Abstract

Continuous urbanization and modernization have increased the burning of fossil fuels to meet energy needs across the globe, emanating environmental pollution and depleting fossil fuels. Therefore, a shift towards sustainable and renewable energy is necessary. Several techniques to exploit biomass to yield energy are trending, with pyrolysis one of them. Usually, a single feedstock is employed in pyrolysis for anoxygenic generation of biochar together with bio-oil at elevated temperatures (350–600 °C). Bio-oil produced through pyrolysis can be upgraded to crude oil after some modification. However, these modifications of bio-oil are one of the major drawbacks for its large-scale adoption, as upgradation increases the overall cost. Therefore, in recent years the scientific community has been researching co-pyrolysis technology that involves the pyrolysis of lignocellulosic biomass waste with non-biodegradable waste. Co-pyrolysis reduces the need for post-modification of bio-oil, unlike pyrolysis of a single feedstock. This review article discusses the recent advancements and technological challenges in waste biomass co-pyrolysis, the mechanism of co-pyrolysis, and factors that affect co-pyrolysis. The current study critically analyzes different recent research articles presented in databases such as PubMed, MDPI, ScienceDirect, Springer, etc. Hence, this review is one-of-a-kind in that it attempts to explain each and every aspect of the co-pyrolysis process and its current progress in the scientific field. Consequently, this review also compiles the remarkable achievements in co-pyrolysis and recommendations for the future.

1. Introduction

The world’s increasing energy demand has led to the very rapid depletion of diminishing fossil fuel reserves [1,2]. By 2040, gross global energy demand is projected to grow by 20% [3]. The excessive burning of fossil fuels releases greenhouse gasses that cause adverse global climate issues such as warmer oceans, increased average temperatures, extinction of flora and fauna, decreased snow and ice cover, variations in precipitation patterns, increasing sea levels, etc. [4]. Moreover, the progressive depletion of fossil fuels, besides having other related environmental impacts, has led to increased pursuit of novel renewable, economically and environmentally sustainable, efficient, and lucrative energy sources.

Among all the renewable sources available, biomass is one of the promising sources that can be used to meet the global energy demand; it is carbon neutral and readily available [1,5]. Energy plants, crops or their residues, organic fractions of municipal and industrial wastes, and algae are some types of biomass that are commonly used for producing fossil fuel-free energy [6,7]. Since all the above-mentioned biomasses are rich in organic materials (such as lignocellulose), they can be transformed into bio-based products that have additional potential for energy production. Therefore, researchers are focusing on the generation of biofuels that are on the verge of commercial establishment and later can be used for electricity generation, as a transportation fuel, and for heating [8,9,10,11]. Among all, available strategies to produce biofuel pyrolysis is one of the promising options, as it not only converts lignocellulose biomass but also helps in the transformation of an array of non-biodegradable wastes into char and bio-oil in a short time [12].

Pyrolysis is anoxygenic thermal decomposition at 350–600 °C [13]. The produced bio-oil, also called pyrolysis liquid, is just like crude oil, and it can be used to produce a wide variety of biofuels. Apart from pyrolysis, several other processes of energy generation from biomass are available. The biological approach uses biomass as a substrate for fermentation to produce biofuels such as biohydrogen, bioethanol, etc. Compared to pyrolysis, these processes are undertaken at much lower temperature ranges and milder conditions and thus have lower energy requirements. However, fermentation can only utilize the biodegradable materials and is relatively slow. Liquefaction is a thermochemical process that has been used for generating fuels from biomass using hot compressed water. The advantage of this process over pyrolysis is that, unlike pyrolysiss it does not require drying of the substrate, thus making the process more suitable for biomass-based substrates, which generally have higher moisture content. However, in this process a lot of organic carbon gets lost, thus affecting the overall efficiency.

Pyrolysis also faces a major challenge due to the fact that the bio-oil produced from it can only be turned into usable forms after certain upgradations, such as catalytic cracking and hydrodeoxygenation (HDO), catalytic cracking, catalytic pyrolysis, molecular distillation, steam reforming, esterification, supercritical fluids, and emulsification, but all these upgradation techniques increase the overall cost of the process. Therefore, a new approach called co-pyrolysis has been researchered and has been reported to result in upgradation of the attained bio-oil [14,15].

Co-pyrolysis is similar to pyrolysis and involves the pyrolysis of two or more biomasses or wastes together. It turns out to be a modest and efficient procedure, yielding the ideal synthetic liquid fuel. Generally, co-pyrolysis is anoxygenic, performed in a closed reactor at moderate operating temperatures with or without catalysts. Various catalysts, such as zeolite, metal oxides (CaO, MgO, NiFe, Na2O3, Al2O3), biochar, etc., can be used to speed up co-pyrolysis [16,17,18]. In addition, co-pyrolysis is governed by numerous factors, such as biomass variety, type of reactor, and operating parameters, such as temperature, heating speed, reaction period, and particle dimensions of feed [19]. These factors along with various biodegradable and non-biodegradable waste combinations greatly affect the overall production of char and bio-oil.

In this paper, a comprehensive overview of co-pyrolysis of biodegradable wastes and non-biodegradable wastes is presented. The main aim of article is to discusses the recent advances and technological challenges in waste biomass co-pyrolysis, the mechanism of co-pyrolysis, and factors that affect co-pyrolysis. The focus is on current techniques utilized in co-pyrolysis, operating parameters, and challenges for different waste biomasses in their conversion to biofuels. Moreover, different products formed during co-pyrolysis are also presented.

2. Co-Pyrolysis: An Alternative Technique to Upgrade Pyrolysis Oil

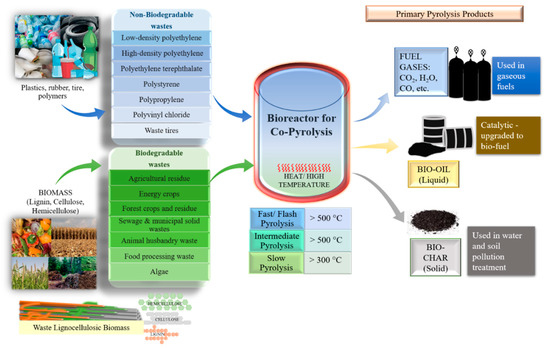

To convert biomass into biofuels, various thermochemical and biological processes are used. Among these, pyrolysis is one of the most convenient methods because it has several advantages, such as easy optimization, variety in product formation, complete utilization of feedstocks, and diversification in feedstocks (both biodegradable and non-biodegradable) that can undergo pyrolysis (Figure 1) [20]. There are three categories of pyrolysis products formed: bio-oil (liquid), biochar (solid), and fuel gas [21]. The yield of pyrolytic products is generally governed by the composition of biomass and the operating parameters [22]. There are three forms of pyrolysis: slow, fast, and flash. Flash pyrolysis operates with a higher heating rate and shorter reaction time than fast pyrolysis, and the main product formed is bio-oil [23,24], whereas slow pyrolysis is done at low temperature, a low heating rate, and longer vapor residence time. The main product formed from slow pyrolysis is biochar [24]. Fast pyrolysis is commonly used and operates at controlled temperatures (~500 °C) for a short residence period (<2 s) and high heating speed (>200 °C s−1). Its main product is bio-oil [23].

Figure 1.

Co-pyrolysis of biodegradable and non-biodegradable feedstocks and its products.

Fuel gas is an undesirable product, but its production is unavoidable during pyrolysis; hence, it can be used to preheat the biomass, but its combustion byproducts are environmentally undesirable and require neutralization before being released. Pretreatment technologies (such as NOX scrubbers, electrostatic precipitators, adsorption systems for volatile organic compounds using activated carbon, SOX fuel gas desulfurization systems, flares, and biofilters) are used before the release of gasses, and/or optimization to lower its production during pyrolysis is implemented. On the other hand, biochar has been used to heat biomass and generate power for the pyrolysis plant, but recently it was observed that it can also be used as a soil enhancer, compost bulking agent, activated carbon, bioremediater of water and soil, bio-catalyst, energy source, and for carbon sequestration because of its composition [25,26,27,28,29]. Bio-oil produced from pyrolysis exists as a dark brown, highly viscous liquid comprised of anhydro sugars, acids, alcohols, aldehydes, phenols, and oligomers. However, since bio-oils produced from biodegradable wastes are chemically unstable owing to high oxygen and water contents, culminating in reduced calorific value, high viscosity, and problems with corrosion and stability, its upgradation or enhancement is essential for its use as an alternative to crude oil [30]. Due to these unfavorable properties, it is incapable of being employed as transportation fuel directly [15]. In addition, pyrolysis of biomass results in minor aromatic yield and major coke production as a result of a decreased hydrogen/carbon effective ratio (H/Ceff) in most biodegradable biomasses [31]. There are several routes for bio-oil enhancement depending on product requirements, such as emulsification, catalytic deoxygenation/hydrogenation, co-pyrolysis, thermal cracking, physical extraction, esterification, or gasification [24]. Among all, co-pyrolysis has clearly shown potential for long-term business implementation due to improved results and cost-effectiveness.

