1. Introduction

Temperature control systems are an essential part of various processes and are widely used in the industrial sector to automatically control large systems. Such control systems are responsible for product quality and efficiency. The precision of temperature control has become one of the decisive factors in terms of operational security and product quality [

1]. In temperature control, a transfer of heat is achieved through various sources or modes, such as convection, radiation, etc. [

2]. For temperature control, proportional integral derivative (PID) algorithms represent one of the most used tools in the industrial sector. PID is a common method used in industry to control processes. There are many other complex systems associated with processes that have non-local dynamics involving long-term memory effects, which, unfortunately, PID controllers lack. Fractional calculus, such as integration and differentiation of the arbitrary order, can be used for higher-accuracy modeling [

3,

4]. A standard PID model used for control purposes is based on integer order calculus [

5], and the non-locality property is not present in integer derivative operators [

6]. However, these techniques struggle with some issues. The major issue that arises in control engineering implementation is fractional calculus, which is a very complex method. However, with the passage of time, researchers found different solutions to overcome these issues by identifying and approximating geometric and physical interpretations [

7]. A fractional-order control system is designed to control systems more effectively. Fractional-order PID (FOPID) controllers, such as PID [

8] and CRONE (French acronym of commande robuste d’ordre non-entier; non-integer-order robust controller) [

9,

10,

11,

12], are widely used in the literature, owing to the effectiveness of such controllers in control systems.

FOPID controllers have a major advantage of better tuning knob systems. The tuned parameters are increased in FOPID controllers. The tuning methods proposed by the fractional-order PID controllers in control system design include optimization with integral criteria [

13], constrained min–max optimization [

14], swarm optimization [

15], autotuning methods [

16], and robust tuning methods [

17]. In [

8,

13], the authors present the FOPID controller as the best among PID controllers, owing to its superior implementation in practical applications.

In this review paper, we aim to explore the advantages of adapting FOPID controllers in industrial systems, with a focus on the specific advantages of using such controllers. The applications of fractional-order PID controllers in temperature control systems and the shifting of PID controllers towards fractional-order PID controllers are discussed in detail. The rest of this review paper is organized as follows. In

Section 2, we present the developing trends of fractional-order PID controllers, along with fractional-order PID control landmarks in

Section 3. Different applications of fractional-order PID controllers, such as the use of PID controllers in temperature control systems and various other sectors, are discussed in

Section 4,

Section 5,

Section 6 and

Section 7. Finally, a conclusion is given about fractional-order PID controllers and their applications in temperature control systems in

Section 8.

2. A Developing Trend of Fractional-Order PID Controllers

In the past, simple PID controllers were used in the industrial sector to efficiently regulate flow, pressure, temperature, and other variables. Recently, FOPID controllers have started to replace PID controllers in industry. To understand FOPID controllers, first, the functionality of PID controllers needs to be made clear. PID controllers have three major parameters: proportional, integral, and derivative constants. These parameters are responsible for managing errors. A transfer function of a PID controller is termed

; a block diagram of a PID controller is shown in

Figure 1. With the growing trend of FOPID, a question arises about acceptance in the industrial sector, which can be summarized as follows: “Do implementation complexity and cost concerns of FOPID controllers outweigh the benefits arising from additional tuning flexibility of FO control?”. A PID controller can easily be implemented with application of the control law mentioned below for a software code:

where,

is the proportional gain (determines the output response to error),

is the derivative gain (the overall contribution of the derivative),

is the integral gain (how much the control output generates), and

is the error at time

k. With time, the industrial sector demands more control and advanced controllers for increased accuracy; this shifts the sector towards fractional-order PID controllers. In fractional-order PID controllers, approximation is used in form of a transfer function because conventional transfer demands more resources. Fractional-order PIDs are more reliable and useful as compared to a typical PID controller, with more efficient and reliable software solutions used for complex implementations. Such tools aid in implementation. The industries shift towards Fractional-order PID controllers offer these benefits, as well as overall performance improvement. The difference between conventional and fractional-order PID controllers is the result of global optimization. An optimization-based method tunes the controller to obtain the best gain. An artificial bee colony algorithm used to controlling a non-linear boost converter [

18] is a simple example of such a controller. Fractional-order PID controllers are used to improve the startup response, with fewer actions compared to PID controllers, which helps to improve fractional-order PID controllers [

19]. Improvements in the control law help the industrial sector by controlling processes. More resistance to disturbance and voltage regulation are beneficial, helping to achieve better quality and regulation, resulting in better product quality and industrial production margins.

A related study was conducted in which the liquid-level control problem was resolved with both

PID- and

-type controllers. The

[

20] controller achieved better performance as compared to the PID controller. More remarkable control law results were achieved by measuring the variance of the control signal. In the liquid control problem, the fractional-order PID controller has a value of 1.4, and this value changes to 3.4 for the PID controller. Similar work is discussed in [

21] wherein the authors reduced the control efforts of the systems by reducing the control efforts of the precision system. Control systems, i.e., precision positioning processes, control heat generation, resulting in a loss of precision. The reduction in energy in the control effort affects the results. Minor changes made to improve the control law may be more valuable for the industrial process. Such changes have an impact on both production and control processes. This improves the quality and efficiency of product manufacturing.

The fractional-order PID controller design presented in [

22] demonstrates that PID controllers are inefficient in modern usage. This inefficiency was resolved by fractional-order PID controllers. In [

23], the authors mentioned that the design of FOPDT plants can be used to address the fragility of fractional-order PID controllers. The researchers supposed that the controller parameters are subject to changes and variations. In a practical approach, the parameters are adjusted manually. Knowledge about FOPID fragility can be very important. Knowledge of control performance fragility can also be useful in the non-ideal realization of fractional-order PID controllers. An important study conducted in [

24] addressed the inadvisability of using FOPID controllers, and the authors stressed the importance of applying a proper optimization procedure. It is possible to use integer-order PID controllers, which are superior to fractional-order PID controllers. However, above theory is unsatisfactory due to a lack of evidence, and its conclusion usually addresses a specific problem.

The robustness method discussed in [

25] suggests that the number of controller parameters is much larger than indicated in the design specifications. More controller parameters can enable improved performance measure of the controller. The requirements are satisfied by using this principle. Such a set or parameters is known as boundaries. The set size is closely related to the fragility of the controller and can impact the robustness of the system. in a communication channel control unit operating in the frequency domain, it is more beneficial to use a fractional-order PID controller for the response loop of the feedback system. These controllers also show fragility. However, there are some research gaps in terms of fragility and selection of controllers. Fractional-order PID controllers are very important and beneficial in terms of control design and frequency domain concepts.

In [

26], multi-input and multi-output controllers with simple designs were used, whereas Schlegel et al. [

27] presented a PI controller design. The upper limit of the sensitivity function allows for computation of an admissible controller parameter region. In contrast, the sensitivity functions defined in cases where the system requires increased bandwidth are frequency-dependent [

28,

29,

30,

31,

32,

33]. Parameter variation of a robust design in a control system can be resolved by using the max sensitivity properties of a controller. A similar study was conducted in [

34], with concluding remarks about the reliability of the controller, raising a question about the risks of such complex implementations of fractional-order PID controllers. Complicated systems with complex components can be risky and may cause system failure [

35]. Theoretically, it is possible to affirm the dependency and reliability of the computations of FOPID systems. The technology readiness level also suggests that such controllers can be deployed at the industrial level [

36]. The performance of a tuned FOPID controller was assessed in [

37]. Increased reliability can be achieved with further research in this domain, which will help the industrial sector to better adapt controllers, especially FOPID controllers.

3. Fractional-Order Control Landmarks

After 20 years of research and investment, fractional-order controllers have become the main component of industrial control systems. Such controllers have revolutionized industrial control, offering considerable benefits in terms of cost and analysis of the control performance. Fractional-order control systems represent a revolution for industry and became a standard in various industries. Implementation of fractional-order systems depends on the cost of the basic fractional elements [

38]. FOPID controllers are more focused on twin rotor systems, wherein disturbance is rejected by the controller. In a boost converter, a FOPID controller can improve the startup response. This can be achieved by using fewer on–off switching actions compared to optimal PID controllers. FOPID controllers have the advantage of better rejection of disturbances and better output regulation.

In this section, our main focus is the benefits of the fractional-order control systems in control implementation. We have on fractional-order control systems for more than twenty years. The benefits can be described as follows:

Control system improvement;

Optimal control time delay contribution;

Disturbance rejection control contribution.

In the below sections, we briefly mention the milestones regarding the abovementioned areas. The evidence relies on a mathematical basis and analytical solutions in optimization.

3.1. Early Fractional Analysis

One of the key advantages of fractional-order control is understanding of the frequency domain, owing to the utilization of fractional calculus. Calculus is a useful tool for allowing and modeling the order of derivatives. The dynamics of the modeling system expand with time because of this magnified tool and the expanded concepts of differential equations. In dynamic system models, the exploitation of fractional calculus increases with the frequency of characterization. Partial tuning of the control system is possible, and finer tuning of controllers for improved performance is a reality. A concrete example of improved performance with fractional-order control in the frequency domain is described [

39]. A loop-shaping design technique was employed to prove the improvement in controller performance. A much better understanding of a fractional-order control system is obtained in [

40], with a focus on the frequency domain and its advantages. FO controllers were also studied [

9,

39]. Such control systems have a property of isodamping and have received much attention due to their potential to improve FO controller performance. In the ideal realization, the researchers focused on establishing a constant phase margin at the gain crossover. Such an approach can improve the stability and robustness of the system. In an open loop, the sporadic gain variations in a transfer function do not lead to a phase shift. Therefore, design that preserve phase margins can also contribute to robust control and stability improvement of the system. This concept is known as fractal robustness and is described in detail in the literature [

41,

42].

A more comprehensible demonstration of isolation is provided in [

13], and a description of property generalization can be found in [

14]. The negative feedback of an amplifier circuit represents an ideal way to determine the robustness to changes [

43]. The ideal shape of the open-loop transfer function, known as Bode’s ideal loop, is expressed as follows [

44]:

where

ωc is the gain crossover frequency, which is defined at

L(

jωc) = 1. The slope of the magnitude curve is defined as parameter

γ, which is determined by the fractional slope of −20

γ dB/dec; this can be on a log-log scale, with a flattened phase characteristic at the value of −

γ π/2 radii for the phase curve of the system [

45]. From a researcher’s point of view, properties associated with fractional-order dynamics can be very beneficial in control systems. The phase margin also remains constant, and its role is independent of gain changes in the frequency range. Both the slope and margin of such a curve can be varied in terms of fractional-order and system preservation, which are very important factors for robust control of the system.

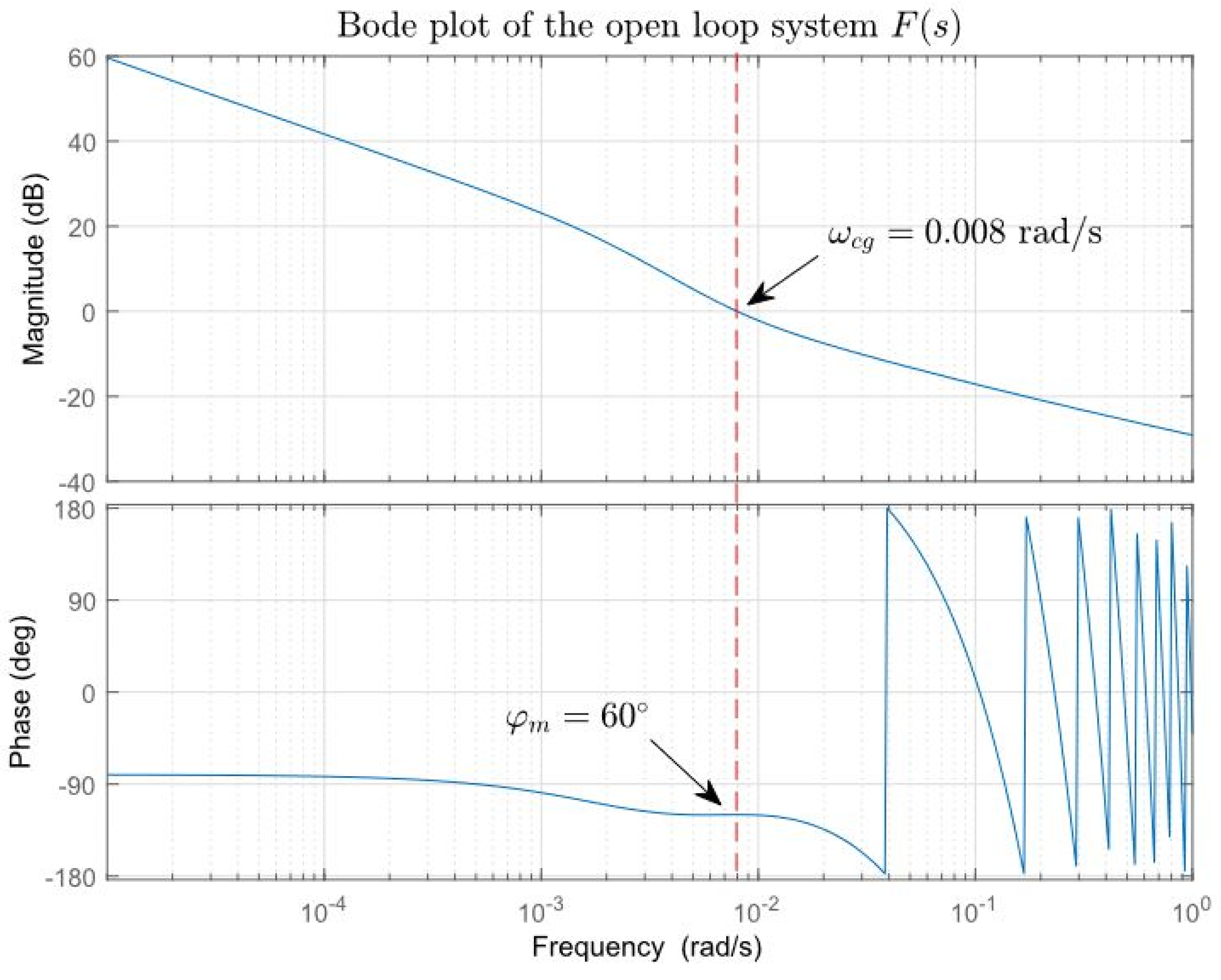

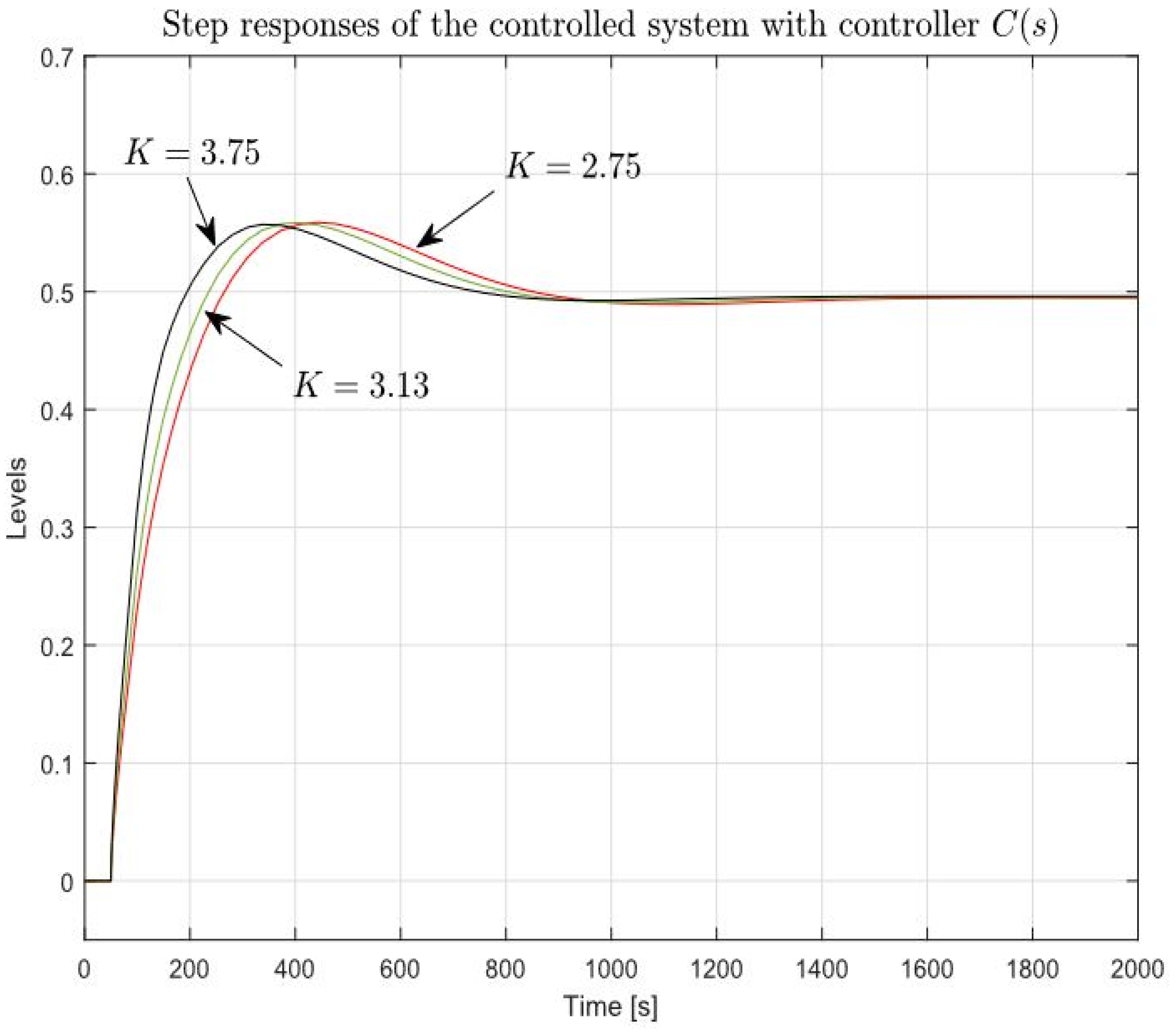

Figure 2 shows the isodamping properties of the open-loop transfer function (Bode plots), and

Figure 3 shows the step response of controlled systems, clearly indicating a flat phase curve at the crossover frequency. Controller parameter variation results in improved robustness of the step response of the system. This transfer function is used to indirectly tune the controller problem and to tune PID controllers [

46,

47] based on Bode’s function. An example presented in [

35] shows the importance and benefits of fractional-order control. Such fundamental systems have potential applications in robotics, such as translation and rotational motor design.

