Numerical Simulation Study on the Flow and Heat Transfer Characteristics of Subcooled N-Heptane Flow Boiling in a Vertical Pipe under External Radiation

Abstract

:1. Introduction

2. Numerical Methodology

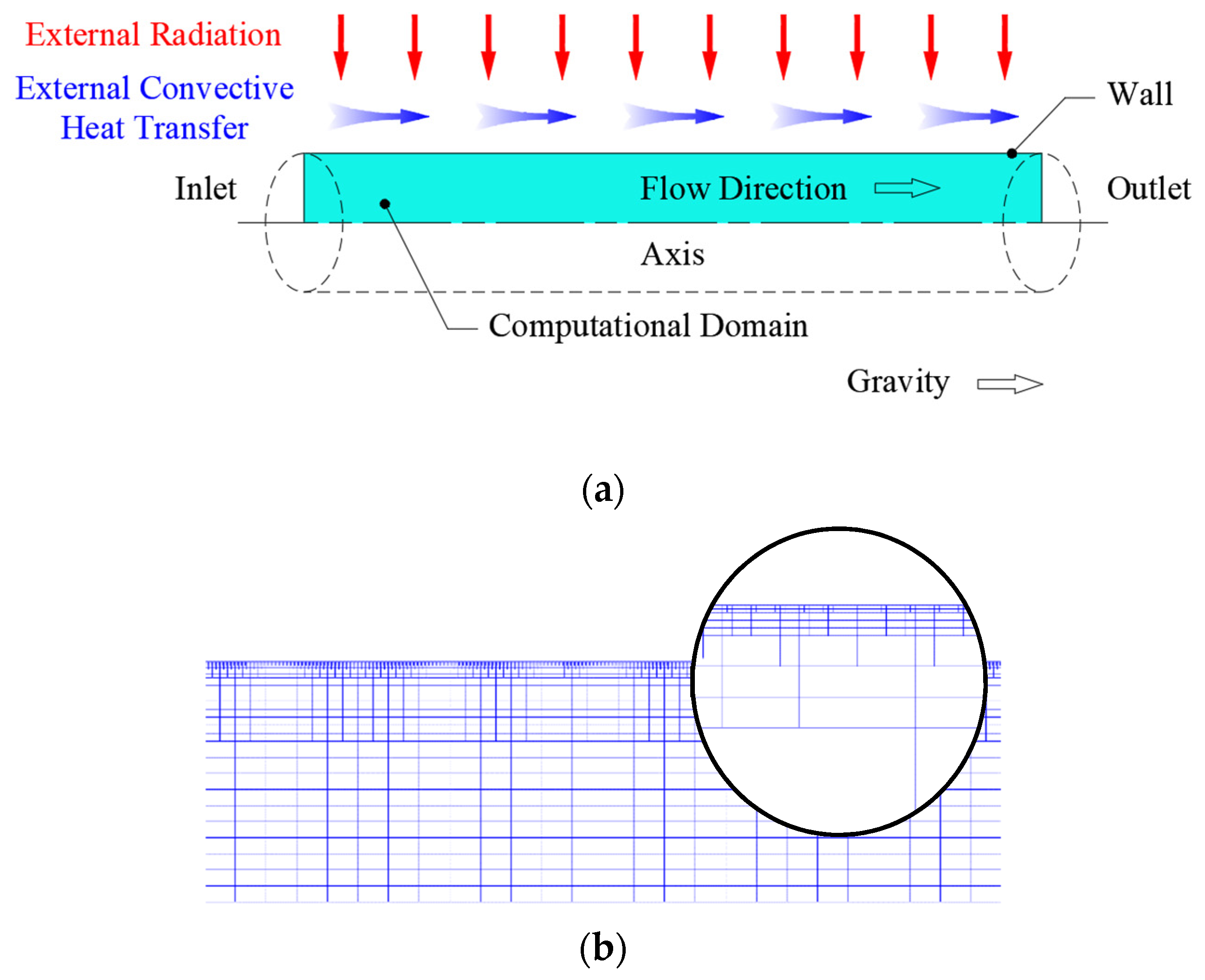

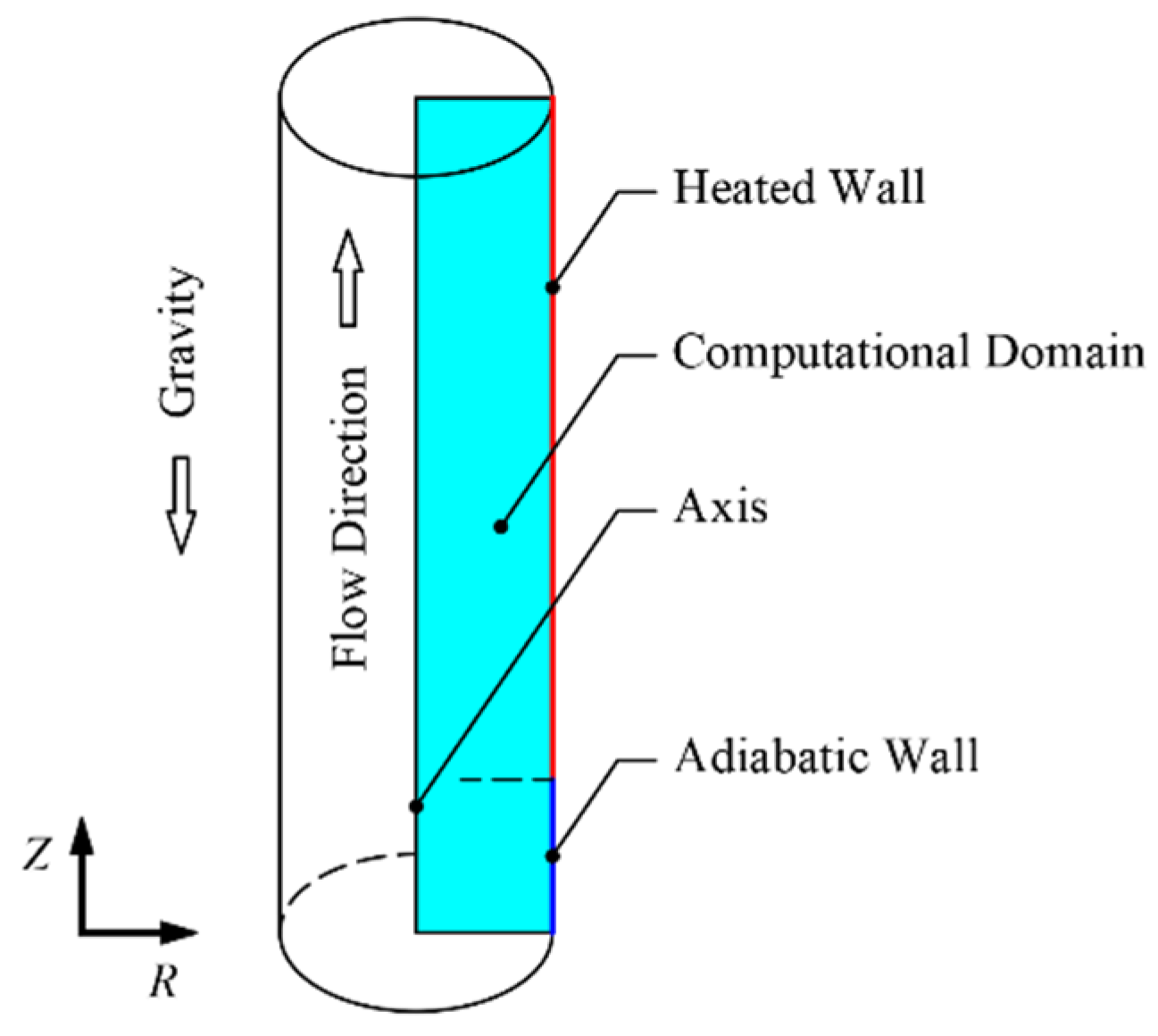

2.1. Definition of the Physical Problem

2.2. Modeling Assumptions

- (1)

- The mass flow rate is steady.

- (2)

- The outer pipe temperature is steady and consistent with the temperature of the off-gas in the furnace.

- (3)

- The inner and outer tube walls are regarded as diffuse surfaces.

- (4)

- The inner pipe is entirely covered by the outer pipe, ignoring the influences of unclosed surfaces at the inlet and outlet. That is, the view factor of radiation between the outer pipe and the inner pipe takes a value of 1.

- (5)

- Since the convective heat transfer caused by the oxygen-enriched air has a limited effect on the overall heating condition of the wall, and the convective heat transfer coefficient changes slightly with the wall temperature, the fluctuations in the convection heat transfer coefficient are ignored.

- (6)

- The oxygen-enriched air in the annular channel is optically transparent.

- (7)

- The average temperature of the oxygen-enriched air in the annular channel is at a fixed value.

- (8)

- The inner pipe wall thickness and thermal resistance are ignored.