Co-pyrolysis constitutes the pyrolysis of more than one type of feedstock, resulting in a positive synergistic effect. For instance, co-pyrolysis of biomass along with non-biodegradable polymer waste (such as plastic waste, e-waste, waste tyres, etc.) has often increased the amount of hydrogen produced and also reduced CO content [32]. In addition, without much alteration to the system, co-pyrolysis results in favorable performance and cost-savings in comparison to other upgradation methods, such as hydrodeoxygenation (HDO) and catalytic cracking [19]. It also results in improved quality and quantity of oil with a high calorific value [33]. This positive synergistic interaction due to the mixing of feedstocks during pyrolysis has led to efficient oil content in combination with a secure and alternate way to handle non-biodegradable waste, such as plastic, tires, and lubricant oil [34]. Thus, co-pyrolysis is an easy, efficient, and feasible strategy for high-quality fuel extraction with the potential to enhance the world’s energy protection, facilitate faster waste management, and decrease dependence on fossil fuels while preserving a healthy climate and ecosystem. The reason that co-pyrolysis has achieved a lot of recognition and success in recent years is that the pyrolysis of biomass and polymer/plastic waste individually and then mixing of their respective bio-oil is uneconomical, as more energy would be required to stabilize the mixture, and there is the possibility of separation after a short period due to the polar characteristic of the biomass pyrolysis oil. However, co-pyrolysis is more consistent in generating homogeneous and stable bio-oil compared to directly blending oil, as the interplay of the radicals leads to the formation of a stable bio-oil and avoids separation. In addition, co-pyrolysis offers a platform to treat a large volume of waste concurrently, which if treated separately would increase the overall cost. Therefore, it not only decreases waste treatment cost, but also solves various environmental issues accompanying traditional treatment methods, such as landfilling and incineration [33].

In the past few years, much research related to co-pyrolysis has been documented in various peer-reviewed journals. For instance, Salvilla et al. [35] studied the co-pyrolysis of polyolefin plastics synergistically with wood and agricultural wastes and concluded that activation energy of plastic decomposition in co-pyrolysis was reduced, and the results could be used in polyolefin plastic and lignocellulosic waste co-pyrolysis for biofuels production. In another study, co-pyrolysis of woody biomass with plastic waste at an analytical and pilot scale by Johansson et al. [36] showed that the addition of plastics considerably impacts the composition and characteristics of the bio-oil. On the other hand, Wang et al. [37] considered sewage sludge co-pyrolysis with rice husk and concluded that pyrolysis behavior was improved synergisticically. Several other latest findings on the co-pyrolysis of different biomasses are listed in Table 1.

3. Mechanism of Co-Pyrolysis

Pyrolysis and co-pyrolysis are basically the same. However, in pyrolysis, only one feedstock is used, while in co-pyrolysis two or more feedstocks are used. Co-pyrolysis is carried out inside a closed reactor in an anoxygenic environment having low operating temperatures (350–600 °C) [38]. Co-pyrolysis essentially requires four basic steps or processes for bio-oil production: selection of feedstocks, sample preparation/pretreatment, co-pyrolysis, and condensation [33]. This section deteails the selection of feedstock and pretreatment strategies for co-pyrolysis, while the main co-pyrolysis step is discussed in the subsequent section.

3.1. Selection of Feedstocks for Co-Pyrolysis

Employing biodegradable and non-biodegradable wastes as raw materials in co-pyrolysis varies extensively among investigations. A list of different biodegradable and non-biodegradable wastes is given in Table 2. Co-pyrolysis has not only emerged as an alternative to manage these biodegradable and non-biodegradable wastes, but has also provided an alternative way to produce energy. This will not only reduce our dependence on fossil fuels, but can also help resolve global warming, eutrophication, acidification, and eco-toxicity problems that the whole world is facing right now. In addition, independent pyrolysis of biomass and non-biodegradable polymers such as plastics (or waste tires) needs more energy, which in turn leads to significantly increased production costs. Therefore, the coincidence of plastic or tire waste during the pyrolysis of various biomass types potentiates a positive influence to the heating rate through synergy [19,39]. In this section, the choice and accessibility of feedstocks that can be employed in co-pyrolysis are discussed.

Table 1.

Composition of different biomasses used for pyrolysis.

Table 1.

Composition of different biomasses used for pyrolysis.

| Biodegradable Wastes | ||||||

|---|---|---|---|---|---|---|

| Type of Biomass | Raw Material | Lignin | Hemicellulose | Cellulose | References | |

| Agriculture Residue | Almond Shell | 27.7–35% | 28.0–38.0% | 29.0–31.1% | [40] | |

| Banana Waste | 24.28% | 10.50% | 40.15% | [41] | ||

| Barley Straw | 13.8% | 21.9% | 33.8% | [42] | ||

| Corn Stalk | 15.59% | 43.01% | 22.82% | [40] | ||

| Corn Stover | 13 (mf * wt.%) | 43 (mf * wt.%) | 31 (mf * wt.%) | [43] | ||

| Cotton Stalk | 20.88% | 32% | 38% | [44] | ||

| Date Palm Waste | 1–25% | 19–33% | 22–40% | [45] | ||

| Flax Straw | 28.90% | 34.40% | 36.70% | [40] | ||

| Groundnut Husk | 28% | 46% | 34% | [46] | ||

| Jatropha De-oiled Cake | 24.9% | 16.6% | 53.5% | [47] | ||

| Millet Husk | 14% | 26.9% | 33.3% | [40] | ||

| Oat Straw | 12.9% | 23.3% | 37.6% | [42] | ||

| Palm Oil Empty Fruit Bunches | 12.09% DB a | 12.78% DB | 25.16% DB | [48] | ||

| Rice Husk | 14.3% | 24.3% | 31.3% | [40] | ||

| Rice Straw | 14.23% DB | 22.20% DB | 38.30% DB | [49] | ||

| Sugarcane Bagasse | 9.6% | 28.2% | 30.9% | [50] | ||

| Wheat Straw | 15–16.4% | 27.3–50% | 27.3–30% | [40] | ||

| Biodegradable Industry Waste | Fruit Industry Waste | Apple Pomace | 24.72% | 27.77% | 47.49% | [51] |

| Pineapple Peels | 10.06% | Not Mentioned | 21.66% | [52] | ||

| Orange Peels | 12.04% | 30.63 | 33.26 | [53] | ||

| Mango Endocarp | 25.9% | 21.4% | 50.13 | |||

| Apricot Kernel Shell | 47.97% | 17.01% | 29.57% | |||

| Date Pits | 16.68% | 18.67% | 45.88% | |||

| Coffee Industry waste | Spent Coffee Grounds | 25% | 42% | 13% | [54,55] | |

| Coffee Pulp | - | 21–32% of carbohydrates | ||||

| Coffee Cherry Husk | - | 58–85% of carbohydrates | ||||

| Textile Waste | Hemp, Flax, Jute, and Abaca | Small Amount | 12-20% | 60% | [56] | |

| Coir | 41–45% | 12–20% | 36–43% | |||

| Paper Biomass | 3.3% | 15.2% | 76.5% | [57] | ||

| Forest Residue | Hardwood | 20–25% | 20–25% | 45–50% | [58] | |

| Pine Wood | 25.3% | 10.5% | 48.6% | [59] | ||

| Softwood | 25–35% | 25–30% | 40–50% | [43] | ||

| Other Wastes | MSW | 16% | 4% | 38% | [60] | |

| Sewage Sludge | 5.86% | 2.37% | 14.65% | [61] | ||

| Manure | 6–16% | 18–27% | 4-23% | [62] | ||

| Energy Crops | Switchgrass | 18–19% | 24–29% | 37–43% | [58] | |

| Non-Lignocellulosic Biomass | Raw Material | Protein | Lipid | Carbohydrates | Reference | |

| Algae (Chlorella vulgaris) | 41.51% | 15.67% | 20.99% | [63] | ||

| Hair Waste | 65–95% | 1–9% | - | [63,64] | ||

| Feather Waste | 82% | 0.8% | 2% | [65] | ||

| Meat Waste | Cattle | 1% | 74.75% | 1.45% | ||

| Pig | 13.13% | 33.25% | 13.86% | |||

| Non-Biodegradable Wastes | ||||||

| Synthetic Polymers | Raw Material | Carbon | Hydrogen | Sulfur | Reference | |

| LDPE | 86.35% | 13.58% | 0.074 | [16] | ||

| HDPE | 84.89% | 14.19% | 0.54% | [66] | ||

| PET | 57.9% | 4.13% | 0.01% | [17] | ||

| Waste Tires | 87.9% | 7.4% | 1.1% | [67] | ||

* mf—moisture free; a DB: dry biomass; LDPE: low-density polyethylene; HDPE: high-density polyethylene; PET: polyethylene terephthalate; PS: polystyrene; PP: polypropylene; PE: polyethylene; PVC: polyvinyl–chlori.de.