The advantage of using a closed-loop system was clear, as such systems provide infinite gain margin while keeping phase margin constant; this characteristic provides the incentive to tune the system in response to the fractional-order changes. However, there is some uncertainty, which is a problem of the frequency domain. In controllers, the flattened phase is a major asset, which becomes the central objective of the frequency domain of fractional controllers.

3.2. Concerns about the Optimality of Time-Delay Systems

Fractional orders are also helpful in the control of time-delay systems. One such time-delay is the time interval in which the control system does not respond to the control signal. These kinds of signals are known as time-delay systems or lags. Some of these systems exhibit very large time delays. These delays cause a decline in the performance factor in control loops, which affect performance affected. Bhambhani et al. [

48] identified an optimal solution for this research question with respect to fractional-order controllers in time-delay systems.

Figure 2.

Bode plot comparison of frequency, phase, and magnitude in isodamping [

49].

Figure 2.

Bode plot comparison of frequency, phase, and magnitude in isodamping [

49].

A study on F-MIGO investigated the utilization and advantages of fractional-order control for time-delay systems. Under real-world conditions, the controller causes large overshoots, and the system requires only a small fractional order, which makes fractional- order control systems more desirable and useful than normal PID control systems [

50]. The contribution of fractional-order integrators to time-delay system control in terms of relative time-delay parameters can be demonstrated by denoting

L as time delay and

T as time constant, as follows:

Overshoots are maintained when plant gains are varied in a tuned FOPID controller system. Both the time delay and constant can be determined from a classical first-order delay plant model:

Figure 3.

Different levels of step responses in isodamping of a control system [

49].

Figure 3.

Different levels of step responses in isodamping of a control system [

49].

This model represents an in/out lag of

L sec upon system startup, and the controller design becomes more complicated when the time delay is larger. This can result in a decline in the performance coefficient of the system. This analysis can determine the impact of fractional order in tuning a system (time delay). The value of

t varies in delay-dominated system (

L>>

T) compared to lag-dominated systems (

T>>

L). A detailed summary of FOPID controllers and usage comparison are shown in

Table 1, which clearly represents a milestones achieved in the literature.

Table 2 is a summary of relevant papers classified according to milestone achieved in the literature related to the use of FOPID for temperature control.

3.3. Contributions of Disturbance Rejection in Systems

Disturbance rejection is an important requirement of fractional-order control systems. In real-world applications, control systems are exposed to environment disturbances, which are usually unpredictable. Control systems are designed in accordance with specifications of the system designer. A robust and practical control system is one that can control the negative impacts of environmental disturbances. Therefore, in control performance, a given disturbance rejection controls the tuning of the frequency domain, and the additive output disturbance of fractional-order controllers employs a constraint function. The constraint function is sensitivity-based, and FO controllers employ sensitivity function constraint to improve the performance the disturbance rejection of controllers.

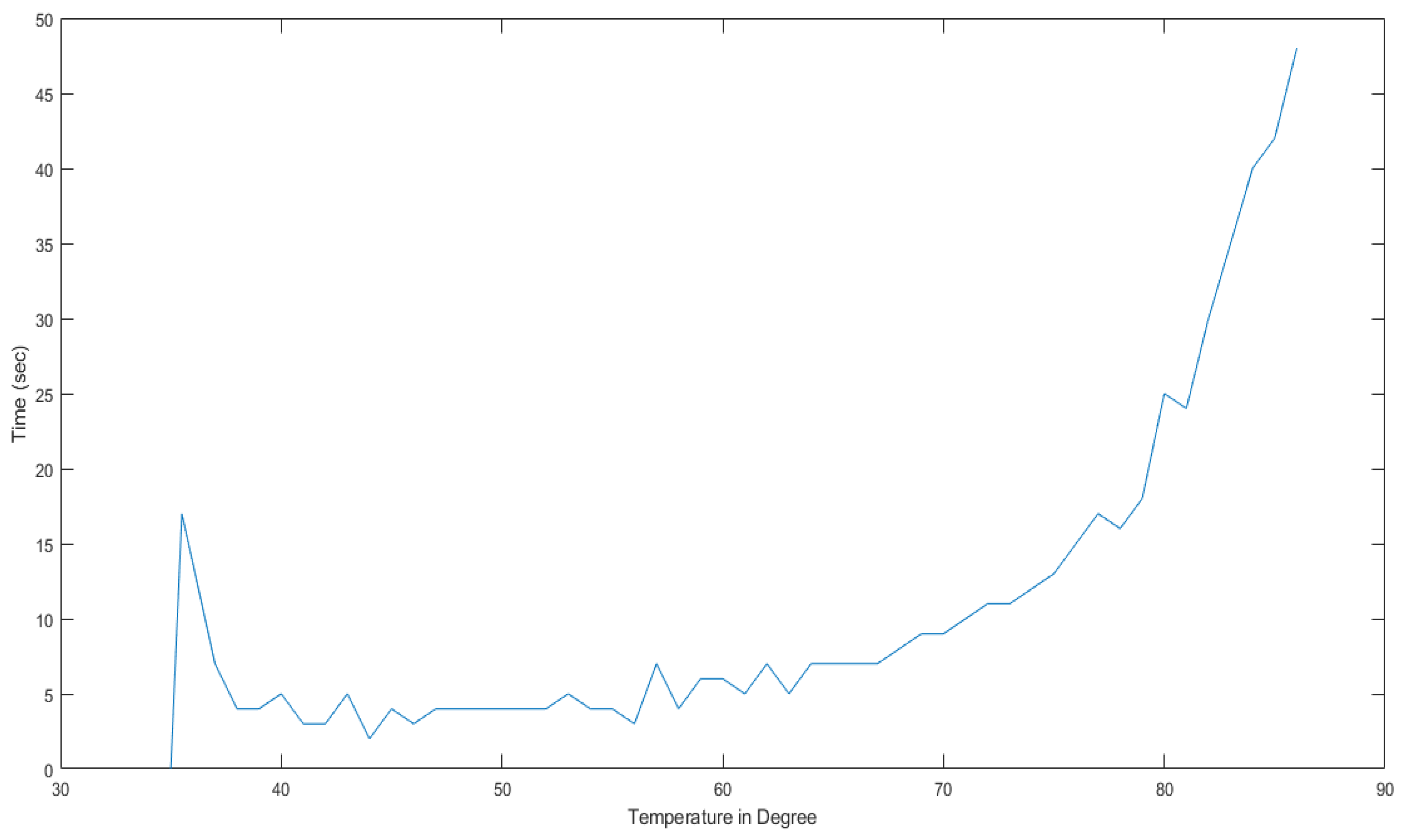

4. Temperature Control Transfer Function

The open-loop system step response obtained from the experiments is shown in

Figure 4. The step response of the open-loop and transfer function model is obtained from the equations. The temperature control transfer function analysis is given using multiple applications of PID controllers in the temperature control systems. The open-loop experimental data are taken from [

2], with the time and temperatures graph shown in

Figure 4. The temperatures rise over time because the temperature increases with heat input.

Temperature control is the main task of PID controllers. The more the system controls the temperature, the more reliably and efficiently the system works. The temperature control system is responsible for heat transfer. Control is achieved through various sources or modes. The PID controller is an essential part of temperature control, as demonstrated by researchers and experts.

5. Fractional-Order PID Controllers in Bioreactors

Bioreactors represent the most complex process in industry. The processes of bioreactors are highly non-linear and used for multiple purposes. Some applications include water treatment and production of medicines, etc. Bioreactor dynamics depend on temperature, pH concentration, and oxygen. Control factors in bioreactors are very important in terms of product quality. There are multiple ways to control bioreactors. Nagy [

51] a model of a predictive controller based on an artificial neural network for temperature control of a bioreactor. Liu et al. [

52] presented a novel non-linear guided intelligent controller inspired by the command properties of glucose in the human body and applied it to bioreactor systems, with temperature as the main process parameter, as it influences thermal movement in bioreactors.

The growth rate is directly affected by temperature. According to previous research, the growth rate increases by two times with a 10 °C rise in temperature, although this growth slows and eventually decreases. Control temperature within a specific range helps to maximize plant growth in the bioreactor.

A bioreactor is tank where many reactions occur simultaneously. These reactions occur in liquid medium; there are three major types of bioreactors:

Batch;

Continuous;

Semi-batch

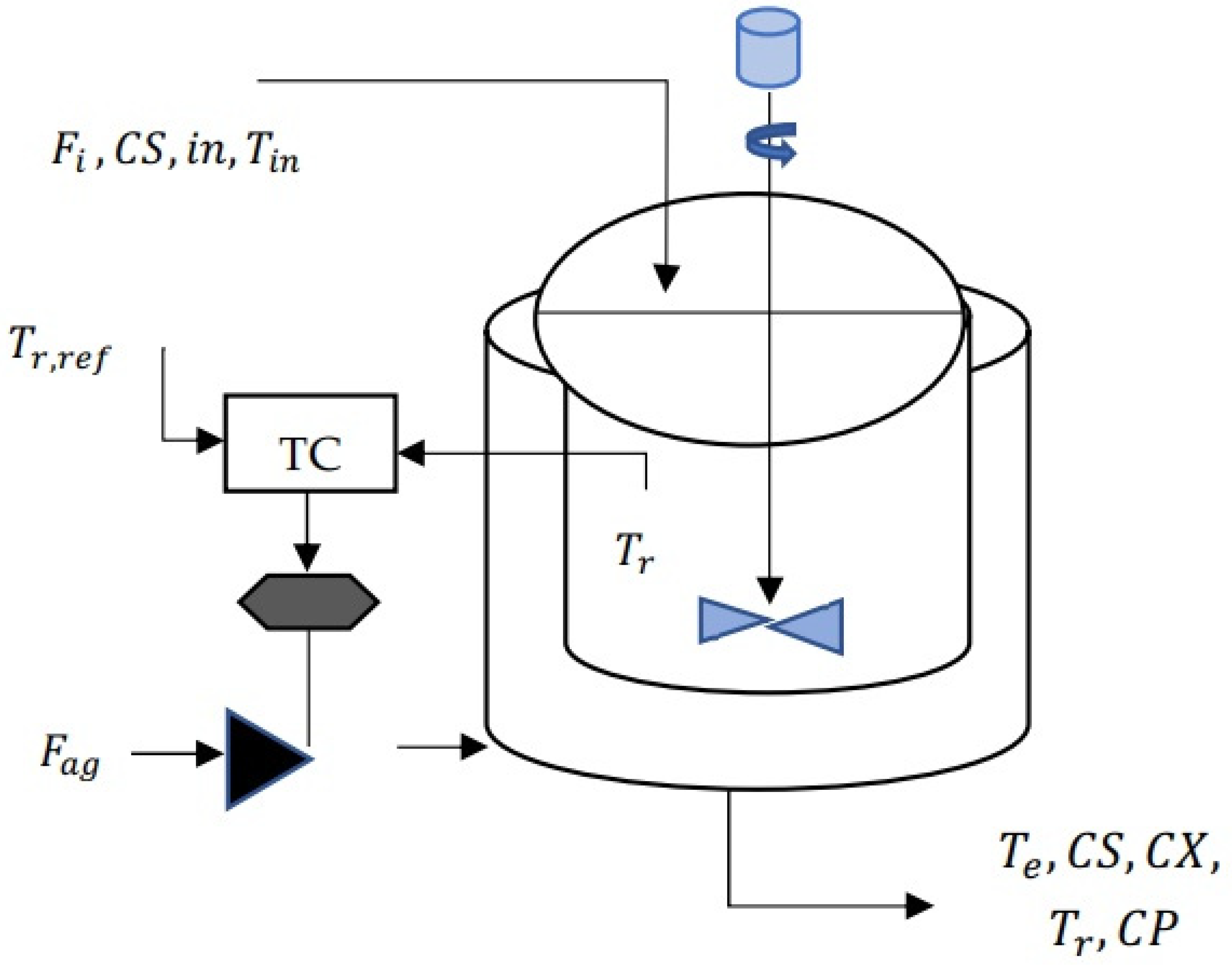

In continuous bioreactor mode, the inflow and outflow work continuously; large-scale production is usually operated in this mode, mainly due to the ease of operation. Because of the continuous flow, cells are washed away as they flow out, which is a major drawback, although better control of the bioreactor system can overcome this effect. A bioreactor is shown in

Figure 5. Bioreactor provides a biologically active environment for different industrial processes to convert raw material into useful products, such as vaccines and pharmaceuticals.

The volume change rate in the reactor is based on the conservation of mass principle, given in mathematical terms as:

where

and

represent the input and output flow, respectively.

The biomass consumes the Grünwald–Letnikov substrate, which is defined by the fractional differential integral

:

where α

is the fractional differointegral, α represents the fractional order of the system, Γ is the Gamma function, and

t and

k are limits.

The Riemann–Liouville’s equation for the fractional differointegral is as follows:

For m > α > (m − 1), is the Euler Gamma function, αis the fractional differointegral, α represents the fractional order of the system, and represents delay. Based on fractional differentiation the Grunwald definition, m is the first integer, and t is the limits of the operation. The fractional-order operator and Laplace transform are and 1/, respectively.

The transfer function of of the controller has an integrator and differentiator. In conventional a PID, the is the integral gain, and is proportional, whereas is the derivative gain with different values for λ and µ.

The controller has many advantages compared with PID, which is less sensitive to parameter variations in a control system.

Dragonfly Optimization

An important task in complex processes is better evaluate the controller parameters of the system. This task is accomplished with the help of the optimization process by adjusting the parameters of the controller. Genetic algorithms, programming, evolution strategies, etc., have attracted the attention of researchers for optimization. Particle swarm optimization is also included in swarm-based techniques. Swarm intelligence-based algorithms, namely Dragonfly optimization, are used in this technique. Such an algorithm is very useful in setting the parameters of fractional-order PID controllers for temperature control systems in bioreactors. There are five main factors in optimization: separation, alignment, cohesion, attraction, and distraction [

54].

The first factor excludes the possibility of static collision.

The attraction towards the food source,

, and distraction from enemies,

, are expressed as:

where

is the position of the food source,

is position of the enemies, and

is the position of the current individual.

Table 1.

Usage Comparison of fractional-order PID controllers.

Table 1.

Usage Comparison of fractional-order PID controllers.

| Fractional-Order Controller | Control Application | Meta-Heuristic Method | Statistical Evaluation | Comparison PID | Comparison with Optimization Methods | Ref. |

|---|

| FOPID | Designed for mathematical model | Particle swarm optimization (PSO) | No | No | GA | [55] |

| FOPID | Designed as automatic voltage regulator | PSO | No | Yes | No | [56] |

| Time-delay | Design for second-order time-delay system | Improved electromagnetism | No | No | GA | [57] |

| FOPID | Designed for fractional-order plant | Self-organizing migrating algorithm | No | Yes | No | [58] |

| FOPID | Designed for integer-order and fractional-order plant | PSO | No | Real-life | No | [59] |

| FOPID | Designed for an invasive real-life analog plant | Invasive weed optimization algorithm | Yes | No | GA & PSO | [60] |

| FOPID | Designed for a full-vehicle non-linear activesuspension system | Evolutionary algorithm | No | No | No | [61] |

| FOPID | Designed for a first-order system with time delay | Generic algorithm | No | Yes | No | [62] |

| FOPID | Designed for a process plant Transfer | Bee colony algorithm | No | No | GA & PSO | [63] |

| FOPID | Designed as a voltage regulator | Chaotic ant Swarm | Yes | No | GA & PSO | [64] |

| FOPID | Designed for speed control | Artificial bee colony | Yes | Yes | No | [65] |

| FOPID (fuzzy) | Designed as an electronic throttle | Fruit fly optimization | No | Yes | No | [66] |

| FOPID | Designed as an automatic voltage regulator | PSO | No | Yes | Chaotic Ant Swarm | [67] |

Table 2.

