Modification of Electromechanical Coupling in Electromagnetic Harvester

Abstract

:1. Introduction

1.1. Background

1.2. Motivation

2. Harvester Design and Methods

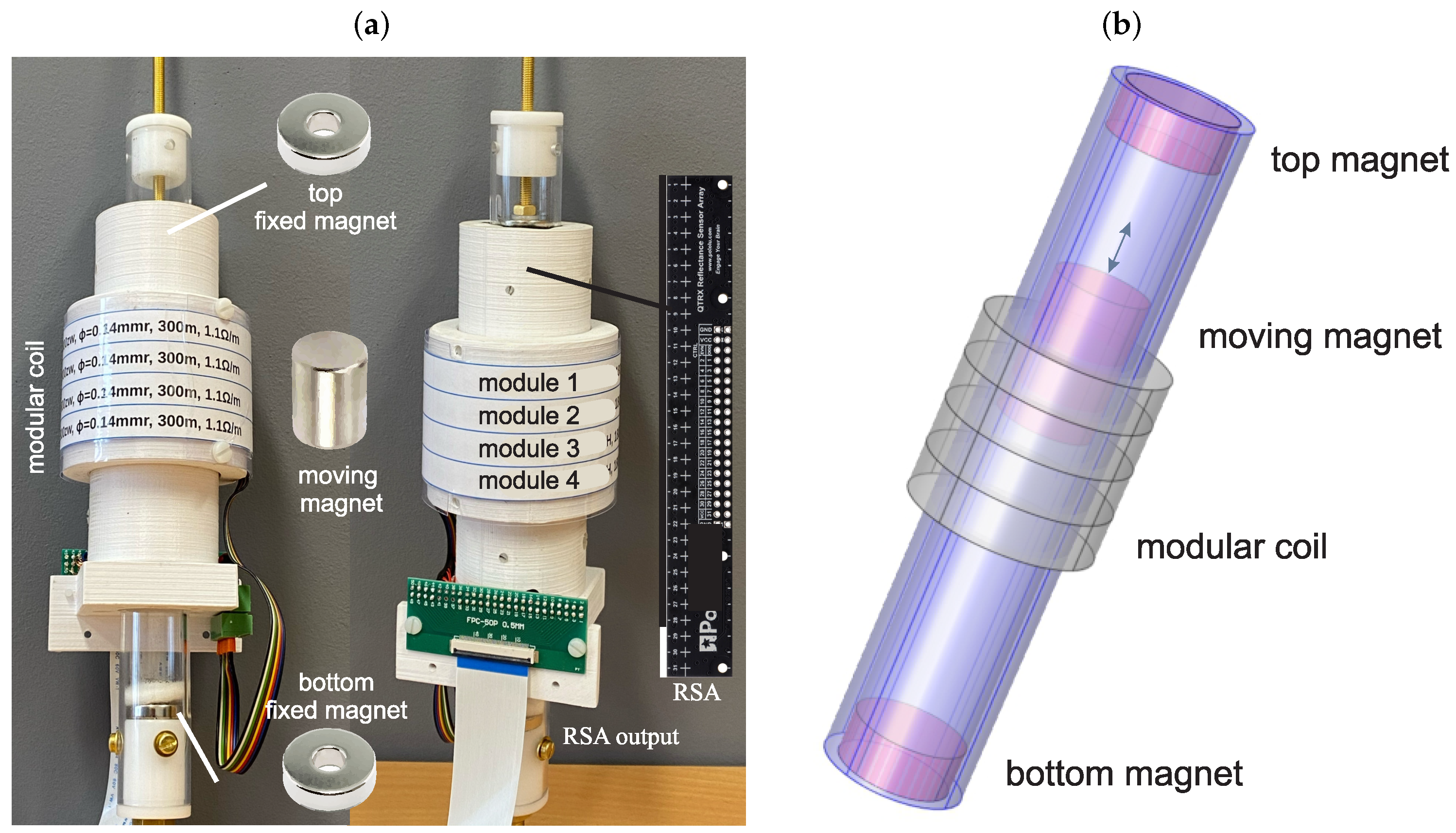