3.1.1. Biodegradable Wastes

Biomass is a biodegradable and renewable organic waste that comes from plants and animals. It is already known to be the world’s only truly viable source of organic carbon and the ideal petroleum equivalent for the commercial production of fuels with net carbon zero emissions [68]. It accounts for about 14% of the globe’s energy supply and can even be assumed to be the predominant form of renewable energy as it may be transformed into a variety of fuels (liquid, gaseous, and solid) and useful chemicals [69]. It includes agricultural residues, forest residues, biogenic parts of industrial and municipal solid wastes (MSW), algal biomass, and dedicated energy crops [70]. Biodegradable waste can be categorized as following:

Lignocellulose Wastes

It is clear from Table 1 that almost all the biomasses (such as agriculture residue, forest residue, industrial wastes, municipal solid wastes, energy crops, etc.) are rich in lignocellulose. Therefore, the most-investigated and successful feedstocks for producing renewable biofuels have been lignocellulosic biomasses. Cellulose, hemicellulose (polysaccharides), and lignin, together with some resins and minerals, are the major components of lignocellulosic biomass [71]. The linear polysaccharide cellulose, a glucose polymer having strong β-1,4-glycosidic linkages, functions as the framework of lignocellulosic cell walls [72,73]. In cellulose chains, an assortment of hydroxyl groups is present, leading to the establishment of hydrogen bonds within the same chains or in neighboring chains [74]. Hemicellulose is a short, highly branched, amorphous heteropolymer formed from monomeric sugars and sugar acids [75]. The role of hemicellulose is to link lignin and cellulose. There are numerous hexoses (galactose, glucose, rhamnose, mannose, and fucose), pentoses (xylose and arabinose), and uronic acids (methyl glucuronic acid, glucuronic acid, and galacturonic acid) in the structure of hemicelluloses [76]. The amorphous, heterogeneous, cross-linked aromatic polymer lignin has a three-dimensional structure composed of trans-sinapyl, trans-coniferyl, and trans-p-coumaryl alcohols [77]. Cellulose is also crosslinked by lignin along with hemicellulose to generate three dimensional cell wall structures. Further, because of its large carbon content, lignin stores around 40 % of the energy in lignocellulosic biomass [78].

Lignocellulose waste pyrolysis normally occurs in three major phases: (i) Temperature <200 °C (required for evaporation of moisture); (ii) Primary decomposition at 475 °C to 655 °C; (iii) Reduction in decomposition reaction at temperature >600 °C. Cellulose and hemicellulose decomposition refers to the second stage, and lignin decomposition happens at temperatures between 455 °C and 1175 °C [79]. Unlike cellulose, hemicellulose decomposition at low temperature ranges (i.e., 200–260 °C) generates increased volatile components and decreased tar and char. Hemicellulose decomposition consists of two phases: dehydration and cracking of the side unit in the first phase, which occurs below 100 °C. Decomposition of the main chain is during the second phase, arising within a temperature range of 240–290 °C [80]. Hydrocellulose and levoglucosan are the primary products of the conversion of cellulose between 320 °C and 380 °C. Lignin degradation at a higher temperature range (i.e., 200–500 °C) generates adequate oxygenates, such as phenols, derived from benzene rings [69]. Especially in comparison to hemicellulose (32 wt.%) and cellulose (5 wt.%), lignin decomposition generates the maximum solid residue (42 wt.%) due to the condensation of lignin fragments through free radicals [80]. Table 2 lists the pyrolysis of a few selected lignocellulosic feedstocks.

Table 2.

Typical properties of bio-oil obtained from pyrolysis of different biodegradable (lignocellulosic) and non-biodegradable feedstock.

Table 2.

Typical properties of bio-oil obtained from pyrolysis of different biodegradable (lignocellulosic) and non-biodegradable feedstock.

| Raw Material | Properties of Bio-Oil Produced by Pyrolysis | Reference |

|---|---|---|

| Acacia nilotica (Babool) Seeds | Rich in hydrocarbons, alcohols, phenols but further upgradation to remove oxygen is required | [81] |

| Cedrus deodara | Rich in acids, alcohols, aromatic ethers, carbonyl compounds, hydrocarbons, phenols, but further refining is required | [82] |

| Corn Cob | Acids, furans, lignin-derived phenols, nonaromatic aldehydes, non-aromatic ketones, sugars, but further upgradation for removing moisture is required | [40] |

| Cotton Residue | Bio-oil contains phenolic compounds but is highly oxygenated | [83] |

| HDPE | Rich in aliphatic hydrocarbon (C8 to C12); lower proportion of aromatic hydrocarbons | [84] |

| LDPE | Rich in aliphatic and simple aromatic hydrocarbons | [85] |

| Mixed Plastic | Heating Value 44.40 MJ/kg | [39] |

| Oil Palm Empty Fruit Bunches | Rich in phenol, furan, ketone, alcohol, acids, pyrans | [40] |

| Palm Fronds | Rich in acids, phenols, ketones, aldehydes, alcohols, but this conversion is still not optimal | [86] |

| PE | High aromatic content having other hydrocarbon compounds and some aliphatic content; higher heating values than conventional diesel | [87] |

| PET | Rich in aromatic hydroxyl groups; lack oxygen, carboxyl, and aliphatic hydroxyl groups | [88] |

| Pinewood | Rich in acids, phenols; however, further optimization and upgradation is required. | [89] |

| Poplar | Bio-oil collected under two fractions: | [90] |

| ||

| PP | Rich in the naphtha range hydrocarbons. | [91] |

| PS | Heating value 43.0 MJ/kg; flash point: 26.1 °C | [39] |

| PVC | Heating value 43.22 MJ/kg; flash point: 40 °C | [39] |

| Rice Husk | Rich in acids, aromatic, heterocyclic compounds, but to use as vehicle fuel it requires some refining | [40] |

| Spruce | Rich in non-aromatic aldehydes, sugars, non-aromatic ketones, guaiacols, acids, furans, pyrans | [40] |

| Sugarcane Bagasse | Bio-oil has significantly less oxygen and higher calorific value due to pressure applied during pyrolysis | [90] |

| Sweet Sorghum Bagasse | Properties of bio-oil were found to vary across the fractional condensers. | [90] |

| Waste Tires | Contains aromatic, aliphatic, polar and hetero-atom fractions. | [92] |

LDPE: low-density polyethylene; HDPE: high-density polyethylene; PET: polyethylene terephthalate; PS: polystyrene; PP: polypropylene; PE: polyethylene; PVC: polyvinyl–chloride.

The low hydrogen/carbon effective ratio (H/Ceff) of biomass results in decreased aromatic yield, more coke production, and increased water, oxygen content, viscosity, and corrosiveness of the bio-oil produced; hence, it cannot be employed commercially for transportation. Additionally, biomass exhibits a low hydrogen/carbon effective ratio (H/Ceff), which results in low aromatic yield and high coke production [15]. All these factors reduce the conversion efficiency of the obtained bio-oil into advanced biofuel. Therefore, effective approaches are desired to enhance the quality of bio-oil and make it identical to those hydrocarbon fuels. A few of the procedures for upgrading bio-oil are catalytic cracking, which involves the introduction of a solid acid catalyst, and hydrodeoxygenation, which involves metal catalysts with a pressurized hydrogen atmosphere. Nevertheless, both processes seem to be unpromising due to great operating costs associated with the use of noble catalysts and substantial catalyst deactivation. Zhang et al. [93] have evaluated catalytic pyrolysis involving the addition of catalysts before quenching volatiles. Catalytic pyrolysis results in highly stable bio-oil, although, even in the existence of extremely efficient catalysts, catalytic pyrolysis of lignocellulosic biomass still results in low carbon yield and great quantities of solid residues, together with biochar and coke. Such a large content of coke can result in deactivation of the catalyst and thus make the whole process impractical to commercialize. Thus, in order to increase carbon yield and curtail coke generation, researchers recently evaluated the amalgamation of high H/Ceff ratio co-reactants (such as non-biodegradable wastes such as plastics) with lignocellulosic biomass to mitigate the issues that arise due to the upgradation of bio-oil produced solely from lignocellulose wastes [94].

Non-Lignocellulosic Wastes

Apart from lignocellulosic biomass, there are some non-lignocellulosic sources, such as algal biomass, which have shown potential for biofuel production through pyrolysis [95]. Algal biomass is comprised mainly of three components: lipids, proteins, and polysaccharides [96]. There are several advantages of using algal biomass as a substrate for co-pyrolysis/pyrolysis such as ease of cultivation and, compared to land plants, relatively lower inputs. Moreover, algae can be grown in fresh, brackish, and marine waters as well as wastewater [97,98]. For instance, pyrolysis of microalgae Scenedesmus dimorphus was found to produce bio-oil rich in aromatics, phenols, heterocyclic hydrocarbons, amides, and indole with the potential to be converted into bioenergy and biomaterial after a few upgradations [99]. In another study, blue–green algae blooms underwent pyrolysis in a fixed-bed reactor and produced bio-oil with great heating value and controlled eutrophication [90]. Other traditional non-lignocellulosic biomasses are sewage sludge and manure, which are usually managed by landfilling, burning, agricultural use, and so on. Therefore, converting sewage sludge and manure to bio-oil through pyrolysis with biochar as a value-added byproduct is an excellent way to manage these non-lignocellulosic wastes [63]. For instance, Ma et al. [61] investigated sewage sludge supercritical water pyrolysis and established that bio-oil formed can be utilized as fuel after refining. However, the conversion of non-lignocellulose waste through pyrolysis still requires further investigation, and not much research is available as of now.