Usage comparison of a fractional-order PID controller for temperature control.

Table 2.

Usage comparison of a fractional-order PID controller for temperature control.

| Fractional-Order Controller | Control Application | Statistical Evaluation | Comparison PID | Ref. |

|---|

| FOPID | Designed for control of super-heated steam temperature | No | Yes | [68] |

| FOPID | Designed for automatic control for an autotuning module | Yes | No | [69] |

| FOPID | Designed the for the safety of medical products | No | No | [70] |

| FOPID | Designed for internal temperature control in a roller system | No | Yes | [71] |

| FOPID | Designed for steam temperature control of essential oil extraction | Yes | No | [72] |

| FOPID | Designed for temperature control assessment | Yes | No | [73] |

| FOPID | Designed to cooling wat | No | Yes | [74] |

| FOPID | Designed for fuzzy fractional control of a heat exchanger | No | Yes | [75] |

| FOPID | Designed for double digital realization | Yes | No | [76] |

| FOPID | Designed for anti-windup for temperature control | Yes | No | [77] |

| FOPID | Designed as a large-scale dynamic matrix controller | Yes | Yes | [78] |

| FOPID | Designed for reheating furnaces with a large time delay | Yes | No | [79] |

| FOPID | Designed as a fuzzy PI+PD controller | Yes | Yes | [80] |

6. Fractional-Order PID Controller for Ambulance Temperature Control

PID and fractional-order PID (FOPID) controls are proposed in this study to manage ambulance temperature and protect paramedic equipment from damage. The regulation of the heating process is widely employed in various fields, particularly in the medical profession, where it is used to transfer medicinal items, such as drugs, blood, and injections. Hit and Ttrial techniques, genetic algorithms (GAs), and particle swarm optimization (PSO) are used to determine the advantages of FOPID [

81,

82,

83]. Moreover, to make the system work, the concept of dead time is introduced. The effectiveness of the proposed simulation strategy is ensured in a variety of situations with different time values. Tasks are recorded in the classic PID, PID + GA, PID + PSO, FOPID, FOPID + GA, and FOPID + PSO controls in terms of different time zones, critical square error (ISE), and absolute total error (IAE). The results show that using FOPID + PSO is effective and keeps the loop in operation better than normal PID controls. Accidents are one of the major problems faced by humans. Rapidly increasing road accidents are the cause of major damage to organs and loss of life, which is a huge setback for humanity. The is a need for alternate means to save the life of accident victims and provide them with treatment. In emergency situations, ambulances outfitted with medical equipment are used to transfer victims to the hospital for treatment. There is an urgent need for patients to get to hospitals during emergencies.

Ambulance carry all necessary equipment and products for dealing with emergency cases. Much medical equipment requires a specific temperature for operation in order to save the lives of patients. As the investigated systems are wireless, an optimal control system inludes a controller that controls all the tools, as well as the temperature, which is our main concern in ambulances, with the goal of protecting medical products from damage. In this article, various methods are discussed for controlling the temperature of ambulances and saving lives. PID controllers and fractional-order PID controllers are proposed in this article based on their specialization for temperature control. Ambulance operation and a temperature control strategies play an important role. The control strategy protects the ambulance from negative influences, such as medical injuries, injections, etc. Additionally, non-linear time of death is included in the system for maximum efficiency.

6.1. Hit and Trial of Genetic Algorithms and Particle Swarm Optimization

To improve the parameters of PID and fractional-order PID controls a genetic algorithm is used, an better output is achieved, improving the operational performance of ambulances. Particle swarm optimization is easy to implement, with a fast response time and reliable parameters. GAs are strong, stochastic, and can be efficiency applied for many purposes. Due to the inaccuracies that exist in the system, PID control is not a viable option. However, FOPID controllers are ideal for control the temperature of ambulances.

The main operational components of an ambulance are the thermal resistor, analog–digital converter, H-bridge driver, STM8S105S4, LED, and TEC. In the temperature measurement thermal resistor, an analog-to-digital converter (AD7705) is used to output a pulse-width-modulated signal (AD7705), which can control the H-Bridge driver and the heating and cooling unit (TEC) [

84]. TEC is driven by an H-bridge to heat and cool the system. LED is used to display the measure of the temperature. Ambulances are also known as mobile hospitals because they perform all the duties a hospital in case of emergency, carrying important equipment, such as medicines, blood, etc., needed in case of emergencies. Ambulance are employed by governments or charitable organizations for emergency response, providing adequate care to patients when an injury or serious illness occurrs. In terms of design ambulance, resemble vans, and vehicles provided by charitable organizations act as special ambulances. Their only aim is to serve the sick or injured, the elderly, or children who are far away from hospitals, and ambulances often resemble a bus in terms of design.

6.2. Control Objectives

The primary goals of this article are mentioned below:

- (1)

Abulance temperature control;

- (2)

Implementation of a FOPID controller an ambulance;

- (3)

Tuning of PID and fractional-order PID controls with genetic algorithms and particle swarm optimization;

- (4)

Adjustment of PID and fractional-order PID controls by GA.

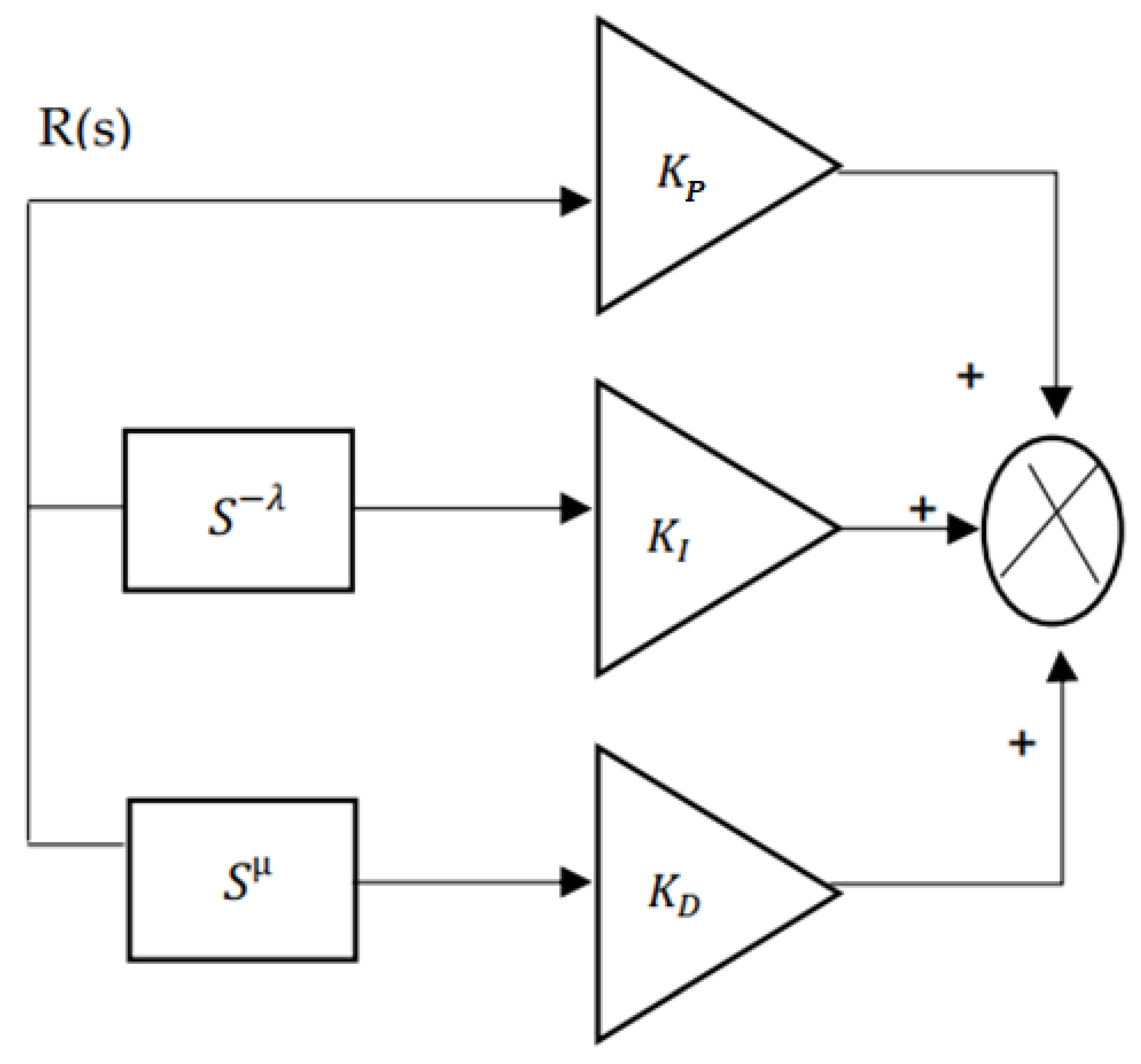

6.3. Proposed Controller

In this paper, the use of fractional-order PID for temperature control is examined in an ambulance to prevent medical items from being damaged. The FOPID controller is a more advanced PID controller that has two more gain conditions, as shown in

Figure 6. It has five types of gain:

- (1)

Proportional gain (KP)

- (2)

Derivative gain (KD)

- (3)

Derivative order (µ)

- (4)

Integral gain (KI)

- (5)

Complete order (λ)

6.4. Suggested Tuning Methods

Particle Swarm Optimization (PSO) and Genetic Algorithm (GA).

6.4.1. Particle Swarm Optimization

In this system, the PSO method is used for testing and for correction of fractional-order PID benefits. Kennedy and Eberhart applied particle swarm optimization, inspired by the behavior of different kinds of flying birds and fish. The headcount in the PSO is updated without modification. The hill intelligence is considered the foundation of PSO [

85,

86,

87,

88,

89,

90,

91,

92,

93]. A whirlwind consists of n particles moving in a search engine with a size of

d. Speed is assigned randomly to all particles. PSO parameters applied to this function include acceleration constants (

á1,

á2), patient size (PS), multiplication number, first and last inertia weights (

ώ1,

ώ2), lower and upper limits (

ú1,

ú2), and stopping criteria.

6.4.2. Genetic Algorithm (GA)

Here, the use of the GA method is tested for correction of fractional-order PID benefits. John Holland developed a genetic algorithm inspired by Darwin’s theory of evolution. The foundation of genetic algorithm evolutionary calculations depends on choice, conversion, and crossover. The main parameters considered in the genetic algorithm are crossover and mutation to determine the optimal solution. GA parameters used in this function include population size, multiplication no., crossover (co), conversion (in), stand (Sc), and lower and upper boundaries (ú1, ú2).

