Numerical Simulation of Fluid Flow in Carbonate Rocks Based on Digital Rock Technology

Abstract

:1. Introduction

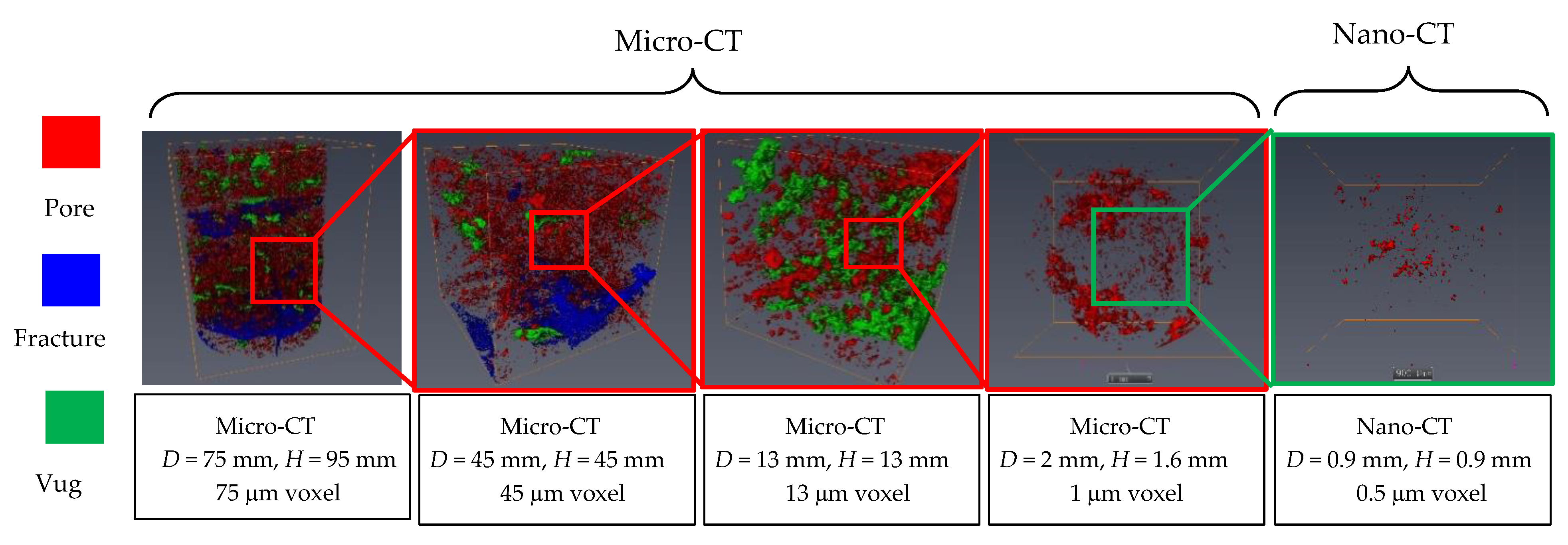

2. Multiscale Pore–Vug–Fracture Characterization of Carbonate Rocks

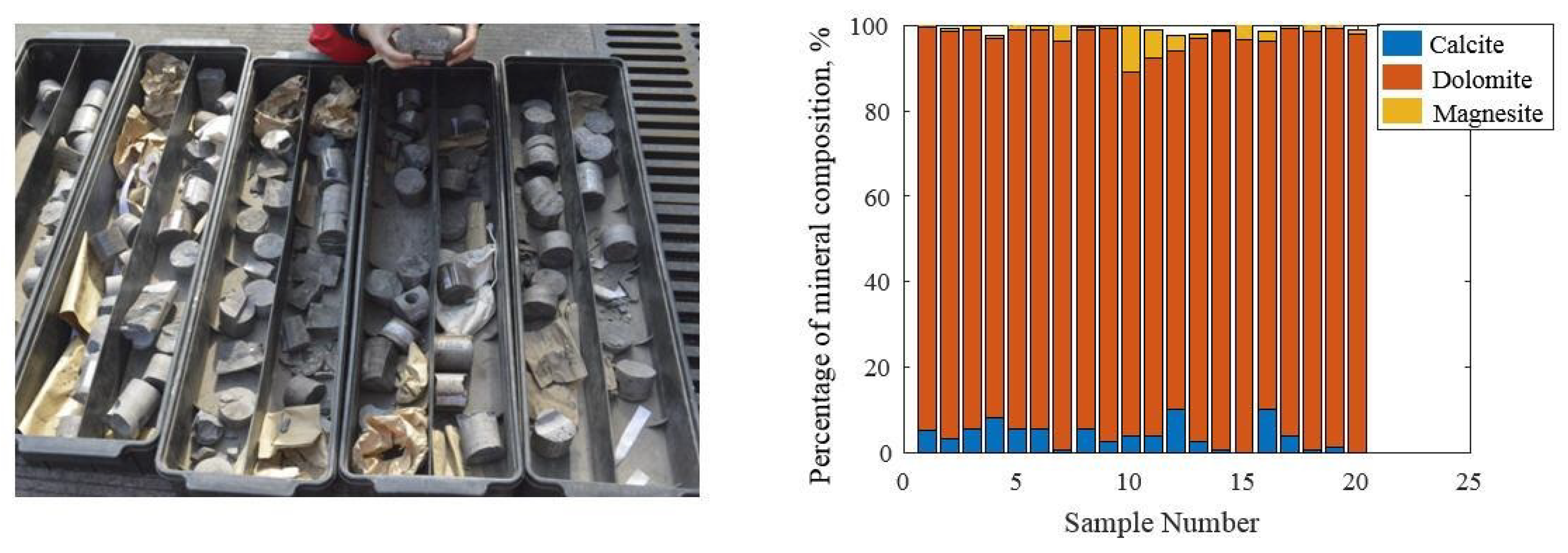

2.1. Reservoir Characteristics in the Study Area

2.2. Test Methods and Samples

2.3. Principle of the Pore, Vug, and Fracture Classification

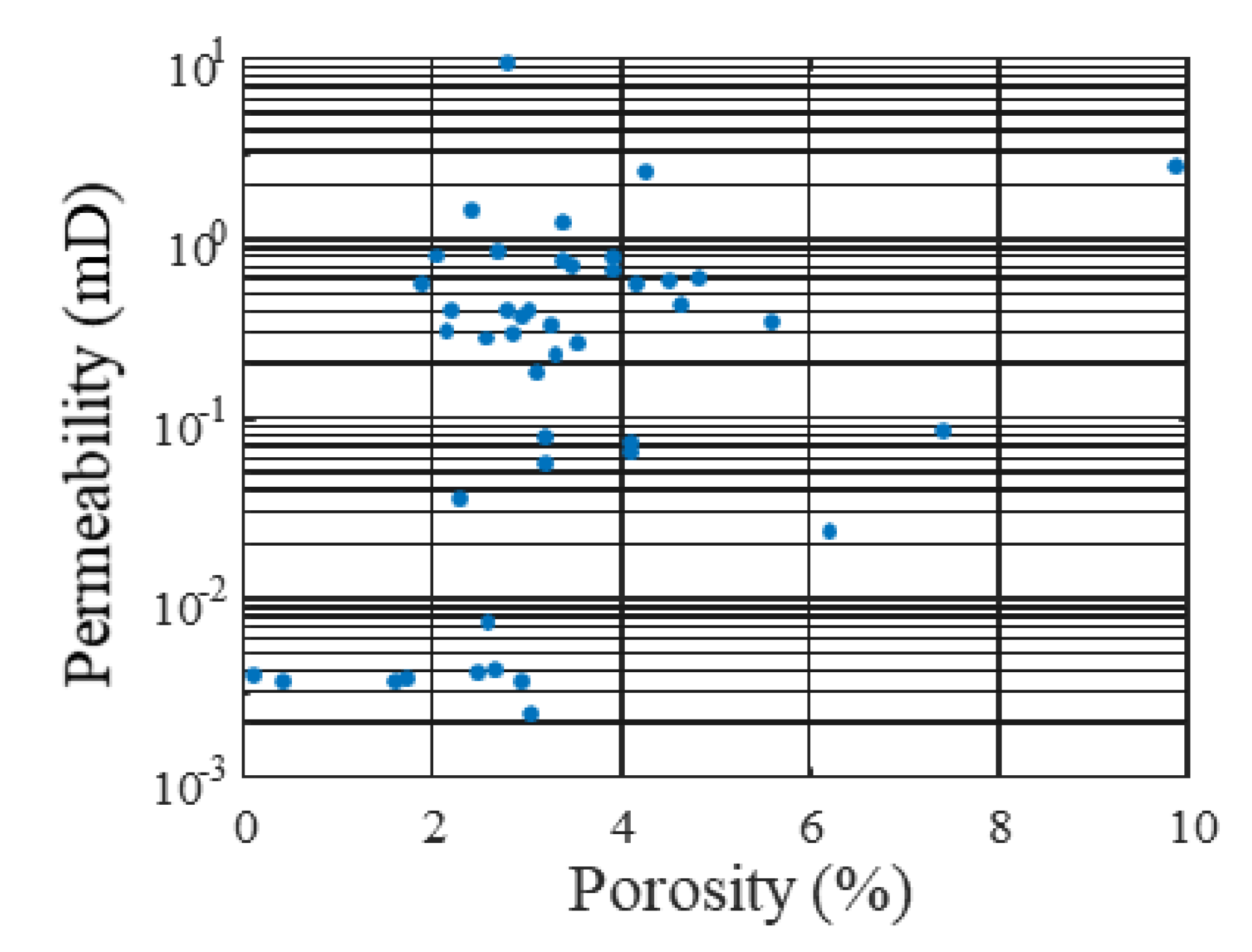

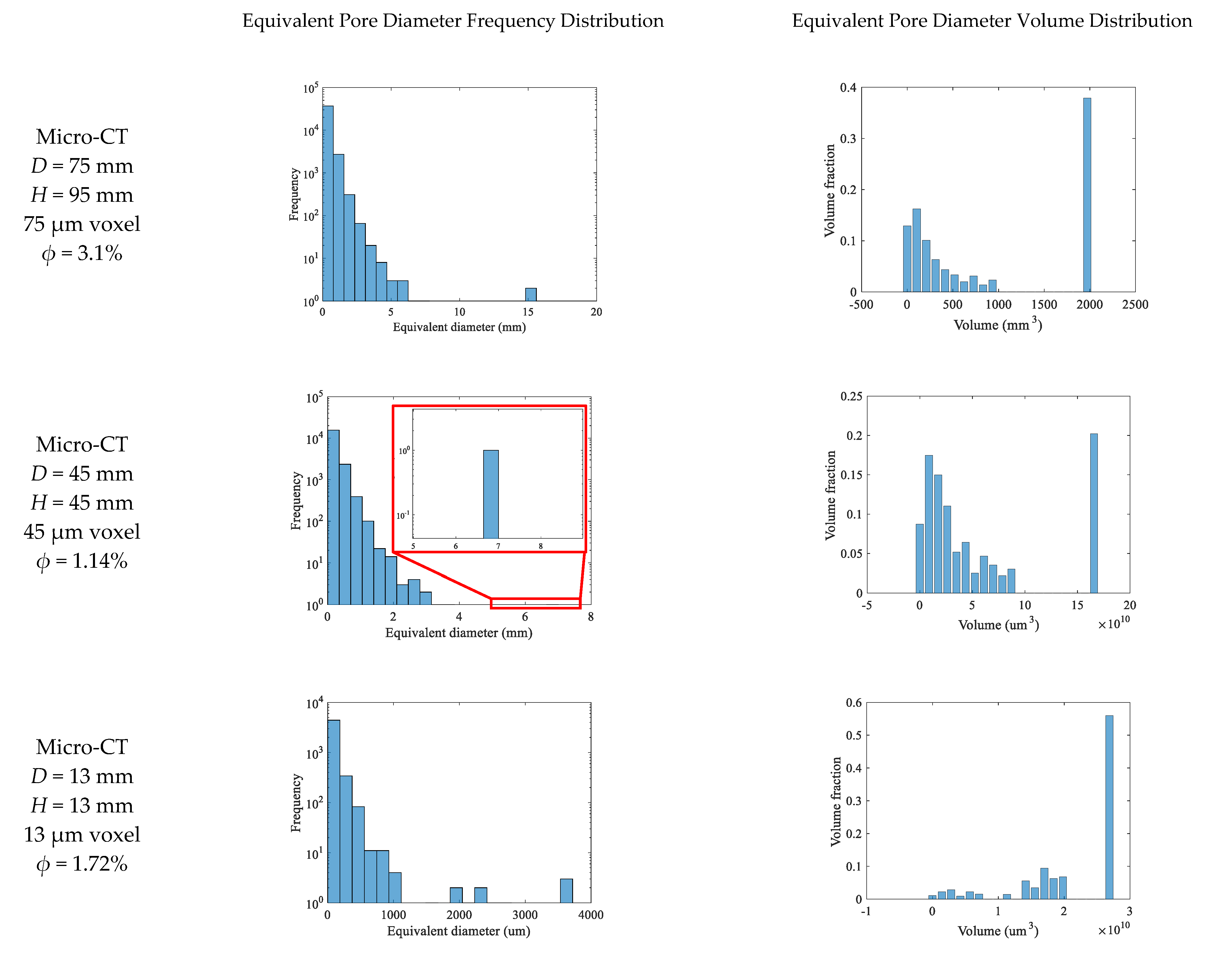

2.4. Quantitative Evaluation of Multiscale Pore–Vug–Fracture Structures Based on CT Data

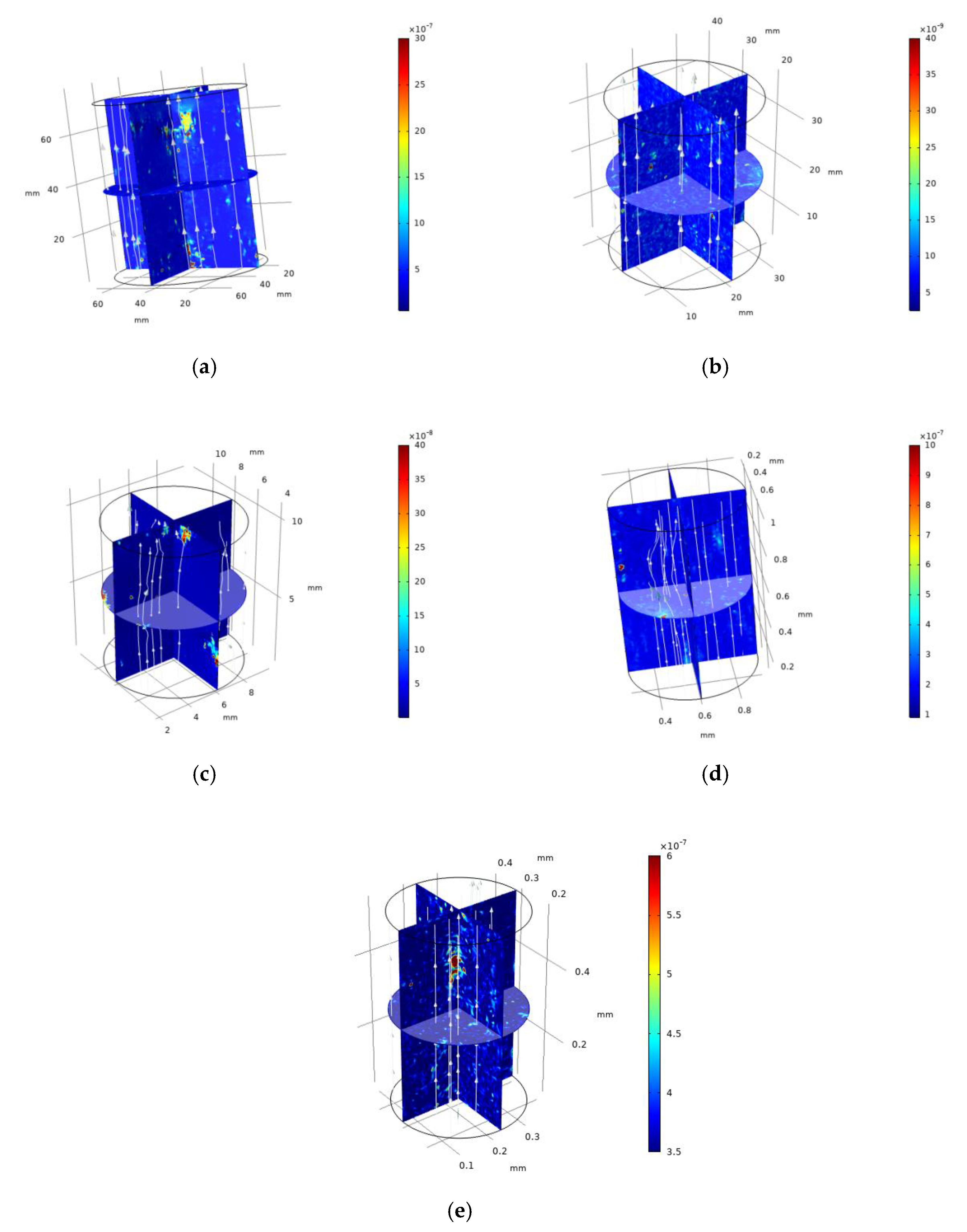

3. Simulation of Single-Phase Flow in Strongly Heterogeneous Carbonate Rocks

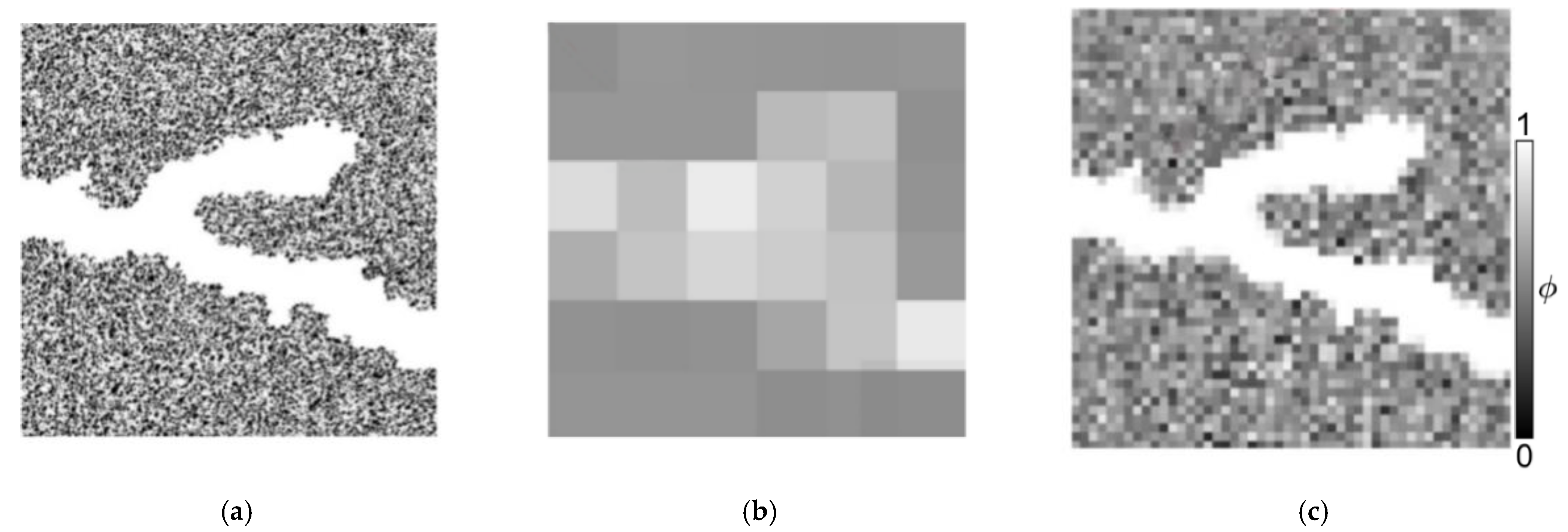

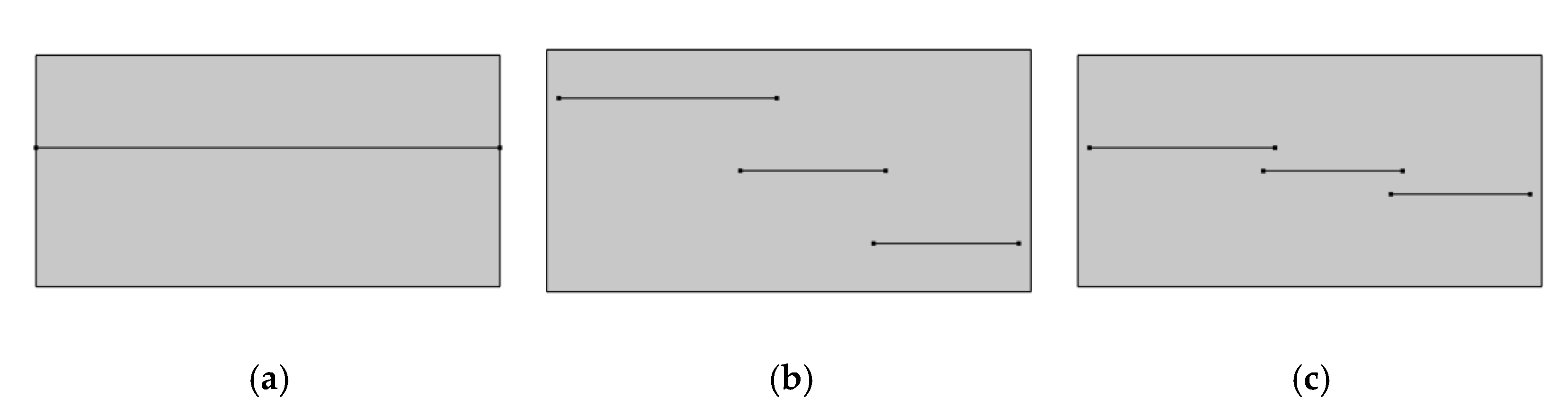

