Developing a Cold Accumulator with a Capsule Bed Containing Water as a Phase-Change Material

Abstract

1. Introduction

2. Materials and Methods

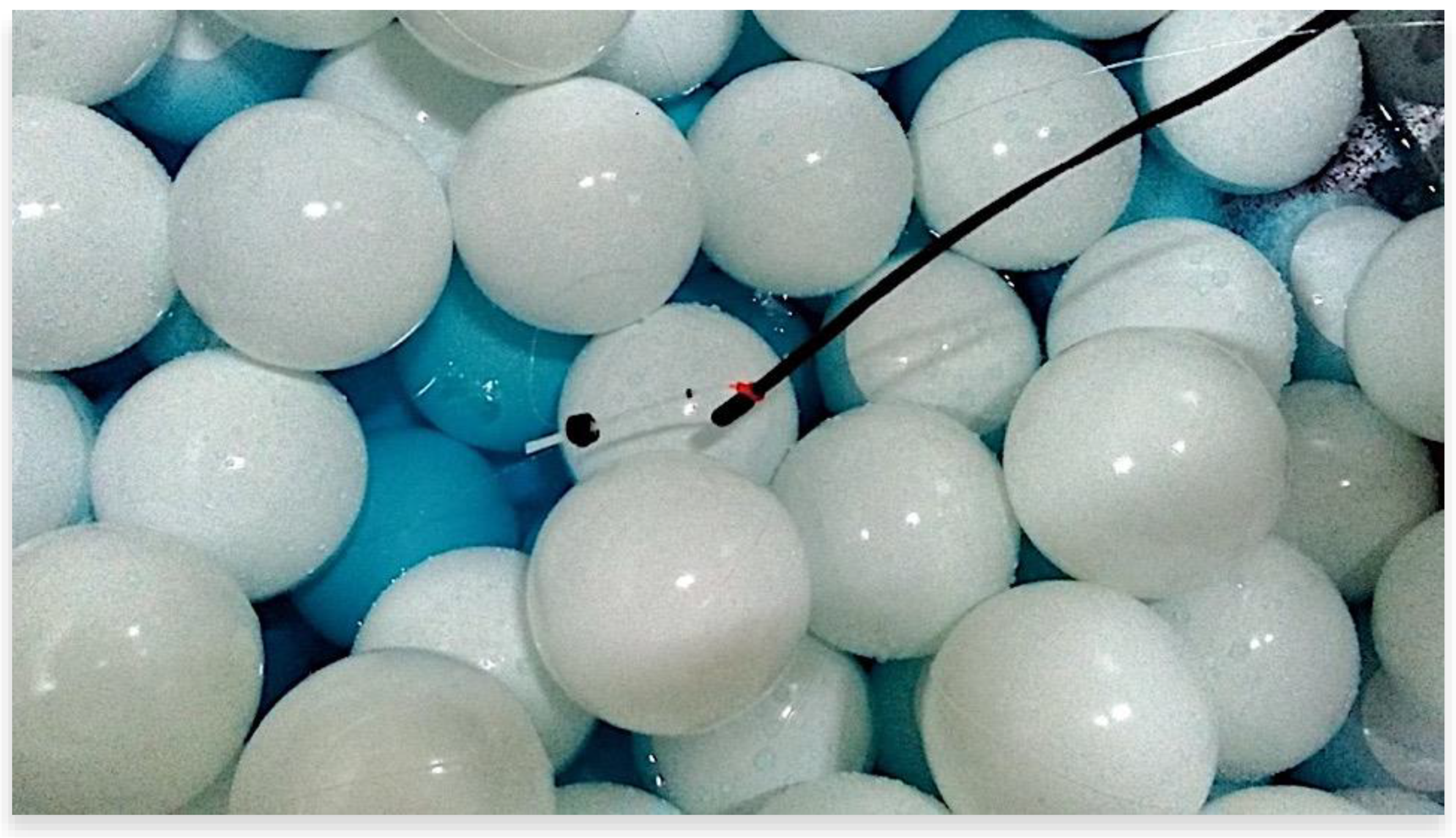

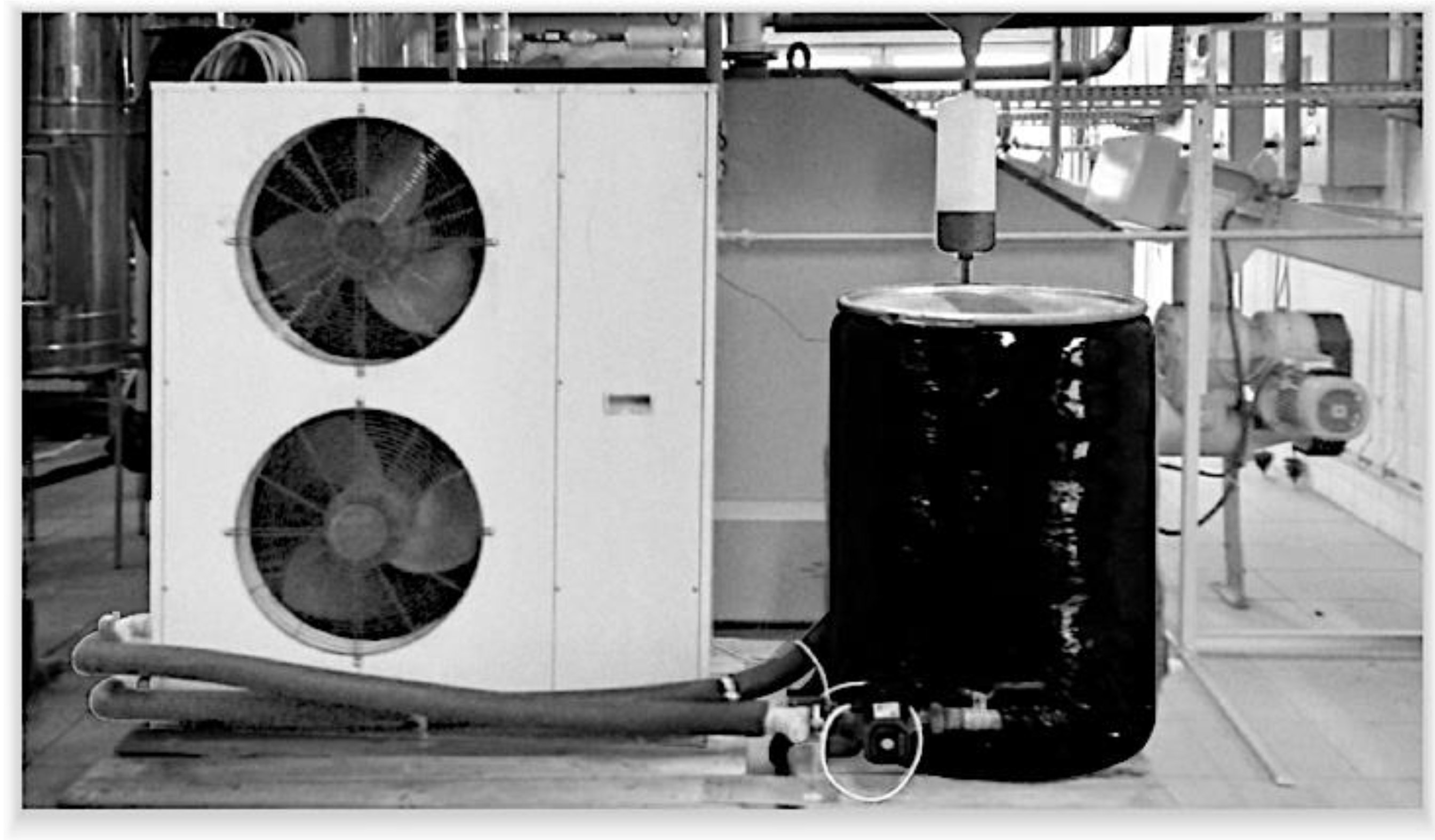

2.1. The Object of Investigation

2.2. Testing Methodology

3. Results and Discussion

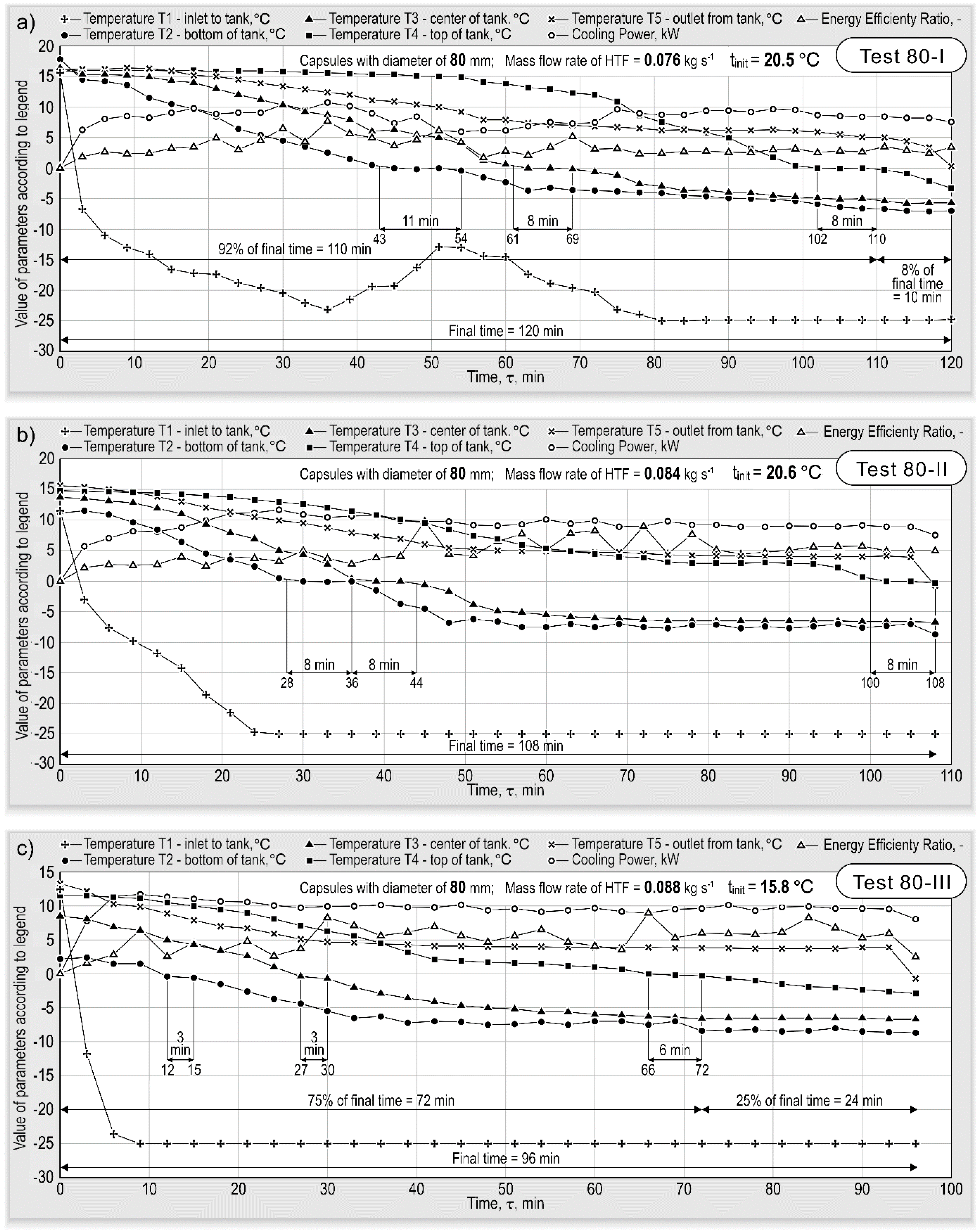

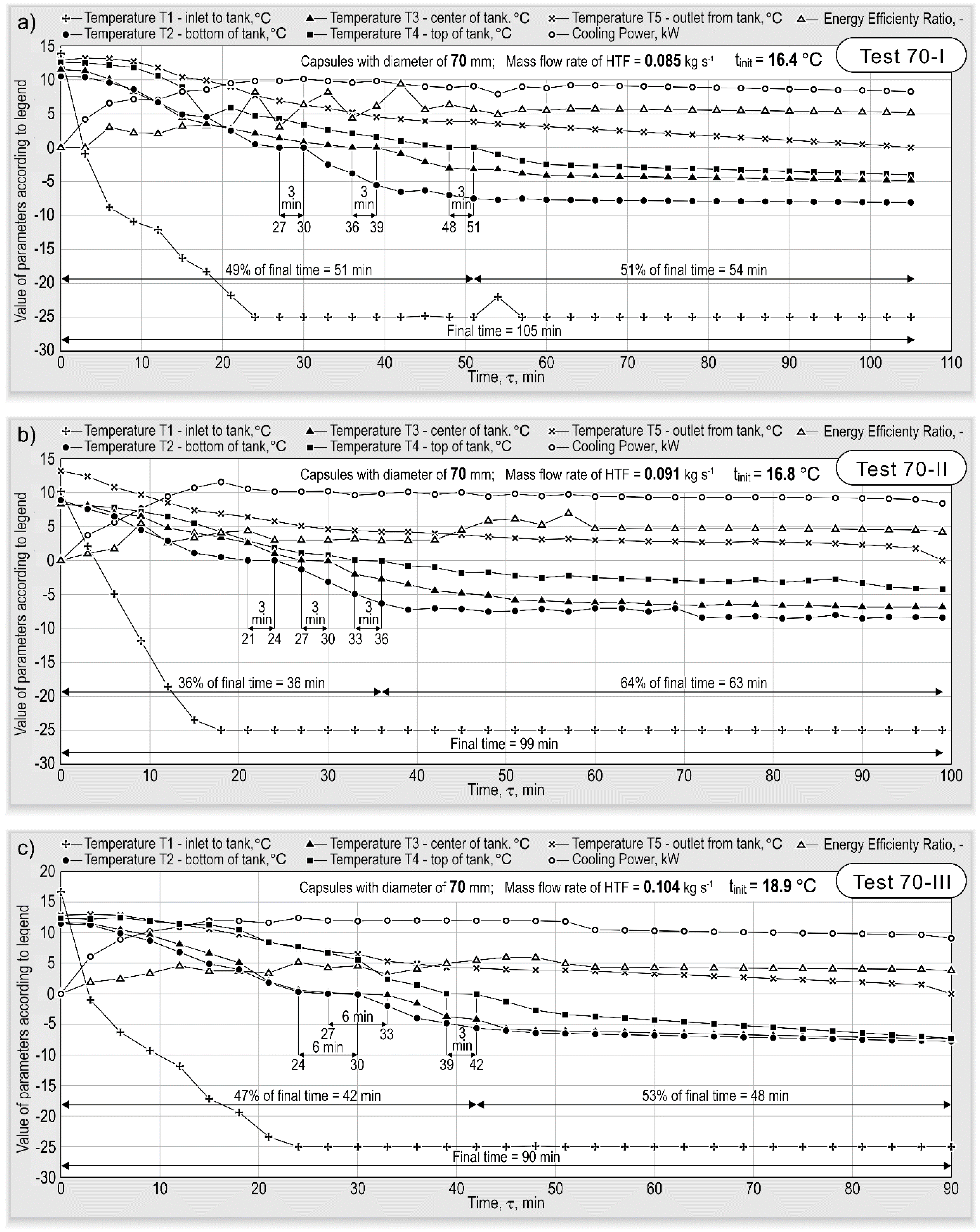

3.1. Measurement Results

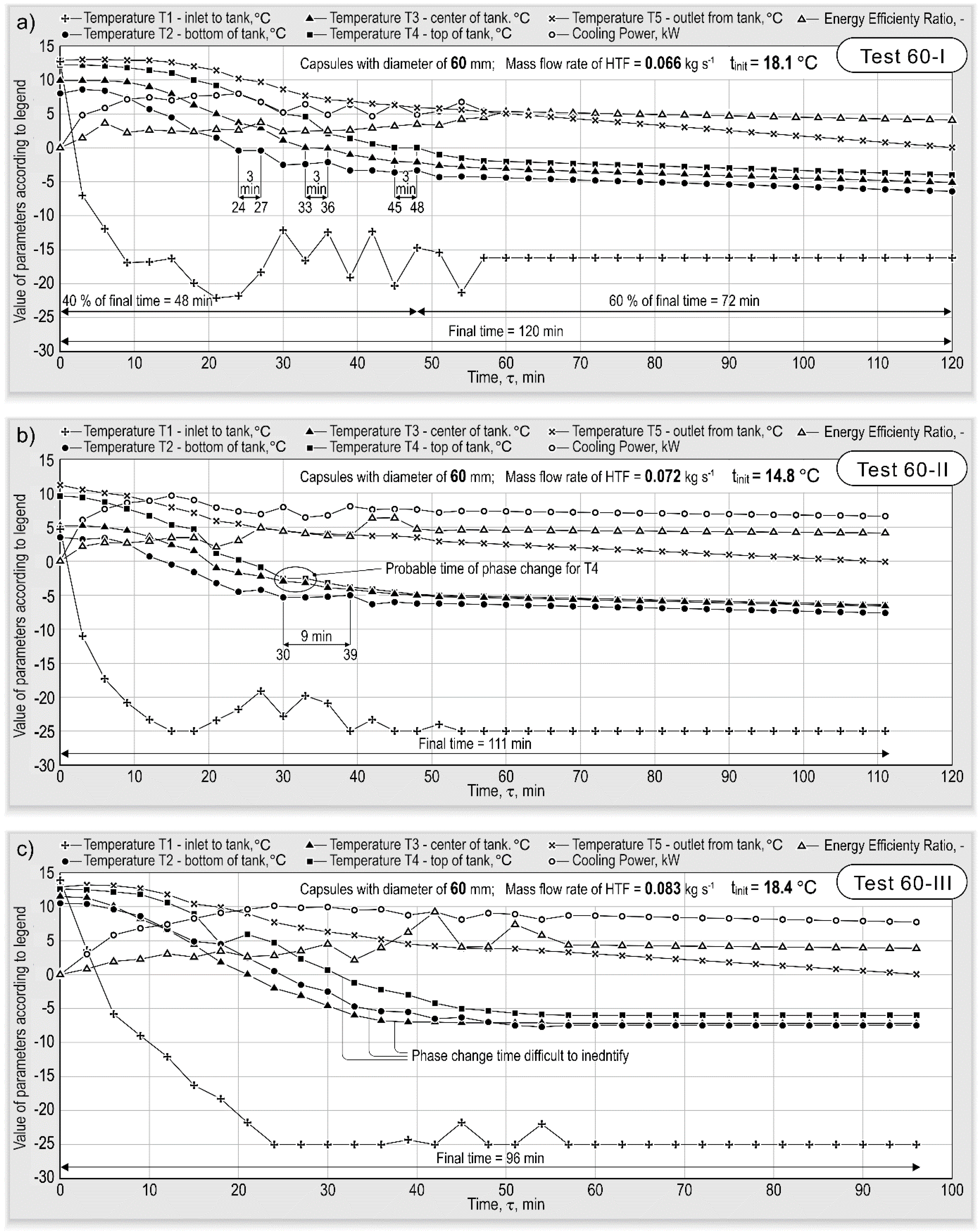

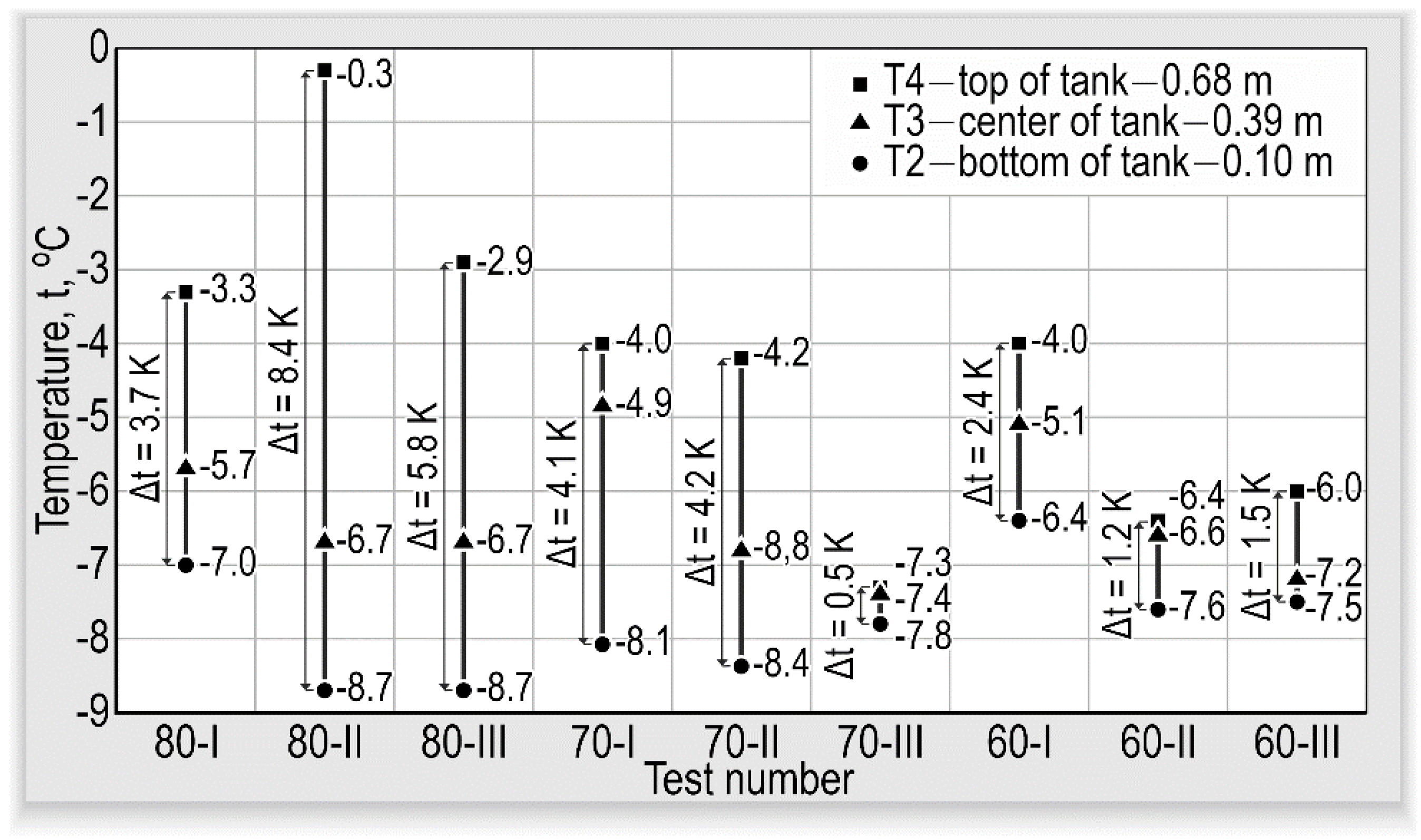