2.1. Prototype Harvester

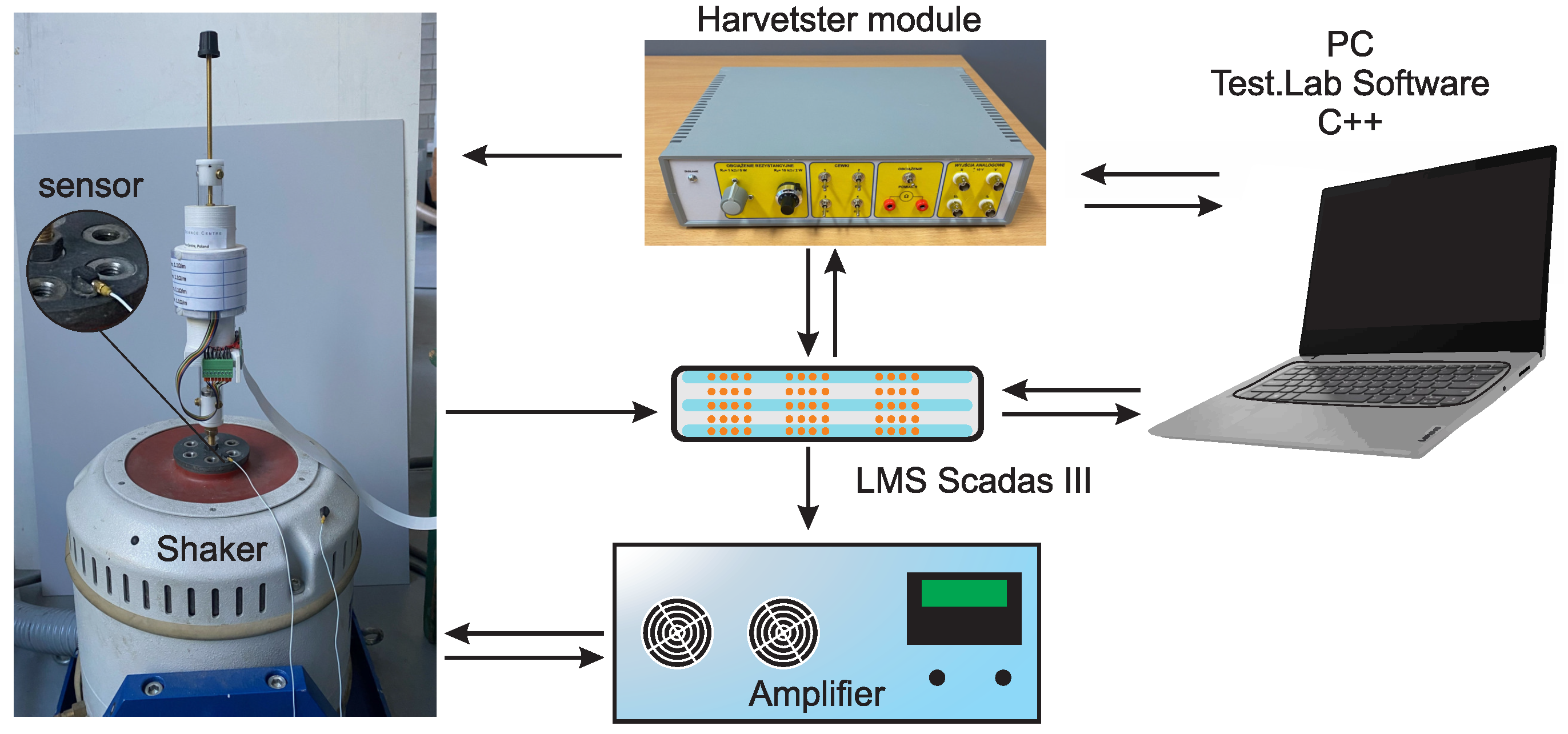

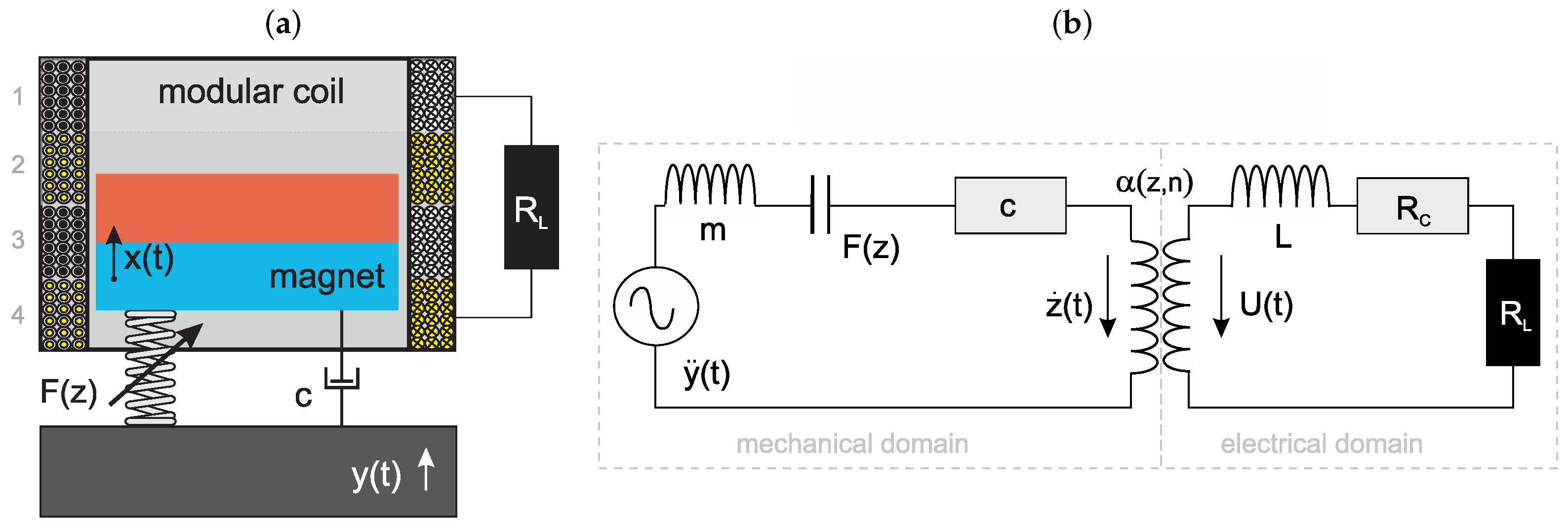

2.2. Equations of Motion

2.3. Magnetic Suspension

2.4. Electromechanical Coupling Determination