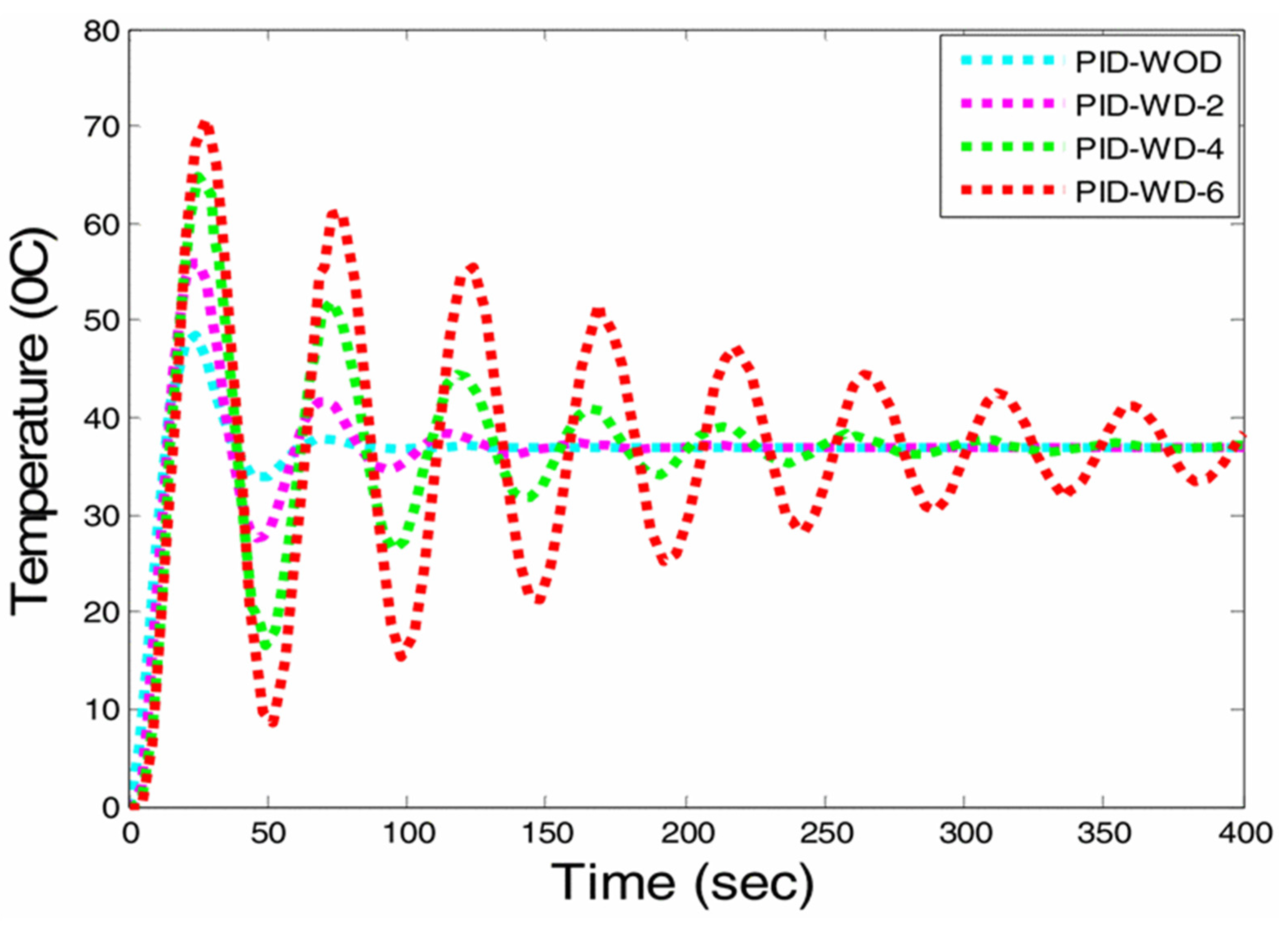

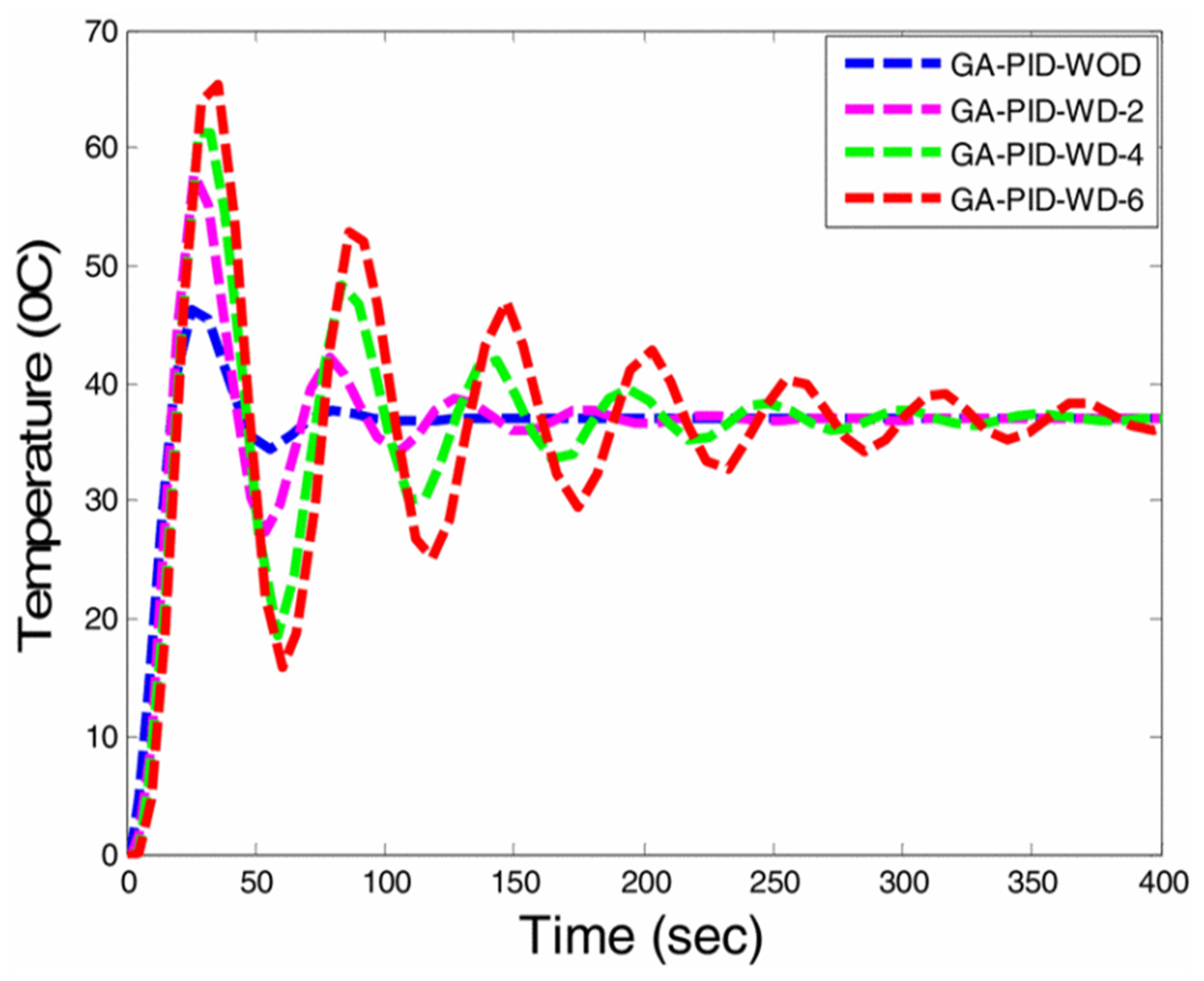

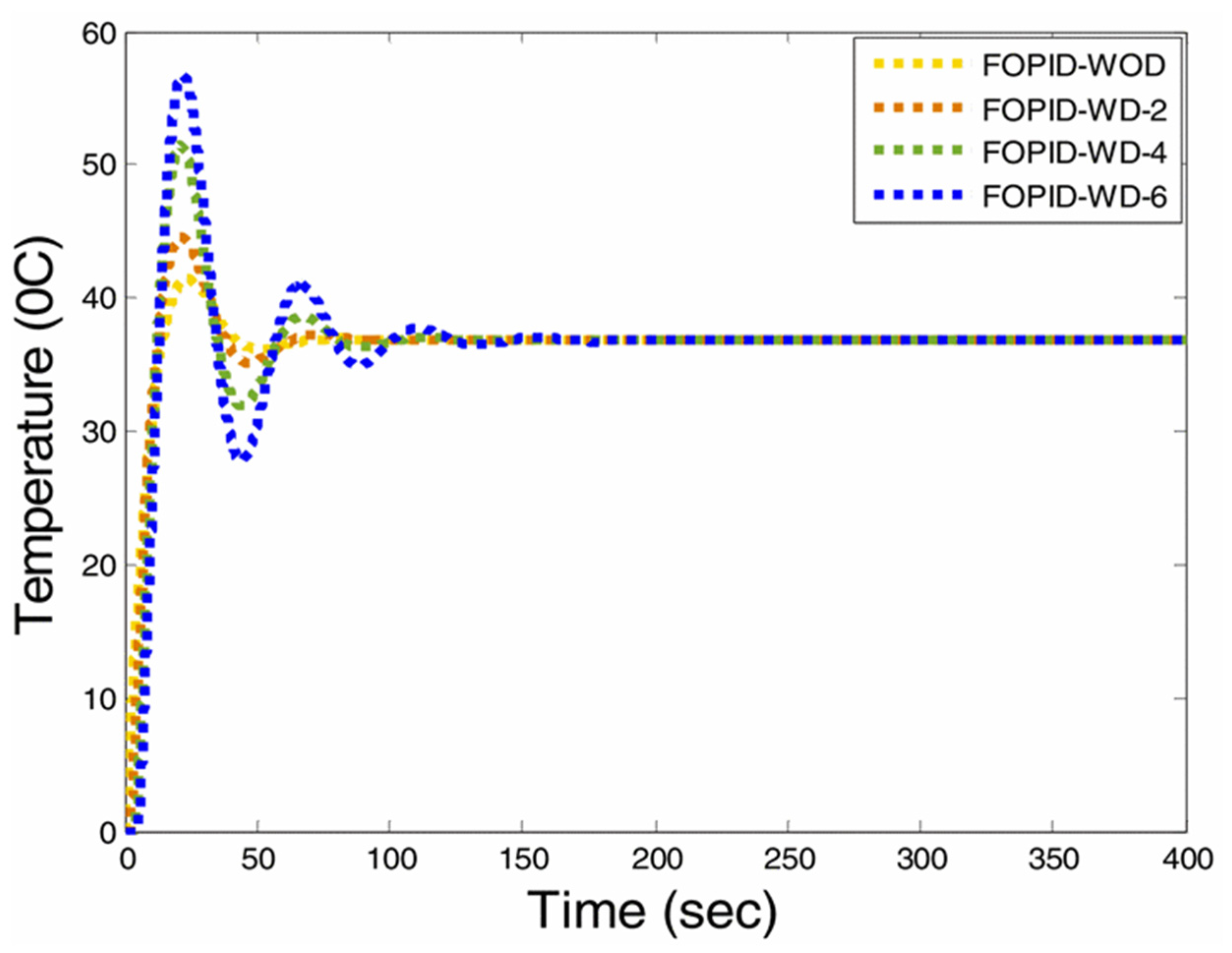

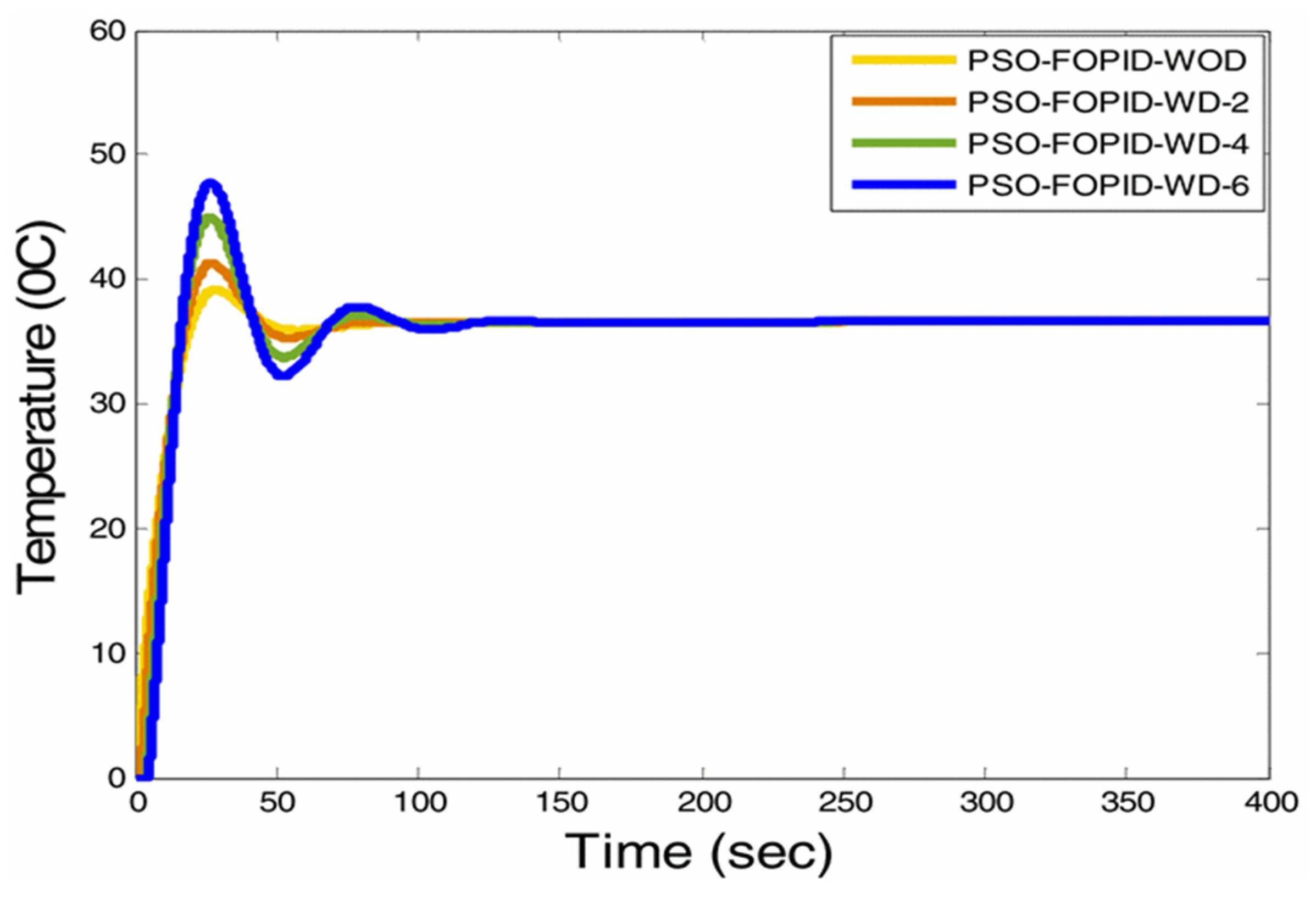

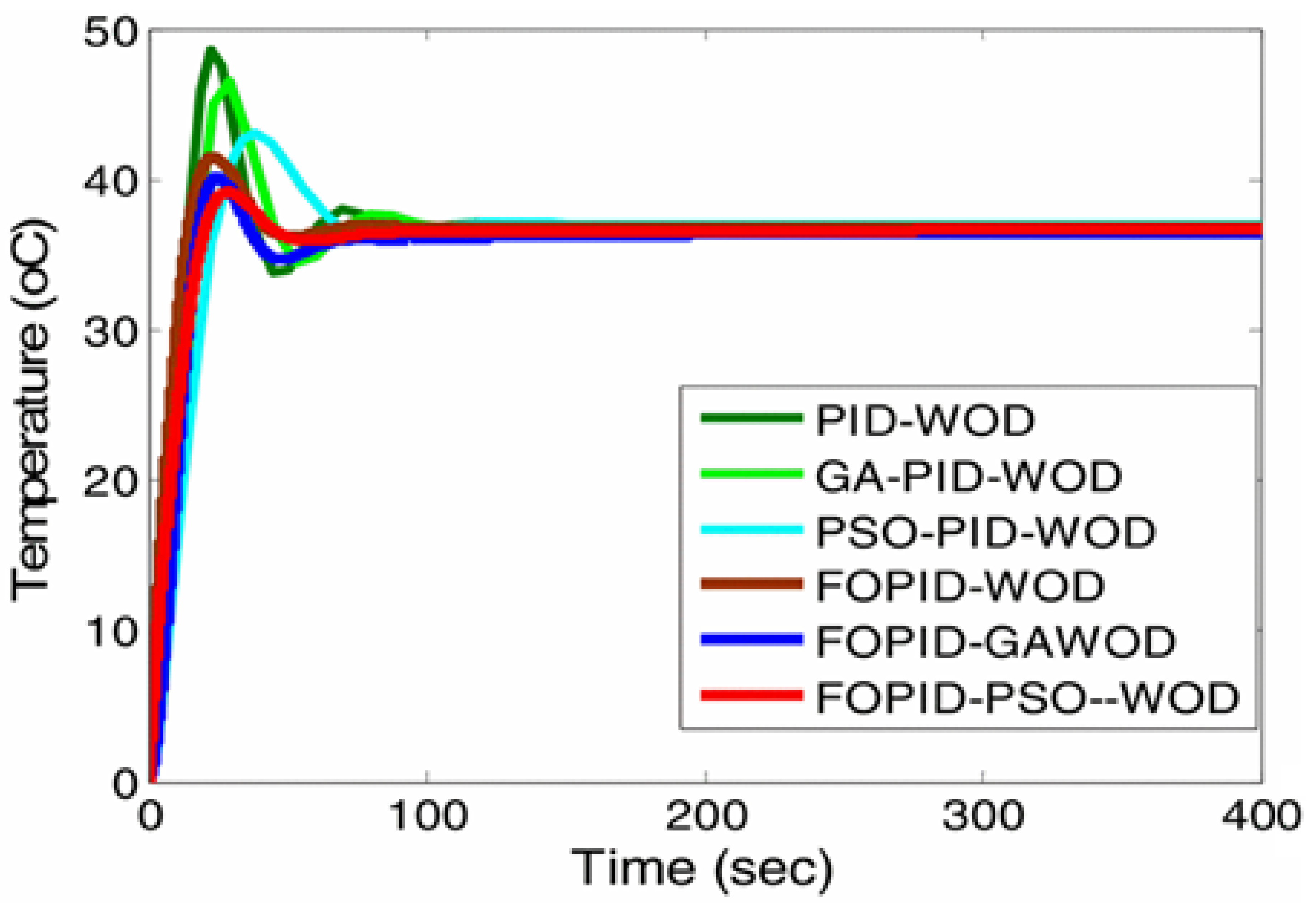

In this paper, performance comparisons made between standard PID and fractional-order PID using hit and trial and artificial ambulance support strategies. A temperature control strategy was developed. The program is very complex, with a dead time of 2–6 s. In comparing the system, it was clear that the performance of the program slows down as the time to death increases. Based on a study of the system response, it was discovered that an old PID with a dead time of 6 s had greater oscillations and error rates than that with a dead time 2 and 4 s. The reaction was somewhat enhanced when PID was combined with GA and PSO. However, when FOPID, FOPID +GA, and FOPID + PSO are compared, FOPID, FOPID +GA, and FOPID + PSO come out on top.

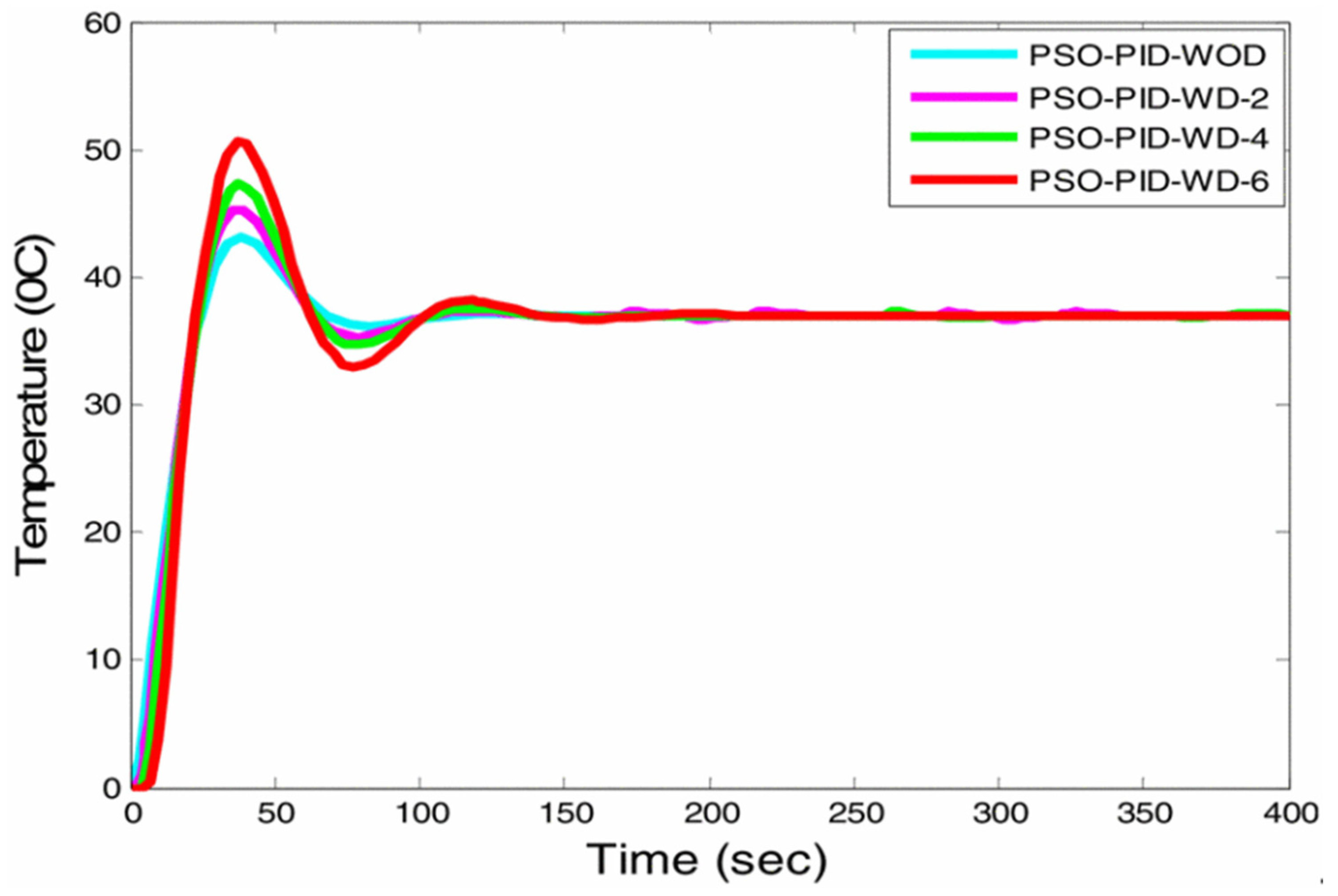

Figure 7,

Figure 8,

Figure 9,

Figure 10,

Figure 11,

Figure 12,

Figure 13,

Figure 14,

Figure 15,

Figure 16,

Figure 17 and

Figure 18 show the application of PID, as well as output response and error response.

