Investigative Study of Vertical Electrodes Encased in Concrete/Mortar with Various Sizes of Air Voids

Abstract

:1. Introduction

2. Test System

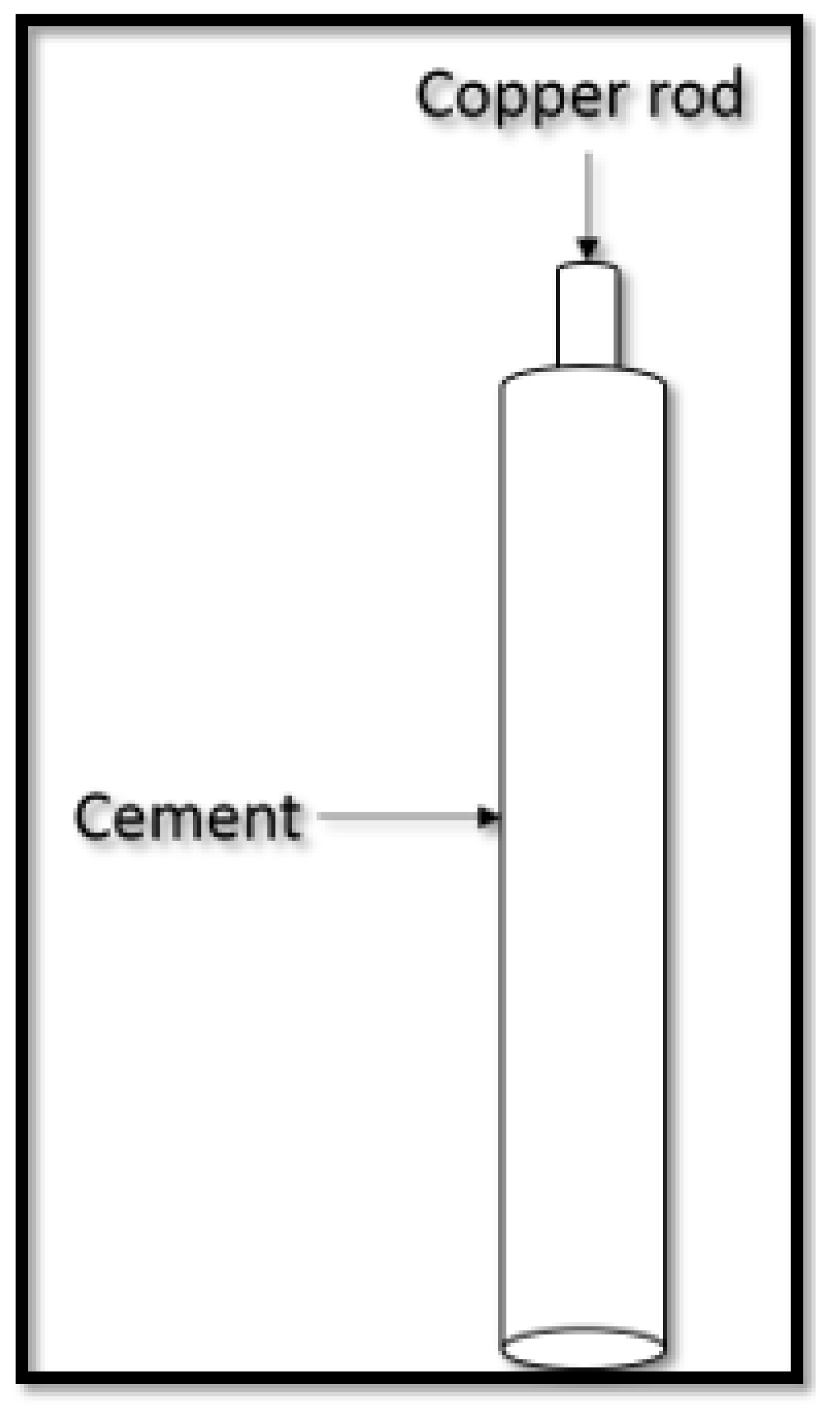

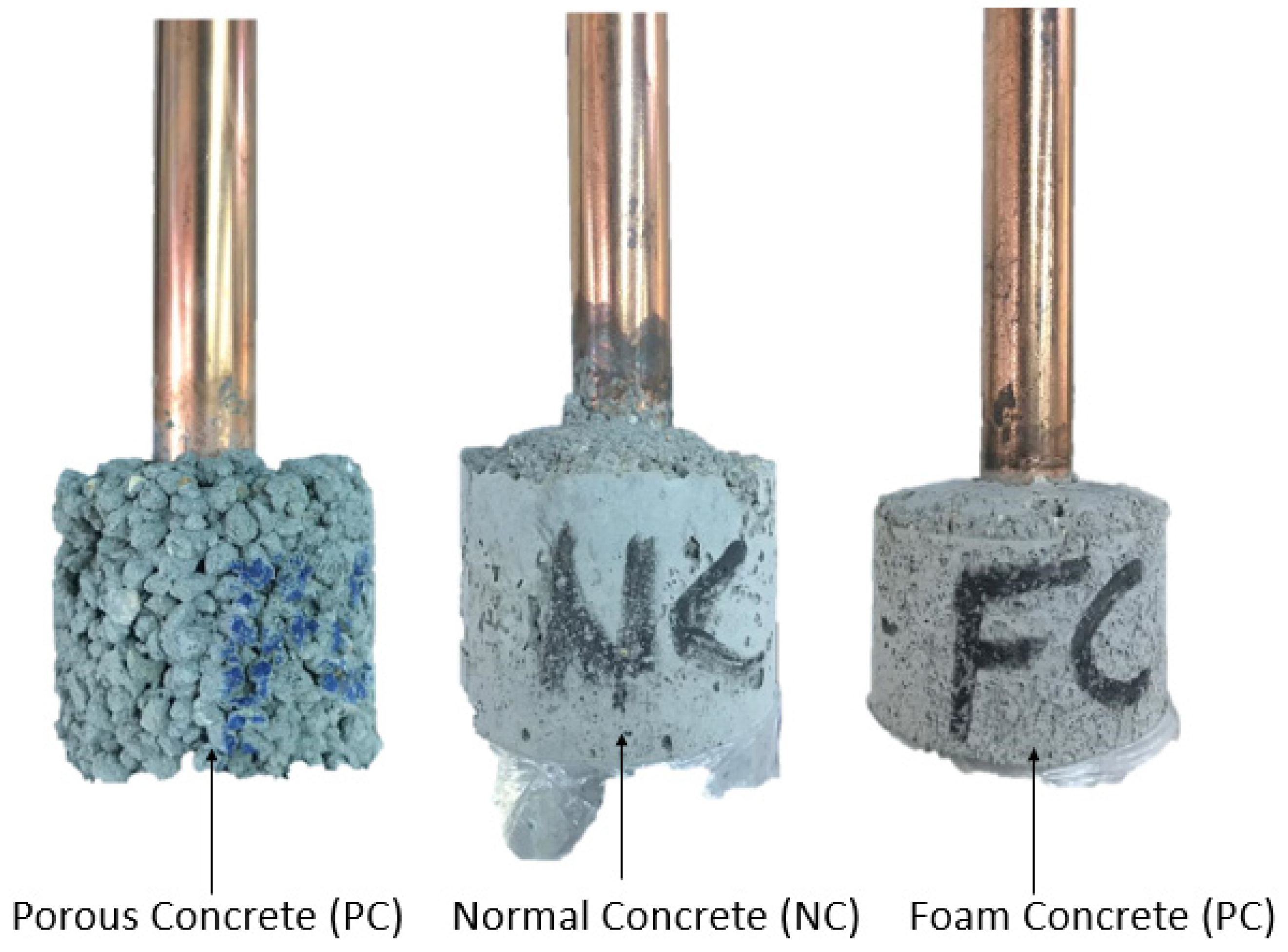

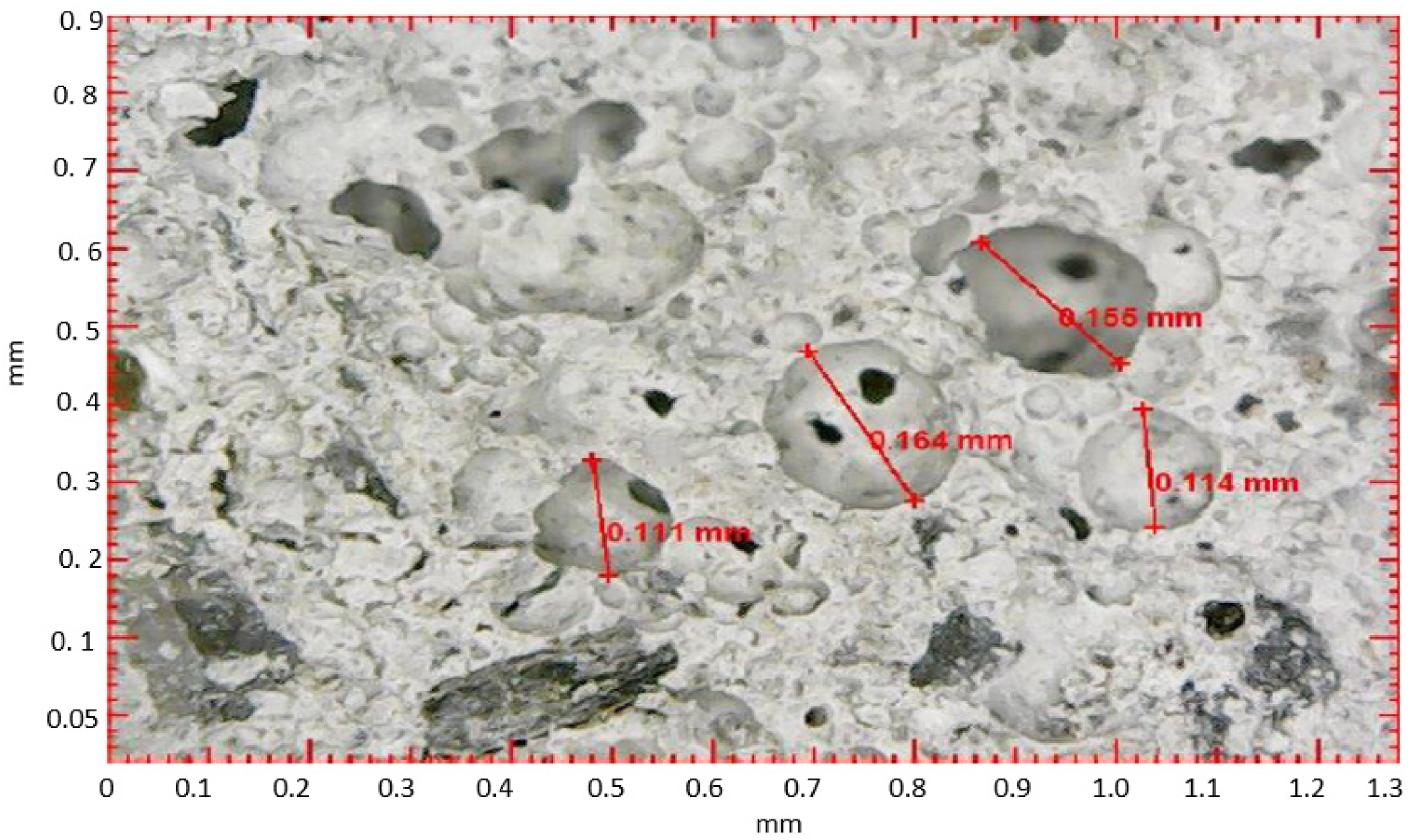

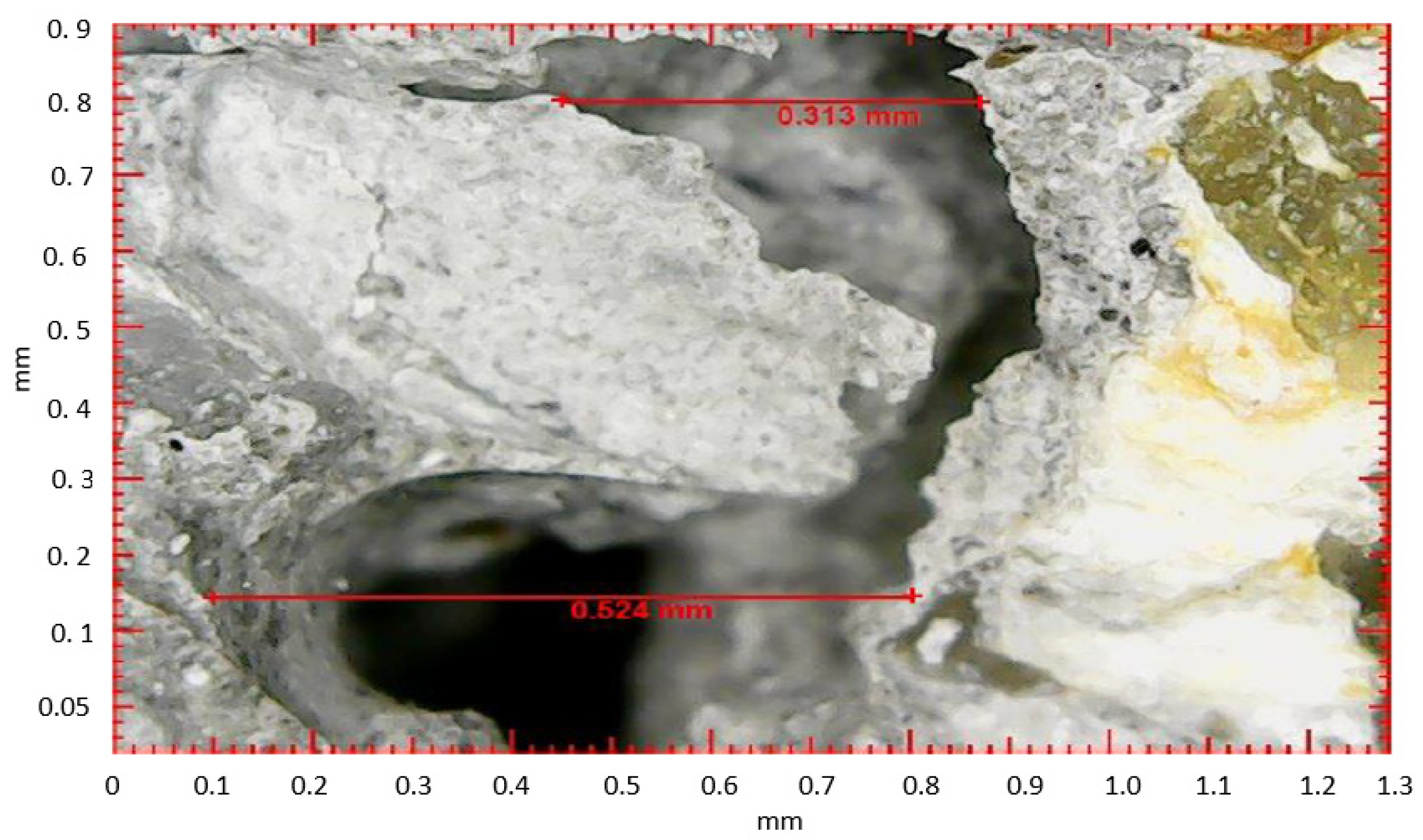

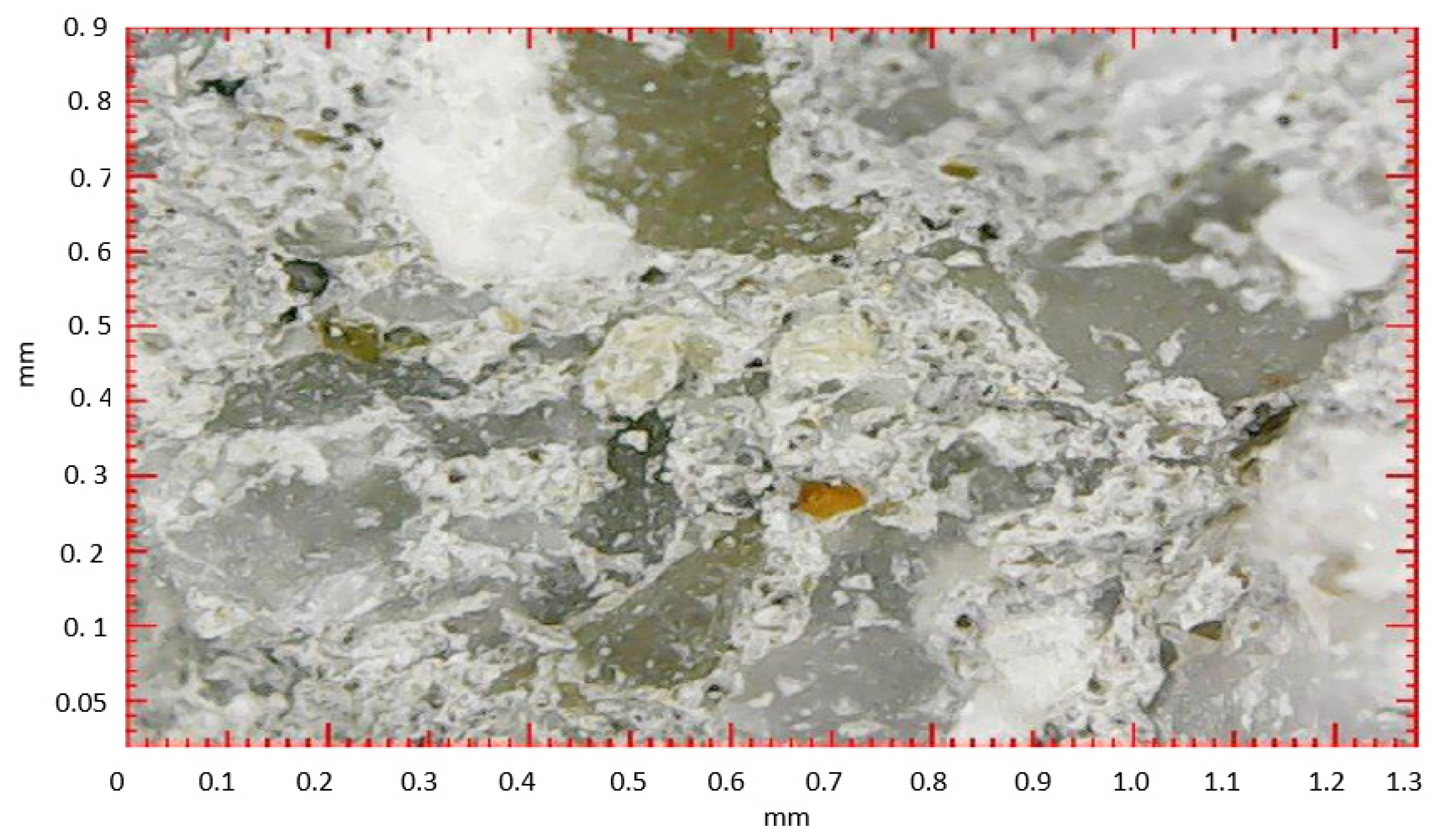