2.3. Governing Equations

2.3.1. Wall Boundary Condition

2.3.2. Eulerian Two-Fluid Model

2.3.3. Improved RPI Model

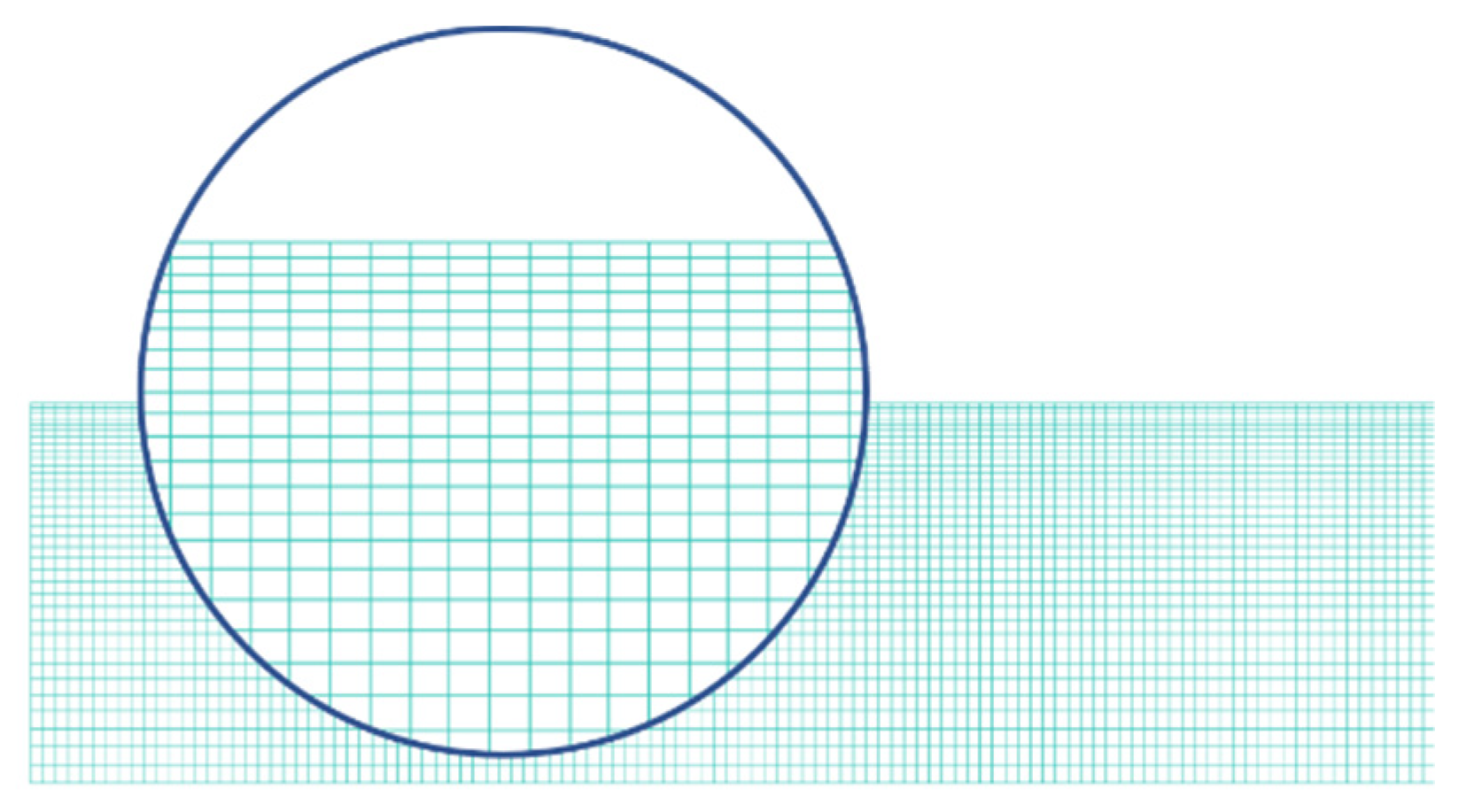

2.4. Model Settings

2.5. Parameter Definition

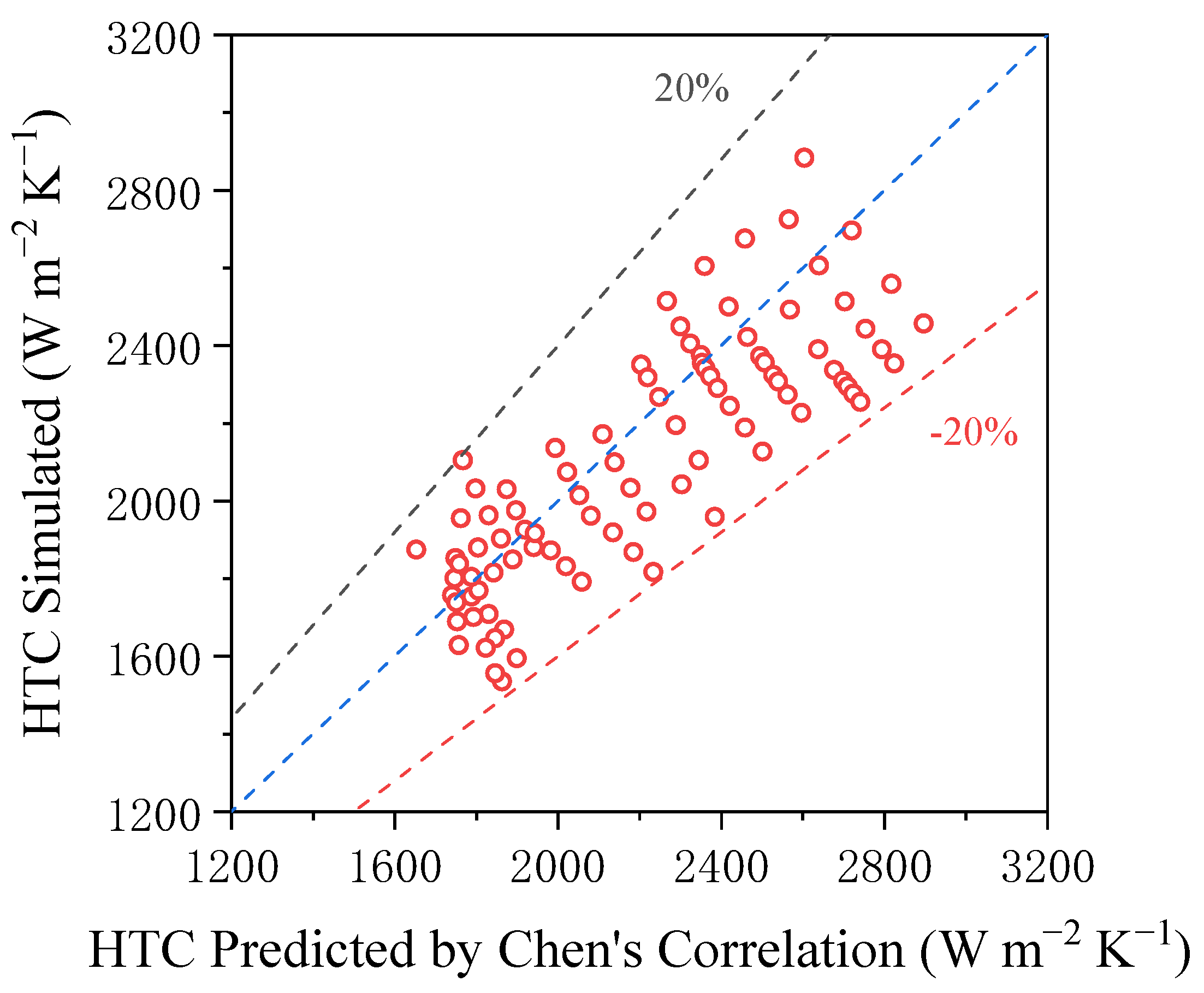

2.6. Model Validation

3. Results and Discussion

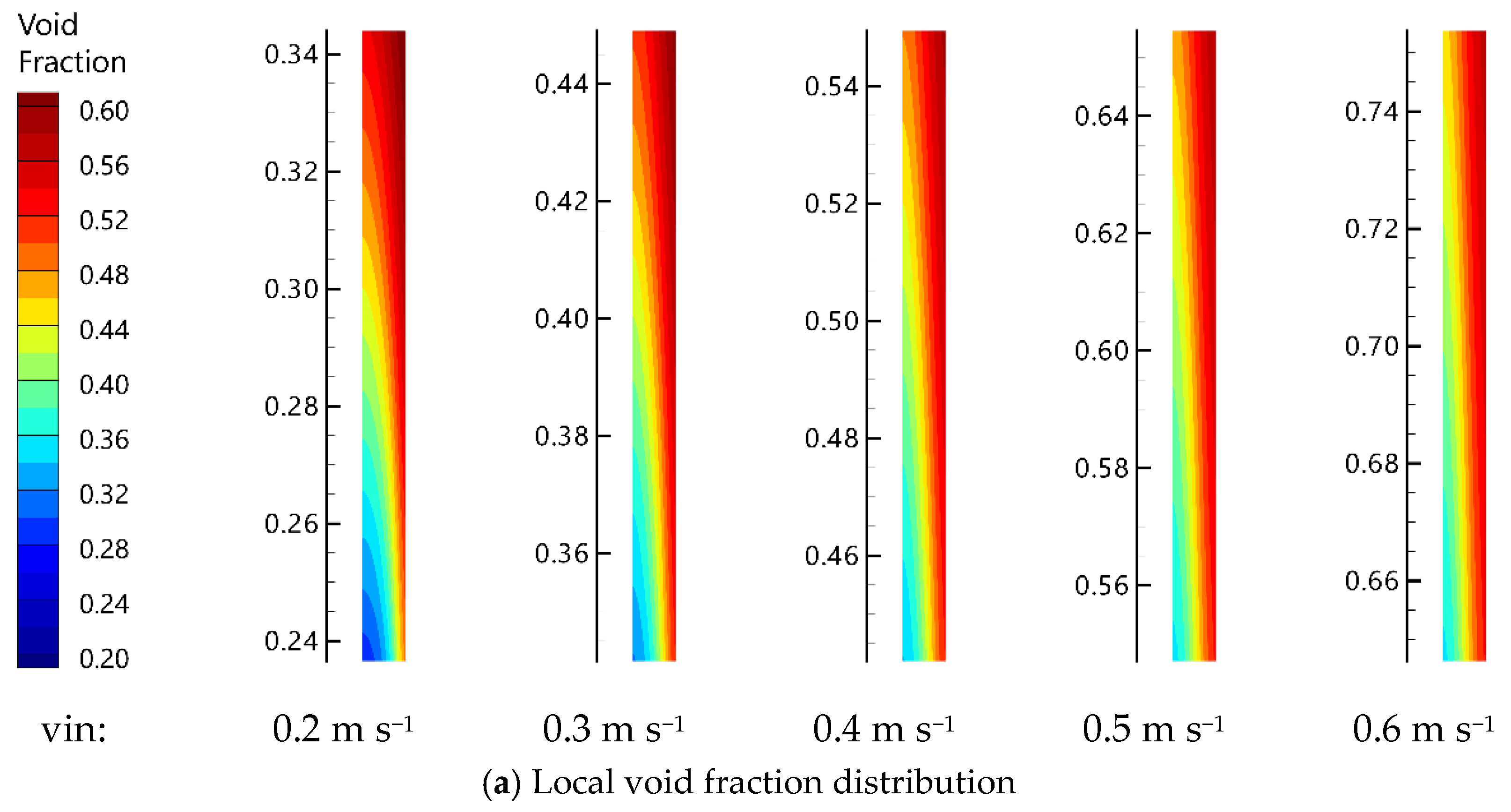

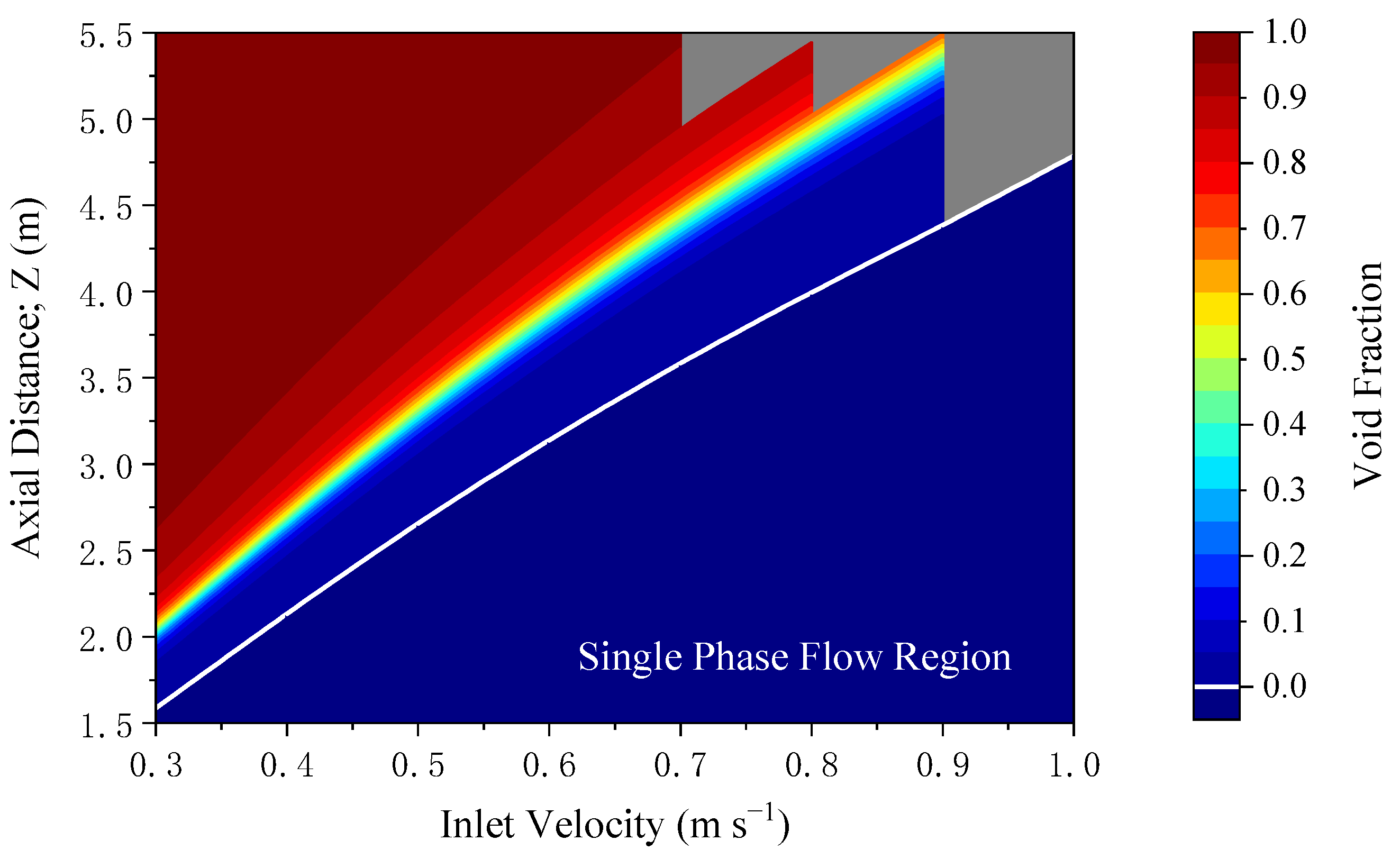

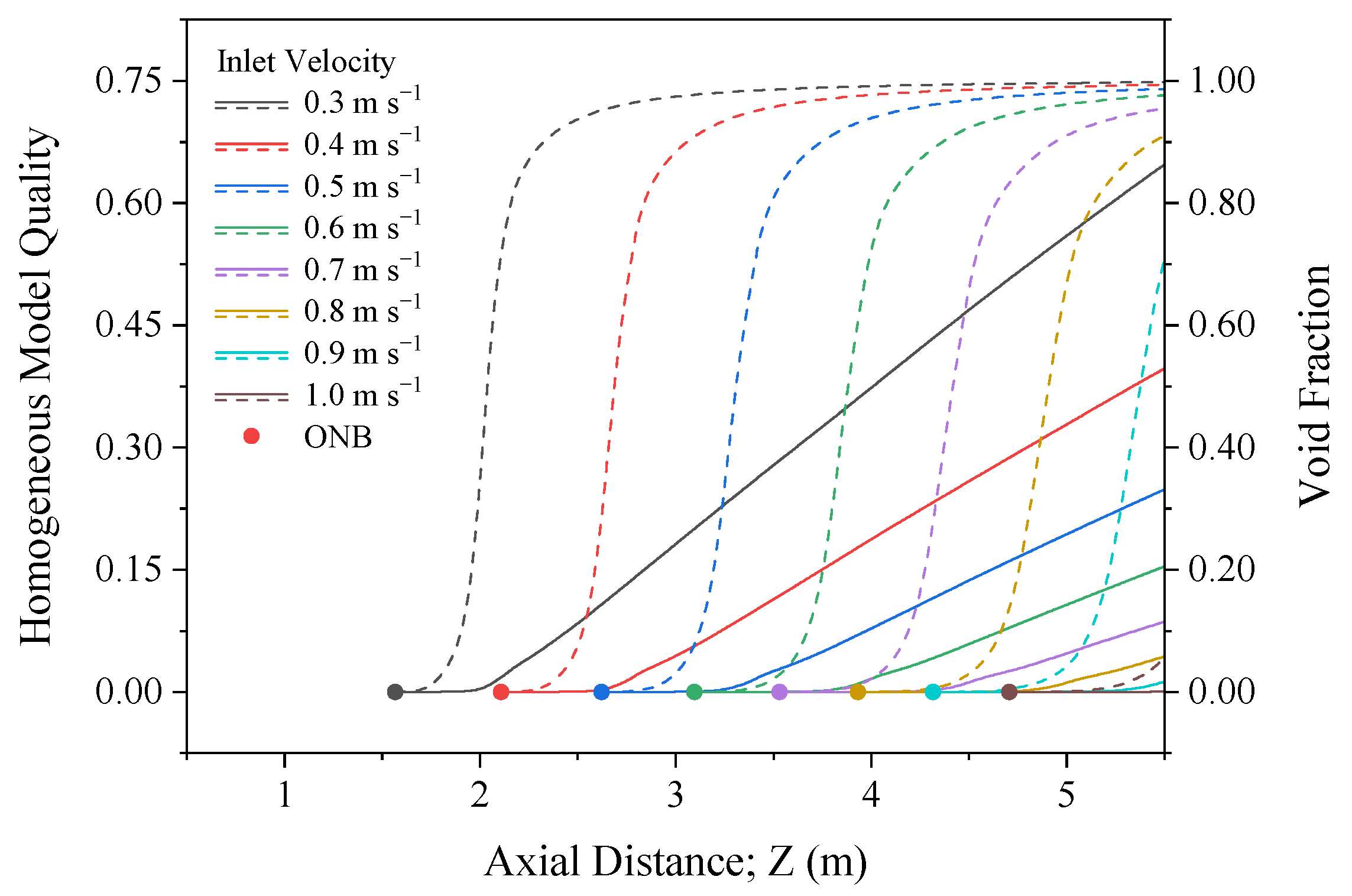

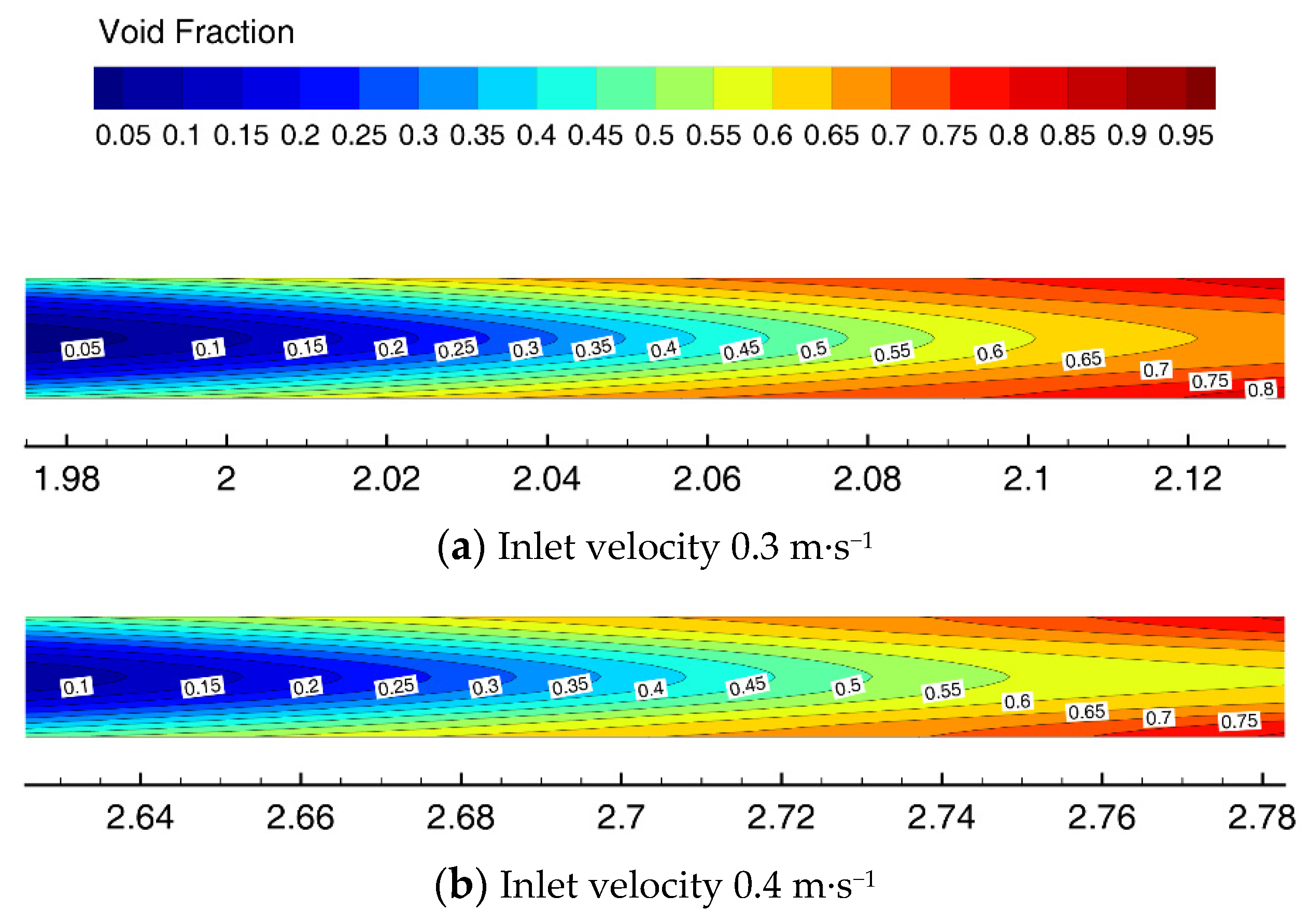

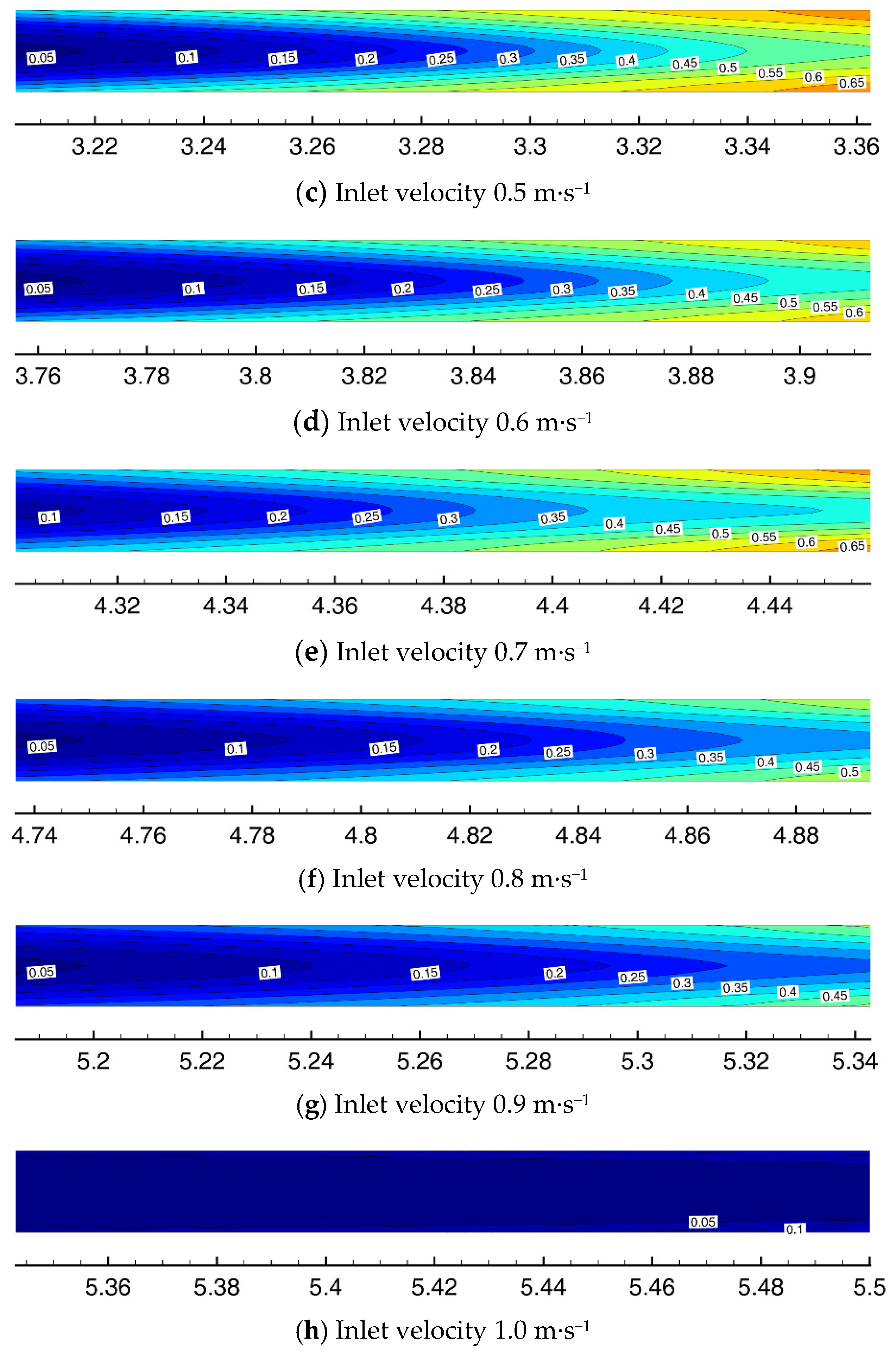

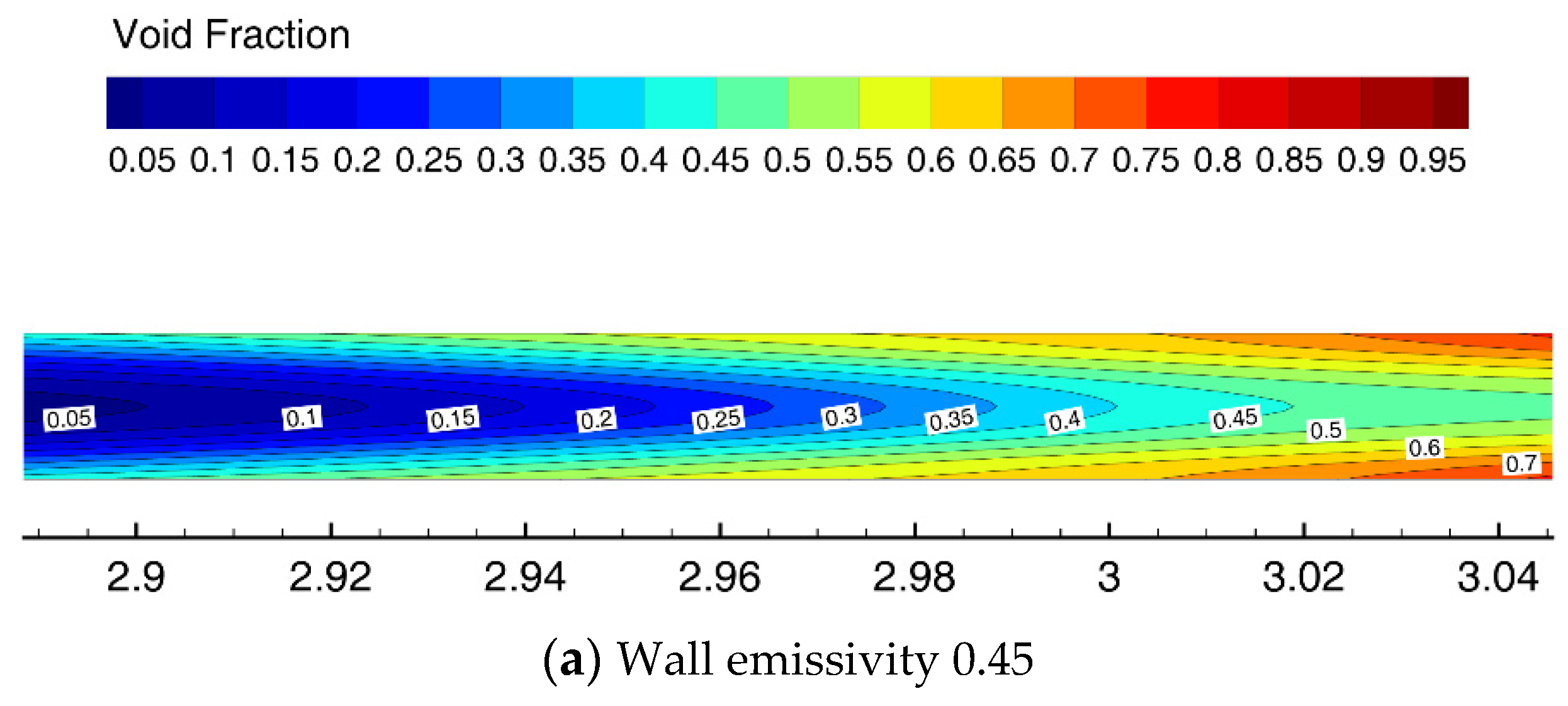

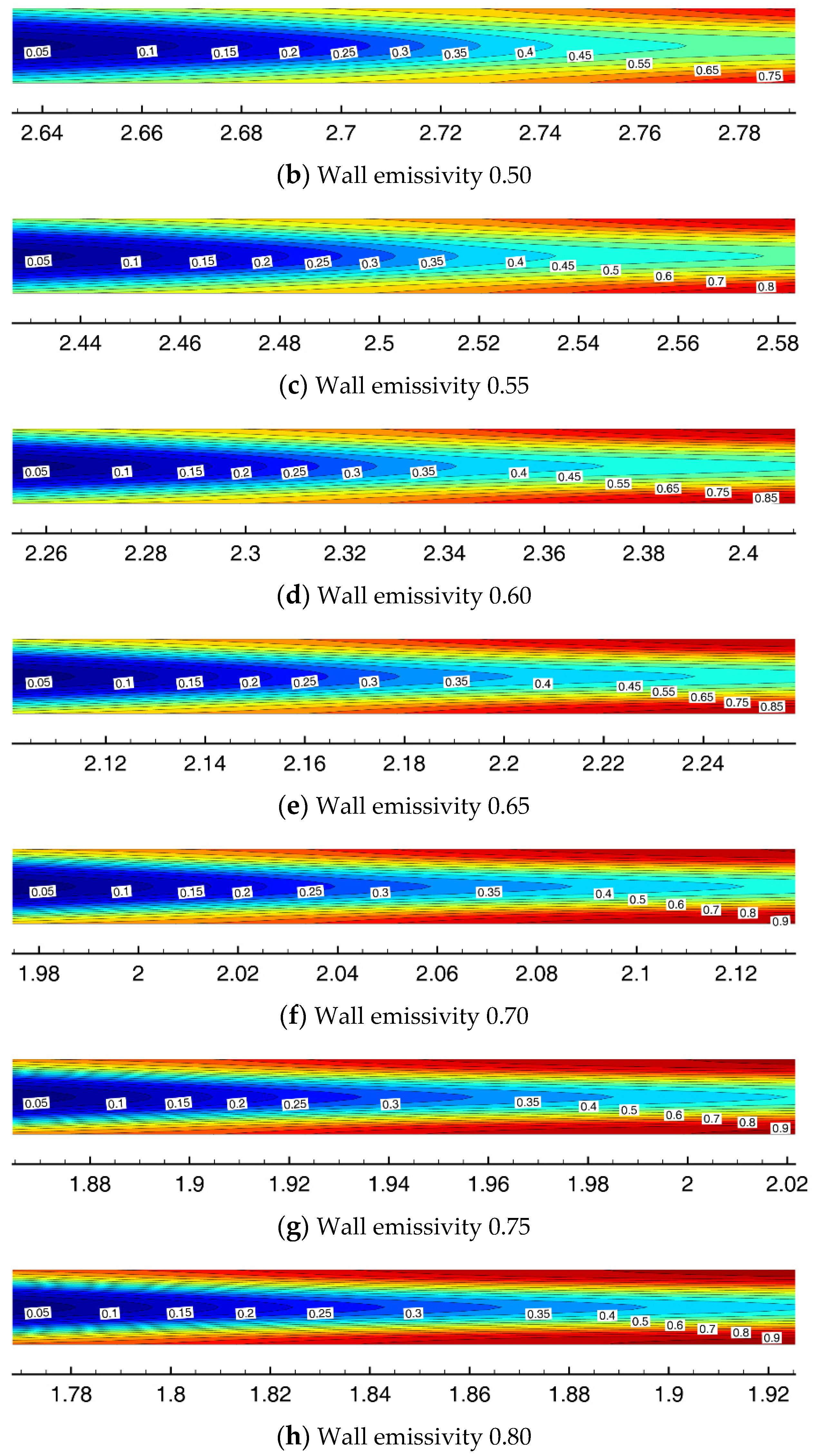

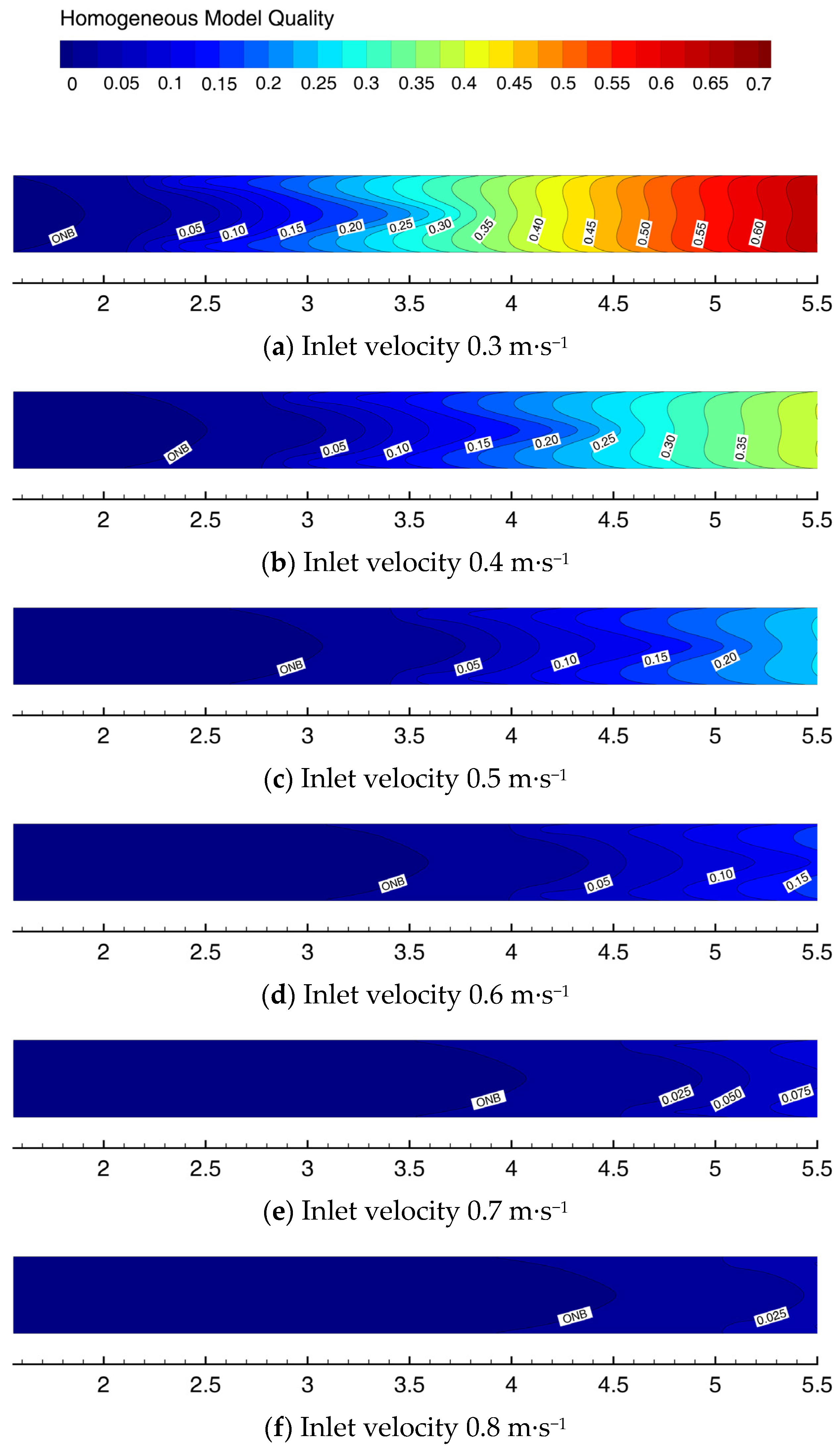

3.1. Void Fraction and Quality

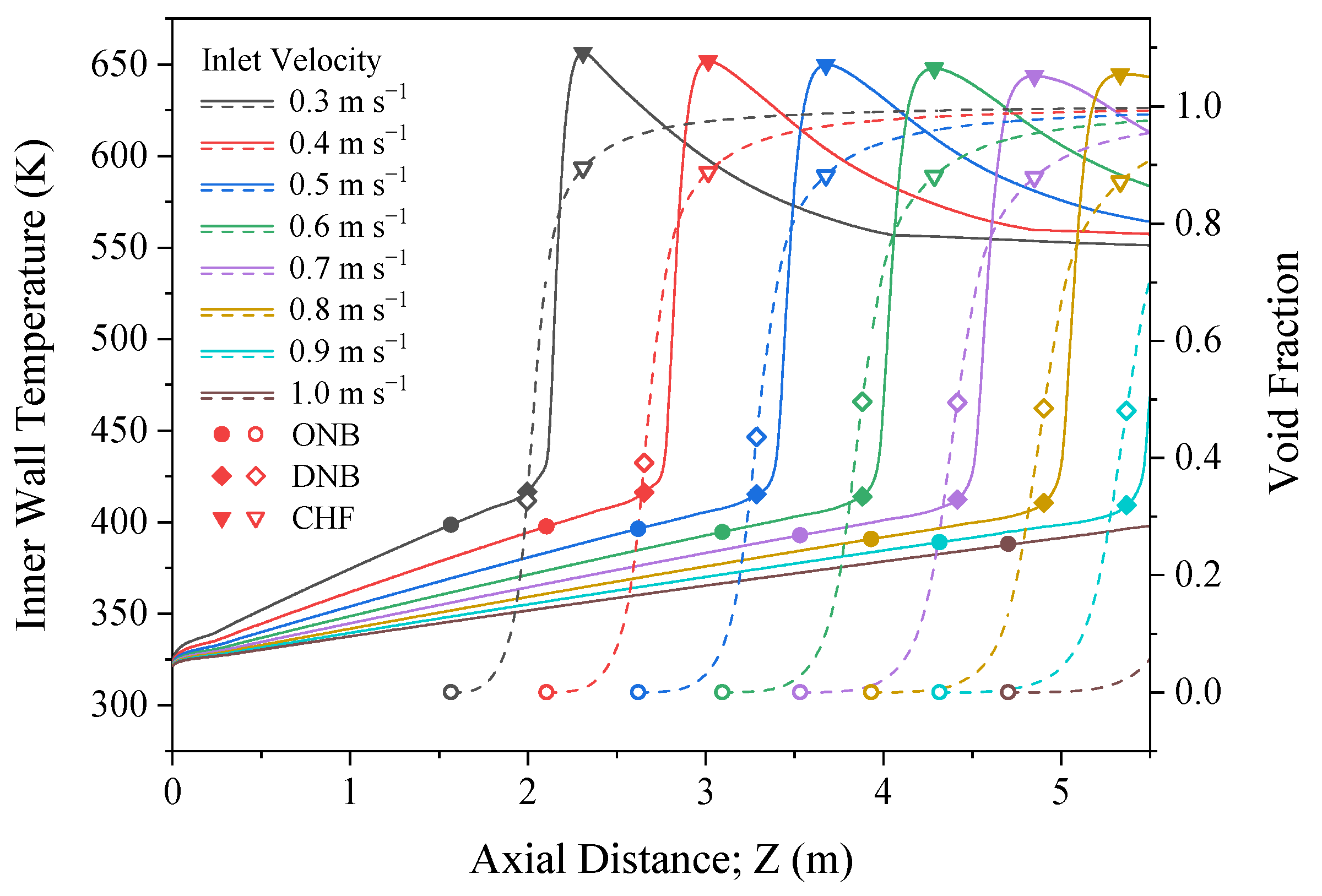

3.2. Wall Heat Flux and Inner Wall Temperature

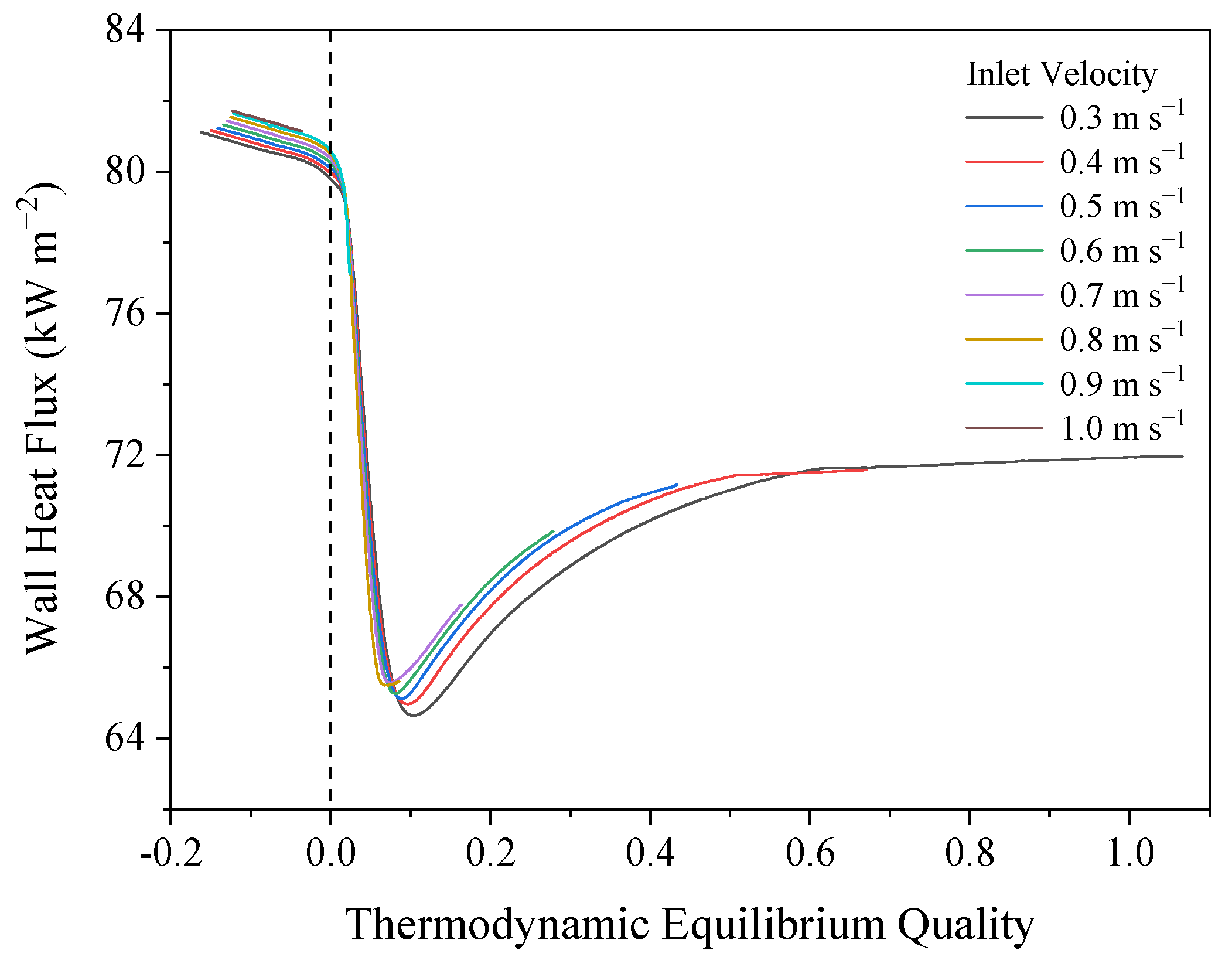

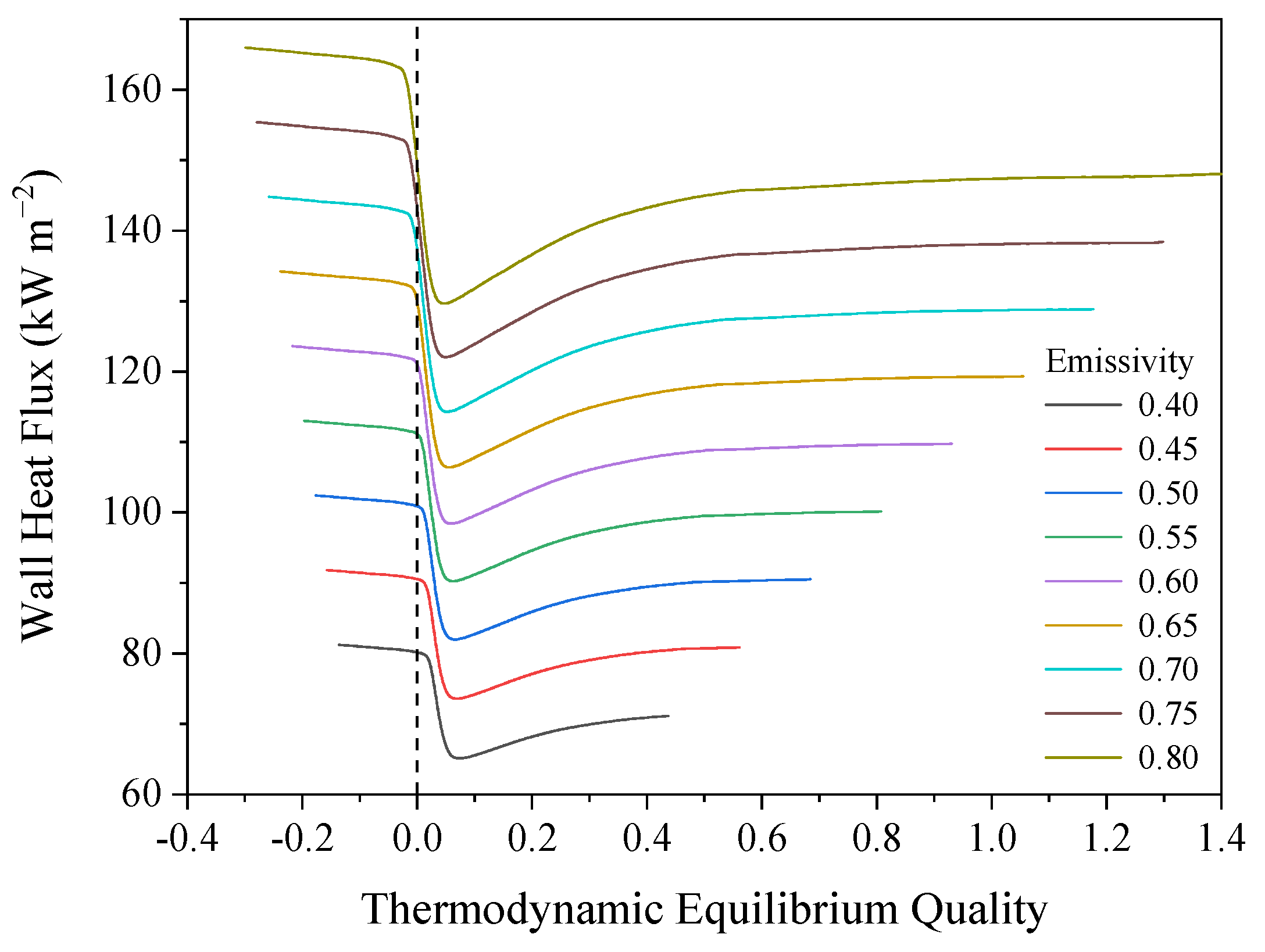

3.3. Heat Transfer Coefficient

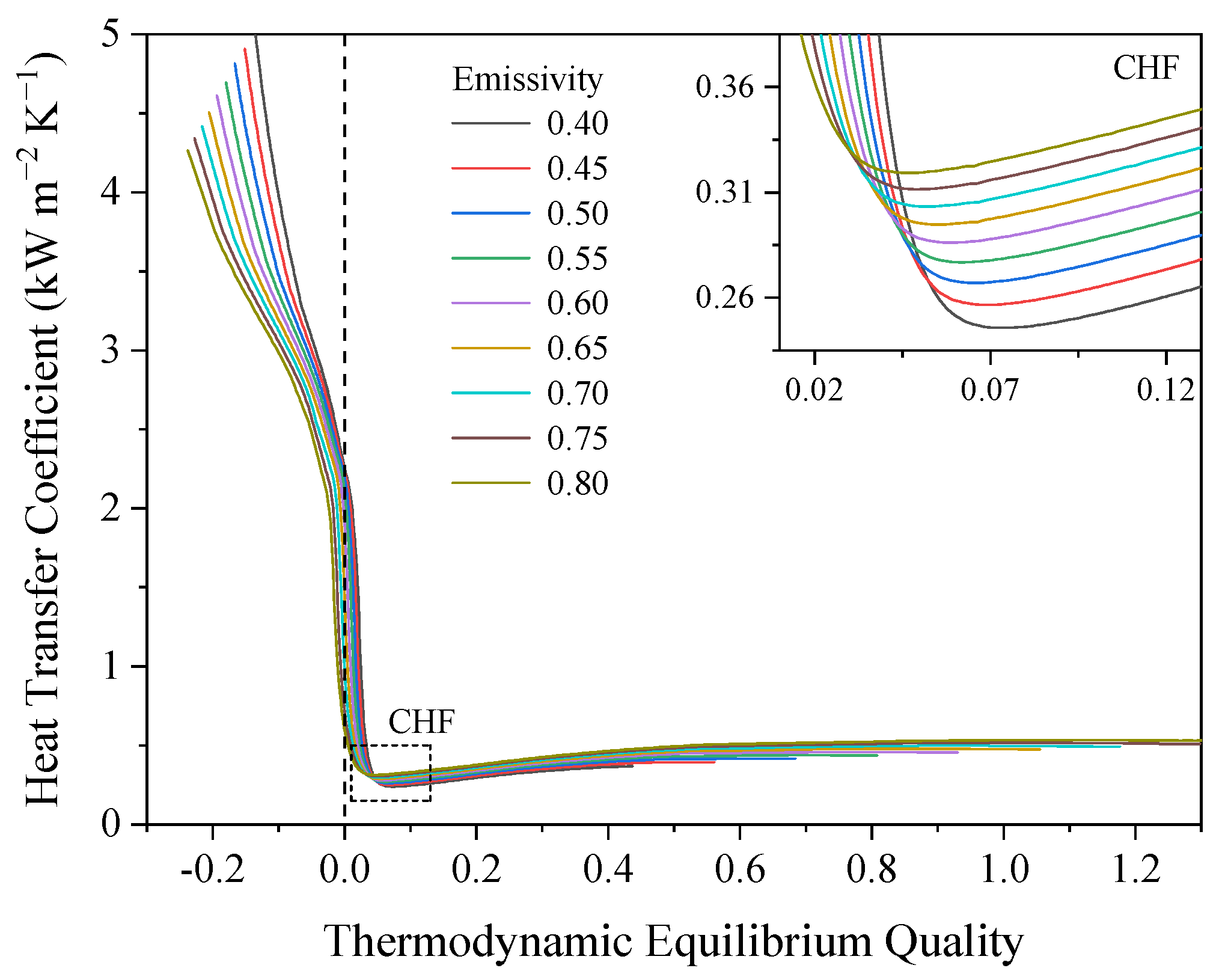

3.4. Temperature of Each Phase

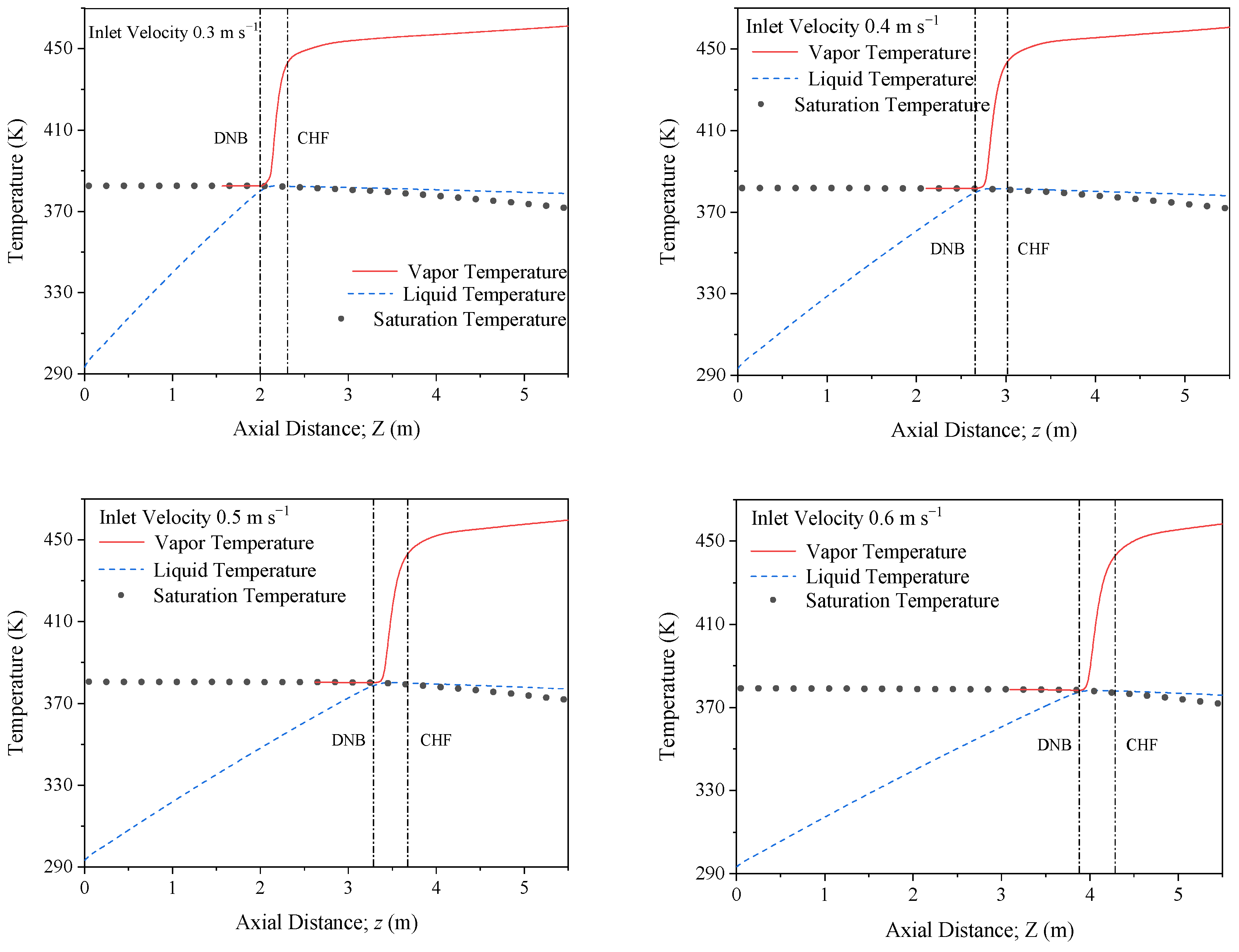

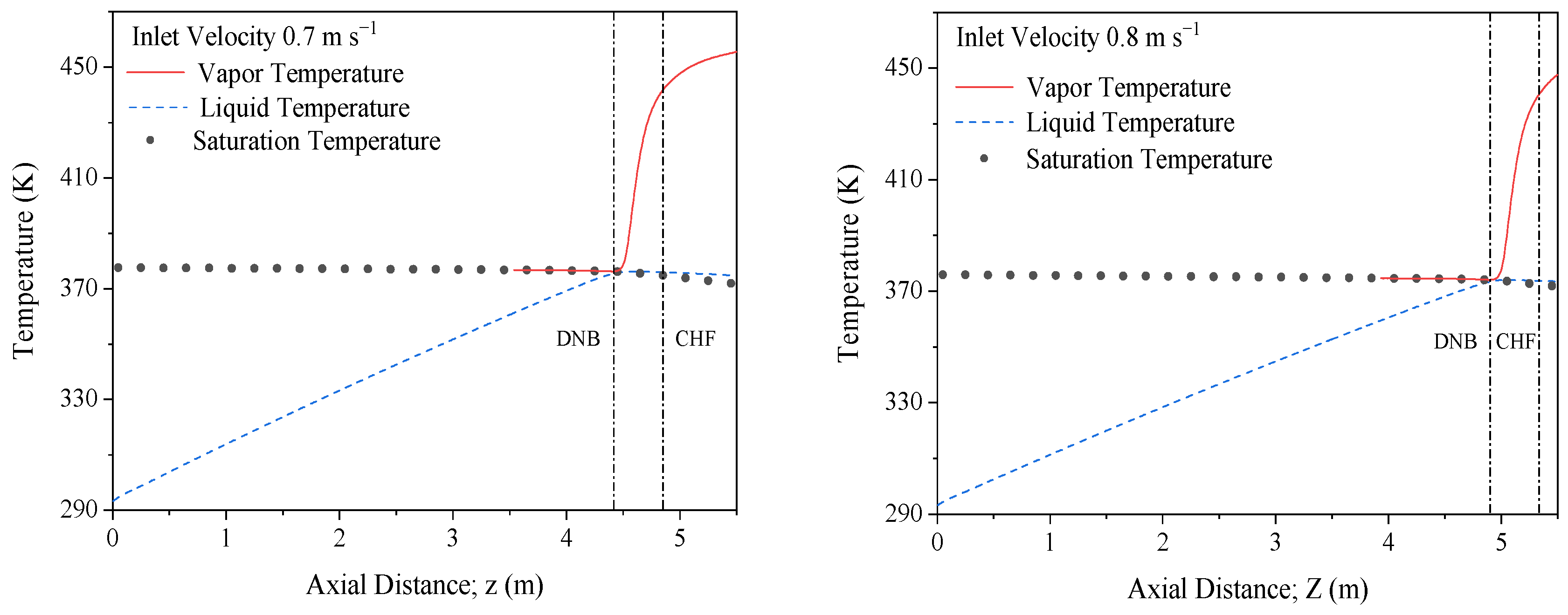

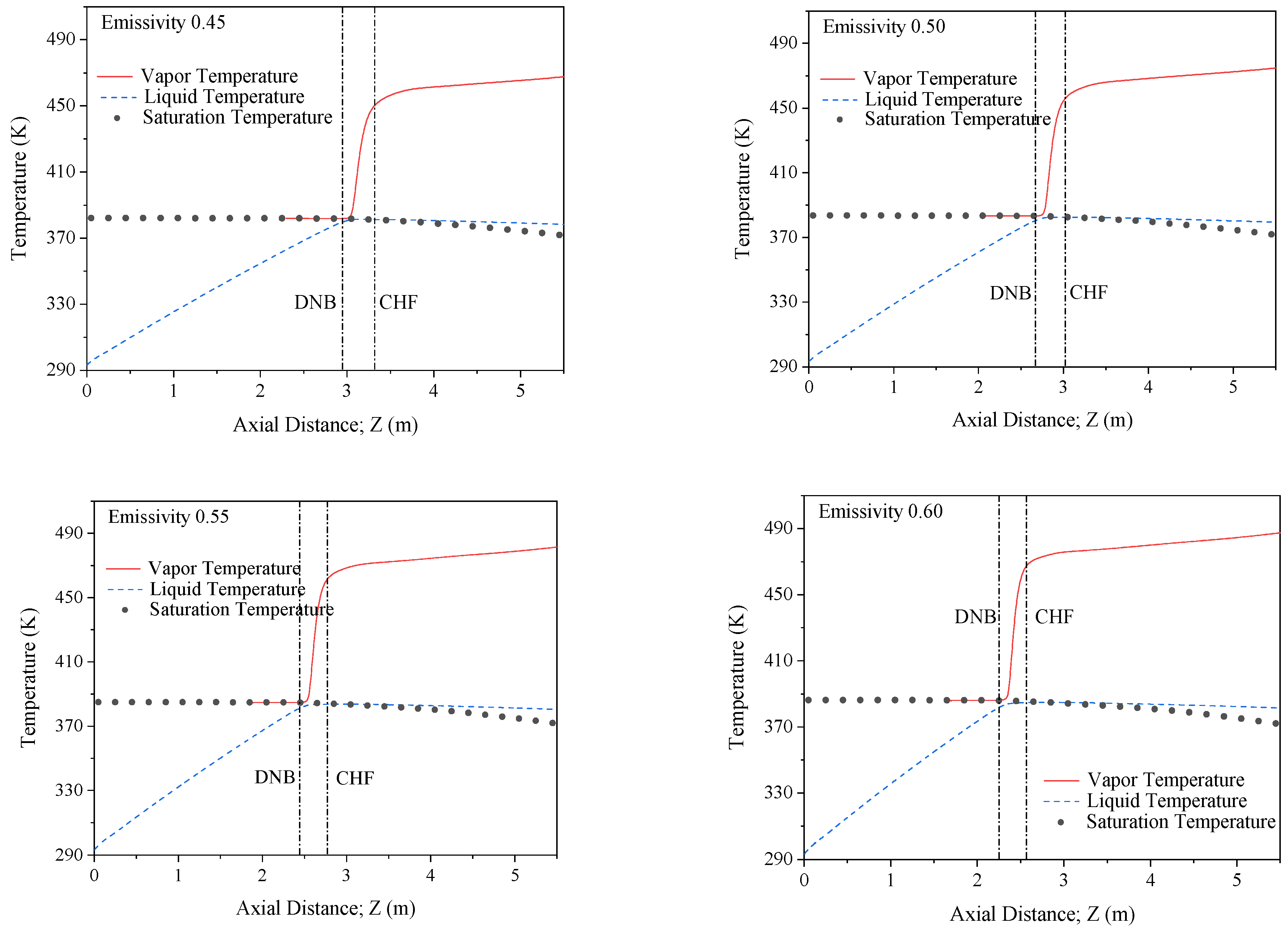

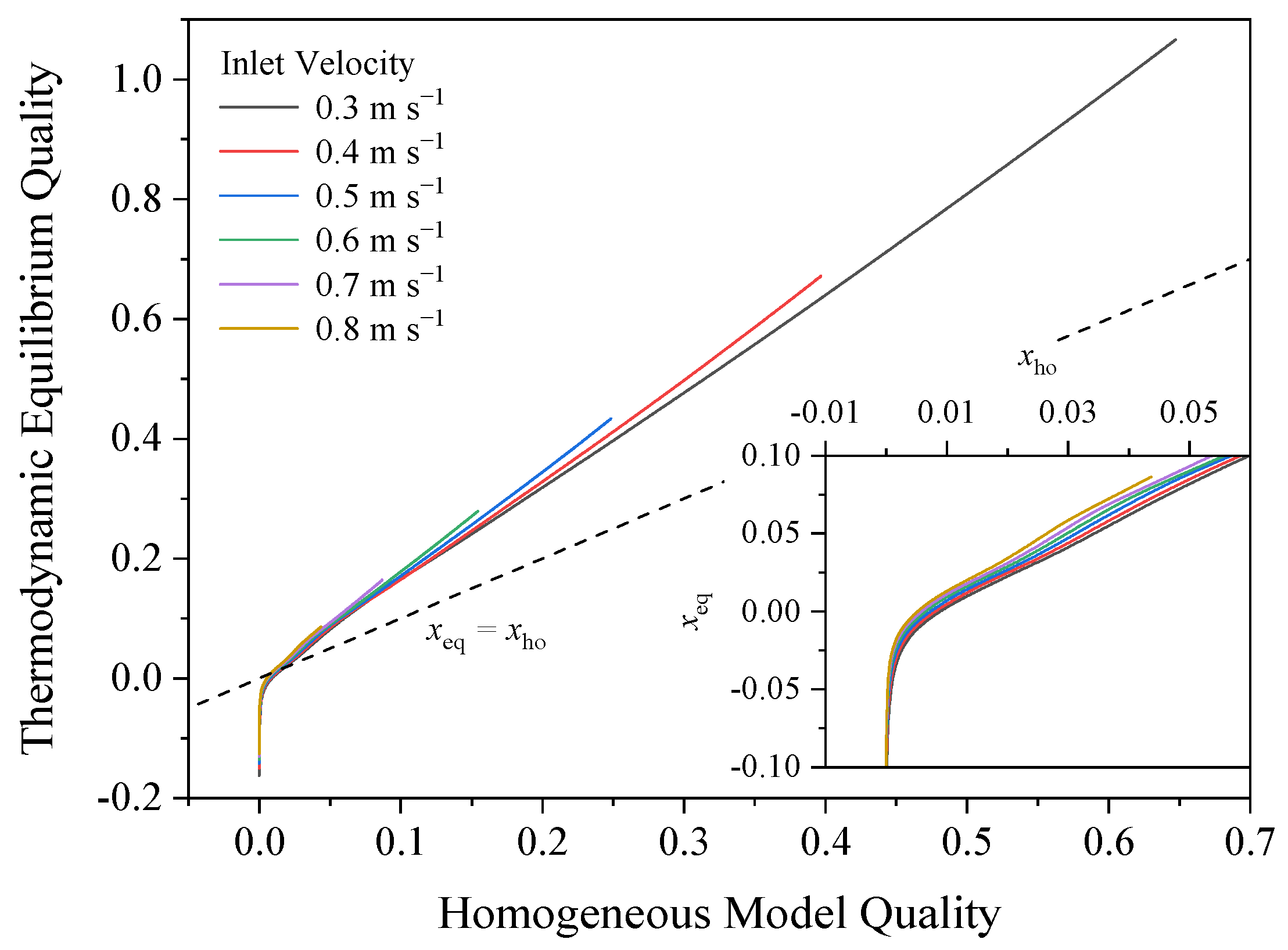

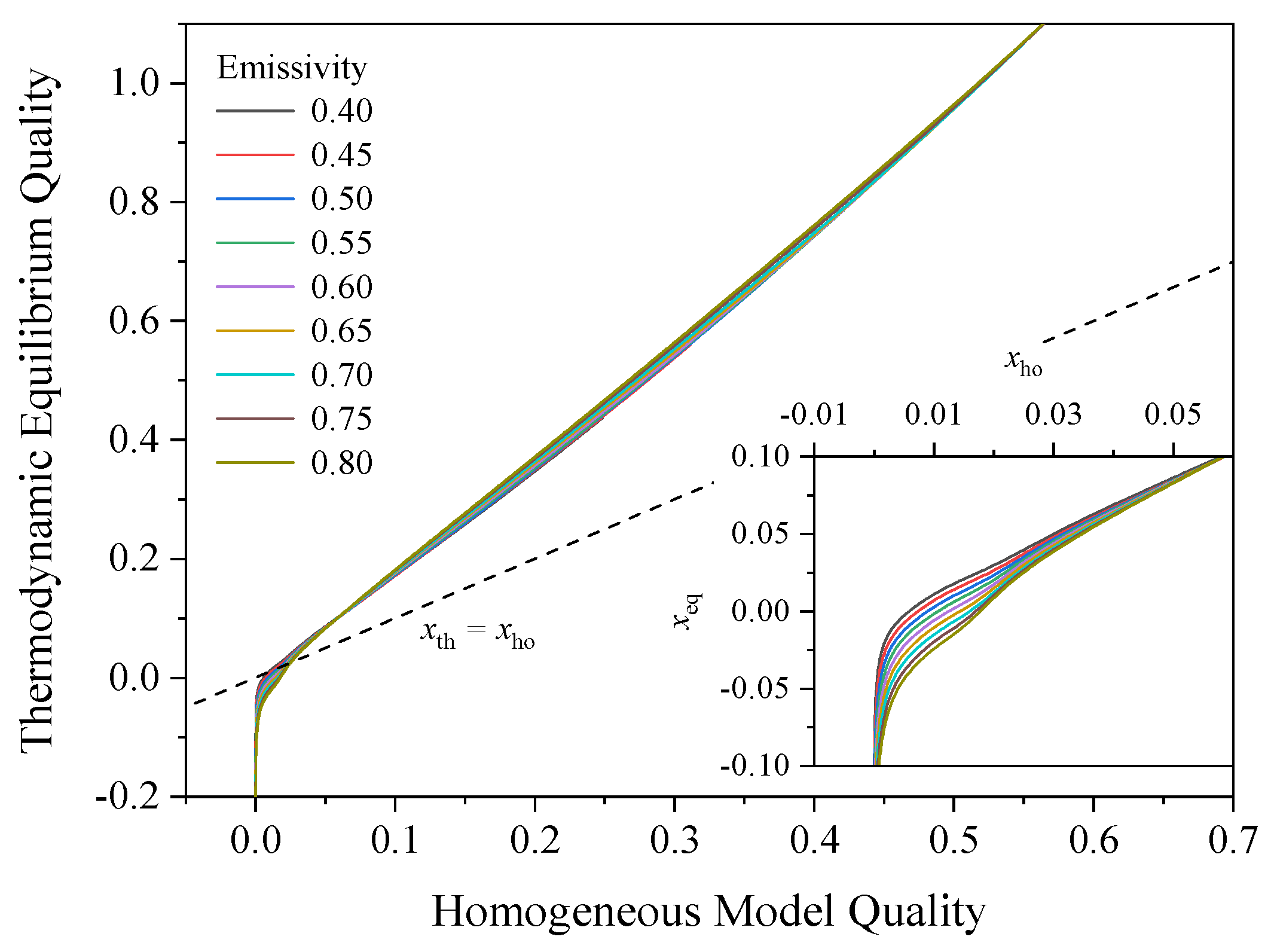

3.5. Non-Equilibrium Effect

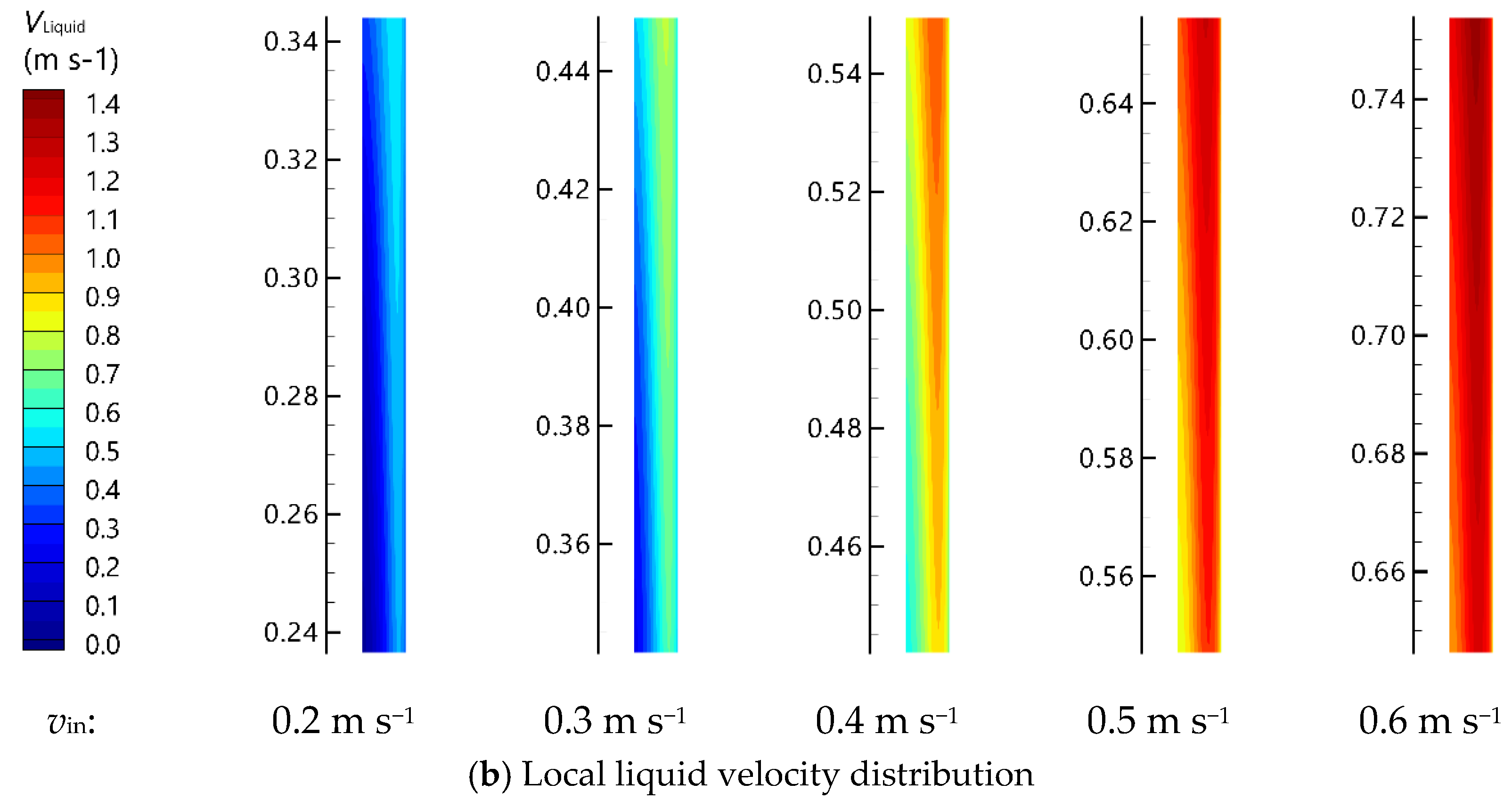

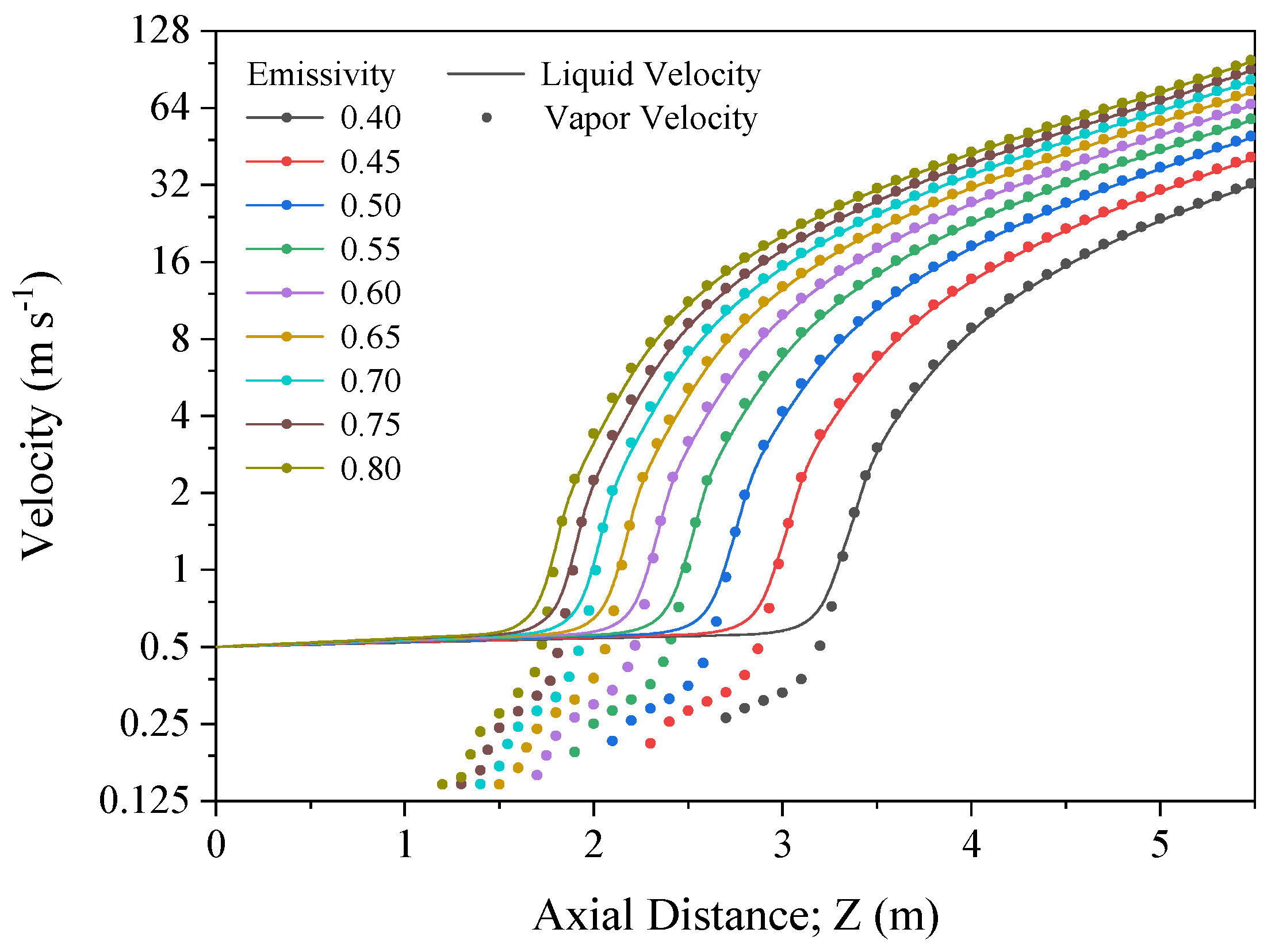

3.6. Velocity of Each Phase