3.1.1. Operation of the Testing Stand

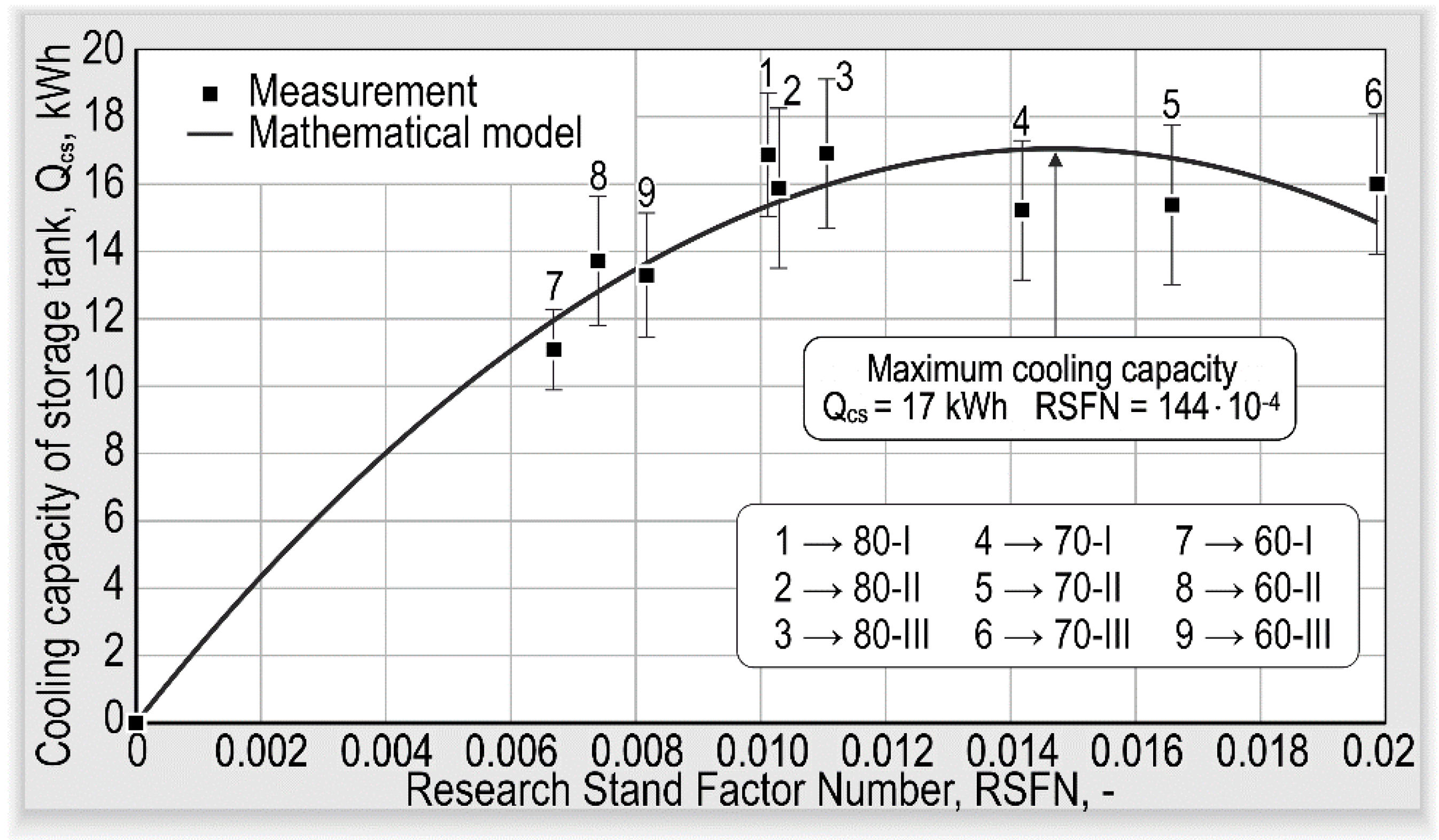

3.1.2. The Cooling Power and Capacity of the Accumulator

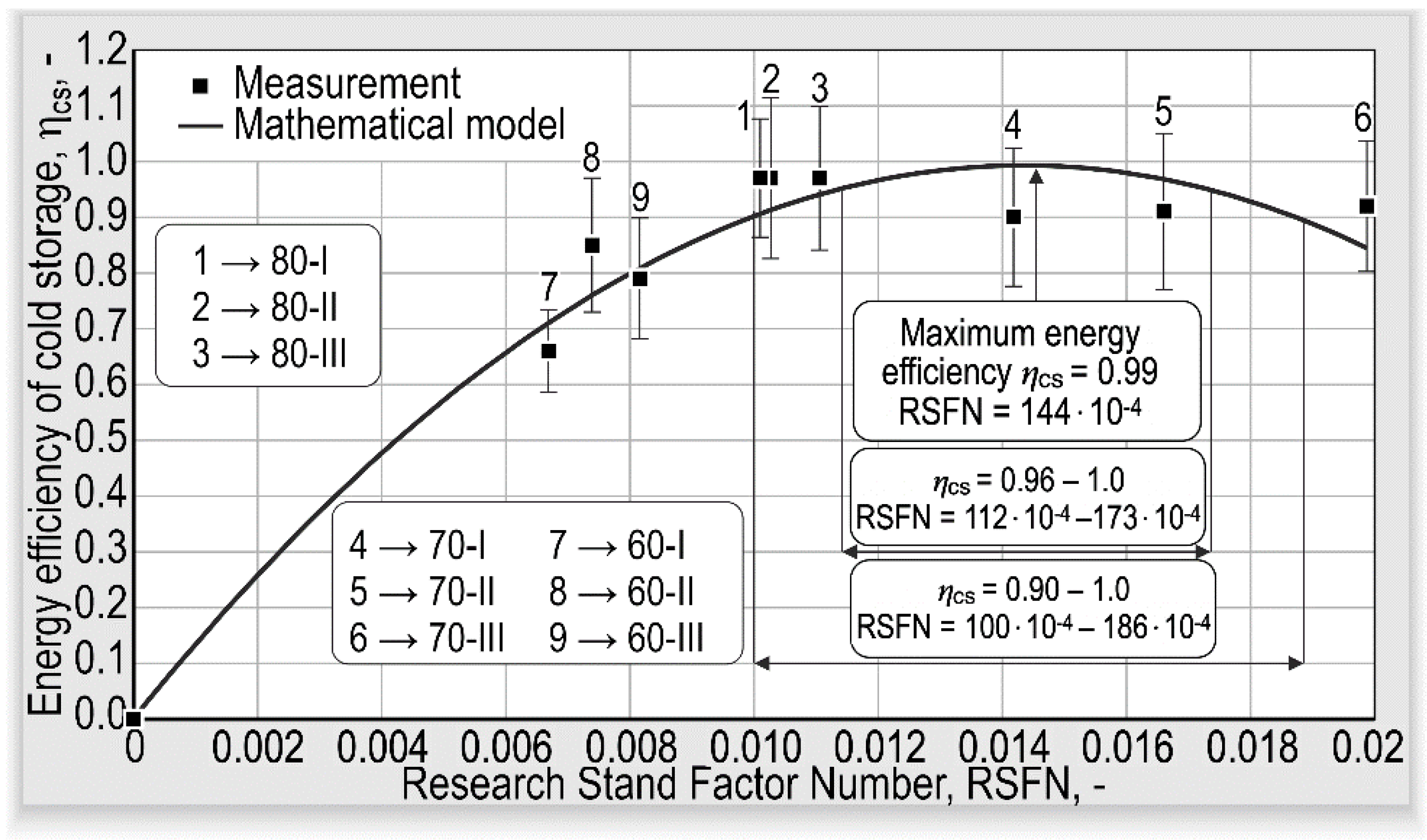

3.1.3. The Energy Efficiency of the Cold Storage Installation

3.2. Analysis of the Obtained Test Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| A | area of horizontal section of cold accumulator (m2) |

| cp | specific heat (J kg−1 K−1) |

| dp | capsule diameter (m) |