3.1. Characterization of Rock Nonuniformity Based on Digital Image Processing

3.2. Numerical Simulation Results

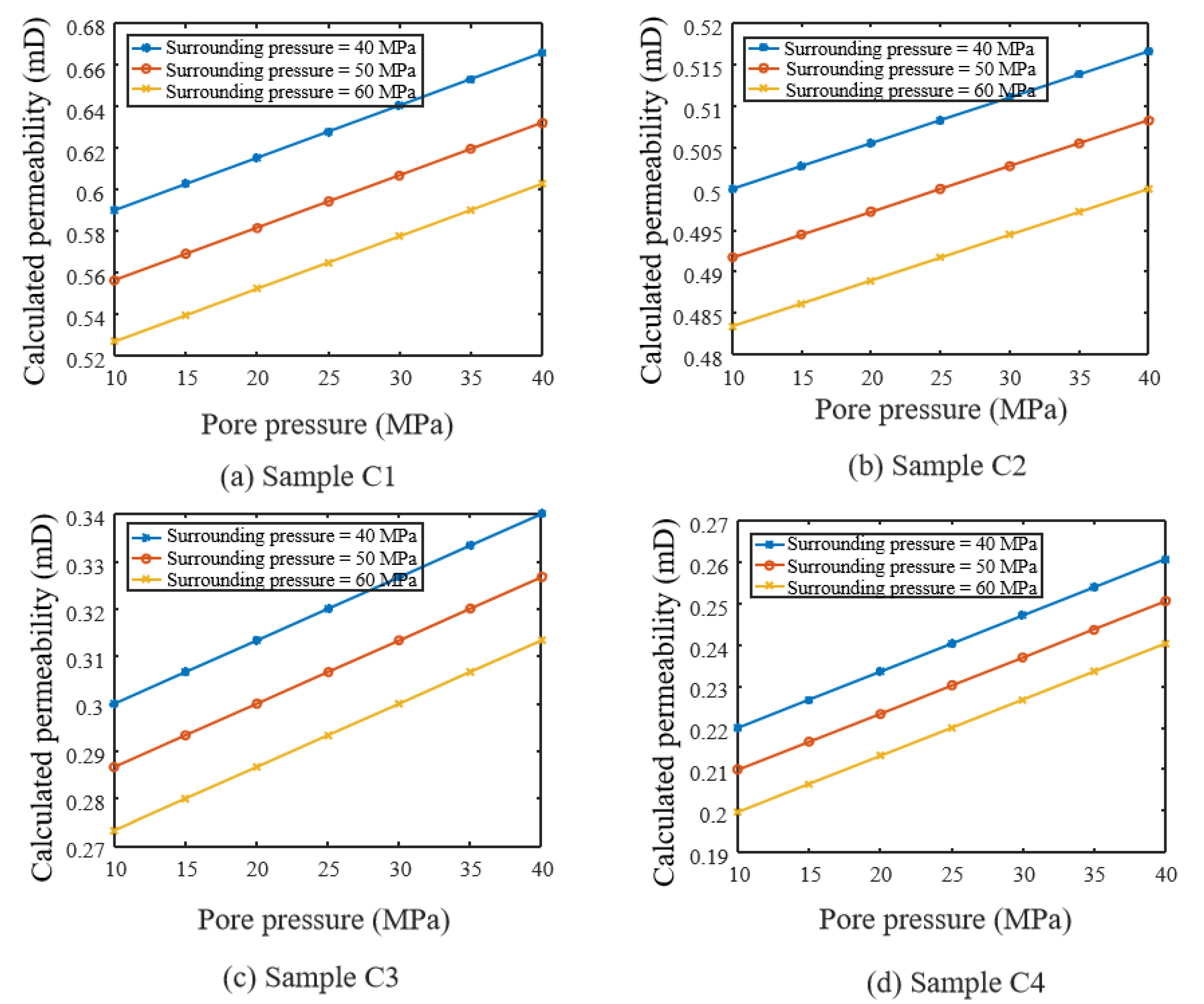

4. Simulation of Gas–Water Two-Phase Seepage in Heterogeneous Carbonate Rocks

4.1. Simulation of Gas–Water Two-Phase Seepage

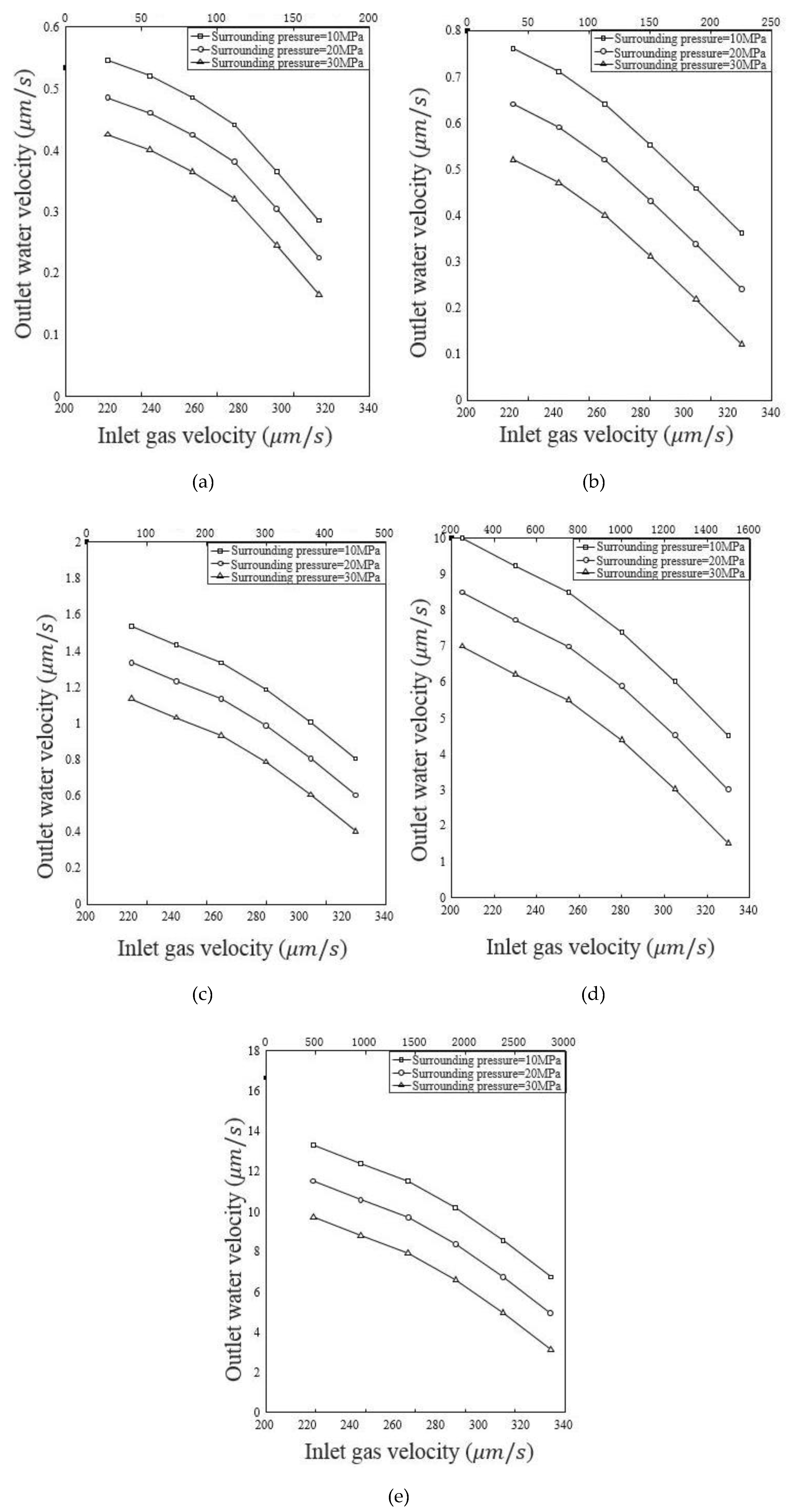

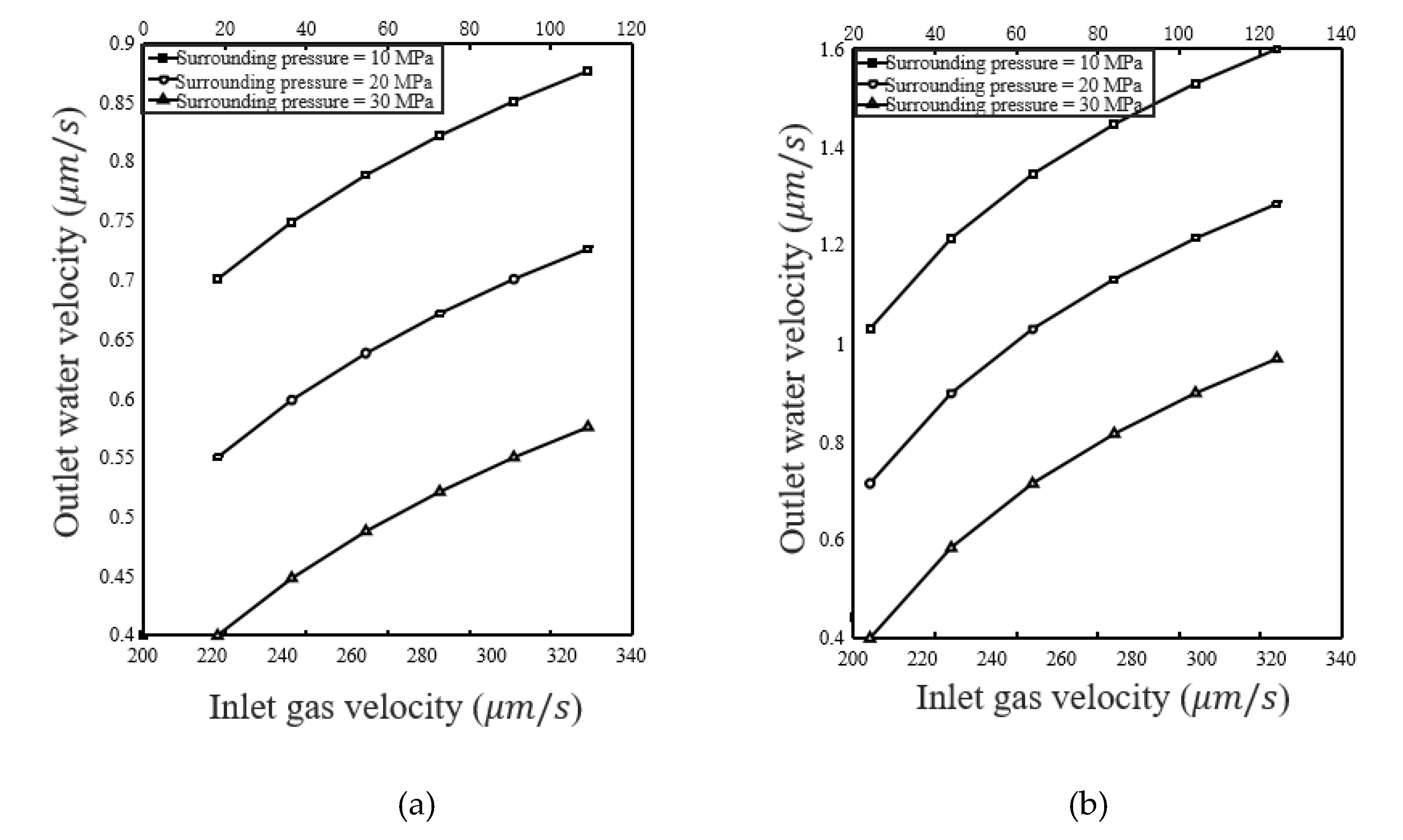

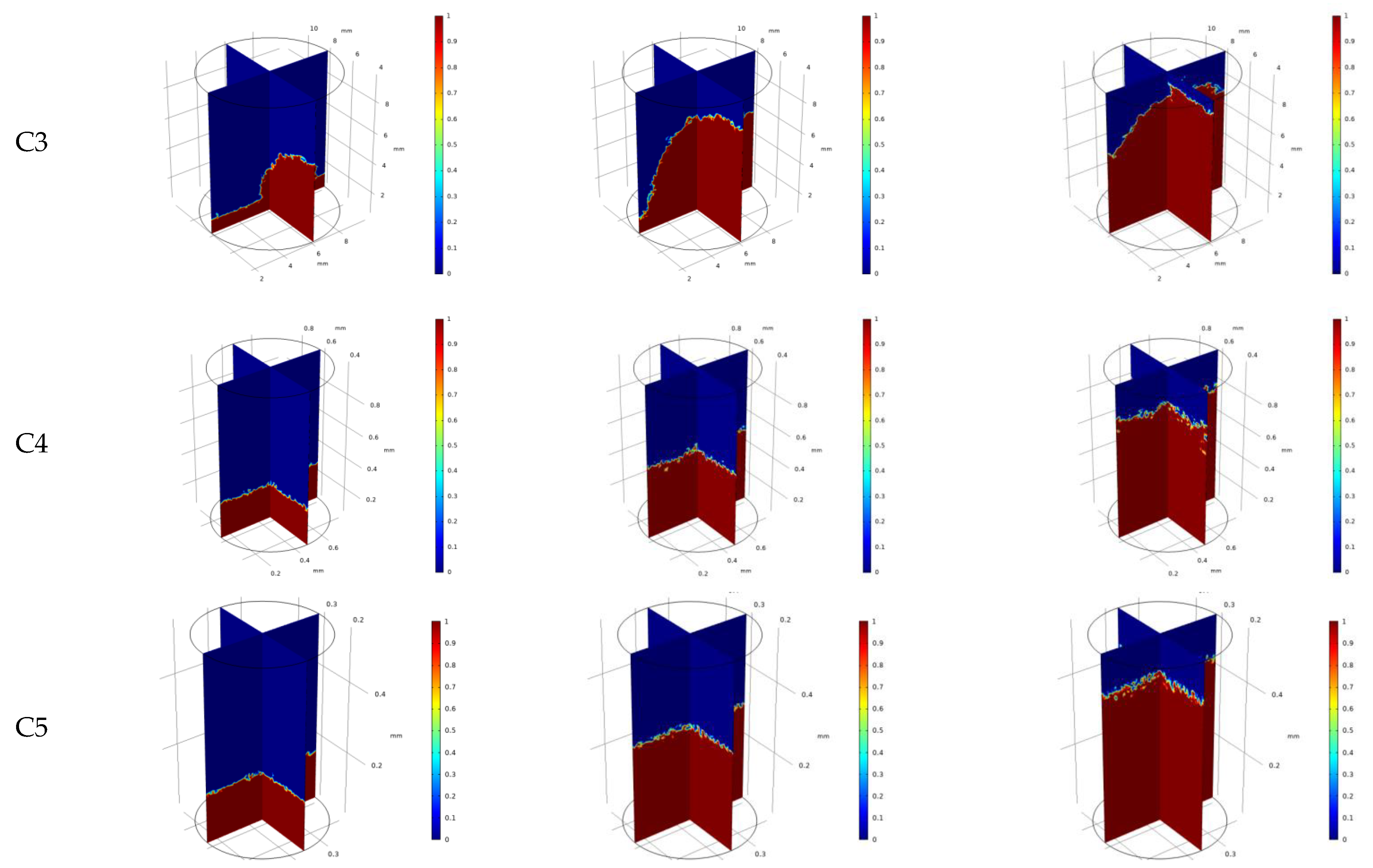

4.2. Simulation Results

5. Conclusions

- (1)

- The carbonate rocks are highly heterogeneous and have developed pores, vugs, and fractures, resulting in no significant correlation between permeability and porosity. The maximum equivalent diameter of pores has an approximate positive correlation with porosity. Multiscale CT scans show that