3.1.2. Non-Biodegradable Wastes

The consumption of plastics and related products has increased enormously over the years due to their various applications. However, non-biodegradable wastes are more voluminous than biodegradable wastes, and most parts of non-biodegradable wastes take millions of years to degrade. Therefore, the massive production and consumption of non-biodegradable materials has created an environmental emergency. Simultaneously, the existing high energy demand in our society is also a matter of great concern. Non-biodegradable wastes usually include materials such as high-density polyethylene (HDPE), polyethylene terephthalate (PET), low-density polyethylene (LDPE), polystyrene (PS), polypropylene (PP), polyamide (PA), polyacrylate (PAC), polyvinyl–chloride (PVC), waste tires, e-waste, etc. Among all, plastic polymers and tire waste are generally available in abundance. To dispose of these wastes, incineration and landfilling are the traditional methods adopted by many countries if recycling is not possible. However, landfills consume massive space and contaminate soil and water of nearby areas, and incineration leads to unacceptable emission of harmful compounds [39,100]. Therefore, pyrolysis of non-biodegradable waste is one of the alternative methods to manage these wastes as well as to recover energy from them. Since plastics and tires are prepared from petroleum, they have the same physical characteristics as fuel. Therefore, their wastes need additional consideration in terms of management for their potential application in the production of second generation biofuels through pyrolysis.

Plastics are non-renewable synthetic materials originating from crude oil. They only contain carbon and hydrogen and lack elemental oxygen. In the pyrolysis of plastics, their polymeric macromolecular structures are cracked down into minor molecules or monomers, and further degradation depends upon the operating conditions and presence of catalysts. The oil formed from pyrolytic degradation of plastics displays a high calorific value similar to conventional fuel. It also has lower oxygen and higher hydrogen content than oil from biomass [19]. Therefore, the presence of plastics during pyrolysis of various biomasses, such as lignocellulosic wastes, can have a desirable synergistic influence on the heating value, and sole pyrolysis of plastic waste can also serve as an alternative management technique and resource/energy recovery option.

Tire waste has also been considered as another excellent candidate for pyrolysis. It contains rubber (60–65 wt.%) and carbon black (25–35 wt.%). Styrene–butadiene rubber, nitrile rubber, natural rubber (polyisoprene), polybutadiene rubber, and chloroprene rubber are some of the natural and synthetic rubbers. The pyrolytic oil generated from the pyrolysis of tire waste has energy up to 44 MJ/kg and shows decreased oxygen levels, an increased H/C atomic ratio (~1.5), and contains both aromatic and aliphatic compounds [15,33].

As already discussed, researchers are finding cost-effective ways to improve the carbon yield in bio-oil formed from biodegradable biomasses. However, the blending of pyrolytic oil from non-biodegradable wastes with bio-oil generated from biomass is uneconomical and next to impossible. Further, the distinct pyrolysis of biomass and non-biodegradable wastes also increases the overall cost. Thus, co-pyrolysis has come out as a more reliable option [19]. In co-pyrolysis, there is an interaction of radicals that can encourage the creation of consistent pyrolysis oil that evades phase separation [32]. Most non-biodegradable wastes can be characterized as potential co-feeds in co-pyrolysis because of their abundant availability. Higher energy content and the creation of high-quality bio-oils occur in co-pyrolysis due to synergism between the diverse materials, especially during co-pyrolysis of biodegradable waste with non-biodegradable wastes. Additionally, the key advantage of co-pyrolysis is that an increased amount of waste is consumed as raw material, reducing the need for landfills and separate waste treatment techniques. Table 2 has already shown the co-pyrolysis of a few raw materials and the properties of the oil produced.

3.2. Sample Preparation/Pretreatment

Prior to co-pyrolysis, feedstocks must be prepared and pre-treated. Pretreatment is another approach to improving the synergistic interactions between biodegradable wastes and non-biodegradable wastes. Pretreatment is an essential step for the generation of bio-oil with higher quality and quantity from co-pyrolysis. Pretreatment of biomass is necessary due to the coincidence of alkali and alkaline earth metals that negatively influence the performance of co-pyrolysis [101]. Numerous pretreatment steps and their consequences on productivity and quality are discussed below.

3.2.1. Physical/Mechanical Pretreatment

Drying and grinding are some common physical pretreatment methods that have been found to make the transformation process easier and more effective [19]. Grinding samples to 2–3 mm in size along with drying is essential to reach high biomass heating levels [33]. Drying is done by oven heating for 24 h at 105 °C. The dried feed material should have a moisture level less than or equal to 10% because higher moisture content generates inferior quality oil with high water content [102]. At an industrial level, char and fuel gasses are employed as sources of energy for drying and grinding [19,33]. Apart from drying and grinding, sorting and dewatering are used for pretreatment and sample preparation [33]. Most recently, microwave irradiation has been used for pretreatment. Zhang et al. [103] explored co-pyrolysis of microwave pre-treated chili straw and PP over HZSM-5 catalyst to yield hydrocarbon-rich bio-oil, and aromatic content increased from 4.46 to 17.34%. Further, thermal biomass pretreatment by dry torrefaction, in which temperatures ranging from 200 °C–290 °C were applied, improved biomass structure and consequently produced improved bio-oil [90]. Torrefaction of biomass into small oxygenates and augmentation of the ring opening resulted in the generation of aliphatic intermediates [15].

3.2.2. Chemical Pretreatment

Chemical pretreatment has been shown to alter product yield and cause structural changes in the raw materials [15]. Acid pretreatment of biomass is one of the common techniques to reduce the harmful effects of alkaline earth metals. Several acid pretreatment studies of co-pyrolysis have been discussed in various articles. Xue and Bai [104] investigated the co-pyrolysis of corn stover treated with sulphuric acid (98%) and PE in a tandem micro-pyrolyzer at 600 °C, and a considerable improvement in the levels of levoglucosan and phenolic monomers were observed. The investigators discussed the synergistic effects of robust Diel–Alder reactions between biomass-derived furans and plastic-derived olefins [104]. Another study investigated acid-washed (aqueous nitric acid (3 wt.%) corn stover–HDPE co-pyrolysis performed in a drop-tube reactor with N2 as a carrier gas at 550 °C, and a high liquid yield of 51% was reported, with enhancement in the bio-oil eminence [105]. Another group of researchers studied co-pyrolysis in a fixed-bed reactor with HCl-treated cotton stalk biomass and waste tires at 550 °C and observed a reduction in light oxygenates. Furthermore, liquid yields were increased from 45 wt% [106]. Alkali pretreatment has also been used in some studies and has improved bio-oil yield by untethering ester and glycosidic bonds within lignin [90]. Krutof and Hawboldt [107] reviewed co-pyrolysis of different feedstocks and stated alkali washing also leads to demineralization.

3.2.3. Physio–Chemical Pretreatment

Wet torrefaction (hydrothermal), ammonia fiber expansion, steam explosion, and CO2 explosion are some of the common physio–chemical pretreatment methods. Wet torrefaction, also identified as hydrothermal pretreatment, is implemented using hot (150–260 °C), compressed water [15]. The group of researchers performed co-pyrolysis of hydrothermally treated (175 °C) high-protein Chlorella sp. (microalgae) and PP (550 °C), and an excellent upsurge in the generation of cyclohexane derivatives and alkenes was observed due to synergistic interactions amongst both feedstocks; further, a reduction in heterocyclic N-containing compounds was also observed [108]. In a separate study, microwave assisted co-pyrolysis of torrefied lignin and LDPE at 550 °C was performed, and a drastic increase in aromatic content was observed in the bio-oil [109]. Dai et al. [110] concluded that hydrothermal pretreatment has great potential to improve aromatic production during biomass–polyethylene co-pyrolysis. Further, ammonia fiber expansion (AFEX) is known to be an effective pretreatment technique to improve the biomass structure [90]. On the other hand, steam explosion has been developed for wood pretreatment, in which wood chips in a vessel are subjected to 285 °C and 35 bar for 2 min, then the pressure increases to 70 bar within 5 s. This process provides more-accessible feedstock for secondary conversion [90].

3.2.4. Biological Pretreatment

In comparison to most of the above-mentioned pretreatments, biological pretreatment is found to be more environment friendly for several reasons, such as nonrequirement of additional chemicals, lesser energy requirements, and very low or negligible production of inhibitory compounds. Moreover, there are no corrosion-related problems, and noninvolvement of harsh chemicals also reduces the burden of harmful waste [111]. This can be done with help of microorganisms or by directly applying the enzyme cocktails. The main constraint of using biological pretreatment is that the rate of degradation is very slow, so researchers need to optimize the strain in such a way that the maximum yield can be obtained in a limited amount of time [90]. In addition, not many studies are present in the literature where biological pretreatment is performed before co-pyrolysis.

4. Different Types of Co-Pyrolysis

After pretreatment, the sample is transferred to a co-pyrolysis unit. The temperature is generally adjusted between 350–600 °C to obtain 45% liquid yield, and intert gasses are used to speed up the movement of vapors from the hot pyrolysis zone to the cool condenser zone. However, the selection of inert gas varies with the required reactor type [19]. The yield of produced oil usually depends on the flow rate of inert gas in the reactor [112]. Mostly, nitrogen is used as the inert gas since it is cheaper than others [113]. To limit secondary reactions and improve the oil yield, short hot-vapor residence times of only about 2 s are required [102]. Co-pyrolysis depends on numerous variables, including the type, composition, particle size, and blending ratio of feedstock, the type of reactor used, and reaction parameters such as rate of heating, temperature range, reaction time, etc. Extensive studies to optimize parameters for bio-oil yield for biomass co-pyrolysis have been conducted by Zhang et al. [93]. The efficiency of co-pyrolysis is also impacted by a special parameter: the co-reactant ratio (proportion of biomass to plastics (or other feedstocks). All these factors are separately discussed in a later section of our review. Thermogravimetric analysis (TGA) is also carried out throughout pyrolysis to assess a sample’s weight loss in terms of temperature and time and to analyze the thermal activity and decomposition kinetics of organic materials [114]. There are two types of co-pyrolysis: non-catalytic and catalytic.

