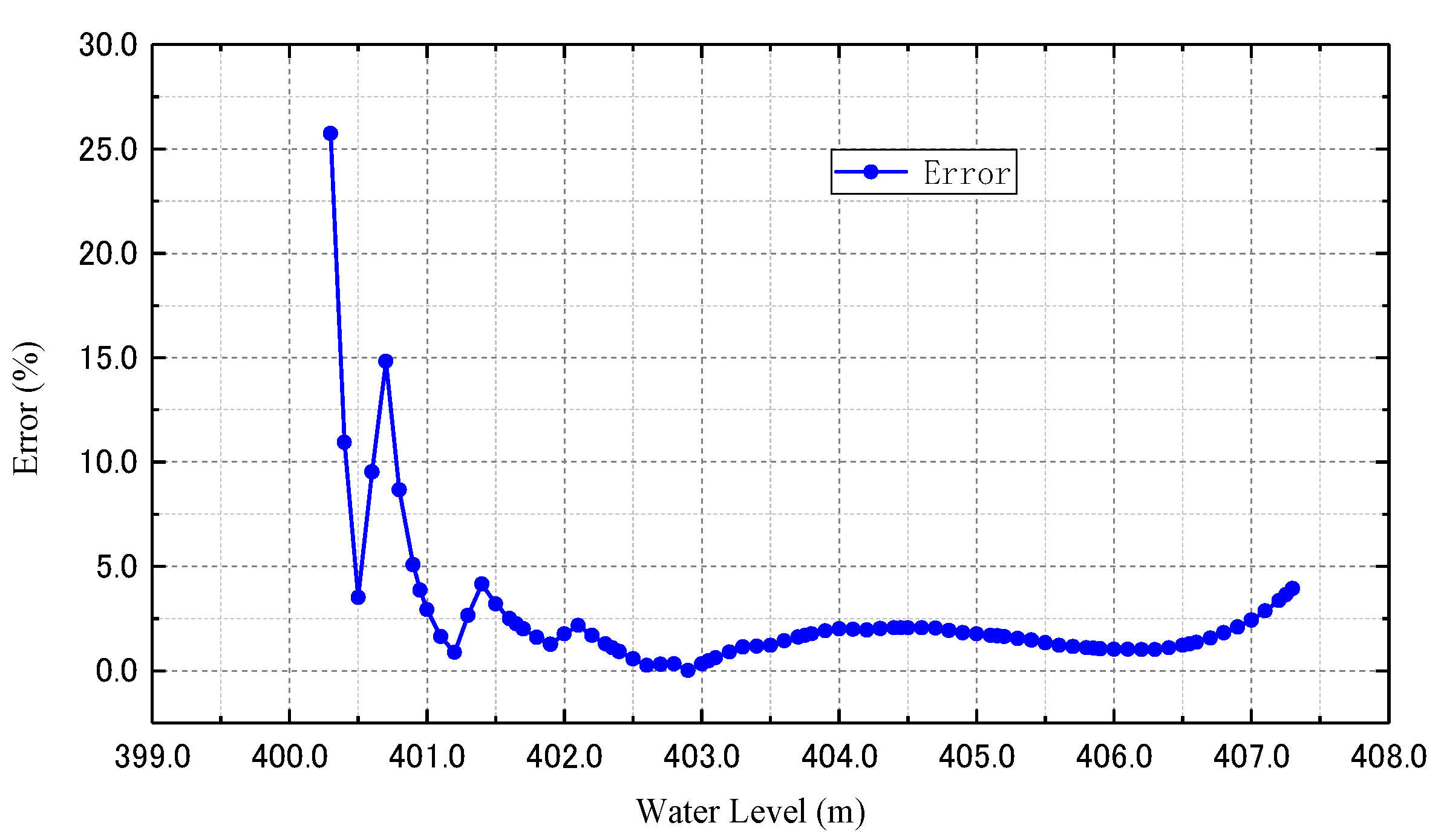

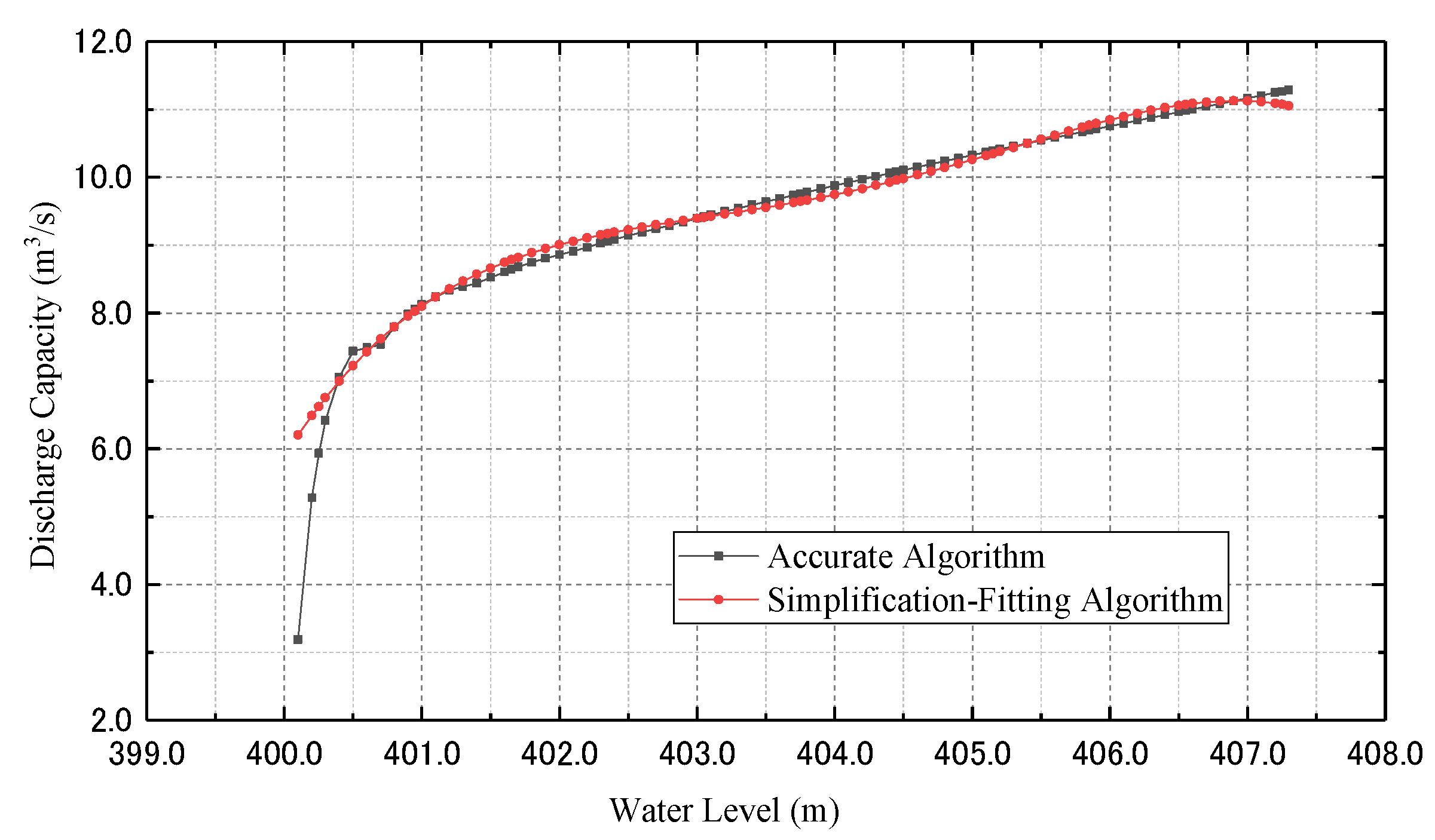

4. Results and Discussion

5. Conclusions

- The “simplification-fitting” algorithm, together with the mathematical fitting method introduced, facilitated the expression of calculation formula for discharge capacity;

- The mathematical relationship existing in the discharge capacity between windows was deduced, thus the discharge capacity at the rest of the discrete points can be directly deduced once the discharge capacity at the first discrete point is known, and the calculation step of orifice flow can be omitted;

- Due to the unique discrete method concerning the water level, the parameters related to the water level in empirical calculation formulas under half-pressure flow and pressure flow were simplified;

- The final discharge capacity curve adopted the minimum value among the free flow, half-pressure flow and pressure flow on each water level step and thus avoided the difficulty in calculating the intersection point among the three discharge capacity curves;

