Capture of Pollutants from Exhaust Gases by Low-Temperature Heating Surfaces †

Abstract

:1. Introduction

- -

- Carrying out the experimental research of pollution processes on condensing LTHS of EGB when fuel oil and WFE combustion;

- -

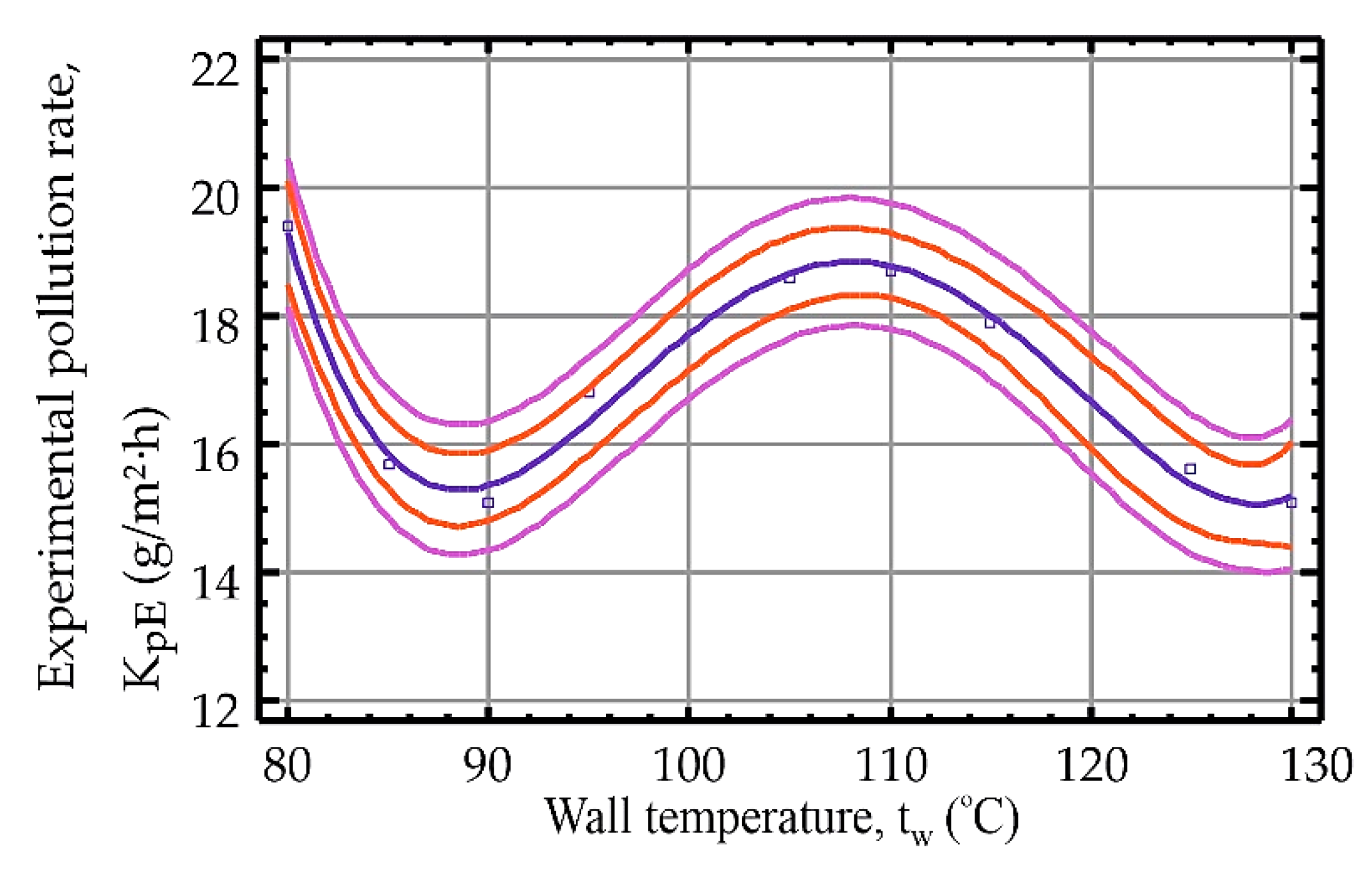

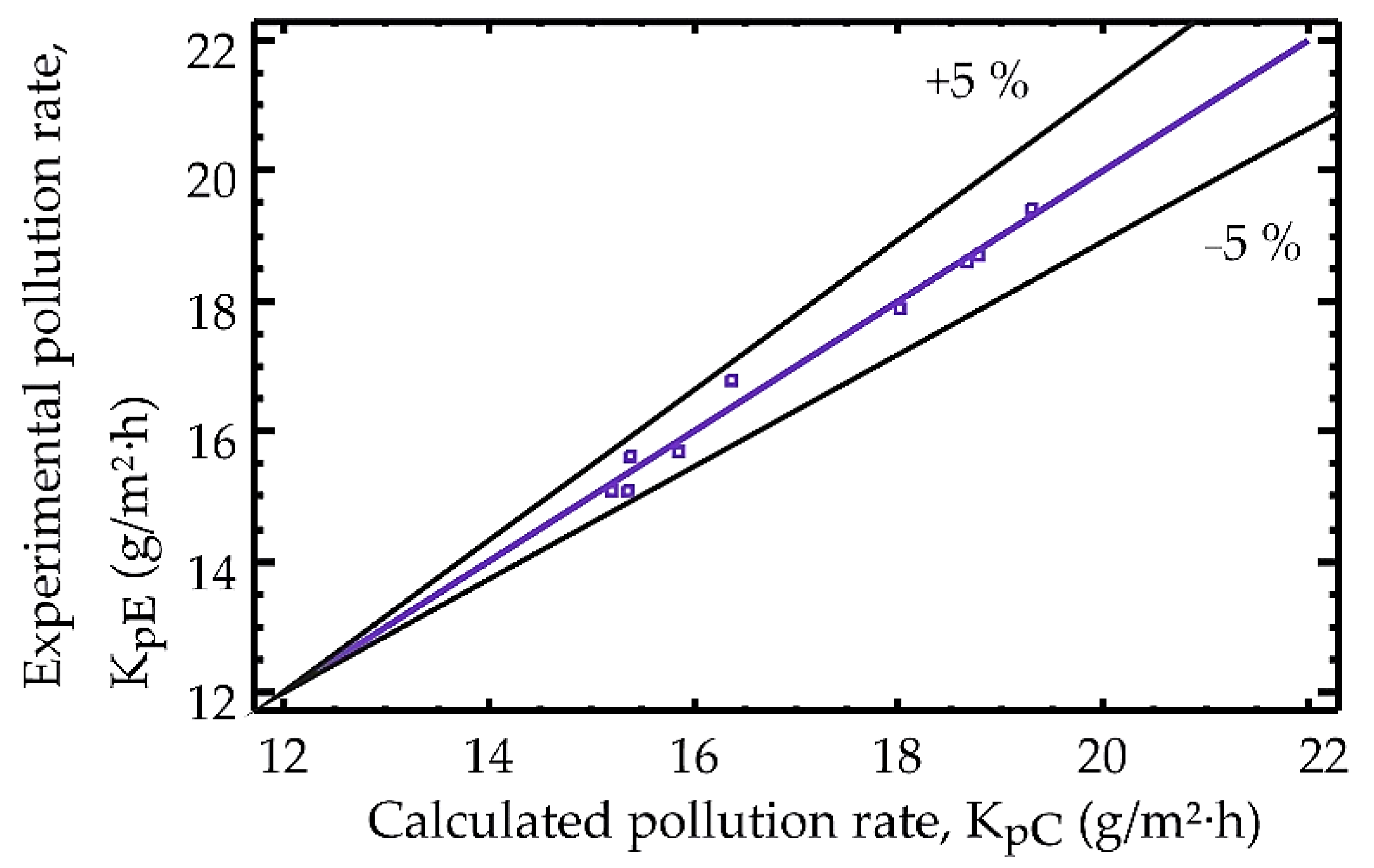

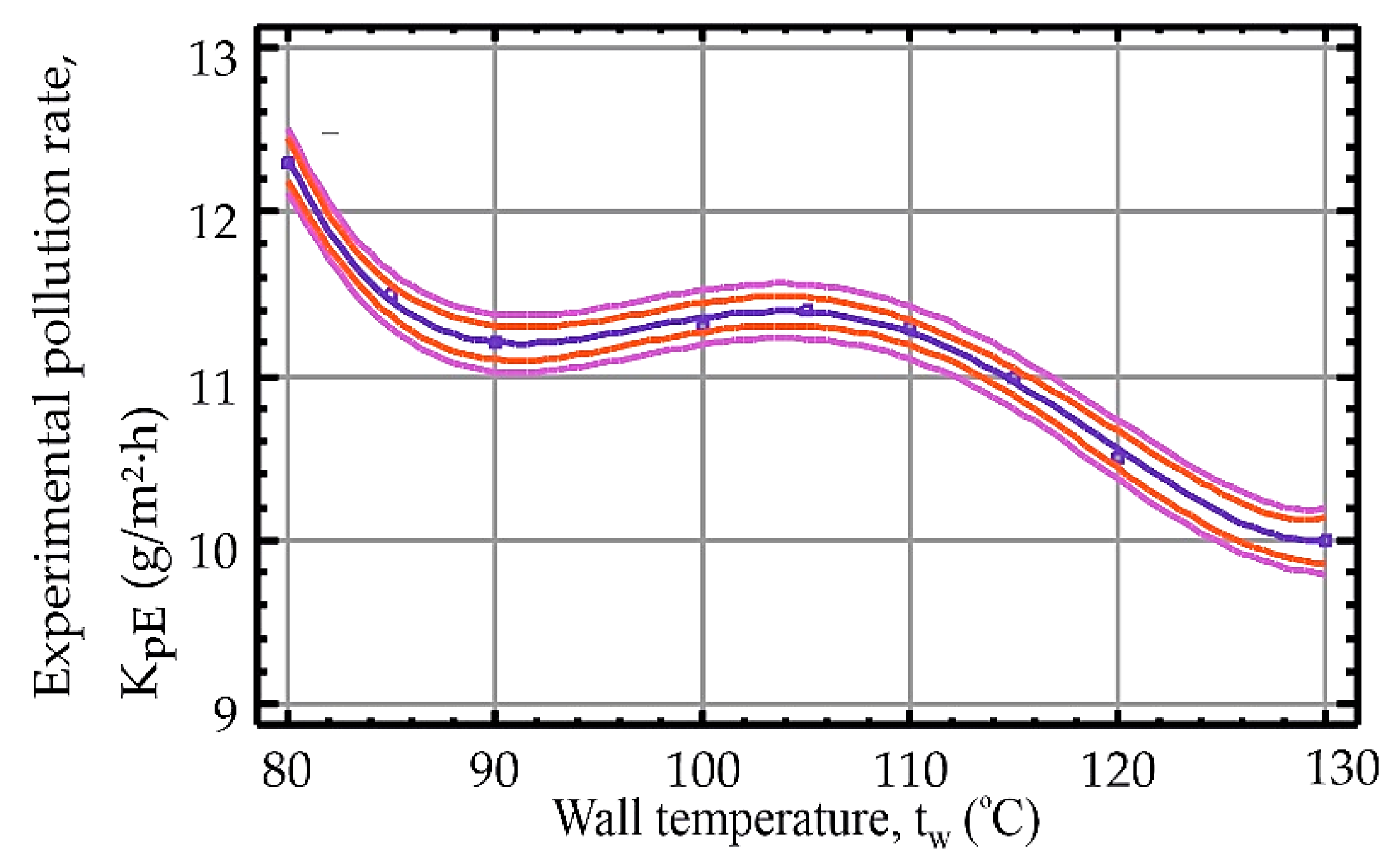