the pore network of the cores is not connected even when the resolution reaches 0.5 μm, which indicates that the carbonate matrix is particularly dense. However, even poorly connected fractures can increase permeability. Fracture aggregation can increase efficient permeability by reducing flow distance through the less permeable matrix.

- (2)

- The simulation of single-phase flow in strongly heterogeneous multiple media is carried out based on the digital image model. Results show that the pore–vug–fracture structure causes local preferential and disturbed flow in the core, which significantly affects the fluid flow path and pressure distribution in the core. The overall permeability of the specimen is a comprehensive representation of the permeability of many microelements in the specimen, and the core permeability calculation results are in good agreement with the experimental results. In the pressure interval of this paper, the permeability increases with the increase of pore pressure and decreases with the increase of surrounding pressure.

- (3)

- The simulation of gas-water two-phase flow in strongly heterogeneous multiple media is carried out based on the digital image model. The variation law of the two-phase outlet flow velocity with the inlet gas pressure and the motion law of the two-phase interface of carbonate rock samples are obtained. Under certain surrounding pressure, the outlet gas velocity is larger than the outlet water velocity. With the increase of the inlet gas pressure, the pore space occupied by the gas phase in the rock becomes larger and larger. With the increase of the surrounding pressure, the velocities of both outlet gas and water decrease. As the sample size decreases, both outlet gas and water velocities increase. The injected gas can flow faster toward the outlet due to the influence of the pores, vugs, and fractures, causing a nonlinearity in the velocity of the displacement front.

Author Contributions

Funding

Conflicts of Interest

Appendix A

Appendix A.1. Mathematical Model of Flow–Solid Coupling in Pore–Vug–Fracture Structure

Appendix A.2. Gas–Water Two-Phase Fluid-Solid Coupling Mathematical Model

Appendix A.2.1. Force Balance Equation

Appendix A.2.2. Gas–Water Two-Phase Flow Equation

References

- Pal, S.; Mushtaq, M.; Banat, F.; Al Sumaiti, A.M. Review of surfactant-assisted chemical enhanced oil recovery for carbonate reservoirs: Challenges and future perspectives. Pet. Sci. 2018, 15, 77–102. [Google Scholar] [CrossRef] [Green Version]

- Xu, X.; Saeedi, A.; Liu, K. An experimental study of combined foam/surfactant polymer (SP) flooding for carbone dioxide-enhanced oil recovery (CO2-EOR). J. Pet. Sci. Eng. 2017, 149, 603–611. [Google Scholar] [CrossRef] [Green Version]

- Li, Y.; Kang, Z.; Xue, Z.; Zheng, S. Theories and practices of carbonate reservoirs development in China. Pet. Explor. Dev. 2018, 45, 669–678. [Google Scholar] [CrossRef]

- Lucia, F.J.; Kerans, C.; Jennings, J.W. Carbonate reservoir characterization. J. Pet. Technol. 2003, 55, 70–72. [Google Scholar] [CrossRef]