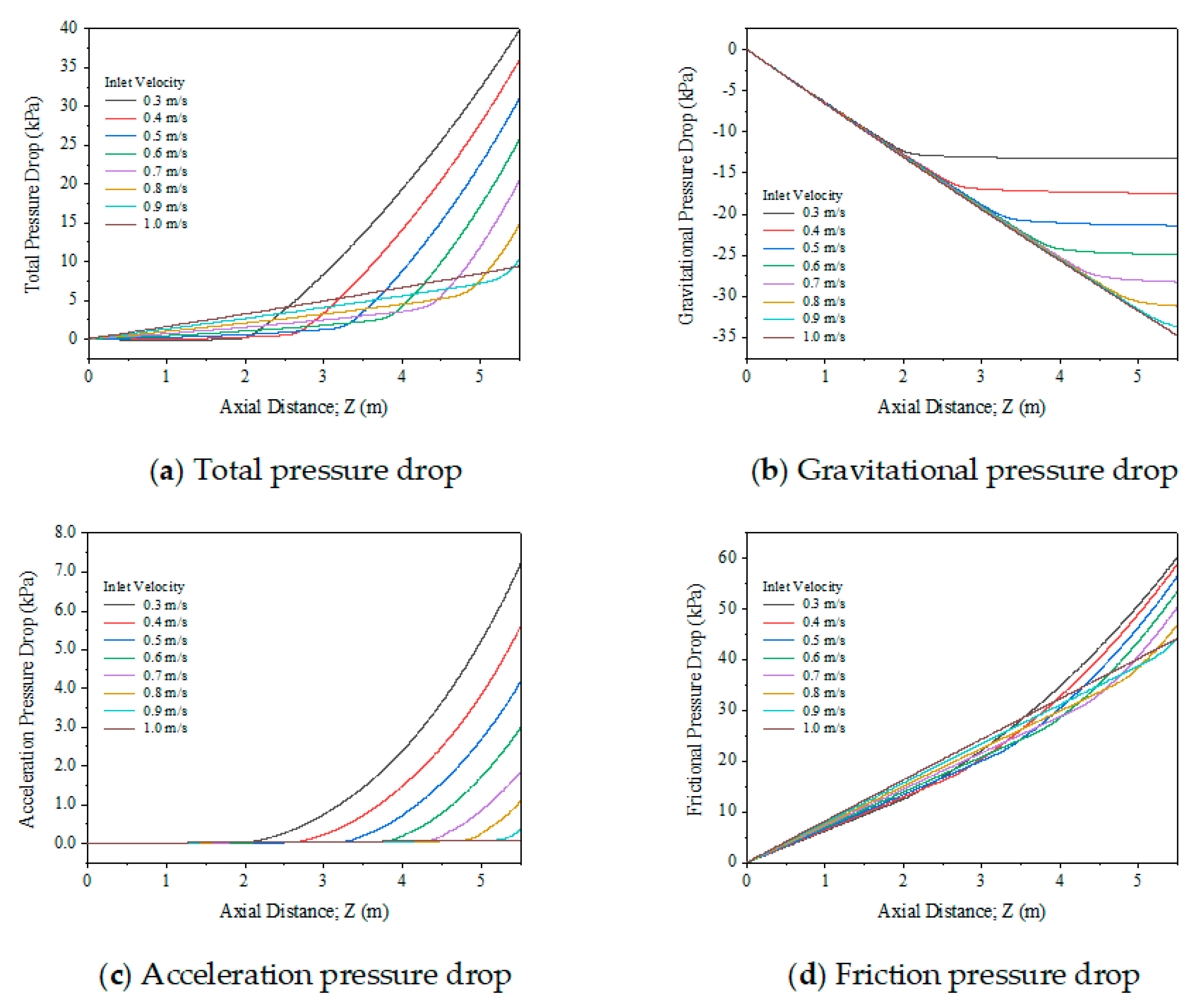

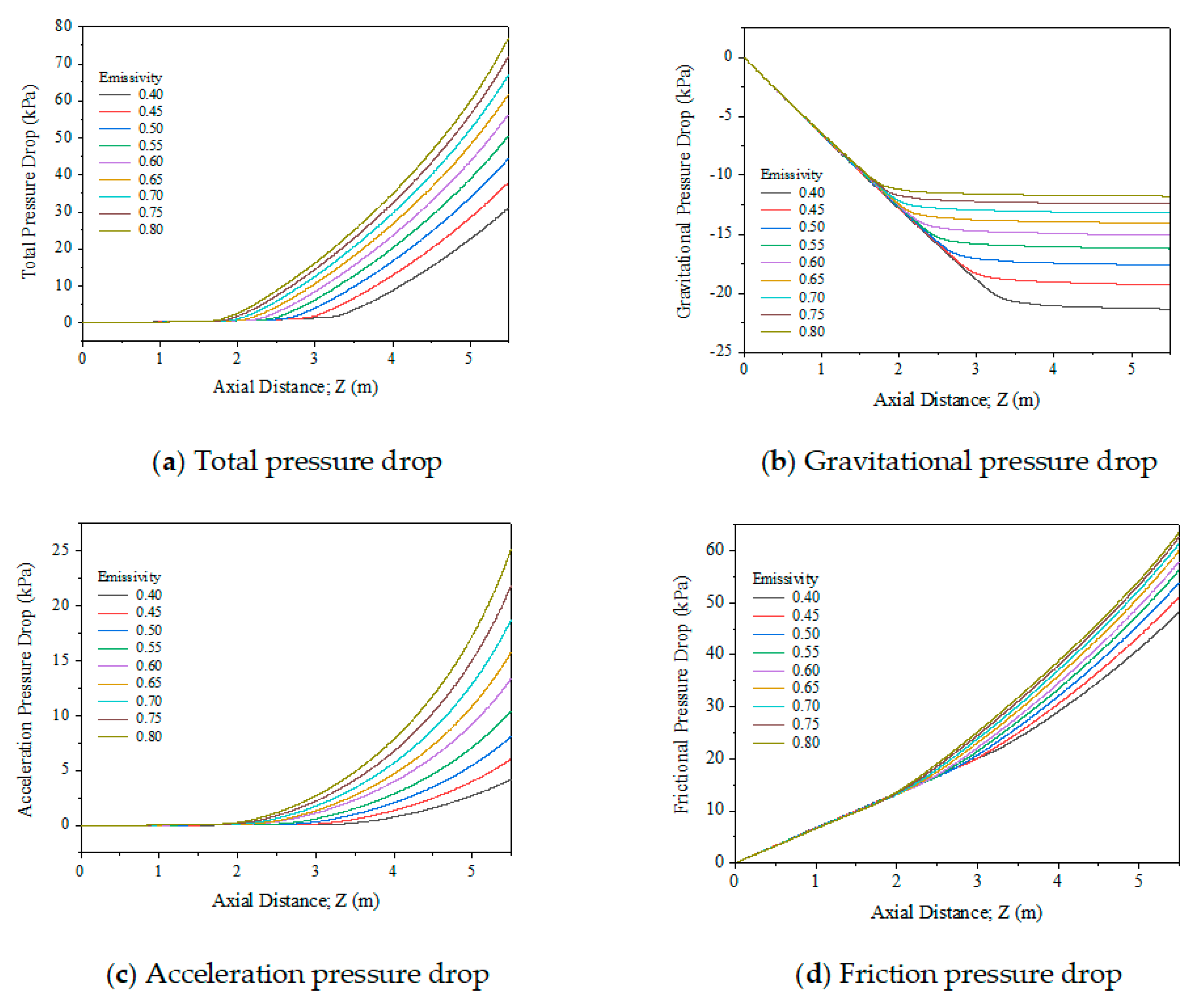

3.7. Pressure Drop

4. Conclusions

- (1)

- As the inlet velocity decreases or the wall emissivity increases, the ONB location approaches the inlet and the void fraction near the outlet increases. The path through which the single-liquid-phase flow converts into the DFFB with a void fraction higher than 0.9 is shorter. Moreover, the increase rate of void fraction gradually decreases along the axial direction after the void fraction reaches 0.9.

- (2)

- The maximum wall temperature corresponding to the CHF point decreases slightly with the increase in inlet velocity but increases significantly with the increase in wall emissivity.

- (3)

- The variations in flow rate barely influence the value of thermodynamic equilibrium quality at the location of the DNB and the CHF. However, increasing the wall emissivity results in a smaller thermodynamic equilibrium quality at the DNB point and the CHF point.

- (4)

- The heat transfer coefficient is greatly affected by the flow rate in the negative thermodynamic equilibrium quality region; the heat transfer coefficient increases as the flow rate increases at the same equilibrium quality condition. In the positive equilibrium quality region, the heat transfer coefficient varies more