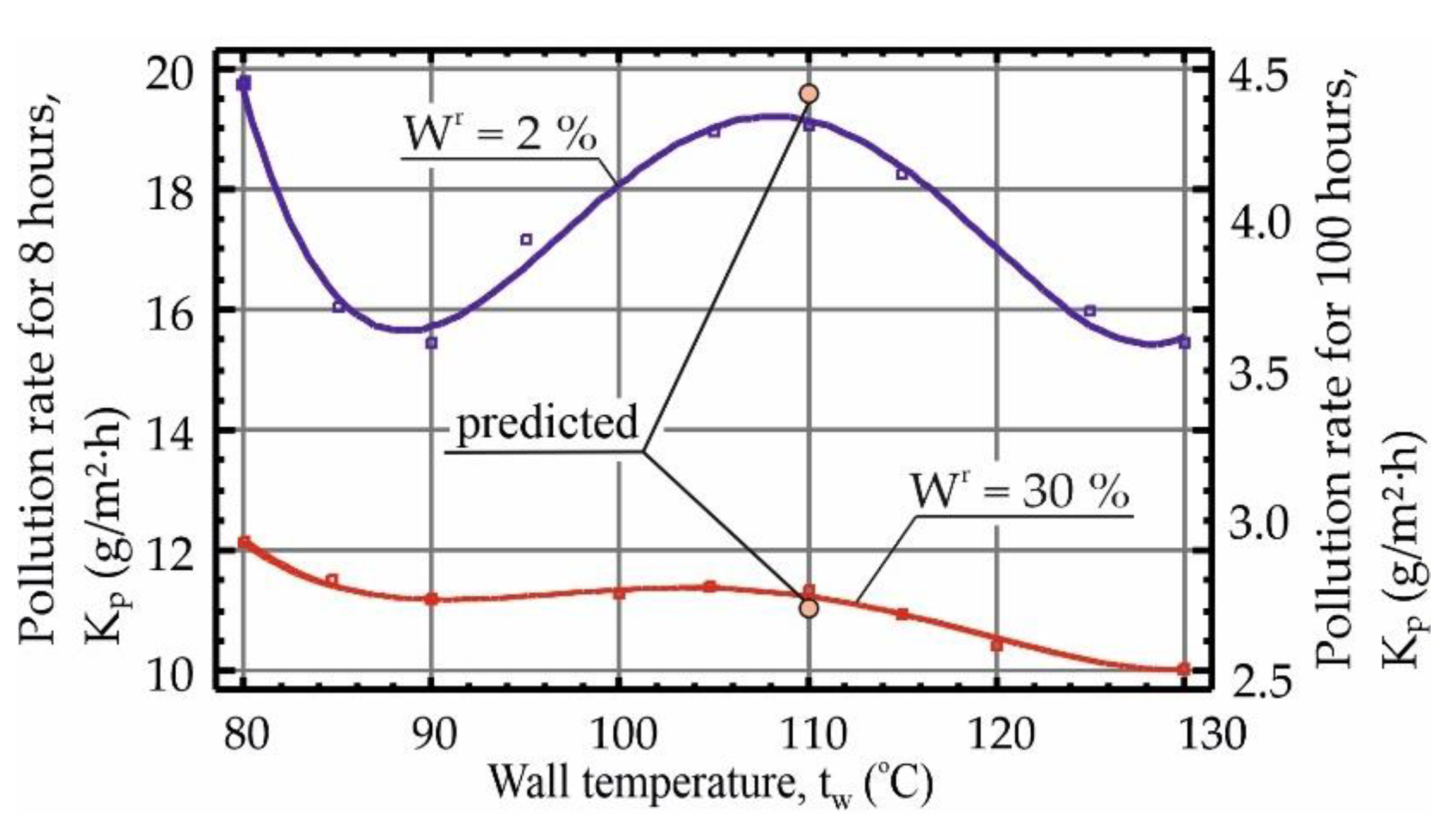

- Obtaining a dependence of pollution rate on the wall temperature, which influences on the number of PM deposited on condensing LTHS;