3. Results

3.1. Electromechanical Coupling Modeling

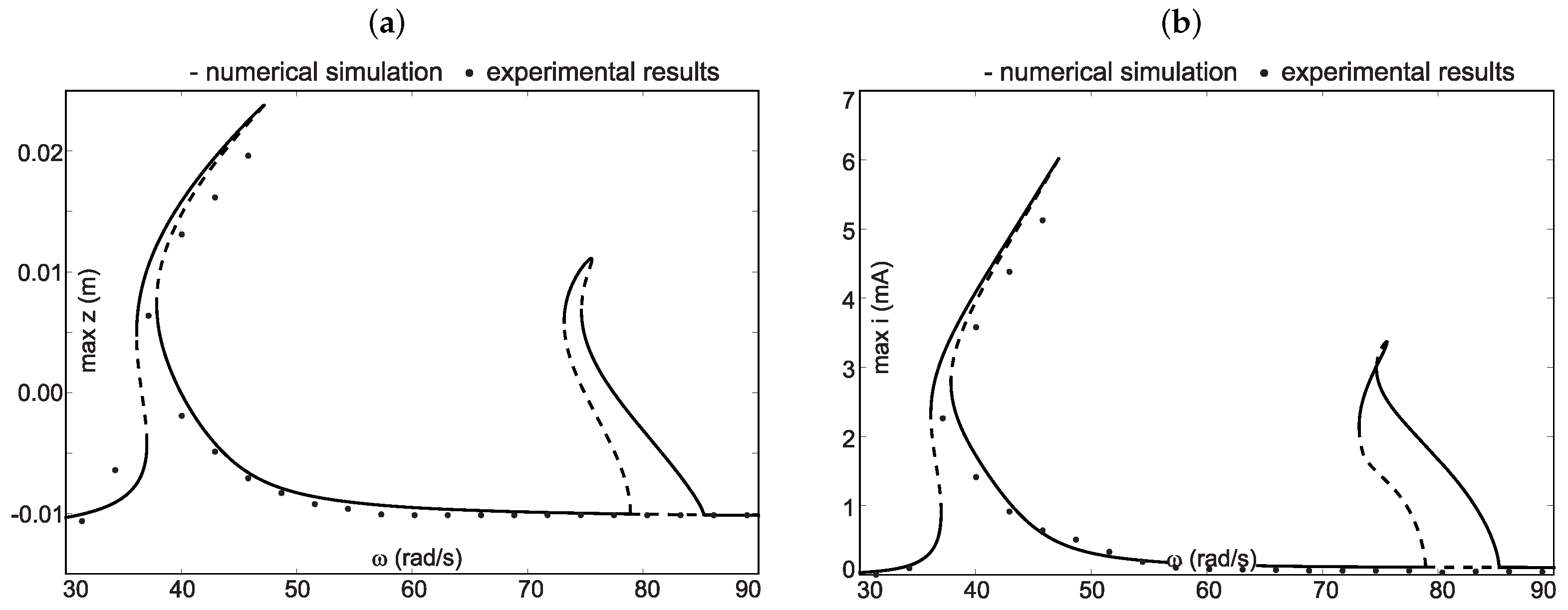

3.2. Experimental Verification

4. Electromechanical Coupling Discussion

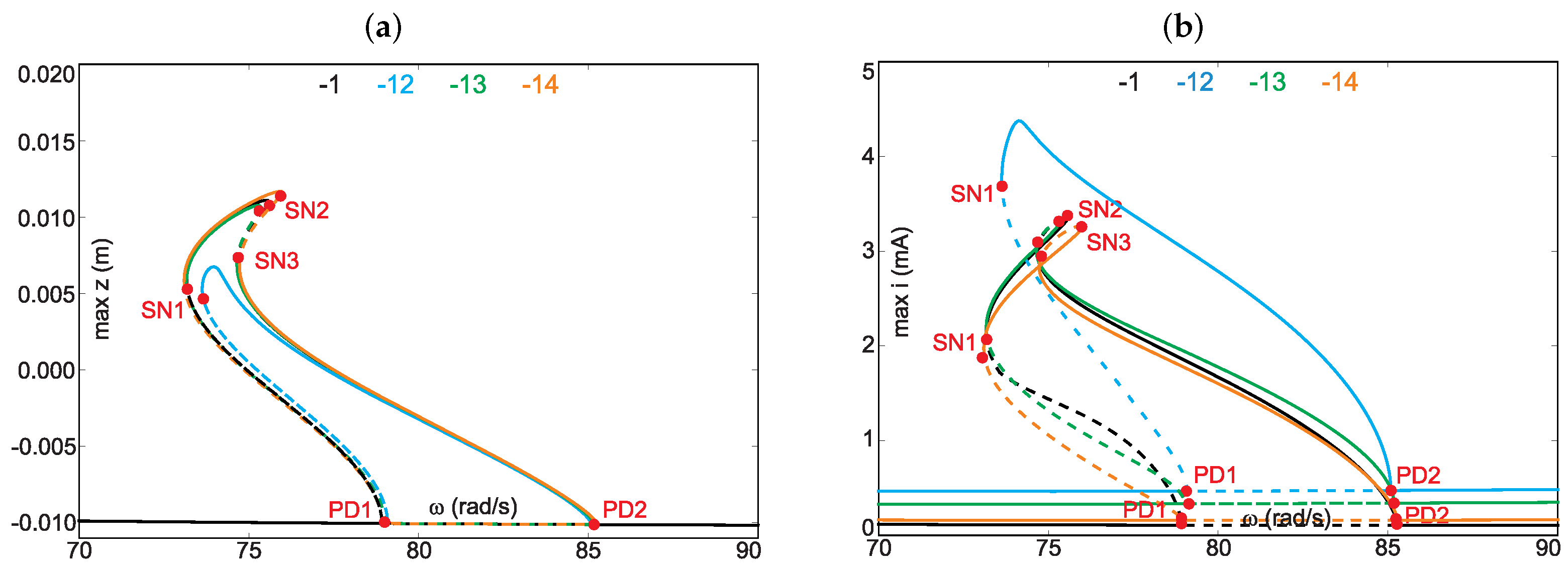