uniformly with the equilibrium quality at different flow rates. Under the same equilibrium quality condition, the heat transfer coefficient decreases in the negative equilibrium quality region and increases in the post-CHF region with the wall emissivity increasing.

- (5)

- As the flow rate decreases or wall emissivity increases, the average temperature and the average velocity of each phase at the outlet increases.

- (6)

- The non-equilibrium effect is evident in the subcooled boiling region and the post-CHF region. The non-equilibrium effect in the subcooled boiling region contributes to the subcooled liquid phase. Additionally, in the post-CHF region, the non-equilibrium effect is caused by the superheated vapor phase and the superheated liquid phase. The flow rate increasing and wall emissivity reducing both lead to a more significant non-equilibrium effect at the outlet.

- (7)

- Since the frictional pressure drop is offset by the gravitational pressure drop in the regions before the DNB to some extent, the total pressure drop varies moderately along the axial direction. However, as the gravitational pressure drop falls off gradually in the post-CHF region, and the total pressure drop varies more obviously. Higher wall emissivity results in a larger total pressure drop of the entire pipe. However, for different flow rate conditions, the total pressure drop of the entire pipe is affected by both the flow rate and the length of the boiling region.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| A | Area, (m2) |

| CpL | Specific heat of liquid phase, (J/kg K) |

| DW | Departure diameter of bubbles, (m) |

| f | Bubble departure frequency |

| F | Force, (N) |

| FD,i | Drag force, (N) |

| FL,i | Lift force, (N) |

| FW,i | Wall lubrication force, (N) |

| FTD,i | Turbulent dispersion force, (N) |

| FVM,i | Virtual mass force, (N) |

| G | Mass flux, (kg/m2 s) |

| Unit tensor | |

| Jasub | Subcooled Jacob number |

| kl | Thermal conductivity of the liquid phase, (W/m k) |

| K | Empirical constant |

| Mass transfer coefficient from the i to j phase | |

| p | Static pressure, (Pa) |

| ptot | Total pressure drop, (Pa) |

| q | Heat flux |

| qw | Wall heat flux, (W/m2) |

| qC | Convective heat flux, (W/m2) |

| qE | Evaporative heat flux, (W/m2) |

| qra | Radiant heat transfer, (W/m2) |

| SM | Mass source term, (K) |

| SE | Energy source term, (K) |

| TO | Temperature of the outer pipe wall, (K) |

| TI | Temperature of the inner pipe wall, (K) |

| Tair | Air temperature, (K) |

| TW | Wall temperature, (K) |

| TL | Liquid temperature, (K) |

| Tsat | Saturation temperature, (K) |