- The average error in the “simplification-fitting” algorithm compared with the accurate algorithm for free flow, half-pressure and pressure flow stage is +4.91%, +1.87%, +1.23%, respectively.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Clarkson, L.; Williams, D. An Overview of Conventional tailing Dam Geotechnical Failure Mechanisms. Min. Metall. Explor. 2021, 38, 1305–1328. [Google Scholar] [CrossRef]

- Koppe, J.C. Lessons Learned from the Two Major tailing Dam Accidents in Brazil. Mine Water Environ. 2021, 40, 166–173. [Google Scholar] [CrossRef]

- Shahriari, M.; Aydin, M.E. Lessons learned from analysis of Los Frailes tailing dam failure. In Proceedings of the International Conference on Applied Human Factors and Ergonomics, San Diego, CA, USA, 16–20 July 2017; Springer: Cham, Switzerland, 2017; pp. 309–317. [Google Scholar]

- Marti, J.; Riera, F.; Martínez, F. Interpretation of the Failure of the Aznalcóllar (Spain) tailing Dam. Mine Water Environ. 2020, 40, 189–208. [Google Scholar] [CrossRef]

- Zhou, Z.G.; Li, P.; Guo, R. Reliability Analysis on Flood Control Capacity of Drainage System of a Certain tailing Pond in Huanren. Min. Eng. 2016, 14, 52–54. [Google Scholar]

- Li, B.H.; Diao, M.J.; Yang, H.B. Hydraulic calculation of drainage system of tailing ponds. J. Southwest Univ. Natl. Nat. Sci. Ed. 2007, 33, 613–617. [Google Scholar]

- Li, Y.H.; Dai, C.J. Discussion on discharge capacity calculations of drainage system of tailing ponds. Heilongjiang Metall. 2009, 29, 26–29. [Google Scholar]

- Tan, J.J. Discharge capacity analysis of a tailing pond after drainage system combined. Mod. Min. 2016, 7, 220–221. [Google Scholar]

- Liu, X.L.; Zhang, P.H.; Wang, X. Hydraulic Characteristic Research of Longtan Reservoir Spillway Diversion Tunnel. J. Water Resour. Archit. Eng. 2015, 13, 4. [Google Scholar]

- Wang, Y.Y.; She, C.X.; Chen, Y.Q.; Chen, J.Y.; Jia, P.; Yin, Z.Q.; Li, Y.; Jin, J.C. Influence of Shaft Depth on Discharge Capacity of tailing Pond Flood System. J. Water Resour. Archit. Eng. 2017, 15, 133–137, 205. [Google Scholar]

- Han, C. Hydraulic Model Test and Hydraulic Calculation of Tailing Pond Drainage System. Master’s Thesis, Shijiazhuang Tiedao University, Shijiazhuang, China, 2017. [Google Scholar]

- Du, Z.F.; Wu, W.W.; Wu, Y.G. Hydraulic Model Test of Flood Discharge System of a Large tailing Reservoir. Nonferrous Met. Min. Sect. 2019, 71, 64–71. [Google Scholar]

- Djillali, K.; Abderrezak, B.; Petrovic, G.A.; Sourenevan, B.E. Discharge capacity of shaft spillway with a polygonal section: A case study of Djedra dam (East Algeria). Water Sci. Technol. Water Supply 2021, 21, 1202–1215. [Google Scholar] [CrossRef]

- Fraga, I.; Cea, L.; Puertas, J. Validation of a 1D-2D dual drainage model under unsteady part-full and surcharged sewer conditions. Urban Water J. 2017, 14, 74–84. [Google Scholar] [CrossRef]

- Zakwan, M.; Khan, I. Estimation of Discharge coefficient for side weirs. Water Energy Int. 2020, 62, 71–74. [Google Scholar]

- Ebtehaj, I.; Bonakdari, H.; Gharabaghi, B. Development of more accurate discharge coefficient prediction equations for rectangular side weirs using adaptive neuro-fuzzy inference system and generalized group method of data handling. Measurement 2018, 116, 473–482. [Google Scholar] [CrossRef]

- Sen, S. Surface pressure and viscous forces on inclined elliptic cylinders in steady flow. Sādhanā 2020, 45, 172. [Google Scholar] [CrossRef]