4.1. Frequency Response Analysis

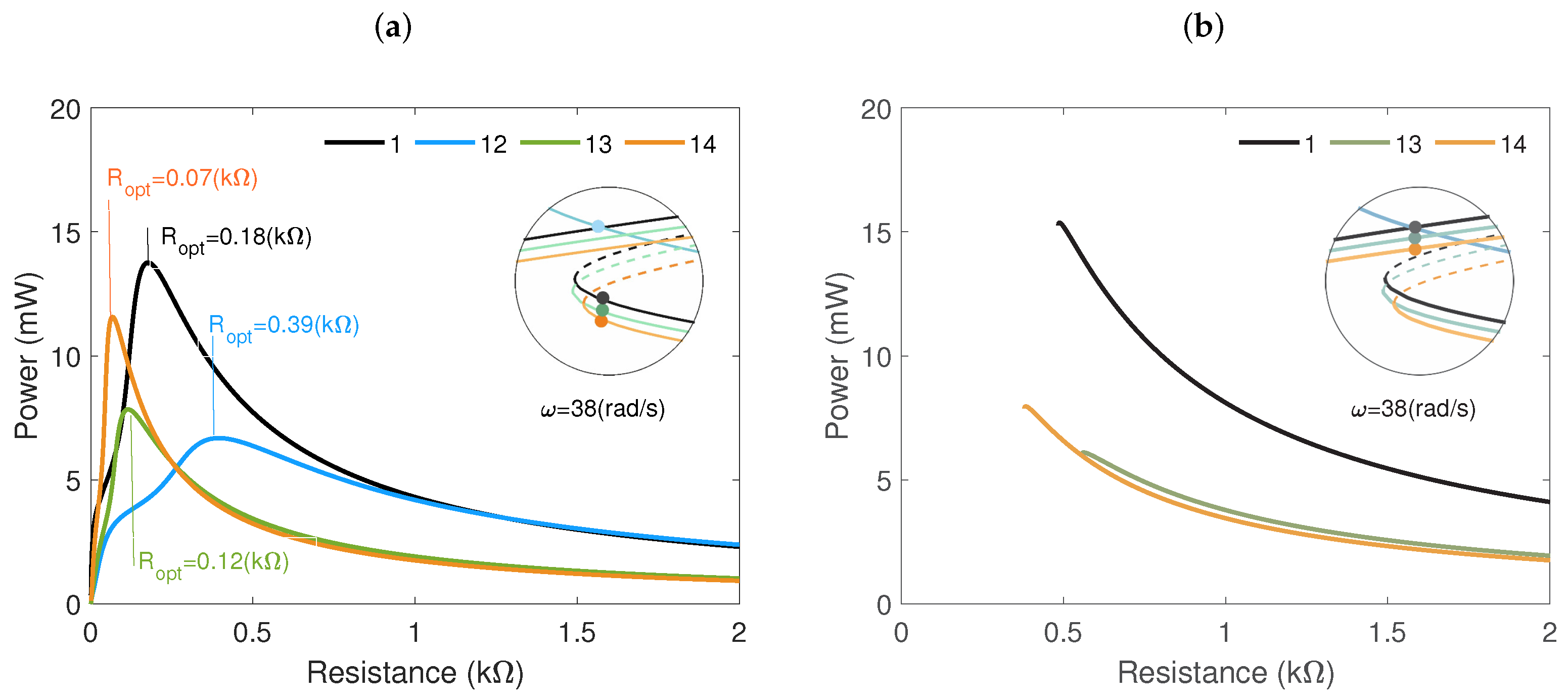

4.2. Influence of Resistance

4.3. Foldover Effect Analysis

5. Conclusions

6. Patents

Funding

Data Availability Statement

Conflicts of Interest

References

- Ghazanfarian, J.; Mohammadi, M.M.; Uchino, K. Piezoelectric Energy Harvesting: A Systematic Review of Reviews. Actuators 2021, 10, 312. [Google Scholar] [CrossRef]