| v | Velocity, (m/s) |

| Greek | |

| εO | Emissivity of the outer pipe wall |

| εI | Emissivity of the inner pipe wall |

| σ | Stefan-Boltzmann constant |

| α | Volume fraction |

| ρ | density |

| Subscripts | |

| O | Outer pipe |

| I | Inner pipe |

| b | Bubbles |

| W | Wall |

| V | Vapor |

| L | Liquid |

| C | Convective heat flux |

| E | Evaporative heat flux |

| M | Mass |

| sat | Saturation |

| i | Phase i |

| j | Phase j |

| Abbreviations | |

| TSL | Top Submerged Lance |

| CHF | Critical Heat Flux |

| DFFB | Dispersed Flow Film Boiling |

| RPI | Rensselaer Polytechnic Institute |

| DNB | Departure from Nucleate Boiling |

| IAFB | Inverted Annular Film Boiling |

| ISFB | Inverted Slug Film Boiling |

References

- Schlesinger, M.E.; King, M.J.; Davenport, W.G. Extractive Metallurgy of Copper; Elsevier: Amsterdam, The Netherlands, 2011. [Google Scholar]

- Deng, W.; Zhang, X.; Wang, H.; Feng, L.; Zhang, H.; Zhang, G. Dispersion characteristics of biodiesel spray droplets in top-blown injection smelting process. Chem. Eng. Process. Process Intensif. 2018, 126, 168–177. [Google Scholar] [CrossRef]

- Alvear, R.G.; Hunt, P.S.; Zhang, B. Copper ISASMELT—Dealing with Impurities. In Advanced Processing of the Metals and Materials, Sohn International Symposium, San Diego, CA, USA, 27–31 August 2006; Kongoli, F., Reddy, R.G., Eds.; Wiley: Hoboken, NJ, USA, 2006; pp. 673–685. [Google Scholar]