- -

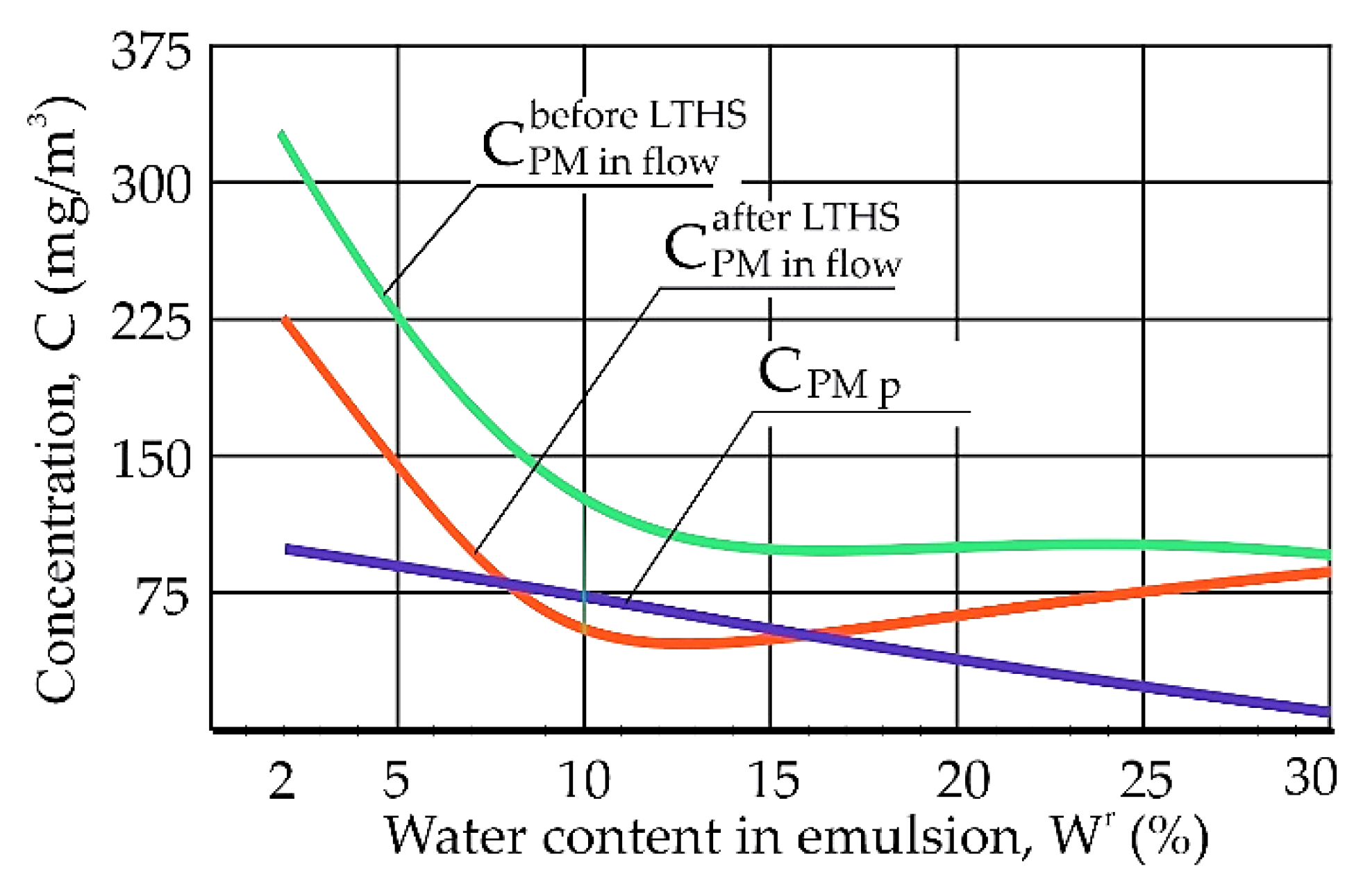

- Determining the concentration of PM before and after the LTHS during WFE combustion; and

- -

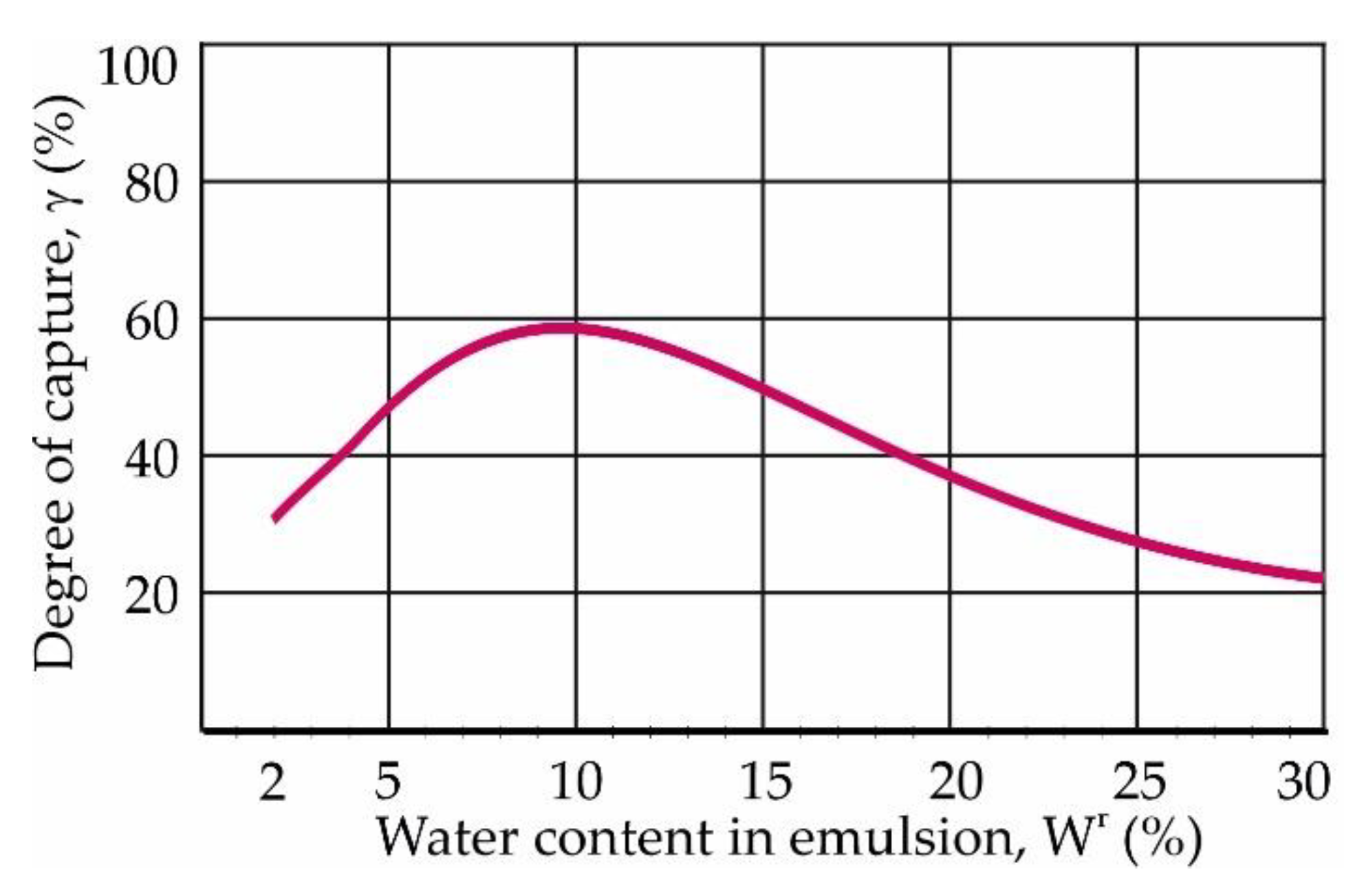

- Obtaining a dependence of “degree of capture” of pollutants by condensing LTHS and the reduction of their amount in gases after LTHS.