- Camacho-Velazquez, R.; Vasquez-Cruz, M.; Castrejon-Aivar, R.; Arana-Ortiz, V. Pressure-transient and decline-curve behavior in naturally fractured vuggy carbonate reservoirs. SPE Reserv. Eval. Eng. 2005, 8, 95–112. [Google Scholar] [CrossRef]

- Guo, J.-C.; Nie, R.-S.; Jia, Y.-L. Dual permeability flow behavior for modeling horizontal well production in fractured-vuggy carbonate reservoirs. J. Hydrol. 2012, 464, 281–293. [Google Scholar] [CrossRef]

- Al-Bazzaz, W.H.; Al-Mehanna, Y. Porosity, permeability, and MHR calculations using SEM and thin-section images for characterizing complex Mauddud-Burgan carbonate reservoir. In Proceedings of the Asia Pacific Oil and Gas Conference and Exhibition, Jacarta, Indonesia, 30 October–1 November 2007. [Google Scholar]

- Zhang, K.; Pang, X.; Zhao, Z.; Shao, X.; Zhang, X.; Li, W.; Wang, K. Pore structure and fractal analysis of Lower Carboniferous carbonate reservoirs in the Marsel area, Chu-Sarysu basin. Mar. Pet. Geol. 2018, 93, 451–467. [Google Scholar] [CrossRef]

- Shi, Z.; Zhou, T.; Wang, H.; Sun, S. Depositional structures and their reservoir characteristics in the Wufeng-Longmaxi Shale in Southern Sichuan Basin, China. Energies 2022, 15, 1618. [Google Scholar] [CrossRef]

- He, J.; Deng, H.; Ma, R.; Wang, R.; Wang, Y.; Li, A. Reservoir characteristics of the Lower Jurassic lacustrine shale in the Eastern Sichuan Basin and its effect on gas properties: An integrated approach. Energies 2020, 13, 4495. [Google Scholar] [CrossRef]

- Ioannidis, M.A.; Chatzis, I. A dual-network model of pore structure for vuggy carbonates. In Proceedings of the SCA2000-09, International Symposium of the Society of Core Analysts, Abu Dhabi, United Arab Emirates, 18–22 October 2000. [Google Scholar]

- Békri, S.; Nardi, C.; Vizika, O. Effect of wettability on the petrophysical parameters of vuggy carbonates: Network modeling investigation. In Proceedings of the International Symposium of the Society of Core Analysts held in Abu Dhabi, United Arab Emirates, 5–9 October 2004. [Google Scholar]

- Xia, C.; Teng, Q.; Qin, L.; Wu, X.; He, X. Crack recognition of 3D rock images. Comput. Eng. Appl. 2018, 54, 186–191. [Google Scholar]

- Yan, Y.; Li, L.; Xu, W.; Chang, C.; Deng, H.; Yang, L. Application of 3D digital core flow simulation technique in the study of gas flow in fractured-vuggy gas reservoir in Sichuan Basin. Nat. Gas Geosci. 2017, 28, 1425–1432. [Google Scholar]

- Gao, S.; Hu, Z.; An, W.; Liu, H.; Li, H. Distribution characteristics of dolomite reservoir pores and caves of Longwangmiao Fm gas reservoirs in the Sichuan Basin. Nat. Gas Ind. 2014, 34, 103–109. [Google Scholar]

- Wei, C.; Tian, C.; Zheng, J.; Cai, K.; Du, D.; Song, B.; Hu, Y. Heterogeneity characteristics of carbonate reservoirs: A case study using whole core data. In Proceedings of the SPE Reservoir Characterisation and Simulation Conference and Exhibition, Abu Dhabi, United Arab Emirates, 14–16 September 2015. [Google Scholar]

- Bruce, G.H.; Peaceman, D.W.; Rachford, H.H.; Rice, J.D. Calculations of unsteady-state gas flow through porous media. J. Pet. Technol. 1953, 5, 79–92. [Google Scholar] [CrossRef]

- Warren, J.E.; Root, P.J. The behavior of naturally fractured reservoirs. Soc. Pet. Eng. J. 1963, 3, 245–255. [Google Scholar] [CrossRef] [Green Version]

- Long JC, S.; Gilmour, P.; Witherspoon, P.A. A model for steady fluid flow in random three-dimensional networks of disc-shaped fractures. Water Resour. Res. 1985, 21, 1105–1115. [Google Scholar] [CrossRef] [Green Version]

- Kang, Z. New method of coupling numerical simulation and application to Fracture-Cavern carbonate reservoir. Xinjiang Pet. Geol. 2010, 31, 514. [Google Scholar]

- Muralidharan, V.; Chakravarthy, D.; Putra, E.; Schechter, D.S. Investigating fracture aperture distributions under various stress conditions using X-ray CT scanner. In Proceedings of the Canadian International Petroleum Conference, Calgary, AB, Canada, 8–10 June 2004. [Google Scholar]

- Zhang, F.; An, M.; Yan, B.; Wang, Y.; Han, Y. A novel hydro-mechanical coupled analysis for the fractured vuggy carbonate reservoirs. Comput. Geotech. 2019, 106, 68–82. [Google Scholar] [CrossRef]

- Hawez, H.K.; Sanaee, R.; Faisal, N.H. Numerical modeling for coupled hydro-mechanical processes in fractured-vuggy carbonate reservoirs. J. China Univ. Pet. 2020, 44, 96–105. [Google Scholar]

- Wang, M.; Cheung, S.W.; Chung, E.T.; Vasilyeva, M.; Wang, Y. Generalized multiscale multicontinuum model for fractured vuggy carbonate reservoirs. J. Comput. Appl. Math. 2020, 366, 112370. [Google Scholar] [CrossRef] [Green Version]

- Yan, X.; Huang, Z.; Yao, J.; Zhang, Z.; Liu, P.; Li, Y.; Fan, D. Numerical simulation of hydro-mechanical coupling in fractured vuggy porous media using the equivalent continuum model and embedded discrete fracture model. Adv. Water Resour. 2019, 126, 137–154. [Google Scholar] [CrossRef]

- Jiang, Z.; Van Dijke MI, J.; Sorbie, K.S.; Couples, G.D. Representation of multiscale heterogeneity via multiscale pore networks. Water Resour. Res. 2013, 49, 5437–5449. [Google Scholar] [CrossRef]

- Liu, L.; Huang, Z.; Yao, J.; Lei, Q.; Di, Y.; Wu, Y.S.; Zhang, K.; Cui, S. Simulating two-phase flow and geomechanical deformation in fractured karst reservoirs based on a coupled hydro-mechanical model. Int. J. Rock Mech. Min. Sci. 2021, 137, 104543. [Google Scholar] [CrossRef]

- Zhang, J.; Zhou, G.; Zhang, G.; Li, G.; Wang, H. Geological characteristics and exploration orientation of Mid-Permian natural gas in the Sichuan Basin. Nat. Gas Ind. 2018, 38, 10–20. [Google Scholar]