2.1. Ground Rod Electrodes under Tests

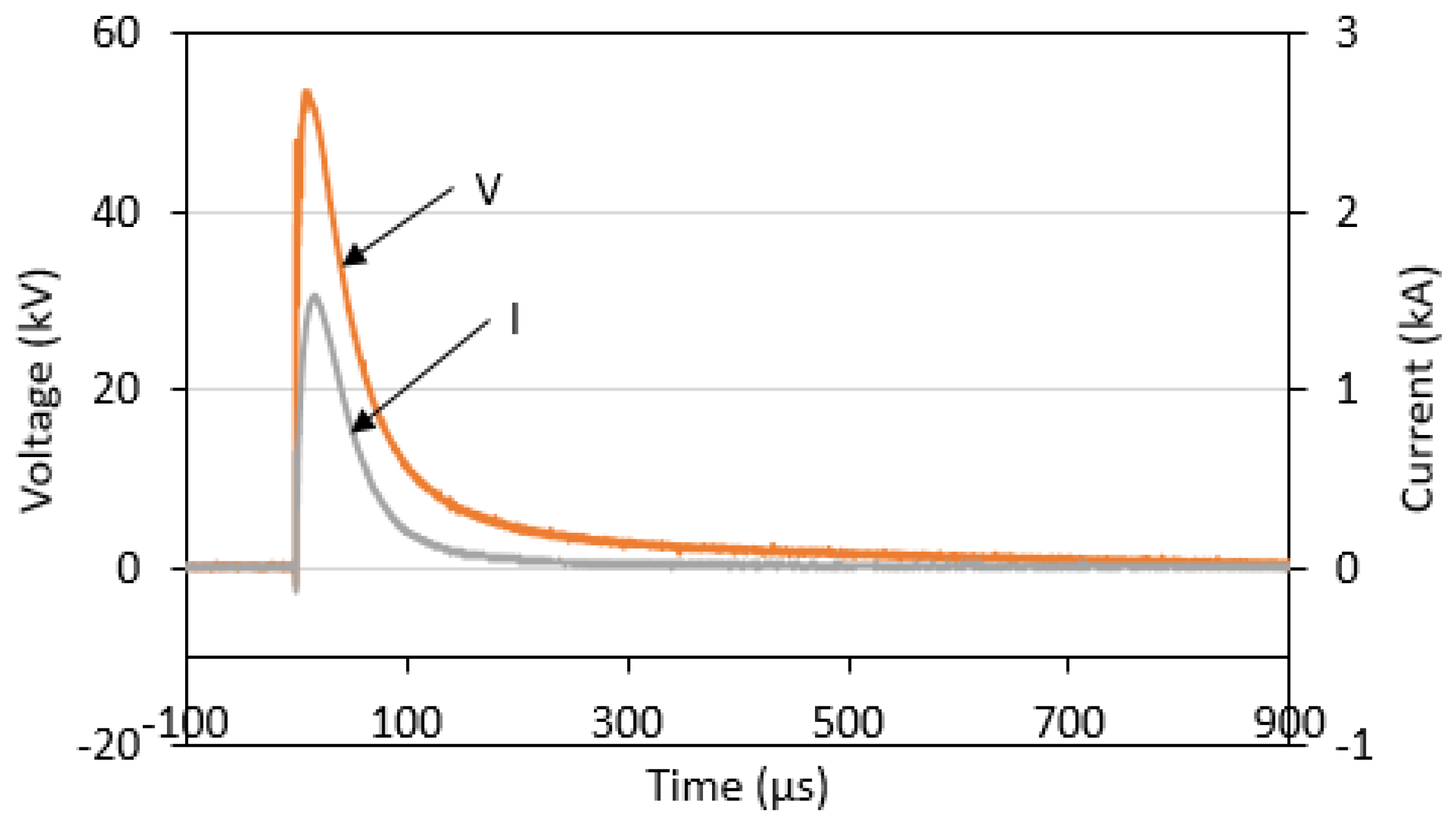

2.2. Impulse Test Arrangement

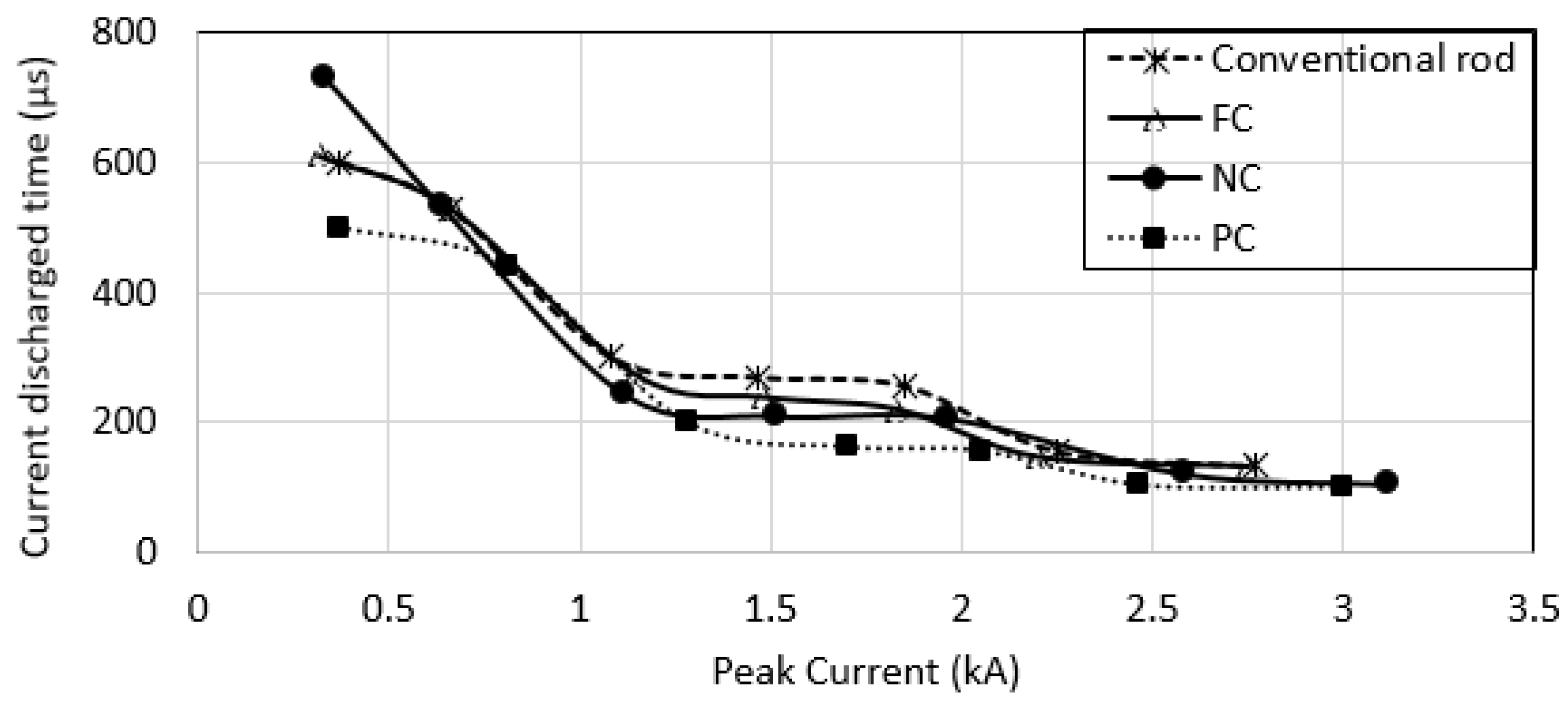

3. Impulse Test Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liew, A.C.; Darveniza, M. Dynamic Model of Impulse Characteristics of Concentrated Earths. Proc. Inst. Electr. Eng. 1974, 121, 123–135. [Google Scholar] [CrossRef]