2. Materials and Methods

2.1. Experimental Research

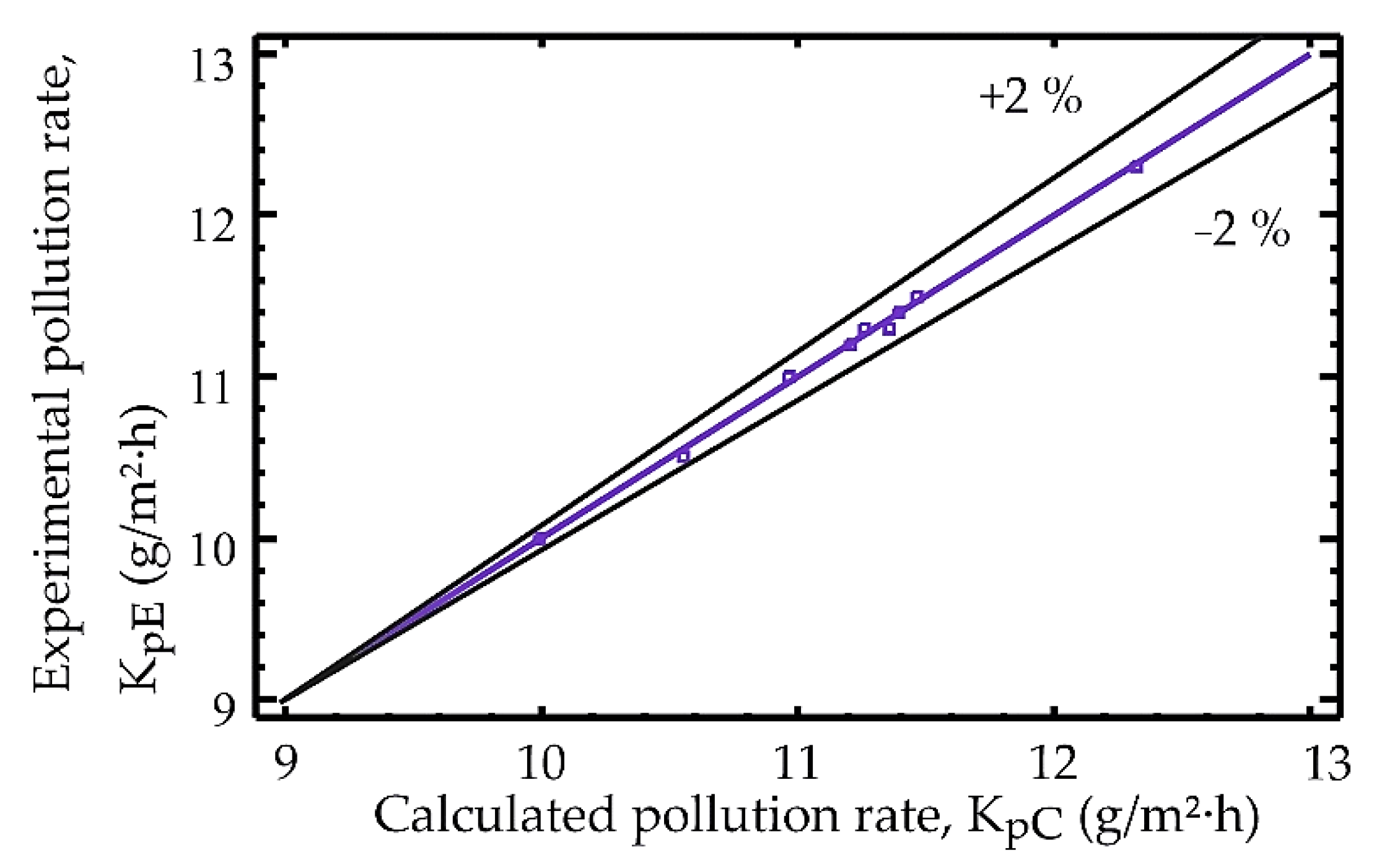

2.2. Processing of Experiment Results

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| DF | standard diesel fuel | |

| EGB | exhaust gas boiler | |

| EGR | exhaust gas recirculation technology | |

| ICE | internal combustion engine | |

| LTC | low-temperature corrosion | |

| LTHS | low-temperature heating surface | |

| PM | particulate matter | |

| WFE | water-fuel emulsion | |

| Symbols and units | ||

| volume concentration of PM in exhaust gas flow after LTHS | m3/kg | |

| volume concentration of PM in exhaust gas flow before LTHS | m3/kg | |

| CPM d | volume concentration of PM deposited on the LTHS | m3/kg |

| F | average area of the outer surface of the sample to the experiment | m2 |

| mass flow rate of PM in exhaust gas flow after LTHS | g/h | |

| mass flow rate of PM in exhaust gas flow before LTHS | g/h | |

| ΔGp | specific mass of pollution | g/m2 |

| m1 | mass of sample before experiment | g |

| m2 | mass of sample after experiment | g |

| m3 | mass of sample after cleaning of soot deposits and corrosion products | g |

| Kp | pollution rate of metal surface | g/(m2·h) |

| tw | wall temperature of heating surface | °C |

| Vgas flow | volume flow rate of exhaust gases through the gas | m3/kg |

| γ | degree of capture | % |

| Subscripts | ||

| p | pollution | |

| PM | ambient | |

References

- Eidan, A.A.; Alwan, K.J. Enhancement of the performance characteristics for air-conditioning system by using direct evaporative cooling in hot climates. Energy Procedia 2017, 142, 3998–4003. [Google Scholar] [CrossRef]