- Renard, F.; Kandula, N.; McBeck, J.; Cordonnier, B. Creep burst coincident with faulting in marble observed in 4-D synchrotron X-ray imaging triaxial compression experiments. J. Geophys. Res. Solid Earth 2020, 125, e2020JB020354. [Google Scholar] [CrossRef]

- Yang, Y.; Liu, Z.; Yao, J.; Wang, C.; Sun, H.; Zhang, L.; Liu, L.; Zhao, J.; An, S.; Zhang, W.; et al. Pore space characterization method of shale matrix formation based on superposed digital rock and pore-network model. Sci. Sin. Technol. 2018, 48, 488–498. [Google Scholar] [CrossRef]

- Matthäi, S.K.; Belayneh, M. Fluid flow partitioning between fractures and a permeable rock matrix. Geophys. Res. Lett. 2004, 31. [Google Scholar] [CrossRef]

- Taud, H.; Martinez-Angeles, R.; Parrot, J.F.; Hernandez-Escobedo, L. Porosity estimation method by X-ray computed tomography. J. Pet. Sci. Eng. 2005, 47, 209–217. [Google Scholar] [CrossRef]

- Zhu, W.C.; Liu, J.; Elsworth, D.; Polak, A.; Grader, A.; Sheng, J.C.; Liu, J.X. Tracer transport in a fractured chalk: X-ray CT characterization and digital-image-based (DIB) simulation. Transp. Porous Media 2007, 70, 25–42. [Google Scholar] [CrossRef]

- Bourbie, T.; Zinszner, B. Hydraulic and acoustic properties as a function of porosity in Fontainebleau sandstone. J. Geophys. Res. Solid Earth 1985, 90, 11524–11532. [Google Scholar] [CrossRef]

- Revil, A.; Kessouri, P.; Torres-Verdín, C. Electrical conductivity, induced polarization, and permeability of the Fontainebleau sandstone. Geophysics 2014, 79, D301–D318. [Google Scholar] [CrossRef] [Green Version]

- Zhou, J.; Wei, J.; Yang, T.; Zhu, W.; Li, L.; Zhang, P. Damage analysis of rock mass coupling joints, water and microseismicity. Tunn. Undergr. Sp. Technol. 2018, 71, 366–381. [Google Scholar] [CrossRef]

- Tan, X.; Konietzky, H.; Frühwirt, T. Experimental and numerical study on evolution of Biot’s coefficient during failure process for brittle rocks. Rock Mech. Rock Eng. 2015, 48, 1289–1296. [Google Scholar] [CrossRef]

- Zhu, W.C.; Wei, C.H.; Li, S.; Wei, J.; Zhang, M.S. Numerical modeling on destress blasting in coal seam for enhancing gas drainage. Int. J. Rock Mech. Min. Sci. 2013, 59, 179–190. [Google Scholar] [CrossRef]

- Yu, Y.; Zhu, W.; Li, L.; Wei, C.; Yan, B.; Li, S. Multi-fracture interactions during two-phase flow of oil and water in deformable tight sandstone oil reservoirs. J. Rock Mech. Geotech. Eng. 2020, 12, 821–849. [Google Scholar] [CrossRef]

- Chen, S.; Yang, T.; Ranjith, P.G.; Wei, C. Mechanism of the two-phase flow model for water and gas based on adsorption and desorption in fractured coal and rock. Rock Mech. Rock Eng. 2017, 50, 571–586. [Google Scholar] [CrossRef]

- Huang, Z.-Q.; Yao, J.; Wang, Y.-Y. An efficient numerical model for immiscible two-phase flow in fractured karst reservoirs. Commun. Comput. Phys. 2013, 13, 540–558. [Google Scholar] [CrossRef] [Green Version]

- Van Genuchten, M.T. A closed-form equation for predicting the hydraulic conductivity of unsaturated soils. Soil Sci. Soc. Am. J. 1980, 44, 892–898. [Google Scholar] [CrossRef] [Green Version]

| Type | Storage Space | Vug Volume Proportion | Fracture Volume Proportion | Porosity, % |

|---|---|---|---|---|

| Pore | Pore | <20% | <10% | 0.11~0.5 |

| Pore–Fracture | Pore, Fracture | <20% | ≥10% | 0.3~0.78 |

| Pore–Vug | Pore, Vug | ≥20% | <10% | 0.14~10 |

| Pore–Fracture–Vug | Pores, Fracture, Vug | ≥20% | ≥10% | 0.51~5.19 |

| Parameter | Value | Unit |

|---|---|---|

| Matrix modulus of elasticity | 60 | GPa |

| Matrix density | 2695 | kg/m3 |

| Poisson’s ratio | 0.33 | - |

| Biot coefficient | 0.9 | - |

| Natural gas kinetic viscosity factor under standard conditions | 1.38 × 10−5 | Pa⋅s |

| Natural gas density under standard conditions | 0.72 | kg/m3 |

| Sample | Permeability (Experiment), mD | Permeability (Simulation), mD | Relative Discrepancy, % |

|---|---|---|---|

| C1 | 0.67 | 0.65 | 2.99 |

| C2 | 0.54 | 0.52 | 3.70 |

| C3 | 0.34 | 0.32 | 5.88 |

| C4 | 0.28 | 0.27 | 3.57 |

| C5 | 0.22 | 0.22 | 0 |

| Parameter | Value | Unit |

|---|---|---|

| Matrix modulus of elasticity | 60 | GPa |

| Matrix density | 2695 | kg/m3 |

| Poisson’s ratio | 0.33 | - |

| Biot coefficient | 0.9 | - |

| Water kinetic viscosity factor | 1 × 10−3 | Pa s |

| Water density | 1000 | kg/m³ |

| Natural gas kinetic viscosity factor under standard conditions | 1.38 × 10−5 | Pa s |

| Natural gas density under standard conditions | 0.72 | kg/m3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, Y.; Wei, J.; Li, T.; Zhu, W.; Gong, W.; Hui, D.; Wang, M. Numerical Simulation of Fluid Flow in Carbonate Rocks Based on Digital Rock Technology. Energies 2022, 15, 3748. https://doi.org/10.3390/en15103748

Hu Y, Wei J, Li T, Zhu W, Gong W, Hui D, Wang M. Numerical Simulation of Fluid Flow in Carbonate Rocks Based on Digital Rock Technology. Energies. 2022; 15(10):3748. https://doi.org/10.3390/en15103748

Chicago/Turabian StyleHu, Yong, Jiong Wei, Tao Li, Weiwei Zhu, Wenbo Gong, Dong Hui, and Moran Wang. 2022. "Numerical Simulation of Fluid Flow in Carbonate Rocks Based on Digital Rock Technology" Energies 15, no. 10: 3748. https://doi.org/10.3390/en15103748

APA StyleHu, Y., Wei, J., Li, T., Zhu, W., Gong, W., Hui, D., & Wang, M. (2022). Numerical Simulation of Fluid Flow in Carbonate Rocks Based on Digital Rock Technology. Energies, 15(10), 3748. https://doi.org/10.3390/en15103748