4.1. Non-Catalytic Co-Pyrolysis

Non-catalytic co-pyrolysis is performed without the aid of a catalyst [115]. Non-catalytic pyrolysis has been performed under several conditions to produce high-grade bio-oil. However, most of the studies have indicated the need of a catalyst to enhance interaction between the different substrates used in co-pyrolysis [15,93]. During non-catalytic co-pyrolysis, positive synergistic interaction between biomass and plastics resulted in increased hydrocarbon content in bio-oil, accompanied by decreased biochar production has been observed by some researchers [116]. However, it was suggested that, despite improvement in several characteristics of the bio-oil, it is still not suitable for being used as commercial fuels. An overview of a few investigations of non-catalytic co-pyrolysis of biomass with plastics is depicted in Table 3.

4.2. Catalytic Co-Pyrolysis

Catalytic co-pyrolysis (CCP) has an advantage over thermal co-pyrolysis, as the reaction mechanism is used to produce specific fuels and chemicals since several reactions occur at the catalyst sites, for example, dehydration, aromatization, isomerization, oligomerization, alkylation, and cyclization [117]. Through the simultaneous feeding of plastics, tires, or other hydrogen-rich substances along with biomass, CCP overcomes the problem of low hydrogen and high oxygen in the biomass and improves the production and characteristics of pyrolysis products. CCP requires hydrogen-rich substances and biomass together just to achieve an optimum H/Ceff ratio, which reduces catalyst deactivation and produces high-quality outputs [118]. To overcome the disadvantages of non-catalytic processes and to obtain better-quality products, a catalyst is applied in co-pyrolysis [93]. Catalysts increase the petrochemical carbon production (particularly monocyclic aromatic hydrocarbons) and also decrease the formation of biochar by applying the required zeolite catalyst during the procedure [33]. Catalytic fast co-pyrolysis (CFP) is an interesting prospect to transform biomass to potentially fuel-quality bio-oil through the deoxygenation of pyrolysis vapors in the form of H2O, CO, and CO2. Biomass CFP promotes the production of aromatics and the removal of oxygen from pyrolysis products, thus improving bio-oil quality [118]. In CFP, the involvement of a catalyst may increase the production of the targeted product. Zeolite-based catalysts are highly advantageous because their usage during reaction increases the aromatic yield [79]. Zeolite-based catalysts (e.g., HZSM-5) are being used predominantly as catalysts in lignocellulosic biomass catalytic co-pyrolysis with plastics. The catalyst plays a critical role in terms of both the chemical reactions occurring during co-pyrolysis as well as the final product distribution. The addition of multiple catalysts complicates the CCP mechanism, but it is required to investigate the catalyst site’s reaction mechanism. The co-feeding of biomass and plastics is generally carried out in the temperature range of 400 to 700 °C [93]. The catalyst works by reducing the activation energy and reaction temperature in biomass and plastics catalytic co-pyrolysis [119]. Continuous-feeding fluidized-bed reactors and tandem micro-pyrolyzer reactors with downstream packed-bed reactors are also applied in these types of co-pyrolytic processes [120].

Zhang et al. [93] investigated a co-pyrolytic process between cellulose and LDPE in the presence of ZSM-5 catalyst with the aim of assessing any synergistic effect and reporting reactions between oxygenates (obtained from cellulose) and light olefins (obtained from LDPE). The addition of catalysts to co-pyrolysis facilitated dehydration, decarboxylation, and decarbonylation reactions, improving bio-oil efficiency. Hydrotreatment of the bio-oil was suggested as an additional process to maximize hydrodeoxygenation and improve the H/C ratio. However, the uncertainty about the possible source and price of hydrogen must be factored into the economic-viability analysis [121]. Another crucial aspect of utilizing a catalyst is to apply it in an in situ catalytic pyrolysis configuration or an ex situ configuration. In the former case, the feed gets exposed to the catalyst, in the latter scenario the catalyst is simply used to upgrade the pyrolysis vapors. A process flow scheme for carrying out in situ catalytic fast co-pyrolysis was suggested by Yildiz et al. [122]. For feedstock with very high mineral matter (such as agricultural residues) and high levels of contaminants, ex situ pyrolysis is preferred because otherwise these feedstocks can severely deactivate catalysts. Ghorbannezhad et al. [17] undertook an ex situ co-pyrolysis process using sugarcane bagasse pith as the biomass and PET as the hydrogen-rich non-biodegradable feedstock at 700 °C with the help of zeolite-based catalysts. Several extensive reviews on the application of various types of catalysts in pyrolysis and co-pyrolysis of biomass and plastics are available [15,33]. Further, the impact of catalysts on promoting or inhibiting particular reaction pathways during co-pyrolysis of biomass with plastics, tires, and scum was reviewed by Ahmed et al. [121]. In a recent review by Gin et al. [123], the impact of various heating methods, such as conventional, microwave, and plasma heating systems on catalytic co-pyrolysis of biomass and plastics was compared. An overview of a few catalytic co-pyrolytic investigations is provided in Table 3.

Table 3.

Catalytic and non-catalytic co-pyrolysis and their various attributes.

Table 3.

Catalytic and non-catalytic co-pyrolysis and their various attributes.

| Feedstocks | Reactor and Operating Conditions | Catalyst | Remarks or Liquid Yield (wt.%) | References |

|---|---|---|---|---|

| Rice husk + PE | Parr reactor, T 350–430 °C | - | 72 | [124] |

| Empty fruit bunch (efb) of palm + solid tire waste | EFB to tire waste ratio of 25:75 at a temperature of 500 °C; tube reactor | - | 44.3 | [115] |

| Pine cone + LDPE | Semi-batch glass reactor, temp. 500 °C | - | 63.9 | [93] |

| Frying oil + plastic waste | FO/PW ratio of 1:1; fast heating rate (up to 50 °C/min) and a lower reaction time (25 min) | - | 81 | [116] |

| Pine cone + PP | Semi-batch glass reactor, T 500 °C | - | 64.1 | [93] |

| Pine cone + PS | Semi-batch glass reactor, T 500 °C | - | 69.7 | [93] |

| Almond shell + HDPE | Fixed-bed reactor, T 500 °C | - | 50.88 | [125] |

| Cellulose + PS | Pyrex reactor, T 450 °C | - | 80.10 | [126] |

| Cellulose + PVC | Fixed-bed reactor, T 450 °C | - | 45 | [127] |

| Sugarcane bagasse + HDPE | Fixed-bed reactor, T 400–700 °C | - | 60.2 | [128] |

| Pine sawdust + LDPE | Fixed-bed reactor; 450 °C | HZSM-5 | Improvement in the yield and selectivity of aromatics in obtained bio-oil. | [16] |

| Sugarcane bagasse + HDPE | Fixed-bed reactor; 400–700 °C | Mesoporous FAU | Increase in liquid yield and enhancement in the quality of bio-oil. | [66] |

| Sugarcane Bagasse + PET | Tandem μ-reactor coupled with GC 400–800 °C | HZSM-5/ Na2CO3/ γ-Al2O3 | Increase in the production of aromatic compounds such as benzene, toluene, xylenes and ethylbenzene (BTXE). | [17] |

| Grape seeds + waste tire | Auger reactor (pilot scale) | CaO | Deoxygenated bio-oil with improved physical properties, such as viscosity and density. | [67] |

| Sugarcane bagasse + PS | Fixed-bed reactor 500 °C | HZSM-5, MgO, CaO | Improvement in aromatic compound yields in obtained bio-oil. Increase in calorific value and density upgradation comparable to standard diesel fuel quality | [129] |

| Camellia shell + take-out solid waste | Pyro-probe pyrolyzer coupled with GC 700 °C | HZSM-5, CaO, MgO | Generation of aliphatic hydrocarbons in obtained bio-oil; inhibited acid formation | [130] |

| Rice straw + ulvaprolifera macroalgae | Fixed-bed reactor 700 °C | NiFe-LDO/AC catalysts | Improved acid sites, and thereby, advanced deoxygenation and aromatization | [18] |

| Seaweeds + cellulose | Fixed-bed reactor 500 °C | ZSM-5/MCM-41 | Improved cracking, dehydration, decarbonylation, decarboxylation, dealkylation, aromatization, oligomerization, and deamination | [131] |

LDPE: low-density polyethylene; HDPE: high-density polyethylene; PET: polyethylene terephthalate; PS: polystyrene; PP: polypropylene; PVC: polyvinyl–chloride; PE: polyethylene.

4.2.1. Catalysts Used in Co-Pyrolysis

The appropriate selection of the catalyst as well as its supplementation in the process go a very long way in determining the process parameters of co-pyrolysis, including the heating rate, required temperature and pressure regimens, the catalyst:feed ratio, and regeneration requirements. The catalyst should be such that it decreases coking or biochar formation, reduces non-condensable gas (fuel-gas) production, and promotes deoxygenation to improve bio-oil quality.