| EER | energy efficiency ratio (-) |

| h | heat transfer coefficient (W m−2 K−1) |

| HCT | heat capacity of tank (kWh) |

| L | heat of phase change (J kg−1) |

| m | weight, (kg) |

| mass flow rate (kg s−1) | |

| N | amount (number) |

| Pel | electric energy usage (kWh) |

| Qcs | cooling capacity (kWh) |

| cooling power (kW) | |

| t | temperature (°C) |

| U | velocity (m s−1) |

| V | volume (m−3) |

| Greek Symbols | |

| Δ | difference |

| ε | voidage of bed in cold accumulator (-) |

| λ | thermal conductivity (W m−1 K−1) |

| η | energy efficiency (-), (%) |

| ρ | density (kg m−3) |

| ν | kinematic viscosity (m2 s−1) |

| τ | time (s or min) |

| ϕ | value based on multicapsule bed |

| Subscripts | |

| A | accumulator |

| cs | cold storage |

| fin | final, total |

| htf | heat transfer fluid in installation |

| i | ice |

| in | inlet—T1 |

| init | start of test |

| iv | instantaneous value related to the length of the measuring interval |

| out | outlet—T5 |

| p | capsule |

| pc | water–ice phase change |

| sf | superficial |

| w | water |

| Abbreviations | |

| HTF | heat transfer fluid |

| PCM | phase-change material |

| RSFN | Research Stand Factor Number |

| Dimensionless numbers | |

| Fo | Fourier number |

| Nu | Nusselt number |

| Rep | Reynolds number based on capsule diameter |

| Reϕ | Reynolds number based on multicapsule bed |

| S | Strouhal number |

References

- Asgharian, H.; Baniasadi, E. Experimental and numerical analyses of a cooling energy storage system using spherical capsules. Appl. Therm. Eng. 2019, 149, 909–923. [Google Scholar] [CrossRef]

- Cerezo, J.; Lara, F.; Romero, R.J.; Rodríguez, A. Analysis and Simulation of an Absorption Cooling System Using a Latent Heat Storage Tank and a Tempering Valve. Energies 2021, 14, 1376. [Google Scholar] [CrossRef]

- Mongibello, L.; Graditi, G. Cold Storage for a Single-Family House in Italy. Energies 2016, 9, 1043. [Google Scholar] [CrossRef]