- Dennis, S.C.R.; Young, P.J.S. Steady flow past an elliptic cylinder inclined to the stream. J. Eng. Math 2003, 47, 101–120. [Google Scholar] [CrossRef]

- Mo, S.J. Numerical Simulation of Hydraulic Characteristics of Tailing Pond. Master’s Thesis, Shijiazhuang Tiedao University, Shijiazhuang, China, 2016. [Google Scholar]

- Zhao, J.Y. The Hydraulic Characteristic Research for Volute. Master’s Thesis, Northwest A & F University, Xianyang, China, 2017. [Google Scholar]

- Bao, Z.J.; Wang, Y.H. Three-Dimensional Numerical Simulation of Spillway Based on Flow—3D. Zhejiang Hydrotech. 2012, 2, 5–9. [Google Scholar]

- Wang, Y.H.; Bao, Z.J.; Wang, B. Three-dimensional Numerical Simulation of Flow in Stilling Basin based on Flow-3D. Eng. J. Wuhan Univ. 2012, 45, 454–457, 476. [Google Scholar]

- Ling, L.; Chen, R.C.; Li, Y.H. Three-dimensional VOF Model and its Application to the Water Flow Calculation in the Spilway. J. Hydroelectr. Eng. 2007, 26, 83–87. [Google Scholar]

- Yi, C. Numerical Simulation of Hydraulic Characteristics of Tailing Pond. Master’s Thesis, Nanchang University, Nanchang, China, 2016. [Google Scholar]

- Yu, K.; Cheng, Y.; Zhang, X. Hydraulic characteristics of a siphon-shaped overflow tower in a long water conveyance system: CFD simulation and analysis. J. Hydrodyn. 2016, 28, 564–575. [Google Scholar] [CrossRef]

- He, M.M. Discussion on Hydraulic Model Test and Numerical Simulation of tailing Pond Drainage System. Constr. Decor. 2021, 7, 48. [Google Scholar]

- Wang, S.X. Discharge Capacity of Shaft Spillway with Framed Inlettower for High tailing Dam. Met. Mine 1994, 5, 36–39,47. [Google Scholar]

- Wu, G.G.; Liu, X.F.; Lu, J.J.; Shen, L.Y. Comparison of Two Hydraulic Calculation Methods for Drainage System of tailing Pond. Nonferrous Met. Eng. Res. 2011, 32, 6–8. [Google Scholar]

- Ning, F.; Li, X.U. Application of GMRES Algorithm in the Predictions of Two-Dimensional Inviscous Steady Flows. Chin. J. Comput. Phys. 2001, 33, 442–451. [Google Scholar]

- Liu, C. Discussion on Flow Capacity of Chute Flood Drainage System in tailing Pond. Ment. Mine 2012, 1, 15–18. [Google Scholar]

- Dang, N. Tailing Drainage Wells Experimental Study on Shape Optimization of Flood Discharge System. Master’s Thesis, Xi’an University of Technology, Xi’an, China, 2010. [Google Scholar]

- Shi, W. Discussion on Flood Discharge System Design of tailing Pond. Nonferrous Mines 2002, 31, 43–46. [Google Scholar]

- Yu, D.X. Design and Optimization Method of Flood Discharge System in tailing Reservoir. China Met. Bull. 2018, 268–269. [Google Scholar]

- Shang, X.J.; Su, X.L. Design and Optimization Method of Flood Discharge System in tailing Reservoir. Hydroelectr. Sci. Tecnol. 2019, 2, 90–91. [Google Scholar]

- Yang, M.J. Study on Optimization Technology of flood discharge system of a tailing pond. World Nonferrous Met. 2020, 9, 273–274. [Google Scholar]

- Zhang, C.H. Software Development and Engineering Application of the Tailing Dam Complex Flood Drainage. Master’s Thesis, Shijiazhuang Tiedao University, Shijiazhuang, China, 2015. [Google Scholar]

- Ma, W.J. Software Development and Application of HydraulicCalculation of the Tailing Dam Drainage System. Master’s Thesis, Shijiazhuang Tiedao University, Shijiazhuang, China, 2014. [Google Scholar]

- Chen, H.; Li, R.L.; Jia, Y.; Wang, J.R. Discussion on calculation method of discharge capacity of drainage system. Mod. Min. 2015, 31, 180–183. [Google Scholar]