4.2.2. Zeolites

Zeolites are a type of crystalline aluminosilicate with a uniform pore structure and a three-dimensional skeleton. Aluminate and silicate species (AlO4 and SiO4), also known as hydro–aluminosilicate compounds, are used to generate zeolite. Through structural upgrading, zeolite can reveal different open cavities and crystal formations during chemical reactions. Natural zeolites such as mordenite have been discovered in rocks, and synthetic zeolites such as HZSM-5, H-Beta, H-Y, and their modified variants are commonly utilized in research and industry [118]. The alkylation and aromatization abilities of zeolite catalysts are particularly robust. They can convert biomass or pyrolysis steam into more desirable compounds such as aromatics, resulting in a low-energy method of improving product quality. They are extensively studied because they catalyze the pyrolysis of lignocellulosic biomass very quickly due to the presence of certain acidic properties and shape selectivity [14,119]. Zeolites are efficient at selectively deoxygenating biomass pyrolysis vapors, forming aromatics and effectively removing carbon dioxide from the atmosphere. HZSM-5 has been used in numerous studies because it can generate a variety of useful materials during the catalytic pyrolysis of biomass, including aromatics and aliphatic unsaturated hydrocarbons (olefins) [132]. The effects of adding a catalyst and waste cooking oil on the peak area yield and chemical selectivity of the identified chemicals were examined utilizing pyrolysis-gas chromatography/mass spectrometry for catalytic rapid co-pyrolysis of lignin and waste cooking oil. The aromatic peak-area output was encouraged by an optimum feedstock-to-catalyst ratio (1:3) and an increase in waste cooking oil. The best mono-aromatic selectivity (82.6%) in the identified compounds was achieved when the catalyst-to-feedstock ratio was 5:1 and the waste cooking oil to lignin ratio was 1:1 [133]. The hydrocarbon pool mechanism, deoxidation, cracking, aromatization, aldehyde condensation, and ketone reaction are the key reaction pathways zeolite catalyst. As a selective catalyst, zeolite is preferable. The shape-selectivity of the pore space and the pore size of the molecular sieve determine the conversion of oxygen-containing chemicals into hydrocarbons in the framework of the molecular sieve [118].

4.2.3. Metal Oxides

Metal oxides are widely used in fast catalytic pyrolysis of biomass because of their redox properties. Various acidic-metal oxides (SiO2 and Al2O3), base-metal oxides (CaO and MgO), transition-metal oxides (ZnO, TiO2, and CuO), and complex-metal oxides (Cu/Al2O3) have been seen as catalysts for supporting pyrolysis to produce bio-oil [134].

CaO is widely used as a major base catalyst for biomass pyrolysis because of its environmenttally friendly nature, and many times its addition increases the quality of bio-oil. It reacts with water, carbon dioxide, and various organics at low temperatures (350–600 °C) but shows proper catalytic effects at a higher temperature. MgO is also a very active catalyst, and its addition increases the quality of bio-oil in terms of calorific value and the removal of oxygenated groups [15]. Stefanidis et al. [135] observed that adding Al2O3 with a surface area of 93 m2/g decreased the oxygen content of bio-oil from 41.68 wt.% to 24 wt.% and increased water yield from 21.38 wt.% to 29.08 wt.%. SiO2 is also effectively used reduce the amount of oxygenated compounds such as ketones and aldehydes. It also inhibits the formation of coke [136]. Basic metal oxides are particularly effective in removing oxygen from acids in the form of CO2, leading to a decrease in acidity and an increase in the heating value of bio-oils [136]. Moreover, the base catalysts also tend to promote reactions such as ketonization, aldol condensation, hydrogen abstraction, etc., which in turn leads to lower acid yields and elevated aromatic hydrocarbon yield. Acid catalysts, on the other hand, tend to enhance deoxygenation reactions plus aromatization mediated by the Diels–Alder reaction and hydrocarbon pool mechanism. Keeping in mind the commercialization of co-pyrolysis, many possible approaches have been put forth, some of which include selecting and designing appropriate catalysts, a high feedstock/catalyst ratio, and operation of a bench-scale reactor (where the conditions can be easily optimized for subsequent scaling up of the process). According to studies, combining base and acid catalysts increases hydrocarbon output. CaO was combined with HZSM-5 and shown to be beneficial in lowering acids and enhancing monoaromatic hydrocarbons during hemicellulose and LDPE CP [15].

Metal oxides have been widely applied in processes involving in situ CFP of rice husks and lignin. Aromatic hydrocarbons with alkoxy groups were produced when lignin was pyrolyzed in the presence of CaO [135]. Anatase TiO2 produces simple phenols via vapor phase upgradation of lignin pyrolysates [137]. CeO2, TiO2, and ZrO2 are reported to be very effective in altering bio-oil composition while performing in situ CFP of alkali lignin, and they also increased the yield of guaiacols [138].

4.2.4. Dual-Catalyst Catalytic Method

This method is applied in CFP of biomass to combine the advantages of two different catalysts. Che et al. [139] reported that the combination of metal oxides and HZSM-5 increased the production of aromatics. The yield increased by 6.14% as compared to that of pure ZSM-5, which was thought to be due to the fact that CaO reduces the yield of compounds with low H/Ceff and large size. The co-CFP of xylan and LLDPE in a dual-catalyst bed of CaO and HZSM-5 improved hydrocarbon output significantly. Acids were initially deoxygenated to ketones by CaO, and the ketones underwent aromatization catalyzed by HZSM-5, ultimately leading to enhancement in the yield of aromatics from 27% to 40% (when this procedure was used instead of HZSM-5 alone) [140]. MCM-41 (a type of mesoporous zeolite) has additional surface area and reaction sites that are more easily accessible. As a result, the mesoporous MCM-41 channel advantage combined with the acidity of microporous ZSM-5 (micro-mesoporous ZSM-5/ MCM-41) was projected to improve bio-oil quality by improving reaction and reactant diffusion in the pores [131].

4.2.5. Biochar as Catalyst

Many catalyst investigations have concentrated on zeolite catalysts, inorganic salts, and metal oxides, but these catalysts are either expensive or quickly deactivated, limiting broad-scale industrial usage. Biochar has a lot of pores and active functional groups, so it can also be used as a catalyst. It has non-acidity or weak acidity with very high dispersion of catalytic sites [141]. Biochar proved excellent at removing oxygen from bio-oil, especially coupled with the use of a biochar catalyst and the co-feeding of hydrogen-rich feedstock (microalgae). The amount of oxygen in the air was substantially lowered, from 35% to 9%, while bio-oil yield was kept constant at 35–37 wt% [14]. Catalytic deoxygenation co-pyrolysis of bamboo waste and microalgae with biochar catalyst was investigated and obtained 35–37 wt.% oil fraction [141]. Biochar is naturally generated during gasification/pyrolysis, thus its use as a catalyst can reduce potential waste disposal costs, increasing its added-value (phenols and hydrocarbons). In a two-stage tube furnace, the effects of several catalysts on catalytic co-pyrolysis were examined. Biochar can enhance the synthesis of hydrocarbons while preventing the formation of O-containing (e.g., acids and phenols) and N-species (e.g., amides/amines and N heterocyclics) according to GC–MS. The bio-quality of oil was improved as shown by enhanced heating value and pH [142].

4.3. Condensation Stage

Condensation is one of the important steps in co-pyrolysis because if excluded, then just charcoal and gas will be formed [33]. The co-pyrolysis vapors formed during the process pass through the condensation unit, where they are transformed from the gas phase to the liquid phase. To get a high liquid yield, rapid cooling is required. The residence time of the vapors in the reactor can be controlled by the addition of inert gas. Co-pyrolysis vapors are characterized as a combination of true vapors, micron droplets, and polar molecules bonded with water [19]. The lower vapor temperature (<400 °C) contributes to subsequent condensation reactions that reduce the liquid product’s average molecular weight [79]. In order to prevent liquid deposition, the temperature in the pipes from the co-pyrolysis unit to the condensation unit should be kept at (>400 °C); blockage of machinery as well as the piping system must also be minimized [19].

5. Factors Affecting Co-Pyrolysis Process

Feedstocks, mixing ratios, pyrolysis, and residence duration each stage play parts in synergism during co-pyrolysis. Co-pyrolysis implements a unique and high mixing ratio in contrast to traditional pyrolysis. A significant component in synergy is the kind of blended feedstocks. A combining or mixing ratio is known as the mass ratio of one feedstock to another. It is a particular parameter for co-pyrolysis. The mixing ratio is an essential component that has an enormous influence on synergy. Temperature is another major factor that affects characteristics and output. Residence time is an essential parameter that allows adequate contact for the complete breakdown between feedstocks. The time of pyrolysis has an influence both on output and physicochemical characteristics. Various factors that affect co-pyrolysis are discussed below:

5.1. Effect of Temperature

When the temperature is greater than 360 °C, water production is also increased up-to a certain temperature. As the temperature rises above 580 °C, there is reduced water production. The concentration of polar, aliphatic, and aromatic chemicals in products of co-pyrolysis is mostly impacted by temperature as temperature goes beyond 600 °C [143]. The reactor temperature has an important influence on conversion during pyrolyse and hence the results [120]. More volatility is created at higher temperatures. In a reactor-tube furnace reactor, Wu et al. [144] investigated the effects of different pyrolysis settings on the behavior of maize pot and polypropylene. The recommended values had an output of 52.1%, 4.5% over the base value, with the proportion of maize stove:polypropylene of 1:3. The pyrolysis oil was first heated to 550 °C with an increase in the temperature of the pyrolysis. For the initial part of the experiment, the ratio was 1:1 and the temperatures tested were 450 °C, 500 °C, 550 °C, 600 °C, and 650 °C. The yield of the corn substance’s co-pyrolyse increased and then decreased with changes in temperature, peaking at 44.8% at 550 °C. SSP reactions increased above 450 °C, from 11.2% at 450 °C to 22.4% at 650 °C; however, the variation between 550 °C (11.0%) and 650 °C (11.2%) was less significant. SSP reactions were boosted at high temperature [145]. Due to greater temperature thermal vapor cracking, unfavorable results included increased noncondensing gas production [146]. With the addition of H-ZSM5 catalyst, the total output of catalytic coke and thermal char decreased from 400–800 °C. Huang et al. (2012) examined co-pyrolysis from 450 to 700 °C, with ethylene and propylene as major components of maximal olefin production at 600 °C [145]. The effect from 340 to 460 °C of the catalyst (5 wt.%) on temperature and the ratio of HDPE with a vegetable-oil-to-waste ratio of 1:1 were measured by Xie et al. [147]. The hydrocarbon fuel attained a maximum output of 63.1 wt.% at 430 °C with temperature growth owing to fatty acid salt decarboxylation, carbon chain cracking, and organic matter volatilisation, and subsequently decreasing when the temperature was maximized due to secondary vapor cracking [147]. Higher temperatures increase the quantity of volatiles produced; however, above a certain point, secondary cracking occurs. Thus, optimal liquid yield balances these two processes. Increased temperature duringco-pyrolysis also increases the quality of biochar by releasing more volatiles and reducing biochar formation. High temperatures affect the production of biochar [121]. The distribution of volatiles changes into fewer liquid products and more permanent gasses when the temperature increases over certain suggested temperature ranges [146].

5.2. Particle Size

The particle size of biomass also plays a vital role in co-pyrolysis. Garg et al. [81] concluded small particles (below 0.4 mm) are suitable for obtaining a high bio-oil yield. The specific surface area of particles affects the efficiency of thermo–chemical conversion and reaction time. Higher gas and char yields at particle sizes below 2.03 mm resulted in a reduction in liquid yield with decreasing particle dimensions. Smaller biomass particle size may influence heat transmission, as lower particle temperatures lead to greater gas and volatile emissions [148]. Ahmad et al. [149] examined pyrolysis of lemongrass waste, leftover cooking oil, and bio-oil in a fixed-bed reactor for optimal yields. Lemongrass particle size between 150–300 μm was optimal for yield. The smaller the particle size, the bigger the area that is required in pyrolysis, and the sample quickly burns and the quality of the volatiles is reduced. Bio-oil production was optimized at 400 °C, a 5 min holding period, particle size 300 m, and 80:20 mixing ratio [149].

5.3. Blending Ratio

With increasing biomass blending ratio (biomass/coal), the char yield falls, while the liquid and gas yields increase [150]. Few studies have established that the biomass mixing ratio is directly linked to the original composition of the mixture. High volatiles encourage high bio-oil and syngas production, while biochar is preferred by fixed carbon. The biomass content of the mixture has a major influence on the distribution of solid, liquid, and gas products [150]. Furthermore, the moisture content influences the liquid product’s stability, viscosity, corrosivity, and pH. Li and Xu [151] created two-stage pyrolysis for rapid biomass and coal pyrolysis in a single reactor separated by a series of reactors, thereby facilitating the best management of each reactor’s operation. This hydrogen-rich gas was then used as a source of hydrogen for the hydropyrolysis of coal. The effect on the output and composition of liquid products was carefully examined at different carbon/EFB blending rates (100/0, 75/25, 50/50, 25/75, and 0/100%, w/w%). The higher the mixing ratio, the greater the output of the liquid product and gas, with decreased char. The coal/EFB mixing ratio of 25/75 generated the highest liquid product return (28.62%) [152].

5.4. Pressure

Pressure has a negative effect on liquid yield from co-pyrolysis. Due to a small pressure gradient at high reactor pressures, liquid yield is reduced. A smaller pressure gradient exists between the internal and external surfaces of a pyrolyzing particle when the reactor pressure is high [146]. Char yield is not affected by the increased pressure due to gas product formation. The residence time of highly reactive volatiles under low pressures is limited, leading to good equilibrium between the yield of char and liquid [153]. The volatile residence time and vapor pressure, as well as the number of heterogeneous (char–gas) and homogeneous (gas–gas) secondary reactions, are affected by pressure. The degree of synergies usually rises with pressure due to greater secondary reactions at high pressure.

Collot et al. [154] examined the liquid yields of pyrolysis oil at different pressures and found a deviation of 15% in liquid yields at 5 bars in comparison to 22% at 20 bars. Huang and coworkers demonstrated the maximum deviation in char and liquid yields at 30 bars [155]. Pressure control is critical for the range of synergies during co-pyrolysis.

5.5. Heating Rate

Quan and Gao [150] studied the influence of the heating rate on biomass and coal co-pyrolysis and concluded that a high heating rate of biomass–coal mixtures favors synergism. Pyrolysis rates of rapeseed up to 1273 K were tested in dynamic 40 cc/min nitrogen flux at heating rates of 5, 10, 20, 30, 40, and 50 K/min. This investigation revealed that when the heating rate changes, the liquid yield is varied [156]. Varma and Mondal [157] reported an increase in sugar cane bagasse bio-oil output as the heating rate increased. Bio-oil output increased from 42.34 to 45.53% at pyrolysis temperatures of 500 °C at various warming rates of 10 °C/min and 50 °C per min., whereas carbon output fell from 31.8% to 29.8%.

6. Co-Pyrolysis Products and Applications

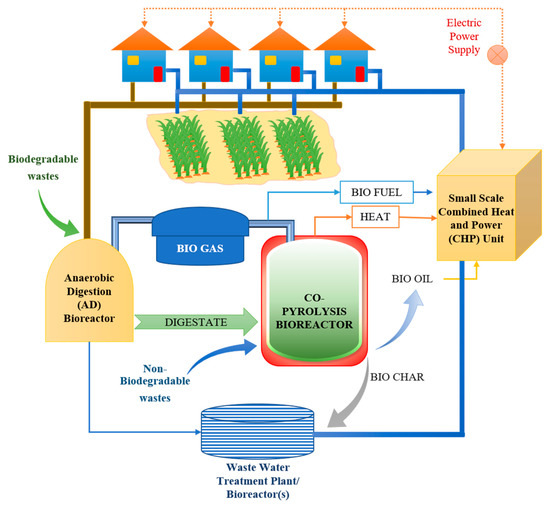

There are three types of products formed from co-pyrolysis:, bio-oil (liquid), biochar (solid), and fuel gas [23]. Their output is dependent on the biomass content and pyrolysis operation parameters [22]. Bio-oil and biochar have numerous industrial uses, but not fuel gas. Fuel gas is not sought, yet during pyrolysis its generation is inevitable. The following covers several uses for fuel gas co-pyrolysis. Figure 2 mentions application of bioreactors for co-pyrolysis in the Integrated Green Energy strategy. The targeted applications and resource availability of fully or partially self-sustaining units such as the one depicted in the figure drive the selection of the co-pyrolysis reactor and process type. Hence, the latter depends on the availability and constitution of the biomass: industrial, household waste, agricultural waste, non-biodegradable wastes, etc. Different types of co-pyrolysis reactors include: fixed bed reactors, bubbling fluidised bed, circulating fluidised bed and transported bed, stirred tank, thermogravimetric analysis, rotating cone, ablative pyrolysis, grinding pyrolysis, auger bioreactor, and microwave assisted reactors. Different reactors are used for different biomass blends in co-pyrolysis. Further, the use of catalysts and operation parameters (temperature, pressure, particle size, heating rate, reaction time) depend on the bioreactor employed as well as physicochemical properties of the feedstock.

Figure 2.

Application of co-pyrolysis bioreactors in integrated green energy approach.

6.1. Bio-Oil

Organic oils or pyrolysis oil is a fluid produced during pyrolysis of various feedstock mixtures. It is an organic, dark brown liquid that may be used as fuel and as a precursor for hydrocarbon production [79]. For example, Mateo et al. [158] found that bio-oil is sufficient for bio-jet fuels from sulfonated activated carbohydrate. Bio-oil has various applications, such as boiler fuels, fuel in heavy-duty engines, biofuel production, hydrogen production, chemical (such as ketones, aldehydes, etc.) production, extraction, binder applications, polyurethane, and bioplastics production [159]. The produced bio-oil can be converted to hydrogen, which is one of the attractive fuels and energy carriers, by gasification or steam reforming [159]. Researchers have recently discovered accessible and economical ways to manufacture bio-oil polyurethane utilized in the production of isolation materials, furniture, and medicinal products [160]. Levoglucosan, an anhydro hexose, is present in abundance in bio-oil derived from co-pyrolysis; however, its yield depends on the operating conditions and type of feedstocks used. Levoglucosan generation by pyrolysis and its recovery from bio-oil was examined by Hakeem et al. [161]. Acid hydrolysis, which can later be utilized in bioethanol generation, can convert levoglucosan to glucose [23]. In addition, researchers identified microorganisms that may be directly used to create high-value biochemicals with levoglucosan. Bio-oil from co-pyrolysis also finds use as a binder in asphalt due to its renewability and low sulfur and nitrogen content [161]. To conclude, commercial application of bio-oil requires further deep fundamental, technical, and economic studies.