Figure 19 shows a comparison of all response outputs.

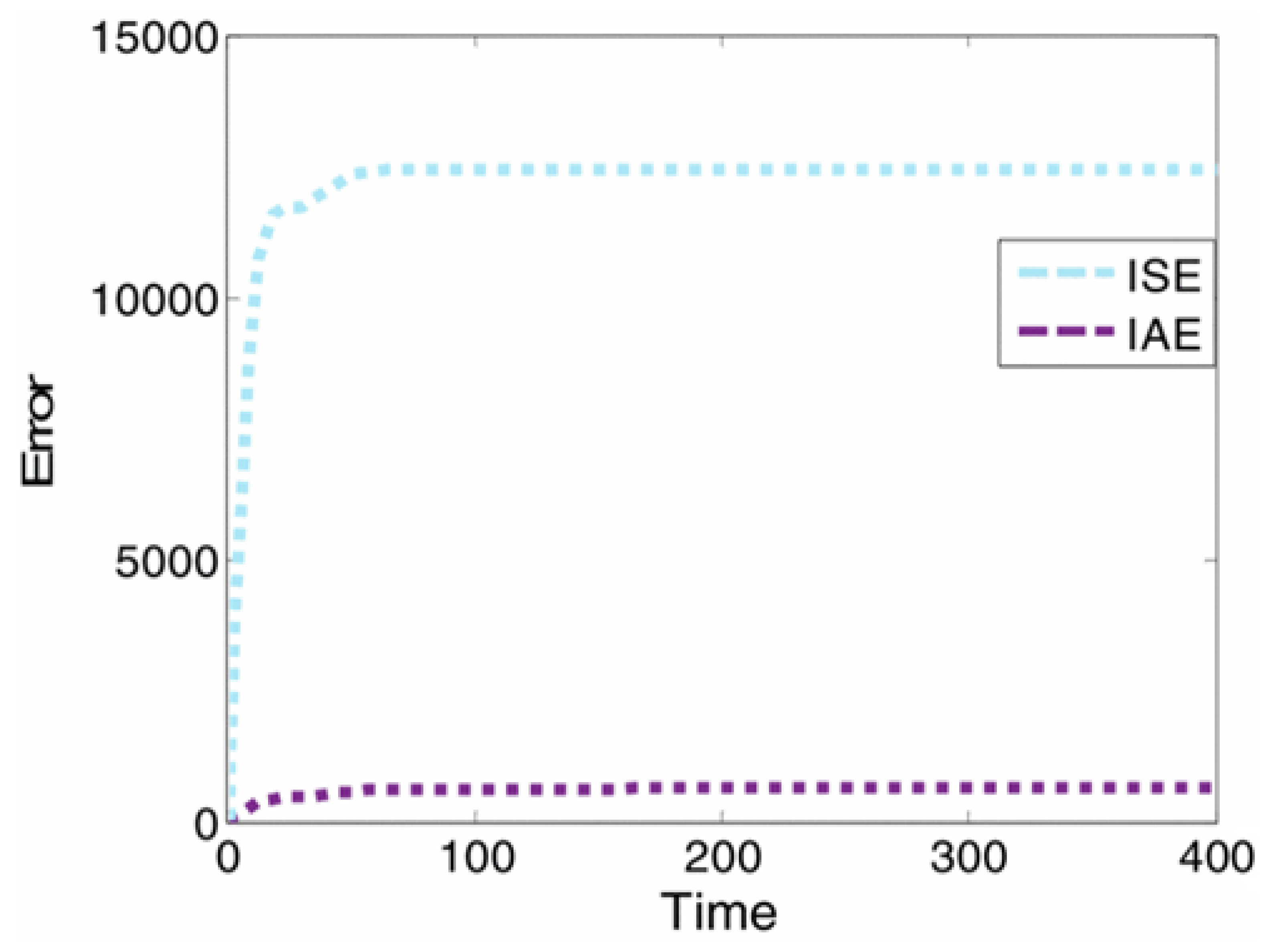

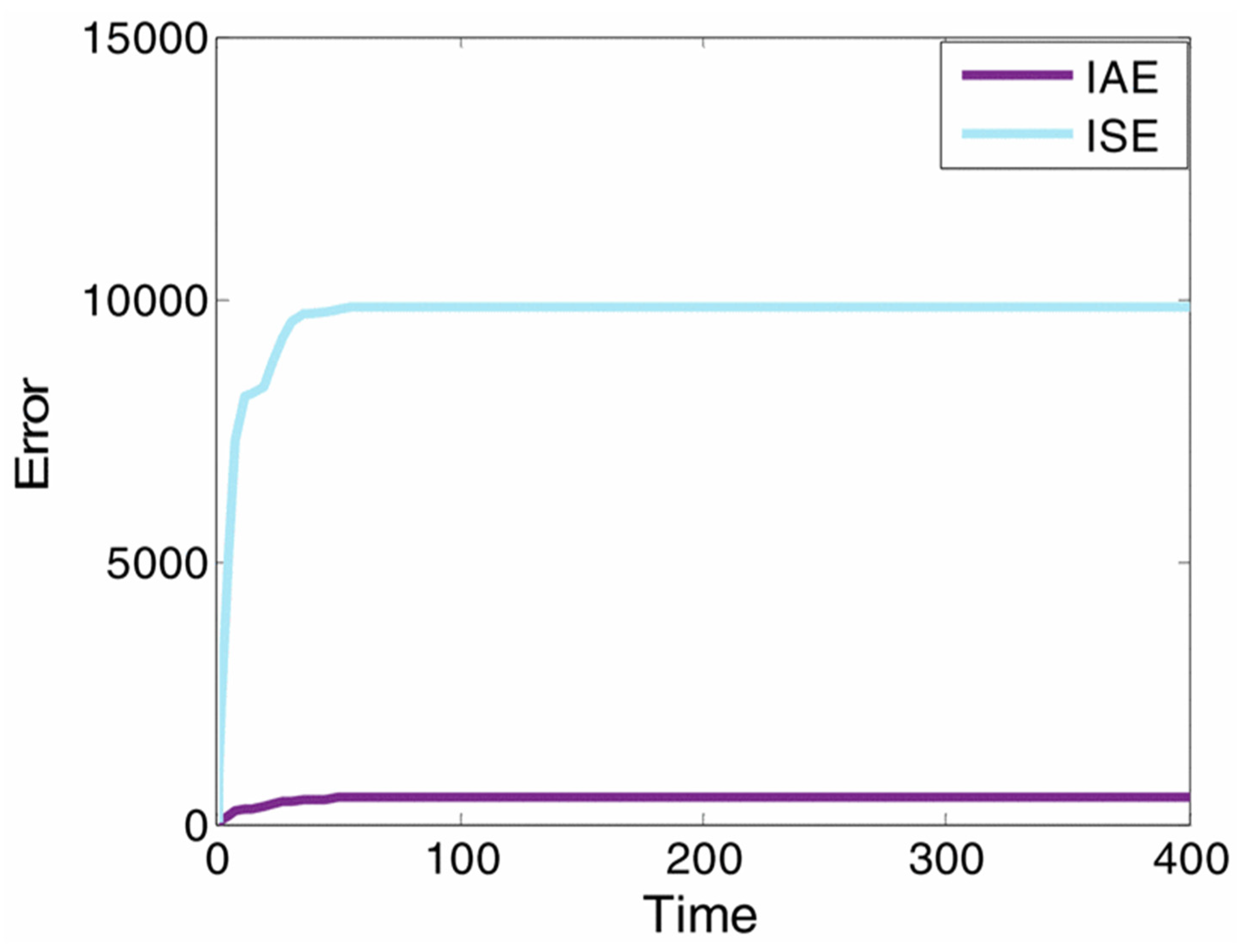

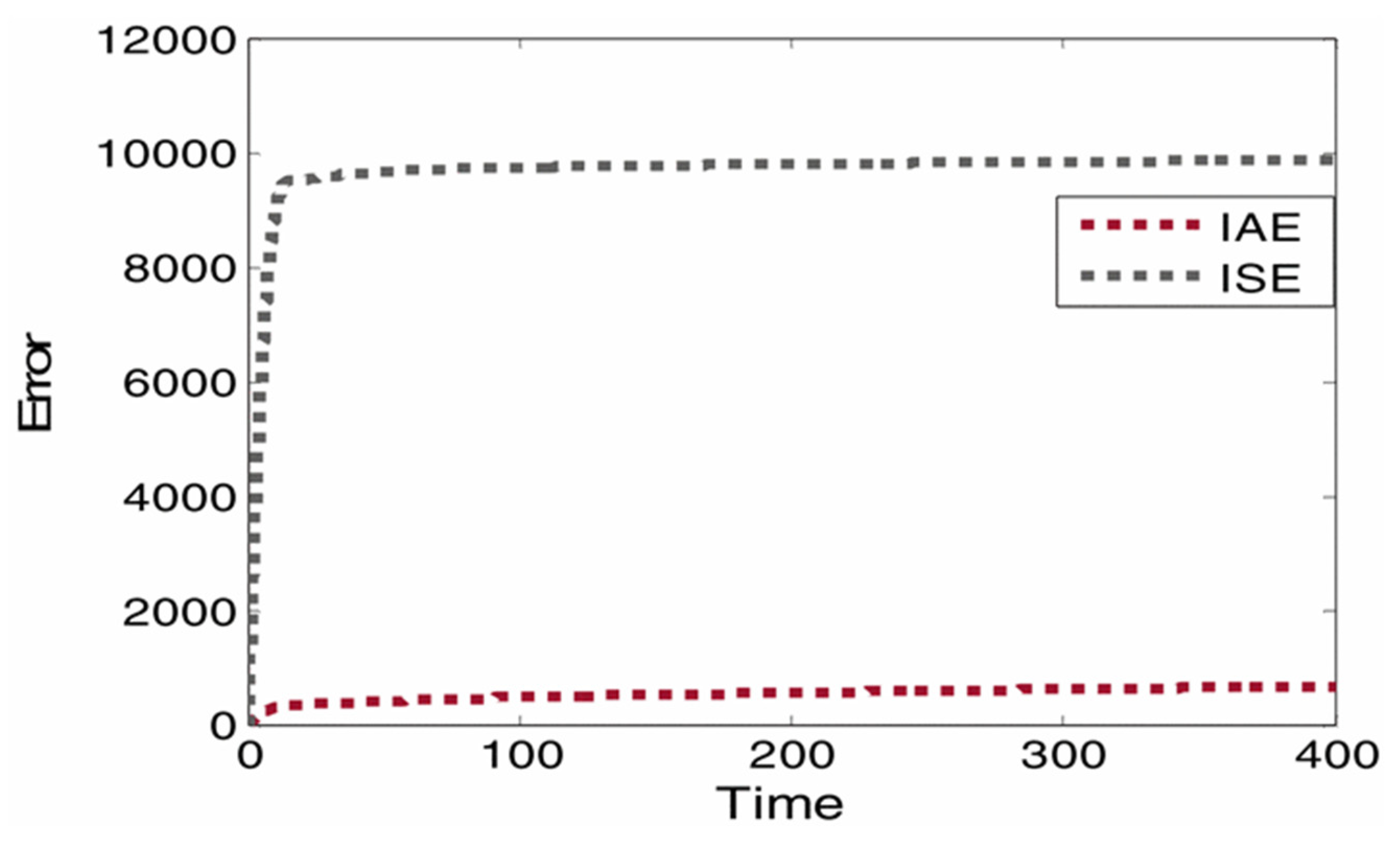

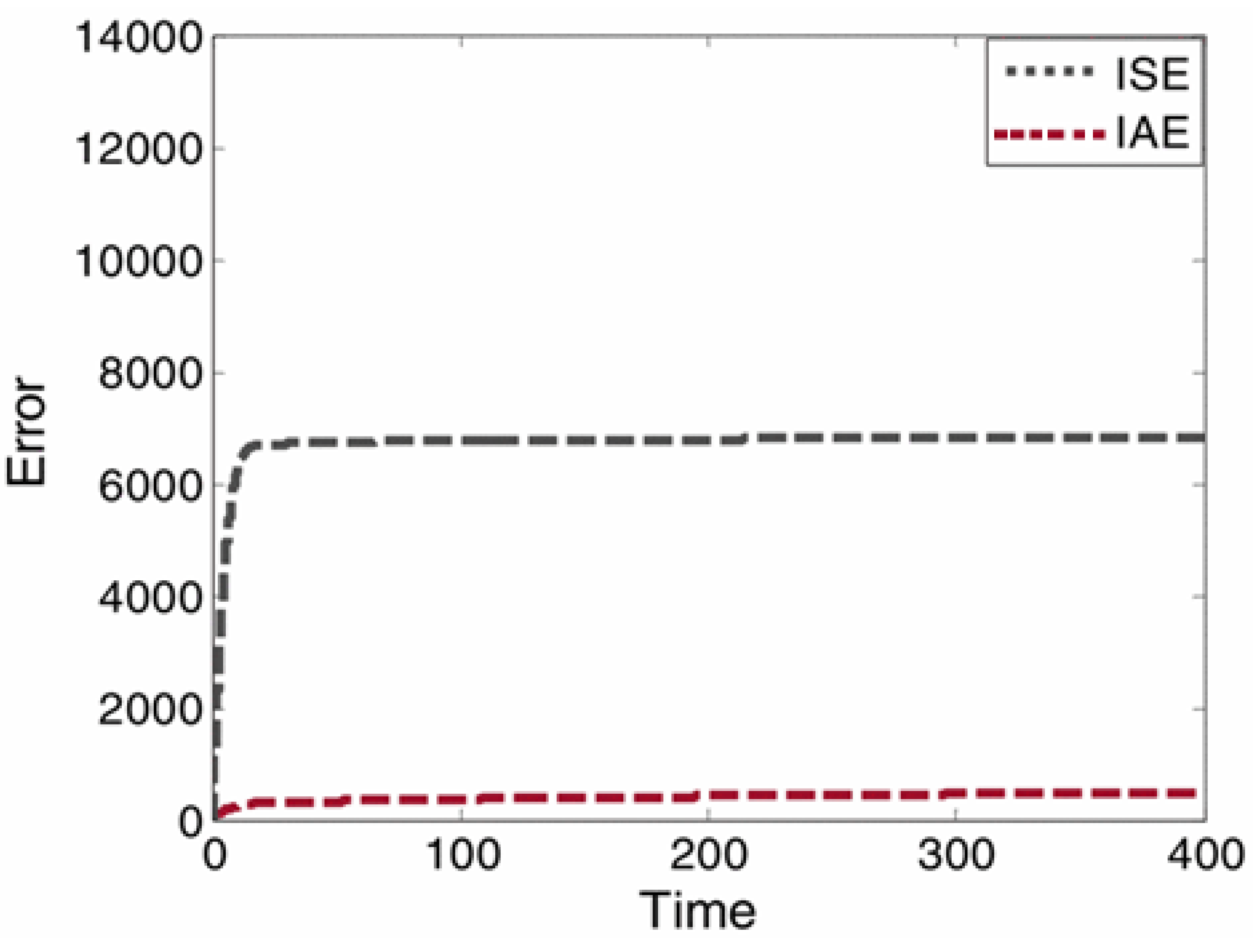

PID controllers with dead time (WD) and without dead time (WOD) represent the response in the time domain, with integral square error (ISE) and integral absolute error (IAE).

The parameters of the PID controllers shown in

Table 3 represent the parameters used in the above output responses. In

Table 4, the fractional-order PID controller gains and parameters are clearly demonstrate that the process works in ambulance error response for GA, PSO, and hit and trail methods.