- Radchenko, M.; Radchenko, R.; Tkachenko, V.; Kantor, S.; Smolyanoy, E. Increasing the operation efficiency of railway air conditioning system on the base of its simulation along the route line. In Advances in Intelligent Systems and Computing, International Scientific and Technical Conference on Integrated Computer Technologies in Mechanical Engineering—Synergetic Engineering, ICTM 2019, Kharkiv, 28–30 November 2019; Nechyporuk, M., Pavlikov, V., Kritskiy, D., Eds.; Springer: Cham, Switzerland, 2020; Volume 1113, pp. 461–467. [Google Scholar] [CrossRef]

- Marques, R.P.; Hacon, D.; Tessarollo, A.; Parise, J.A.R. Thermodynamic analysis of trigeneration systems taking into account refrigeration, heating and electricity load demands. Energy Build. 2010, 42, 2323–2330. [Google Scholar] [CrossRef]

- Trushliakov, E.; Radchenko, A.; Radchenko, M.; Kantor, S.; Zielikov, O. The efficiency of refrigeration capacity regulation in the ambient air conditioning systems. In Lecture Notes in Mechanical Engineering, Advances in Design, Simulation and Manufacturing III, Proceedings of the 3rd International Conference on Design, Simulation, Manufacturing: The Innovation Exchange, DSMIE-2020, Kharkiv, Ukraine 9–12 June 2020; Ivanov, V., Pavlenko, I., Liaposhchenko, O., Machado, J., Edl, M., Eds.; Springer: Cham, Switzerland, 2020; pp. 343–353. [Google Scholar] [CrossRef]

- Alahmer, A.; Alsaqoor, S. Simulation and optimization of multi-split variable refrigerant flow systems. Ain. Shams Eng. J. 2017, 9, 1705–1715. [Google Scholar] [CrossRef]

- Radchenko, A.; Stachel, A.; Forduy, S.; Portnoi, B.; Rizun, O. Analysis of the efficiency of engine inlet air chilling unit with cooling towers. In Lecture Notes in Mechanical Engineering, Advances in Design, Simulation and Manufacturing III, Proceedings of the 3rd International Conference on Design, Simulation, Manufacturing: The Innovation Exchange, DSMIE-2020, Kharkiv, Ukraine, 9–12 June 2020; Ivanov, V., Pavlenko, I., Liaposhchenko, O., Machado, J., Edl, M., Eds.; Springer: Cham, Switzerland, 2020; pp. 322–331. [Google Scholar] [CrossRef]

- Butrymowicz, D.; Gagan, J.; Śmierciew, K.; Łukaszuk, M.; Dudar, A.; Pawluczuk, A.; Łapiński, A.; Kuryłowicz, A. Investigations of Prototype Ejection Refrigeration System Driven by Low Grade Heat. In Proceedings of the HTRSE-2018, E3S Web of Conferences, Międzyzdroje, Poland, 2–5 September 2018; Volume 70. [Google Scholar] [CrossRef]

- Radchenko, A.; Trushliakov, E.; Tkachenko, V.; Portnoi, B.; Prjadko, O. Improvement of the refrigeration capacity utilizing for the ambient air conditioning system. In Lecture Notes in Mechanical Engineering, Advanced Manufacturing Processes II, Selected Papers from the 2nd Grabchenko’s International Conference on Advanced Manufacturing Processes (InterPartner-2020), Odessa, Ukraine, 8–11 September 2020; Tonkonogyi, V., Ivanov, V., Trojanowska, J., Oborskyi, G., Grabchenko, A., Pavlenko, I., Edl, M., Kuric, I., Dasic, P., Eds.; Springer: Cham, Switzerland, 2021; pp. 714–723. [Google Scholar]

- Shukla, A.K.; Singh, O. Thermodynamic investigation of parameters affecting the execution of steam injected cooled gas turbine based combined cycle power plant with vapor absorption inlet air cooling. Appl. Therm. Eng. 2017, 122, 380–388. [Google Scholar] [CrossRef]

- Radchenko, M.; Mikielewicz, D.; Tkachenko, V.; Klugmann, M.; Andreev, A. Enhancement of the operation efficiency of the transport air conditioning system. In Lecture Notes in Mechanical Engineering, Advances in Design, Simulation and Manufacturing III, Proceedings of the 3rd International Conference on Design, Simulation, Manufacturing: The Innovation Exchange, DSMIE-2020, Kharkiv, Ukraine, 9–12 June 2020; Ivanov, V., Pavlenko, I., Liaposhchenko, O., Machado, J., Edl, M., Eds.; Springer: Cham, Switzerland, 2020; pp. 332–342. [Google Scholar] [CrossRef]

- Sur, A.; Das, R.K.; Sah, R.P. Influence of initial bed temperature on bed performance of an adsorption refrigeration system. Therm. Sci. 2018, 22, 2583–2595. [Google Scholar] [CrossRef]

- Konovalov, D.; Kobalava, H.; Radchenko, M.; Scurtu, I.C.; Radchenko, R. Determination of Hydraulic Resistance of the Aerothermopressor for Gas Turbine Cyclic Air Cooling. In Proceedings of the TE-RE-RD 2020, E3S Web of Conferences, Constanta, Romania, 26–27 June 2020; Volume 180, p. 01012. [Google Scholar]

- Kjolholt, J. Assessment of Possible Impacts of Scrubber Water Discharges on the Marine Environment. The Danish Environmental Protection Agency (Environmental Project No. 1431. 2012, 93p). Available online: https://www2.mst.dk/Udgiv/publications/2012/06/978-87-92903-30-3.pdf (accessed on 22 June 2021).