- Ibrahim, P.; Arafa, M.; Anis, Y. An Electromagnetic Vibration Energy Harvester with a Tunable Mass Moment of Inertia. Sensors 2021, 21, 5611. [Google Scholar] [CrossRef] [PubMed]

- Iannacci, J. Microsystem based Energy Harvesting (EH-MEMS): Powering pervasivity of the Internet of Things (IoT)—A review with focus on mechanical vibrations. J. King Saud Univ.-Sci. 2019, 31, 66–74. [Google Scholar] [CrossRef]

- Kecik, K.; Kowalczuk, M. Effect of Nonlinear Electromechanical Coupling in Magnetic Levitation Energy Harvester. Energies 2021, 14, 2715. [Google Scholar] [CrossRef]

- Tang, X.; Lin, T.; Zuo, L. Design and Optimization of a Tubular Linear Electromagnetic Vibration Energy Harvester. IEEE/ASME Trans. Mechatron. 2014, 19, 615–622. [Google Scholar] [CrossRef]

- Glynne-Jones, P.; Tudor, M.; Beeby, S.; White, N. An electromagnetic, vibration-powered generator for intelligent sensor systems. Sens. Actuators A Phys. 2004, 110, 344–349. [Google Scholar] [CrossRef] [Green Version]

- Foong, F.M.; Thein, C.K.; Ooi, B.L.; Yurchenko, D. Increased power output of an electromagnetic vibration energy harvester through anti-phase resonance. Mech. Syst. Signal Process. 2019, 116, 129–145. [Google Scholar] [CrossRef]

- Nguyen, H.T.; Genov, D.; Bardaweel, H. Mono-stable and bi-stable magnetic spring based vibration energy harvesting systems subject to harmonic excitation: Dynamic modeling and experimental verification. Mech. Syst. Signal Process. 2019, 134, 106361. [Google Scholar] [CrossRef]

- Gratuze, M.; Alameh, A.H.; Nabki, F. Design of the Squared Daisy: A Multi-Mode Energy Harvester, with Reduced Variability and a Non-Linear Frequency Response. Sensors 2019, 19, 3247. [Google Scholar] [CrossRef] [Green Version]

- Kecik, K.; Mitura, A. Energy recovery from a pendulum tuned mass damper with two independent harvesting sources. Int. J. Mech. Sci. 2020, 174, 105568. [Google Scholar] [CrossRef]

- Wei, C.; Jing, X. A comprehensive review on vibration energy harvesting: Modelling and realization. Renew. Sustain. Energy Rev. 2017, 74, 1–18. [Google Scholar] [CrossRef]

- Yang, X.; Wang, C.; Lai, S. A magnetic levitation-based tristable hybrid energy harvester for scavenging energy from low-frequency structural vibration. Eng. Struct. 2020, 221, 110789. [Google Scholar] [CrossRef]

- Carneiro, P.; Soares dos Santos, M.P.; Rodrigues, A.; Ferreira, J.A.; Simões, J.A.; Marques, A.T.; Kholkin, A.L. Electromagnetic energy harvesting using magnetic levitation architectures: A review. Appl. Energy 2020, 260, 114191. [Google Scholar] [CrossRef] [Green Version]

- Wang, W.; Cao, J.; Zhang, N.; Lin, J.; Liao, W.H. Magnetic-spring based energy harvesting from human motions: Design, modeling and experiments. Energy Convers. Manag. 2017, 132, 189–197. [Google Scholar] [CrossRef]

- Munaz, A.; Lee, B.C.; Chung, G.S. A study of an electromagnetic energy harvester using multi-pole magnet. Sens. Actuators A Phys. 2013, 201, 134–140. [Google Scholar] [CrossRef]