A performance comparison of FOPID and PID cases, including all the above mentioned factors with time specifications, is shown in

Table 5. The rise time of the FOPID controller is much less than any other type of controller used.

The responsiveness of the system significantly improved. As shown in

Figure 19, FOPID and PSO achieved oscillatory behavior with lower error rates. In addition, it was proven that these systems achieved better system performance in terms of dead time.

In this article, a statistical model was created compared to PID and FOPID control systems. As shown in the figures, comparison of the responses was based on time frame details. The standard PID controllers are more flexible to time specification values. To reduce these oscillations and specified value times, FOPID control with GA and PSO is recommended. The performance comparison is shown in

Table 4. According to analysis, the FOPID controller and the FOPID controller with GA showed an improved response relative to the original PID controller with GA and PSO. Moreover, in comparing FOPID, FOPID + GA, and FOPID + PSO, it was found that FOPID with PSO is the optimal solution.

7. Fractional-Order PID Controller for Induction Heating

Induction heating, especially vacuum induction melting technology, has the characteristics of high speed, high efficiency, and high heating with low consumption [

94]. The system was developed and optimized on a standard furnace. With the advancement of the industrial sector, the requirements for advanced performance have also increased. Many researchers working on this, as well as fabrication of alloys made for edge cutting in a vacuum, have satisfied the performance requirements with high precision. Heating temperature control systems are used in induction heating furnaces using PID control [

95,

96,

97,

98]. The temperature is measured using thermocouples and a vacuum induction furnace. When the observed temperature differs from the predetermined value determined by a traditional feedback system, the heating system is modified.

However, as technology has advanced, quality and performance factors have improved with better and more precise control systems. In [

99,

100], a fuzzy PID control system was applied to control the temperature of a heating the furnace, improving the response speed of the temperature control system. However, the ant-interference capability is not strong, and the induction heating furnace has a large inertia and time lag.

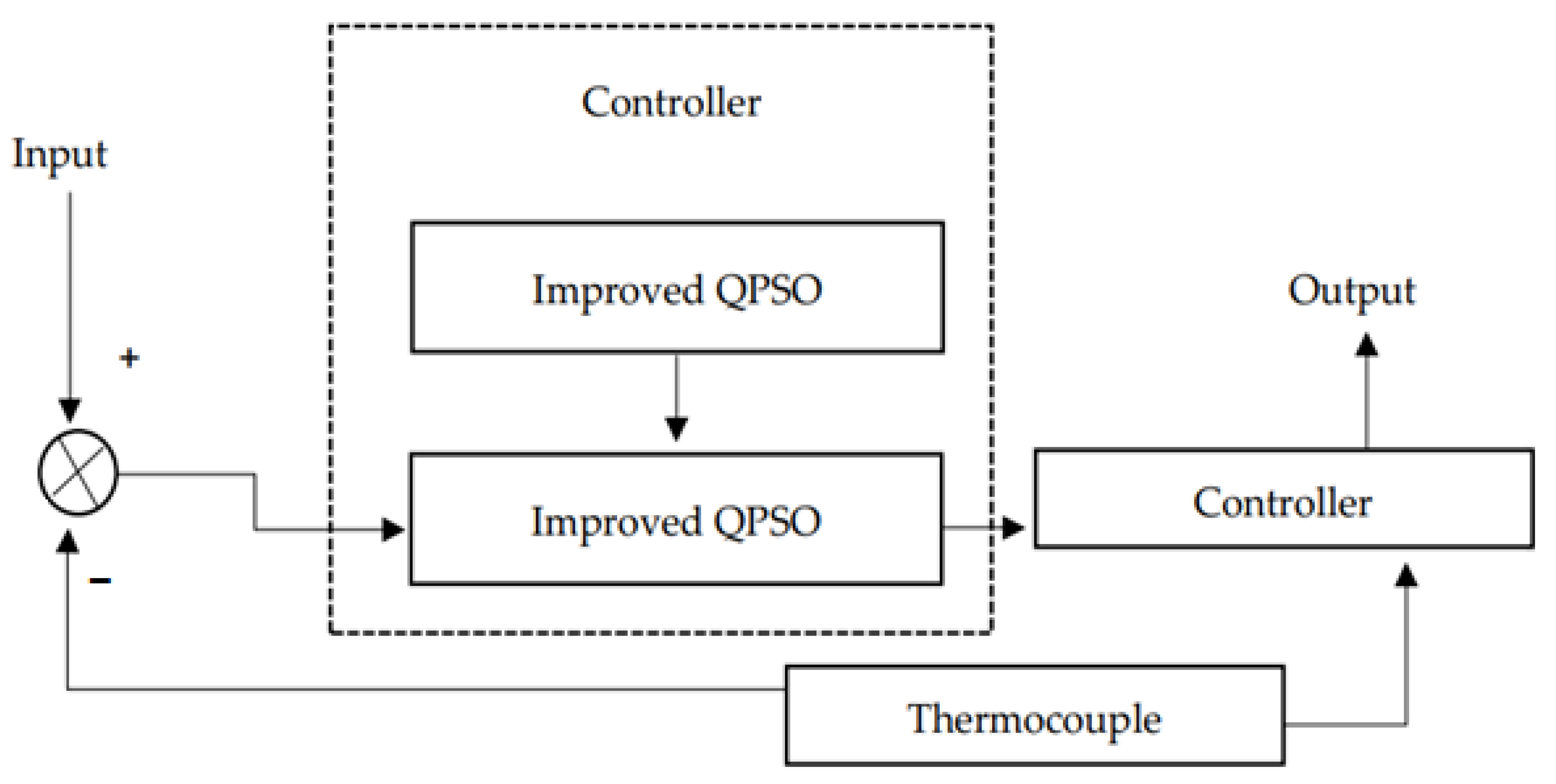

The heating skin effect and conduction are the main phenomena in the process. If the force is reduced, alternating current and alternating magnetic lines of force are generated and pass through the coil magnetic field. According to electromagnetic field theory, the induced electric potential formed by a changing magnetic field generates a closed circuit of current on the workpiece surface, which is generally referred to as an eddy current. A simplified block diagram of an induction heating system is shown in

Figure 20.

The temperature control system as a transfer function can be defined as:

An increasing-order method is adopted for the time lag in the system. In the transfer function, the time lag operator is approximated as a first-order inertia link:

where

is the time lag coefficient, and

K is the scale factor, which is equal to

K = 1/

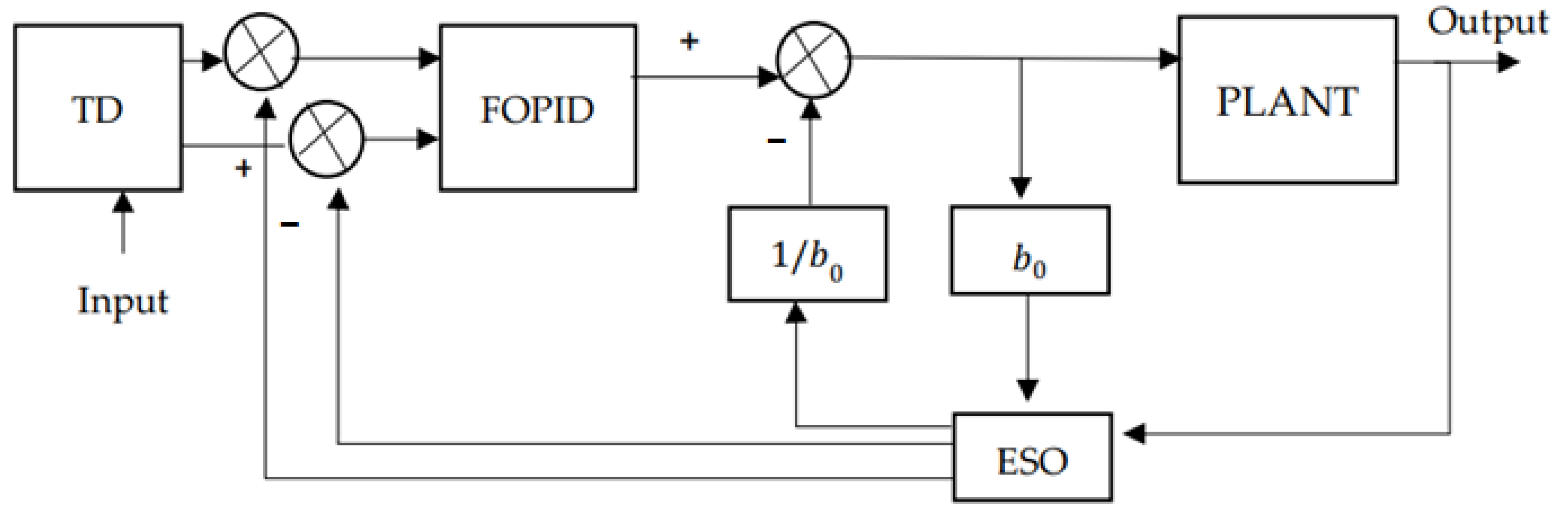

S FOPID-ADRC Design Optimized with QPSO

Fractional-order PID is developed from a classical PID to control the system. The performance factor improved and a much better controller was achieved as compared to classical PID. In the fractional-order PID controller, two variables (integral and differential order) are free, and control is realized, resulting in a considerable improvement in terms of control and performance. Active disturbance rejection control (ADRC) was proposed [

29,

30,

31,

32,

33] as a better control strategy to improving temperature control accuracy in combination with a fractional-order PID controller. ADRC has a tracking differentiator, non-linear state error feedback, and extended state observer [

99,

101]. The input is taken from the differentiator, and the estimated value and total disturbance are obtained based on the data (input and output) of the extended-state observer. The control signal is calculated by the non-linear feedback.

Figure 21 shows a structural diagram of the active disturbance rejection control based on the error. In this research, the authors investigated fractional-order PID controllers, along with an ADRC system; the virtual control law can be stated as:

There are multiple control parameters in ADRC; however, the performance cannot be obtain with an empirical method. The quantum particle swarm algorithm-based fractional-order ADRC has an optimized algorithm that is based on group intelligence theory [

103,

104,

105,

106,

107,

108]. A search mechanism is developed, and according to the algorithm, the search mechanism simulates the movement of a particle in this mechanism. Moreover, with the increase in performance factor due to the QPSO algorithm, this system can be used for controller parameters. Multiple control parameters in ADRC are adjusted, and better performance is achieved. A QPSO-optimized structure diagram for parameter control is shown in

Figure 22. There are multiple optimization steps of QPSO, which are as follows:

- (1)

Initial parameters set, position and speed initialized;

- (2)

Parameters adjusted and passed to fractional-order PID ADRC controller, which runs the control and passed fitness value (output);

- (3)

Through initial fitness value, the initial global optimal and individual particles are determined;

- (4)

Update operation and, through the previous step, obtain the fitness value to update and optimize the optimal value. Finally, when the fitness value equals the condition or reaches its extent, the algorithm stops working, and an optimal solution is obtained.

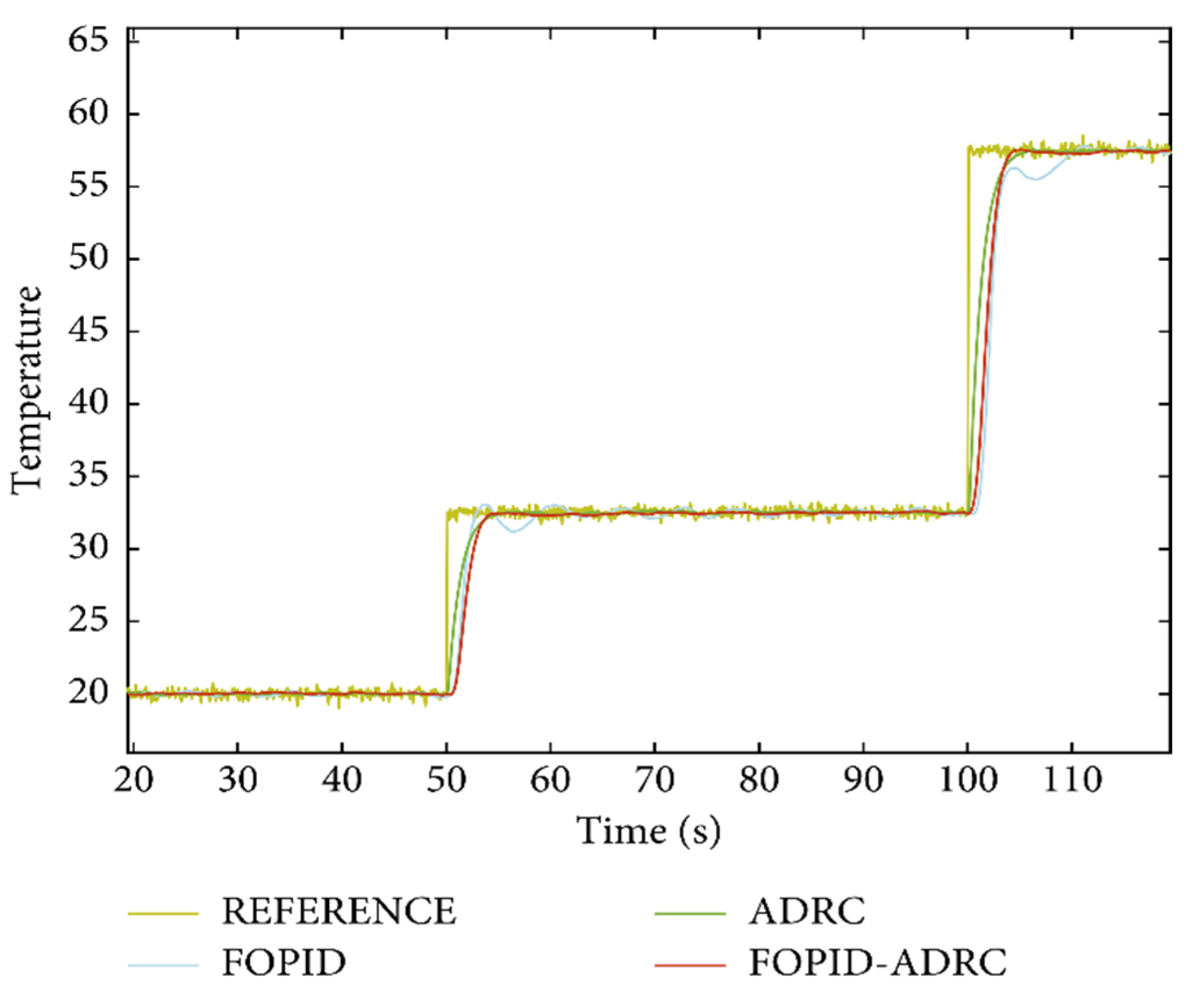

A vacuum furnace was taken as the experimental object, and the anti-disturbance performance of a designed controller was assessed. The control effect of three different controllers were evaluated with temperature jumps of 50 s and 100 s using Gaussian noise simulation, external disturbance, and model uncertainty. From the analysis of the result, it is clear that the fractional-order PID controllers, along with ADRC, have the best anti-disturbance performance.

With this application, the unknown interference problem was resolved with a fractional-order PID controller, and the proposed strategy, along with the ADRC controller, also improved the performance interference problem in the induction heating process. One problem with parameter tuning is the use of a more advanced QPSO algorithm to optimize the various parameters of the controller. In comparison to QPSO, the upgraded QPSO has a superior global search capability and a local optimal fitness value, and it also increases the composite controller’s parameter tuning efficiency.

Moreover, the conventional temperature control gained from the PID controller is far less complex than that of the composite controller combining fractional PID and active disturbance rejection control. The temperature change monitor is shown in

Figure 23, representing the control effects. The uncertainty gained by these controllers in industrial production may be helpful to further focus on the usage and implementation of this controller in real-time systems.

8. Conclusions

In this review, we investigated the benefits of fractional-order PID controllers for temperature control and performance improvement in the industrial sector. This can benefit the whole system by generating more accurate results and increasing the production and management. PID controllers are also useful, but they lack some features, as discussed earlier. Moreover, with a complete understanding of fractional-order PID controllers, we discussed their development from classical PID controllers and their use for temperature control in various sectors. Based on the results of our review, it is clear that fractional-order PID controllers have more advantages than PID and other methods. Further development is important to understand growth opportunities and tuning factors that may affect the performance measurement of FOPID. The application of fractional-order PID in bioreactors, which represent an important industrial component, and the effect of temperature controllers on bioreactor were also investigated. In this paper, models of ambulance statistics, PID, and fractional-order PID controls were used to make comparisons. Comparison of their responses was based on time frame details. According to the data presented in the figures, the standard PID controller is more flexible to time specification values. To reduce these oscillations and specified time values, fractional-order PID control with a genetic algorithm and particle swarm optimization is recommended. Based on performance comparison analysis, we conclude that fractional-order PID controllers and fractional-order PID controllers with genetic algorithm and particle swarm optimization show achieve a better response PID controllers with GA and PSO. Moreover, in comparing fractional-order PID, fractional-order PID+ genetic algorithm, and FOPID + particle swarm optimization, it is found that fractional-order PID with particle swarm optimization is the optimal solution. The transfer function and temperature control output represent this effect. According to our analysis, the dragonfly algorithm used in bioreactors converges faster, which can also minimize the objective function. The temperature of the bioreactor in an industrial sector can be easily controlled by a Fractional-order PID controller, with the help of the dragonfly algorithm. Disturbance and point tracking were also analyzed and set. It is concluded fractional-order PID controllers are more robust and efficient in the industrial sector for temperature control. The advantage of using a fractional-order PID with ADRC controller is an improved performance effect in induction heating furnaces. The multiple disturbing factors removed by fractional-order PID-ADRC combine the advantages of the control system in induction heating. Finally, a literature review showed that FOPID controllers have multiple applications in the industrial sector as temperature control systems and that FOPID works much better as a control system as compared to other control methods.