- Krepper, E.; Končar, B.; Egorov, Y. CFD modelling of subcooled boiling—Concept, validation and application to fuel assembly design. Nucl. Eng. Des. 2007, 237, 716–731. [Google Scholar] [CrossRef]

- Vadlamudi, S.R.G.; Nayak, A.K. CFD simulation of Departure from Nucleate Boiling in vertical tubes under high pressure and high flow conditions. Nucl. Eng. Des. 2019, 352, 110150. [Google Scholar] [CrossRef]

- Wojtan, L.; Ursenbacher, T.; Thome, R.J. Investigation of flow boiling in horizontal tubes: Part II—Development of a new heat transfer model for stratified-wavy, dryout and mist flow regimes. Int. J. Heat Mass Transf. 2005, 48, 2970–2985. [Google Scholar] [CrossRef]

- Arcanjo, A.A.; Tibiriçá, C.B.; Ribatski, G. Evaluation of flow patterns and elongated bubble characteristics during the flow boiling of halocarbon refrigerants in a micro-scale channel. Exp. Therm. Fluid Sci. 2010, 34, 766–775. [Google Scholar] [CrossRef]

- Hu, G.; Ma, Y.; Liu, Q. Evaluation on Coupling of Wall Boiling and Population Balance Models for Vertical Gas-Liquid Subcooled Boiling Flow of First Loop of Nuclear Power Plant. Energies 2021, 14, 7357. [Google Scholar] [CrossRef]