- Reference Materials for Tailing Facility Design Writing Group. Reference Materials for Tailing Facility Design; Metallurgical lndustry Press: Beijing, China, 1980; pp. 621–628. [Google Scholar]

| Working Conditions | Calculation Formulas | |

|---|---|---|

| Free Flow (a) When the water level is between two layers of windows. (b) When the water level is in the window position. | (1) | |

| Half-Pressure Flow | (2) | |

| Pressure Flow | (3) |

| Water Level (m) | Discharge Capacity from the Accurate Algorithm (m3/s) | Discharge Capacity from Simplification-Fitting Algorithm (m3/s) | Error (%) | Average Error (%) |

|---|---|---|---|---|

| 400.5 | 1.60 | 1.86 | 15.80 | |

| 401.5 | 7.70 | 8.31 | 8.01 | |

| 402.5 | 16.04 | 16.41 | 2.31 | |

| 403.5 | 26.34 | 26.16 | 0.69 | 4.19 |

| 404.5 | 37.94 | 37.54 | 1.06 | |

| 405.5 | 51.30 | 50.57 | 1.42 | |

| 406.5 | 65.30 | 65.24 | 0.08 |

| Water Level (m) | Discharge Capacity from the Accurate Algorithm (m3/s) | Discharge Capacity from Simplification-Fitting Algorithm (m3/s) | Error (%) | Average Error (%) |

|---|---|---|---|---|

| 400.5 | 4.04 | 4.19 | 3.52 | |

| 401.5 | 6.79 | 7.00 | 3.20 | |

| 402.5 | 8.52 | 8.57 | 0.57 | |

| 403.5 | 9.75 | 9.63 | 1.22 | 1.87 |

| 404.5 | 10.83 | 10.61 | 2.07 | |

| 405.5 | 11.78 | 11.63 | 1.34 | |

| 406.5 | 12.66 | 12.50 | 1.21 |

| Water Level (m) | Discharge Capacity from the Accurate Algorithm (m3/s) | Discharge Capacity from Simplification-Fitting Algorithm (m3/s) | Error (%) | Average Error (%) |

|---|---|---|---|---|

| 400.5 | 7.44 | 7.22 | 2.91 | |

| 401.5 | 8.53 | 8.66 | 1.59 | |

| 402.5 | 9.14 | 9.23 | 0.97 | |

| 403.5 | 9.64 | 9.56 | 0.86 | 1.23 |

| 404.5 | 10.10 | 9.98 | 1.21 | |

| 405.5 | 10.54 | 10.56 | 0.17 | |

| 406.5 | 10.96 | 11.06 | 0.89 |

| Water Level (m) | Discharge Capacity (m3/s) |

|---|---|

| 400.5 | 1.86 |

| 401.5 | 7.00 |

| 402.5 | 8.57 |

| 403.5 | 9.56 |

| 404.5 | 9.98 |

| 405.5 | 10.56 |

| 406.5 | 11.06 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, S.; Mei, G.; Guo, L.; Xie, X.; Skrzypkowski, K. Research on Calculation Method for Discharge Capacity of Draining Well in Tailing Ponds Based on “Simplification-Fitting” Method. Energies 2022, 15, 4194. https://doi.org/10.3390/en15124194

Wang S, Mei G, Guo L, Xie X, Skrzypkowski K. Research on Calculation Method for Discharge Capacity of Draining Well in Tailing Ponds Based on “Simplification-Fitting” Method. Energies. 2022; 15(12):4194. https://doi.org/10.3390/en15124194

Chicago/Turabian StyleWang, Sha, Guodong Mei, Lijie Guo, Xuyang Xie, and Krzysztof Skrzypkowski. 2022. "Research on Calculation Method for Discharge Capacity of Draining Well in Tailing Ponds Based on “Simplification-Fitting” Method" Energies 15, no. 12: 4194. https://doi.org/10.3390/en15124194

APA StyleWang, S., Mei, G., Guo, L., Xie, X., & Skrzypkowski, K. (2022). Research on Calculation Method for Discharge Capacity of Draining Well in Tailing Ponds Based on “Simplification-Fitting” Method. Energies, 15(12), 4194. https://doi.org/10.3390/en15124194