- Masoumi, M.; Wang, Y. Repulsive magnetic levitation-based ocean wave energy harvester with variable resonance: Modeling, simulation and experiment. J. Sound Vib. 2016, 381, 192–205. [Google Scholar] [CrossRef] [Green Version]

- Saha, C.; O’Donnell, T.; Wang, N.; McCloskey, P. Electromagnetic generator for harvesting energy from human motion. Sens. Actuators A Phys. 2008, 147, 248–253. [Google Scholar] [CrossRef]

- Saravia, C.M. A formulation for modeling levitation based vibration energy harvesters undergoing finite motion. Mech. Syst. Signal Process. 2019, 117, 862–878. [Google Scholar] [CrossRef]

- Mann, B.; Sims, N. Energy harvesting from the nonlinear oscillations of magnetic levitation. J. Sound Vib. 2009, 319, 515–530. [Google Scholar] [CrossRef] [Green Version]

- Morais, R.; Silva, N.M.; Santos, P.M.; Frias, C.M.; Ferreira, J.A.; Ramos, A.M.; Simões, J.A.; Baptista, J.M.; Reis, M.C. Double permanent magnet vibration power generator for smart hip prosthesis. Sens. Actuators A Phys. 2011, 172, 259–268. [Google Scholar] [CrossRef]

- Apo, D.J.; Priya, S. High Power Density Levitation-Induced Vibration Energy Harvester. Energy Harvest. Syst. 2014, 1, 79–88. [Google Scholar] [CrossRef]

- Saravia, C.M.; Ramírez, J.M.; Gatti, C.D. A hybrid numerical-analytical approach for modeling levitation based vibration energy harvesters. Sens. Actuators A Phys. 2017, 257, 20–29. [Google Scholar] [CrossRef]

- Foisal, A.R.M.; Hong, C.; Chung, G.S. Multi-frequency electromagnetic energy harvester using a magnetic spring cantilever. Sens. Actuators A Phys. 2012, 182, 106–113. [Google Scholar] [CrossRef]

- Kecik, K.; Mitura, A.; Lenci, S.; Warminski, J. Energy harvesting from a magnetic levitation system. Int. J. Non-Linear Mech. 2017, 94, 200–206. [Google Scholar] [CrossRef]

- Kecik, K. Architecture and Optimization of a Low-Frequency Maglev Energy Harvester. Int. J. Non-Linear Mech. 2019, 19, 1950097. [Google Scholar] [CrossRef]

- Constantinou, P.; Mellor, P.; Wilcox, P. A magnetically sprung generator for energy harvesting applications. IEEE/ASME Trans. Mechatron. 2012, 17, 415–424. [Google Scholar] [CrossRef]

- Berdy, D.; Valentino, D.; Peroulis, D. Design and optimization of a magnetically sprung block magnet vibration energy harvester. Sens. Actuators A Phys. 2014, 218, 69–79. [Google Scholar] [CrossRef]

- Avila Bernal, A.; Linares García, L. The modelling of an electromagnetic energy harvesting architecture. Appl. Math. Model. 2012, 36, 4728–4741. [Google Scholar] [CrossRef]

- Soares dos Santos, M.P.; Ferreira, J.A.F.; Simões, J.A.O.; Pascoal, R.; Torrão, J.; Xue, X.; Furlani, E.P. Magnetic levitation-based electromagnetic energy harvesting: A semi-analytical non-linear model for energy transduction. Sci. Rep. 2016, 6, 2045–2322. [Google Scholar] [CrossRef]

- Mösch, M.; Fischerauer, G. A Comparison of Methods to Measure the Coupling Coefficient of Electromagnetic Vibration Energy Harvesters. Micromachines 2019, 10, 826. [Google Scholar] [CrossRef] [Green Version]

- Donoso, G.; Ladera, C.; Martin, P. Magnet fall inside a conductive pipe: Motion and the role of the pipe wall thickness. Eur. J. Phys. 2009, 30, 855–869. [Google Scholar] [CrossRef]

- Sneller, A.; Mann, B. On the nonlinear electromagnetic coupling between a coil and an oscillating magnet. J. Phys. D Appl. Phys. 2010, 43, 295005. [Google Scholar] [CrossRef]