- Mousa, S.; Harid, N.; Griffiths, H.; Haddad, A. Experimental Investigation on High-Frequency and Transient Performance of a Vertical Earth Electrode. In Proceedings of the 46th International Universities’ Power Engineering Conference (UPEC), Soest, Germany, 5–8 September 2011. [Google Scholar]

- Vainer, A.L. Impulse Characteristics of Complex Earth Grids. Elektrichestvo 1967, 3, 107–117. [Google Scholar]

- Harid, N.; Griffiths, H.; Mousa, S.; Clark, D.; Robson, S.; Haddad, A. On the Analysis of Impulse Test Results on Grounding Systems. IEEE Trans. Ind. Appl. 2015, 51, 5324–5334. [Google Scholar] [CrossRef]

- Ali, A.; Ahmad, N.; Mohamad Nor, N. Investigations on the Performance of Grounding Device with Spike Rods (GDSR) with the Effects of Soil Resistivity and Configurations. Energies 2020, 13, 14. [Google Scholar]

- Ali, A.; Ahmad, N.; Mohamad Nor, N. Effect of impulse polarity on a new grounding device with spike rods (GDSR). Energies 2020, 13, 18. [Google Scholar]

- Cabrera, V.M.; Lundquist, M.S.; Cooray, V. On the Physical Properties of Discharges in Sand under Lightning Impulses. J. Electrost. 1993, 30, 17–28. [Google Scholar]

- Mohamad Nor, N.; Haddad, A.; Griffiths, H. Characterisation of Ionisation Phenomena in Soils under Fast Impulses. IEEE Trans. Power Deliv. 2006, 21, 353–361. [Google Scholar]

- Rodrigues, M.A.O.; da Costa, E.G.; de Castro, M.S. Performance Evaluation of a New Grounding System. In Proceedings of the IEEE International Power Modulator and High Voltage Conference (IPMHVC), San Diego, CA, USA, 3–7 June 2012. [Google Scholar]

- Dick, W.K.; Holliday, H.R. Impulse and Alternating Current Tests on Grounding Electrodes in Soil Environment. IEEE Trans. Power Appar. Syst. 1978, 1, 102–108. [Google Scholar] [CrossRef]