- Prabakaran, R.; Sidney, S.; Mohan Lal, D.; Selvam, C.; Harish, S. Solidification of Graphene-Assisted Phase Change Nanocomposites inside a Sphere for Cold Storage Applications. Energies 2019, 12, 3473. [Google Scholar] [CrossRef]

- Qureshi, W.A.; Nair, N.-K.C.; Farid, M.M. Impact of energy storage in buildings on electricity demand side management. Energy Convers. Manag. 2011, 52, 2110–2120. [Google Scholar] [CrossRef]

- Avghad, S.N.; Keche, A.J.; Kousal, A. Thermal energy storage: A review. J. Mech. Civ. Eng. 2016, 13, 72–77. [Google Scholar]

- Basecq, V.; Michaux, G.; Inrad, C. Short-term storage systems of thermal energy for buildings: A review. Adv. Build. Energy Res. 2013, 7, 66–119. [Google Scholar] [CrossRef]

- Mehling, H.; Cabeza, L.F. Heat and Cold Storage with PCM. An Up to Date Introduction into Basic and Applications; Springer: Berlin/Heidelberg, Germany, 2008. [Google Scholar]

- Chaiyat, N. Energy and economic analysis of a building air-conditioner with a phase change material. Energy Convers. Manag. 2015, 94, 150–158. [Google Scholar] [CrossRef]

- Allouche, Y.; Varga, S.; Bouden, C.; Oliveira, A.C. Experimental determination of the heat transfer and cold storage characteristics of a microencapsulated phase change material in a horizontal tank. Energy Convers. Manag. 2015, 94, 275–285. [Google Scholar] [CrossRef]

- Rahdar, H.H.; Emamzadeh, A.; Ataei, A. A comparative study on PCM and ice thermal energy storage tank for air- conditioning systems in office buildings. Appl. Therm. Eng. 2016, 96, 391–399. [Google Scholar] [CrossRef]

- Souayfane, F.; Fardoun, F.; Biwole, P.H. Phase change materials (PCM) for cooling applications in buildings: A review. Energy Build. 2016, 129, 396–431. [Google Scholar] [CrossRef]

- Pardinńas, Á.Á.; Alonso, M.J.; Diz, R.; Kvalsvik, K.H.; Fernández-Seara, J. State-of-the-art for the use of phase-change materials in tanks coupled with heat pumps. Energy Build. 2017, 140, 28–41. [Google Scholar] [CrossRef]

- Ma, Z.; Ren, H.; Lin, W. A review of heating, ventilation and air conditioning technologies and innovations used in solar-powered net zero energy Solar Decathlon houses. J. Clean. Prod. 2019, 240, 118158. [Google Scholar] [CrossRef]

- Tola, V.; Arena, S.; Cascetta, M.; Cau, G. Numerical Investigation on a Packed-Bed LHTES System Integrated into a Micro Electrical and Thermal Grid. Energies 2020, 13, 2018. [Google Scholar] [CrossRef]

- Zender-Świercz, E. A Review of Heat Recovery in Ventilation. Energies 2021, 14, 1759. [Google Scholar] [CrossRef]

- Cervera-Vazquez, J.; Montagud-Montalava, C.; Corberan, J.M. Sizing of the buffer tank in chilled water distribution air-conditioning systems. Sci. Technol. Built Environ. 2016, 22, 290–298. [Google Scholar] [CrossRef]

- Guo, L.; Ye, H. Numerical and Experimental Study on a High-Power Cold Achieving Process of a Coil-Plate Ice-Storage System. Energies 2019, 12, 4085. [Google Scholar] [CrossRef]

- Kang, Z.; Wang, R.; Zhou, X.; Feng, G. Research Status of Ice-storage Air-conditioning System. Procedia Eng. 2017, 205, 1741–1747. [Google Scholar] [CrossRef]

- Chung-Tai, W.; Chih-Ling, F.; Yao-Hsu, T. Application of an ice thermal energy storage system as ways of energy management in a multi-functional building. J. Renew. Sustain. Energy 2015, 7, 1–7. [Google Scholar]

- Patent. Storage Tank Device for an Energy Storage System and Energy Storage System with a Storage Tank Device. Available online: https://patents.google.com/patent/DE102010037474A1/de (accessed on 5 April 2021).

- Hollmuller, P.; De Oliveira, F.; Graf, O.; Thiele, W. Solar assisted heat pump with ice storage for a 19,000 m2 retrofitted multi-family building complex. Energy Procedia 2017, 122, 271–276. [Google Scholar] [CrossRef]

- Davies, T.W. Slurry ice as a heat transfer fluid with a large number of application domains. Int. J. Refrig. 2005, 28, 108–114. [Google Scholar] [CrossRef]

- Waquas, A.; Ud Din, Z. Phase change material (PCM) storage of free cooling of buildings—A review. Renew. Sustain. Energy Rev. 2013, 18, 607–625. [Google Scholar] [CrossRef]

- Moreno, P.; Solé, C.; Castell, A.; Cabeza, L.F. The use of phase change materials in domestic heat pump and air-conditioning system for short term storage: A review. Renew. Sustain. Energy Rev. 2014, 39, 1–13. [Google Scholar] [CrossRef]

- Oró, E.; de Gracia, A.; Castell, A.; Farid, M.M.; Cabeza, L.F. Review on phase change materials (PCMs) for cold thermal energy storage applications. Appl. Energy 2012, 99, 513–533. [Google Scholar] [CrossRef]

- Podara, C.V.; Kartsonakis, I.A.; Charitidis, C.A. Towards Phase Change Materials for Thermal Energy Storage: Classification, Improvements and Applications in the Building Sector. Appl. Sci. 2021, 11, 1490. [Google Scholar] [CrossRef]