- Saisorn, S.; Wongpromma, P.; Wongwises, S. The difference in flow pattern, heat transfer and pressure drop char-acteristics of mini-channel flow boiling in horizontal and vertical orientations. Int. J. Multiph. Flow 2018, 101, 97–112. [Google Scholar] [CrossRef]

- Bediako, E.G.; Dančová, P.; Vít, T. Experimental study of horizontal flow boiling heat transfer coefficient and pressure drop of R134afrom subcooled liquid region to superheated vapor region. Energies 2022, 15, 681. [Google Scholar] [CrossRef]

- Wang, J.; Zhu, S.; Xie, J. Investigation of R290 Flow Boiling Heat Transfer and Exergy Loss in a Double-Concentric Pipe Based on CFD. Energies 2021, 14, 7121. [Google Scholar] [CrossRef]

- El Nakla, M.; Groeneveld, D.; Cheng, S. Experimental study of inverted annular film boiling in a vertical tube cooled by R-134a. Int. J. Multiph. Flow 2011, 37, 67–75. [Google Scholar] [CrossRef]

- Shah, M.M. A General Predictive Technique for Heat Transfer during Saturated Film Boiling in Tubes. Heat Transf. Eng. 1980, 2, 51–62. [Google Scholar] [CrossRef]

- Shah, M.M.; Siddiqui, M.A. A general correlation for heat transfer during dispersed-flow film boiling in tubes. Heat Transf. Eng. 2000, 21, 18–32. [Google Scholar]

- Shah, M.M. Comprehensive correlation for dispersed flow film boiling heat transfer in mini/macro tubes. Int. J. Refrig. 2017, 78, 32–46. [Google Scholar] [CrossRef]

- Liu, Q.; Sun, X. Wall heat transfer in the inverted annular film boiling regime. Nucl. Eng. Des. 2020, 363, 110660. [Google Scholar] [CrossRef]

- Hammouda, N.; Groeneveld, D.; Cheng, S. An experimental study of subcooled film boiling of refrigerants in vertical up-flow. Int. J. Heat Mass Transf. 1996, 39, 3799–3812. [Google Scholar] [CrossRef]

- Hammouda, N.; Groeneveld, D.; Cheng, S. Two-fluid modelling of inverted annular film boiling. Int. J. Heat Mass Transf. 1997, 40, 2655–2670. [Google Scholar] [CrossRef]

- Mohanta, L.; Riley, M.P.; Cheung, F.B.; Bajorek, S.M.; Kelly, J.M.; Tien, K.; Hoxie, C.L. Experimental Investigation of Inverted Annular Film Boiling in a Rod Bundle during Reflood Transient. Nucl. Technol. 2015, 190, 301–312. [Google Scholar] [CrossRef]

- Mohanta, L.; Sohag, F.A.; Cheung, F.-B.; Bajorek, S.M.; Kelly, J.M.; Tien, K.; Hoxie, C.L. Heat transfer correlation for film boiling in vertical upward flow. Int. J. Heat Mass Transf. 2017, 107, 112–122. [Google Scholar] [CrossRef]

- Xu, Y.; Fang, X. A new correlation of two-phase frictional pressure drop for evaporating flow in pipes. Int. J. Refrig. 2012, 35, 2039–2050. [Google Scholar] [CrossRef]

- Müller-Steinhagen, H.; Heck, K. A simple friction pressure drop correlation for two-phase flow in pipes. Chem. Eng. Process. Process Intensif. 1986, 20, 297–308. [Google Scholar] [CrossRef]

- Xu, Y.; Fang, X.; Li, D.; Li, G.; Yuan, Y.; Xu, A. An experimental study of flow boiling frictional pressure drop of R134a and evaluation of existing correlations. Int. J. Heat Mass Transf. 2016, 98, 150–163. [Google Scholar] [CrossRef]

- Muszynski, T.; Andrzejczyk, R.; Dorao, C.A. Detailed experimental investigations on frictional pressure drop of R134a during flow boiling in 5 mm diameter channel: The influence of acceleration pressure drop component. Int. J. Refrig. 2017, 82, 163–173. [Google Scholar] [CrossRef]

- Zivi, S.M. Estimation of steady-state steam void-fraction by means of the principle of minimum entropy production. J. Heat Transder 1964, 86, 247–251. [Google Scholar] [CrossRef]

- Vadlamudi, S.R.G.; Nayak, A.K. Review of literature on departure from nucleate boiling in subcooled flow boiling. Multiph. Sci. Technol. 2018, 30, 247–266. [Google Scholar] [CrossRef]

- Murallidharan, J.S.; Prasad BV SS, S.; Patnaik BS, V.; Hewitt, G.F.; Badalassi, V. CFD investigation and as-sessment of wall heat flux partitioning model for the prediction of high pressure subcooled flow boiling. Int. J. Heat Mass Transf. 2016, 103, 211–230. [Google Scholar] [CrossRef]

- Colombo, M.; Fairweather, M. Accuracy of Eulerian–Eulerian, two-fluid CFD boiling models of subcooled boiling flows. Int. J. Heat Mass Transf. 2016, 103, 28–44. [Google Scholar] [CrossRef]

- Kurul, N. On the modeling of multidimensional effects in boiling channels. In Proceedings of the ANS. Proc. National Heat Transfer Conference, Minneapolis, MN, USA, 28–31 July 1991. [Google Scholar]

- Tu, J.; Yeoh, G. On numerical modelling of low-pressure subcooled boiling flows. Int. J. Heat Mass Transf. 2002, 45, 1197–1209. [Google Scholar] [CrossRef]

- Zhang, R.; Cong, T.; Tian, W.; Qiu, S.; Su, G. Effects of turbulence models on forced convection subcooled boiling in vertical pipe. Ann. Nucl. Energy 2015, 80, 293–302. [Google Scholar] [CrossRef]

- Talebi, S.; Abbasi, F.; Davilu, H. A 2D numerical simulation of sub-cooled flow boiling at low-pressure and low-flow rates. Nucl. Eng. Des. 2009, 239, 140–146. [Google Scholar] [CrossRef]

- Tao, H.-Z.; Xie, C.-Y.; Wang, M.-M. Numerical simulation study on the flow and heat transfer characteristics of sub-cooled boiling in vertical round and flattened tubes. Ann. Nucl. Energy 2019, 140, 107144. [Google Scholar] [CrossRef]

- Gu, J.; Wang, Q.; Wu, Y.; Lyu, J.; Li, S.; Yao, W. Modeling of subcooled boiling by extending the RPI wall boiling model to ultra-high pressure conditions. Appl. Therm. Eng. 2017, 124, 571–584. [Google Scholar] [CrossRef]

- Pothukuchi, H.; Kelm, S.; Patnaik, B.; Prasad, B.; Allelein, H.-J. CFD modeling of critical heat flux in flow boiling: Validation and assessment of closure models. Appl. Therm. Eng. 2019, 150, 651–665. [Google Scholar] [CrossRef]

- Lavieville, J.; Quemerais, E.; Mimouni, S.; Boucker, M.; Mechitoua, N. NEPTUNE CFD V1. 0 theory manual. Rapport Interne EDF H-I81-2006-04377-EN. Rapport NEPTUNE Nept_2004_L 2006, 1, 3. [Google Scholar]

- Zhang, R.; Cong, T.; Tian, W.; Qiu, S.; Su, G. Prediction of CHF in vertical heated tubes based on CFD methodology. Prog. Nucl. Energy 2015, 78, 196–200. [Google Scholar] [CrossRef]

- Celata, G.; Cumo, M.; Mariani, A. Burnout in highly subcooled water flow boiling in small diameter tubes. Int. J. Heat Mass Transf. 1993, 36, 1269–1285. [Google Scholar] [CrossRef]

- Li, Q.; Avramova, M.; Jiao, Y.; Chen, P.; Yu, J.; Pu, Z.; Chen, J. CFD prediction of critical heat flux in vertical heated tubes with uniform and non-uniform heat flux. Nucl. Eng. Des. 2018, 326, 403–412. [Google Scholar] [CrossRef]

- Maytorena, V.; Hinojosa, J. Three-dimensional numerical study of direct steam generation in vertical tubes receiving concentrated solar radiation. Int. J. Heat Mass Transf. 2019, 137, 413–433. [Google Scholar] [CrossRef]

- Končar, B.; Borut, M. Wall function approach for boiling two-phase flows. Nucl. Eng. Des. 2010, 240, 3910–3918. [Google Scholar] [CrossRef]

- Mali, C.R.; Vinod, V.; Patwardhan, A.W. Comparison of phase interaction models for high pressure subcooled boiling flow in long vertical tubes. Nucl. Eng. Des. 2017, 324, 337–359. [Google Scholar] [CrossRef]

- Chen, J.; Zeng, R.; Zhang, X.; Qiu, L.; Xie, J. Numerical modeling of flow film boiling in cryogenic chilldown process using the AIAD framework. Int. J. Heat Mass Transf. 2018, 124, 269–278. [Google Scholar] [CrossRef]

- Lillo, G.; Mastrullo, R.; Mauro, A.; Viscito, L. Flow boiling heat transfer, dry-out vapor quality and pressure drop of propane (R290): Experiments and assessment of predictive methods. Int. J. Heat Mass Transf. 2018, 126, 1236–1252. [Google Scholar] [CrossRef]

- Daubert, T.E.; Danner, R.P. API Technical Data Book Petroleum Refining: American Petroleum Institute; API: Washington, DC, USA, 1997. [Google Scholar]

- Beaton, C.F.; Hewitt, G.F. (Eds.) Physical Property Data for the Design Engineer; Hemisphere: New York, NY, USA, 1989; p. 394. [Google Scholar]

- Zhao, H.; Lu, T.; Yin, P.; Mu, L.; Liu, F. An Experimental and Simulated Study on Gas-Liquid Flow and Mixing Behavior in an ISASMELT Furnace. Metals 2019, 9, 565. [Google Scholar] [CrossRef] [Green Version]

- Xu, Y.; Fang, X. Correlations of void fraction for two-phase refrigerant flow in pipes. Appl. Therm. Eng. 2014, 64, 242–251. [Google Scholar] [CrossRef]

- He, H.; Pan, L.-M.; Wei, L.; Zhang, M.-H.; Zhang, D.-F. On the importance of non-equilibrium effect in microchannel two-phase boiling flow. Int. J. Heat Mass Transf. 2019, 149, 119185. [Google Scholar] [CrossRef]

- Kuang, Y.; Wang, W.; Miao, J.; Zhang, H. Non-linear analysis of nitrogen pressure drop instability in mi-cro/mini-channels. Int. J. Heat Mass Transf. 2020, 147, 118953. [Google Scholar] [CrossRef]

- Huang, H.; Thome, J.R. An experimental study on flow boiling pressure drop in multi-microchannel evaporators with different refrigerants. Exp. Therm. Fluid Sci. 2017, 80, 391–407. [Google Scholar] [CrossRef]

- Chen, J.C. Correlation for Boiling Heat Transfer to Saturated Fluids in Convective Flow. Ind. Eng. Chem. Process Des. Dev. 1966, 5, 322–329. [Google Scholar] [CrossRef] [Green Version]

- Wang, Y.-J.; Pan, C. A one-dimensional semi-empirical model considering transition boiling effect for dispersed flow film boiling. Nucl. Eng. Des. 2017, 316, 99–111. [Google Scholar] [CrossRef]

| Name | Unit | Value |

|---|---|---|

| Furnace Height | m | 7.173 |

| Furnace Diameter | m | 3.84 |

| Lance Diameter | m | 0.303–0.4 |

| Molten Bath Level | m | 1.85–2 |

| Lance Submergence Depth | m | 0.3 |

| Series 1 | Series 2 | |

|---|---|---|

| Inlet Velocity (m·s−1) | 0.3, 0.4, 0.5, 0.6, 0.7, 0.8, 0.9, 1.0 | 0.5 |

| Inlet Temperature (K) | 293.15 | 293.15 |

| Inner Pipe Wall Emissivity | 0.40 | 0.40, 0.45, 0.50, 0.55, 0.60, 0.65, 0.70, 0.75, 0.80 |

| Outer Pipe Temperature (K) | 1400 | 1400 |

| Oxygen-enriched Air Temperature (K) | 293.15 | 293.15 |

| External Heat Transfer Coefficient (W·m−2·K−1) | 50 | 50 |

| Operating Pressure (atm) | 1 | 1 |

| Model Category | Model Selection |

|---|---|

| Turbulence Model | Standard k-ε Model |

| Wall Function: Non-equilibrium Wall Function | |

| Turbulence Multiphase Model: Per Phase | |

| Interphase Force Model | Drag Force Model: Universal Drag Model |

| Lift Force Model: Moraga Model | |

| Wall Lubrication Force: No Wall Lubricating Force | |

| Turbulence Dispersion Force: Lopez de Bertodano Model | |

| Turbulence Interaction Force: Troshko-Hassan Model | |

| Interfacial Heat Transfer Model | Hughmark Model |

| Interfacial Area Concentration Model | Symmetric IAC Model |

| Correlation of Bubble Diameter | Unal Correlation |

| Series 1 | Series 2 | |

|---|---|---|

| Inlet Velocity (m s−1) | 0.2, 0.3, 0.4, 0.5, 0.6 | 0.6 |

| Inlet Subcooling (K) | 0.5 | 0.5 |

| Wall Heat Flux (kW m−2) | 10 | 12, 14, 16, 18, 20, 22, 24, 26 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lin, J.; Zhang, X.; Huang, X.; Chen, L. Numerical Simulation Study on the Flow and Heat Transfer Characteristics of Subcooled N-Heptane Flow Boiling in a Vertical Pipe under External Radiation. Energies 2022, 15, 3777. https://doi.org/10.3390/en15103777

Lin J, Zhang X, Huang X, Chen L. Numerical Simulation Study on the Flow and Heat Transfer Characteristics of Subcooled N-Heptane Flow Boiling in a Vertical Pipe under External Radiation. Energies. 2022; 15(10):3777. https://doi.org/10.3390/en15103777

Chicago/Turabian StyleLin, Jinhu, Xiaohui Zhang, Xiaoyan Huang, and Luyang Chen. 2022. "Numerical Simulation Study on the Flow and Heat Transfer Characteristics of Subcooled N-Heptane Flow Boiling in a Vertical Pipe under External Radiation" Energies 15, no. 10: 3777. https://doi.org/10.3390/en15103777

APA StyleLin, J., Zhang, X., Huang, X., & Chen, L. (2022). Numerical Simulation Study on the Flow and Heat Transfer Characteristics of Subcooled N-Heptane Flow Boiling in a Vertical Pipe under External Radiation. Energies, 15(10), 3777. https://doi.org/10.3390/en15103777