- Cannarella, J.; Selvaggi, J.; Salon, S.; Tichy, J.; Borca-Tasciuc, D.A. Coupling Factor between the Magnetic and Mechanical Energy Domains in Electromagnetic Power Harvesting Applications. IEEE Trans. Magn. 2011, 47, 2076–2080. [Google Scholar] [CrossRef]

- Jensen, T.W.; Insinga, A.R.; Ehlers, J.C.; Bjørk, R. The full phase space dynamics of a magnetically levitated electromagnetic vibration harvester. Sci. Rep. 2021, 11, 2045–2322. [Google Scholar] [CrossRef] [PubMed]

- Saravia, C.M. On the electromechanical coupling in electromagnetic vibration energy harvesters. Mech. Syst. Signal Process. 2020, 136, 106027. [Google Scholar] [CrossRef]

- Kecik, K.; Kapitaniak, M. Parametric analysis of magnetorheologically damped pendulum vibration absorber. Int. J. Struct. Stab. Dyn. 2014, 14, 1440015. [Google Scholar] [CrossRef]

- Kecik, K. Dynamics and control of an active pendulum system. Int. J. Non-Linear Mech. 2015, 70, 63–72. [Google Scholar] [CrossRef]

| Parameters | Module 1 | Module 2 | Module 3 | Module 4 |

|---|---|---|---|---|

| Wire diameter (mm) | 0.14 | 0.14 | 0.14 | 0.14 |

| Number of turns (−) | 1800 | 1800 | 1800 | 1800 |

| Resistance (Ω) | 330 | 330 | 330 | 330 |

| Inductance (H) | 0.25 | 0.25 | 0.25 | 0.25 |

| n | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 1 | 0.1514 | −0.8818 | −0.915 | −1.651 | −0.0038 | −1.045 | 1.013 | −0.0839 | 1.072 |

| 12 | 0.1907 | −1.279 | −1.652 | −2.592 | −0.6408 | −2.094 | 0.8981 | −0.8861 | 1.356 |

| 13 | 0.2163 | −0.7958 | −1.632 | −1.769 | −1.087 | −1.415 | −0.1359 | −0.718 | 0.1624 |

| 14 | 0.2426 | −0.7538 | −1.599 | −1.49 | −1.028 | −0.876 | −0.1482 | −0.0785 | −0.1259 |

| n | w | ||||||||

| 1 | 0.4296 | 0.5979 | 0.491 | 0.0928 | 0.2442 | −0.1362 | 0 | 0 | 66.57 |

| 12 | −0.0208 | 1.042 | 0.3705 | 0.5264 | 0.2844 | 0.1271 | 0 | 0 | 66.66 |

| 13 | −0.2258 | 0.0835 | −0.0586 | −0.0992 | −0.1312 | −0.1678 | −0.1303 | −0.0914 | 63.81 |

| 14 | 0.2122 | −0.3735 | 0.1808 | −0.5032 | 0.0094 | −0.5009 | −0.0939 | −0.3074 | 67.63 |

| n | R-Square | Adj R-Square | RMSE | SSE |

|---|---|---|---|---|

| 1 | 0.9936 | 0.9935 | 0.1480 | 13.69 |

| 12 | 0.9975 | 0.9974 | 0.1462 | 13.36 |

| 13 | 0.9960 | 0.9959 | 0.1319 | 10.84 |

| 14 | 0.9889 | 0.9886 | 0.1899 | 22.46 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kecik, K. Modification of Electromechanical Coupling in Electromagnetic Harvester. Energies 2022, 15, 4007. https://doi.org/10.3390/en15114007

Kecik K. Modification of Electromechanical Coupling in Electromagnetic Harvester. Energies. 2022; 15(11):4007. https://doi.org/10.3390/en15114007

Chicago/Turabian StyleKecik, Krzysztof. 2022. "Modification of Electromechanical Coupling in Electromagnetic Harvester" Energies 15, no. 11: 4007. https://doi.org/10.3390/en15114007

APA StyleKecik, K. (2022). Modification of Electromechanical Coupling in Electromagnetic Harvester. Energies, 15(11), 4007. https://doi.org/10.3390/en15114007