- Landet, R.D. PM Emissions and NOx—Reduction Due to Water in Fuel Emulsions in Marine Diesel Engines. Master’s Thesis, Norwegian University of Scienceand Technology, Department of Marine Technology, Trondheim, Norway, 2010; 73p. Available online: https://ntnuopen.ntnu.no/ntnu-xmlui/bitstream/handle/11250/237793/375078_FULLTEXT01.pdf?sequence=1&isAllowed=yhttp://hdl.handle.net/11250/237793 (accessed on 22 June 2021).

- MAN Diesel Turbo. Available online: https://marine.man-es.com/two-stroke/ceas (accessed on 22 June 2021).

- PureSOx Exhaust Gas Cleaning. Available online: https://www.alfalaval.com/globalassets/documents/microsites/puresox/puresox-brochure-2018.pdf (accessed on 23 March 2021).

- Ecospec CSNOxTM Broshure. Available online: https://www.environmental-expert.com/downloads/ecospec-csnox-3-in-1-emission-abatement-system-brochure-785875 (accessed on 22 June 2021).

- Miao, Y.C.; Yu, C.L.; Wang, B.H.; Chen, K. The applied research of emulsified heavy fuel oil used for the marine diesel engine. Adv. Mater. Res. 2013, 779, 469–476. [Google Scholar] [CrossRef]

- Radchenko, R.; Pyrysunko, M.; Radchenko, A.; Andreev, A.; Kornienko, V. Ship engine intake air cooling by ejector chiller using recirculation gas. In Lecture Notes in Mechanical Engineering, Advanced Manufacturing Processes II, Selected Papers from the 2nd Grabchenko’s International Conference on Advanced Manufacturing Processes (InterPartner-2020), Odessa, Ukraine, 8–11 September 2020; Tonkonogyi, V., Ivanov, V., Trojanowska, J., Oborskyi, G., Grabchenko, A., Pavlenko, I., Edl, M., Kuric, I., Dasic, P., Eds.; Springer: Cham, Switzerland, 2021; pp. 734–743. [Google Scholar]

- Hansen, J.P. Exhaust Gas Scrubber Installed Onboard MV Ficaria Seaways. Public Test Report the Danish Environmental Protection Agency. 2012. 30p. Available online: https://www2.mst.dk/Udgiv/publications/2012/06/978-87-92903-28-0.pdf (accessed on 22 June 2021).

- Baskar, P.; Senthil Kumar, A. Experimental investigation on performance characteristics of a diesel engine using diesel-water emulsion with oxygen enriched air. Alex. Eng. J. 2017, 56, 137–146. [Google Scholar] [CrossRef] [Green Version]

- Wojs, M.K.; Orliński, P.; Kamela, W.; Kruczyński, P. Research on the influence of ozone dissolved in the fuel-water emulsion on the parameters of the CI engine. IOP Conf. Ser. Mater. Sci. Eng. 2016, 148, 1–8. [Google Scholar] [CrossRef]

- Zang, T.; Okada, H.; Tsukamoto, T.; Ohe, K. Experimental Study on Water Particles in the Combustion of Marine Four-Stoke Diesel Engine Operated with Emulsified Fuels; Paper 193; CIMAK: Vienna, Austria, 2007. [Google Scholar]

- Vellaiyan, S.; Amirthagadeswaran, K.S. The role of water-in-diesel emulsion and its additives on diesel engine performance and emission levels: A retrospective review. Alex. Eng. J. 2016, 55, 2463–2472. [Google Scholar] [CrossRef] [Green Version]

- Gupta, R.K.; Sankeerth, K.A.; Sharma, T.K.; Rao, G.; Murthy, K.M. Effects of water-diesel emulsion on the emission characteristics of single cylinder direct injection diesel engine—A review. Appl. Mech. Mater. 2014, 592, 1526–1533. [Google Scholar] [CrossRef]

- Patel, K.R.; Dhiman, V. Research study of water- diesel emulsion as alternative fuel in diesel engine—An overview. Int. J. Latest Eng. Res. Appl. 2017, 2, 37–41. [Google Scholar]

- Patel, N.; Modi, M.; Patel, T. Investigation of diesel engine with water emulsifier—A review. Int. Res. J. Eng. Technol. 2017, 4, 879–883. [Google Scholar]

- Sugeng, D.A.; Ithnin, A.M.; Amri, N.S.M.S.; Ahmad, M.A.; Yahya, W.J. Water content determination of steam generated water-in-diesel emulsion. J. Adv. Res. Fluid Mech. Therm. Sci. 2018, 49, 62–68. [Google Scholar]

- Kruczyński, P.; Orliński, P.; Kamela, W.; Ślęzak, M. Analysis of selected toxic components in the exhaust gases of a CI engine supplied with water-fuel emulsion. Pol. J. Environ. Stud. 2018, 27, 129–136. [Google Scholar] [CrossRef]

- Katin, V.; Kosygin, V.; Akhtiamov, M.; Vol’khin, I. Mathematical models of the output of major pollutants in the process of burning water fuel oil emulsions in boiler plants. In Proceedings of the 19th International Scientific Conference Energy Management of Municipal Transportation Facilities and Transport, EMMFT, Khabarovsk, Russia, 10–13 April 2017; Springer: Amsterdam, The Netherlands, 2018; Volume 692, pp. 987–997. [Google Scholar]

- Kornienko, V.; Radchenko, R.; Bohdal, Ł.; Kukiełka, L.; Legutko, S. Investigation of condensing heating surfaces with reduced corrosion of boilers with water-fuel emulsion combustion. In Lecture Notes in Networks and Systems: In Advances in Intelligent Systems and Computing, International Scientific and Technical Conference on Integrated Computer Technologies in Mechanical Engineering—Synergetic Engineering, ICTM 2020, Kharkiv, 29–30 October 2020; Nechyporuk, M., Pavlikov, V., Kritskiy, D., Eds.; Springer: Cham, Switzerland, 2021; Volume 188, pp. 300–309. [Google Scholar] [CrossRef]