6.2. Biochar

Biochar is a carbon-rich solid that possesses unique features, such as favorable porosity, high surface function, and capacity to trade in cations generated using co-pyrolysis. However, biochar output and attributes rely on particular pyrolysis factors, feedstock characteristics, and feedstock mixes [121]. Co-pyrolysis of cotton stalk and sewage sludge, for example, provided biochar production of 32.5% [162], and rice straw or sapstraw and sewage sludge 53.5 or 55% biochar [163]. The results and physicochemical characteristics of biochars produced by co-pyrolysis of various composite feedstocks have been examined by Ahmed and Hameed [121]. Biochar was used for a biomass heater and energy generation in previous industrial facilities, but recently has also be applied as a soil enhancer, compost bulking agent, activated carbon, water and soil remediation, energy, and carbon sequestration owing to its composition [23]. Recently, numerous studies identified the use of biochar adsorption. Due to its advantageous features, such as significantly larger pores, high cation exchange capability, and improved surface function grouping, co-pyrolysis-produced biochar has been shown to adsorb various contaminants such as synthetic colors, metals, phenols, medications, and pesticides [121,164]. Sewu et al. [165] evaluated cationic crystal violet (CV) adsorption capability on biochar produced from kelp algae co-pyrolysis and mushroom subtraction. Zhao et al. [166] investigated the adsorption capability of copper Cu(II) by biochar produced by hazelnut and sewage sludge mixture co-pyrolysis. Gao et al. [167] investigated atrazine adsorption on biochar produced by maize straw and sawdust co-pyrolysis. A new approach of utilizing chemical fertilizers with biochar was examined by Oliveira et al. [168] to minimize the use of chemical fertilizers, increase crop production, and improve water retention. Biochar is a great alternative fertilizer for sustainable agriculture due to the high proportion of non-volatile minerals such as phosphorus and potassium [169]. Amin et al. [169] thoroughly studied several biochar uses.

7. Challenges and Future Perspectives

Biomass pyrolysis is a significant opportunity for both energy and waste disposal. The use of plant or algal biomass, however, is full of numerous deficiencies, including low-quality production of bio-oil (e.g., high oxygen and moisture, corrosive and unstable), coke, biocarbon, and flew gas production. On the other hand, it not only increases the quality and quantity of bio-oil but also provides a wonderful chance to handle these non-biodiagonal wastes by including hydrocarbon-rich waste items such as plastics, old tires, etc. as substrates during co-pyrolysis. However, co-pyrolysis is still challenging and requires further development. Increased levels of heavy bio-oil hydrocarbons contain polyolefins in bio-oil, for example. The rapid use of polyolefins in order to generate light paraffins and olefins is limited by decomposition, which means that high-temperature (above 700 °C) is necessary, which in turn can increase costs. Bio-oils from co-pyrolysis of agricultural biomass also create an excessive amount of oxygenated ingredients, such as acid, acetones, aldehydes, furans, phenols, and anhydrous sugar, because of the pyrolysis of biomass. Thus, to incorporate oil as a liquid fuel, a further upgraded method is necessary. Through standardizing substrate ratios and compositions, co-pyrolysis settings, selection of appropriate bioreactor designs, etc., the improvement of process parameters must be sought. In biomass–plastics co-pyrolysis for high-quality bio-oil generation, the use of proper catalysts is one of the areas of concern. The impact of biomass quality, catalyst, and process variables on biomass and other raw material co-pyrolysis is essential for practical large-scale reactors. Ratios of feedback to catalyst varied from 1:2 to 1:20, which are far too weak for commercialization. The appealing approach to reducing this kind of trash is catalytic co-pyrolysis (CCP) of plastic waste with lignocellulosic biomass. However, the economy of production has to be considered in catalytic processes as the added costs of the catalyst tend to increase overall process costs. One more element requiring substantial research relates to the discovery with diverse substrates of the reaction mechanisms and the reaction kinetics of co-pyrolysis. This will not only allow us to better understand the intricacies of co-pyrolysis, but will also be helpful in identifying the conditions leading to favorable cost-to-benefit ratios.

Fuel gas is a co-pyrolysis byproduct composed of CO2, CO, NOX, SOX, H2S, H2, aldehydes, ketones, volatile carboxylic acids, and gaseous hydrocarbons. It may be used to pre-heat biomass, but it cannot be utilized directly in the environment due to its combustion products. There are, however, numerous treatment and purification alternatives, including electrostatic precipitation, NOX scrubbing, activated carbon adsorption systems for volatile organic compounds, flares, SOX-based fuel gas desulfurization systems, and biofilters [29]. There is, therefore, a need for further detailed investigations to determine the kinetic parameters and different response models to improve handling of process byproducts for the output and composition of liquid fuels from co-pyrolysis of biomass waste in different biological reactor configurations.

8. Conclusions

This review focused on recent advancements and technological challenges in co-pyrolysis of waste biomass to biofuels. To summarize, this review examined a cutting-edge approach for catalytic co-pyrolysis of lignocellulosic biomass with various feedstocks. Researchers are increasingly recognizing that co-pyrolysis can considerably improve the quantity and quality of pyrolysis oil without the need for solvents or free hydrogen pressure. The use of hazardous feedstock reduces the demand for harmful waste disposal into the environment, reduces soil and water pollution, and replaces non-renewable feedstocks, such as fossil fuels. For the manufacture of aromatics, co-pyrolysis of lignocellulosic biomass with waste polymers such as polyethylene, polystyrene, and old tires etc. is far more promising than catalytic pyrolysis of lignocellulosic biomass alone. In comparison to normal pyrolysis, co-pyrolysis could lower the temperature and time required to produce high-quality biofuels. Some researchers have also reported synergistic effects among the substrates used in co-pyrolysis, enhancing bio-oil yield as well as improving its applicability as a liquid biofuel. However, although co-pyrolysis of biomass and hydrocarbon is gaining importance day by day, there are several issues that need to be addressed before the process can be commercialized on a large scale. For example, there is still a knowledge gap in comprehending the reaction kinetics of co-pyrolysis with different types of substrates. Further, different researchers have reported different ideal conditions for co-pyrolysis. Therefore, there is a need to optimize various process parameters, including substrate attributes and co-pyrolysis conditions. Thus, it can be concluded that co-pyrolysis of biomass and non-biodegradable wastes can serve as an effective and efficient alternative waste management method and, more importantly, as an opportunity for achieving energy security in the future. However, there is a need to explore this vista to a greater extent for the betterment of society as well as mankind.

Author Contributions

H.G.: Conceptualization, Writing—Review and Editing. D.S.: Writing—Review and Editing, S.Y.: Writing—Original Draft. P.S.: Writing—Original Draft. C.P.: Writing—Original Draft, R.K.B.: Writing—Original Draft, A.K.B.: Writing—Review and Editing, S.V.: Writing—Review and Editing. Y.-H.Y.: Review and Editing, S.K.B.: Conceptualization, Writing—Review and Editing. A.W.: Conceptualization, Writing—Review and Editing. All authors have read and agreed to the published version of the manuscript.

Funding

This study was supported by the National Research Foundation of Korea (NRF), funded by the Ministry of Science and ICT (grant number 2021R1F1A1050325). This study was also performed with the support of the R&D Program of MOTIE/KEIT (grant number 20014350 and 20009508).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Acknowledgments

The authors would like to acknowledge the KU Research Professor Program of Konkuk University, Seoul, South Korea.

Conflicts of Interest

The authors report no declarations of interest in any capacities, competing or financial.

References

- Bhatia, S.K.; Jagtap, S.S.; Bedekar, A.A.; Bhatia, R.K.; Rajendran, K.; Pugazhendhi, A.; Rao, C.V.; Atabani, A.; Kumar, G.; Yang, Y.-H. Renewable biohydrogen production from lignocellulosic biomass using fermentation and integration of systems with other energy generation technologies. Sci. Total Environ. 2020, 765, 144429. [Google Scholar] [CrossRef] [PubMed]

- Walia, A.; Sharma, S. A Renewable Source of Hydrocarbons and High Value Co-Products from Algal Biomass. In Liquid Biofuel Production; Singh, L.K., Chaudhary, G., Eds.; Wiley Scrivener Publishing House: Beverly, MA, USA, 2019; pp. 35–72. [Google Scholar]

- Mobil, E. Outlook for Energy: A Perspective to 2040; Exxon Mobil: Irving, TX, USA, 2019. [Google Scholar]

- Bhatt, A.K.; Bhatia, R.K.; Thakur, S.; Rana, N.; Sharma, V.; Rathour, R.K. Fuel from Waste: A Review on Scientific Solution for Waste Management and Environment Conservation. In Prospects of Alternative Transportation Fuels. Energy, Environment, and Sustainability; Singh, A., Agarwal, R., Agarwal, A., Dhar, A., Shukla, M., Eds.; Springer: Singapore, 2018; pp. 205–233. [Google Scholar] [CrossRef]

- Walia, A.; Sharma, A.; Sharma, S.; Mehta, P. Microalgae based biofuels—production, improvement, processing and extraction. In Biofuels; Kumar, A., Ed.; Nova Science Publishers: New York, NY, USA, 2018; pp. 137–187. [Google Scholar]