- Androvitsaneas, V.P.; Ioannis, F.G.; Stathopulos, A. Experimental Study on Transient Impedance of Grounding Rods Encased in Ground Enhancing Compounds. Electr. Power Syst. Res. 2016, 139, 109–115. [Google Scholar] [CrossRef]

- Mohamad Nor, N.; Haddad, A.; Griffiths, H. Determination of Threshold Electric Field, Ec under High Impulse Currents. IEEE Trans. Power Deliv. 2005, 20, 2108–2113. [Google Scholar]

- BS EN 12390-2: Testing Hardened Concrete. Making and Curing Specimens for Strength Tests, Committee B/517/1; BSI: London, UK, 2019. [Google Scholar]

- MacNeill, J.D. Electrical Conductivity of Soils and Rocks; Geonics Limited: Mississauga, ON, Canada, 1980. [Google Scholar]

- Snowden, D.P.; Erler, J.W. Initiation of Electrical Breakdown of Soil by Water Vaporization. IEEE Trans. Nucl. Sci. 1983, 30, 4568–4571. [Google Scholar] [CrossRef]

| Mixture | Mix Proportion (kg/m3) | ||||

|---|---|---|---|---|---|

| Cement | Water | Aggregate | Sand | Foaming Agent | |

| Mortar with foaming agent (FC) | 533 | 267 | Nil | 800 | 262 |

| Porous concrete (PC) | 558 | 167 | 1674 | Nil | Nil |

| Mortar (NC) | 500 | 250 | Nil | 1500 | Nil |

| Types of Electrodes | Density of Block 1 (kg/m3) | Density of Block 2 (kg/m3) | Density of Block 3 (kg/m3) | Average (kg/m3) |

|---|---|---|---|---|

| Mortar with foaming agent (FC) | 1505 | 1575.5 | 1453.7 | 1511.4 |

| Porous concrete (PC) | 1981.8 | 2022.5 | 1987.5 | 1997.27 |

| Mortar (NC) | 2115.9 | 2084.6 | 2096.4 | 2098.97 |

| Types of Electrodes | Day | Compressive Strength of Block 1 (N/mm2) | Compressive Strength of Block 2 (N/mm2) | Compressive Strength of Block 3 (N/mm2) | Average (N/mm2) |

|---|---|---|---|---|---|

| Mortar with foaming agent (FC) | 3 | 2.01 | 1.76 | 2.0 | 1.92 |

| 7 | 3.67 | 3.82 | 3.61 | 3.7 | |

| 28 | 4.52 | 3.51 | 4.72 | 4.25 | |

| Porous concrete (PC) | 3 | 13.7 | 12.5 | 11.6 | 12.6 |

| 7 | 14.7 | 15.6 | 15 | 15.1 | |

| 28 | 16.48 | 17.7 | 18.8 | 17.6 | |

| Mortar (NC) | 3 | 16.2 | 13.7 | 14.5 | 14.2 |

| 7 | 17.65 | 15.8 | 18.6 | 17.4 | |

| 28 | 22.22 | 19.5 | 20.2 | 20.6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hizamul-Din, H.H.; Nor, N.M.; Samad, D.A.; Muhd Sidek, M.N. Investigative Study of Vertical Electrodes Encased in Concrete/Mortar with Various Sizes of Air Voids. Energies 2021, 14, 2659. https://doi.org/10.3390/en14092659

Hizamul-Din HH, Nor NM, Samad DA, Muhd Sidek MN. Investigative Study of Vertical Electrodes Encased in Concrete/Mortar with Various Sizes of Air Voids. Energies. 2021; 14(9):2659. https://doi.org/10.3390/en14092659

Chicago/Turabian StyleHizamul-Din, Hanis Hamizah, Normiza Mohamad Nor, Dzulkafley Abd Samad, and Muhd Norhasri Muhd Sidek. 2021. "Investigative Study of Vertical Electrodes Encased in Concrete/Mortar with Various Sizes of Air Voids" Energies 14, no. 9: 2659. https://doi.org/10.3390/en14092659

APA StyleHizamul-Din, H. H., Nor, N. M., Samad, D. A., & Muhd Sidek, M. N. (2021). Investigative Study of Vertical Electrodes Encased in Concrete/Mortar with Various Sizes of Air Voids. Energies, 14(9), 2659. https://doi.org/10.3390/en14092659