- Raj, V.A.; Velraj, R. Review on free cooling of buildings using phase change materials. Renew. Sustain. Energy Rev. 2010, 14, 2819–2829. [Google Scholar] [CrossRef]

- Farid, M.M.; Khudhair, A.M.; Razack, S.A.K.; Al-Hallaj, S. A review on phase change energy storage: Materials and applications. Energy Convers. Manag. 2004, 45, 1597–1615. [Google Scholar] [CrossRef]

- Peng, G.; Dou, G.; Hu, Y.; Sun, Y.; Chen, Z. Phase Change Material (PCM) Microcapsules for Thermal Energy Storage. Adv. Polym. Technol. 2020. [Google Scholar] [CrossRef]

- Zalba, B.; Marin, J.M.; Cabeza, L.F.; Mehling, H. Review on thermal energy storage with phase change: Materials, heat transfer analysis and applications. Appl. Therm. Eng. 2003, 23, 251–283. [Google Scholar] [CrossRef]

- Pasupathy, A.; Velraj, R.; Seeniraj, R.V. Phase change material-based building architecture for thermal management in residential and commercial establishments. Renew. Sustain. Energy Rev. 2008, 12, 39–64. [Google Scholar] [CrossRef]

- Medved, S.; Arkar, C. Correlation between the local climate and free-cooling potential of latent head storage. Energy Build. 2008, 40, 429–437. [Google Scholar] [CrossRef]

- Genc, A.M.; Karadeniz, Z.H.; Ekren, O.; Toksoy, M. A Novel Spherical Packed Bed Application on Decentralized Heat Recovery Ventilation Units. E3s Web Conf. 2019, 111, 01012. [Google Scholar] [CrossRef]

- Kalaiselvam, S.; Parameshwaran, R. Thermal Energy Storage Technologies for Sustainability. Systems Design, Assessment and Applications, Chapter 5—Latent Thermal Energy Storage, 1st ed.; Academic Press: Cambridge, MA, USA, 2014; pp. 83–126. [Google Scholar]

- Guo, H.; ELSihy, E.S.; Liao, Z.; Du, X. Comparative Study on the Performance of Single and Multi-Layer Encapsulated Phase Change Materials Packed-Bed Thermocline Tank. Energies 2021, 14, 2175. [Google Scholar] [CrossRef]

- Yang, W.-C. Flow Through Fixed Beds. In Handbook of Fluidization and Fluid-Particle Systems, 1st ed.; Yang, W.-C., Ed.; Marcel Dekker, Inc.: New York, NY, USA, 2003; pp. 39–62. [Google Scholar]

- Yu, Q.; Romagnoli, A.; Al-Duri, B.; Xie, D.; Ding, Y.; Li, Y. Heat storage performance analysis and parameter design for encapsulated phase change materials. Energy Convers. Manag. 2018, 157, 619–630. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Density, ρf (kg m−3) | 1053 |

| Specific heat, cp,f (kJ kg−1 K−1) | 3.66 |

| Thermal conductivity, λ (W m−1 K−1) | 0.404 |

| Kinematic viscosity, ν (m2 s−1) | 0.0000124 |

| No. | Test | Capsule Diameter, dp (mm) | Mass Flow Rate of HTF | |

|---|---|---|---|---|

| Description | Value | |||

| 1 | 80-I | 80 | lowest flow | 0.076 |

| 2 | 80-II | 80 | medium flow | 0.084 |

| 3 | 80-III | 80 | highest flow | 0.089 |

| 4 | 70-I | 70 | lowest flow | 0.084 |

| 5 | 70-II | 70 | medium flow | 0.091 |

| 6 | 70-III | 70 | highest flow | 0.104 |

| 7 | 60-I | 60 | lowest flow | 0.066 |

| 8 | 60-II | 60 | medium flow | 0.072 |

| 9 | 60-III | 60 | highest flow | 0.083 |

| No. | Parameter | Test | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 80-I | 80-II | 80-III | 70-I | 70-II | 70-III | 60-I | 60-II | 60-III | ||

| 1 | Voidage of bed, ε (-) | 0.46 | 0.51 | 0.46 | ||||||

| 2 | Superficial fluid velocity, (m s−1) | 0.28 | 0.31 | 0.33 | 0.31 | 0.34 | 0.39 | 0.25 | 0.27 | 0.31 |

| 3 | Fluid velocity based on multicapsule bed, (m s−1) | 0.89 | 0.98 | 1.04 | 1.25 | 1.36 | 1.55 | 0.75 | 0.81 | 0.94 |

| 4 | Rep, (-) | 1.83 | 2.02 | 2.14 | 1.76 | 1.91 | 2.19 | 1.19 | 1.30 | 1.50 |

| 5 | Reϕ, (-) | 0.57 | 0.63 | 0.67 | 0.71 | 0.77 | 0.88 | 0.36 | 0.39 | 0.45 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sekret, R.; Starzec, P. Developing a Cold Accumulator with a Capsule Bed Containing Water as a Phase-Change Material. Energies 2021, 14, 2703. https://doi.org/10.3390/en14092703

Sekret R, Starzec P. Developing a Cold Accumulator with a Capsule Bed Containing Water as a Phase-Change Material. Energies. 2021; 14(9):2703. https://doi.org/10.3390/en14092703

Chicago/Turabian StyleSekret, Robert, and Przemysław Starzec. 2021. "Developing a Cold Accumulator with a Capsule Bed Containing Water as a Phase-Change Material" Energies 14, no. 9: 2703. https://doi.org/10.3390/en14092703

APA StyleSekret, R., & Starzec, P. (2021). Developing a Cold Accumulator with a Capsule Bed Containing Water as a Phase-Change Material. Energies, 14(9), 2703. https://doi.org/10.3390/en14092703