Author Contributions

Methodology, A.A.J. and Y.T.; validation, A.A.J. and S.W.A.; investigation, visualization, A.A.J. and Y.T.; conceptualization, software, writing—original draft preparation, A.A.J.; formal analysis, resources, data curation, A.A.J., S.W.A. and Y.T.; writing—review and editing, S.W.A., Y.T. and J.M.G.; supervision, Y.T., W.F.T. and J.M.G. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Zhang, R.; Zou, Q.; Cao, Z.; Gao, F. Design of fractional order modeling based extended non-minimal state space MPC for temperature in an industrial electric heating furnace. J. Process Control 2017, 56, 13–22. [Google Scholar] [CrossRef]

- Singh, Y.K.; Kumar, J.; Pandey, K.K.; Rohit, K.; Bhargav, A. Temperature Control System and its Control using PID Controller. Int. J. Eng. Res. Technol. 2016, 4, 4–6. [Google Scholar]

- Kochubei, A.; Luchko, Y. Fractional differential equations. Fract. Differ. Equ. 2019, 2013, 1–519. [Google Scholar] [CrossRef]

- Monje, C.A.; Chen, Y.; Vinagre, B.M.; Xue, D.; Feliu, V. Fractional Order Systems and Controls; Springer: Berlin/Heidelberg, Germany, 2010. [Google Scholar]

- Chen, Y.; Moore, K. Discretization schemes for fractional-order differentiators and integrators. IEEE Trans. Circuits Syst. I Regul. Pap. 2002, 49, 363–367. [Google Scholar] [CrossRef]

- Lepik, Ü.; Hein, H. Fractional Calculus. In Haar Wavelets; Springer: Berlin/Heidelberg, Germany, 2014; pp. 107–122. [Google Scholar] [CrossRef]

- Podlubny, I. Geometric and Physical Interpretation of Fractional Integration and Fractional Differentiation. 2001, pp. 1–18. Available online: http://arxiv.org/abs/math/0110241 (accessed on 18 December 2021).

- Ma, C.; Hori, Y. Backlash Vibration Suppression Control of Torsional System by Novel Fractional Order PIDk Controller. IEEE J. Trans. Ind. Appl. 2004, 124, 312–317. [Google Scholar] [CrossRef][Green Version]

- Oustaloup, A.; Moreau, X.; Nouillant, M. The CRONE suspension. Control Eng. Pract. 1996, 4, 1101–1108. [Google Scholar] [CrossRef]

- Biro, O.; Preis, K. On the use of the magnetic vector potential in the finite-element analysis of three-dimensional eddy currents. IEEE Trans. Magn. 1989, 25, 3145–3159. [Google Scholar] [CrossRef]

- Oustaloup, A. La Commande CRONE: Commande Robuste d’Ordre Non Entier; Hermès: Paris, France, 1991. [Google Scholar]

- Oustaloup, A.; Sabatier, J.; Moreau, X. From fractal robustness to the CRONE approach. ESAIM Proc. 1998, 5, 177–192. [Google Scholar] [CrossRef]

- El-Khazali, R. Fractional-order PIλDμ controller design. Comput. Math. Appl. 2013, 66, 639–646. [Google Scholar] [CrossRef]

- Beschi, M.; Padula, F.; Visioli, A. The generalised isodamping approach for robust fractional PID controllers design. Int. J. Control 2015, 90, 1157–1164. [Google Scholar] [CrossRef]

- Kumar, A.; Kumar, V. Hybridized ABC-GA optimized fractional order fuzzy pre-compensated FOPID control design for 2-DOF robot manipulator. AEU-Int. J. Electron. Commun. 2017, 79, 219–233. [Google Scholar] [CrossRef]

- Monje, C.A.; Vinagre, B.M.; Feliu-Batlle, V.; Chen, Y. Tuning and auto-tuning of fractional order controllers for industry applications. Control Eng. Pract. 2008, 16, 798–812. [Google Scholar] [CrossRef]

- Valério, D.; da Costa, J.S. Tuning of fractional PID controllers with Ziegler–Nichols-type rules. Signal Process. 2006, 86, 2771–2784. [Google Scholar] [CrossRef]

- Macia, N.F.; Thaler, G.J. Modeling and Control of Dynamic Systems; Thomson Delmar Learning: New York, NY, USA, 2005. [Google Scholar]

- Merrikh-Bayat, F.; Jamshidi, A. Comparing the performance of optimal PID and optimal fractional-order PID controllers applied to the nonlinear boost converter. Presented at the 5th Symposium on Fractional Differentiation and Its Applications (FDA12), Nanjing, China, 17 May 2012. [Google Scholar]

- Podlubny, I. Fractional-order system and PIλDμ controllers. IEEE Trans. Autom. Control. 1999, 44, 208–214. [Google Scholar] [CrossRef]

- Marinangeli, L.; Alijani, F.; HosseinNia, S.H. Fractional-order positive position feedback compensator for active vibration control of a smart composite plate. J. Sound Vib. 2018, 412, 1–16. [Google Scholar] [CrossRef]

- Badri, V.; Tavazoei, M.S. Achievable Performance Region for a Fractional-Order Proportional and Derivative Motion Controller. IEEE Trans. Ind. Electron. 2015, 62, 7171–7180. [Google Scholar] [CrossRef]

- Padula, F.; Visioli, A. On the fragility of fractional-order PID controllers for FOPDT processes. ISA Trans. 2016, 60, 228–243. [Google Scholar] [CrossRef] [PubMed]

- Tepljakov, A.; Alagoz, B.B.; Yeroglu, C.; Gonzalez, E.; HosseinNia, S.H.; Petlenkov, E. FOPID Controllers and Their Industrial Applications: A Survey of Recent. IFAC-PapersOnLine 2018, 51, 25–30. [Google Scholar] [CrossRef]

- Čech, M.; Schlegel, M. Generalized robust stability regions for fractional PID controllers. In Proceedings of the 2013 IEEE International Conference on Industrial Technology (ICIT), Cape Town, South Africa, 25–28 February 2013; pp. 76–81. [Google Scholar] [CrossRef]

- Polyakov, A.; Efimov, D.; Perruquetti, W. Robust Stabilization of MIMO Systems in Finite/Fixed Time. Int. J. Robust Nonlinear Control. 2015, 26, 69–90. [Google Scholar] [CrossRef]

- Schlegel, M.; Medvecová, P. Design of PI Controllers: H∞ Region Approach. IFAC-PapersOnLine 2018, 51, 13–17. [Google Scholar] [CrossRef]

- Xu, Y.; Bai, W.; Zhao, S.; Zhang, J.; Zhao, Y. Mitigation of forced oscillations using VSC-HVDC supplementary damping control. Electr. Power Syst. Res. 2020, 184, 106333. [Google Scholar] [CrossRef]

- Chen, Z.; Qin, B.; Sun, M.; Sun, Q. Q-learning-based parameters adaptive algorithm for active disturbance rejection control and its application to ship course control. Neurocomputing 2020, 408, 51–63. [Google Scholar] [CrossRef]

- Nasirpour, N.; Balochian, S. Optimal design of fractional-order PID controllers for multi-input multi-output (variable air volume) air-conditioning system using particle swarm optimization. Intell. Build. Int. 2016, 9, 1–14. [Google Scholar] [CrossRef]

- Shahri, M.E.; Balochian, S.; Balochian, H.; Zhang, Y. Design of fractional order PID controllers for time delay systems using differential evolution algorithm. Indian J. Sci. Technol. 2014, 7, 1311–1319. [Google Scholar] [CrossRef]

- Li, D.; Ding, P.; Gao, Z. Fractional active disturbance rejection control. ISA Trans. 2016, 62, 109–119. [Google Scholar] [CrossRef] [PubMed]

- Koksal, E. Fractional-order PID and active disturbance rejection control of nonlinear two-mass drive system. IEEE Trans. Ind. Electron. 2013, 60, 3806–3813. [Google Scholar]

- Alagoz, B.B.; Deniz, F.N.; Keles, C.; Tan, N. Disturbance rejection performance analyses of closed loop control systems by reference to disturbance ratio. ISA Trans. 2015, 55, 63–71. [Google Scholar] [CrossRef] [PubMed]

- Deniz, F.N.; Keles, C.; Alagoz, B.B.; Tan, N. Design of fractional-order PI controllers for disturbance rejection using RDR measure. In Proceedings of the ICFDA’14 International Conference on Fractional Differentiation and Its Applications 2014, Catania, Italy, 23–25 June 2014; pp. 1–6. [Google Scholar] [CrossRef]

- Héder, M. From NASA to EU: The evolution of the TRL scale in Public Sector Innovation. Innov. J. 2017, 22, 1–23. [Google Scholar]

- Uǧuz, H.; Goyal, A.; Meenpal, T.; Selesnick, I.W.; Baraniuk, R.G.; Kingsbury, N.G.; Haiter Lenin, A.; Mary Vasanthi, S.; Jayasree, T.; Adam, M.; et al. Ce pte d M us pt. J. Phys. Energy. 2020, 2, 1–31. [Google Scholar]

- Tepljakov, A.; Gonzalez, E.A.; Petlenkov, E.; Belikov, J.; Monje, C.A.; Petráš, I. Incorporation of fractional-order dynamics into an existing PI/PID DC motor control loop. ISA Trans. 2016, 60, 262–273. [Google Scholar] [CrossRef]

- Dastjerdi, A.A.; Vinagre, B.M.; Chen, Y.; HosseinNia, S.H. Linear fractional order controllers; A survey in the frequency domain. Annu. Rev. Control 2019, 47, 51–70. [Google Scholar] [CrossRef]

- Tepljakov, A.; Petlenkov, E.; Belikov, J. A flexible MATLAB tool for optimal fractional-order PID controller design subject to specifications. In Proceedings of the 31st Chinese Control Conference, Hefei, China, 25–27 July 2012; pp. 4698–4703. [Google Scholar]

- Morand, A.; Moreau, X.; Melchior, P.; Moze, M. Robust cruise control using CRONE approach. IFAC Proc. 2013, 46, 468–473. [Google Scholar] [CrossRef]

- Wang, C.; Jin, Y.; Chen, Y. Auto-tuning of FOPI and FO[PI] controllers with iso-damping property. In Proceedings of the 48h IEEE Conference on Decision and Control (CDC) held jointly with 2009 28th Chinese Control Conference, Shanghai, China, 15–18 December 2009; pp. 7309–7314. [Google Scholar] [CrossRef]

- Bode, H.W.; Phelps, G. Network Analysis and Feedback Amplifier Design|Hendrik W Bode|Digital Library Bookzz. 1945. Available online: http://bookzz.org/book/565696/cd0c74 (accessed on 22 December 2021).

- Åström, K. Limitations on Control System Performance. Eur. J. Control 2000, 6, 2–20. [Google Scholar] [CrossRef]

- Nielsen, P. Coastal and Estuarine Processes; World Scientific: Singapore, 2009; pp. 1–360. [Google Scholar] [CrossRef]

- Baños, A.; Cervera, J.; Lanusse, P.; Sabatier, J. Bode optimal loop shaping with CRONE compensators. J. Vib. Control 2010, 17, 1964–1974. [Google Scholar] [CrossRef]

- Pommier-Budinger, V.; Janat, Y.; Nelson-Gruel, D.; Lanusse, P.; Oustaloup, A. Fractional robust control with iso-damping property. In Proceedings of the 2008 American Control Conference, Seattle, WA, USA, 11–13 June 2008. [Google Scholar]

- Bhambhani, V. Optimal Fractional Order Proportional And Integral Controller For Processes With Random Time Delays. Master’s Thesis, Utah State University, Logan, UT, USA, 2009. [Google Scholar]

- Tepljakov, A.; Alagoz, B.B.; Yeroglu, C.; Gonzalez, E.A.; Hosseinnia, S.H.; Petlenkov, E.; Ates, A.; Cech, M. Towards Industrialization of FOPID Controllers: A Survey on Milestones of Fractional-Order Control and Pathways for Future Developments. IEEE Access 2021, 9, 21016–21042. [Google Scholar] [CrossRef]

- Bhaskaran, T.; Chen, Y.; Bohannan, G. Practical Tuning of Fractional Order Proportional and Integral Controller (II): Experiments. In Proceedings of the ASME 2007 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Las Vegas, NV, USA, 4–7 September 2007; pp. 1371–1384. [Google Scholar] [CrossRef]

- Nagy, Z.K. Model based control of a yeast fermentation bioreactor using optimally designed artificial neural networks. Chem. Eng. J. 2007, 127, 95–109. [Google Scholar] [CrossRef]

- Liu, B.; Ding, Y.; Gao, N.; Zhang, X. A bio-system inspired nonline ar intelligent controller with application to bio-reactor system. Neurocomputing 2015, 168, 1065–1075. [Google Scholar] [CrossRef]

- Tiwari, D.; Pachauri, N.; Rani, A.; Singh, V. Fractional order PID (FOPID) controller based temperature control of bioreactor. In Proceedings of the 2016 International Conference on Electrical, Electronics, and Optimization Techniques (ICEEOT), Chennai, India, 3–5 March 2016; pp. 2968–2973. [Google Scholar] [CrossRef]

- Cheng, J.-K.; Lee, H.-Y.; Huang, H.-P.; Yu, C.-C. Optimal steady-state design of reactive distillation processes using simulated annealing. J. Taiwan Inst. Chem. Eng. 2009, 40, 188–196. [Google Scholar] [CrossRef]

- Cao, J.-Y.; Cao, B.-G. Design of Fractional Order Controllers Based on Particle Swarm Optimization. In Proceedings of the 2006 1ST IEEE Conference on Industrial Electronics and Applications, Singapore, 24–26 May 2006; pp. 1–6. [Google Scholar] [CrossRef]

- Zamani, M.; Karimi-Ghartemani, M.; Sadati, N.; Parniani, M. Design of a fractional order PID controller for an AVR using particle swarm optimization. Control Eng. Pract. 2009, 17, 1380–1387. [Google Scholar] [CrossRef]

- Lee, C.-H.; Chang, F.-K. Fractional-order PID controller optimization via improved electromagnetism-like algorithm. Expert Syst. Appl. 2010, 37, 8871–8878. [Google Scholar] [CrossRef]

- Abraham, A.; Biswas, A.; Das, S.; Dasgupta, S. Design of fractional order PIλDμ controllers with an improved differential evolution. In Proceedings of the 10th annual conference on Genetic and evolutionary computation—GECCO’08, Atlanta, GA, USA, 12–16 July 2008. [Google Scholar]

- Maiti, D.; Biswas, S.; Konar, A. Design of a fractional order PID controller using particle Swarm Optimization technique. arXiv 2008, arXiv:0810.3776. [Google Scholar]

- Kundu, D.; Suresh, K.; Ghosh, S.; Das, S. Designing Fractional-order PIλDμ controller using a modified invasive Weed Optimization algortihm. In Proceedings of the 2009 World Congress on Nature & Biologically Inspired Computing (NaBIC), Coimbatore, India, 9–11 December 2009; pp. 1315–1320. [Google Scholar] [CrossRef]

- Aldair, A.A.; Wang, W.J. Design of Fractional Order Controller Based on Evolutionary Algorithm for a Full Vehicle Nonlinear Active Suspension Systems. Int. J. Control. Autom. 2010, 3, 33–46. [Google Scholar]

- Zhang, Y.; Li, J. Fractional-order PID controller tuning based on genetic algorithm. In Proceedings of the 2011 International Conference on Business Management and Electronic Information, Guangzhou, China, 13–15 May 2011. [Google Scholar]

- Rajasekhar, A.; Chaitanya, V.; Das, S. Fractional-Order PIλDμ Controller Design Using a Modified Artificial Bee Colony Algorithm. In Swarm, Evolutionary, and Memetic Computing; Springer: Berlin/Heidelberg, Germany, 2011; Volume 7076, pp. 670–678. [Google Scholar] [CrossRef]