- Chen, H.; Pan, P.; Wang, Y.; Zhao, Q. Field study on the corrosion and ash deposition of low–temperature heating surface in a large–scale coal–fired power plant. Fuel 2017, 208, 149–159. [Google Scholar] [CrossRef]

- Radchenko, R.; Pyrysunko, M.; Kornienko, V.; Scurtu, I.-C.; Patyk, R. Improving the ecological and energy efficiency of internal combustion engines by ejector chiller using recirculation gas heat. In Lecture Notes in Networks and Systems: In Advances in Intelligent Systems and Computing, International Scientific and Technical Conference on Integrated Computer Technologies in Mechanical Engineering—Synergetic Engineering, ICTM 2020, Kharkiv, 29–30 October 2020; Nechyporuk, M., Pavlikov, V., Kritskiy, D., Eds.; Springer: Cham, Switzerland, 2021; Volume 188, pp. 531–541. [Google Scholar] [CrossRef]

- Kornienko, V.; Radchenko, M.; Radchenko, R.; Konovalov, D.; Andreev, A.; Pyrysunko, M. Improving the efficiency of heat recovery circuits of cogeneration plants with combustion of water-fuel emulsions. Therm. Sci. 2021, 25, 791–800. [Google Scholar] [CrossRef] [Green Version]

- Konur, O.; Saatcioglu, O.Y.; Korkmaz, S.A.; Erdogan, A.; Colpan, C.O. Anil Erdogan. Heat exchanger network design of an organic Rankine cycle integrated waste heat recovery system of a marine vessel using pinch point analysis. Int. J. Energy Res. 2020, 44, 12312–12328. [Google Scholar] [CrossRef]

- Vainio, E.; Kinnunen, H.; Laurén, T.; Brink, A.; Yrjas, P.; DeMartini, N.; Hupa, M. Low-temperature corrosion in co-combustion of biomass and solid recovered fuels. Fuel 2016, 184, 957–965. [Google Scholar] [CrossRef]

- Bohdal, L.; Kukiełka, L.; Legutko, S.; Patyk, R.; Radchenko, A.M. Modeling and experimental analysis of shear-slitting of AA6111-T4 aluminum alloy sheet. Materials 2020, 13, 3175. [Google Scholar] [CrossRef]

- Akimov, O.V. Dynamics of reduction of ash and soot emissions during combustion of water-oil emulsions in boilers. Scientific works: Scientific and methodical journal. Technog. Saf. 2008, 95, 39–46. [Google Scholar]

- Shia, Y.-T.; Gao, M.; Tang, G.-H.; Sun, F.-Z.; Tao, W.-Q. Experimental research of CFB ash deposition on helical finned tubes. Appl. Therm. Eng. 2012, 37, 420–429. [Google Scholar] [CrossRef]

- Han, H.; He, Y.L.; Tao, W.Q. A numerical study of the deposition characteristics of sulfuric acid vapor on heat exchanger surfaces. Chem. Eng. Sci. 2013, 101, 620–630. [Google Scholar] [CrossRef]

- Trushliakov, E.; Radchenko, A.; Forduy, S.; Zubarev, A.; Hrych, A. Increasing the operation efficiency of air conditioning system for integrated power plant on the base of its monitoring. In Advances in Intelligent Systems and Computing, International Scientific and Technical Conference on Integrated Computer Technologies in Mechanical Engineering—Synergetic Engineering, ICTM 2019, Kharkiv, 28–30 November 2019; Nechyporuk, M., Pavlikov, V., Kritskiy, D., Eds.; Springer: Cham, Switzerland, 2020; Volume 1113, pp. 351–360. [Google Scholar] [CrossRef]

- Radchenko, M.; Radchenko, A.; Radchenko, R.; Kantor, S.; Konovalov, D.; Kornienko, V. Rational loads of turbine inlet air absorption-ejector cooling systems. Proc. Inst. Mech. Eng. Part A J. Power Energy 2021. [Google Scholar] [CrossRef]

- Radchenko, A.; Trushliakov, E.; Kosowski, K.; Mikielewicz, D.; Radchenko, M. Innovative turbine intake air cooling systems and their rational designing. Energies 2020, 13, 6201. [Google Scholar] [CrossRef]

- Kumar, P. Thermal Calculation of Boiler Units (Normative Method), 3rd ed.; NGO CKTI: St. Petersburg, Russia, 1998. [Google Scholar]

- Kornienko, V.; Radchenko, M.; Radchenko, R.; Kruzel, M.; Konovalov, D.; Andreev, A. Absorption of Pollutants from Exhaust Gases by Low-Temperature Heating Surfaces. In Proceedings of the V International Scientific and Technical Conference Modern Power Systems and Units (MPSU 2021), E3S Web of Conferences, Cracow, Poland, 19–21 May 2021; Volume 323, p. 00018. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, Z.; Kornienko, V.; Radchenko, M.; Radchenko, A.; Radchenko, R.; Pavlenko, A. Capture of Pollutants from Exhaust Gases by Low-Temperature Heating Surfaces. Energies 2022, 15, 120. https://doi.org/10.3390/en15010120

Yang Z, Kornienko V, Radchenko M, Radchenko A, Radchenko R, Pavlenko A. Capture of Pollutants from Exhaust Gases by Low-Temperature Heating Surfaces. Energies. 2022; 15(1):120. https://doi.org/10.3390/en15010120

Chicago/Turabian StyleYang, Zongming, Victoria Kornienko, Mykola Radchenko, Andrii Radchenko, Roman Radchenko, and Anatoliy Pavlenko. 2022. "Capture of Pollutants from Exhaust Gases by Low-Temperature Heating Surfaces" Energies 15, no. 1: 120. https://doi.org/10.3390/en15010120

APA StyleYang, Z., Kornienko, V., Radchenko, M., Radchenko, A., Radchenko, R., & Pavlenko, A. (2022). Capture of Pollutants from Exhaust Gases by Low-Temperature Heating Surfaces. Energies, 15(1), 120. https://doi.org/10.3390/en15010120