- Tang, Y.; Cui, M.; Hua, C.; Li, L.; Yang, Y. Optimum design of fractional order PIλDμ controller for AVR system using chaotic ant swarm. Expert Syst. Appl. 2012, 39, 6887–6896. [Google Scholar] [CrossRef]

- Rajasekhar, A.; Das, S.; Abraham, A. Fractional Order PID controller design for speed control of chopper fed DC Motor Drive using Artificial Bee Colony algorithm. In Proceedings of the 2013 World Congress on Nature and Biologically Inspired Computing, Fargo, ND, USA, 12–14 August 2013; pp. 259–266. [Google Scholar] [CrossRef]

- Sheng, W.; Bao, Y. Fruit fly optimization algorithm based fractional order fuzzy-PID controller for electronic throttle. Nonlinear Dyn. 2013, 73, 611–619. [Google Scholar] [CrossRef]

- Wu, Z.; Li, D.; Wang, L. Control of the superheated steam temperature: A comparison study between PID and fractional order PID controller. In Proceeding of the 35th Chinese Control Conference, Chengdu, China, 27–29 July 2016; pp. 10521–10526. [Google Scholar] [CrossRef]

- Merzlikina, E.; Van Va, H.; Farafonov, G. Automatic Control System with an Autotuning Module and a Predictive PID-Algorithm for Thermal Processes. In Proceedings of the 2021 International Conference on Industrial Engineering, Applications and Manufacturing (ICIEAM), Sochi, Russia, 17–21 May 2021; pp. 525–529. [Google Scholar] [CrossRef]

- Mukhtar, A. Ambulance Temperature Control for the Safety of Medical Products using Fractional Order PID Controller Based on Artificial Intelligence Techniques. In Proceedings of the 2020 International Conference on Advances in Computing, Communication & Materials (ICACCM), Dehradun, India, 21–22 August 2020; pp. 205–211. [Google Scholar] [CrossRef]

- Chen, X.; Liu, J.; Sun, X. Self-adaption FOPID controller design for internal temperature in roller system based on data-driven technique. In Proceedings of the 2019 Chinese Control And Decision Conference (CCDC), Nanchang, China, 3–5 June 2019. [Google Scholar]

- Pezol, N.S.; Rahiman, M.H.F.; Adnan, R.; Tajjudin, M. Comparison of the CRONE-1 and FOPID Controllers for Steam Temperature Control of the Essential Oil Extraction Process. In Proceedings of the 2021 IEEE International Conference on Automatic Control & Intelligent Systems (I2CACIS), Shah Alam, Malaysia, 26 June 2021; pp. 253–258. [Google Scholar] [CrossRef]

- Li, R.; Wu, F.; Hou, P.; Zou, H. Performance Assessment of FO-PID Temperature Control System Using a Fractional Order LQG Benchmark. IEEE Access 2020, 8, 116653–116662. [Google Scholar] [CrossRef]

- Mei, J.; Li, Z. Fractional order PID control of temperature of supply cooling water. In Proceedings of the 2017 4th International Conference on Information Science and Control Engineering (ICISCE), Changsha, China, 21–23 July 2017. [Google Scholar]

- Aldhaifallah, M. Heat Exchanger Control Using Fuzzy Fractional-Order PID. In Proceedings of the 2019 16th International Multi-Conference on Systems, Signals & Devices (SSD), Istanbul, Turkey, 21–24 March 2019; pp. 73–77. [Google Scholar] [CrossRef]

- Vinagre, B.M.; Petras, I.; Merchan, P.; Dorcak, L. Two digital realizations of fractional controllers: Application to temperature control of a solid. In Proceedings of the 2001 European Control Conference (ECC), Porto, Portugal, 4–7 September 2001. [Google Scholar]

- Pandey, S.; Soni, N.K.; Pandey, R.K. Fractional order integral and derivative (FOID) controller with anti-windup for temperature profile control. In Proceedings of the 2015 2nd International Conference on Computing for Sustainable Global Development (INDIACom), New Delhi, India, 11–13 March 2015. [Google Scholar]

- Teng, Y.; Li, H.; Wu, F. Design of Distributed Fractional Order PID Type Dynamic Matrix Controller for Large-Scale Process Systems. IEEE Access 2020, 8, 179754–179771. [Google Scholar] [CrossRef]

- Feliu-Batlle, V.; Rivas-Perez, R.; Castillo-García, F.J. Robust fractional-order temperature control of a steel slab reheating furnace with large time delay uncertainty. In Proceedings of the ICFDA’14 International Conference on Fractional Differentiation and Its Applications 2014, Catania, Italy, 23–25 June 2014. [Google Scholar] [CrossRef]

- Tajjudin, M.; Ishak, N.; Rahiman, M.H.F.; Adnan, R. Design of fuzzy fractional-order PI + PD controller. In Proceedings of the 2016 IEEE 12th International Colloquium on Signal Processing & Its Applications (CSPA), Melaka, Malaysia, 4–6 March 2016. [Google Scholar]

- Ahn, H.-S.; Bhambhani, V.; Chen, Y. Fractional-order integral and derivative controller design for temperature profile control. In Proceedings of the 2008 Chinese Control and Decision Conference, Yantai, China, 2–4 July 2008; pp. 4766–4771. [Google Scholar] [CrossRef]

- Yu, W. Simulation and research of PID parameter tuning based on PSO. J. Chongqing Technol. Bus. Univ. (Nat. Sci.) 2020, 7, 18–23. [Google Scholar]

- Mukhtar, A.; Mukhtar, F. Liquid Level Control Strategy using Fractional Order PID Controller Based on Artificial Intelligence. Int. Res. J. Eng. Technol. 2020, 7, 1675–1680. [Google Scholar]

- Sondhi, S.; Hote, Y.V. Fractional order PID controller for load frequency control, Energy Conversion and Management. Energy Convers. Manag. 2014, 85, 343–353. [Google Scholar] [CrossRef]

- Wu, Z.; Zhao, L.; Feng, L. Intelligent vehicle control based on fractional order PID controller. Control. Eng. China 2011, 18, 401–404. [Google Scholar]

- Padhy, S.; Khadanga, R.K.; Panda, S. A modified GWO technique based fractional order PID controller with derivative filter coefficient for AGC of power systems with plug in electric vehicles. In Proceedings of the 2018 Technologies for Smart-City Energy Security and Power (ICSESP), Bhubaneswar, India, 28–30 March 2018. [Google Scholar] [CrossRef]

- Asl, R.M.; Pourabdollah, E.; Salmani, M. Optimal fractional order PID for a robotic manipulator using colliding bodies design. Soft Comput. 2017, 22, 4647–4659. [Google Scholar] [CrossRef]

- Haji, V.H.; Monje, C.A. Fractional-order PID control of a chopper-fed DC motor drive using a novel firefly algorithm with dynamic control mechanism. Soft Comput. 2017, 22, 6135–6146. [Google Scholar] [CrossRef]

- Yeroğlu, C.; Ateş, A. A stochastic multi-parameters divergence method for online auto-tuning of fractional order PID controllers. J. Frankl. Inst. 2014, 351, 2411–2429. [Google Scholar] [CrossRef]

- Oustaloup, A.; Melchior, P.; Lanusse, P.; Cois, O.; Dancla, F. The CRONE toolbox for Matlab. In Proceedings of CACSD. In In Proceedings of the IEEE International Symposium on Computer-Aided Control System Design, Anchorage, AK, USA, 25–27 September 2000. [Google Scholar] [CrossRef]

- Ateş, A.; Yeroglu, C. Optimal fractional order PID design via Tabu Search based algorithm. ISA Trans. 2016, 60, 109–118. [Google Scholar] [CrossRef]

- Ates, A.; Alagoz, B.B.; Yeroglu, C. Master–slave stochastic optimization for model-free controller tuning. Iranian J. Sci. Technol. Trans. Electr. Eng. 2017, 41, 153–163. [Google Scholar] [CrossRef]

- Ates, A.; Yeroglu, C.; Yuan, J.; Chen, Y.Q.; Hamamci, S.E. Optimization of the FO[PI] controller for MTDS using MAPO with multi objective function. SSRN Electron. J. 2018, 1–6. [Google Scholar] [CrossRef]

- Bingul, Z.; Karahan, O. Comparison of PID and FOPID controllers tuned by PSO and ABC algorithms for unstable and integrating systems with time delay. Optim. Control Appl. Methods 2018, 39, 1431–1450. [Google Scholar] [CrossRef]

- Sotner, R.; Jerabek, J.; Kartci, A.; Domansky, O.; Herencsar, N.; Kledrowetz, V.; Alagoz, B.B.; Yeroglu, C. Electronically reconfigurable two-path fractional-order PI/D controller employing constant phase blocks based on bilinear segments using CMOS modified current differencing unit. Microelectron. J. 2019, 86, 114–129. [Google Scholar] [CrossRef]

- Song, J.; Lin, J.; Wang, L.; Wang, X.; Guo, X. Nonlinear FOPID and Active Disturbance Rejection Hypersonic Vehicle Control Based on DEM Biogeography-Based Optimization. J. Aerosp. Eng. 2017, 30, 04017079. [Google Scholar] [CrossRef]

- Nie, C.; Yang, H.; Mu, X. Development and trend of vacuum induction melting technology. Vacuum 2015, 52, 52–57. [Google Scholar]

- Mazumder, A.; Kumar, V.D.; Sethi, S.; Mukherjee, J. Continuous monitoring of temperature of electron beam heated metal evaporation surface using controlled gas purge at viewing port in a vacuum chamber. Vacuum 2019, 161, 157–161. [Google Scholar] [CrossRef]

- Liu, Z. Research on Temperature Control Technology of Medium Frequency Induction Heating Furnace; Xi’an Shiyou University: Xi’an, China, 2014. [Google Scholar]

- Dequan, S.; Guili, G.; Zhiwei, G.; Peng, X. Application of Expert Fuzzy PID Method for Temperature Control of Heating Furnace. Procedia Eng. 2012, 29, 257–261. [Google Scholar] [CrossRef]

- Aware, M.V.; Junghare, A.S.; Khubalkar, S.W.; Dhabale, A.; Das, S.; Dive, R. Design of new practical phase shaping circuit using optimal pole–zero interlacing algorithm for fractional order PID controller. Anal. Integr. Circuits Signal Process. 2017, 91, 131–145. [Google Scholar] [CrossRef]

- Hao, X.; Gu, J.; Chen, N.; Zhang, W.; Zuo, X. 3-D Numerical analysis on heating process of loads within vacuum heat treatment furnace. Appl. Therm. Eng. 2008, 28, 1925–1931. [Google Scholar] [CrossRef]

- Buliński, P.; Smolka, J.; Golak, S.; Przyłucki, R.; Palacz, M.; Siwiec, G.; Lipart, J.; Białecki, R.; Blacha, L. Numerical and experimental investigation of heat transfer process in electromagnetically driven flow within a vacuum induction furnace. Appl. Therm. Eng. 2017, 124, 1003–1013. [Google Scholar] [CrossRef]

- Fang, H.; Yuan, X.; Liu, P. Active-disturbance-rejection-control and fractional-order proportional integral derivative hybrid control for hydroturbine speed governor system. Meas. Control. 2018, 51, 192–201. [Google Scholar] [CrossRef]

- Xue, D.; Zhao, C. Fractional order PID controller design for fractional order system. Control. Theory Appl. 2007, 24, 771–776. [Google Scholar]

- Li, M.; Li, D.; Wang, J.; Zhao, C. Active disturbance rejection control for fractional-order system. ISA Trans. 2013, 52, 365–374. [Google Scholar] [CrossRef]

- Han, J. The Technique for Estimating and Compensating the Uncertainties: Active Disturbance Rejection Control Technique; National Defense Industry Press: Beijing, China, 2008. [Google Scholar]

- Chen, Z. Some advances in linear active disturbance rejection control theory and engineering applications. Inf. Control 2017, 46, 257–266. [Google Scholar]

- Li, J. Active disturbance rejection control: Summary and prospects of research achievements. Control. Theory Appl. 2017, 34, 281–294. [Google Scholar]

Figure 1.

Block diagram of PID controllers [

2].

Figure 1.

Block diagram of PID controllers [

2].

Figure 4.

Step response of open-loop experimental data [

2].

Figure 4.

Step response of open-loop experimental data [

2].

Figure 5.

Flow diagram of a bioreactor tank [

53].

Figure 5.

Flow diagram of a bioreactor tank [

53].

Figure 6.

Block digram of a fractional-order PID controller.

Figure 6.

Block digram of a fractional-order PID controller.

Figure 7.

Ambulance output comparison plot of PID controller in terms of time and temperature.

Figure 7.

Ambulance output comparison plot of PID controller in terms of time and temperature.

Figure 8.

Error response plot of PID controller in terms of time and error.

Figure 8.

Error response plot of PID controller in terms of time and error.

Figure 9.

Ambulance output comparison plot of PID Controller and ga in terms of time and temperature.

Figure 9.

Ambulance output comparison plot of PID Controller and ga in terms of time and temperature.

Figure 10.

Error response plot of an ambulance with GA PID in terms of time and error.

Figure 10.

Error response plot of an ambulance with GA PID in terms of time and error.

Figure 11.

Ambulance output comparison plot with PSO, along with PID, in terms of time and temperature.

Figure 11.

Ambulance output comparison plot with PSO, along with PID, in terms of time and temperature.

Figure 12.

Ambulance error response plot comparison with PSO, along with PID.

Figure 12.

Ambulance error response plot comparison with PSO, along with PID.

Figure 13.

Output plot comparison of ambulance response with fractional-order PID.

Figure 13.

Output plot comparison of ambulance response with fractional-order PID.

Figure 14.

Ambulance error response with fractional-order PID in terms of time and error.

Figure 14.

Ambulance error response with fractional-order PID in terms of time and error.

Figure 15.

Ambulance output plot comparison with fractional-order PID, along with GA.

Figure 15.

Ambulance output plot comparison with fractional-order PID, along with GA.

Figure 16.

Ambulance error response comparison with fractional-order PID, along with GA.

Figure 16.

Ambulance error response comparison with fractional-order PID, along with GA.

Figure 17.

Ambulance output response comparison of fractional-order PID, along with PSO.

Figure 17.

Ambulance output response comparison of fractional-order PID, along with PSO.

Figure 18.

Ambulance error response comparison of fractional-order PID, along with PSO.

Figure 18.

Ambulance error response comparison of fractional-order PID, along with PSO.

Figure 19.

Final output plot of ambulance response in terms of time and temperature.

Figure 19.

Final output plot of ambulance response in terms of time and temperature.

Figure 20.

Simplified block diagram of induction heating [

101].

Figure 20.

Simplified block diagram of induction heating [

101].

Figure 21.

Block diagram of ADRC structural control system [

102].

Figure 21.

Block diagram of ADRC structural control system [

102].

Figure 22.

Flow Diagram of QPSO parameter optimization algorithm [

102].

Figure 22.

Flow Diagram of QPSO parameter optimization algorithm [

102].

Figure 23.

Frequency graph of temperature order monitor control effects (four cases) [

102].

Figure 23.

Frequency graph of temperature order monitor control effects (four cases) [

102].

Table 3.

Different parameters used for PID controllers.

Table 3.

Different parameters used for PID controllers.

| Sr.# | Gains | PID | PID+GA | PID + PSO |

|---|

| 1 | | 18.81 | 0.50 | 60.61 |

| 2 | | 2.26 | 1.50 | 1.19 |

| 3 | | 8.59 | 5.00 | 6.99 |

Table 4.

PID Controller Parameters (Fractional Order) in terms of Gains.

Table 4.

PID Controller Parameters (Fractional Order) in terms of Gains.

| Gains | GA | PSO | Hit & Trial |

|---|

| 6.02 | 7.98 | 11.79 |

| 2.001 | 2.09 | 2.39 |

| λ | 0.85 | 0.89 | 0.99 |

| 1.002 | 33.62 | 34.62 |

| µ | 0.85 | 0.89 | 0.79 |

Table 5.

Comparison of FOPID and PID performance in terms of different time specifications.

Table 5.

Comparison of FOPID and PID performance in terms of different time specifications.

| Sr.# | Time Specification | PID | PID + PSO | FOPID + PSO | PID + GA | FOPID + GA | FOPID |

|---|

| 1. | ISE | | 9846 | 5437 | | 6821 | 9878 |

| 2. | Peak Value | 48.6 | 43.1 | 39.1 | 46.5 | 40.2 | 41.5 |

| 3. | IAE | 625 | 531 | 360 | 590 | 498 | 675 |

| 4. | Rise Time | 5.8 | 7.2 | 2.5 | 6.5 | 3.5 | 4.4 |

| 5. | Setting Time | 64.2 | 50.8 | 47 | 55 | 48.8 | 48.8 |

| Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).